Skimming and mud scraping device

A technology of scraper and mounting plate, which is applied in the direction of settling tanks, chemical instruments and methods, separation methods, etc., can solve the problems of poor connection reliability, high false trigger probability, and the scraper cannot be turned over, so as to achieve high reliability and reduce agitation Degree, the effect that is not easy to trigger by mistake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

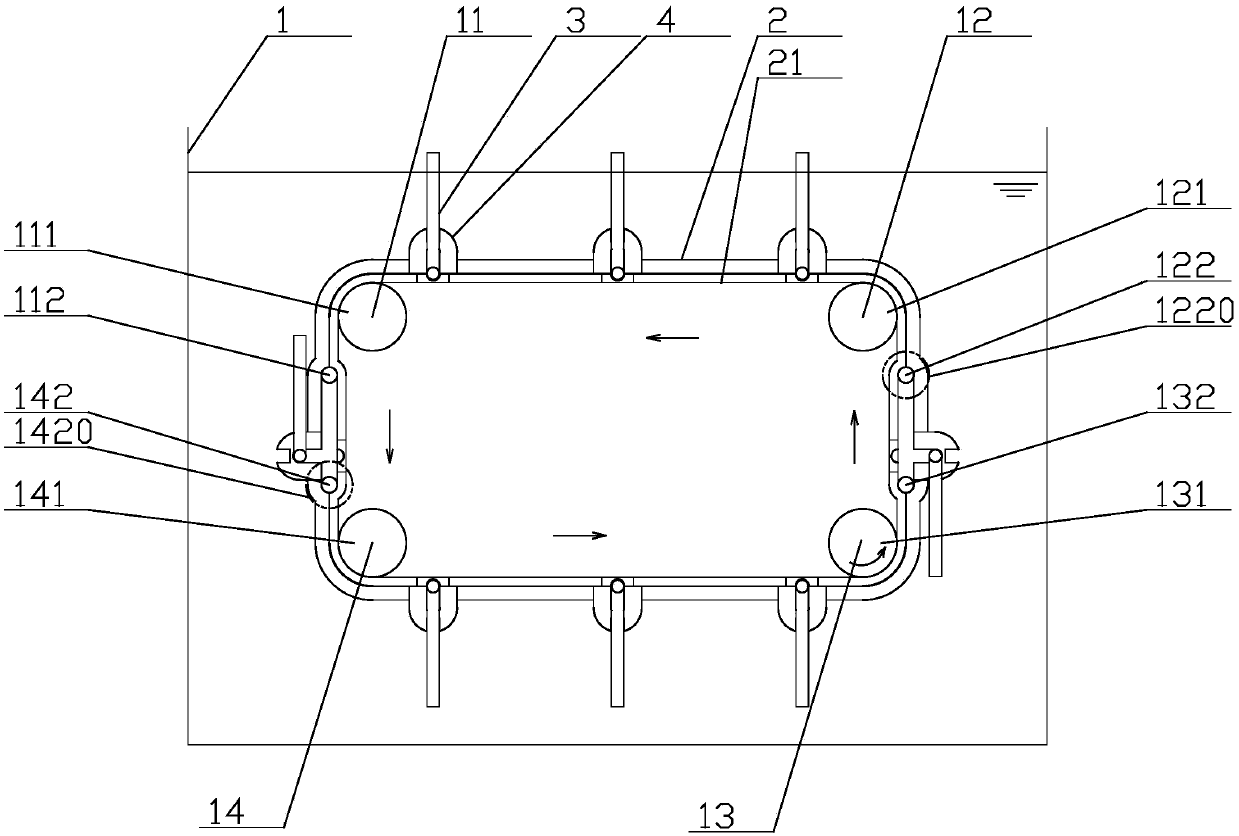

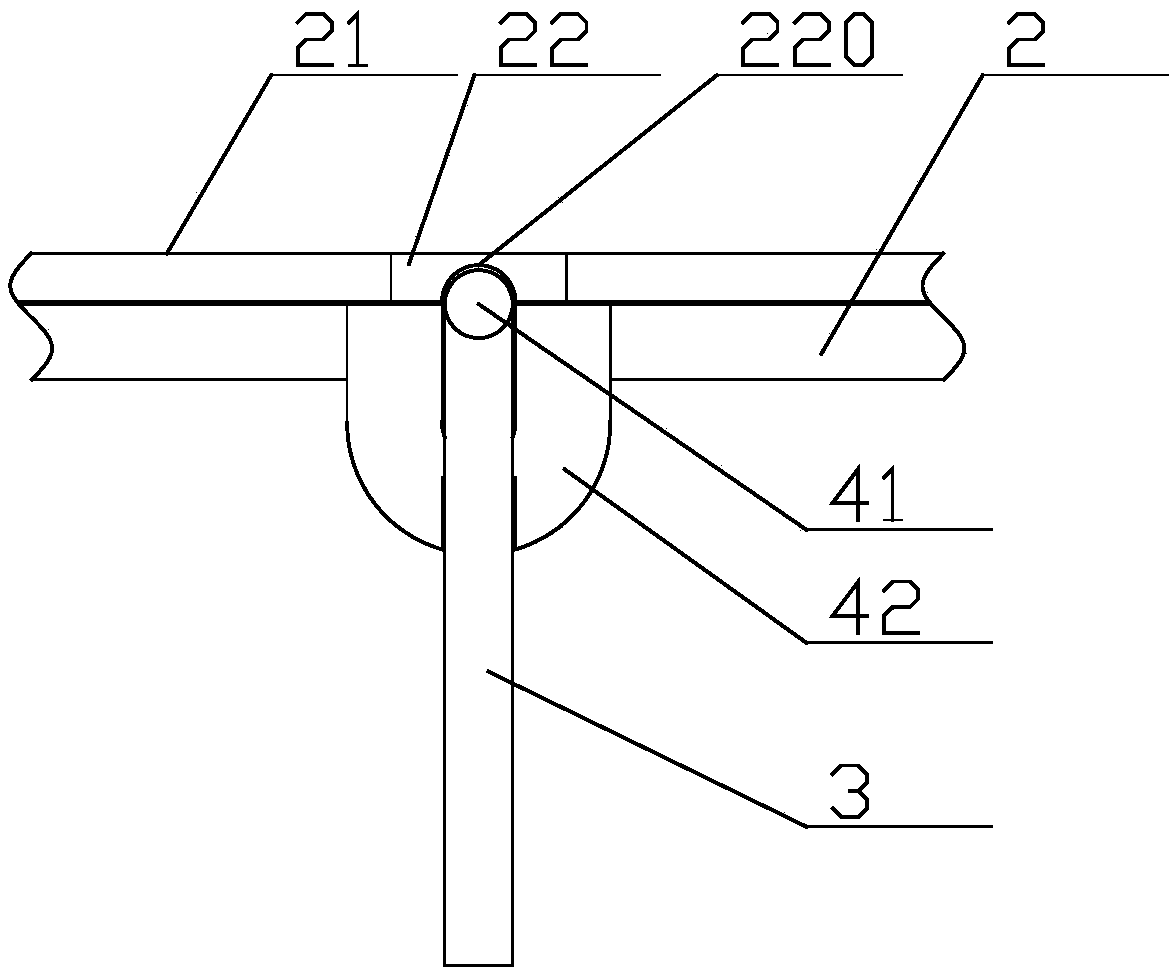

[0056] Example as Figure 1-9 As shown, the inner side of the conveyor belt 2 is further provided with an auxiliary conveyor belt 21, and a plurality of magnets 22 are fixedly connected to the auxiliary conveyor belt 21, and the magnets 22 correspond to the connecting assembly 4 one by one;

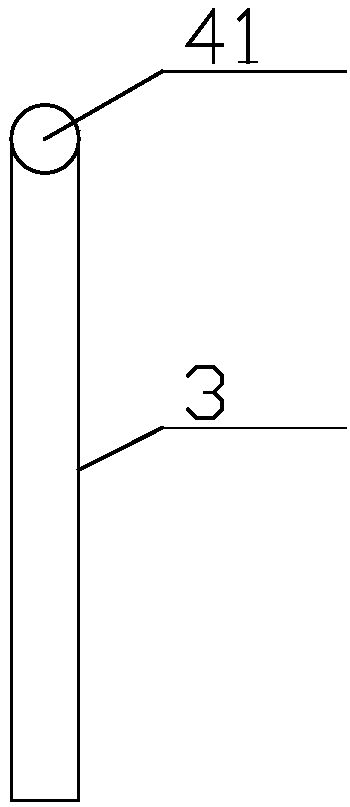

[0057] The connecting assembly 4 includes a main shaft 41, a mounting seat 42 and a pair of connecting plates 43, the conveyor belt 2 has a fracture, the mounting seat 42 is arranged perpendicular to the conveyor belt 2, and its two ends are respectively fixedly connected to both ends of the fracture The end surface of the mounting seat 42 facing the magnet 22 is provided with a U-shaped slot 421 for accommodating the spindle 41, the end surface of the mounting seat 42 facing away from the magnet 22 is semicircular, and the middle of the end surface is provided with The accommodating groove 422 for accommodating the scraper 3, the main shaft 41 is made of magnetic material, the main shaft 41 ...

Embodiment 2

[0067] Example two Figure 10-20 As shown, the connecting assembly 4 includes a rotating shaft 44, an inner drive tooth 45, an outer drive plate 46, and a pair of mounting plates 47. The conveyor belt has a cutout. The mounting plates 44 are arranged perpendicular to the conveyor belt 2 and have two ends. They are respectively fixedly connected to the two ends of the fracture, the rotating shaft 44 is fixedly connected to one end of the scraper 3, and both ends of the rotating shaft 44 are hinged to the two mounting plates 44, and the internal driving teeth 45 are fixedly connected to the rotating shaft 44, And extend to the outside of the mounting plate 3, the external drive teeth 46 are hinged to one of the mounting plates 44 on the side away from the scraper 3 through the central shaft 460, and the central shaft 460 is in contact with the rotating shaft 44; in this way, the internal drive teeth The rotation of will drive the scraper to flip toward one side, and the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com