Patents

Literature

211results about How to "Reduce icing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

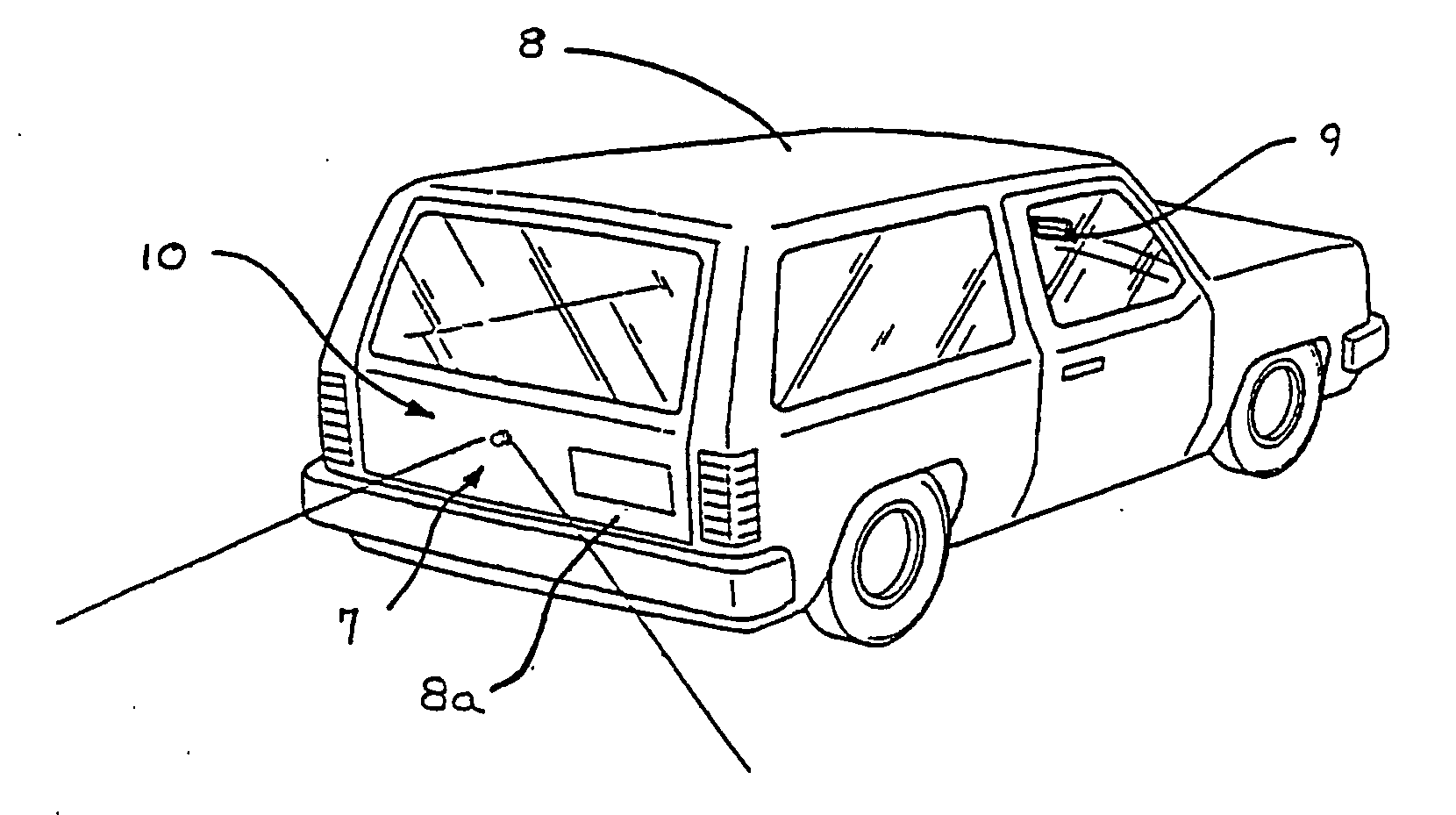

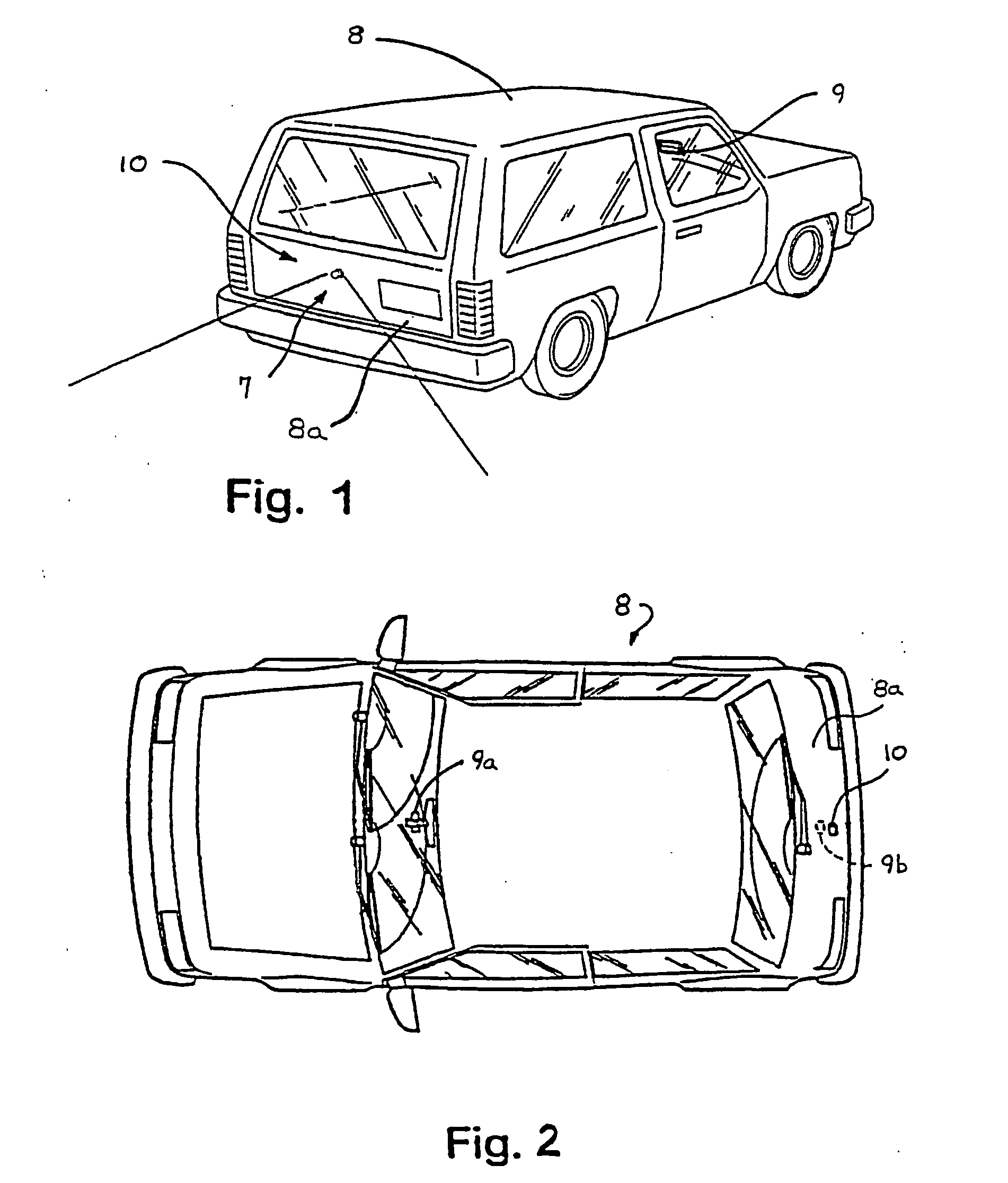

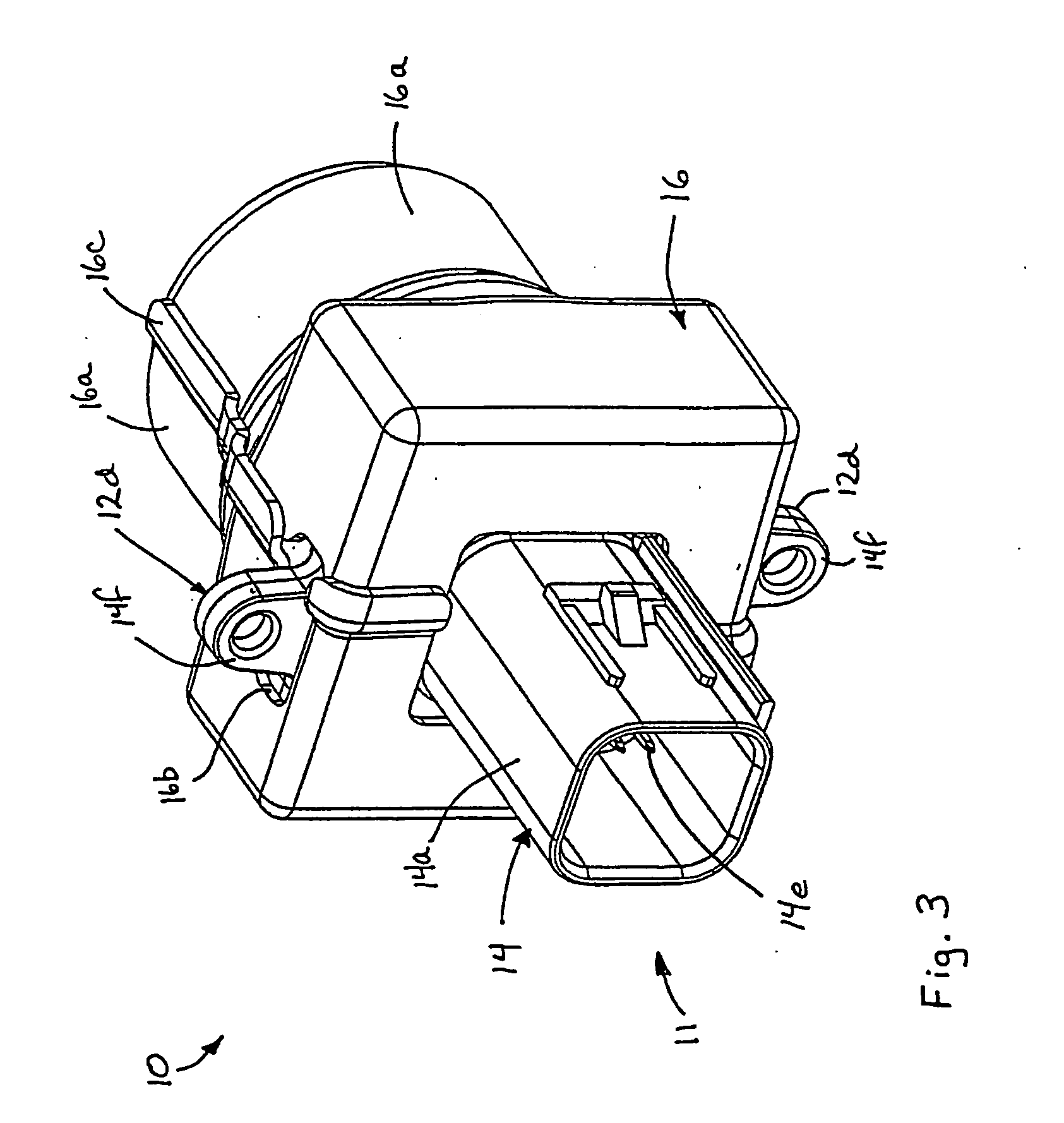

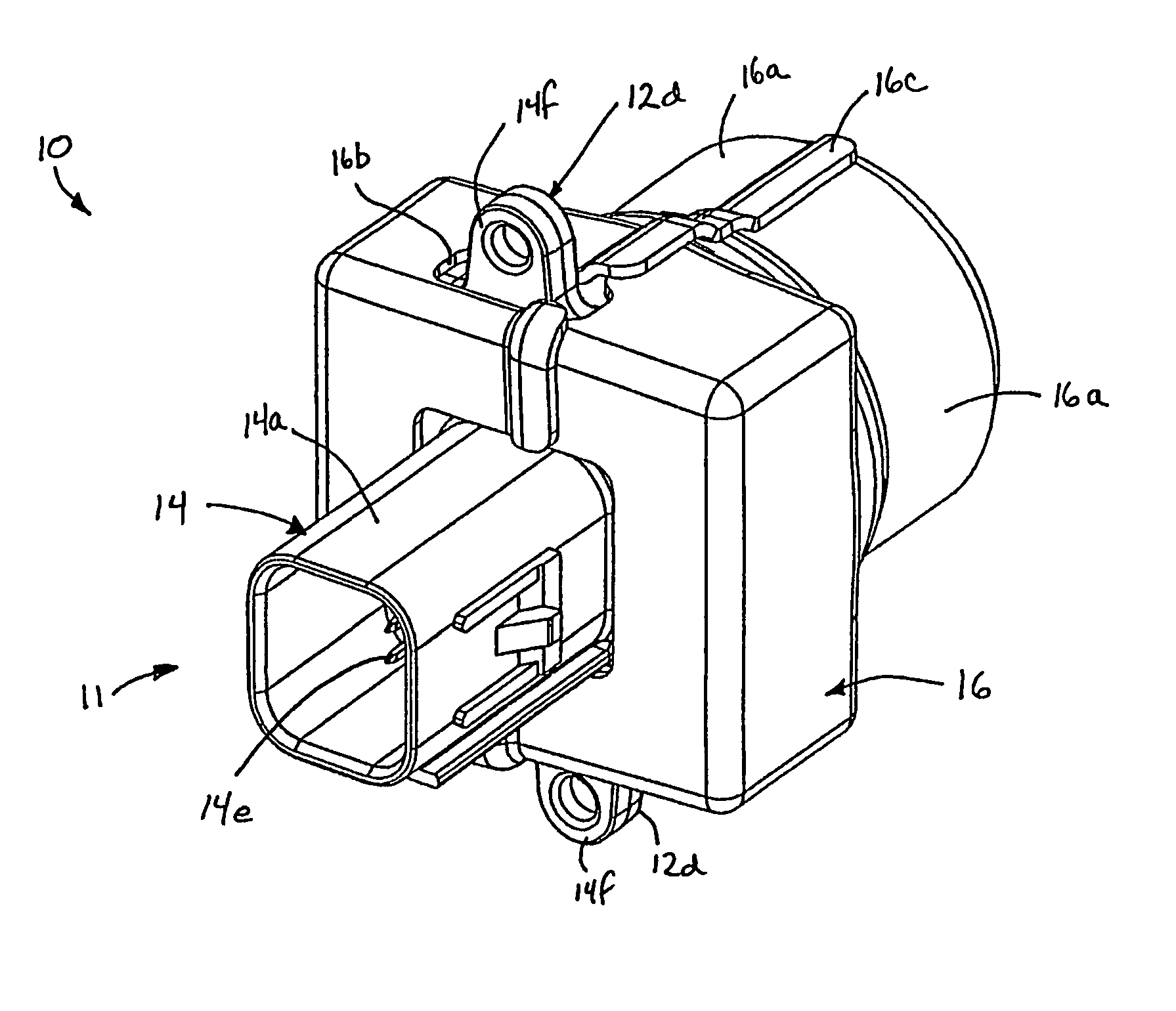

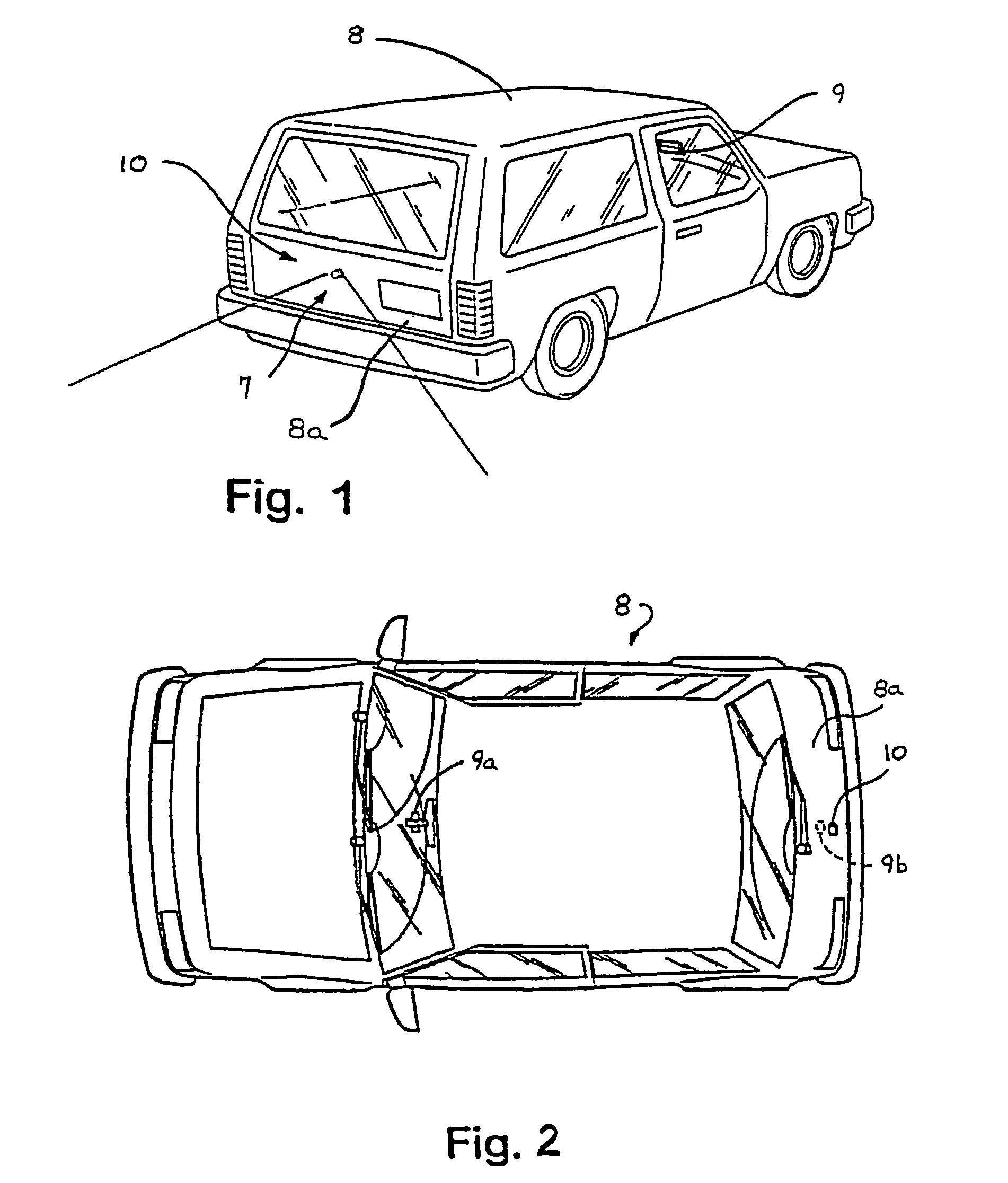

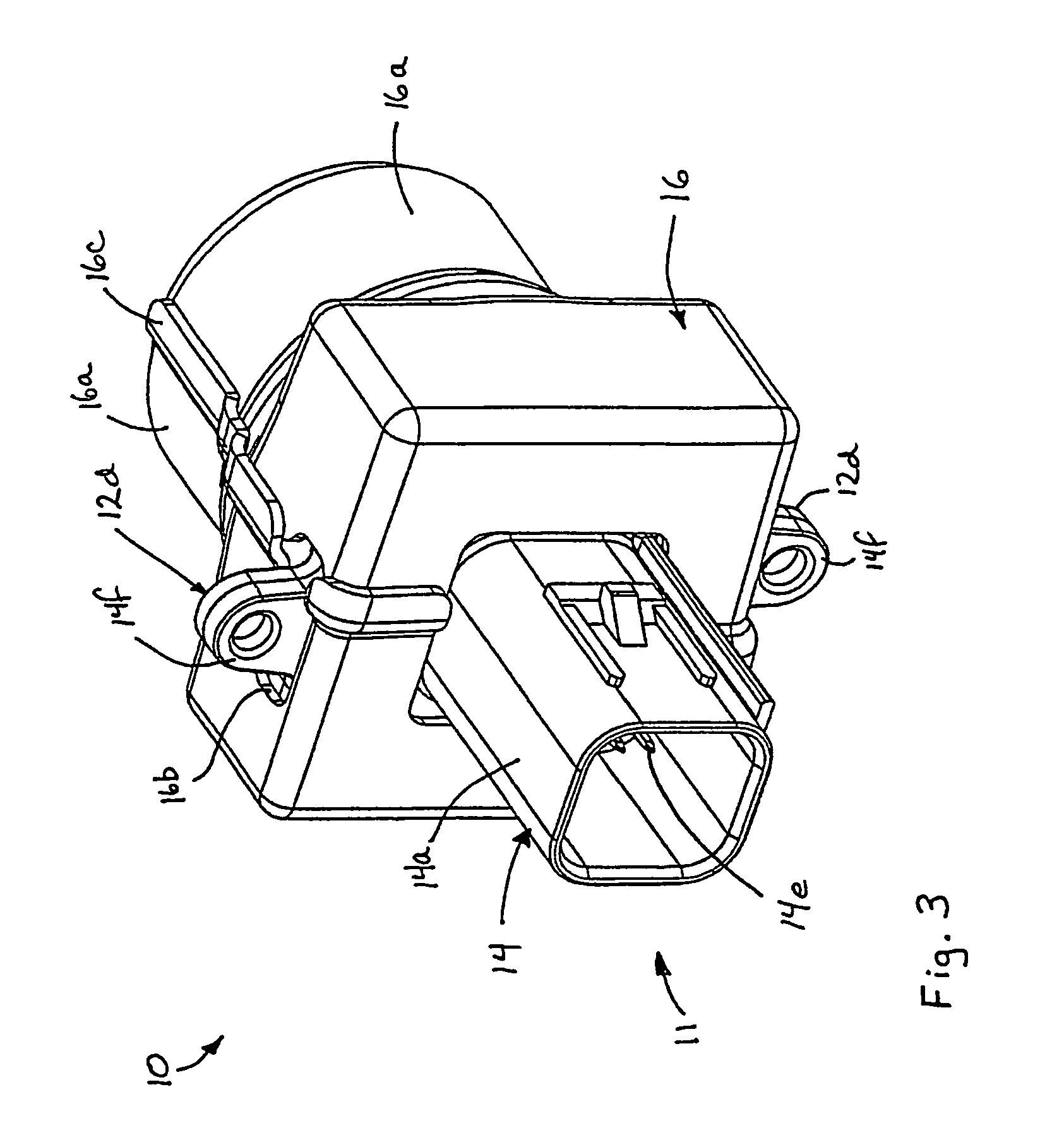

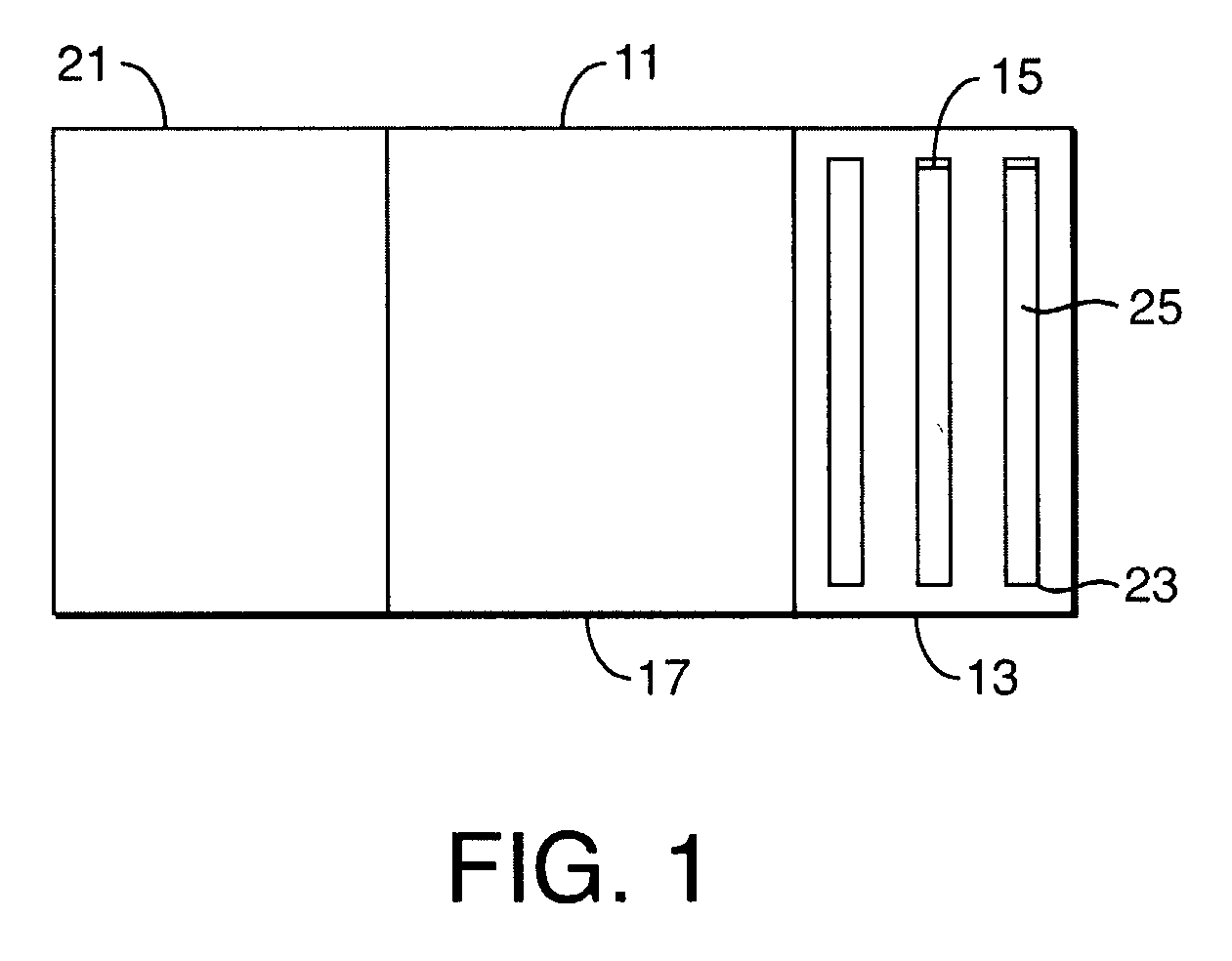

Imaging system for vehicle

ActiveUS20060171704A1Reduce vibration effectsReduce foggingTelevision system detailsPrintersWater vaporEngineering

An imaging system for a vehicle includes a camera module positionable at the vehicle and a control. The camera module includes a plastic housing that houses an image sensor, which is operable to capture images of a scene occurring exteriorly of the vehicle. The control is operable to process images captured by the image sensor. The portions of the housing may be laser welded or sonic welded together to substantially seal the image sensor and associated components within the plastic housing. The housing may include a ventilation portion that is at least partially permeable to water vapor to allow water vapor to pass therethrough while substantially precluding passage of water droplets and / or other contaminants. The housing may be movable at the vehicle between a stored position and an operational position, where the image sensor may be directed toward the exterior scene.

Owner:MAGNA ELECTRONICS

Imaging system for vehicle

ActiveUS7965336B2Reduce vibration effectsReduce foggingTelevision system detailsPrintersWater vaporCamera module

An imaging system for a vehicle includes a camera module positionable at the vehicle and a control. The camera module includes a plastic housing that houses an image sensor, which is operable to capture images of a scene occurring exteriorly of the vehicle. The control is operable to process images captured by the image sensor. The portions of the housing may be laser welded or sonic welded together to substantially seal the image sensor and associated components within the plastic housing. The housing may include a ventilation portion that is at least partially permeable to water vapor to allow water vapor to pass therethrough while substantially precluding passage of water droplets and / or other contaminants. The housing may be movable at the vehicle between a stored position and an operational position, where the image sensor may be directed toward the exterior scene.

Owner:MAGNA ELECTRONICS

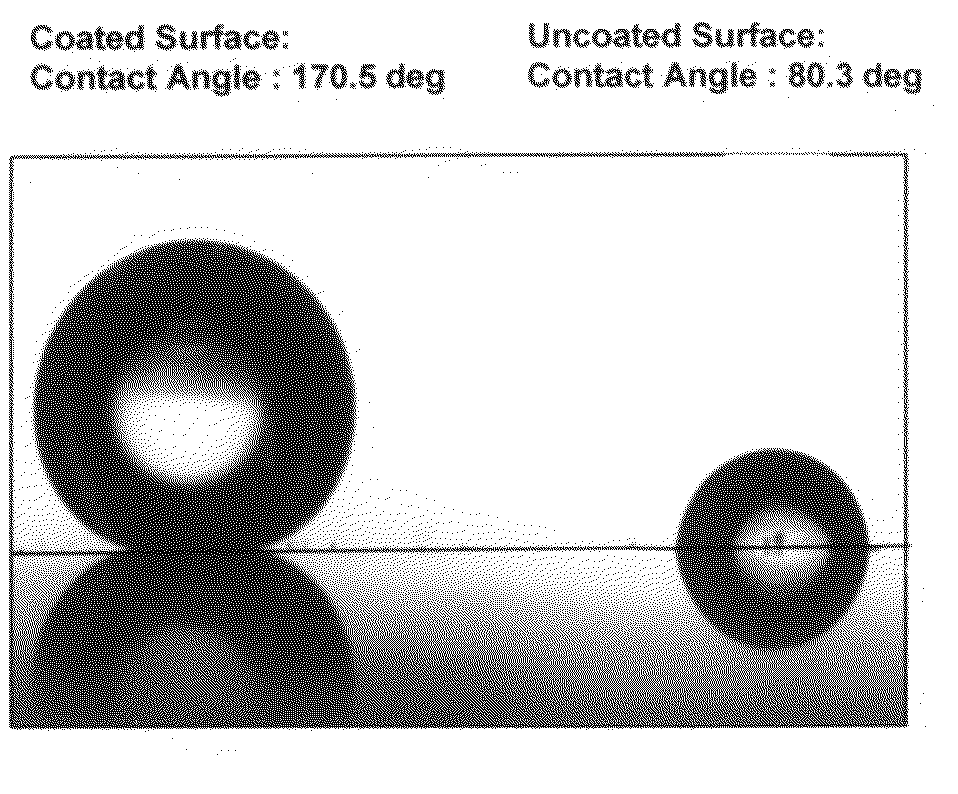

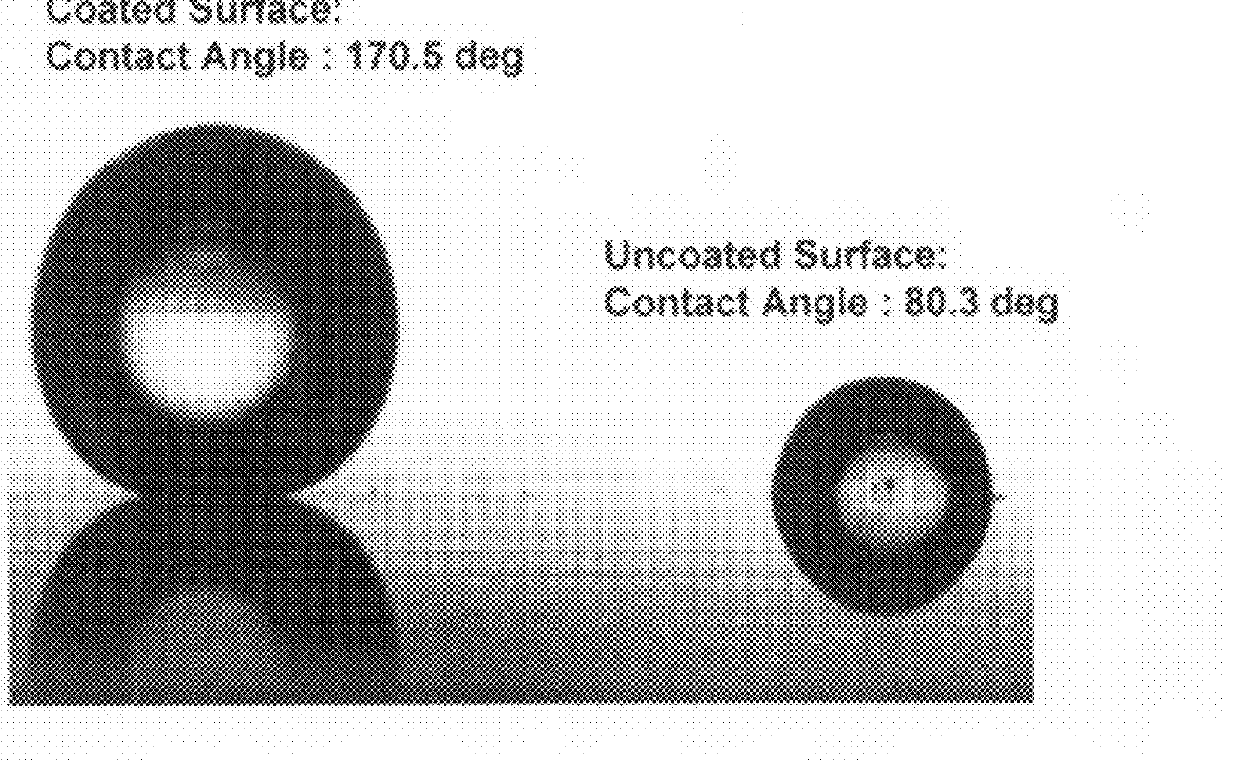

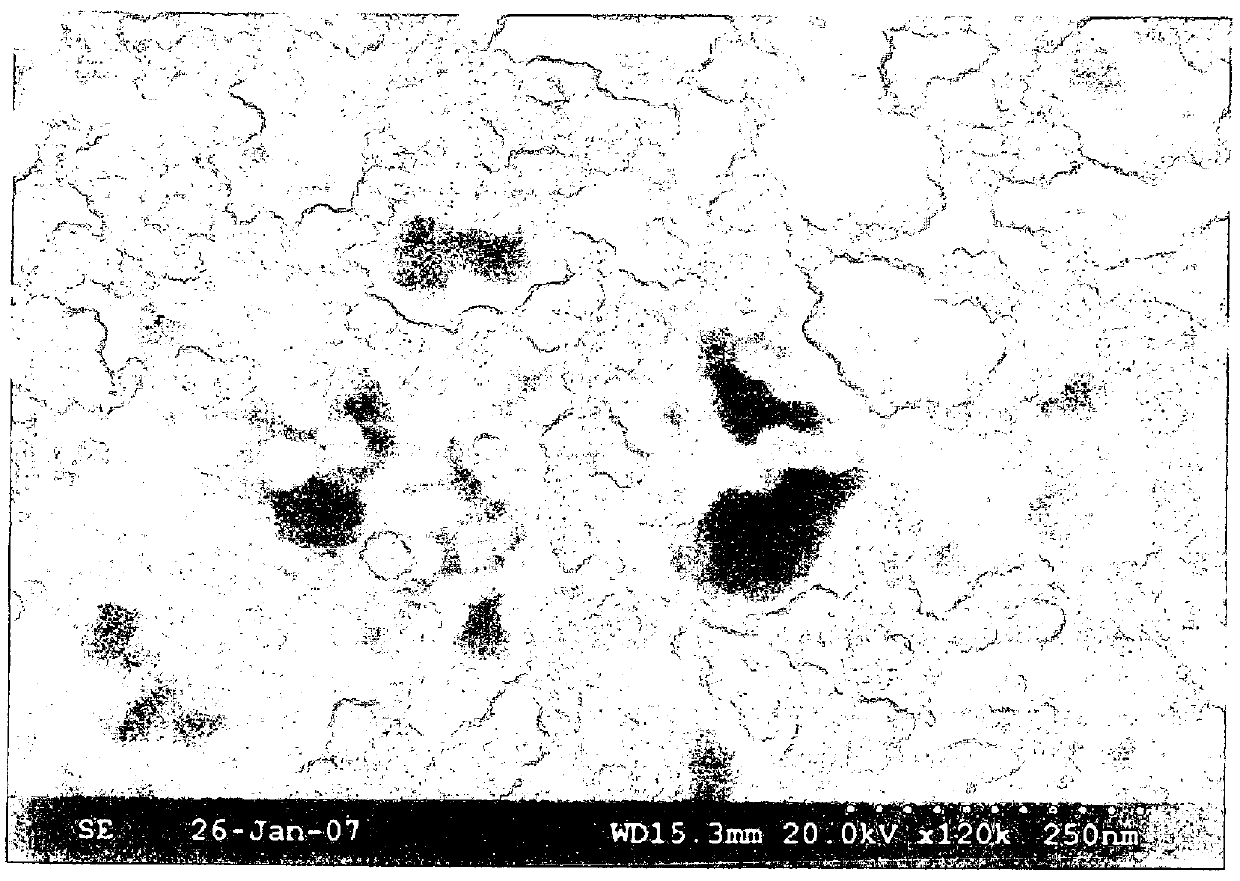

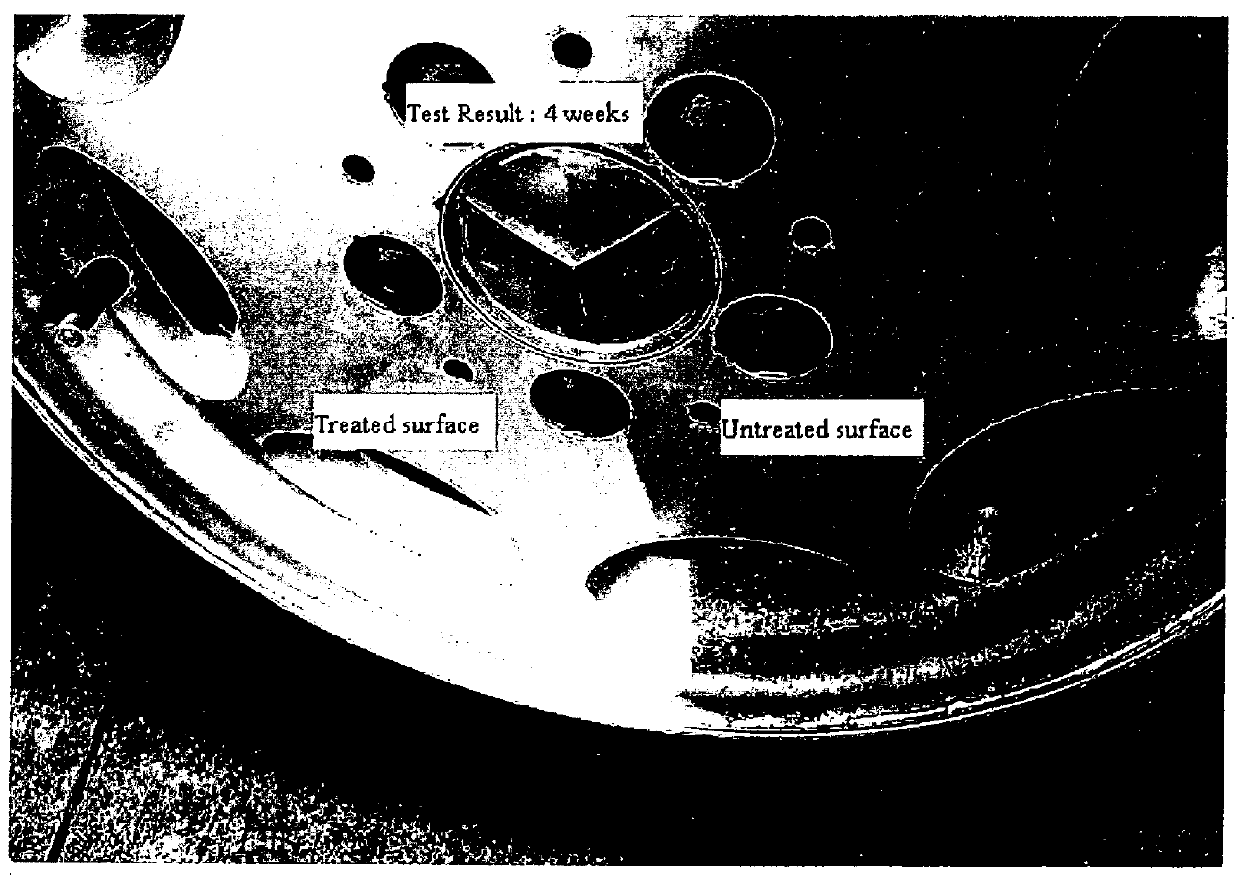

Hydrophobic self-cleaning coating compositions

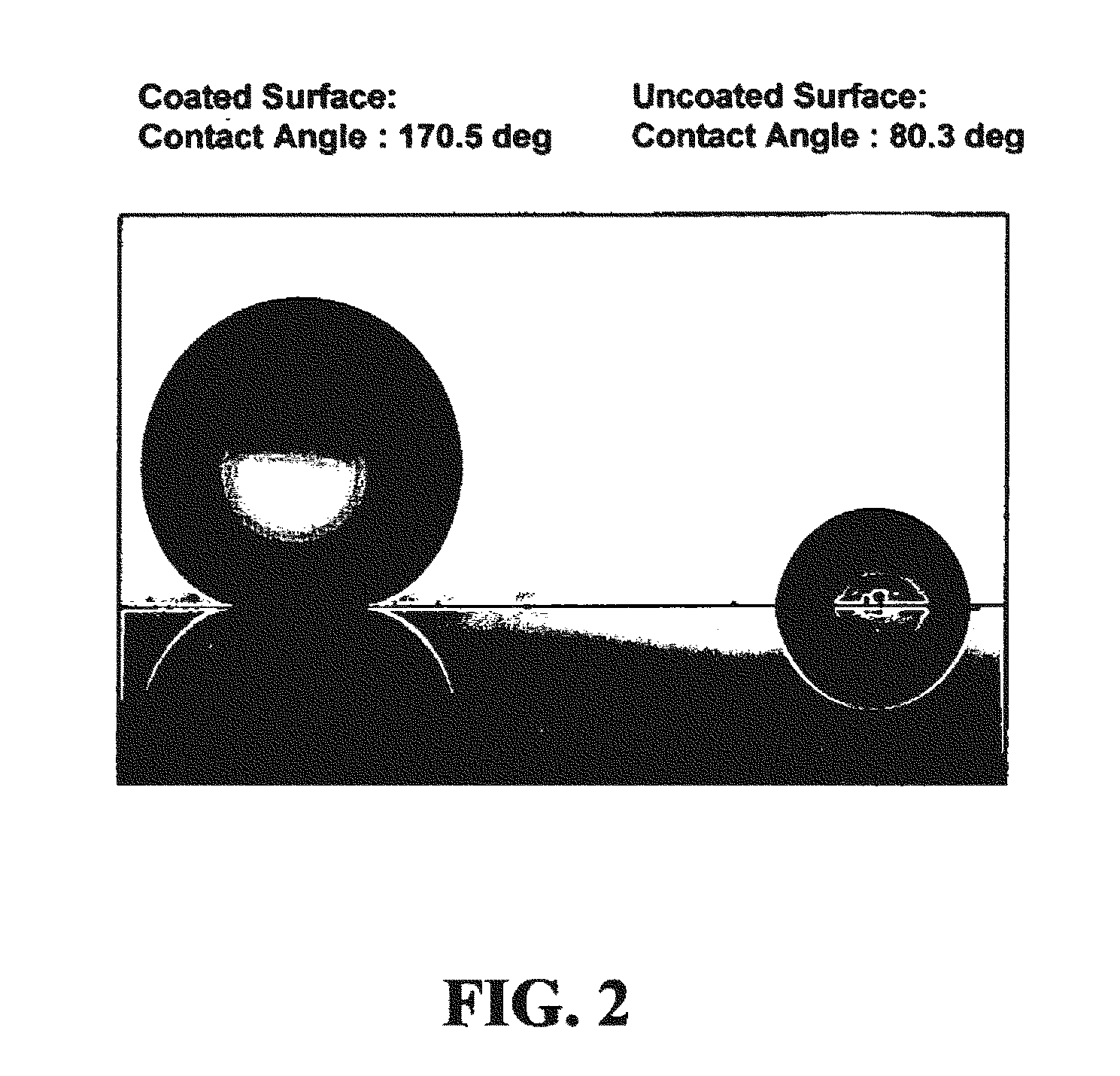

InactiveUS20090018249A1Reduce icingInexpensive comparedOther chemical processesSpecial tyresEvaporationSolvent

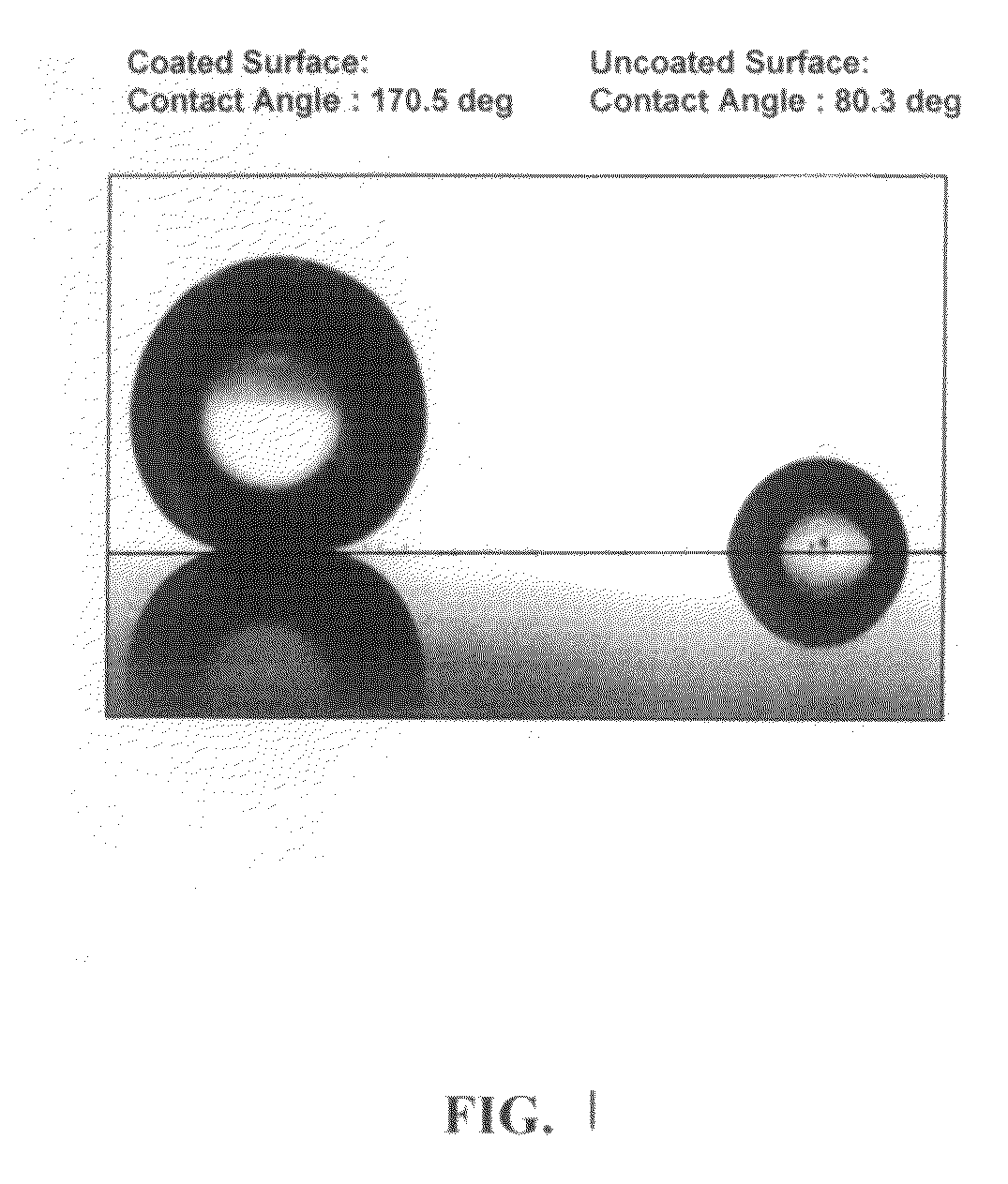

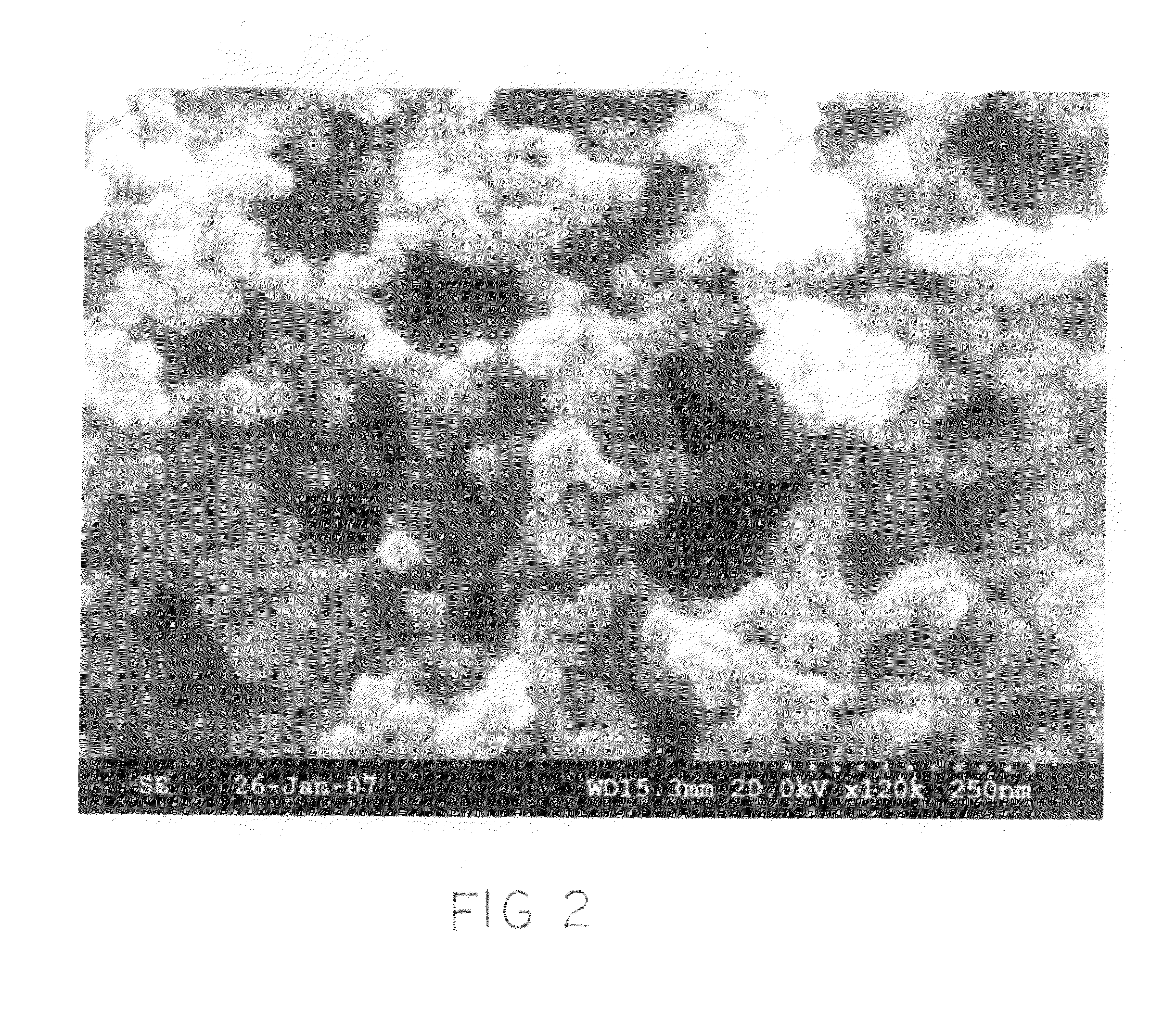

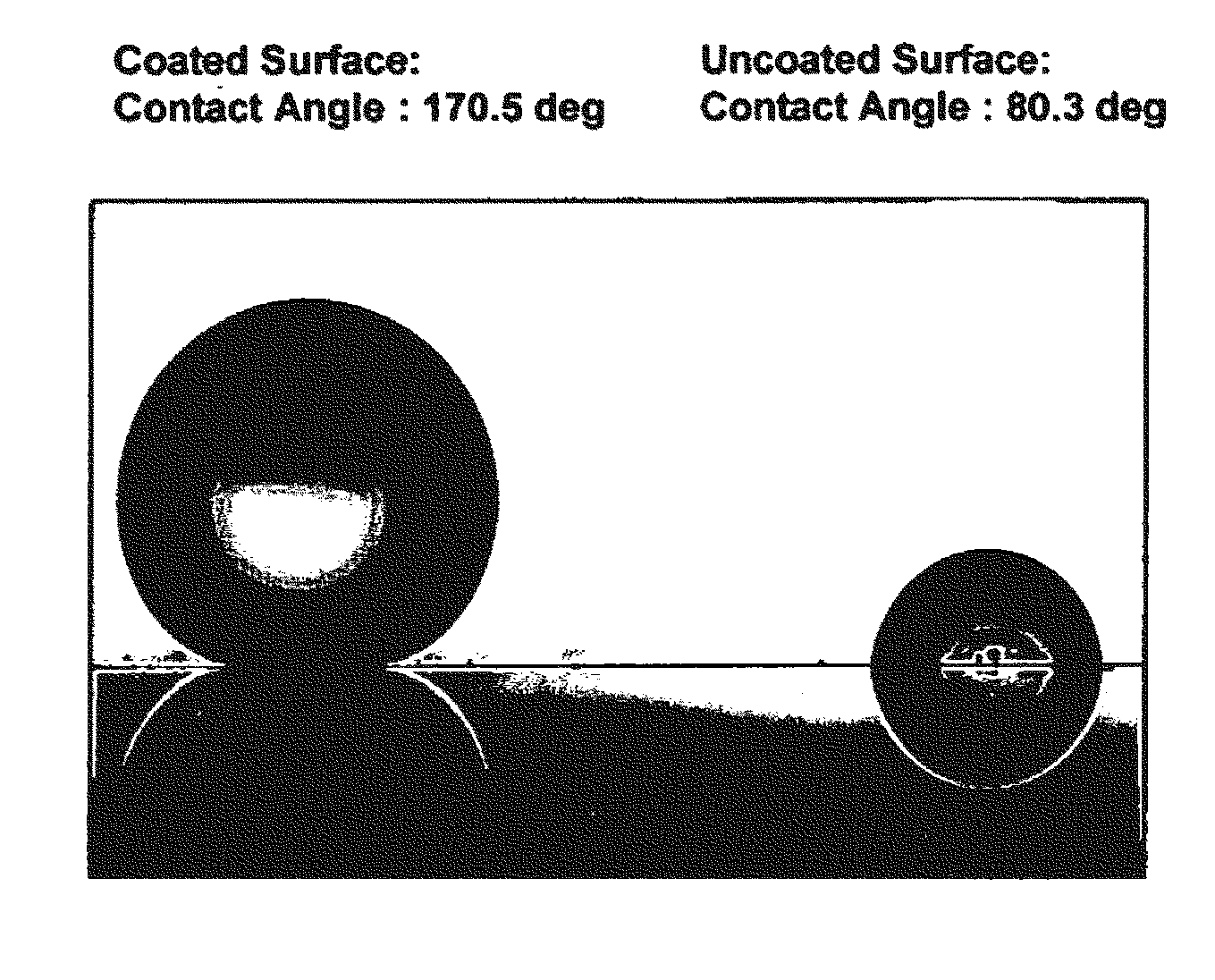

A hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface forming creating a wet and dry dirt repellent coating on the surface. The coating utilizes hydrophobic nanoparticles of fumed silica and / or titania in a solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. Virtually transparent coating are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. One preferred coating composition utilizing an effective amount of a treated fumed silica in a solvent forms a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The self-cleaning coating composition imparts a degree of hydrophobicity to a surface so that the treated surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher.

Owner:ASHLAND LICENSING & INTPROP LLC

Hydrophobic self-cleaning coating compositions

InactiveUS20080221009A1Not to damageEfficient use ofNon-ionic surface-active compoundsNon-surface-active detergent compositionsEvaporationEngineering

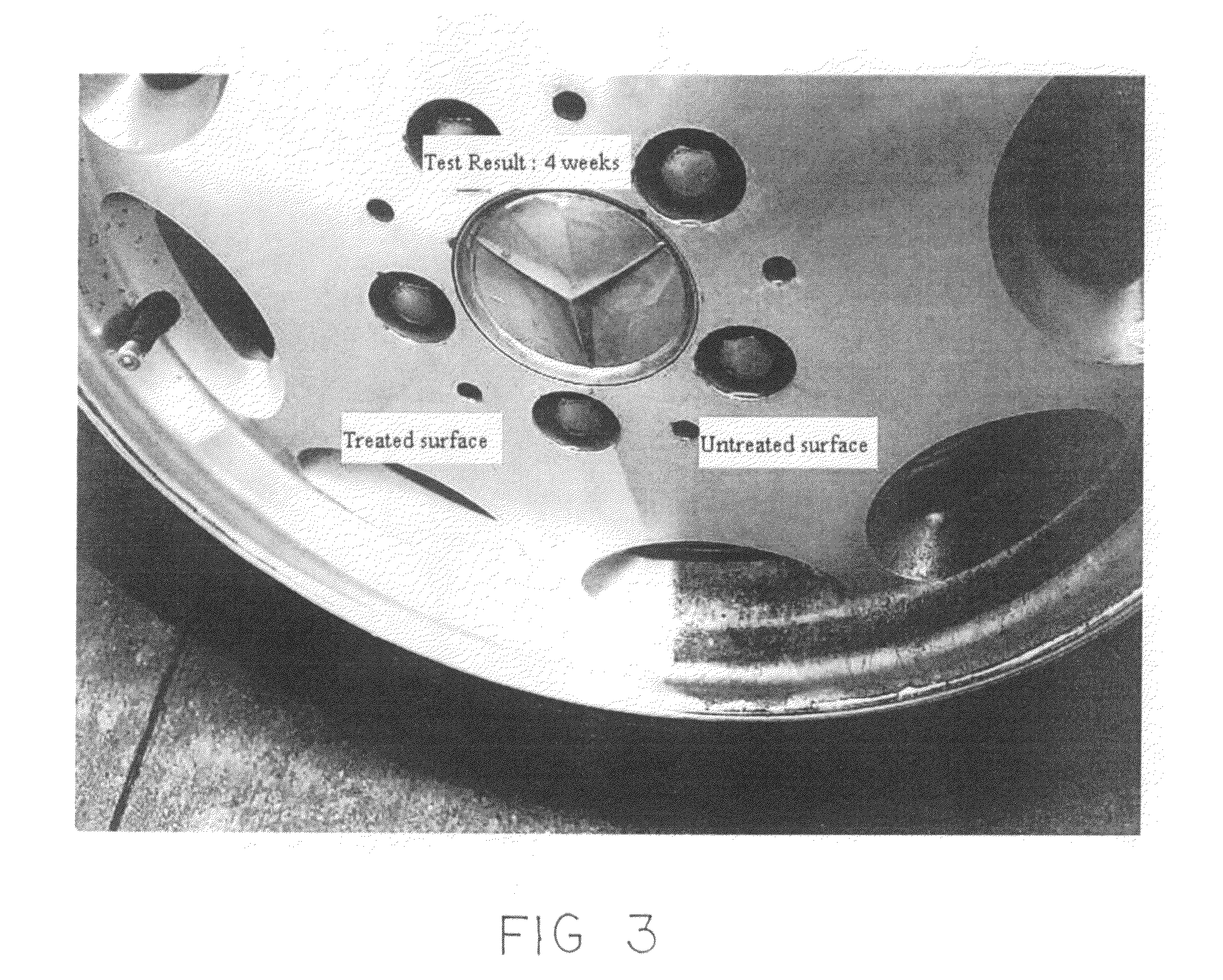

A super hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The super hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or some abrasion resistance not found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the super hydrophobic self-cleaning coating composition result in a clear coating or in some cases a translucent dirt repellant film for coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent. At least one preferred coating composition comprising an effective amount of a treated fumed silica in a solvent resulting in a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

Hydrophobic coating compositions for drag reduction

Owner:VGP IPCO LLC

Coating compositions for producing transparent super-hydrophobic surfaces

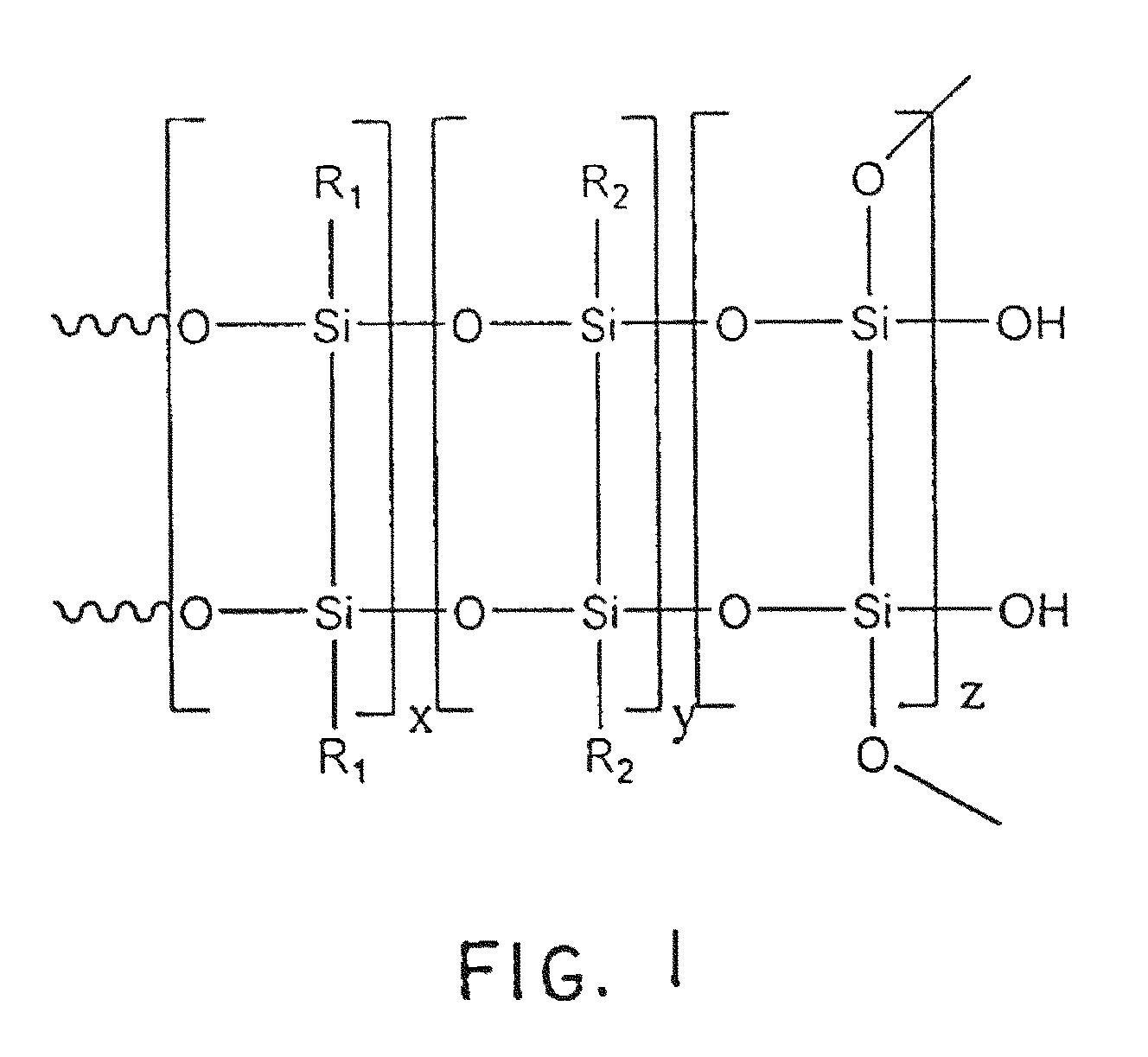

ActiveUS20110177252A1Improves UV resistanceAbrasion resistanceMaterial nanotechnologyOrganic detergent compounding agentsNanoparticleSilsesquioxane

Owner:VGP IPCO LLC

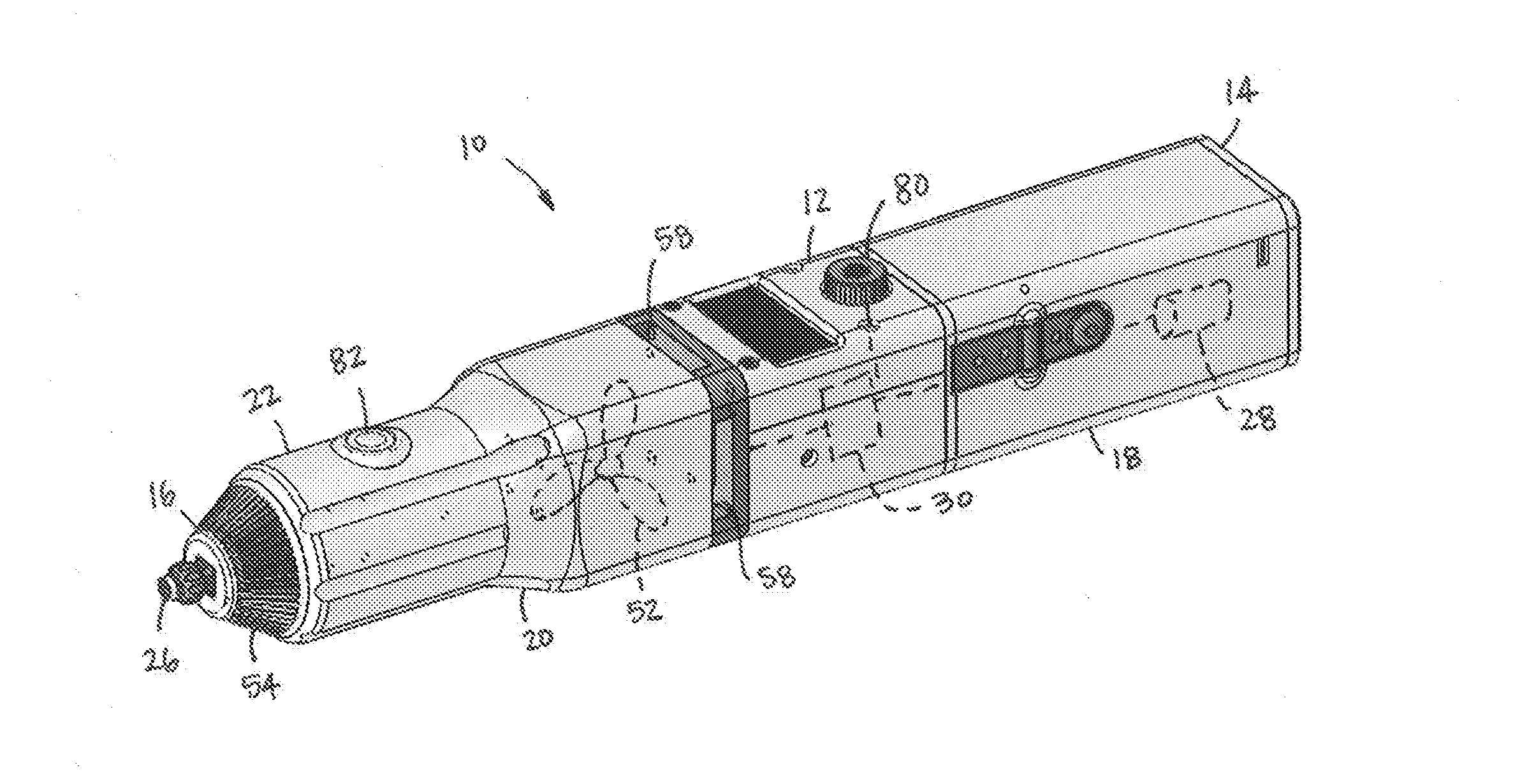

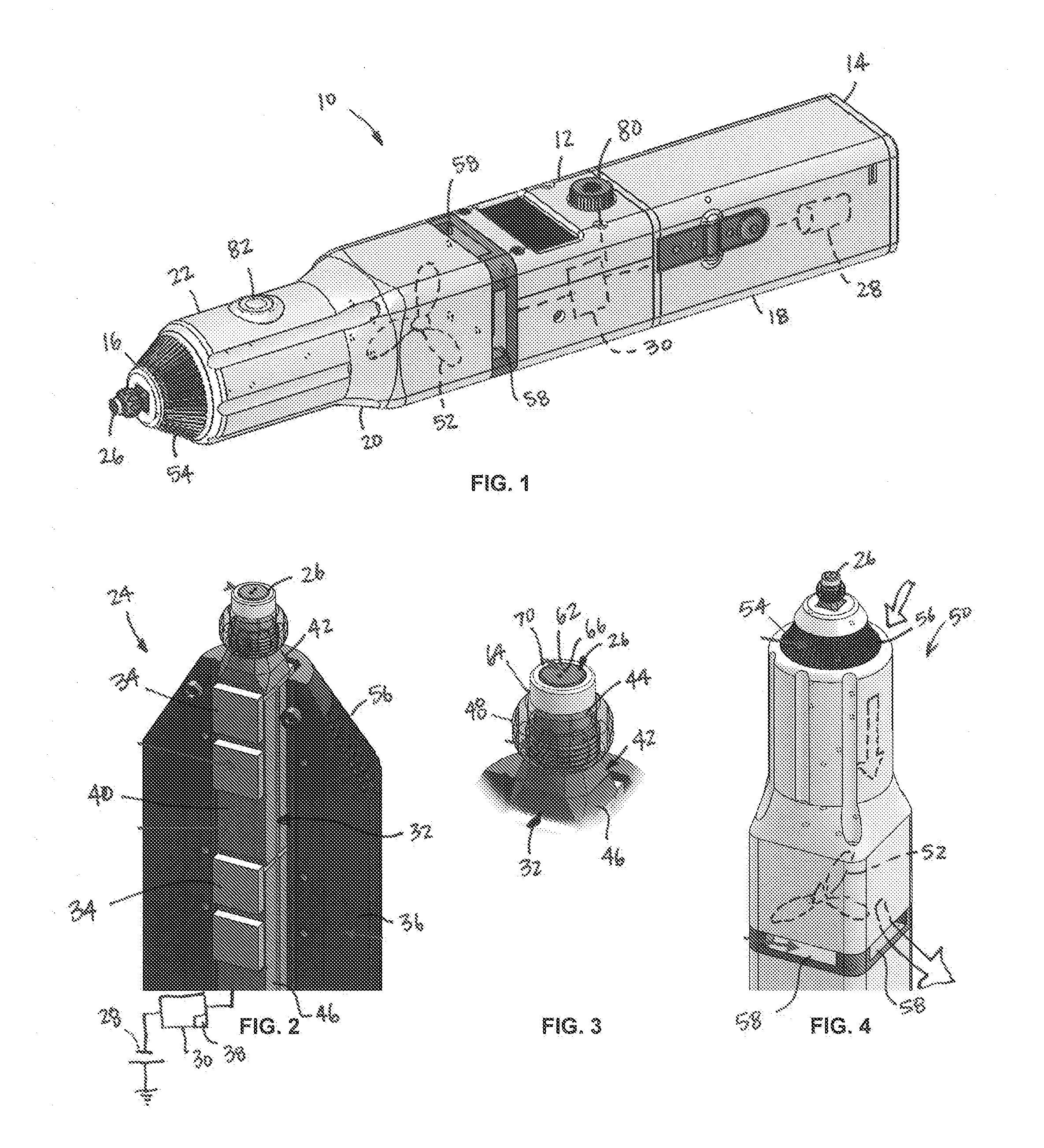

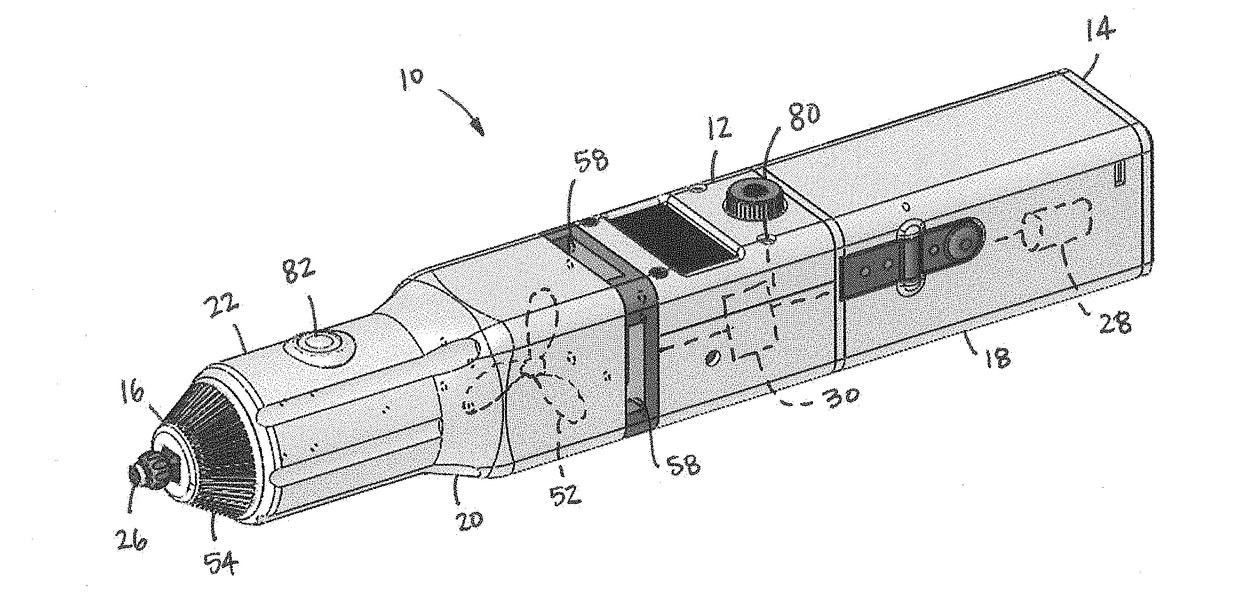

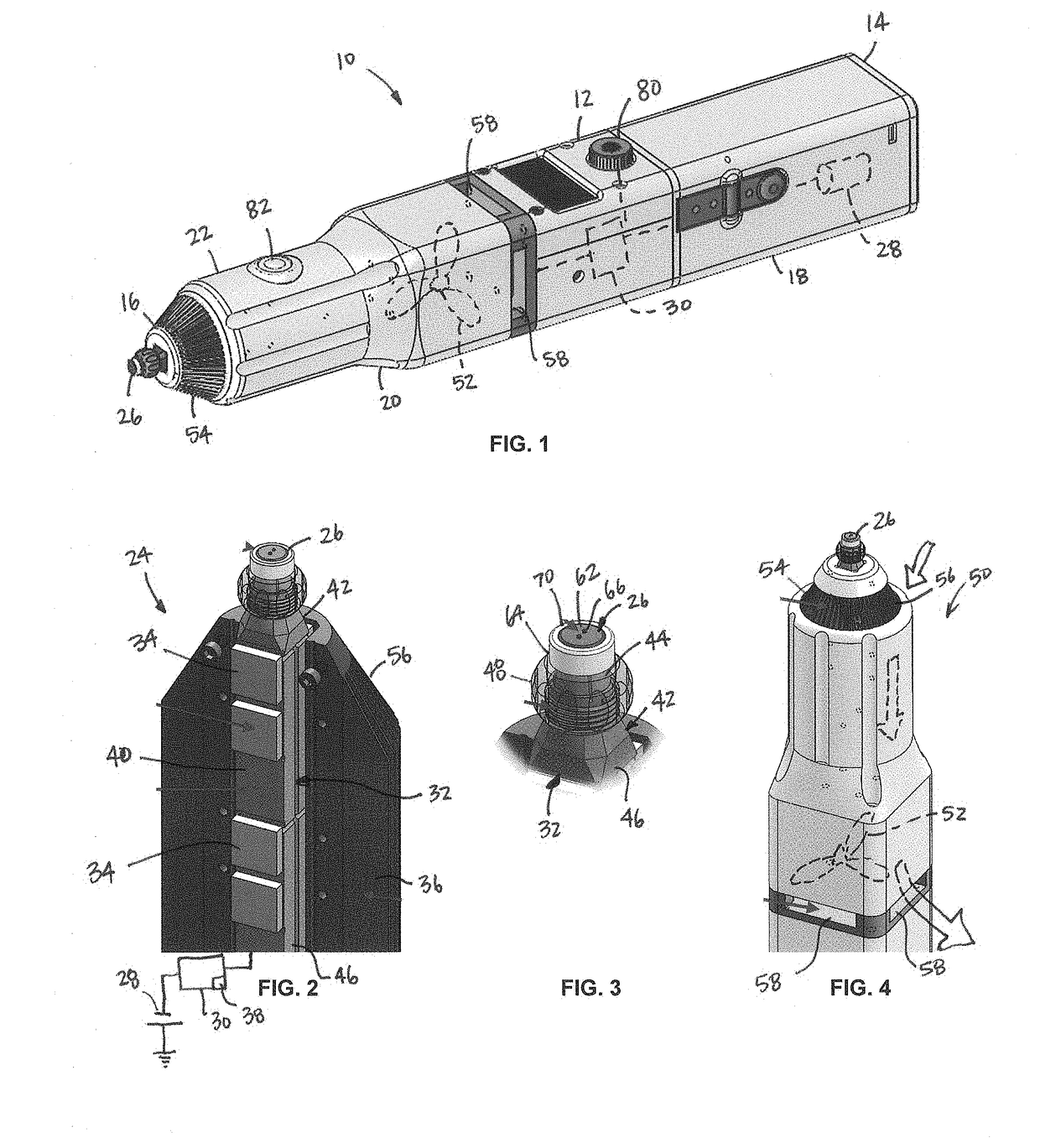

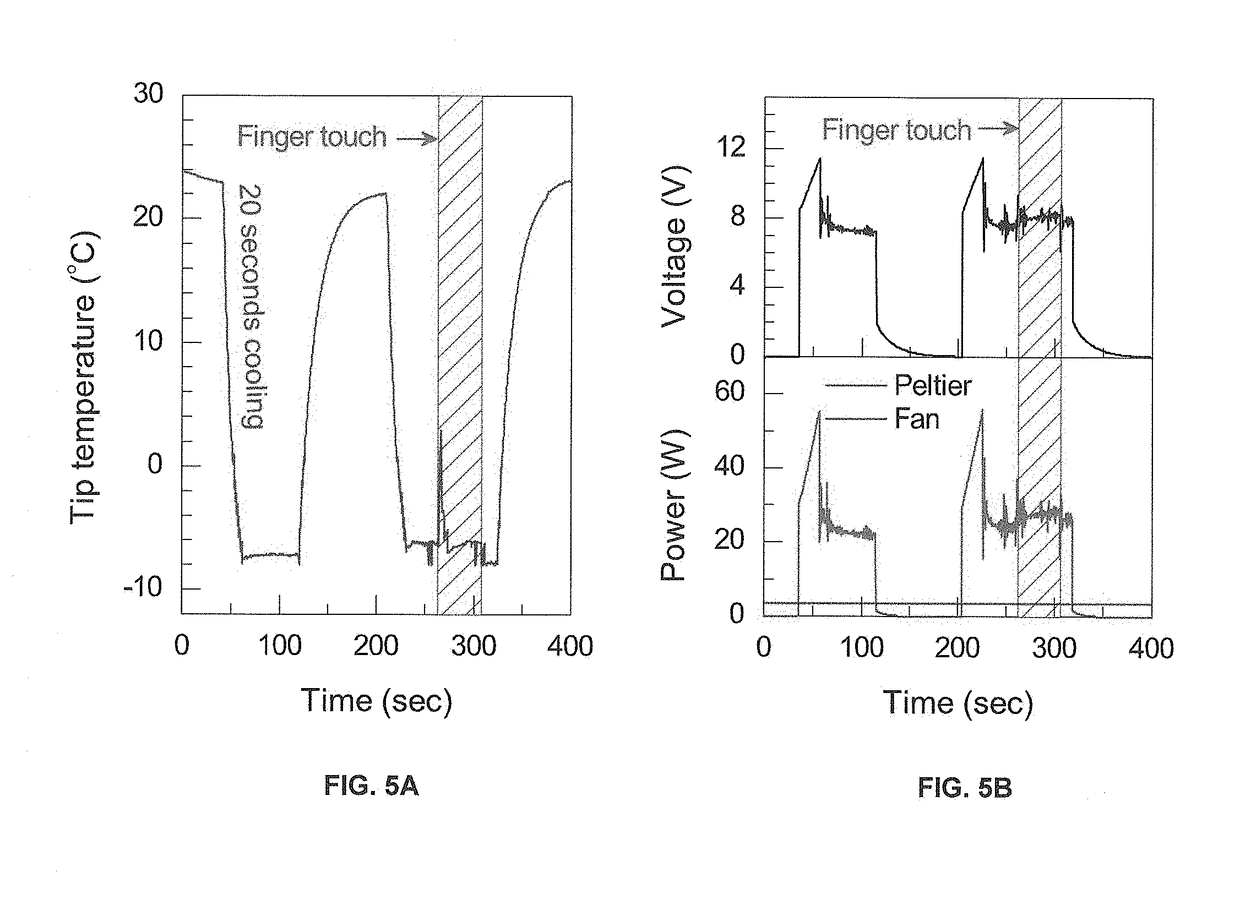

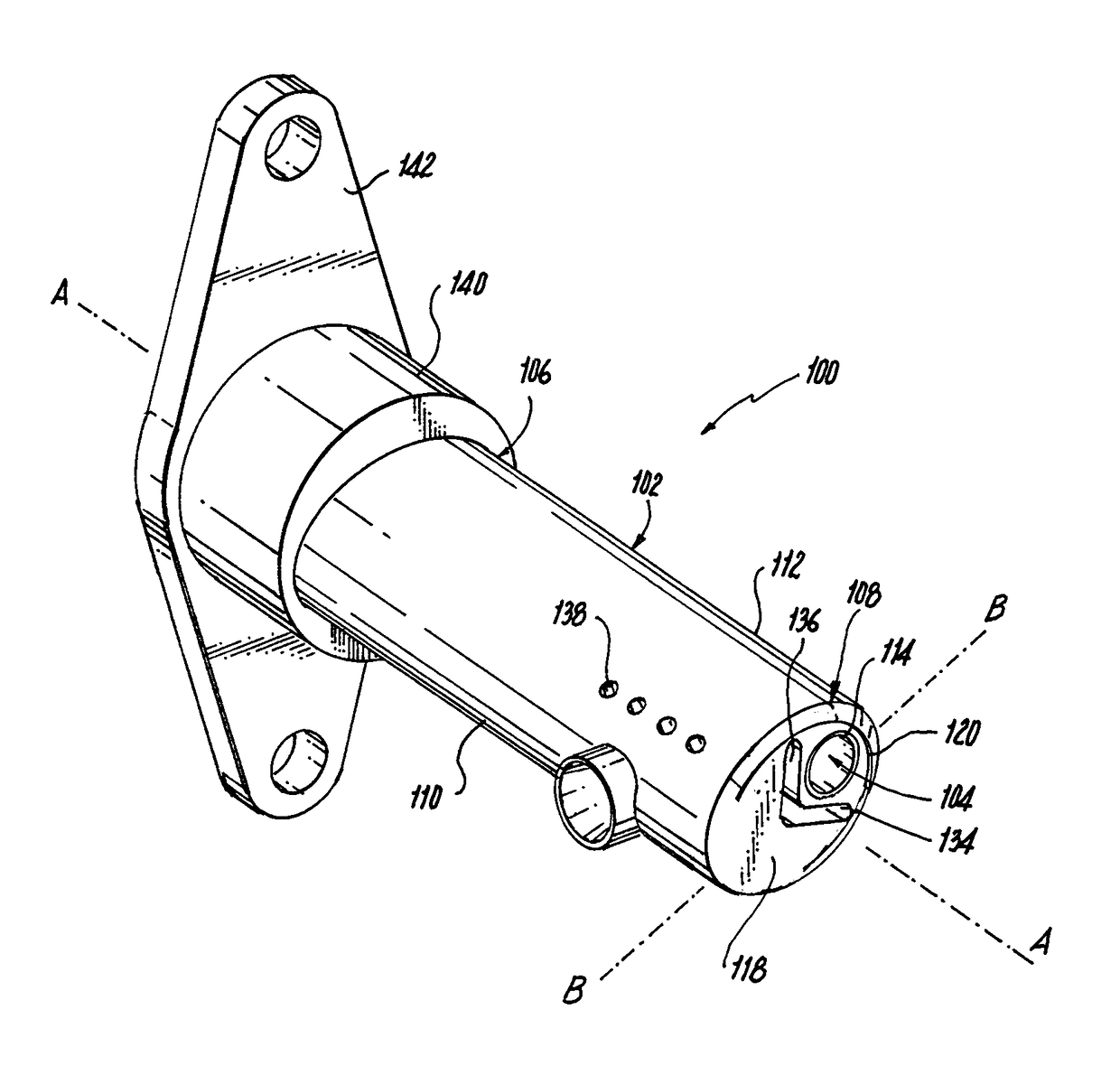

Applicator for cryoanesthesia and analgesia

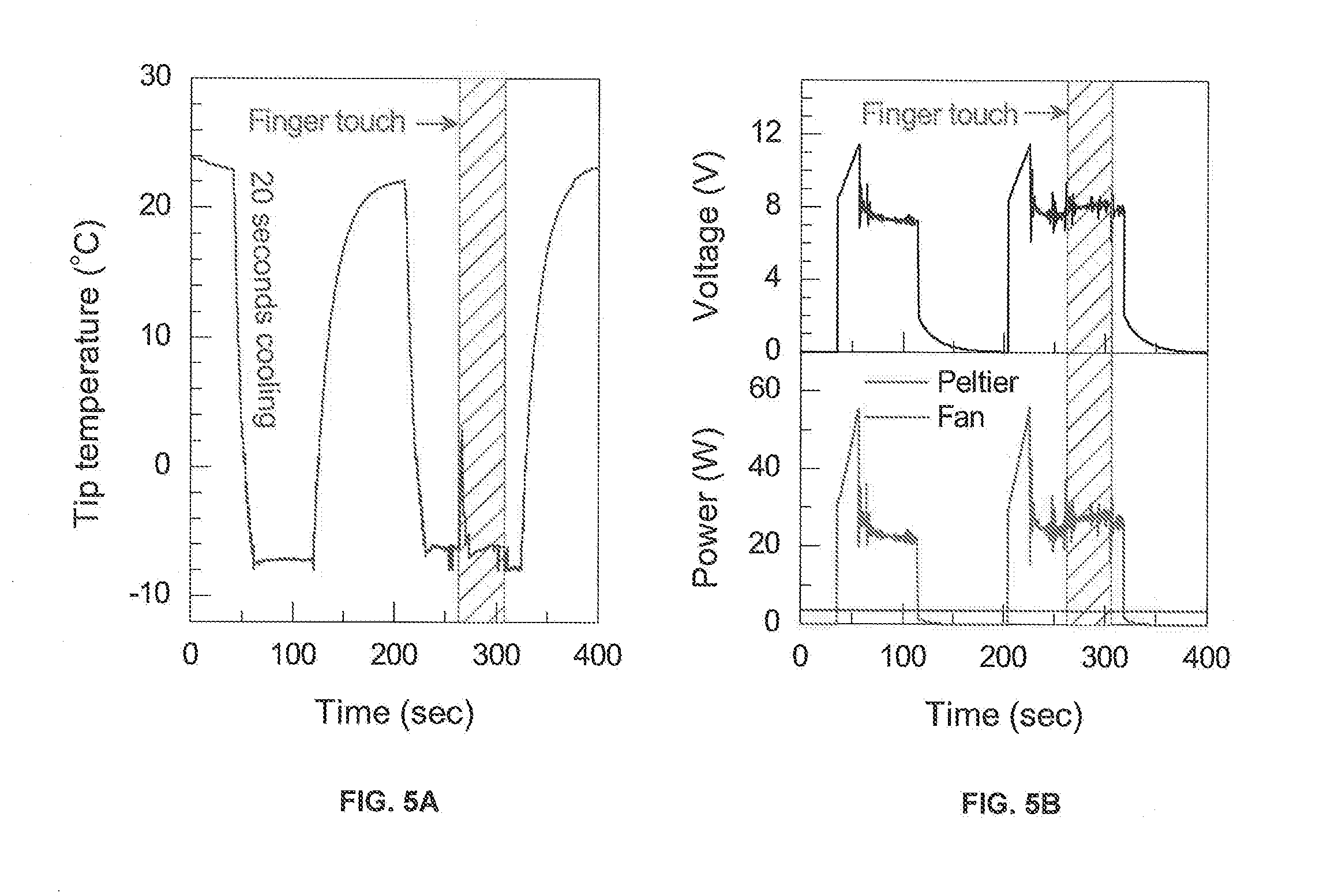

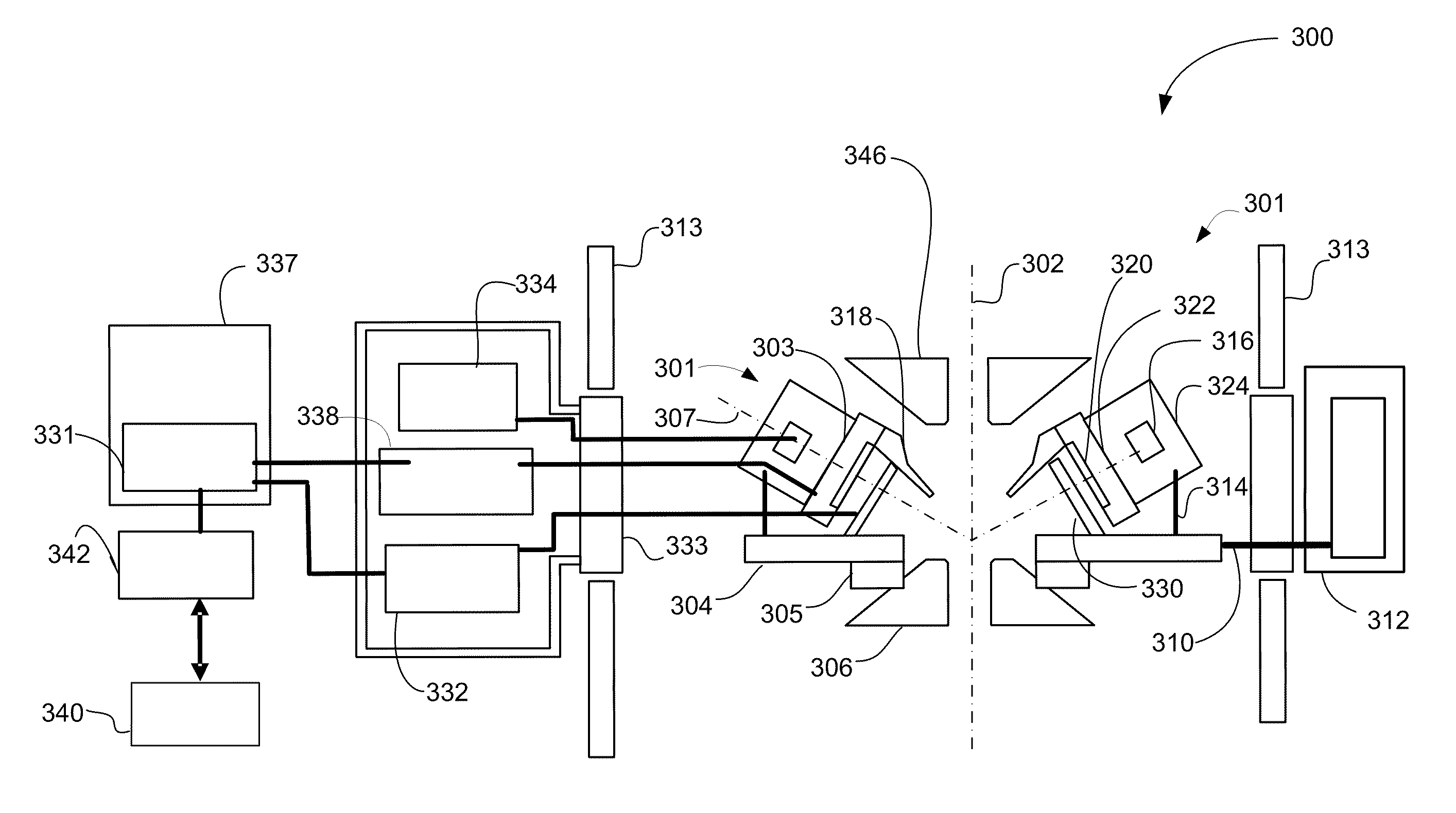

ActiveUS20160279350A1Keep sterileDesired performanceAutomatic syringesMedical devicesThermoelectric coolingMedicine

A handheld cryoanesthesia or analgesia device for cooling a target area on cutaneous membranes, mucous membranes, and tissue of the mucocutaneous zone having an elongated body and a thermoelectric cooling system disposed within the elongated body. The thermoelectric cooling system is configured to physically contact and thermally couple the target area of the cutaneous membranes, mucous membranes, and tissue of the mucocutaneous zone to induce cryoanesthesia or analgesia. The thermoelectric cooling system includes a thermally-conductive cold tip, a thermally-conductive cooling power concentrator thermally coupled to the cold tip, at least one Peltier unit module thermally coupled to the cooling power concentrator, a heatsink thermally coupled to at least one Peltier unit module, a power source, at least one thermal sensor, and a controller operably outputting a control signal to the Peltier unit module to maintain a predetermined temperature.

Owner:RGT UNIV OF MICHIGAN

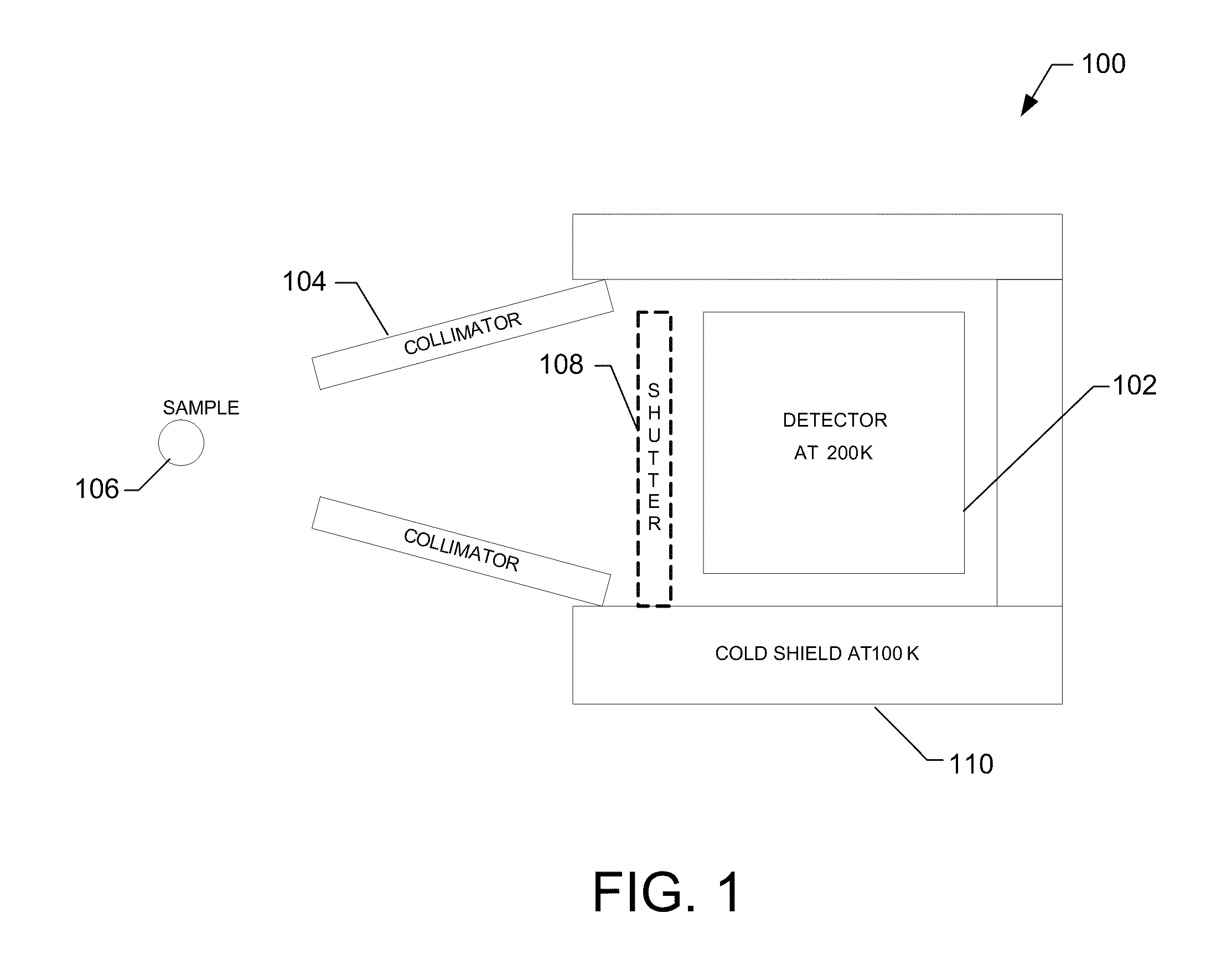

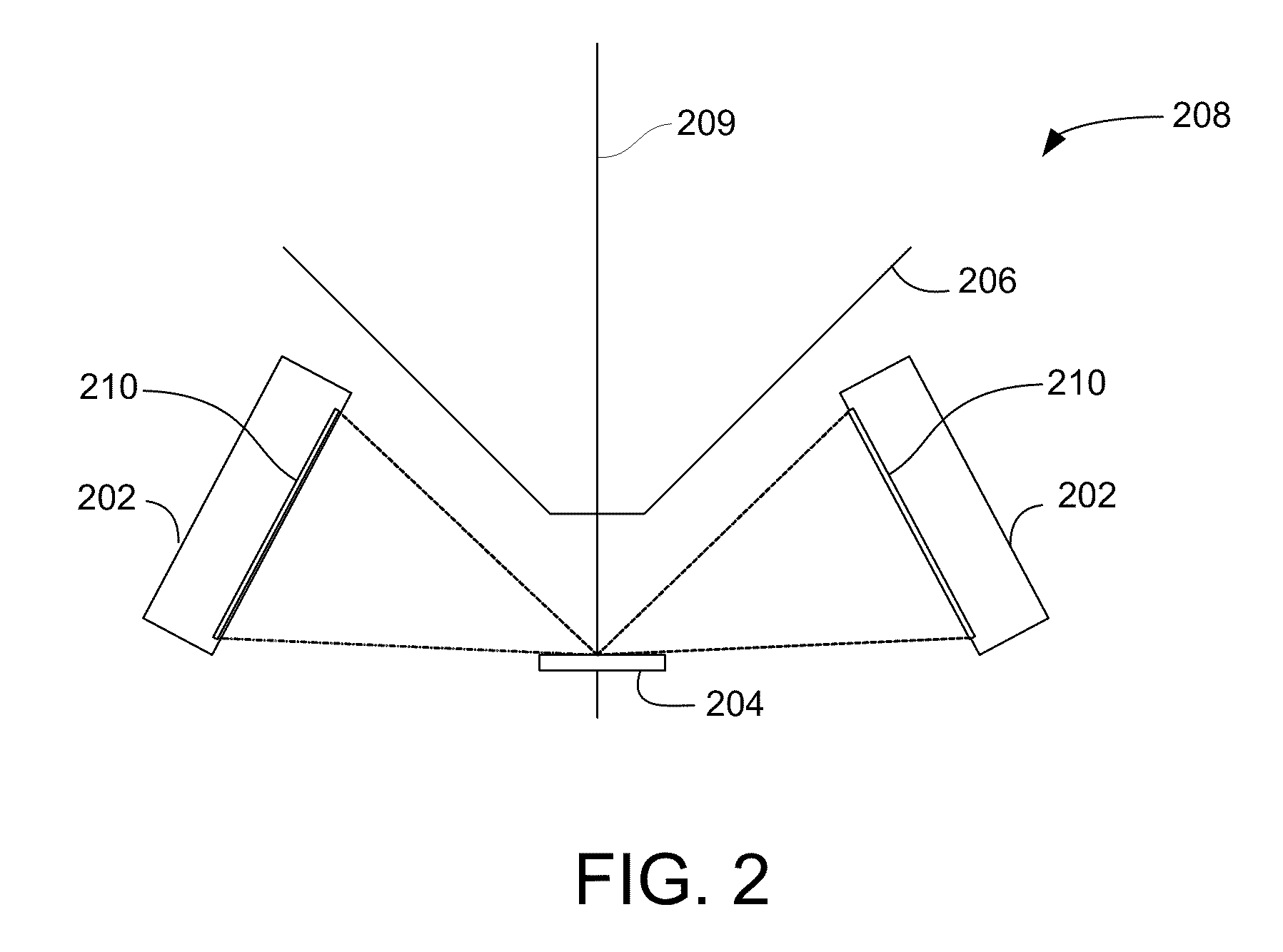

X-ray detector for electron microscope

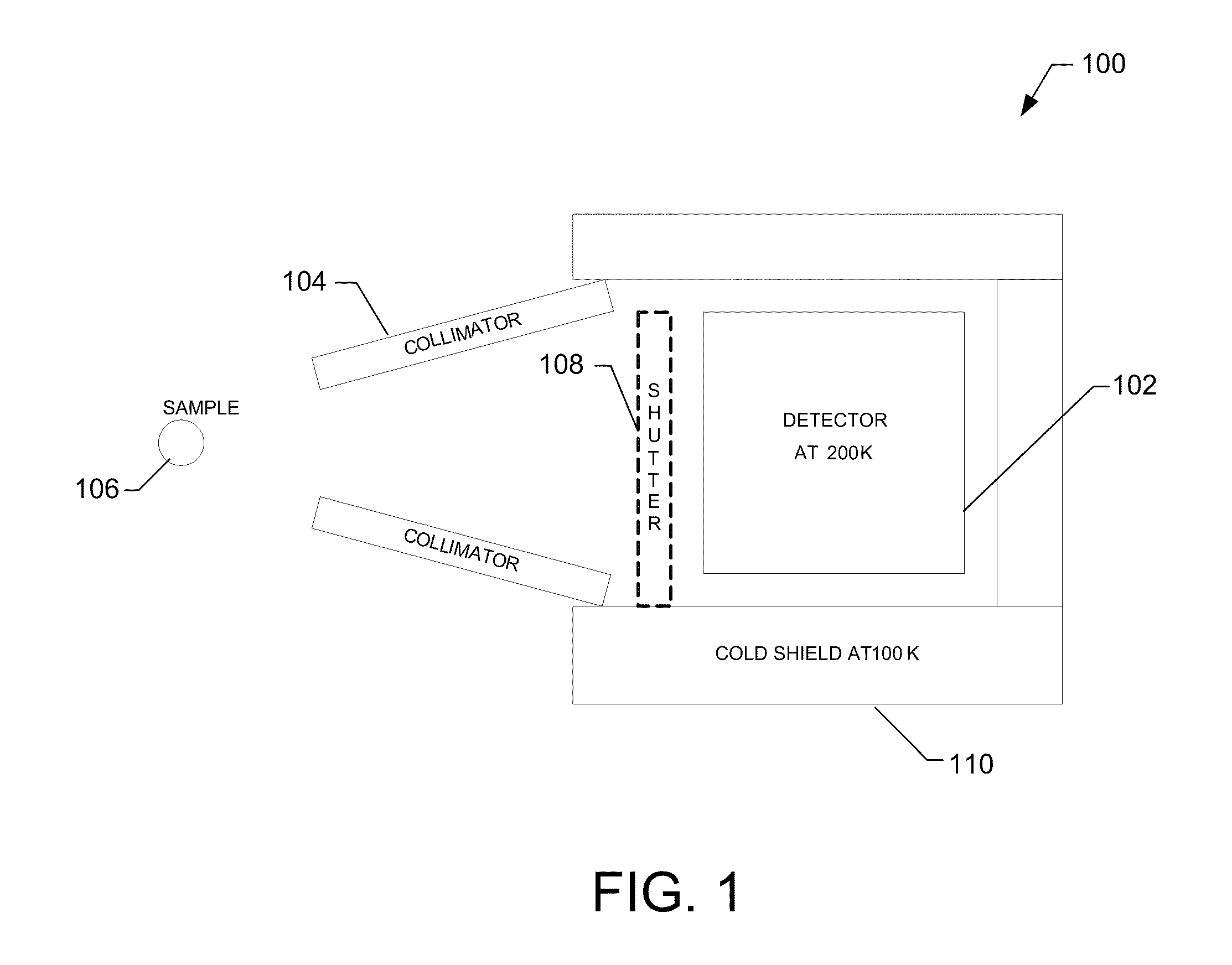

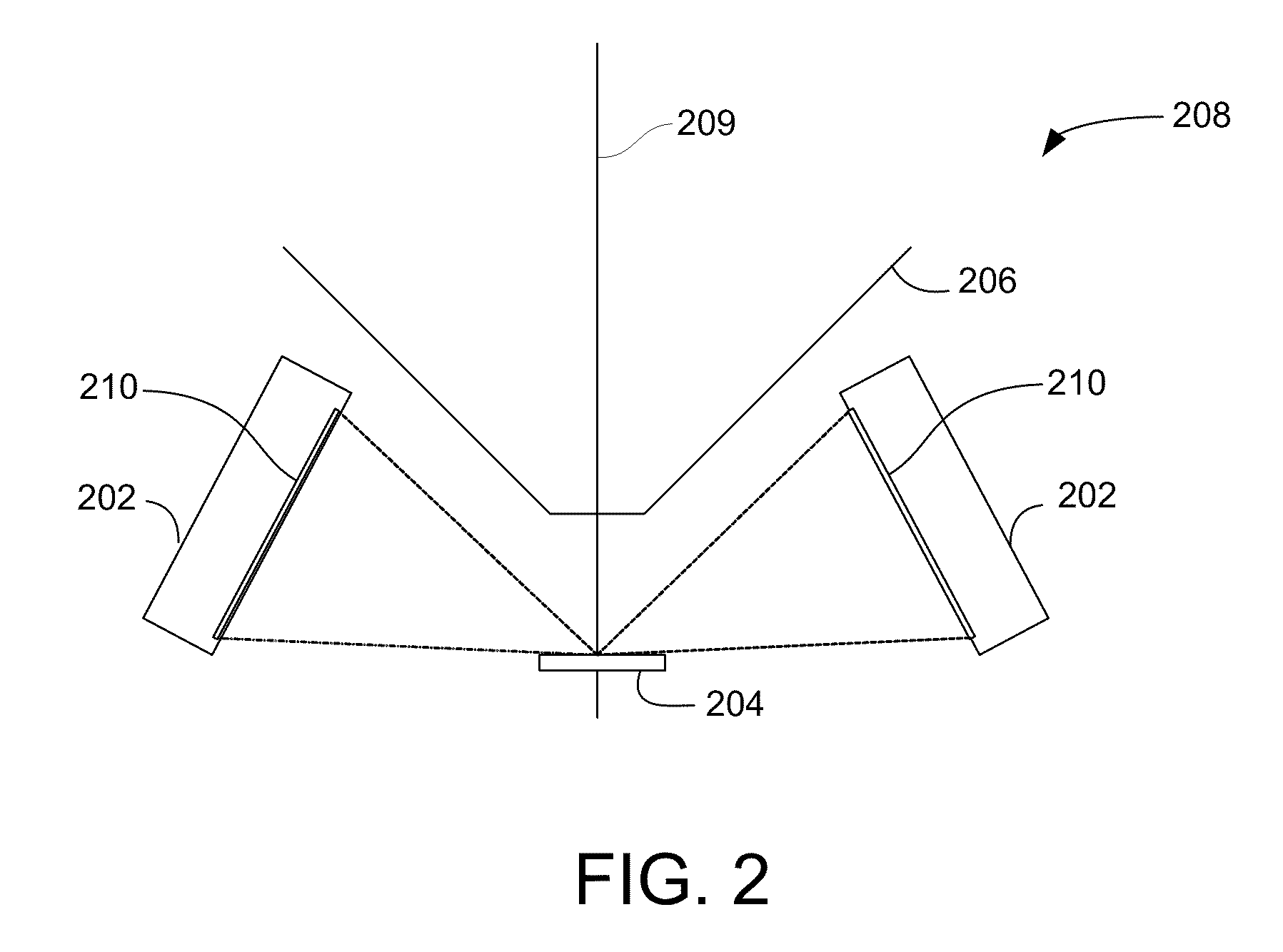

ActiveUS8080791B2Easy to detectReduce icingMaterial analysis using wave/particle radiationElectric discharge tubesCold shieldX-ray

Owner:FEI CO

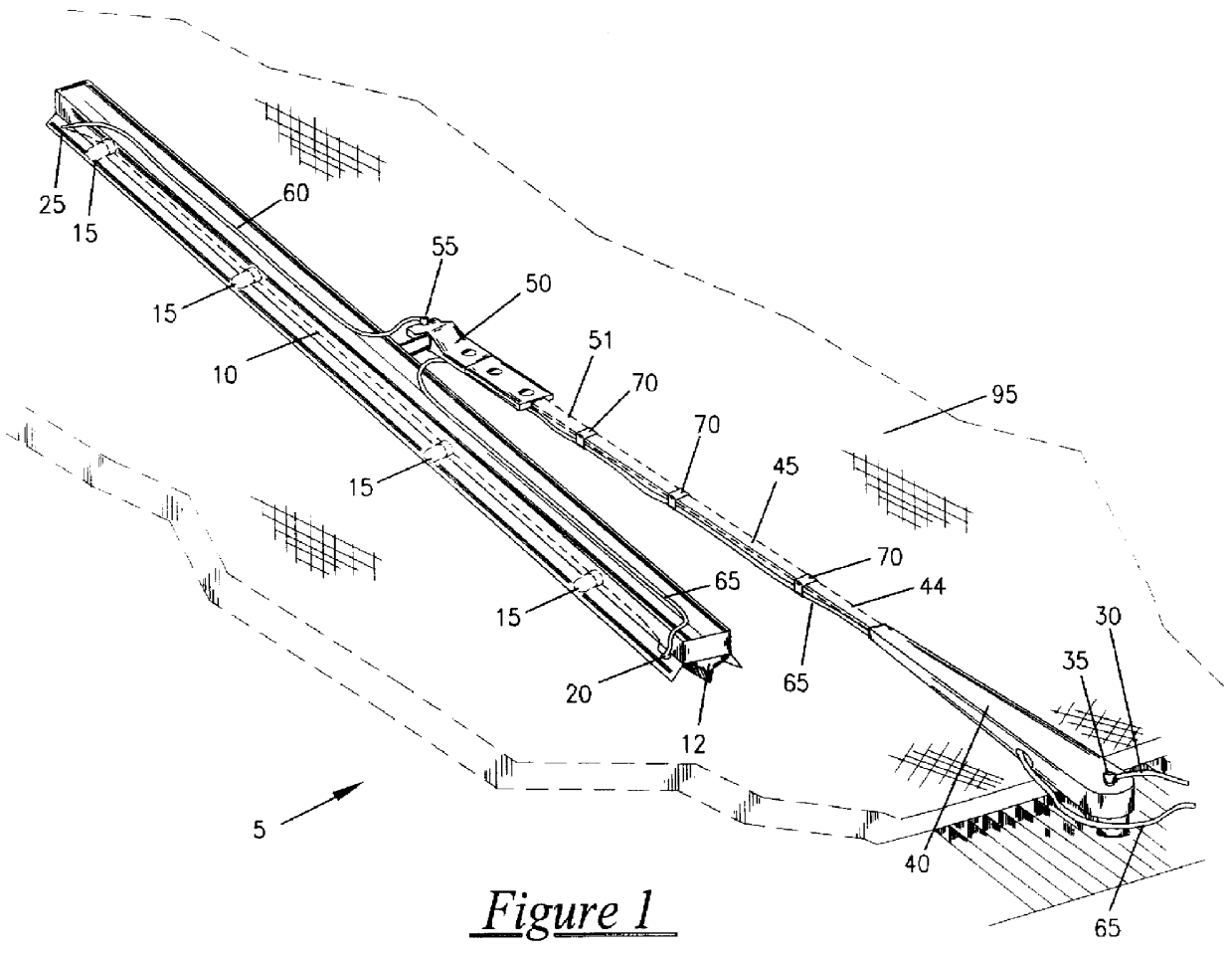

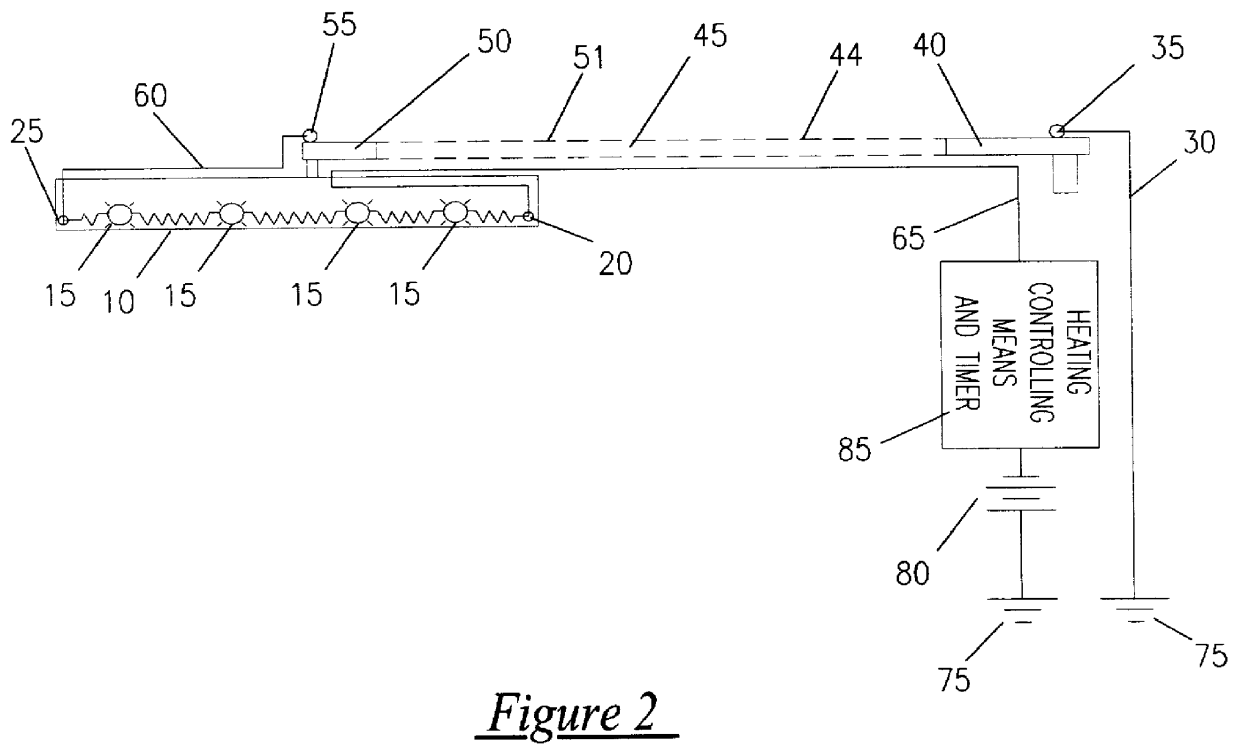

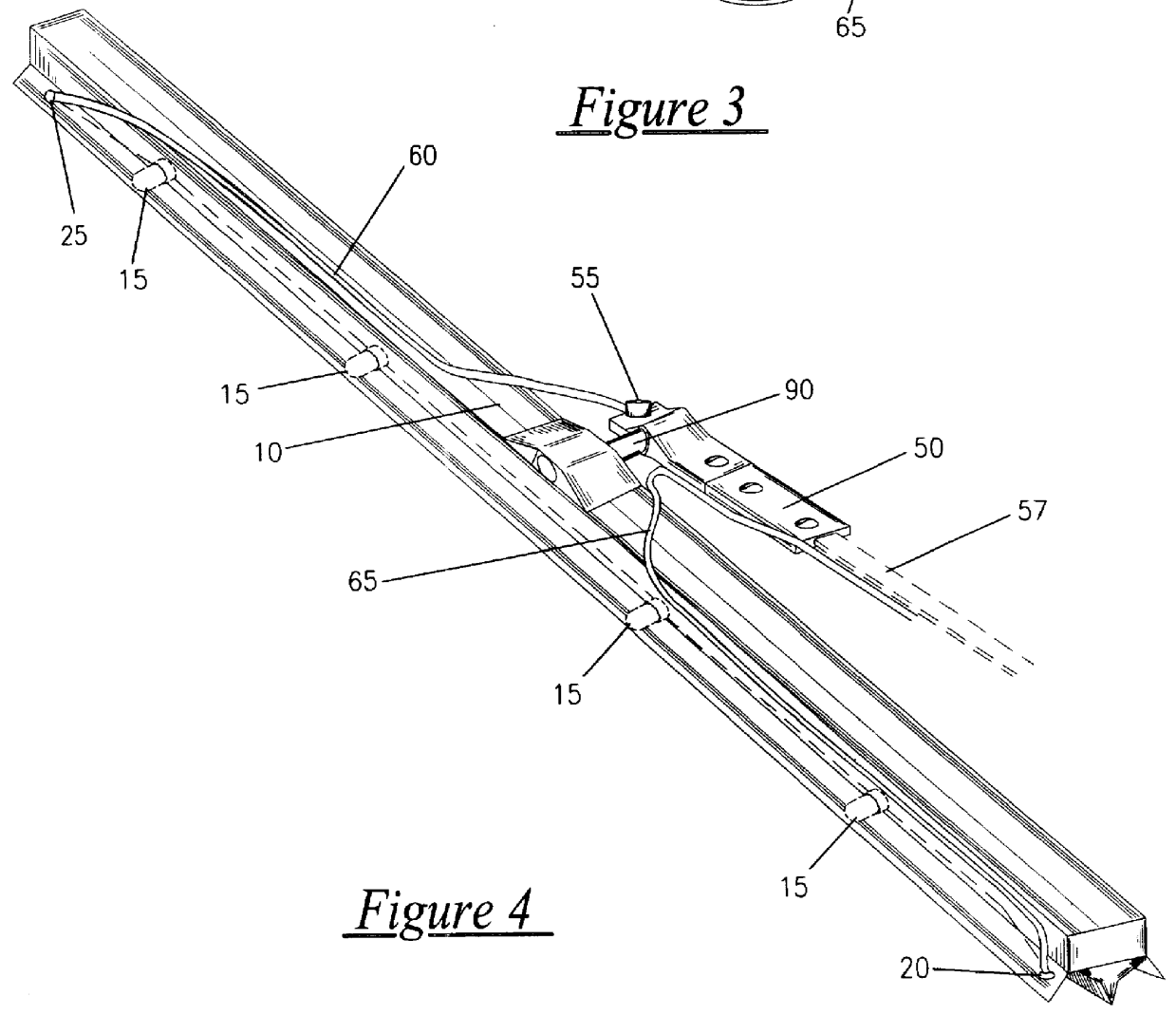

Heated and lighted windshield wiper assembly

InactiveUS6100499AReduce frostingReduce snowTransparent/reflecting heating arrangementsWindow cleanersMobile vehicleDriver/operator

An apparatus to be used by motor vehicle drivers under conditions such as freezing rain, sleet or snow to allow improved forward vision. Comprised of a conventional windshield wiper assembly having an electrically conductive arm and a first elongated conductor, such as an insulated wire having a first end opposite a second end is provided, wherein the first end terminated by a first terminal connection at the base end of the wiper arm, and the second end is terminated at the electrical ground plane of the motor vehicle. A second elongated conductor is terminated at one end by a second terminal connection at the distal end of the wiper arm, and at the opposing end is electrically connected to an imbedded heating element in the wiper blade. A third elongated conductor is electrically connected at one end to the electrically opposing terminal on the imbedded heating element in the wiper blade and is routed down the wiper arm and is held close the wiper arm by a harnessing means such as a plurality of spaced clip connectors. The opposing end of the third elongated conductor communicates directly with a voltage control regulator for controlling or stopping electrical current. The system is electrically connected to the motor vehicle's existing fuse box to serve as the electrical power source.

Owner:DAVILA SR RICHARD A

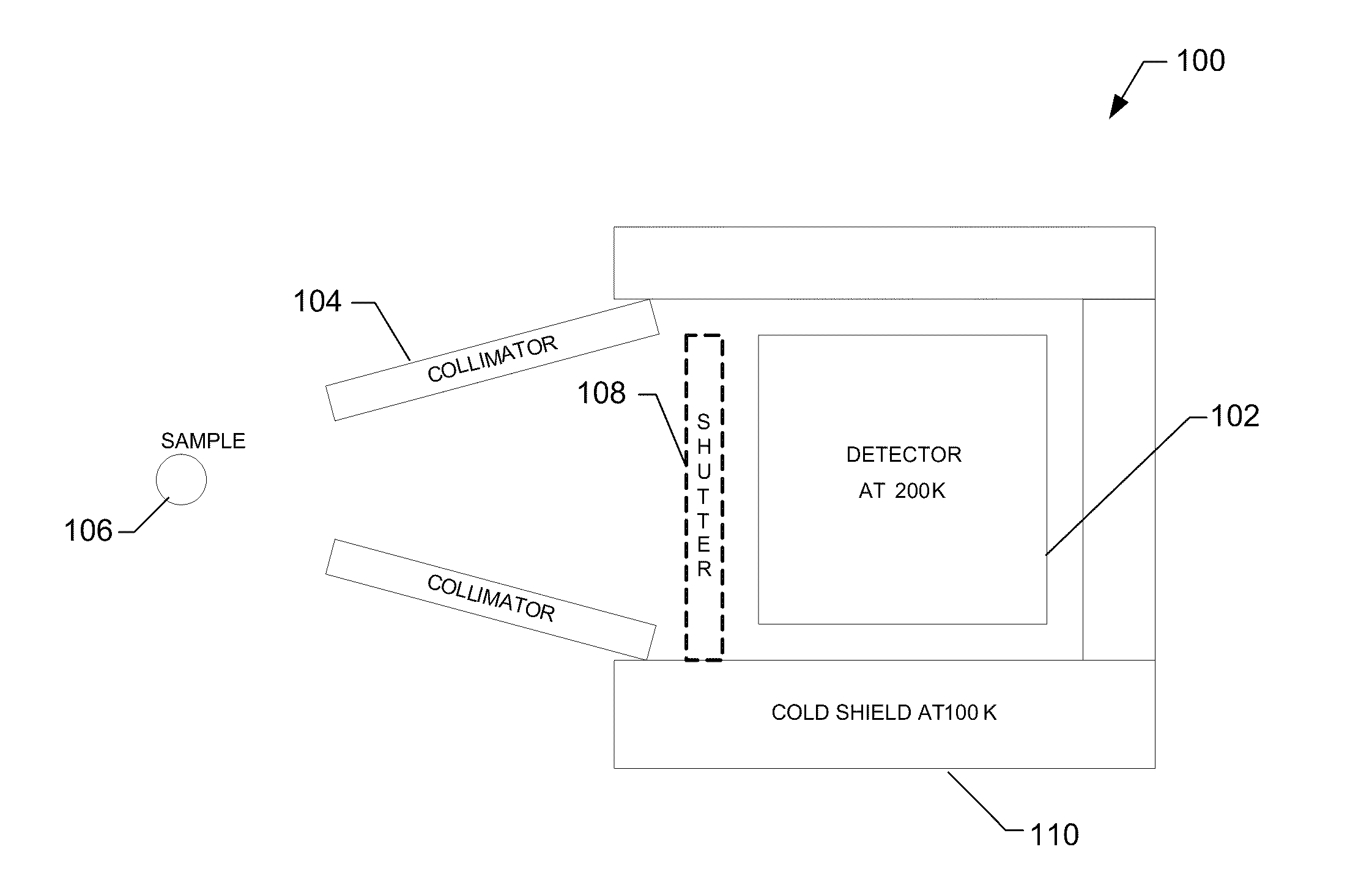

X-ray detector for electron microscope

ActiveUS20100148064A1Easy to detectReduce icingMaterial analysis using wave/particle radiationElectric discharge tubesCold shieldElectron microscope

Multiple detectors arranged in a ring within a specimen chamber provide a large solid angle of collection. The detectors preferably include a shutter and a cold shield that reduce ice formation on the detector. By providing detectors surrounding the sample, a large solid angle is provided for improved detection and x-rays are detected regardless of the direction of sample tilt.

Owner:FEI CO

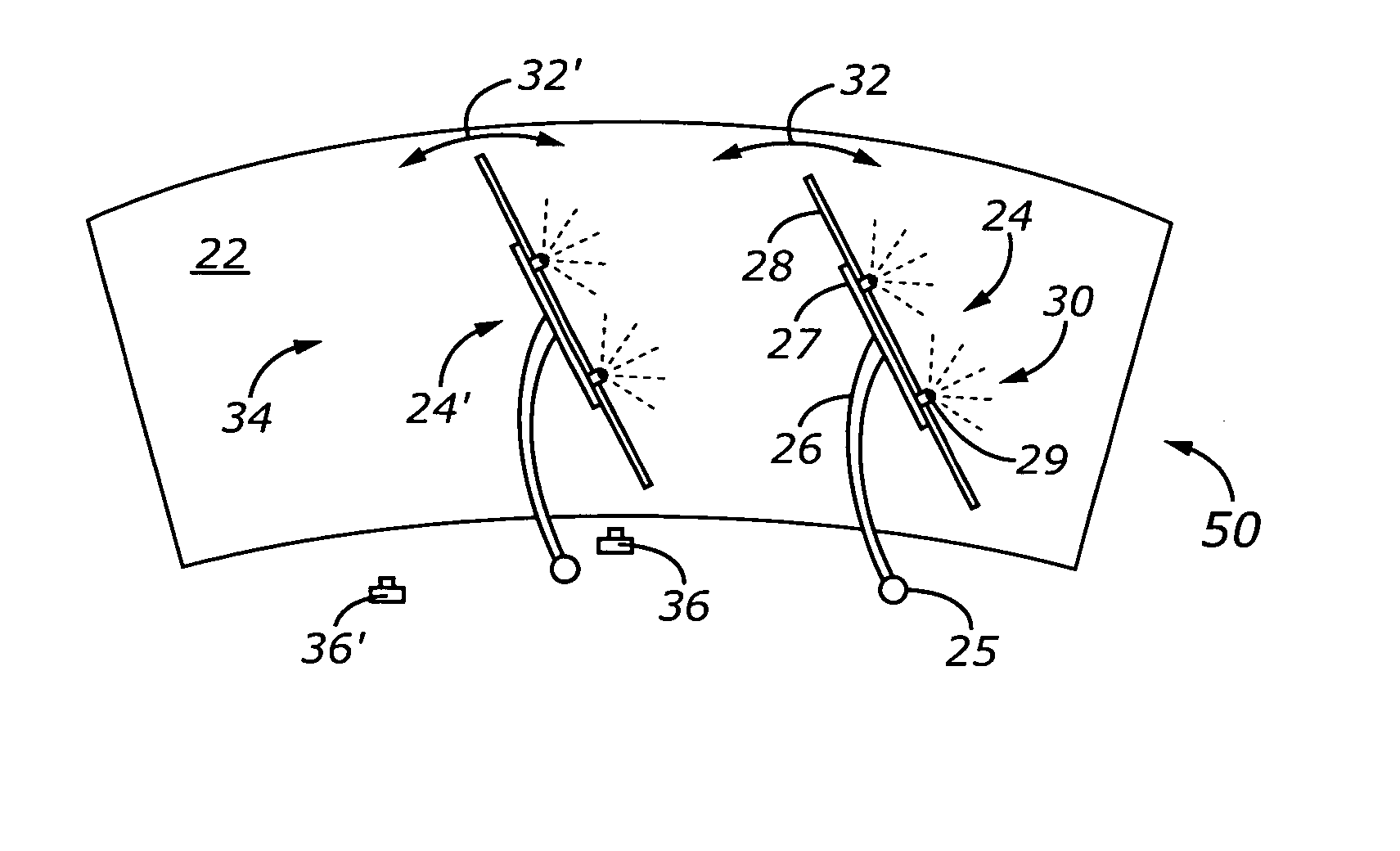

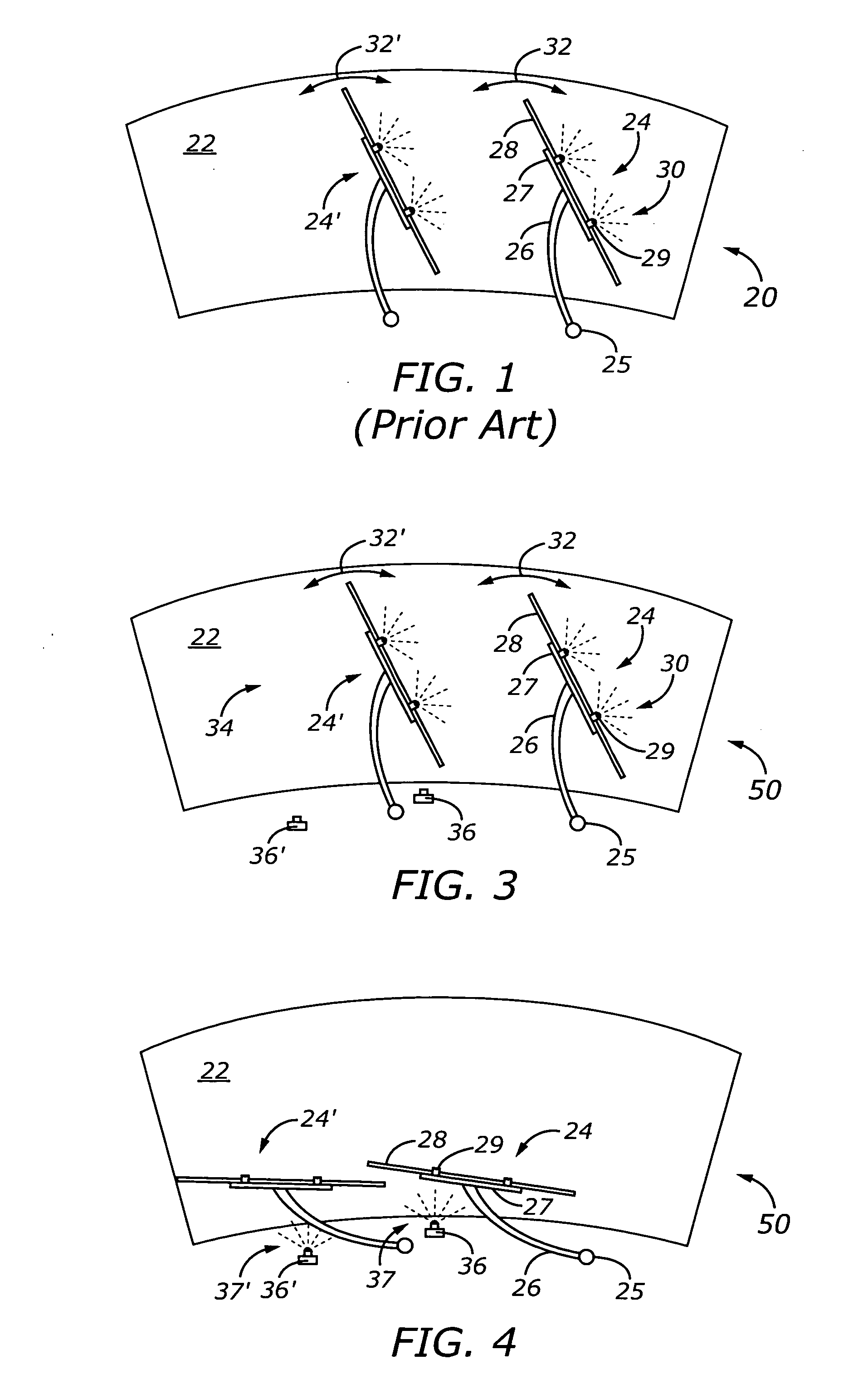

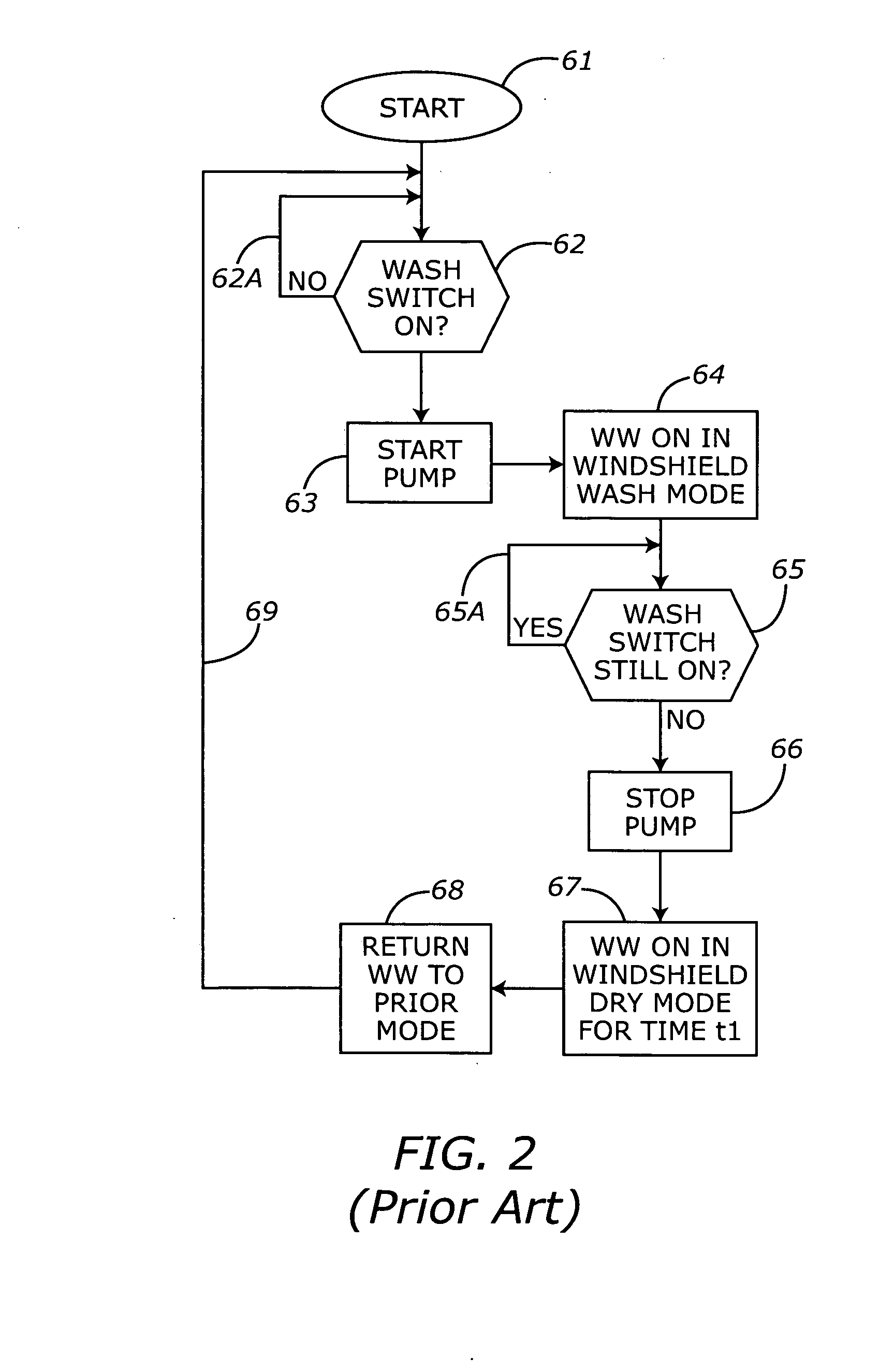

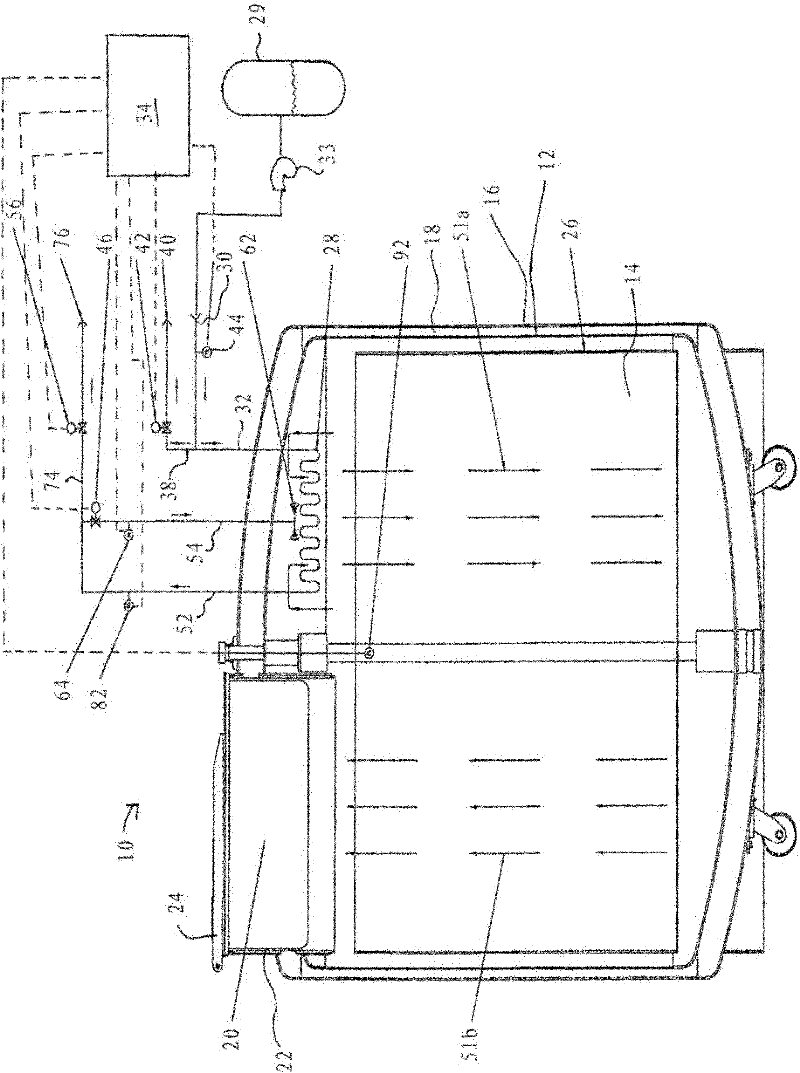

Windshield wiper de-icing

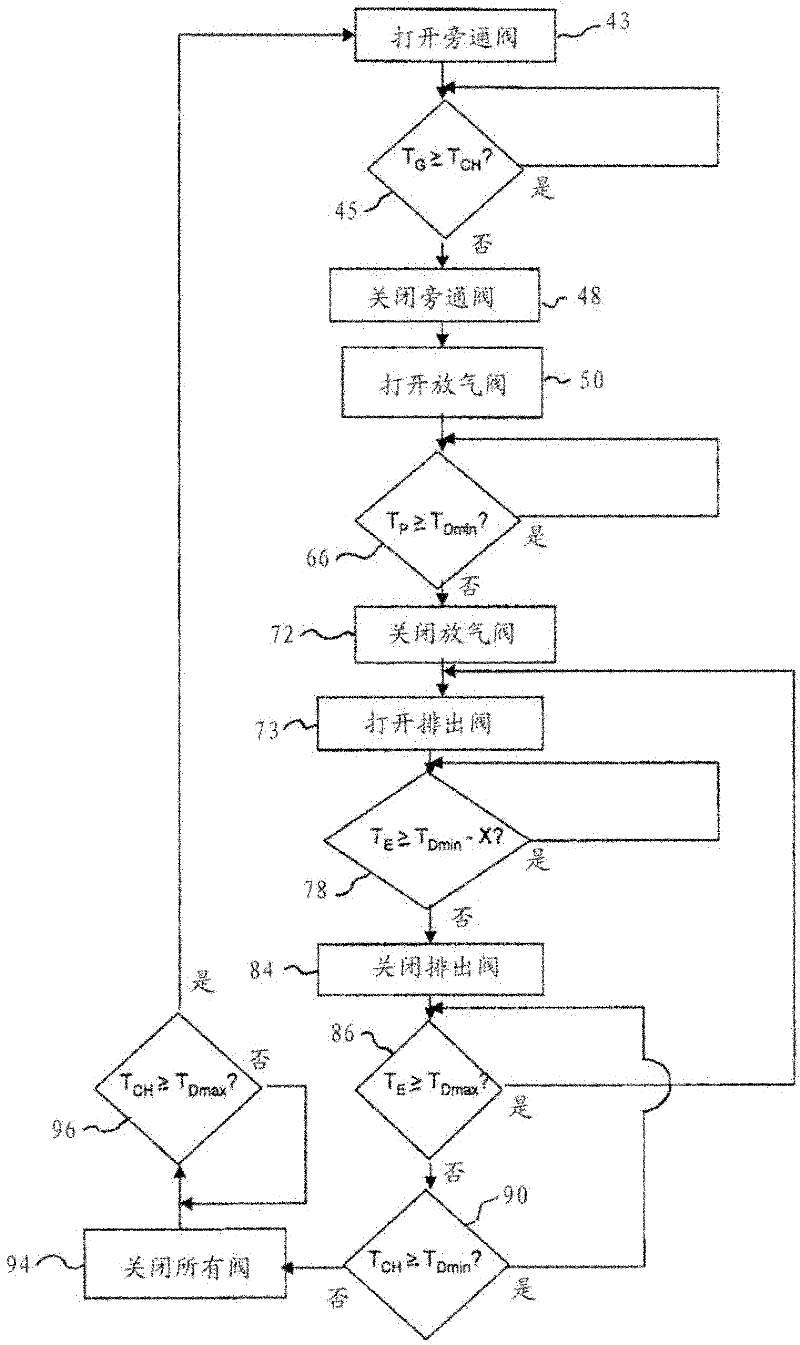

Methods and apparatus are provided for vehicle windshield washing-wiping and wiper de-icing. Primary nozzles provide washing fluid to the windshield during normal operations and secondary nozzles bathe the wiper arms with washing fluid to de-ice the wipers during a de-icing mode. Washing fluid is drawn from a reservoir and delivered to the nozzles by a pump. When the outside air temperature T is greater than Tc, the critical temperature for ice formation, the wipers and washing-wiping proceed normally with washing fluid delivered to the primary nozzles for windshield washing. When T≦Tc and the wipers are not moving, a washer fluid supply line valve delivers washing fluid to the secondary nozzles to de-ice the wipers. The wiper motor, washing fluid pump and valve are operated by a controller based on inputs from wiper position and air temperature sensors, using predetermined information stored in on-board memory.

Owner:GM GLOBAL TECH OPERATIONS LLC

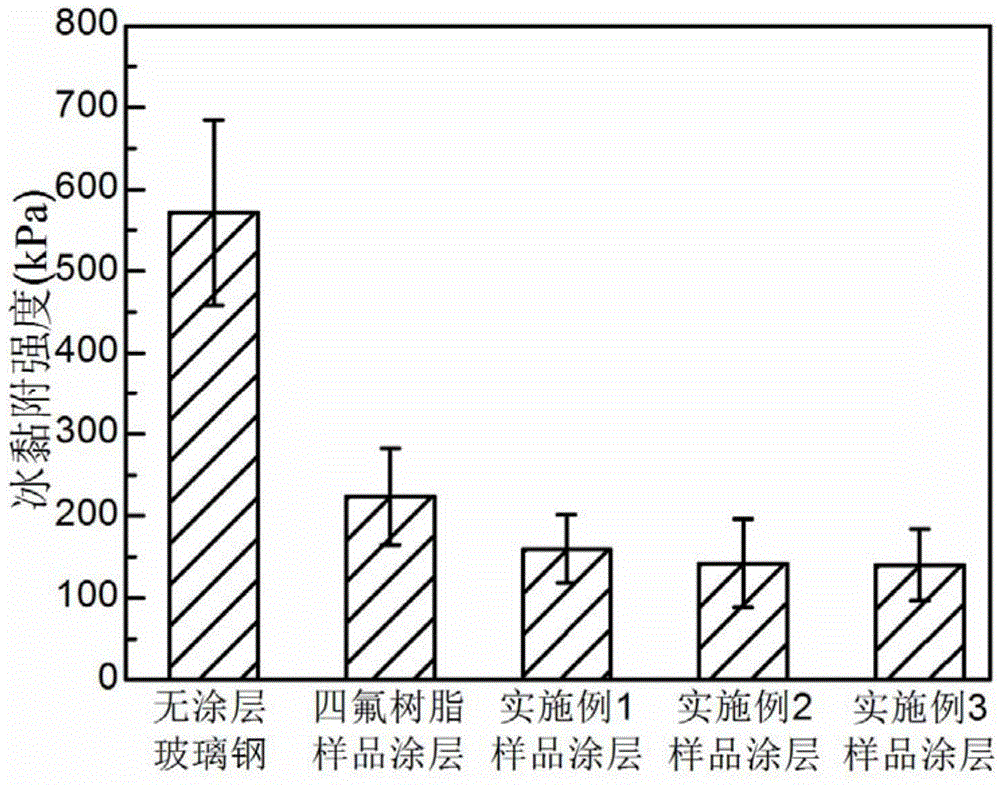

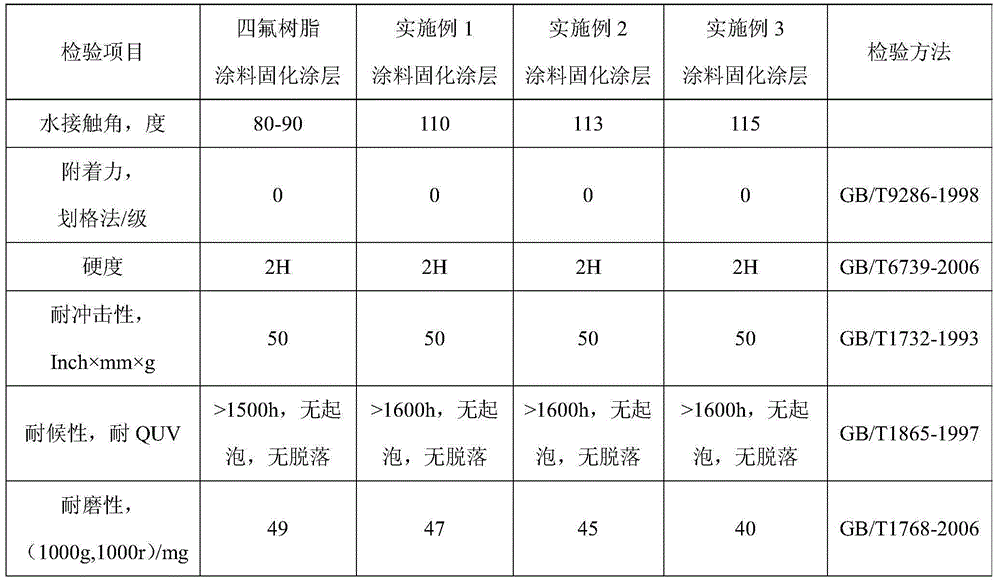

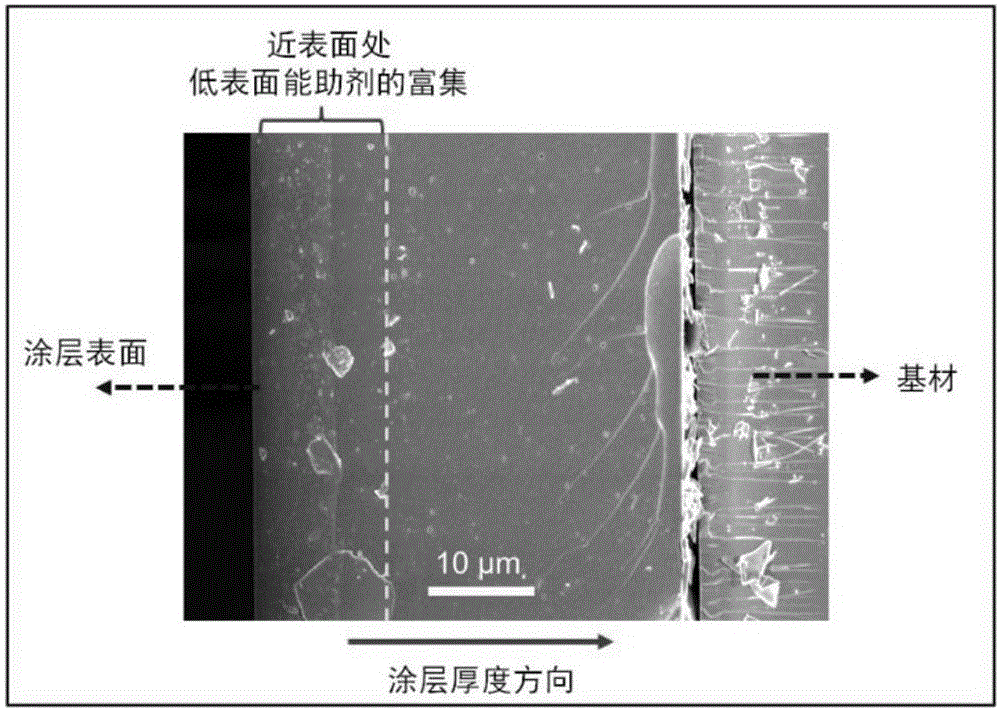

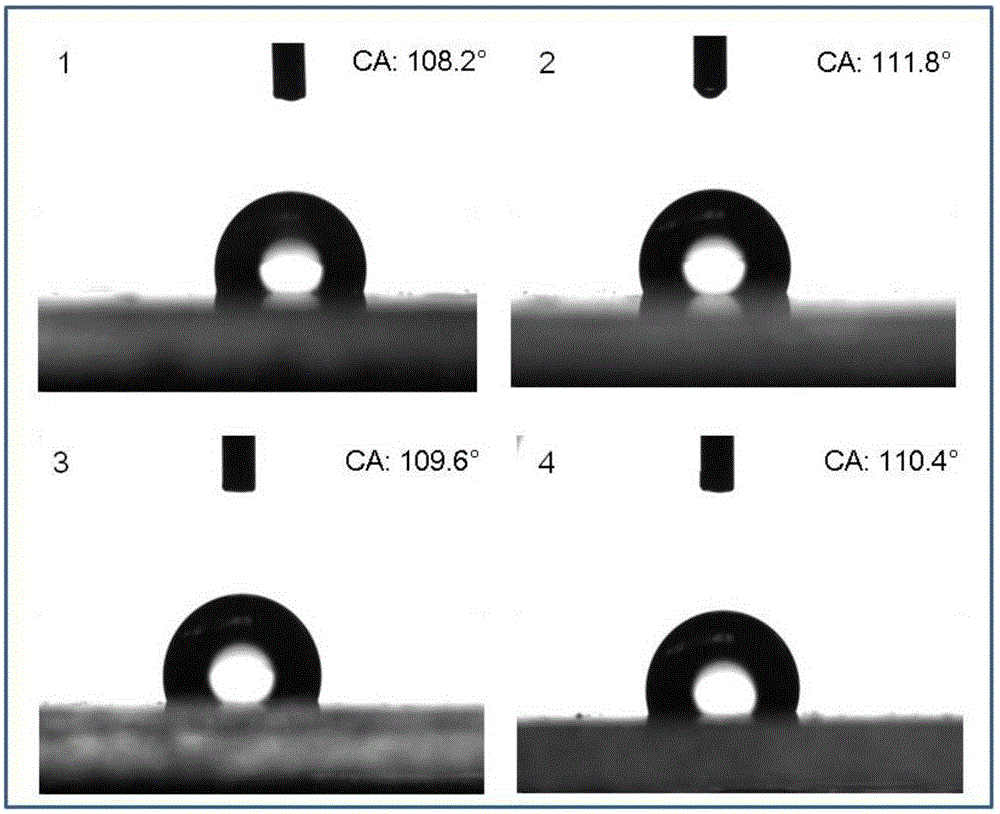

Anti-icing paint, as well as preparation and application thereof

ActiveCN104530974AExcellent weather resistanceLower surface energyOther chemical processesCoatingsSolventSurface energy

The invention discloses an anti-icing paint. The paint comprises a component A and a component B in a mass ratio of (4-7):1, wherein the component A is prepared from the following ingredients in percentage by mass: 20-80 percent of fluorosilicon resin with solid content of 20-70 percent, 0.05-2 percent of a defoaming agent, 0.05-2 percent of a flatting agent, 0.05-2 percent of a rheological agent, 0.05-5 percent of a light stabilizer, 0.05-2 percent of a matting agent, 0.05-2 percent of drier, 10-60 percent of rutile titanium dioxide, 0.1-20 percent of a dispersant and 20-70 percent of a solvent A; and the component B is prepared from the following ingredients in percentage by mass: 20-80 percent of a polyisocyanate curing agent and 20-80 percent of a solvent B. The anti-icing coating formed by the anti-icing paint has low surface energy and good hydrophobicity, can be used for effectively reducing the ice adhering strength of a base material, has excellent weather resistance and abrasion resistance, has high hardness and strong adhesive force to the base material, can be applied to wind blades, electric wires and cables and other cold surfaces with anti-icing requirement, and can be used for effectively relieving the icing phenomenon of cold surfaces, guaranteeing efficient working of the wind blades, the electric wires and cables and the like and prolonging the service lives of the wind blades, the electric wires and cables.

Owner:NINGBO NOVO NEW MATER TECH

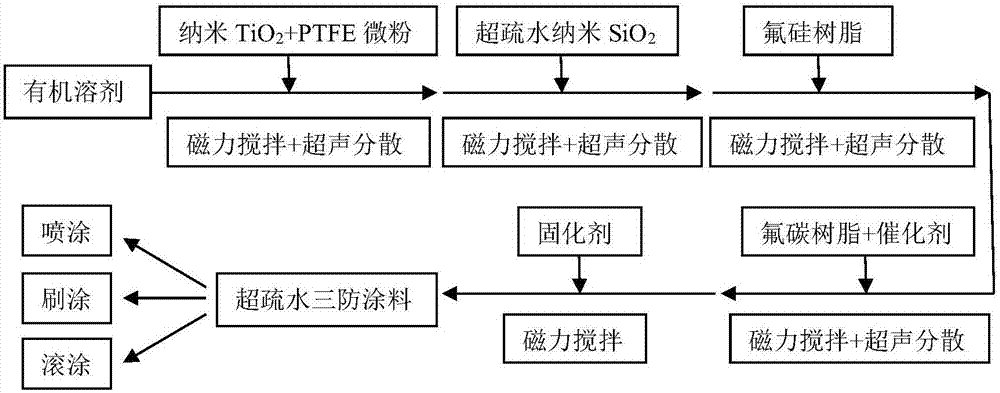

Super-hydrophobic conformal coating, and preparation method and application method thereof

InactiveCN107446424AImprove overall performanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesChemistryNanometre

The invention discloses a super-hydrophobic conformal coating, and a preparation method and an application method thereof. The super-hydrophobic conformal coating is composed of, by mass, 5 to 40% of fluorocarbon resin, 10 to 30% of fluorosilicon resin, 20 to 60% of an organic solvent, 10 to 30% of silica, 1 to 10% of titanium dioxide, 1 to 10% of polytetrafluoroethylene, 0.1 to 0.5% of a catalyst, and 1 to 5% of a curing agent. According to the preparation method, the ingredients are subjected to stirring mixing and ultrasonic uniform dispersion in sequence at a certain ratio. According to the application method, the super-hydrophobic conformal coating is subjected to direct spraying or brush coating onto the surfaces of insulators and outdoor electric power facilities; the thickness of obtained coating layers is controlled to be 0.1 to 0.5mm preferably; and 20 to 60min of normal temperature curing is needed. The preparation method is simple; the cost is low; the super-hydrophobic conformal coating is convenient to use, possesses extremely high hydrophobicity and weatherability, is capable of realizing self cleaning, is a nanometer composite hybrid normal-temperature cured fluorocarbon coating, is capable of realizing stain prevention, pollution flashover prevention, and corrosion prevention of insulators and outdoor electric power facilities effectively, and is promising in application prospect.

Owner:昆明理工大电力工程技术有限公司

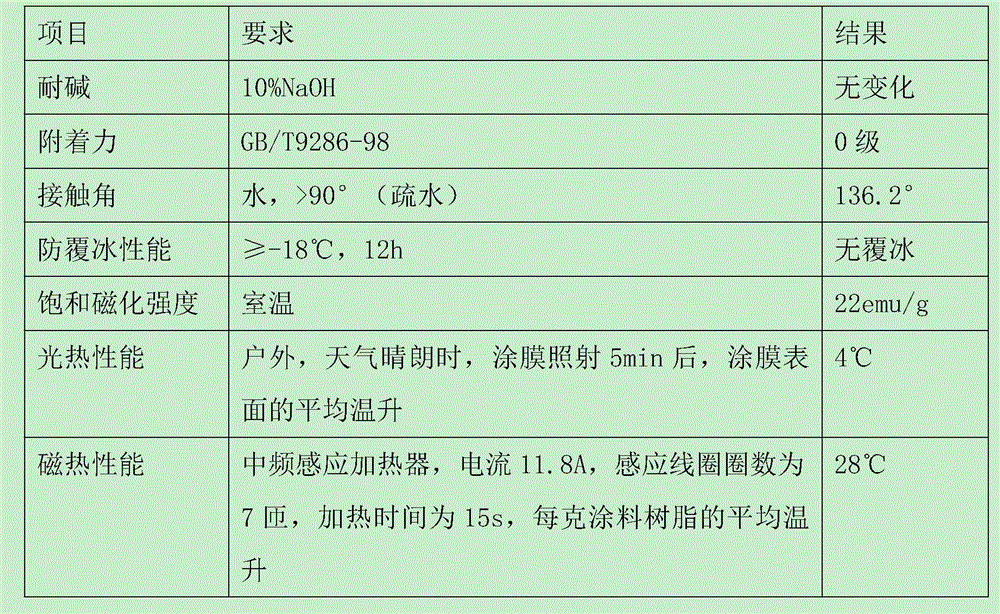

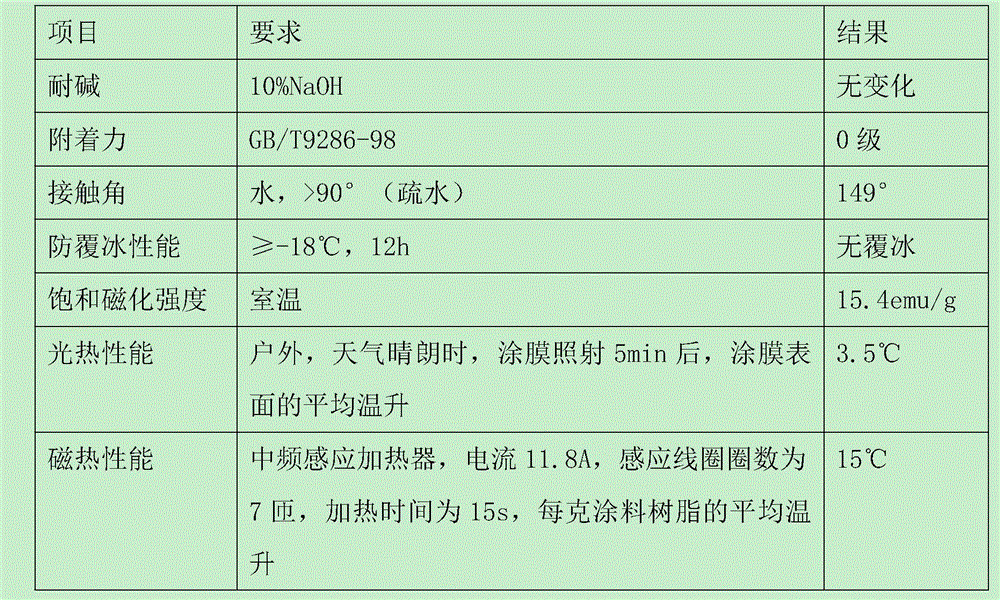

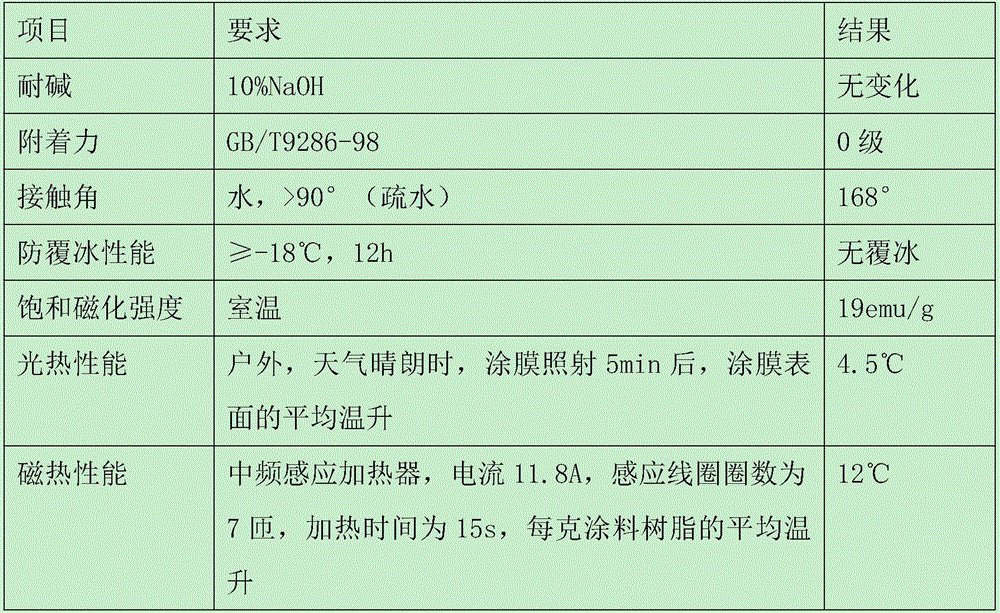

Super-hydrophobic ice-over resistant coating with thermomagnetic property and preparation method of super-hydrophobic ice-over resistant coating

ActiveCN104804603AExcellent magnetocaloric performanceDelayed icingCoatingsWeather resistanceHydrocarbon

The invention discloses a super-hydrophobic ice-over resistant coating with a thermomagnetic property and a preparation method of the super-hydrophobic ice-over resistant coating. The super-hydrophobic ice-over resistant coating comprises the following components by mass percent: 20-68% of fluorine-containing acrylic acid epoxy resin, 19-69% of an organic solvent, and 10-50% of inorganic particles which are magnetic particles or mixture of magnetic particles and nonmagnetic particles, wherein the fluorine-containing acrylic acid epoxy resin is obtained through reaction of two components; one component is obtained through free radical polymerization of a fluorine-containing acrylate monomer, a hydrocarbon chain acrylate monomer and an expoxy group-containing acrylic acid ester monomer; the other component belongs to polyamines or acid anhydrides. The coating provided by the invention is environmentally friendly, and excellent in weather resistance and chemical resistance, has excellent adhesion with a base material, can be heated in the external alternating magnetic field or light condition, and can be used for preventing and controlling icing on the surfaces of telecommunication lines and the like; the preparation method is simple in process and convenient to operate.

Owner:ZHEJIANG UNIV

Applicator for cryoanesthesia and analgesia

ActiveUS20170304558A1Improve comfortReduce icingAutomatic syringesMedical devicesThermoelectric coolingControl signal

A handheld cryoanesthesia or analgesia device for cooling a target area on cutaneous membranes, mucous membranes, and tissue of the mucocutaneous zone having an elongated body and a thermoelectric cooling system disposed within the elongated body. The thermoelectric cooling system is configured to physically contact and thermally couple the target area of the cutaneous membranes, mucous membranes, and tissue of the mucocutaneous zone to induce cryoanesthesia or analgesia. The thermoelectric cooling system includes a thermally-conductive cold tip, a thermally-conductive cooling power concentrator thermally coupled to the cold tip, at least one Peltier unit module thermally coupled to the cooling power concentrator, a heatsink thermally coupled to at least one Peltier unit module, a power source, at least one thermal sensor, and a controller operably outputting a control signal to the Peltier unit module to maintain a predetermined temperature.

Owner:RGT UNIV OF MICHIGAN

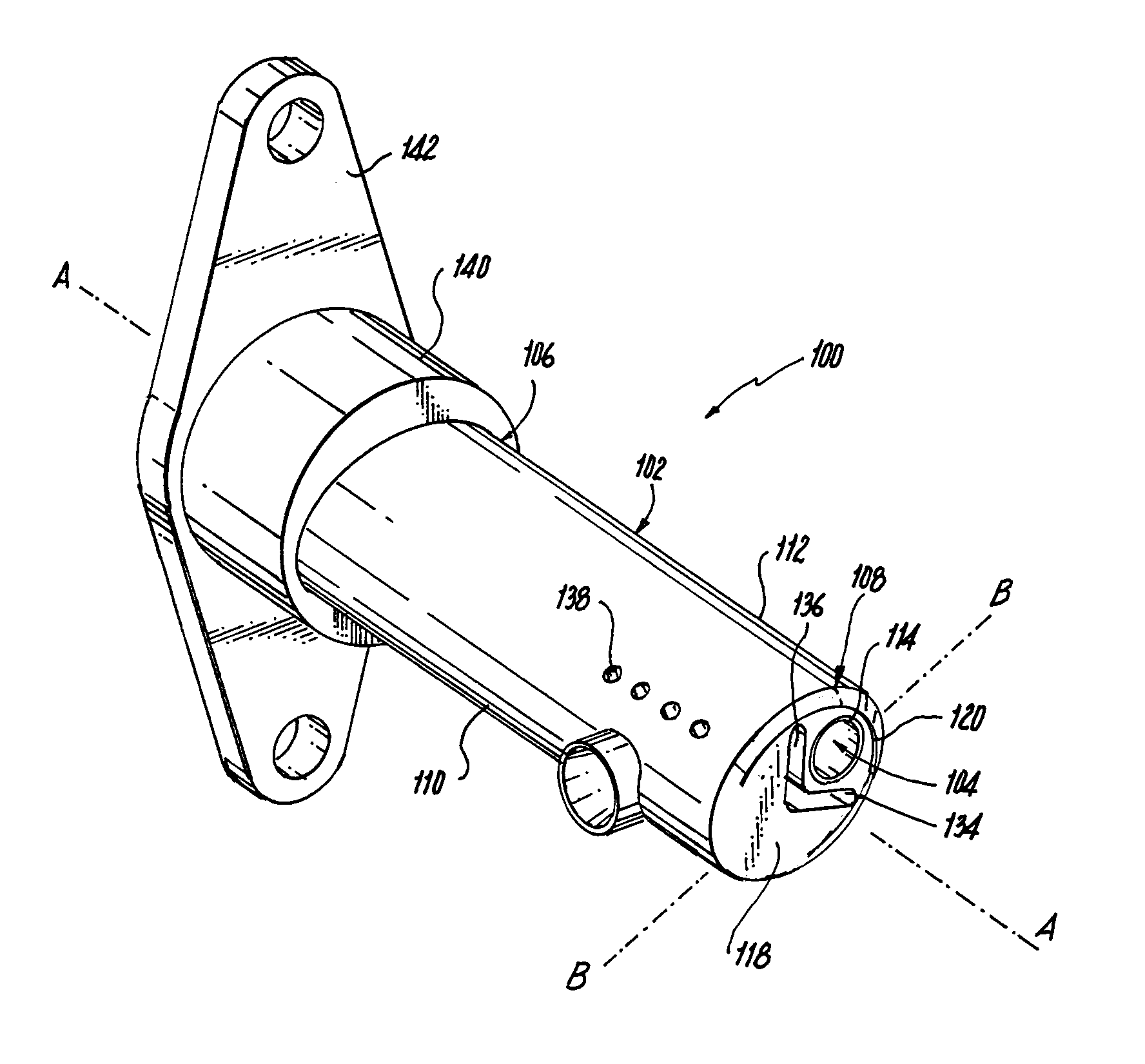

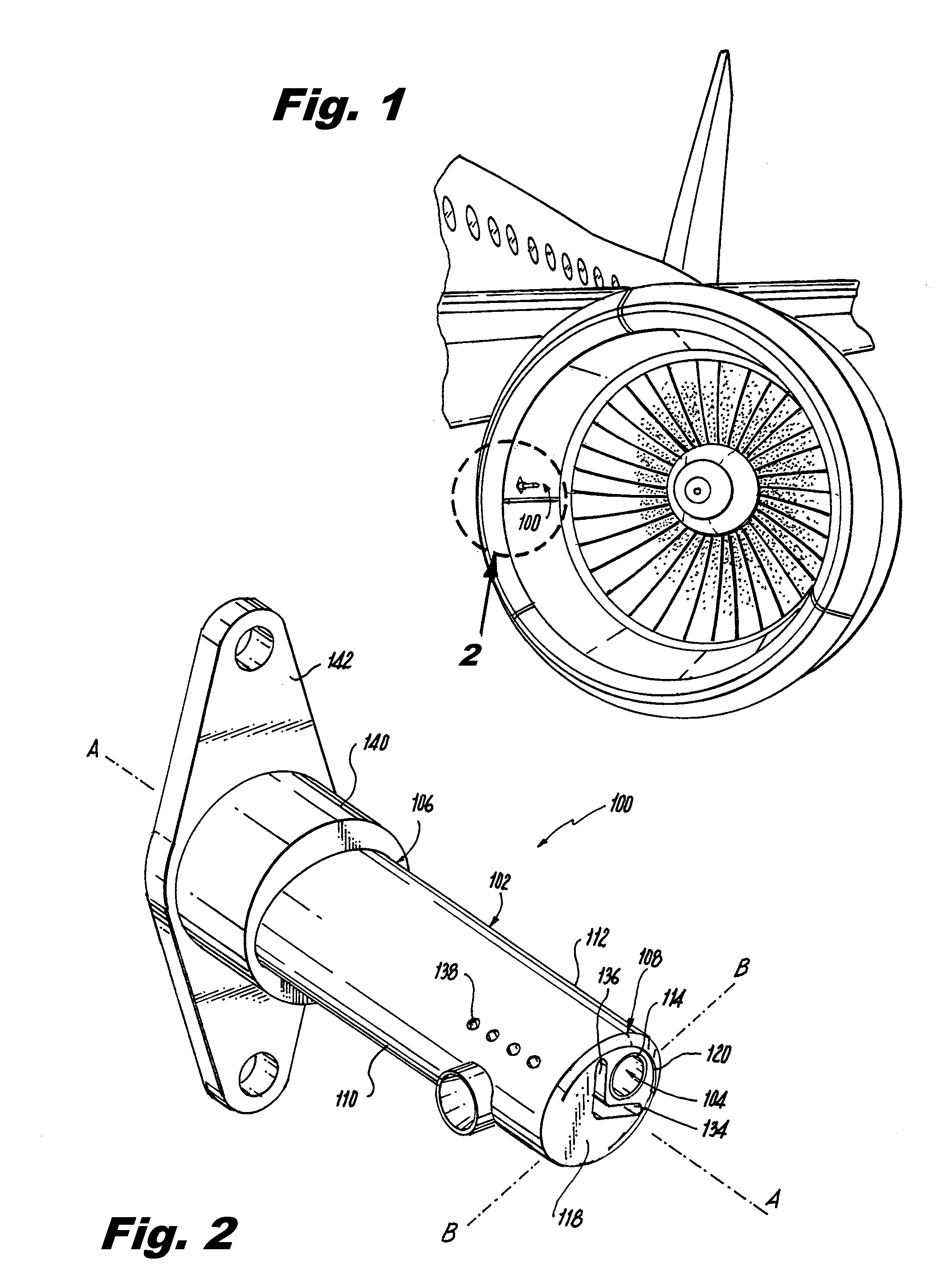

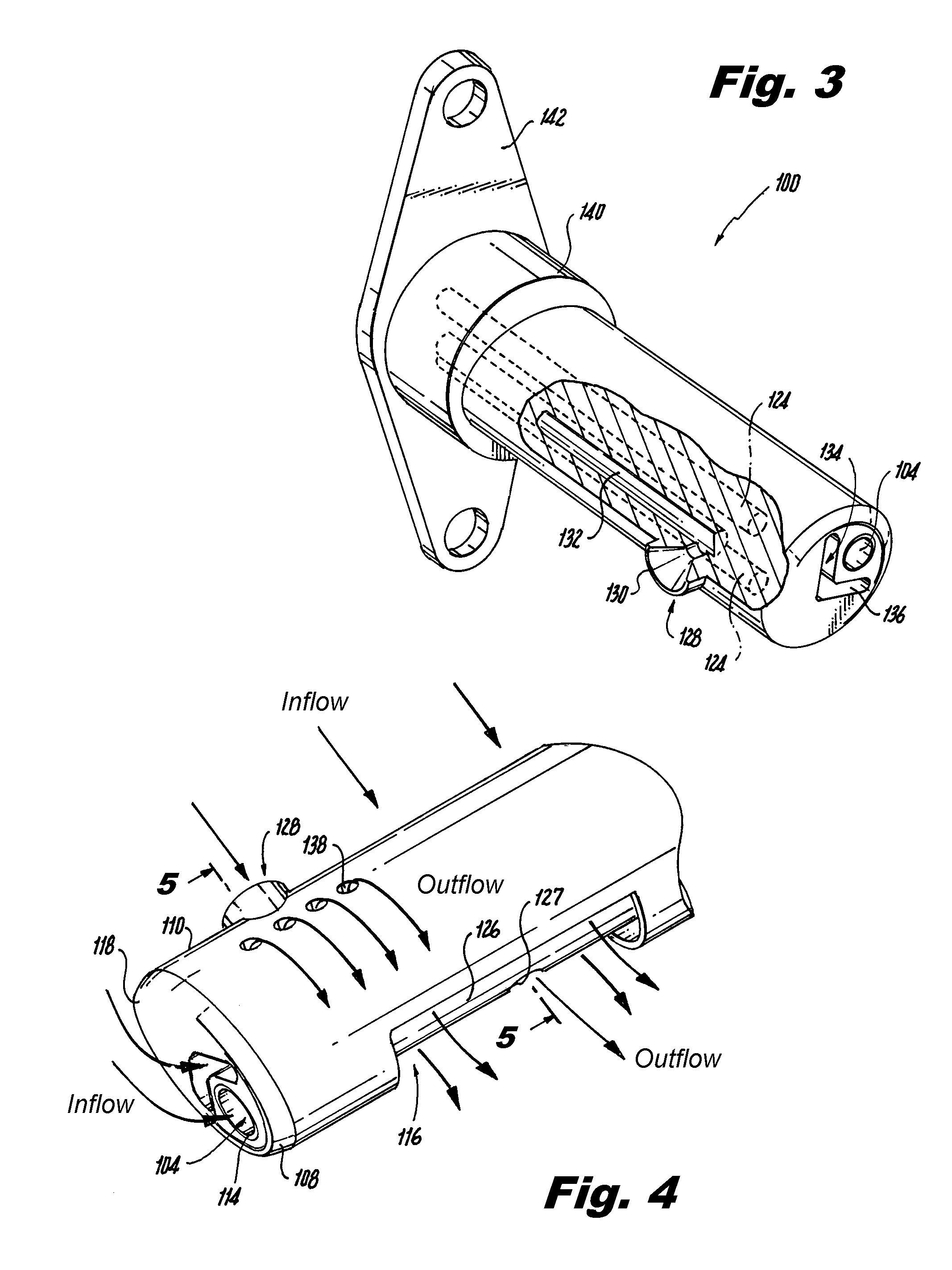

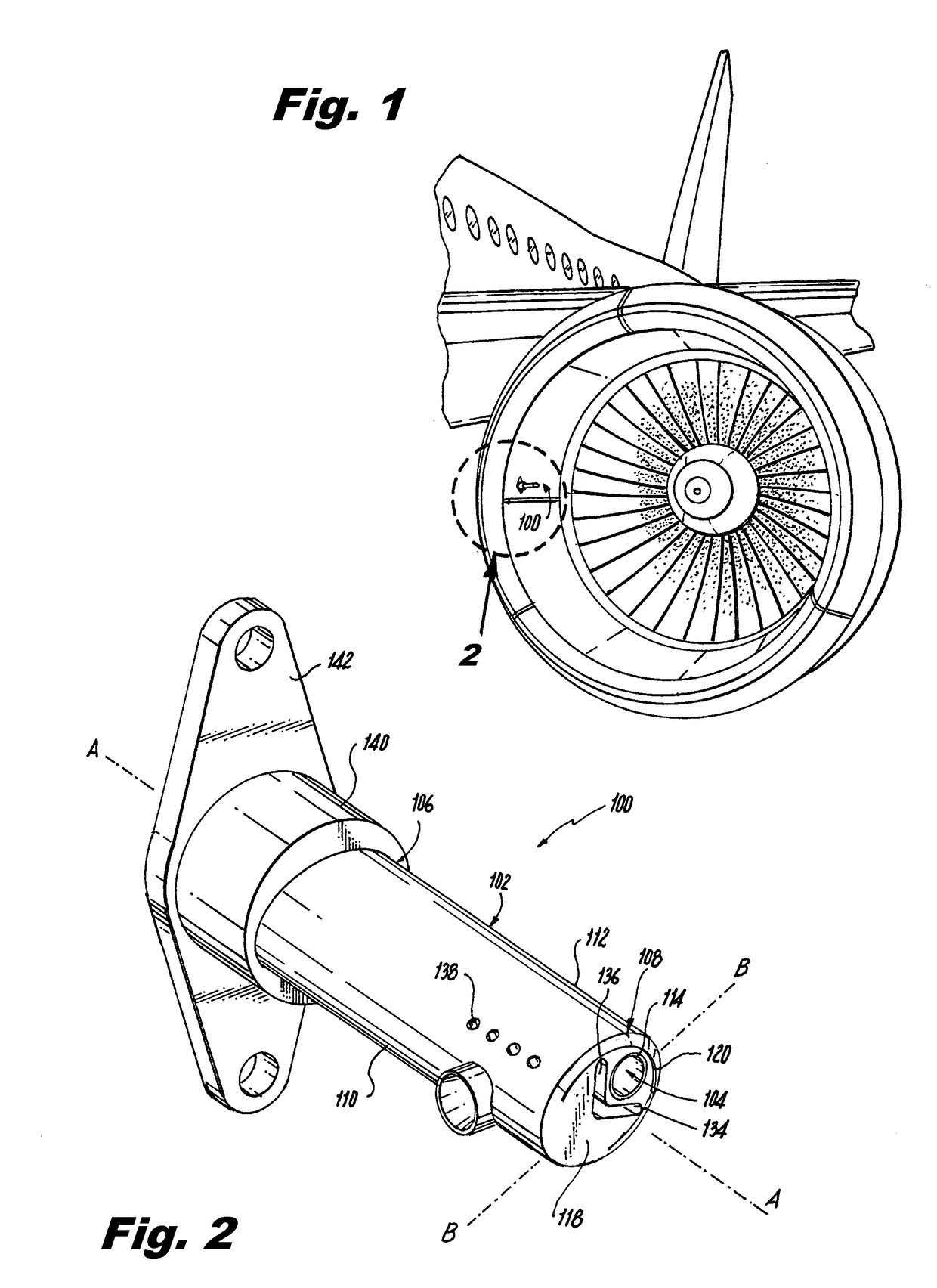

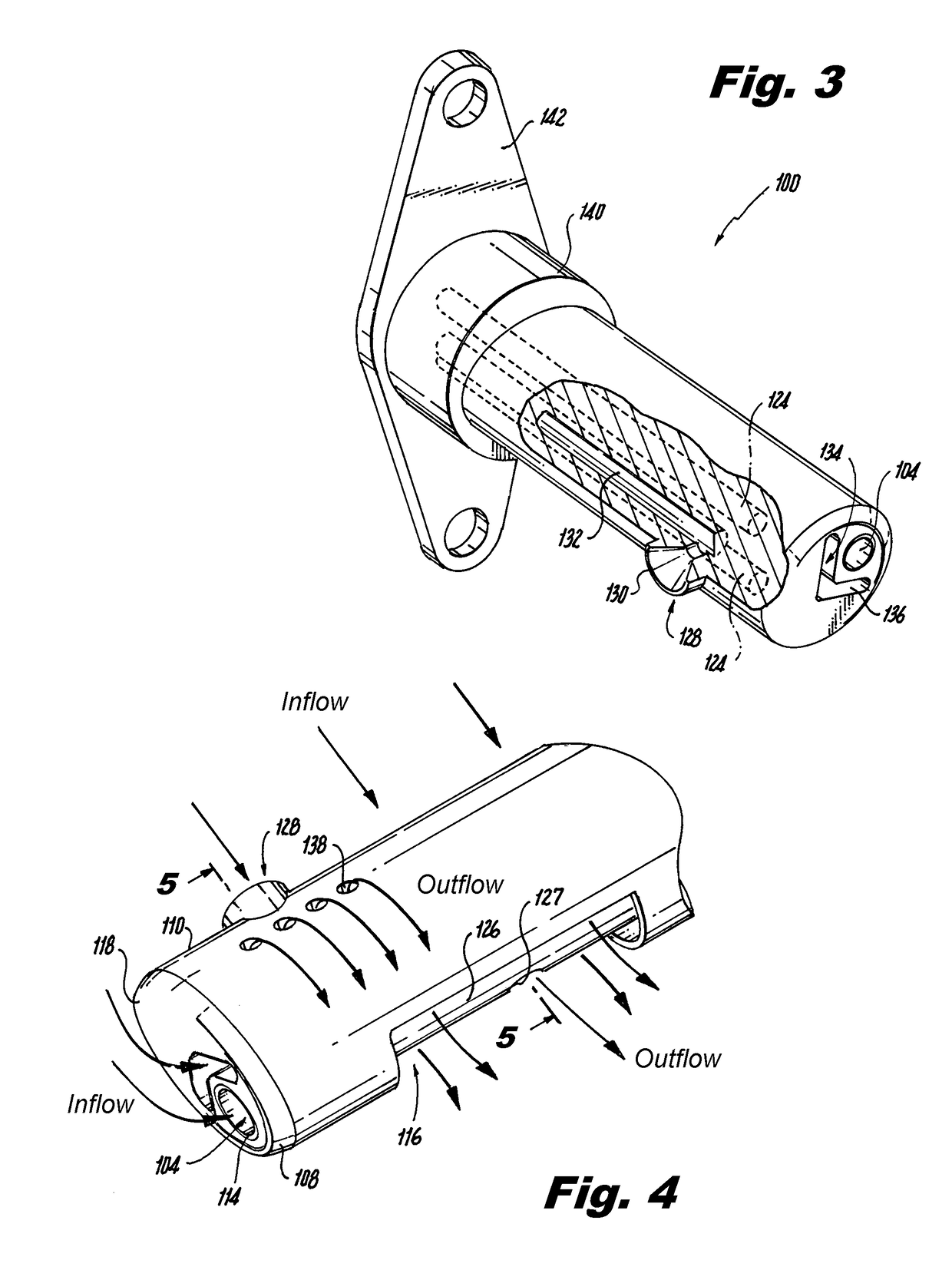

Total air temperature sensors

ActiveUS20150103863A1Reduce icingTemperature measurement of flowing materialsLeading edgeTrailing edge

A total air temperature probe includes a probe body extending from a probe base to an opposed probe tip along a longitudinal axis defining a leading edge and opposed trailing edge, an interior flow passage aligned with longitudinal axis defined in probe body with an inlet defined on probe tip for fluid communication with interior flow passage, and an outlet for exhausting fluid out from interior flow passage. A sloped surface on probe tip extends from leading edge to trailing edge. A temperature sensor is mounted within interior flow passage for measuring temperature of flow through interior flow passage to determine total air temperature. Sloped surface is flush with leading edge and set in from trailing edge with respect to longitudinal axis to define a lip proximate the trailing edge. The sloped surface and lip are configured to create a high pressure region proximate inlet of interior flow passage.

Owner:ROSEMOUNT AEROSPACE

Hydrophobic coating compositions for drag reduction

ActiveUS20120142814A1Broaden applicationEfficient use ofOther chemical processesSpecial surfacesSolventSilicon dioxide

A hydrophobic coating has been made for use on interior pipe surfaces, exterior boat surfaces, and in many other applications, to reduce drag in fluid flow, thus providing an energy savings. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a solvent. The coating solves the problem of poor resistance to UV light and / or abrasion found in previous coatings of similar nature. The coating of the present invention can be made to be translucent and nearly transparent whereas previous coatings of comparable hydrophobicity have all been white or opaque. The coating can be applied in a single application by an easy spraying method and the super hydrophobic property can be achieved by drying the film at room temperature for 5 to 10 minutes. A preferred coating has good resistance to UV light and some resistance to abrasion. The hydrophobic drag reduction coating composition forms an almost clear, translucent film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or polymer substrate. A preferred coating composition comprising an effective amount of a treated fumed silica in a solvent resulting in a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher.

Owner:VGP IPCO LLC

Devices and methods for preventing ice build-up and articles of manufacture that are resistant to ice build-up

ActiveUS20090159751A1Reduce surface tensionPrevent freezingDe-icing equipmentsCorrosion preventionEngineeringCoating

Embodiments of the present invention feature heat exchange surfaces having a layer or coating having a lower surface tension than water, to repel water and prevent the formation of condensate on said surface.

Owner:WATERS TECH CORP

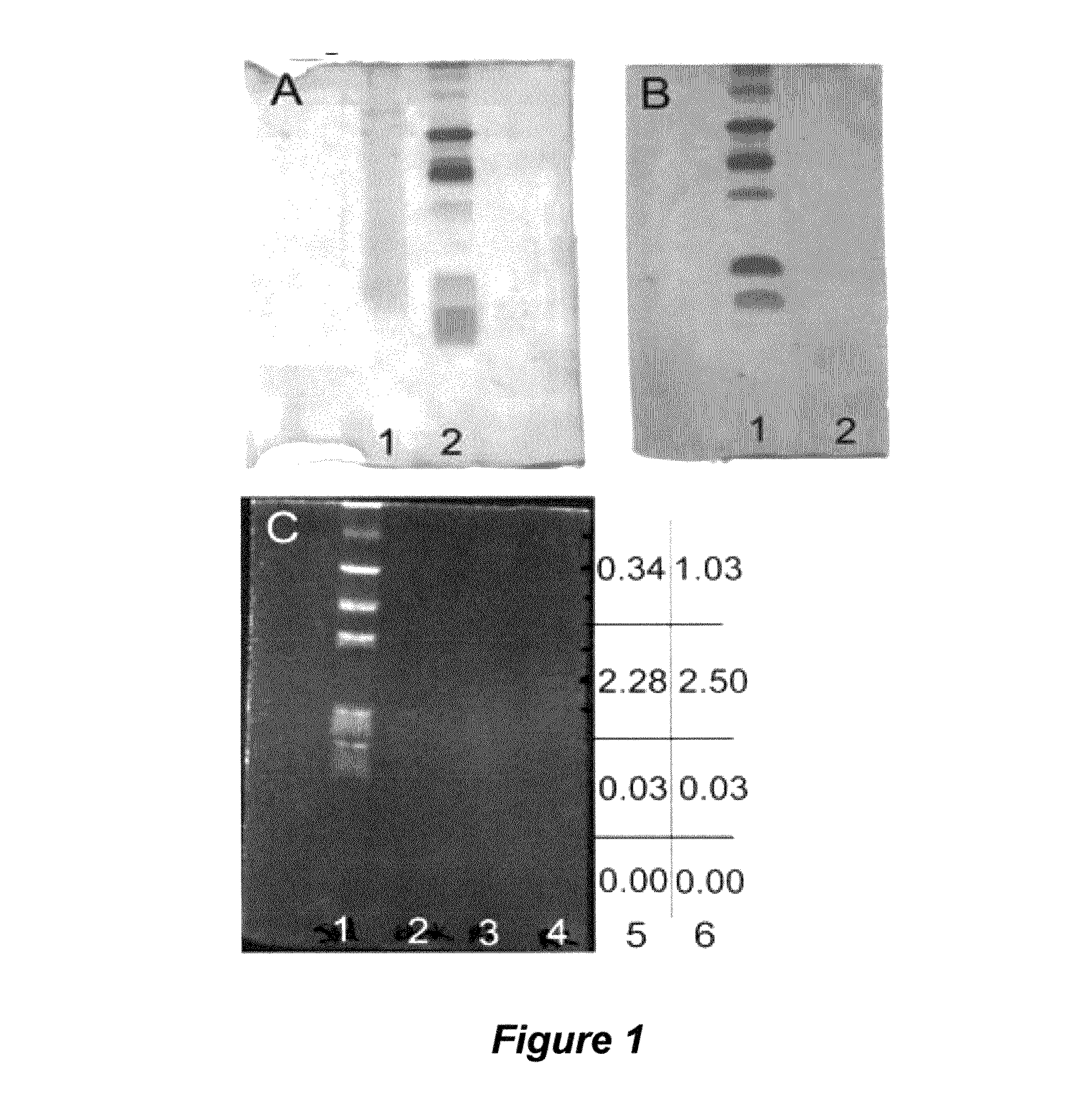

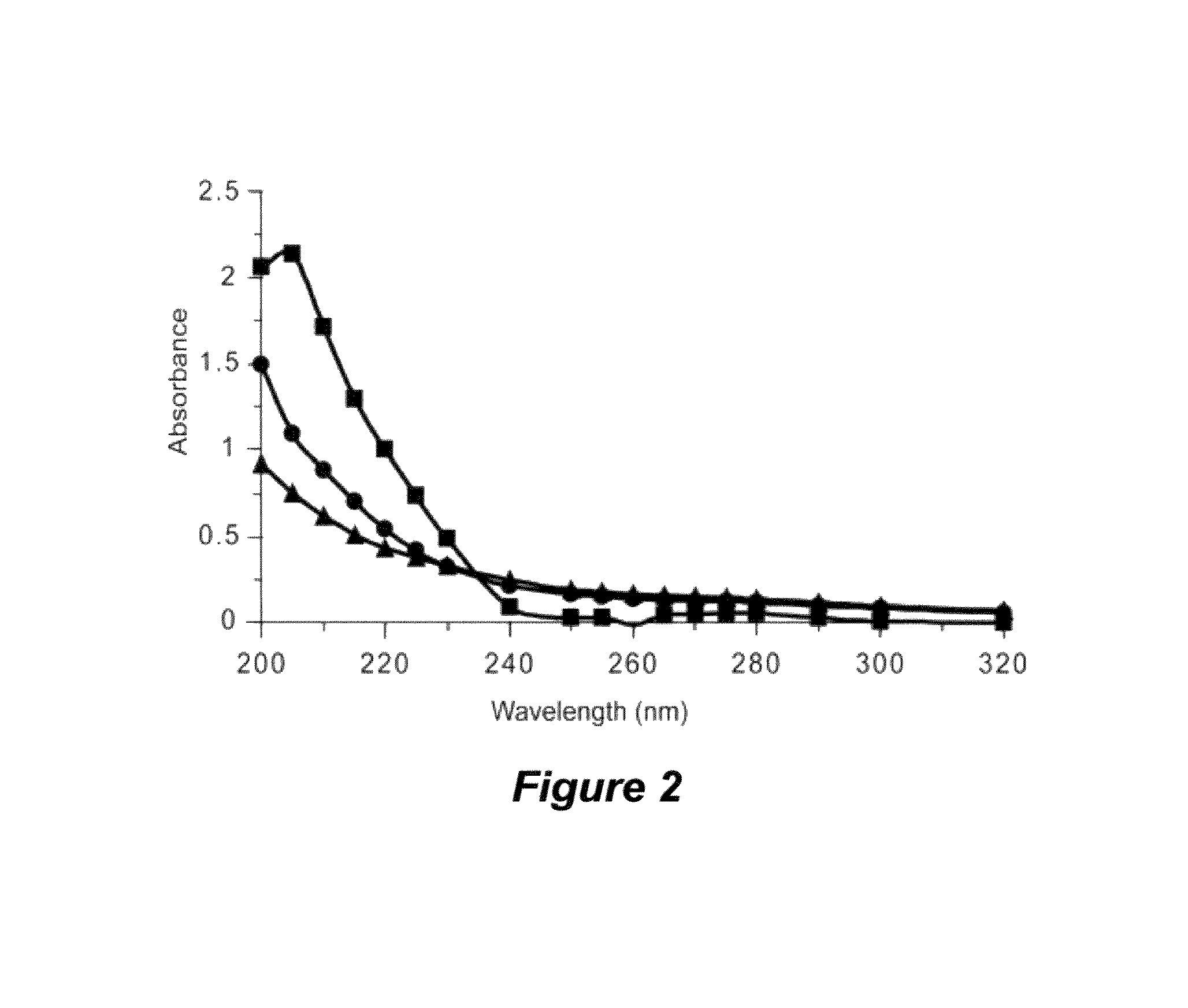

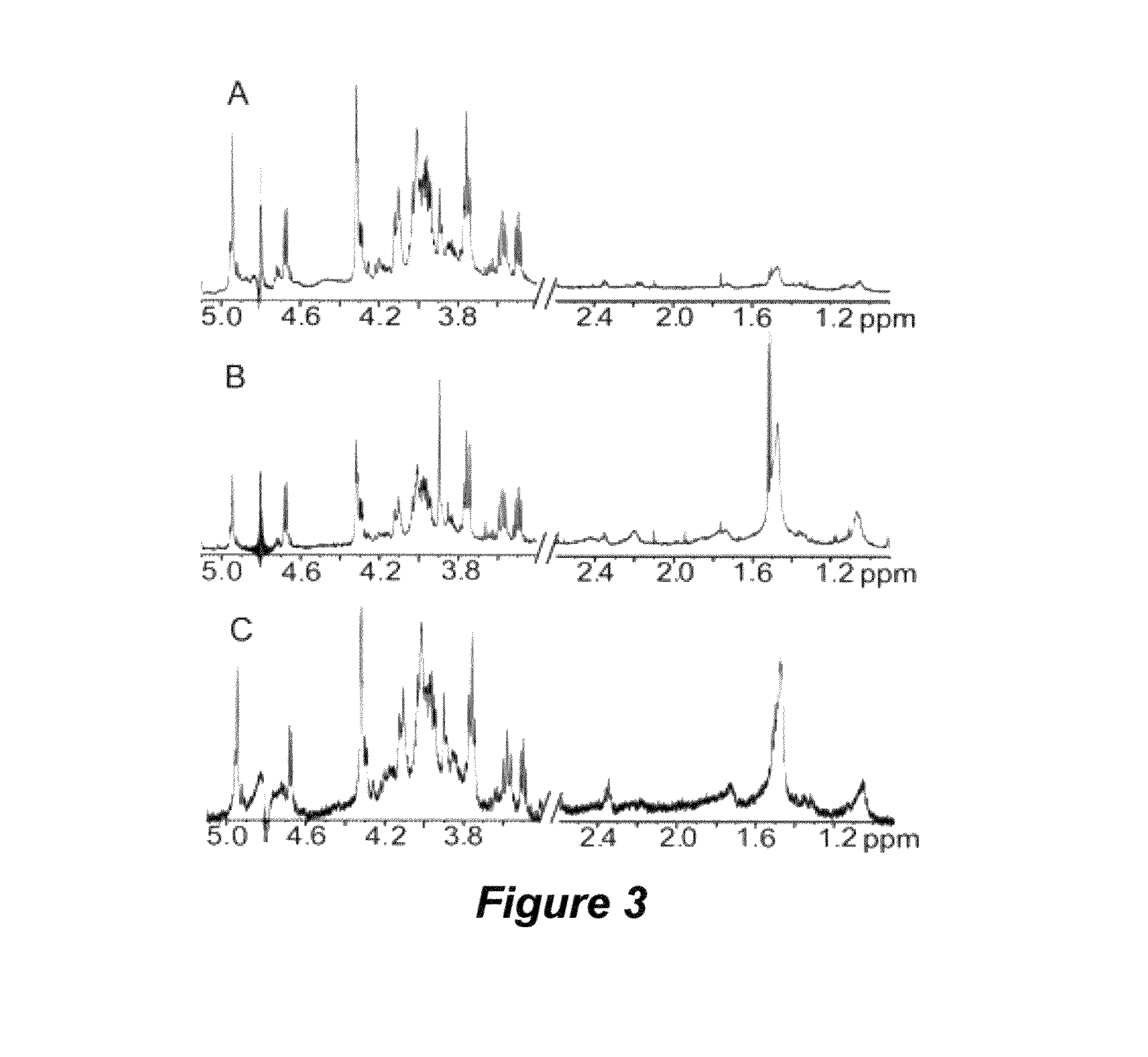

Saccharide antifreeze compositions

InactiveUS8604002B1Reducing crystal formationReducing and avoiding frostbiteBiocideOrganic active ingredientsGlycolipidXylose

The invention provides an antifreeze glycolipid compounds and composition comprising a polysaccharide moiety of Formula I:wherein D-Manp represents a D-mannopyranose moiety, D-Xylp represents a D-xylopyranose moiety, and n is about 5 to about 70; and one or more lipid moieties covalently linked to the polysaccharide moiety of Formula I or electrostatically associated with the polysaccharide moiety of Formula I. The antifreeze glycolipid compounds and compositions can be used for a variety of industrial, agricultural, medical, and cosmetic applications where recrystallization-inhibition, cyroprotection, or cryopreservation is desired. The antifreeze glycolipid compounds or compositions can be used as, for example, as cryoprotectants for tissue preservation and transplantation, improving the texture of processed frozen food and frozen meats, frostbite protection, crop protection, and green alternatives for land vehicle antifreeze and aircraft de-icing.

Owner:UNIV OF NOTRE DAME DU LAC

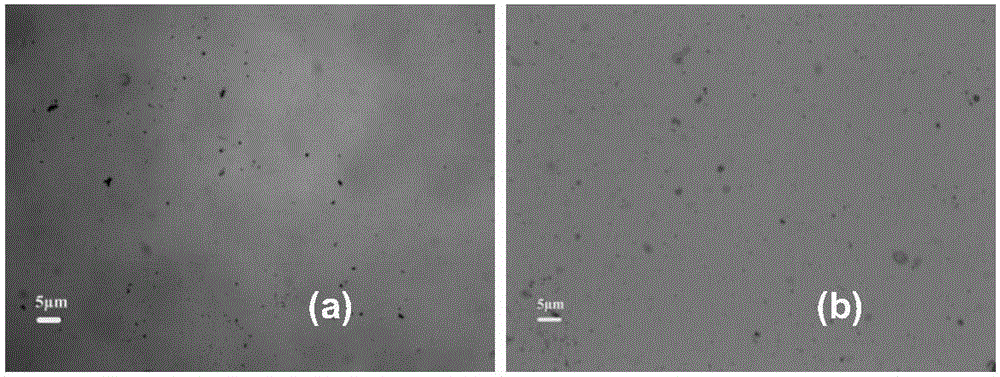

Ice-coating-resistant coating and preparation method and application thereof

ActiveCN105315870AStrong anti-icing durabilityIncreased durabilityPolyurea/polyurethane coatingsAcrylic resinDiluent

The invention is applicable to the field of coatings and provides an ice-coating-resistant coating and a preparation method and application thereof. The ice-coating-resistant coating comprises a component A and a component B, wherein the component A comprises hydroxy acrylic resin, a silane coupling agent, low-surface energy auxiliaries containing silicon, surface modification auxiliaries, diluents and other auxiliaries, and the component B is fatty acids isocyanate. The ice-coating-resistant coating is good in ice-coating-resistant durability, the water contact angle of the coating is large, the adhesive force between the coating and a substrate is good, mechanical performance is excellent, and the process is simple.

Owner:安徽足迹新材料科技有限公司

Total air temperature sensors

ActiveUS9631985B2Reduce icingThermometer detailsTemperature measurement of flowing materialsLeading edgeEngineering

A total air temperature probe includes a probe body extending from a probe base to an opposed probe tip along a longitudinal axis defining a leading edge and opposed trailing edge, an interior flow passage aligned with longitudinal axis defined in probe body with an inlet defined on probe tip for fluid communication with interior flow passage, and an outlet for exhausting fluid out from interior flow passage. A sloped surface on probe tip extends from leading edge to trailing edge. A temperature sensor is mounted within interior flow passage for measuring temperature of flow through interior flow passage to determine total air temperature. Sloped surface is flush with leading edge and set in from trailing edge with respect to longitudinal axis to define a lip proximate the trailing edge. The sloped surface and lip are configured to create a high pressure region proximate inlet of interior flow passage.

Owner:ROSEMOUNT AEROSPACE

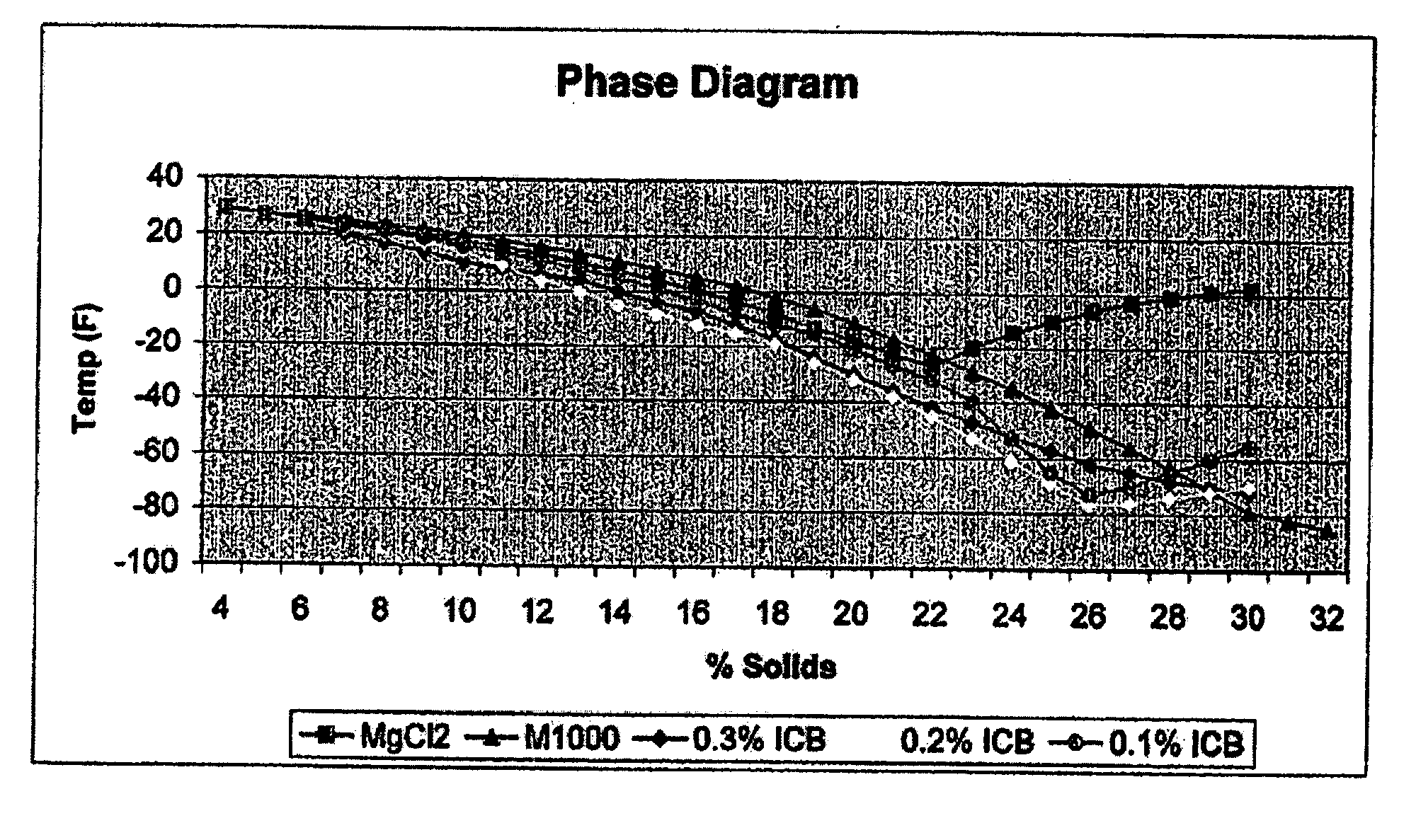

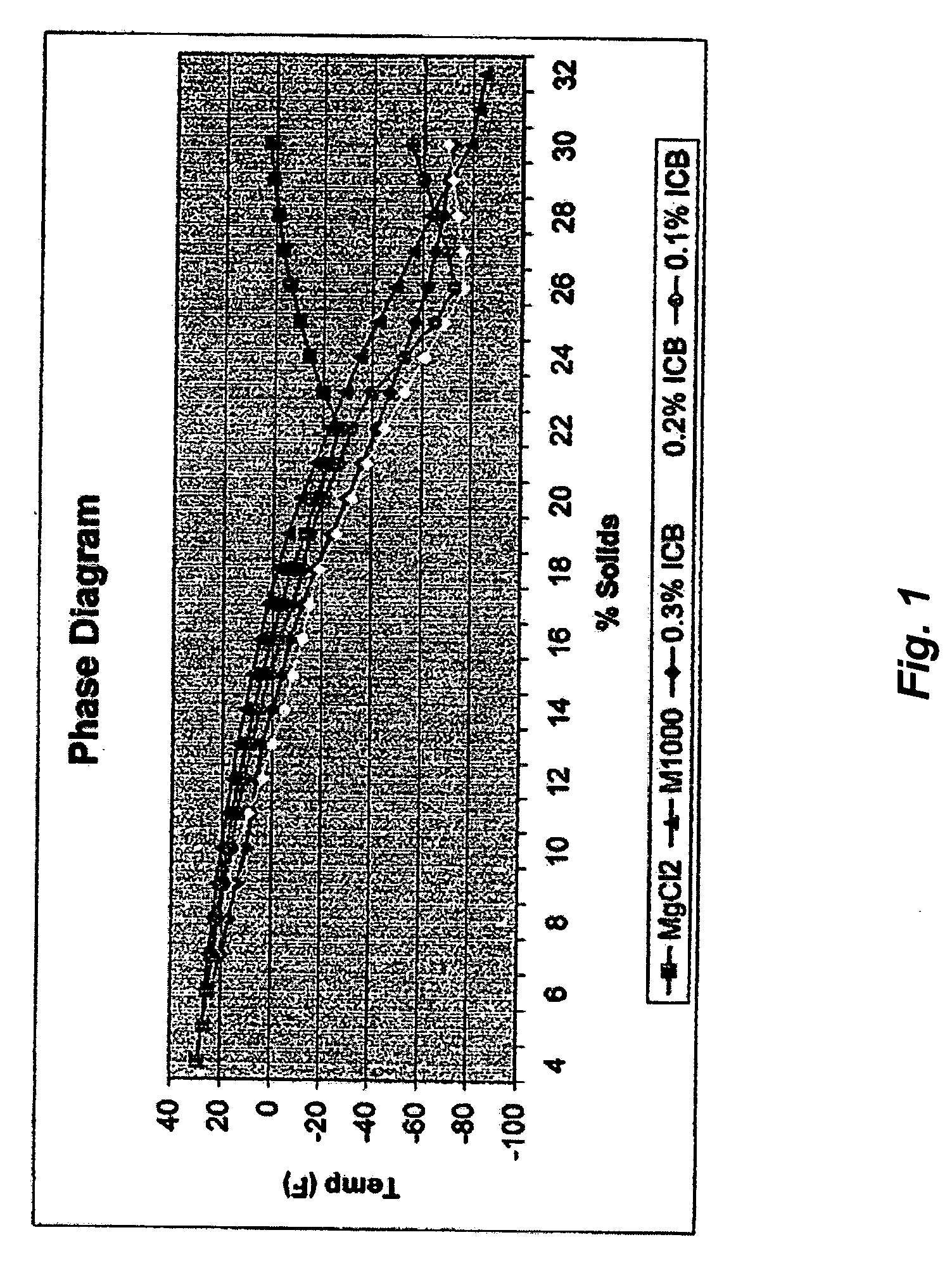

Low viscosity de-icing compositions

A composition to reduce ice buildup on a surface, the composition that includes salt, water, and starch, where the composition has a viscosity of about 60 centipoise or less at 0° F. Also, a composition to enhance deicing capabilities on a roadway, where the composition includes about 10% to about 98%, by weight, water; less than 0.5%, by weight, starch; and about 5% to about 90%, by weight, salt. In addition, a deicing composition that includes salt, water, and gelatin, where the composition has a viscosity of about 60 centipoise or less at 0° F.

Owner:ENVIROTECH SERVICES

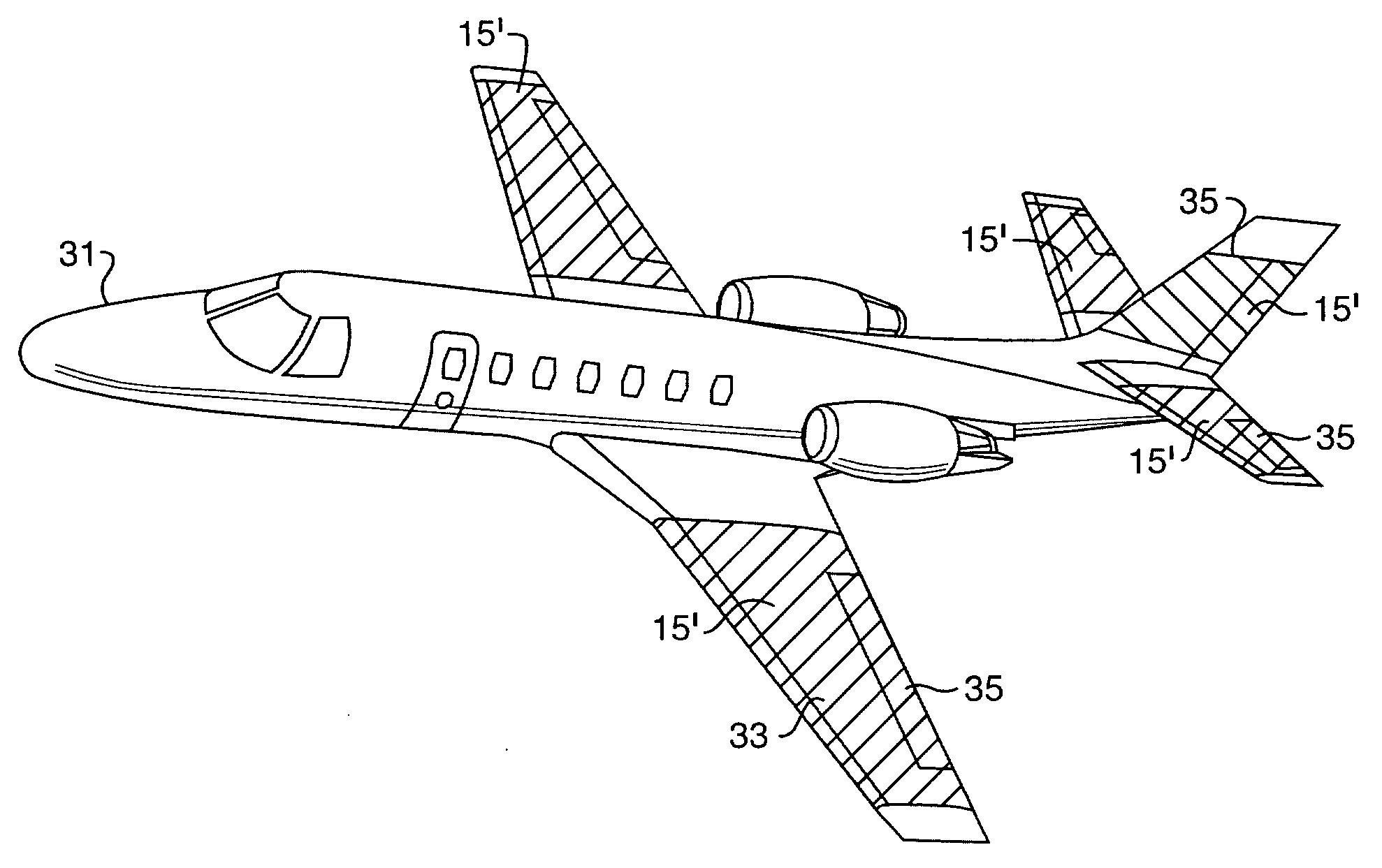

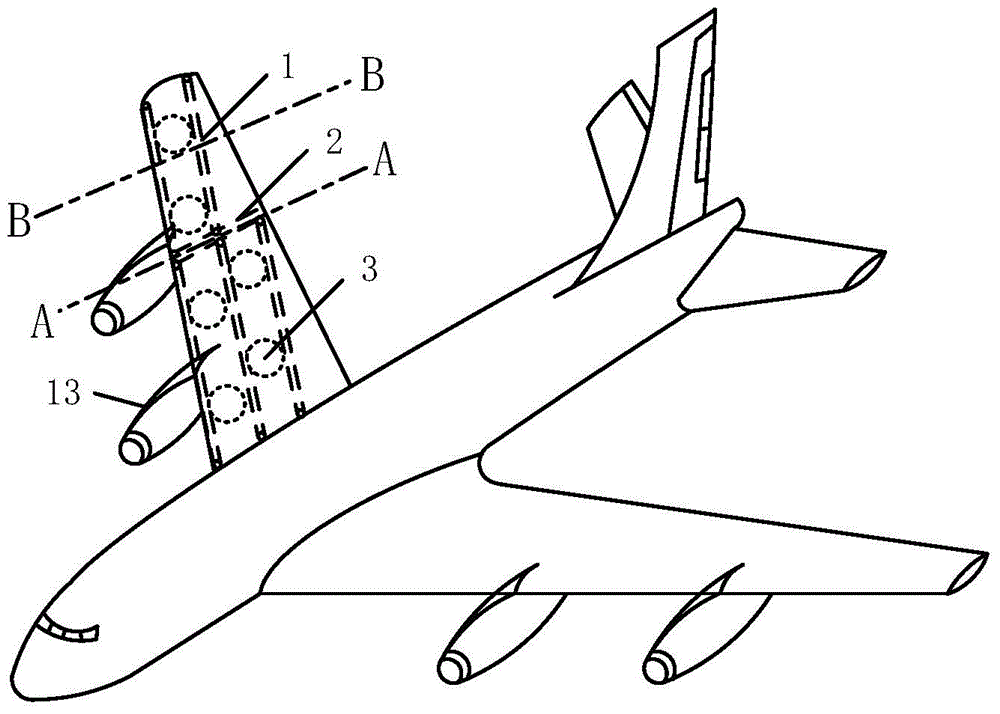

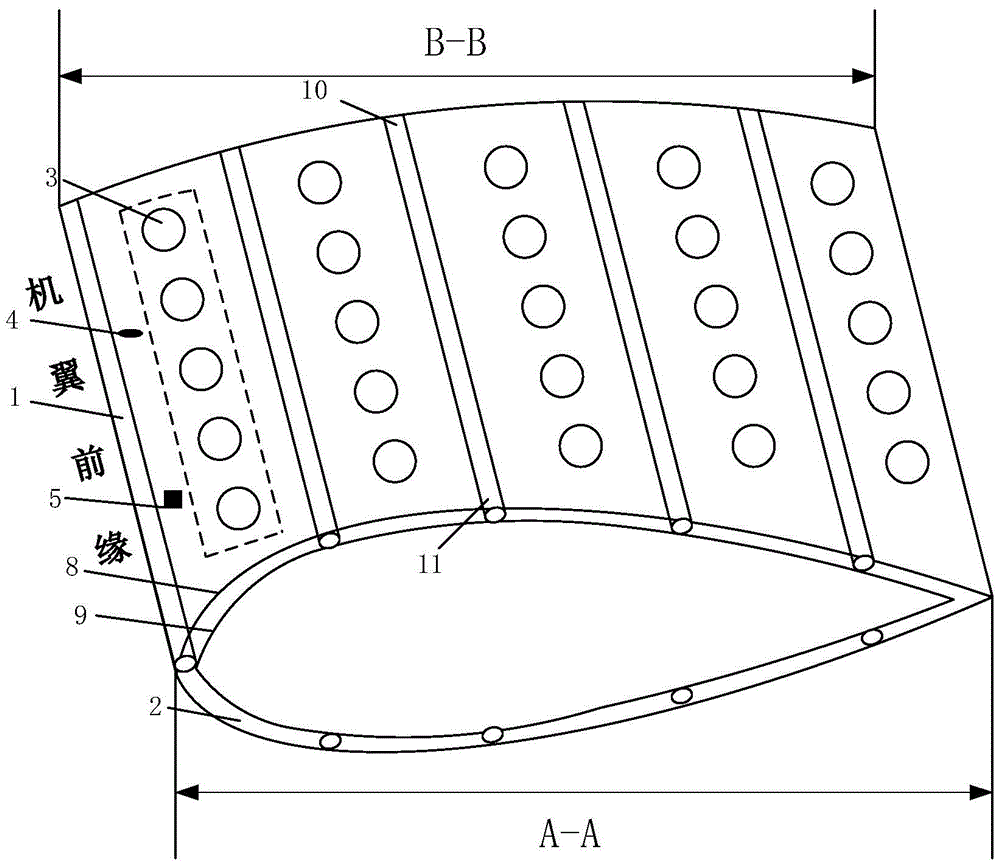

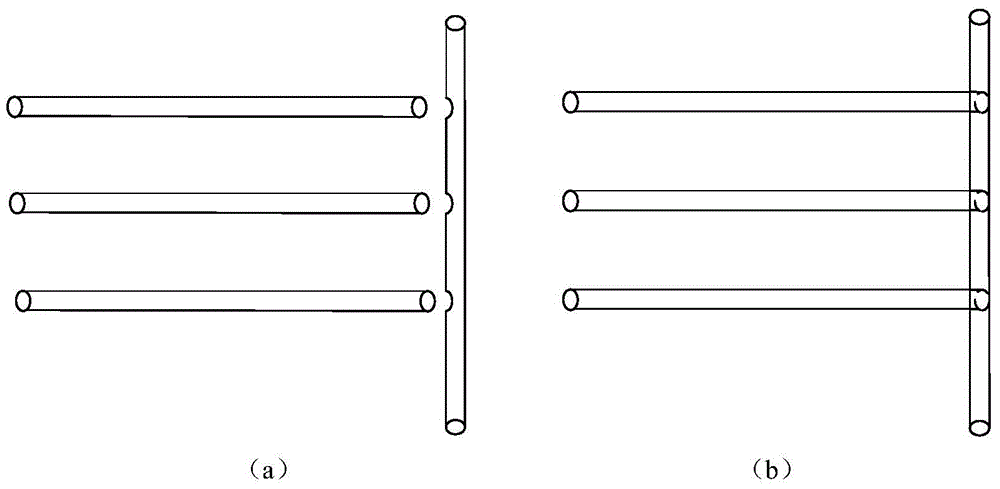

Heat pipe and ultrasonic wave combined ice preventing and removing device and method utilizing waste heat of aircraft engine

InactiveCN105691620APrevent freezingStable anti-icing temperatureDe-icing equipmentsEvaporationAtmospheric temperature

The invention provides a heat pipe and ultrasonic wave combined ice preventing and removing device and method utilizing waste heat of an aircraft engine. The device comprises a heat pipe ice-preventing system, an ultrasonic oscillation ice removing system, a program control system, an atmospheric temperature sensor and an icing strength annunciator. The heat pipe ice-preventing system comprises a communicating pipe installed at the tail portion of the engine to absorb exhaust waste heat and a heat pipe bank bundle with an evaporation section connected with the communicating pipe. The ultrasonic oscillation ice removing system comprises an ultrasonic generator and an ultrasonic transducer unit connected with the output end of the ultrasonic generator through a connecting cable. The program control system automatically controls on and off between the heat pipe bank bundle and the communicating pipe and starting or stopping of the ultrasonic generator according to a temperature signal and an icing strength signal. By means of the synergistic effect of heat pipes and ultrasonic waves, preventing and removing can be combined, compared with a method for removing ice simply through ultrasonic waves, the icing phenomenon of wings is greatly reduced, the flying stability of an aircraft is ensured, and a system is safe and reliable.

Owner:NANJING NORMAL UNIVERSITY

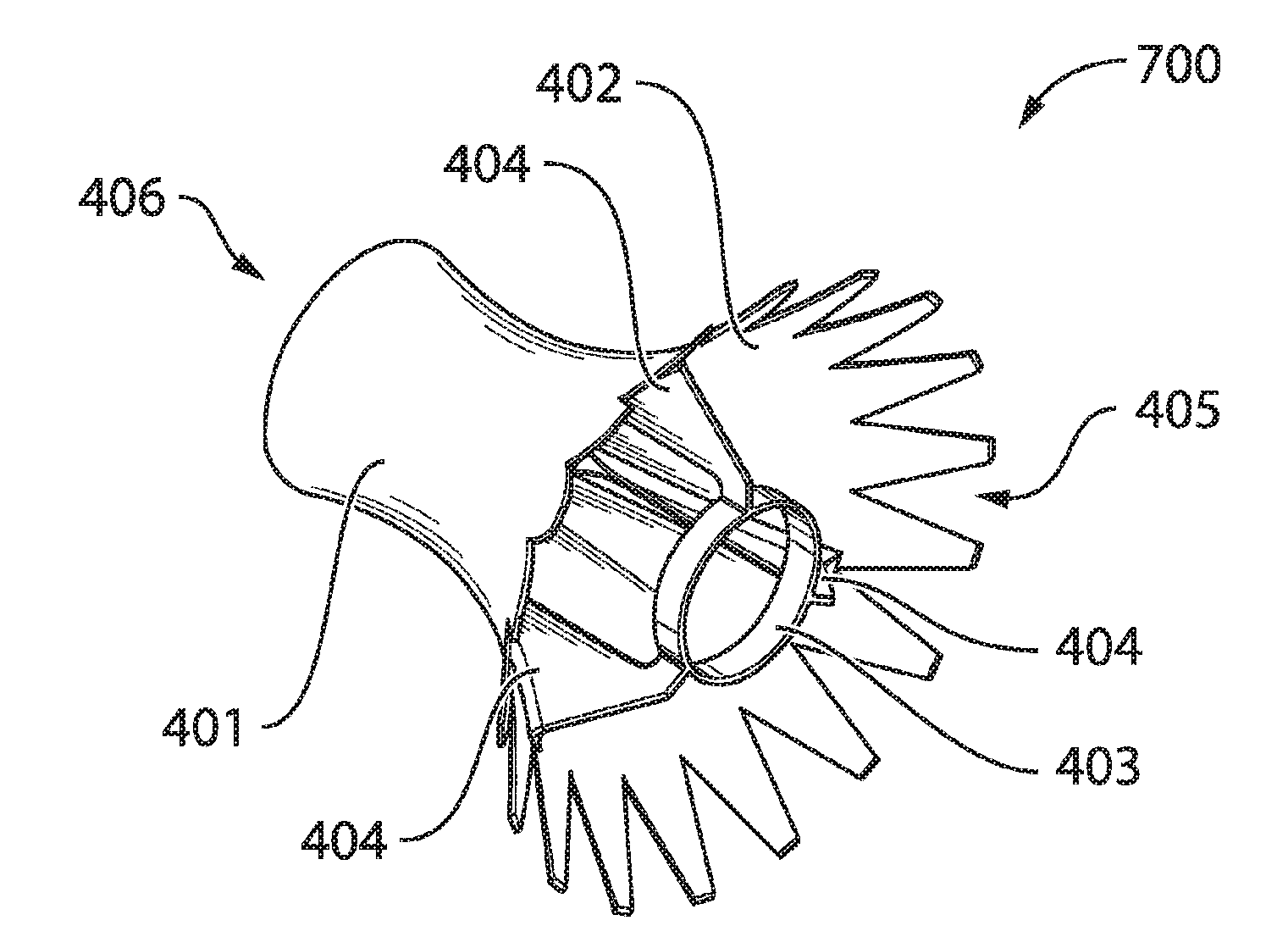

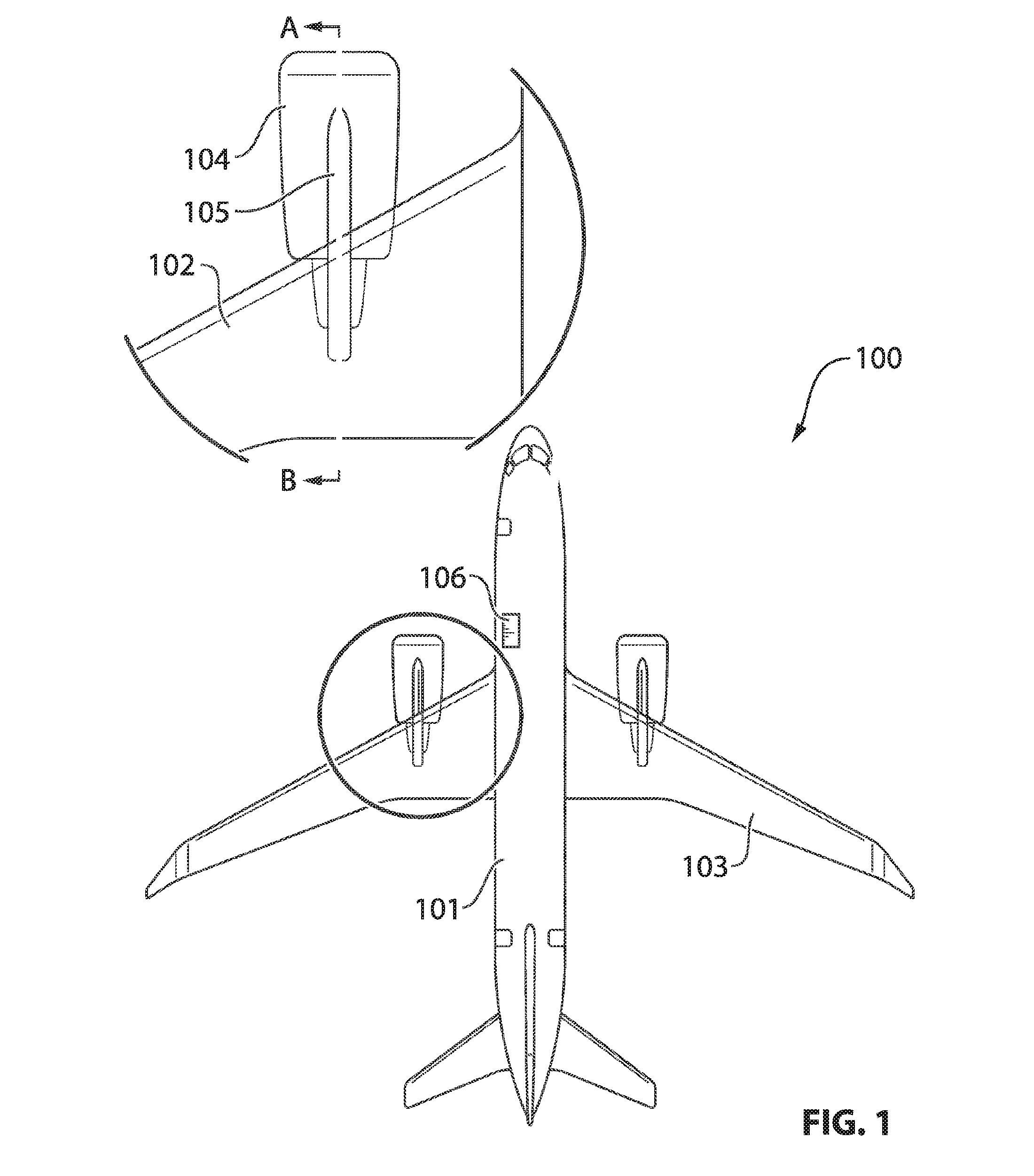

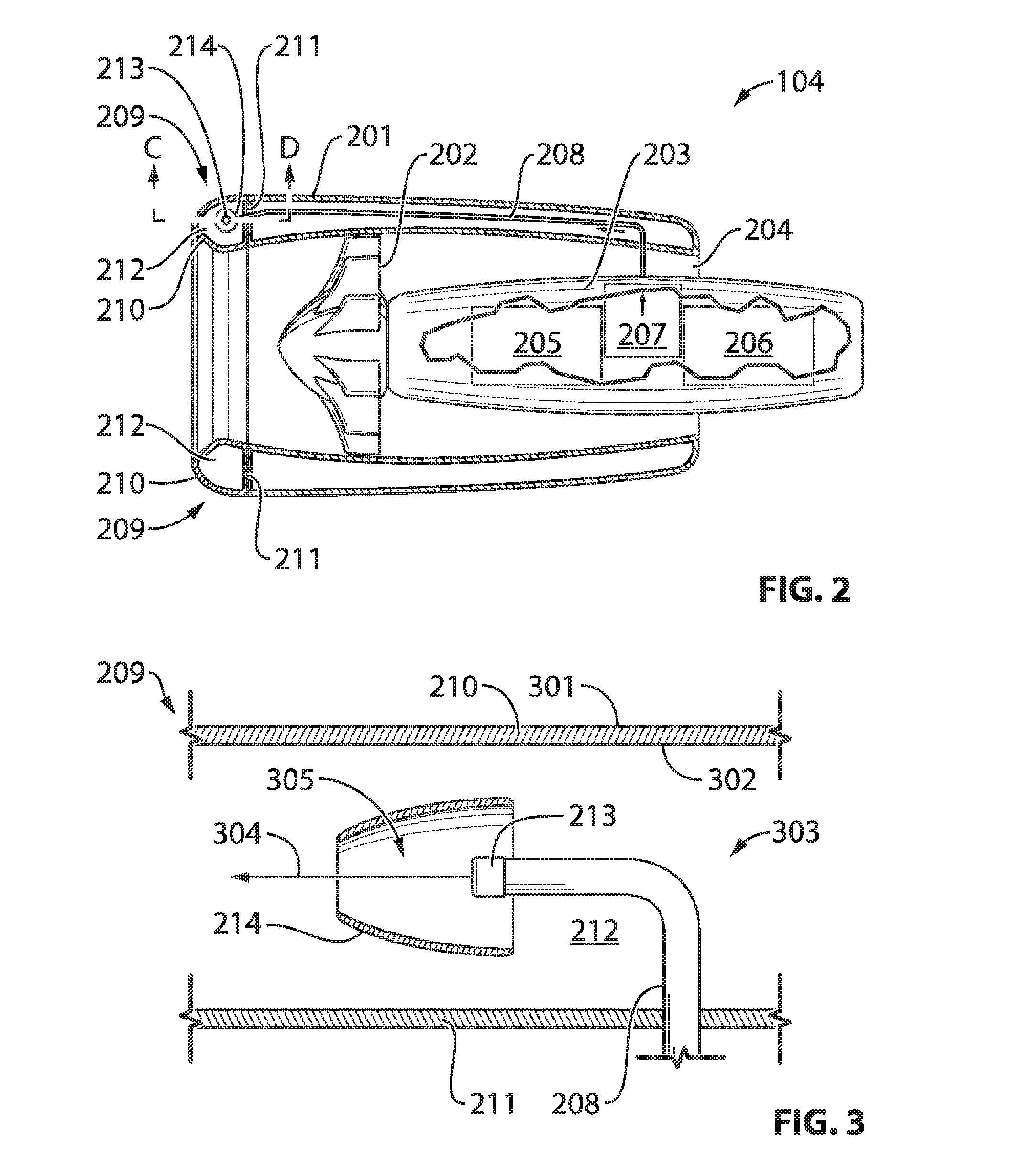

Anti-icing system for an aircraft

ActiveUS20160257413A1Improve efficiencyUniform temperature distributionEngine fuctionsDe-icing equipmentsAirplaneIce protection system

An anti-icing system is provided within a chamber having an exterior wall of which an outer surface may be subject to ice formation. The anti-icing system comprises a nozzle arranged to inject hot gas within the chamber. A gas-mixing device defines a channel for receiving hot gas from the nozzle. The gas-mixing device includes a swirl-inducing feature for causing gas from the chamber to be drawn into the channel with a swirling effect when hot gas from the nozzle is injected into the channel.

Owner:SHORT BROTHERS

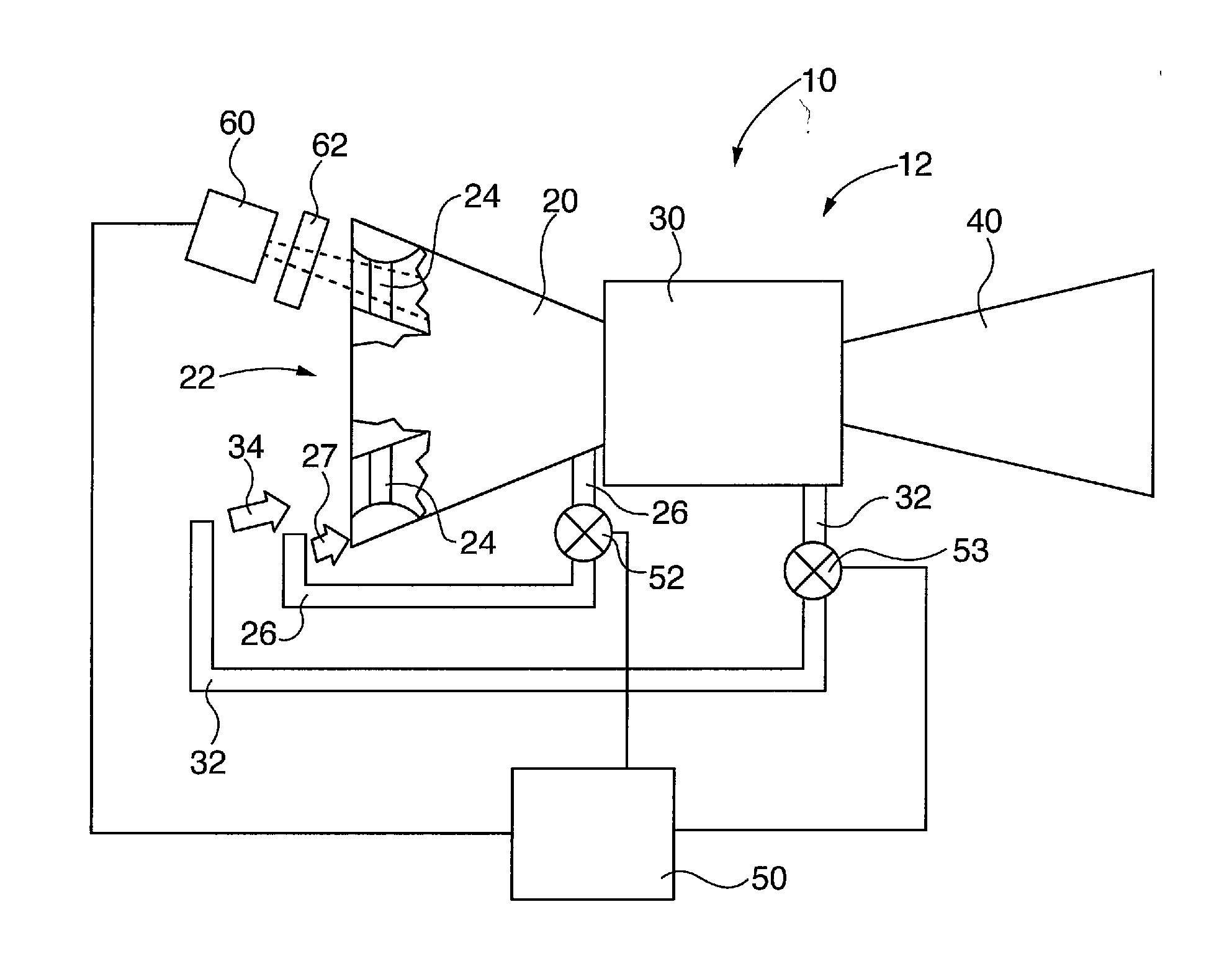

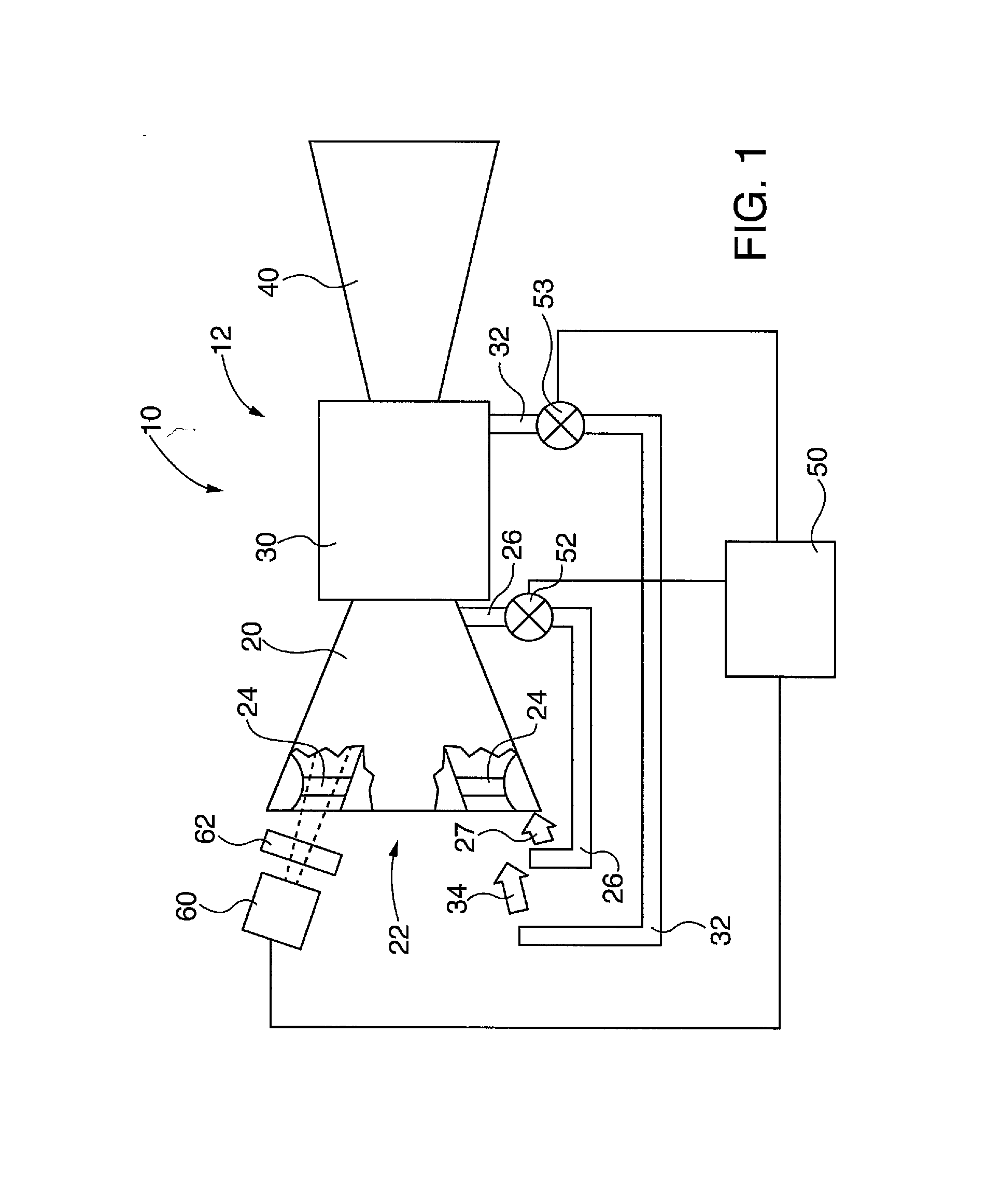

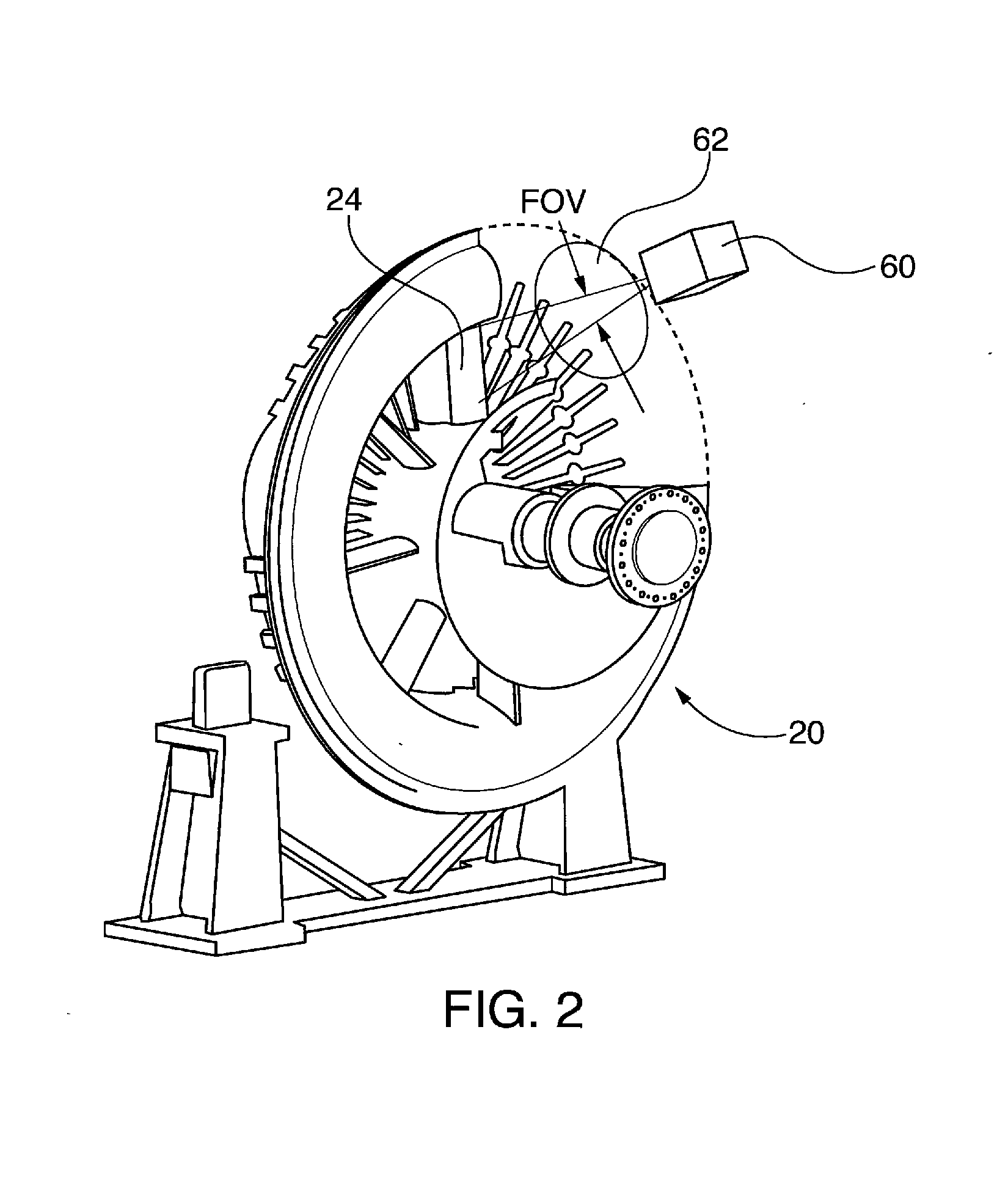

System and method for controlling ice formation on gas turbine inlet guide vanes

ActiveUS20140356122A1Operation efficiency can be improvedEasy to operateRadiation pyrometryGas-turbine engine testingEmissivityControl system

Gas turbine inlet guide vane ice detection and control systems and methods that utilize active infra-red monitoring of inlet guide vanes, detection of ice formation on the guide vanes and elimination of the ice by altering properties of the gas turbine inlet intake airflow, such as by introducing compressed and / or heated air bled from the turbine. Ice has lower detectable emissivity intensity in the infra-red spectrum than ice-free inlet guide vane surfaces. Ice formation is inhibited by direct monitoring of inlet guide vane icing conditions, rather than by indirect empirical assumptions of ice formation based on atmospheric condition monitoring. Direct monitoring mitigates ice formation in real time without reliance on excessive use of gas turbine compressed or heated air bleed, which enhances turbine operational efficiency.

Owner:SIEMENS ENERGY INC

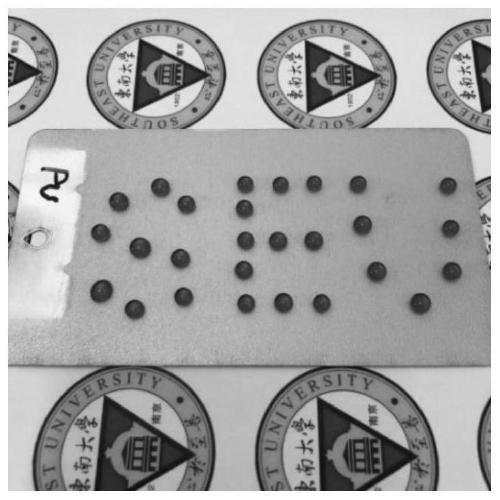

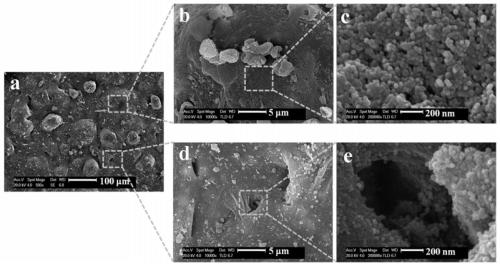

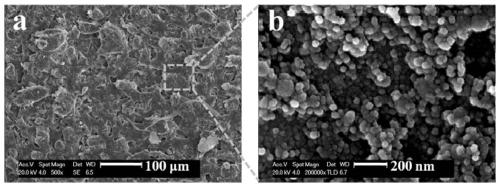

Super-wear-resistant and super-amphiphobic coating as well as preparation method and application thereof

ActiveCN110240849AImprove wear resistanceExcellent ice-phobic performanceLiquid surface applicatorsPolyurea/polyurethane coatingsWear resistantKitchen utensils

The invention relates to a super-wear-resistant and super-amphiphobic coating as well as a preparation method and application thereof, belonging to the technical field of coating preparation. The preparation process comprises the following steps: mixing resin powder, hydrophobic powder and an auxiliary agent, then putting the obtained mixture into a twin-screw mixer for melting and extruding, and then tabletting and crushing; grinding the crushed the sheets, and sieving to obtain a powder coating; dispersing aqueous silica sol into an aqueous solution, adding ammonia water for carrying out alkalization treatment, then adding the solution into an ethanol solution, mixing uniformly and then adding a hydrophobic modifier, stirring and standing to obtain a nano-super-amphiphobic coating; electrostatically spraying the powder coating to obtain a primer coating, and then spraying the nano-super-amphiphobic coating onto the surface of the primer coating to obtain the super-wear-resistant and super-amphiphobic coating. According to the preparation method provided by the invention, a large roughness surface structure is prepared by means of an electrostatic powder spraying process; due to the introduction of the functional finish coating, the super-amphiphobic coating with ultra-high wear resistance and anti-icing performance can be obtained; the super-wear-resistant and super-amphiphobic coating can be applied to preparation of kitchen utensils and equipment, inner walls of refrigeration equipment or outer walls of outdoor facilities in cold areas.

Owner:SOUTHEAST UNIV

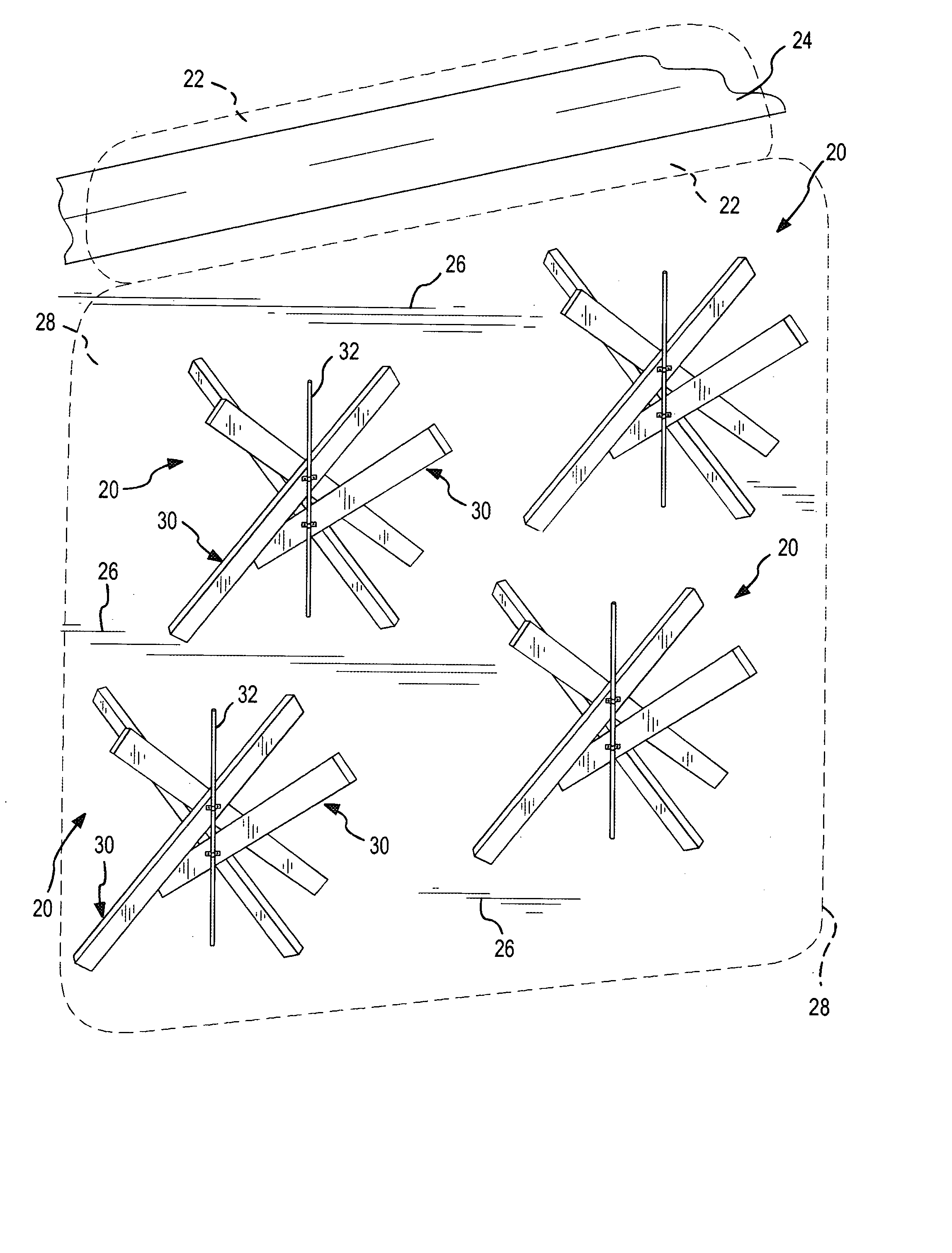

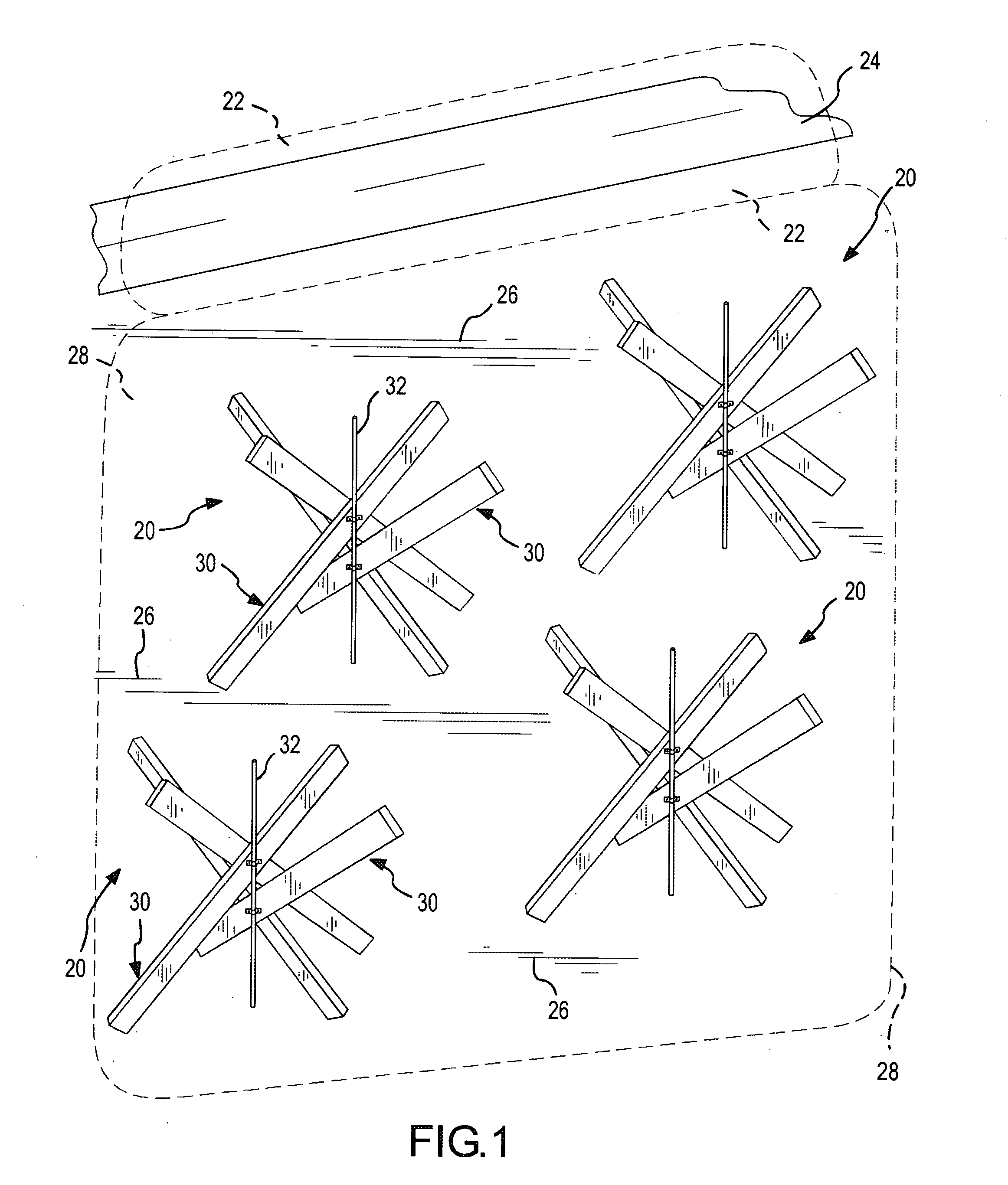

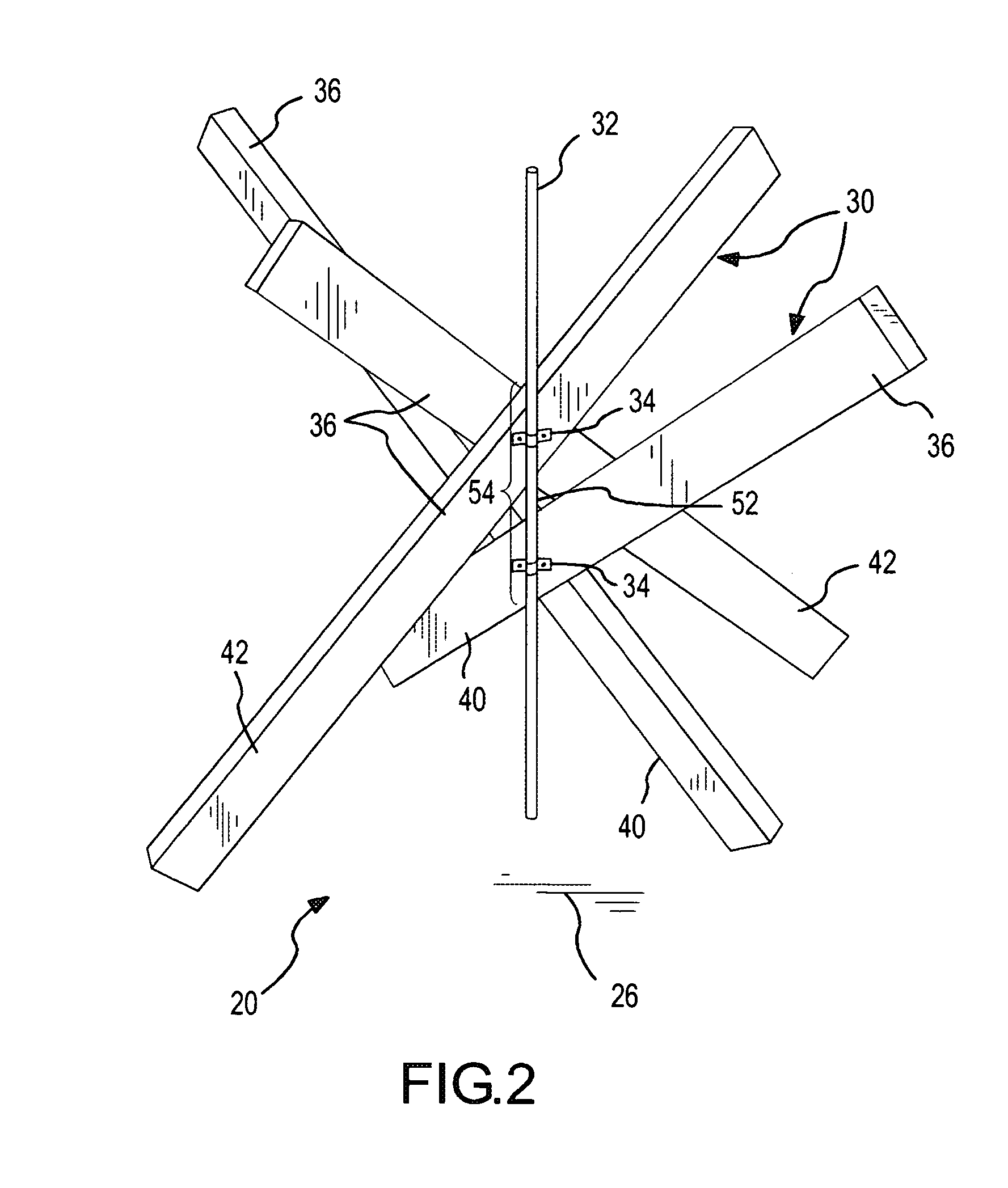

Tetrapod control device and method for stabilizing, depositing and retaining windblown particles

InactiveUS7097385B2Easy to repositionObstruction in may takeBreakwatersQuaysEngineeringEarth surface

A three-dimensional multi-pod windblown particle control device is used to control the deposition, accumulation and retention of windblown particles. The multi-pod device is formed by connecting beams to create legs which intersect one another at a crossing area. The ends of some of the legs contact the earth surface to support the device while the ends of the other legs extend in three dimensions to interact with the wind. The device may be formed by substantially identical X-shaped frame structures which intersect and connect with one another. The optimal spacing for using the devices in an array is within a range of approximately 0.5–1.5 of a transverse dimension across the surface area occupied by each particle control device.

Owner:TABLER RONALD D

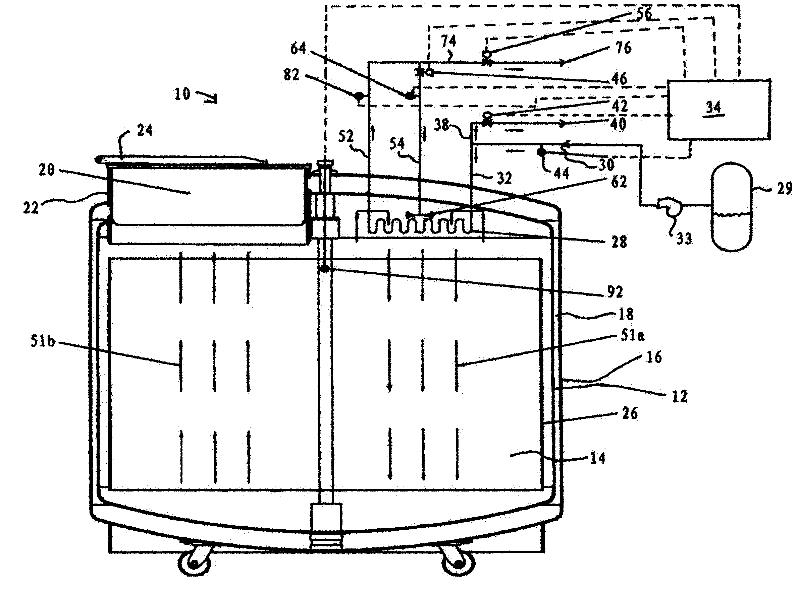

Freezer with liquid cryogen refrigerant and method

ActiveCN102192626AReduce icingLighting and heating apparatusPreparing sample for investigationEngineeringIce formation

The invention relates to a freezer with liquid cryogen refrigerant and method. The freezer includes an inner vessel defining a storage chamber and an outer jacket generally surrounding the inner vessel so that an insulation space is defined there between. A heat exchanger is positioned in a top portion of the storage chamber and has an inlet in communication with a supply of the liquid cryogen refrigerant so that the liquid cryogen refrigerant selectively flows through the heat exchanger to cool the storage chamber while being vaporized. A purge line is in communication with the outlet of the heat exchanger and includes a purge outlet positioned over the exterior of the heat exchanger. A purge valve is positioned within the purge line so that the vaporized liquid cryogen from the heat exchanger is selectively directed to the exterior of the heat exchanger to reduce ice formation on the heat exchanger.

Owner:엠브이이바이오로지컬솔루션스유에스엘엘씨

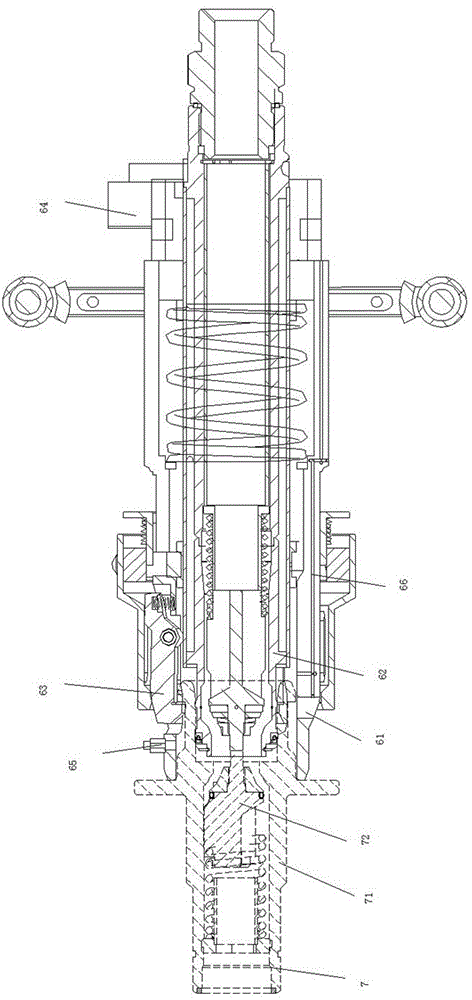

Intelligent filling gun

ActiveCN106195630AReduce labor intensityEasy to operateVessel mounting detailsFluid handledElectricityEngineering

The invention relates to the technical field of low-temperature or ultralow-temperature application, in particular to an intelligent filling gun and a mating system thereof. The intelligent filling gun comprises a filling gun body, an LNG system, a filling pipeline, a controller and a discharge pipeline. The filling gun body communicates with the LNG system through the filling pipeline. A detector used for detecting whether leakage happens to the filling pipeline or not is arranged on the filling pipeline or the filling gun body. The filling pipeline communicates with the discharge pipeline through a pressure-relief electromagnetic valve. The detector and the pressure-relief electromagnetic valve are electrically connected with the controller. By the adoption of the structure, filling of LNG or other low-temperature media can be made intelligent through the cooperation of the detector, the controller and the electromagnetic valve, leakage detection and pressure relief can be effectively achieved, and thus the situation that personnel injuries are caused by leakage of LNG or other low-temperature media left in the filling pipeline and the filling gun body is prevented.

Owner:CHENGDU ANDERSON MEASUREMENT

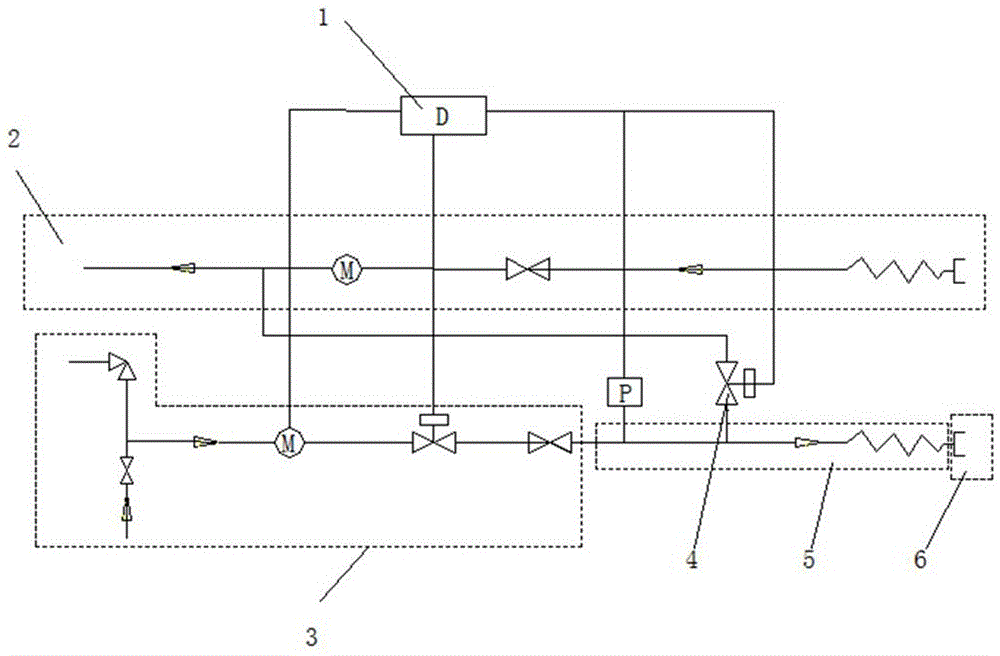

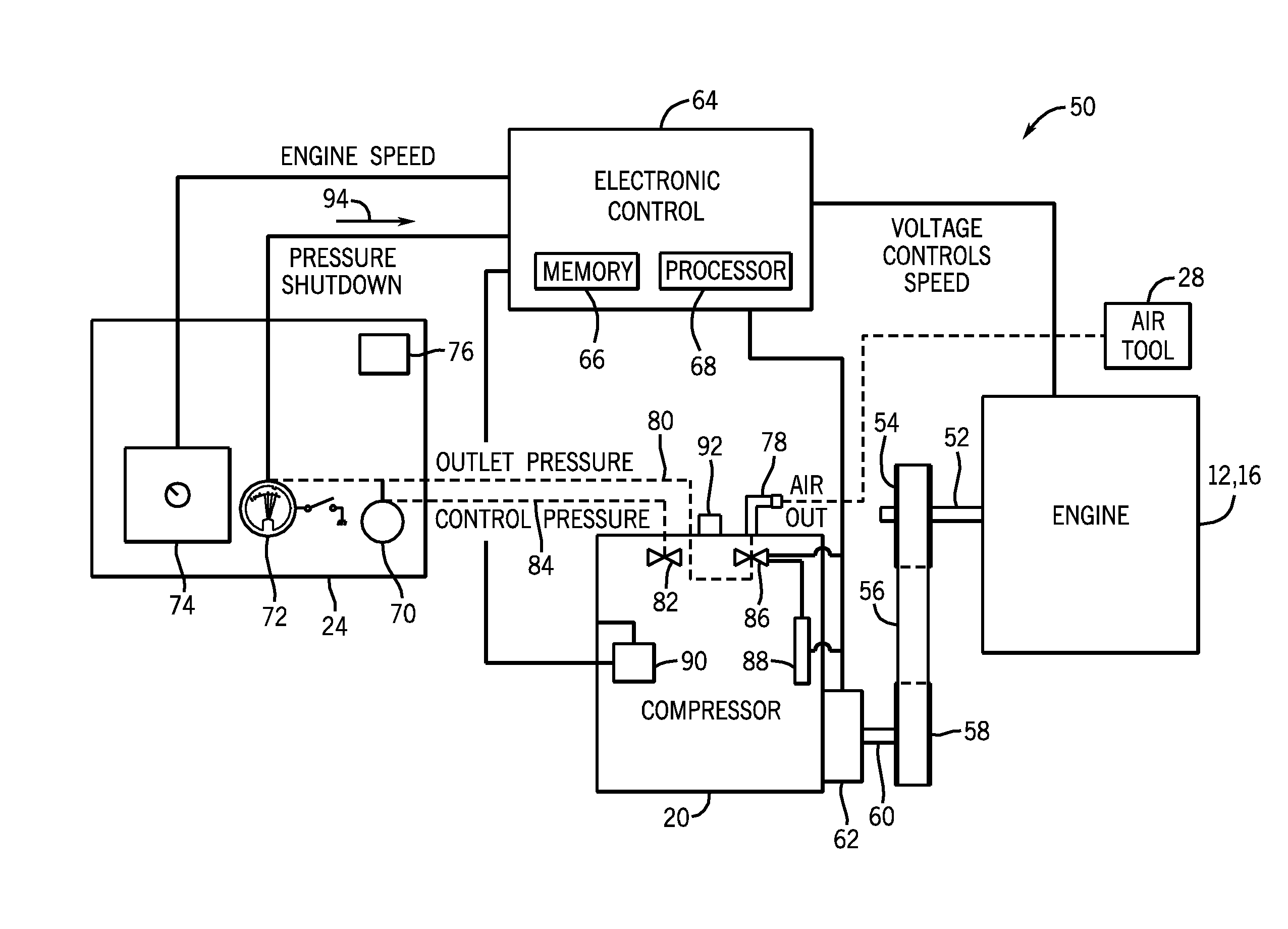

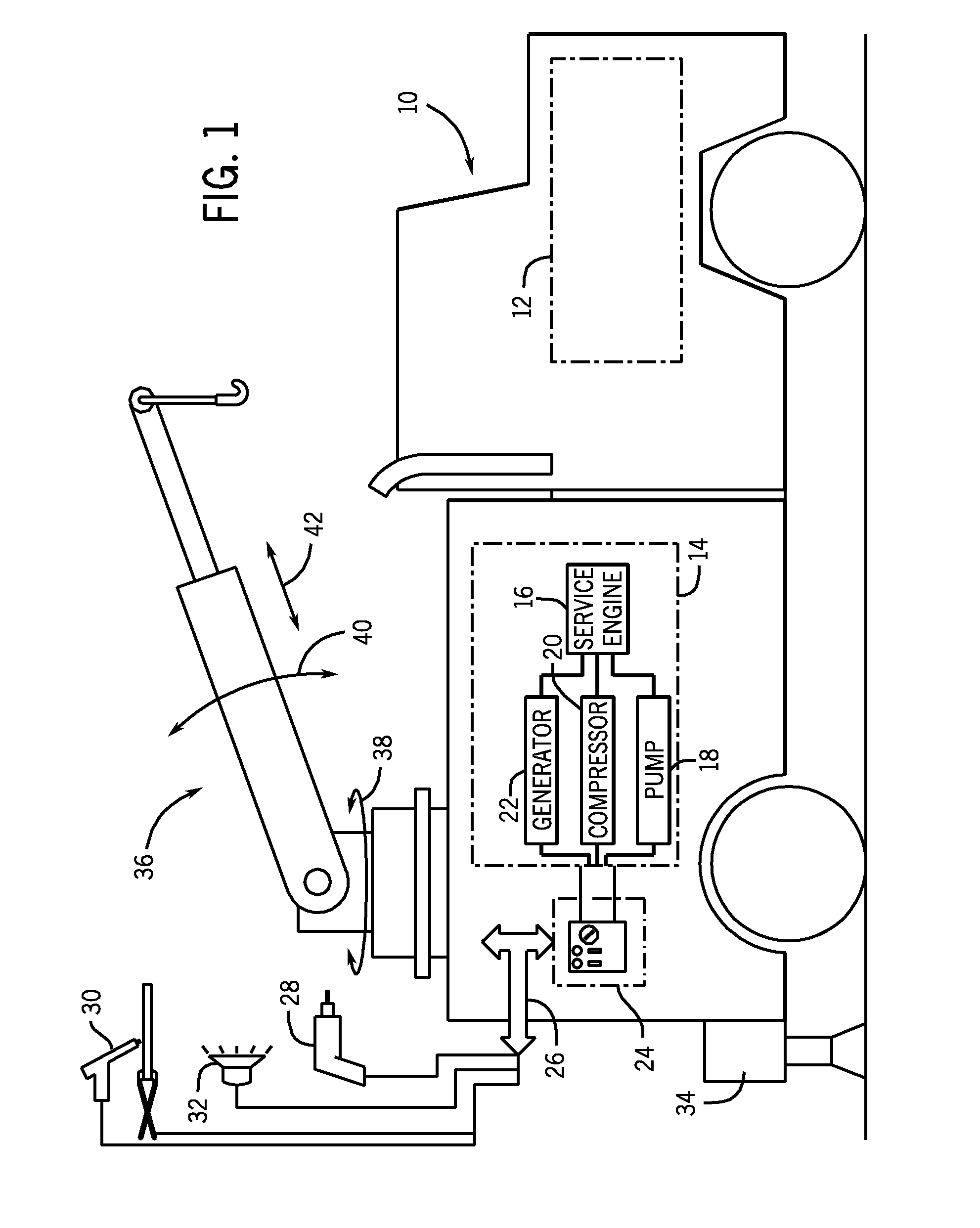

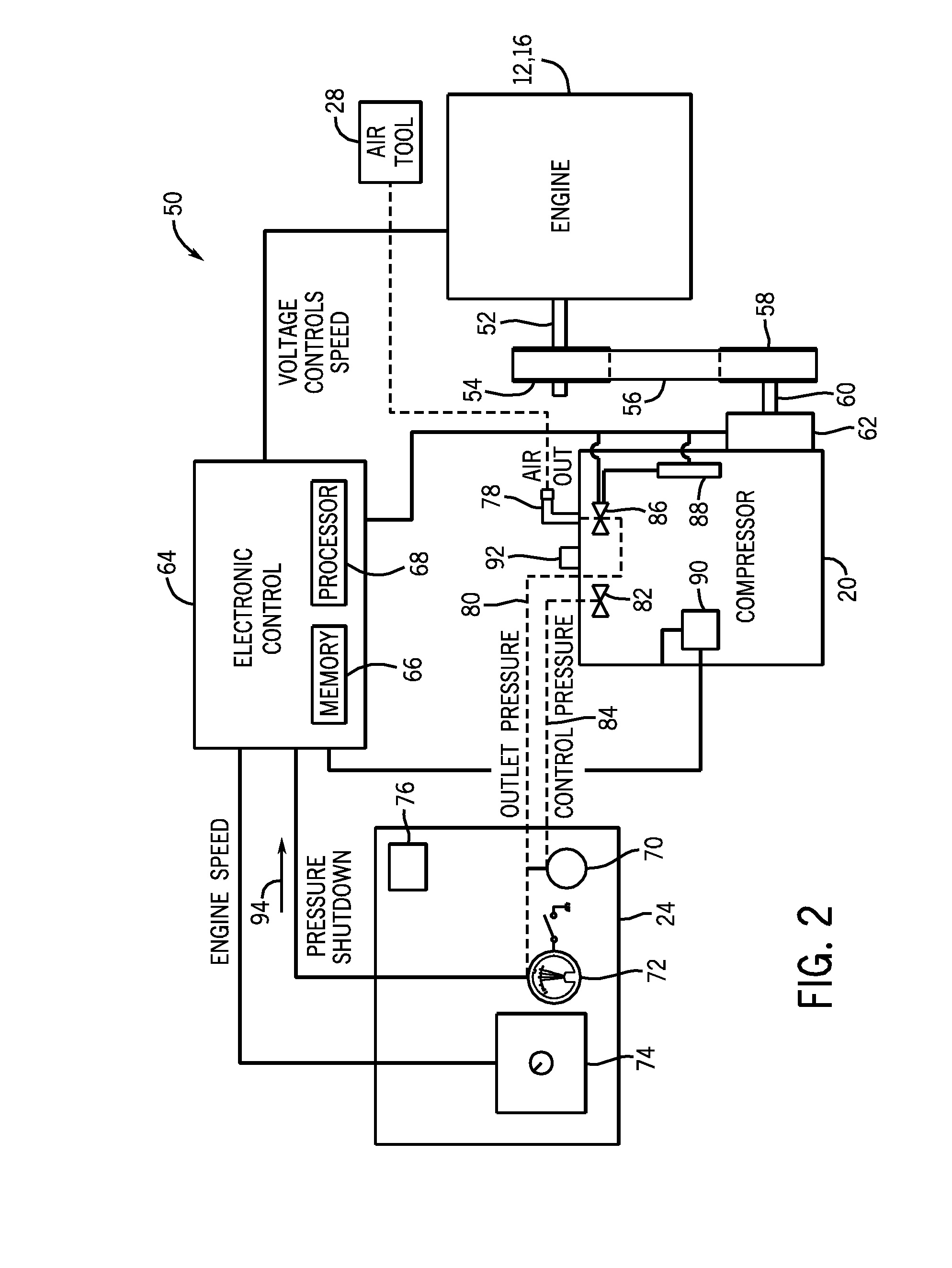

Compressor Freeze Up Prevention in Cold Weather

ActiveUS20100316505A1Reduce buildIncrease pressurePositive displacement pump componentsFlexible member pumpsControl systemCompression device

The present embodiments provide a control system and method that is able to automatically cycle one or more compressor valves, for example to prevent freeze up. For example, in one embodiment, a system includes a compressor having a compression device configured to increase a pressure of a gas, a valve configured to control flow of the gas from the compression device, and a controller configured to cycle the valve to reduce buildup of contaminants in the compressor.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com