Heat pipe and ultrasonic wave combined ice preventing and removing device and method utilizing waste heat of aircraft engine

An aircraft engine and ultrasonic technology, applied in deicing devices, aircraft parts, transportation and packaging, etc., can solve the problems of reducing the adhesion between the ice layer and the surface of the wing, reducing the time for heat pipes to melt ice, and reducing energy consumption. To achieve the effect of guaranteed performance, strong implementability and prevention of icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings and embodiments.

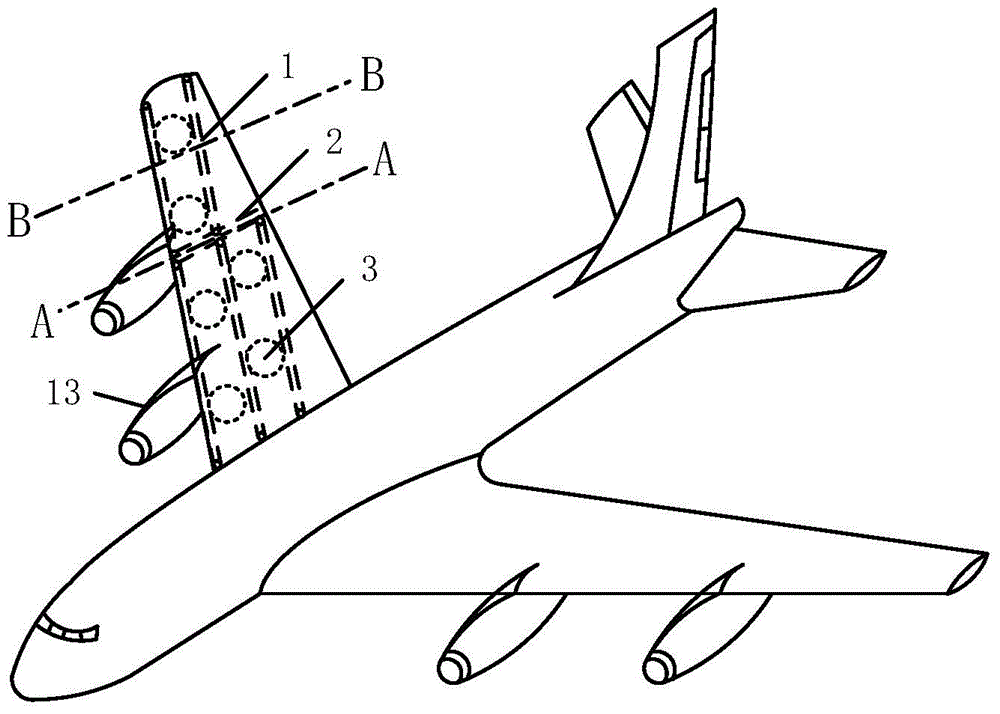

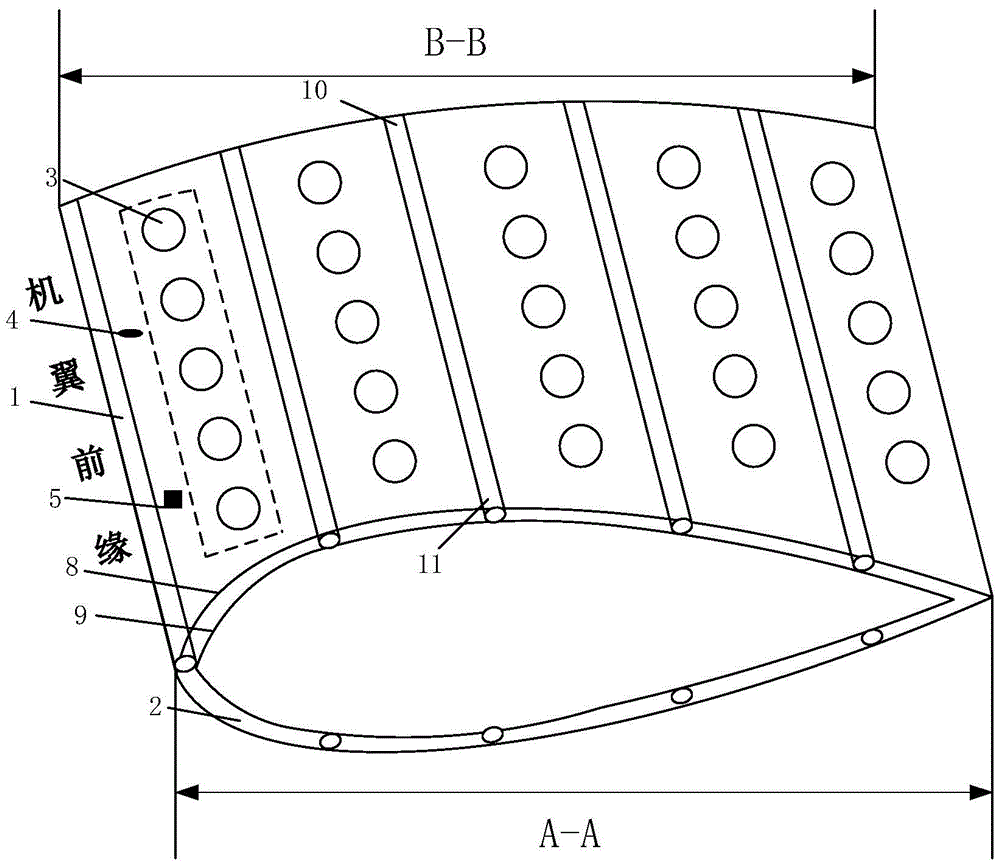

[0034] The heat pipe ultrasonic combined anti-icing and deicing device of this embodiment includes a heat pipe anti-icing system, an ultrasonic oscillation deicing system, a program control system, an atmospheric temperature sensor 4 for detecting the outside air temperature, and an outer skin 9 for detecting the airfoil. The icing intensity signal 5 of the thickness of the ice layer on the surface. The atmospheric temperature sensor 4 and the icing intensity signal 5 are both installed on the outer surface of the outer skin 8 of the wing. The overall structure of the combined anti-icing and deicing device of this embodiment is close to the airfoil skin, and does not affect the aerodynamic shape of the aircraft; it can effectively and uniformly deicing, and the overall distribution is evenly distributed (specifically, Figure 1-2 Shown).

[0035] Among them, the heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com