Windshield wiper de-icing

a technology for windshield wipers and washers, applied in the field of windshield wiper and washer systems, can solve the problems of ice build-up, wiper blades losing contact with the windshield, and the present day wiper-washer systems still suffer from a number of limitations, and achieve the effect of reducing ice formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following detailed description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any expressed or implied theory presented in the preceding technical field, background, brief summary or the following detailed description.

[0017] The words “rest” or “pause” or “retracted” are used interchangeably herein to refer to the position or status of the wipers generally when motion is temporarily stopped during intermittent operation and the word “stowage” is used generally to refer to the wiper position or status when the wipers are OFF.

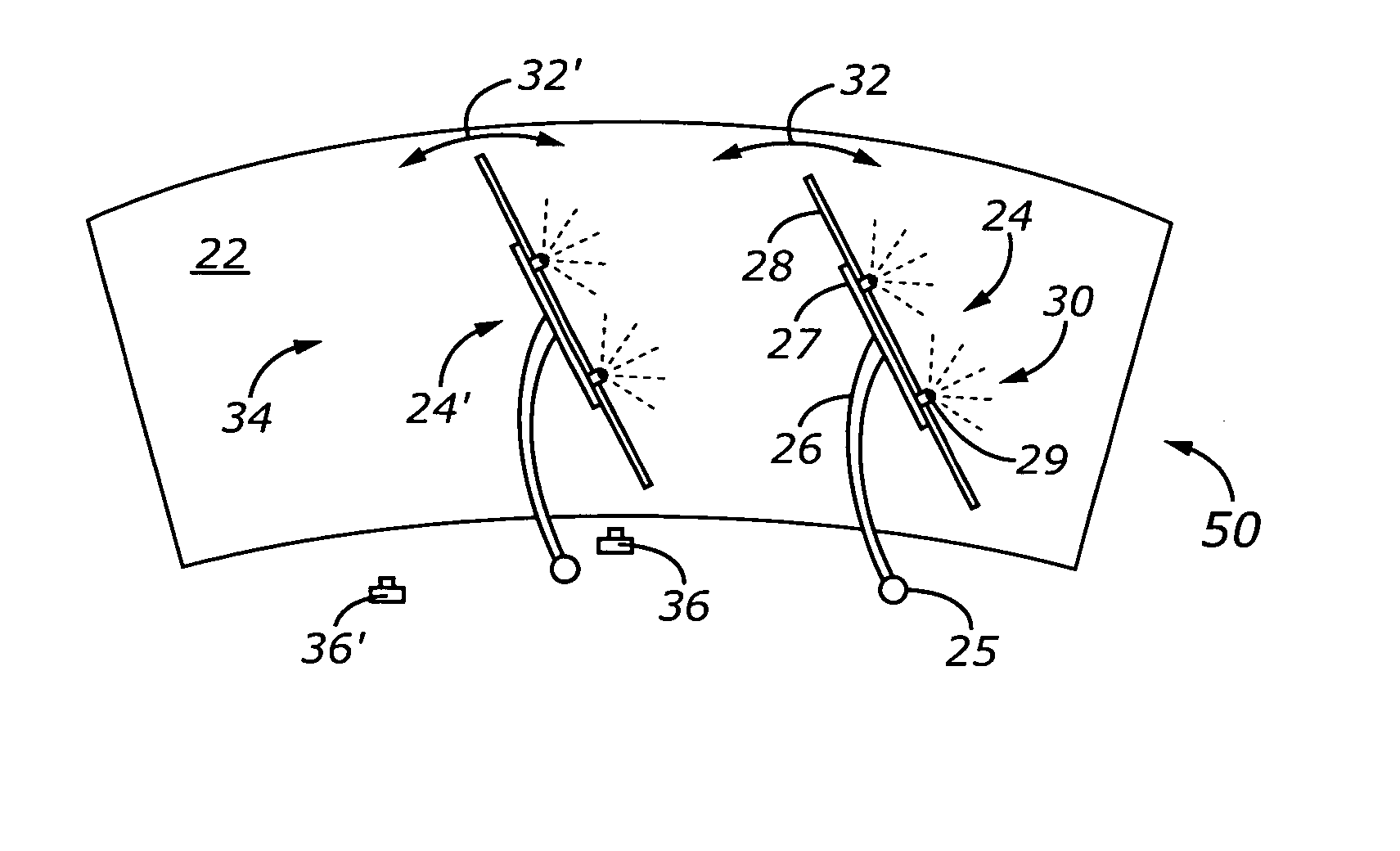

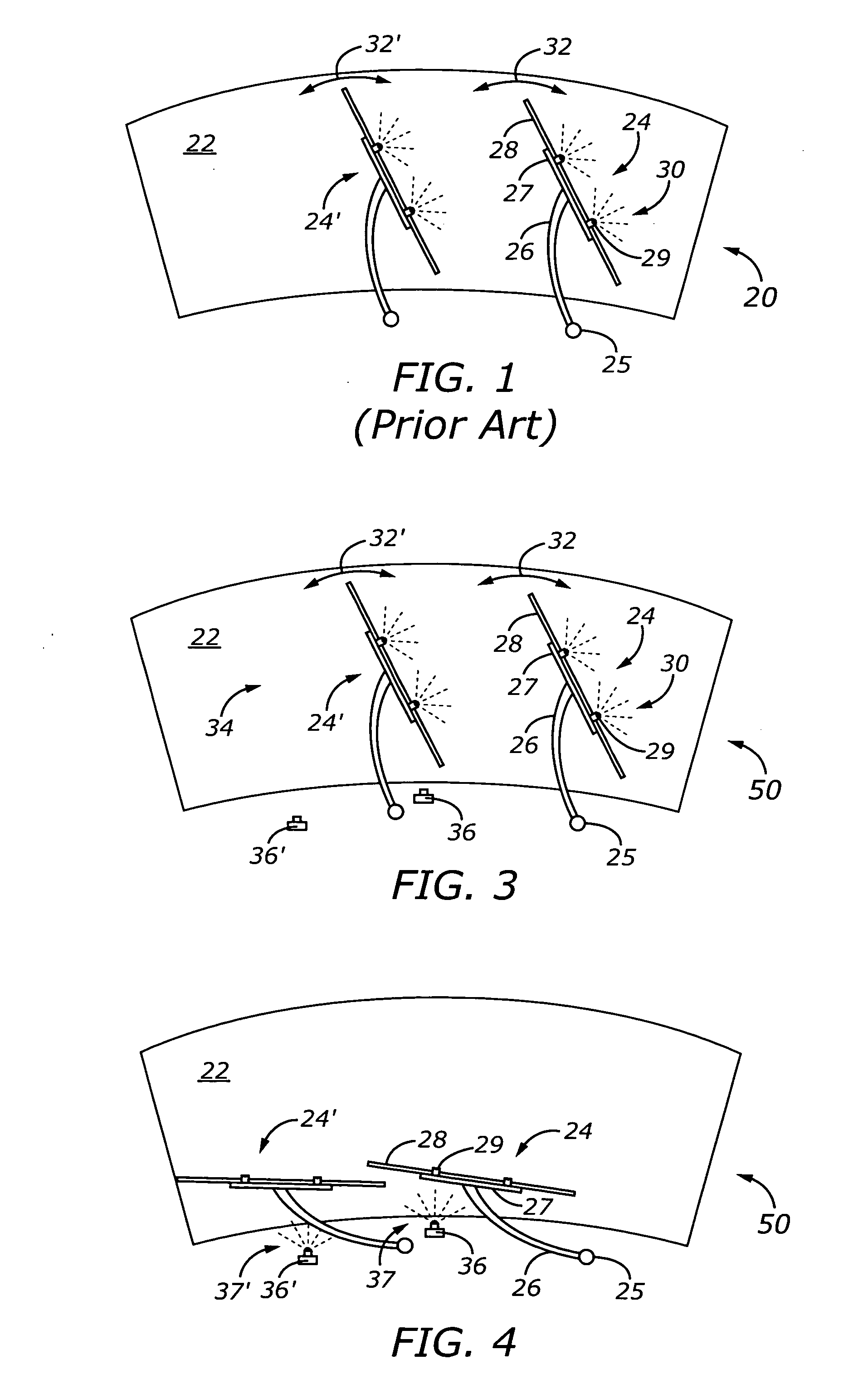

[0018]FIGS. 3-4 are simplified representations of the windshield wiping-washing and wiper de-icing system 50 of the present invention for different wiper arm positions 34, 35. In FIG. 3, wiper assemblies 24, 24′ are shown in standard wiping-washing state 34, similar to that shown in FIG. 1, that is, wiper assemblies 24, 24′ are up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com