Super-hydrophobic ice-over resistant coating with thermomagnetic property and preparation method of super-hydrophobic ice-over resistant coating

A super-hydrophobic, anti-icing technology, applied in the coating and other directions, can solve the problems of difficult to remove, destroy the coating, and the adhesion between the ice and the substrate surface, and achieve the effect of delaying icing and excellent magnetocaloric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

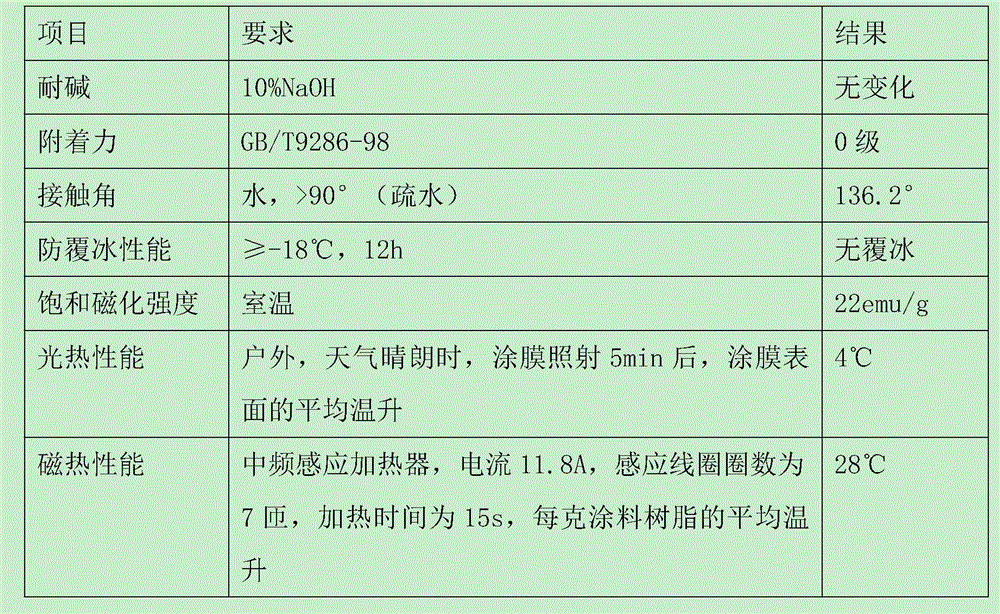

example 1

[0049] The 2,2'-azobisisobutyronitrile (AIBN) of 0.096g is dissolved in the butyl acetate of 1.6g, puts into and is connected with condenser tube and N 2 Preheat the three-necked flask of the air blowing device to 75°C; add 0.96g of [N-methyl perfluorohexanesulfonamido]ethyl acrylate, 6.4g of octadecyl methacrylate, and 0.64g of methacrylic acid Glycidyl esters, 0.04g of dodecyl mercaptan and 0.24g of AIBN were dissolved in 14.4g of butyl acetate, put into a constant pressure dropping funnel, and added dropwise to a three-necked flask, and the dropping speed was controlled to make it drop for 4 hours ; Then under the protection of nitrogen, after 4 hours of polymerization reaction, add 0.144g of AIBN, heat up to 85 ° C, and keep warm for 4 hours; Acrylate polymer 7.9g; The obtained epoxy group-containing acrylate polymer is carried out 1 H NMR test, calculate the molar weight of epoxy group 0.56mmol / g.

[0050] Put 5g of epoxy group-containing acrylate polymer, 0.288g of die...

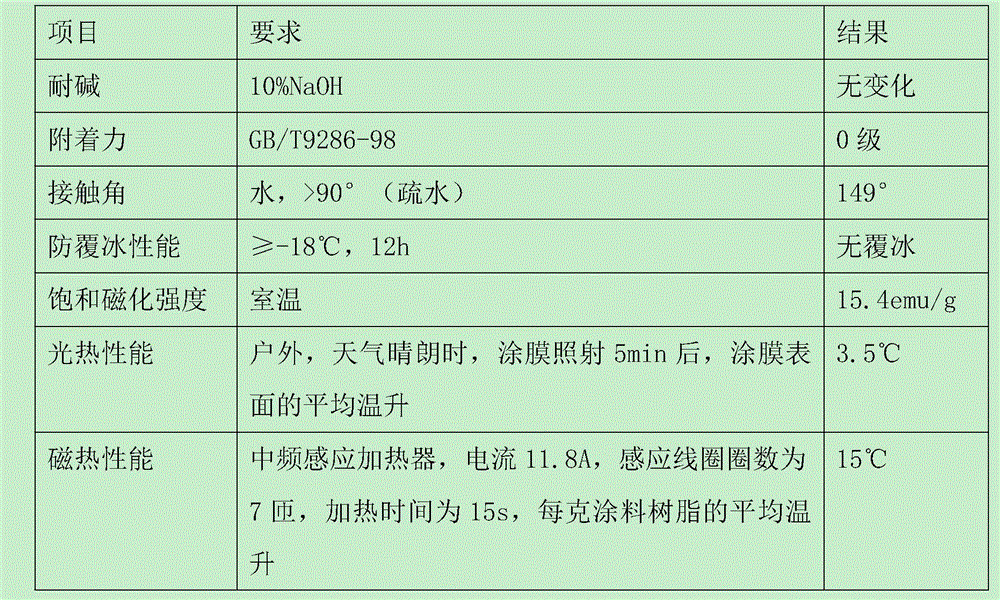

example 2

[0053] The 2,2'-azobisisobutyronitrile (AIBN) of 0.0025g is dissolved in the butyl acetate of 24.99g, puts into and is connected with condenser tube and N 2 Preheat the three-neck flask of the air blowing device to 75°C; add 15g of [N-methyl perfluorohexanesulfonamido] ethyl methacrylate, 7.5g of octadecyl acrylate, 27.5g of glycidyl acrylate, 3g of dodecyl mercaptan and 0.225g of AIBN were dissolved in 58.33g of butyl acetate, put into a constant pressure dropping funnel, and added dropwise to a three-necked flask, and the drop rate was controlled to make it drop in 4 hours; then under the protection of nitrogen, After 4 hours of polymerization, 0.025 g of AIBN was added, the temperature was raised to 85° C., and the temperature was kept for 12 hours; after the polymerization was completed, the polymerization product was precipitated with methanol, centrifuged, and vacuum-dried to obtain 49.5 g of epoxy-containing acrylate polymer. The obtained epoxy group-containing acrylate...

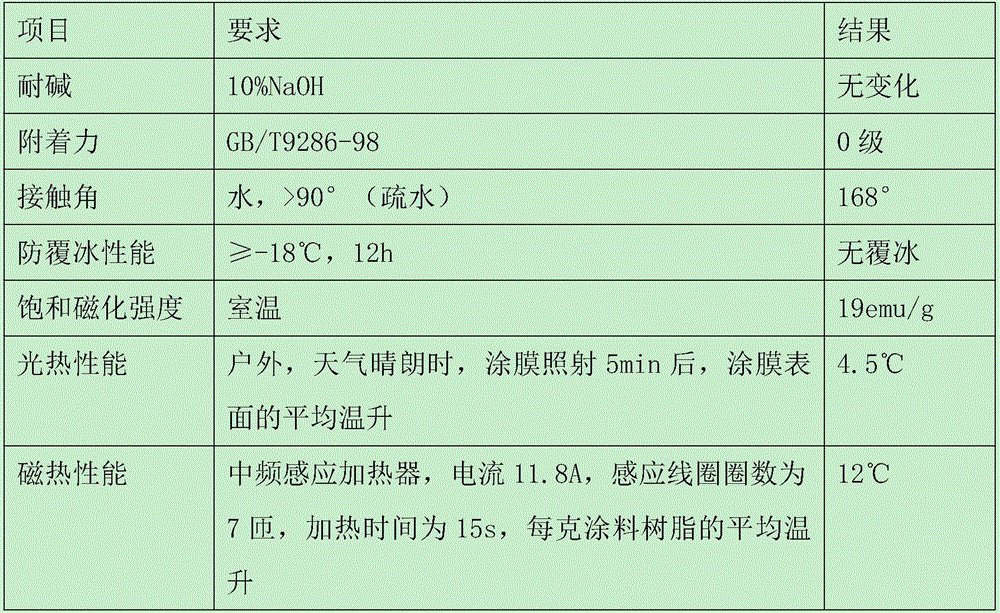

example 3

[0057] The 2,2'-azobisisobutyronitrile (AIBN) of 0.0113g is dissolved in the methyl ethyl ketone of 4.545g, puts into and is connected with condenser tube and N 2 Preheat the three-necked flask with gas blowing device to 55°C. 6.3g of [N-methyl perfluorobutanesulfonamido]ethyl acrylate, 3.78g of butyl acrylate, 2.52g of glycidyl methacrylate, 0.189g of dodecyl mercaptan, 0.1493g The AIBN was dissolved in 25.755g of methyl ethyl ketone, put into a constant pressure dropping funnel, and added dropwise to a three-necked flask, and the drop rate was controlled so that it would finish dropping within 4 hours. Under the protection of nitrogen, after the polymerization reaction for 4 hours, 0.0284 g of AIBN was added, the temperature was raised to 70° C., and the temperature was kept for 6 hours. After the polymerization reaction was completed, the polymerization product was precipitated by using a mixed solvent of methanol and petroleum ether, centrifuged, and vacuum-dried to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com