A kind of superhydrophobic anti-icing coating with magnetocaloric performance and preparation method thereof

A super-hydrophobic and anti-icing technology, applied in the coating and other directions, can solve the problems of damage to the coating, difficulty in removal, loss of super-hydrophobic properties of the coating, etc., and achieve excellent magnetocaloric performance and delay the effect of icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

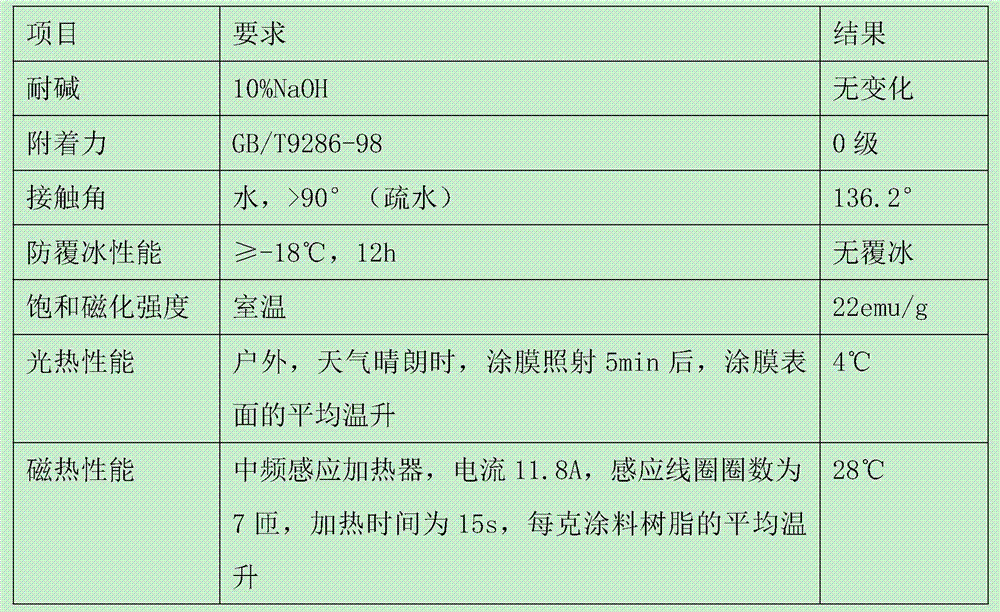

example 1

[0049] The 2,2'-azobisisobutyronitrile (AIBN) of 0.096g is dissolved in the butyl acetate of 1.6g, puts into and is connected with condenser tube and N 2 Preheat the three-necked flask of the air blowing device to 75°C; add 0.96g of [N-methyl perfluorohexanesulfonamido]ethyl acrylate, 6.4g of octadecyl methacrylate, and 0.64g of methacrylic acid Glycidyl esters, 0.04g of dodecyl mercaptan and 0.24g of AIBN were dissolved in 14.4g of butyl acetate, put into a constant pressure dropping funnel, and added dropwise to a three-necked flask, and the dropping speed was controlled to make it drop for 4 hours ; Then under the protection of nitrogen, after 4 hours of polymerization reaction, add 0.144g of AIBN, heat up to 85 ° C, and keep warm for 4 hours; Acrylate polymer 7.9g; The obtained epoxy group-containing acrylate polymer is carried out 1 H NMR test, calculate the molar weight of epoxy group 0.56mmol / g.

[0050] Put 5g of epoxy group-containing acrylate polymer, 0.288g of die...

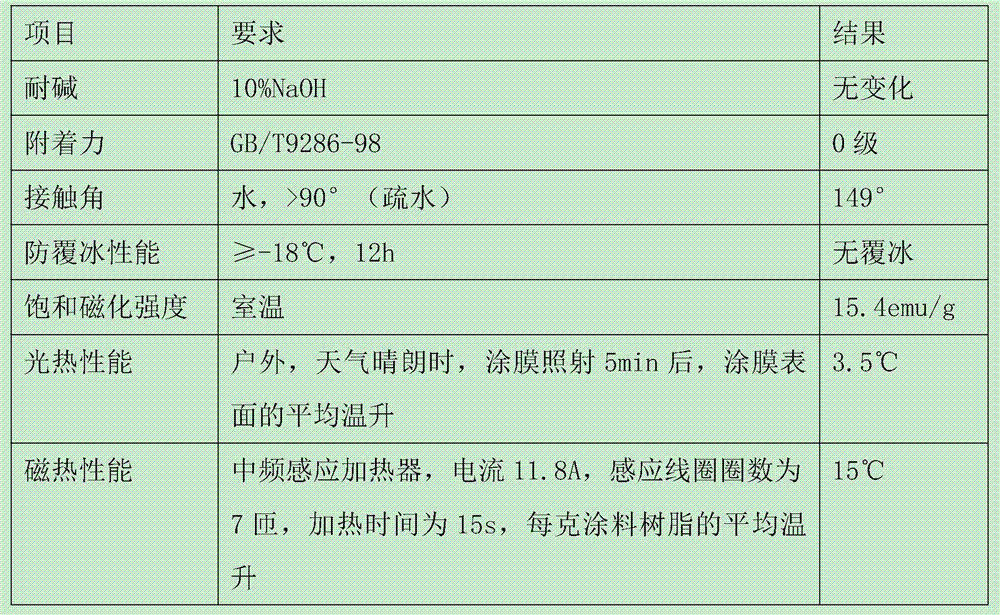

example 2

[0053] The 2,2'-azobisisobutyronitrile (AIBN) of 0.0025g is dissolved in the butyl acetate of 24.99g, puts into and is connected with condenser tube and N 2 Preheat the three-neck flask of the air blowing device to 75°C; add 15g of [N-methyl perfluorohexanesulfonamido] ethyl methacrylate, 7.5g of octadecyl acrylate, 27.5g of glycidyl acrylate, 3g of dodecyl mercaptan and 0.225g of AIBN were dissolved in 58.33g of butyl acetate, put into a constant pressure dropping funnel, and added dropwise to a three-necked flask, and the drop rate was controlled to make it drop in 4 hours; then under the protection of nitrogen, After 4 hours of polymerization, 0.025 g of AIBN was added, the temperature was raised to 85° C., and the temperature was kept for 12 hours; after the polymerization was completed, the polymerization product was precipitated with methanol, centrifuged, and vacuum-dried to obtain 49.5 g of epoxy-containing acrylate polymer. The obtained epoxy group-containing acrylate...

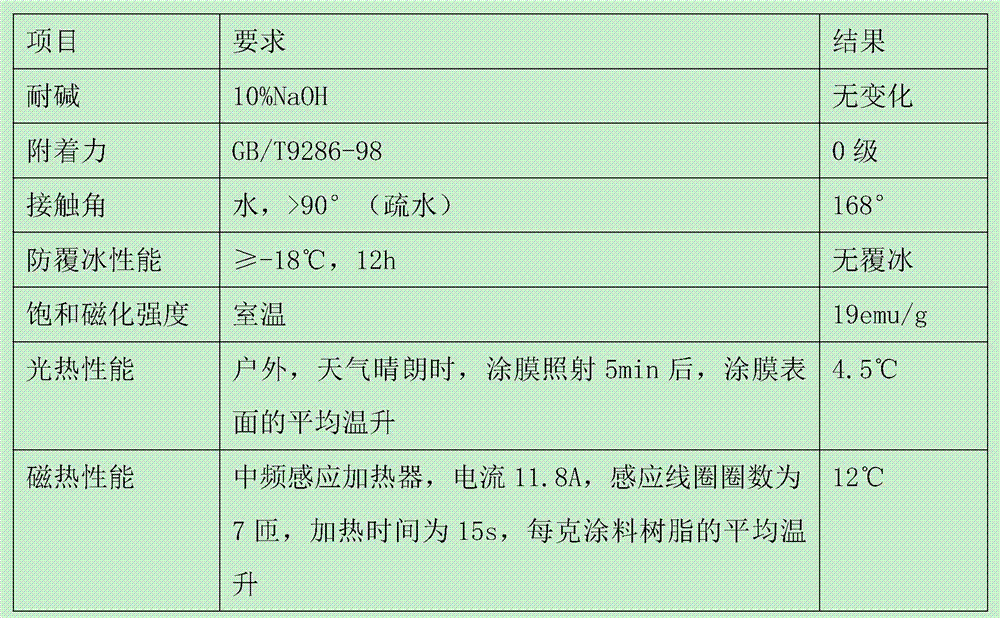

example 3

[0057] The 2,2'-azobisisobutyronitrile (AIBN) of 0.0113g is dissolved in the methyl ethyl ketone of 4.545g, puts into and is connected with condenser tube and N 2 Preheat the three-necked flask with gas blowing device to 55°C. 6.3g of [N-methyl perfluorobutanesulfonamido] ethyl acrylate, 3.78g of butyl acrylate, 2.52g of glycidyl methacrylate, 0.189g of dodecyl mercaptan, 0.1493g The AIBN was dissolved in 25.755g of methyl ethyl ketone, put into a constant pressure dropping funnel, and added dropwise to a three-necked flask, and the drop rate was controlled so that it would finish dropping within 4 hours. Under the protection of nitrogen, after the polymerization reaction for 4 hours, 0.0284 g of AIBN was added, the temperature was raised to 70° C., and the temperature was kept for 6 hours. After the polymerization reaction was completed, the polymerization product was precipitated by using a mixed solvent of methanol and petroleum ether, centrifuged, and vacuum-dried to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com