Method for improving magnetocaloric performance of LaFeSi through adding low-melting-point LaAl

A low melting point phase and performance technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of long preparation cycle, increased cost, difficult to process and shape, shorten annealing time, reduce sample preparation cycle and cost , the effect of excellent magnetocaloric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

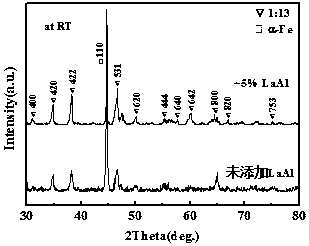

[0026] (1) Sample preparation: Proportion LaFe respectively according to the stoichiometric method 11.85 Si 1.15 Alloy and La 0.77 al 0.23 Alloy, using elemental La with a purity of 99.5% or more, Fe with a purity of 99.95% or more, Si with a purity of 99.9% or more, and Al with a purity of 99.996% or more. Among them, the La block needs to be polished and cleaned with ultrasonic vibration before use. 20 min to remove the oxide on the surface. In order to compensate for the loss of La during the smelting process, it is generally necessary to add an additional 5 wt.% La when preparing samples;

[0027] (2) Smelting: Put the prepared elemental elements into a high vacuum water-cooled copper crucible electric arc furnace for smelting. When the vacuum reaches 1.0×10 -3 After Pa is below, it is filled with high-purity Ar at an atmospheric pressure. When smelting, it is necessary to melt the block first to make it absorb the residual oxygen in the furnace, and repeatedly smelt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com