Extremely low temperature magnetic refrigeration material and preparation method and application thereof

A magnetic refrigeration material and extremely low temperature technology, applied in the field of extremely low temperature magnetic refrigeration materials and their preparation, can solve the problems of not providing the magnetic entropy change value of the material, difficult to achieve mass production, and unsuitable for mass production, etc., and achieve excellent magnetic properties. Thermal performance, environmental advantages, short cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

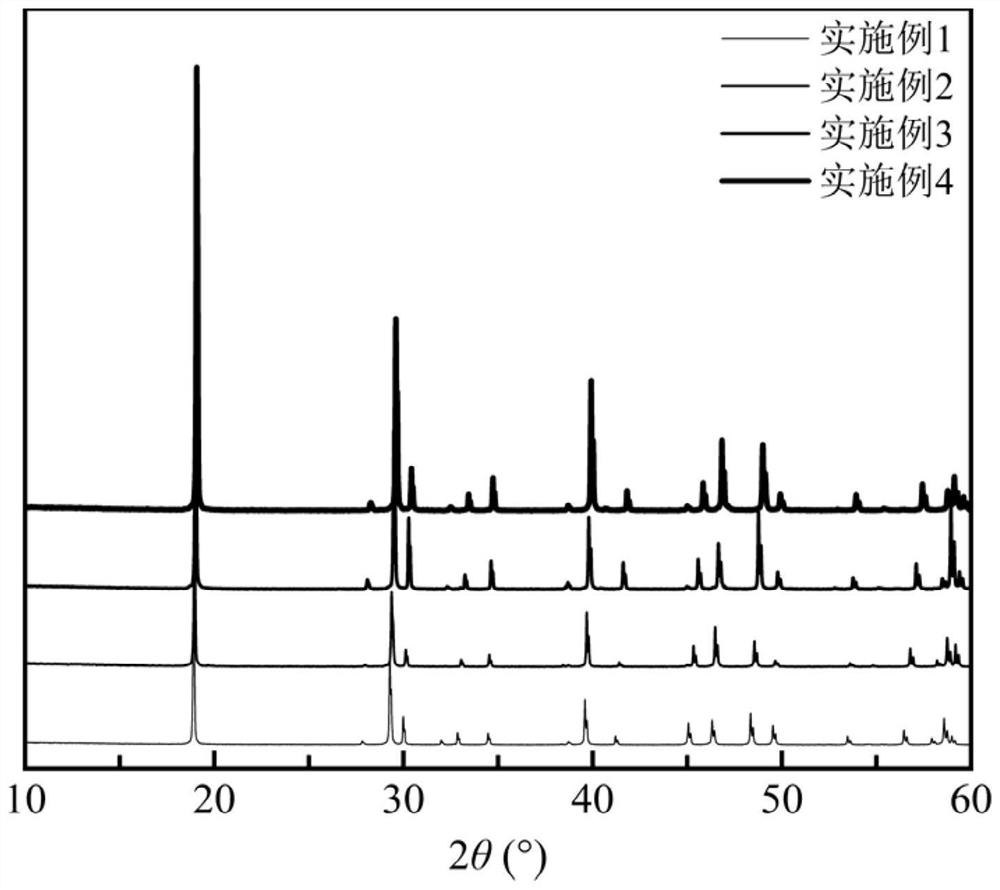

Embodiment 1

[0031] This embodiment provides a LiTbF 4 The preparation of the extremely low temperature magnetic refrigeration material comprises the following steps:

[0032] (1) According to lithium fluoride (LiF) and terbium fluoride (TbF) 3 ) The ratio of the amount of substances is 1.8:1 Weighing LiF powder 0.4669g and TbF 3 Powder 2.1592g, fully ground to make it evenly mixed;

[0033] (2) Filling the graphite crucible with the mixed powder obtained in step (1), sealing with a lid, placing it in a heat treatment furnace, and treating it at 800° C. for 2 hours to obtain the chemical formula of LiTbF 4 Extremely low temperature magnetic refrigeration material.

Embodiment 2

[0035] This embodiment provides a LiDyF 4 The preparation of the extremely low temperature magnetic refrigeration material comprises the following steps:

[0036] (1) According to lithium fluoride (LiF) and dysprosium fluoride (DyF) 3 ) The ratio of the amount of substances is 1.5:1 Weighing LiF powder 0.3891g and DyF 3 Powder 2.1950g, fully ground to make it evenly mixed;

[0037] (2) Filling the graphite crucible with the mixed powder obtained in step (1), sealing with a lid, placing it in a heat treatment furnace, and treating it at 1200° C. for 10 min to obtain a chemical formula of LiDyF 4 Extremely low temperature magnetic refrigeration material.

Embodiment 3

[0039] This embodiment provides a LiHoF 4 The preparation of the extremely low temperature magnetic refrigeration material comprises the following steps:

[0040] (1) According to lithium fluoride (LiF) and holmium fluoride (HoF) 3 ) The ratio of the amount of substances is 1.3:1 Weighing LiF powder 0.3372g and HoF 3 Powder 2.2193g, fully ground to make it evenly mixed;

[0041] (2) Filling the graphite crucible with the mixed powder obtained in step (1), sealing with a lid, placing it in a heat treatment furnace, and treating it at 1000° C. for 1 h to obtain the chemical formula of LiHoF 4 Extremely low temperature magnetic refrigeration material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum magnetic entropy change | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com