Patents

Literature

52 results about "Propionic acid ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethylcyclohexenylcyclopropyl ketones perfume composition

InactiveUS6051548ANeed can be quite largeCosmetic preparationsOrganic compound preparationPropionateAcetic acid

Described are trimethylcyclohexenylcyclopropyl ketones having the structure: wherein one of the dashed lines is a carbon-carbon double bond and the other of the dashed lines is a carbon-carbon single bond, uses thereof in augmenting, enhancing or imparting aromas in or to perfume compositions, colognes and perfumed articles, and mixtures of same with 3-methyl-1-phenylpentanol-5 and / or butanoylcyclohexane derivatives and / or acetic or propionic acid esters of o-methylphenyl isopropanol.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

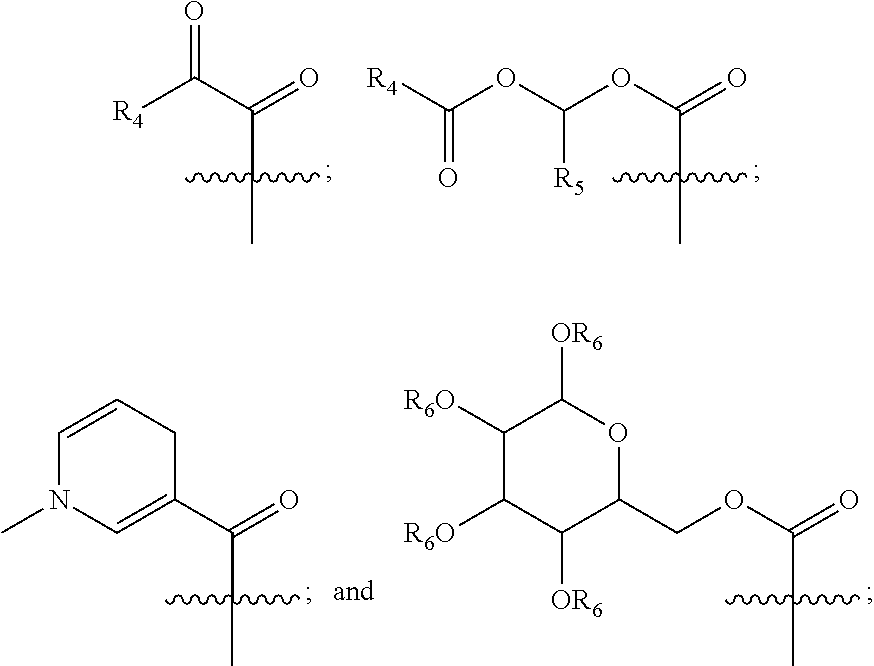

Arctigenin pro-drug, preparation method and use thereof

InactiveCN101284823AImprove oral bioavailabilityGood water solubilityOrganic active ingredientsOrganic chemistryGlutaric acidPhosphate

The invention relates to the following general formula compound (I) and use of the general formula compound in preparing anti-inflammatory and anti-endotoxin medicines. In formula I, R is an acid solubilizing side chain of hydroxide radical in an arctigenin molecule, and can be an acid group or side chain imported through alkylation reaction or acylating reaction, such as sulphonic acid ester, sulfuric acid ester, organic phosphate, succinate, propionic ether, butyric ester, semi-succinate, semi-glutaric acid ester, semi-tartrate, semi-phthalic acid ester, m-benzene sulfonic acid ester and so on.

Owner:YANTAI TARGET DRUG RES

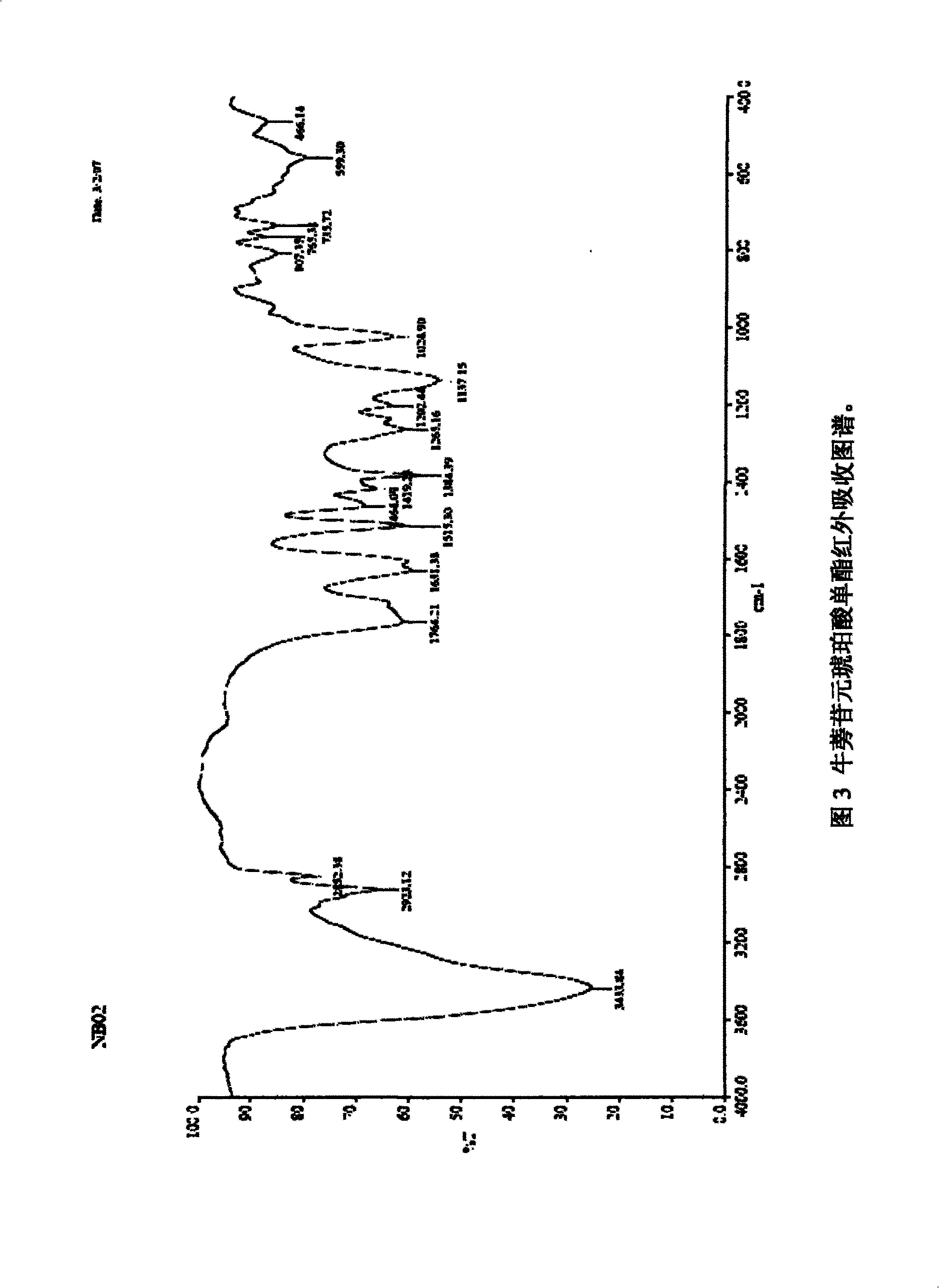

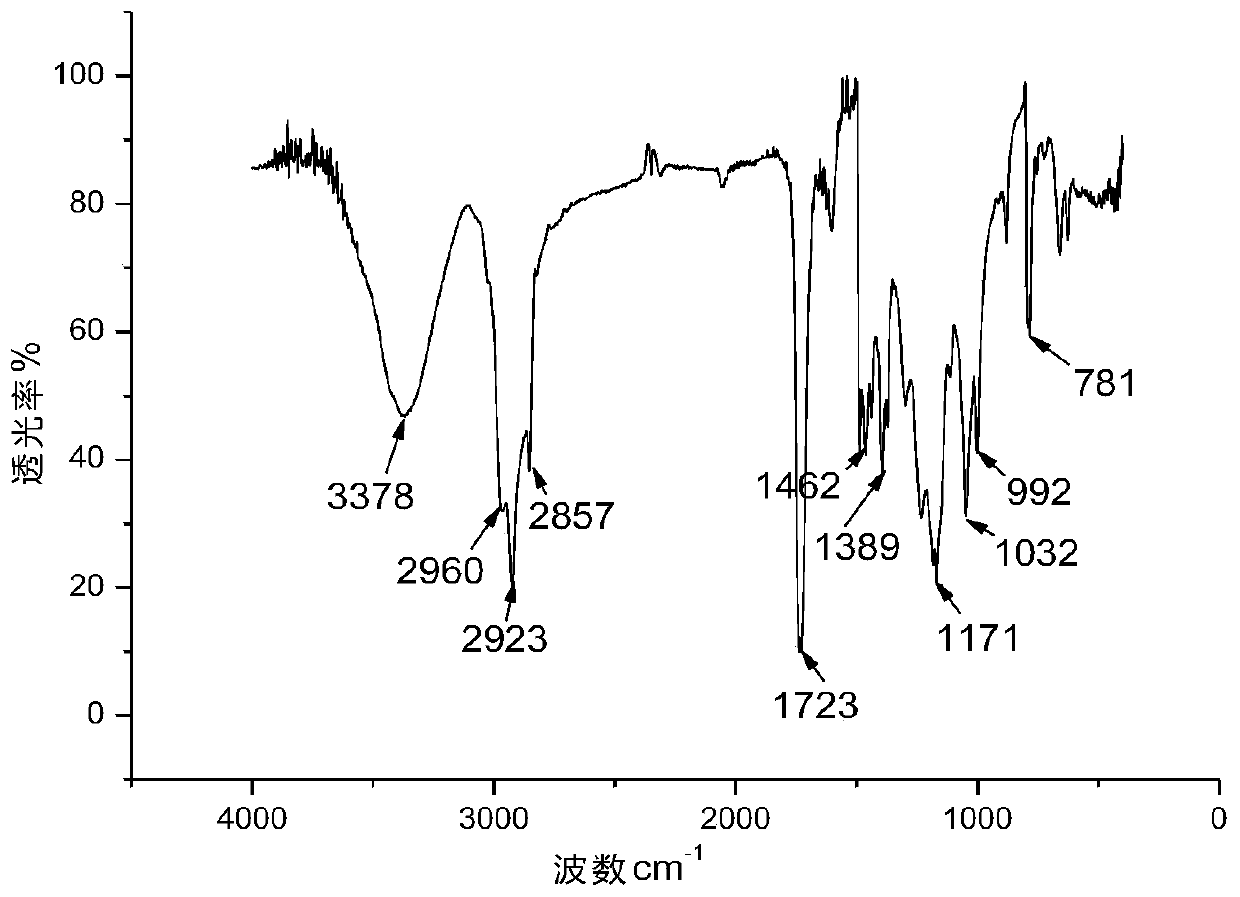

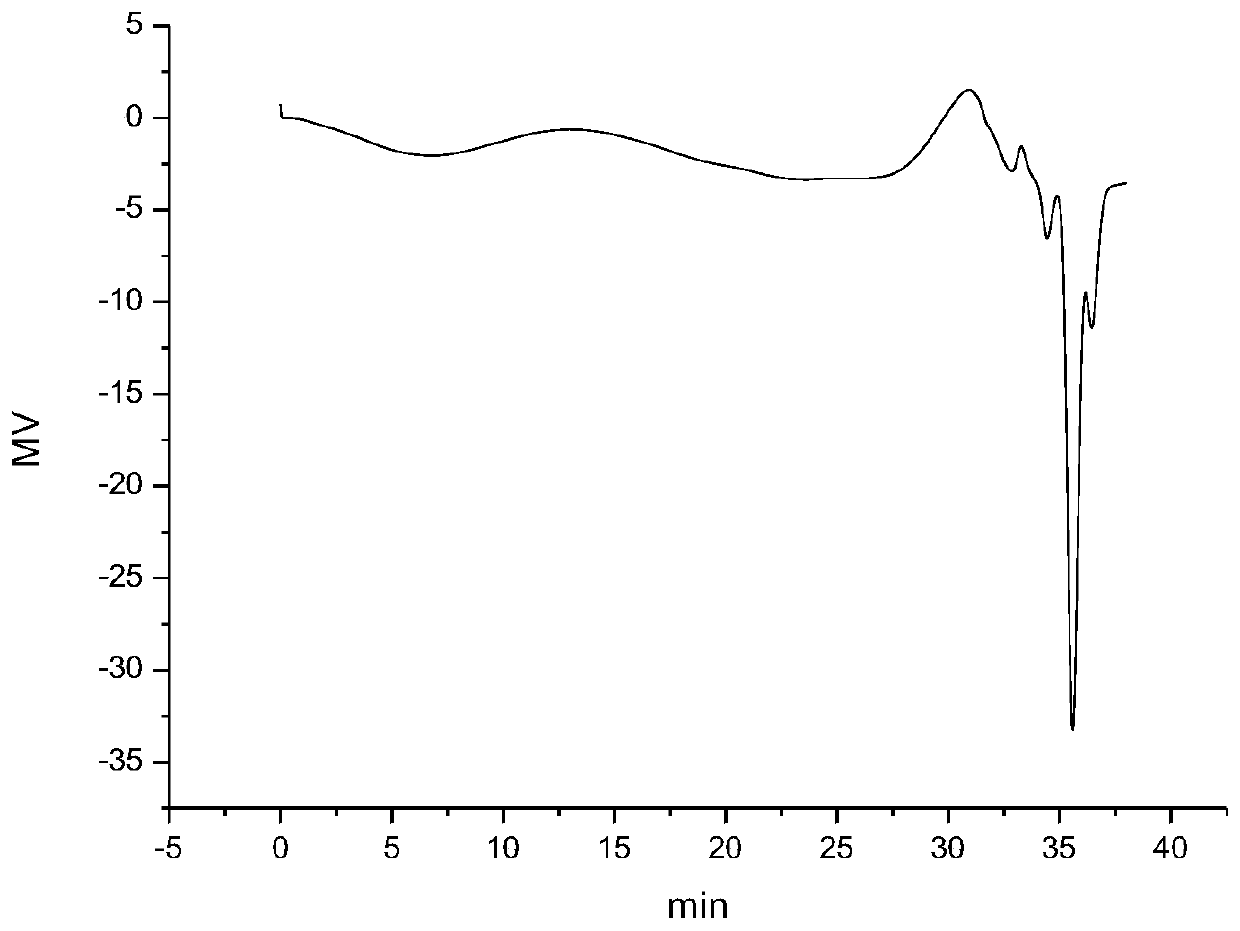

Water-based hyperbranched polyester resin as well as preparation method and application thereof

ActiveCN110183678AGood water dispersibilityImprove hydrolysis resistanceCoatingsSolubilityWater based

The invention relates to the technical field of synthetic polyester resin and particularly discloses water-based hyperbranched polyester resin as well as a preparation method and an application thereof. The preparation method comprises the steps as follows: dihydroxyl methyl propionic acid, an esterification catalyst and partial polyol are added to a container, heated to 140-150 DEG C and kept atthe constant temperature for 3-3.5 h to obtain first-generation hyperbranched hydroxyl polyester resin; when the reaction degree reaches 90% or above, polyol and organic sulfonate are added, the mixture is heated to 180-200 DEG C and reacts until the solution in the container is transparent; then, unary fatty acid and binary acid are added, the mixture is heated to 200-220 DEG C, when the acid value is decreased to 15 mgKOH / g, heating is stopped, cooling is performed, and alcohol ether cosolvents are added for dilution to obtain the water-based hyperbranched polyester resin. The polyester resin has good water solubility and high soil content, paint prepared from the polyester resin has low construction viscosity and good construction fluidity and forms thick films once, and the films are compact and have good physical and mechanical performance and chemical resistance.

Owner:CHANGSHA UNIVERSITY

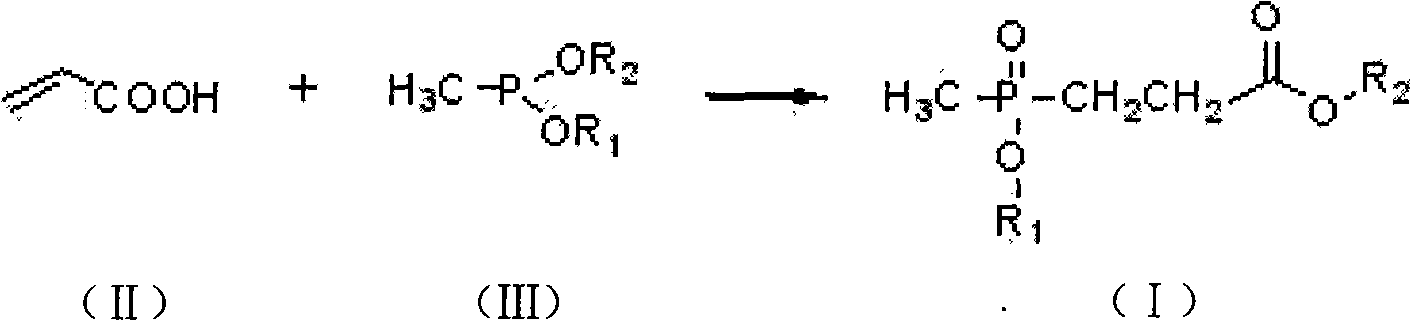

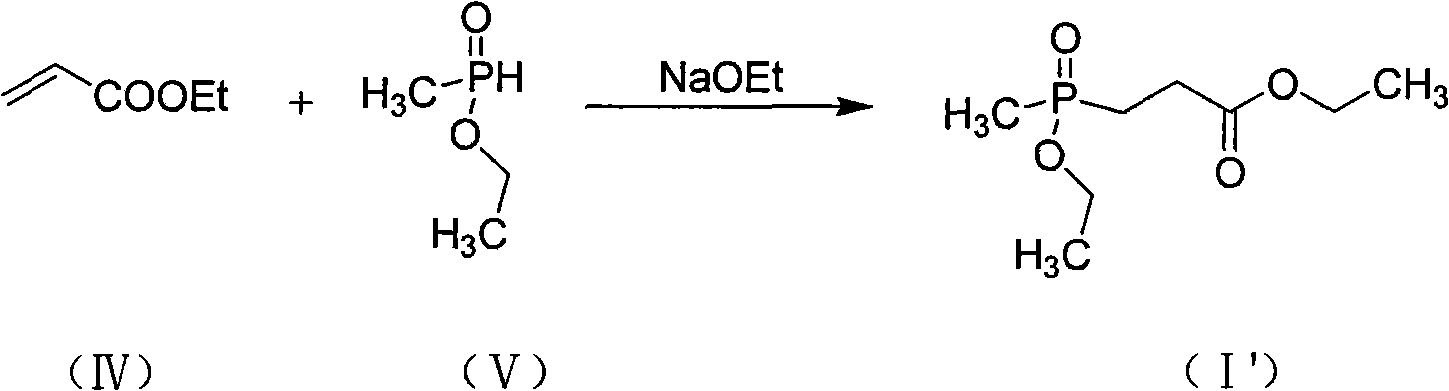

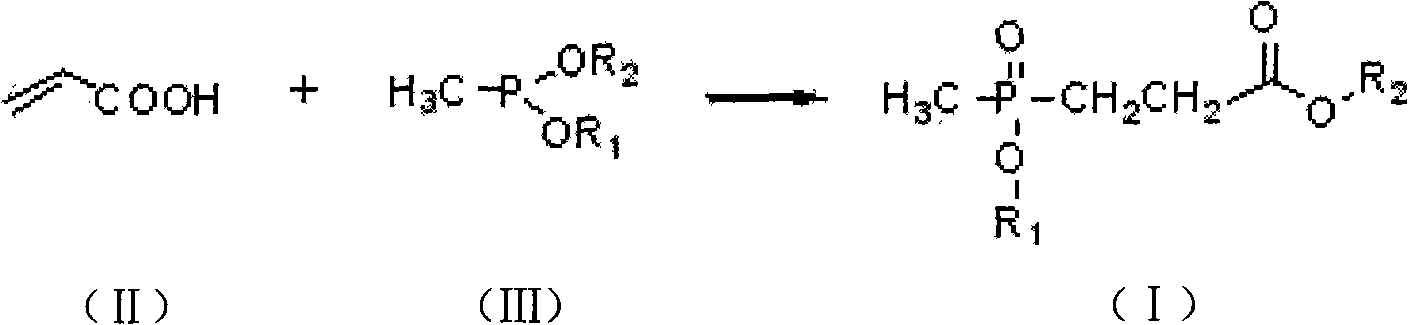

Preparation method of 3-(methyl alkoxy phosphoryl) propionic acid ester compound

InactiveCN101665514ASolve the above problems in productionEasy to operateGroup 5/15 element organic compoundsPropanoic acidPhosphoric acid

The invention provides a preparation method of 3-(methyl alkoxy phosphoryl) propionic acid ester compound (I). Methyl ferro phosphoric acid dialkyl ester (III) and acrylic acid (II) are taken as raw materials to react under anhydrous and anaerobic conditions at 0 DEG C to 30 DEG C; and the reaction process is shown as the formula, wherein, R1 in the formula is equal to R2 and is methyl or ethyl. The product yield of the method can reach 96% and the operation is simple with no generation of three wastes, thus being beneficial to industrial amplifying production.

Owner:LIER CHEM CO LTD

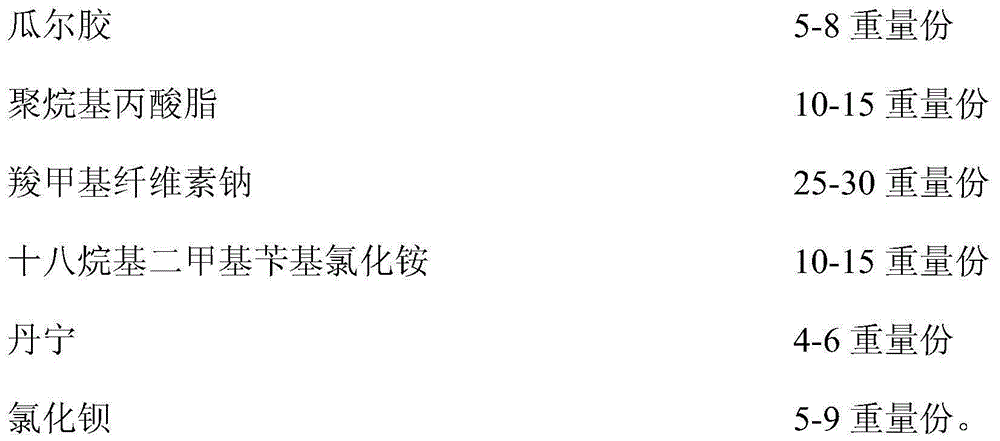

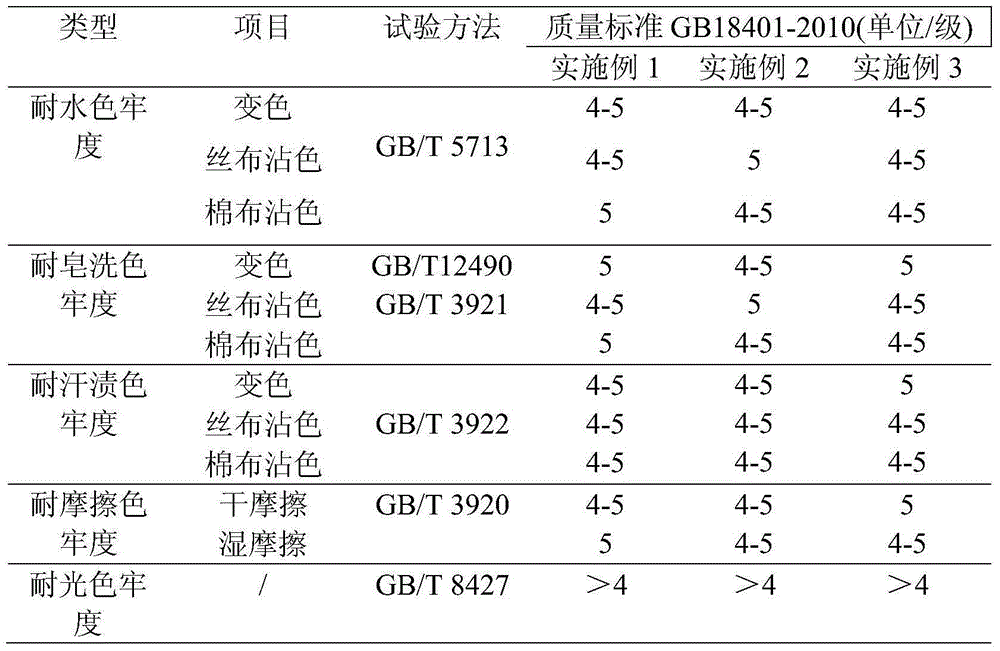

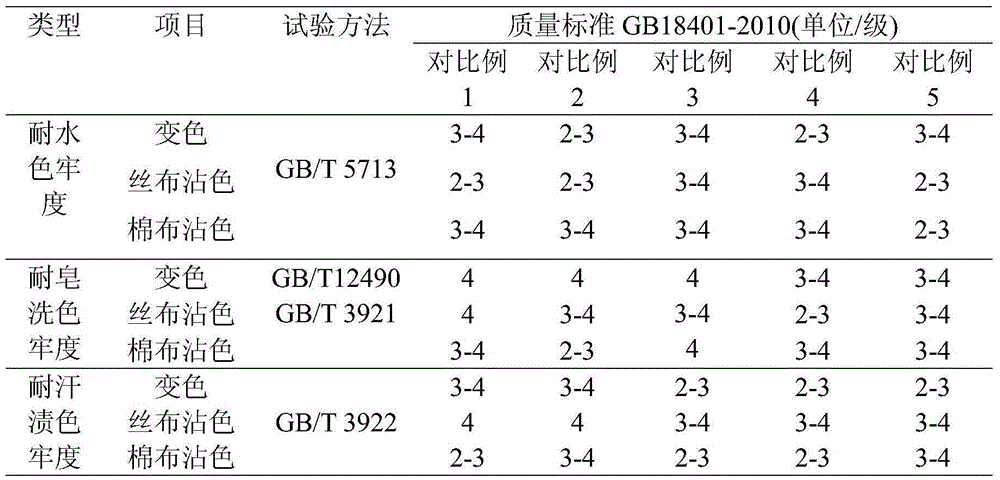

Denim printing and dyeing method

The invention provides a denim printing and dyeing method. The denim printing and dyeing method comprises the following steps that printing and dyeing paste is prepared, and a printing and dyeing auxiliary is added in preparation; ultrasonic pretreatment is performed on the printing and dyeing paste, and a grey cloth is dyed; the dyed grey cloth is aged at the temperature of 100 DEG C-105 DEG C for 10 minutes; the cloth is soaked in a sodium bicarbonate solution for 3-5 hours; aftertreatment is performed, and dyeing is completed. The printing and dyeing auxiliary is prepared from, by weight, 5-8 parts of guar gum, 10-15 parts of poly-alkyl propionic acid esters, 25-30 parts of sodium carboxymethylcellulose, 10-15 parts of octadecyl dimethyl benzyl ammonium chloride, 4-6 parts of tannin and 5-9 parts of barium chloride. According to the method, by adding the auxiliary, denim can be printed and dyed at the low ageing temperature of 100 DEG C to 105 DEG C on the condition of 3-5 hours of short-time sodium bicarbonate solution soaking, the color fastness of the denim can be promoted to 4-5 level, and discoloring in washing is reduced.

Owner:朱忠良

Quick-dry type high-damping oil damper paint and preparation method thereof

ActiveCN101041759AFast dryingExtended drying timePolyurea/polyurethane coatingsPolyester coatingsInorganic saltsPropanoic acid

The invention discloses a quick-drying type highly damped oiliness damper paint, which comprises the following steps: allocating oiliness solution with one or several poly-propionic ester resin, polyurethane resin and alcohol acid resin; adopting the oiliness solution as host; setting chip layer structure as layered metasilicate and so on inorganic salt; making calcium carbonate material with light calcium carbonate and heavy calcium carbonate with miscellaneous number; using the structure and the calcium carbonate material as filler; setting aids with combustion inhibitor, disperser, defoamer and thickener; allocating with 0-7 wt combustion inhibition, 0-2 wt disperser, 0-3 deformer and 0-3 thickener as aids; adding into the aids; setting mass ratio of host and filler and aids at 100 : 40-120 : 1-10 wt; stirring; getting the paint.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

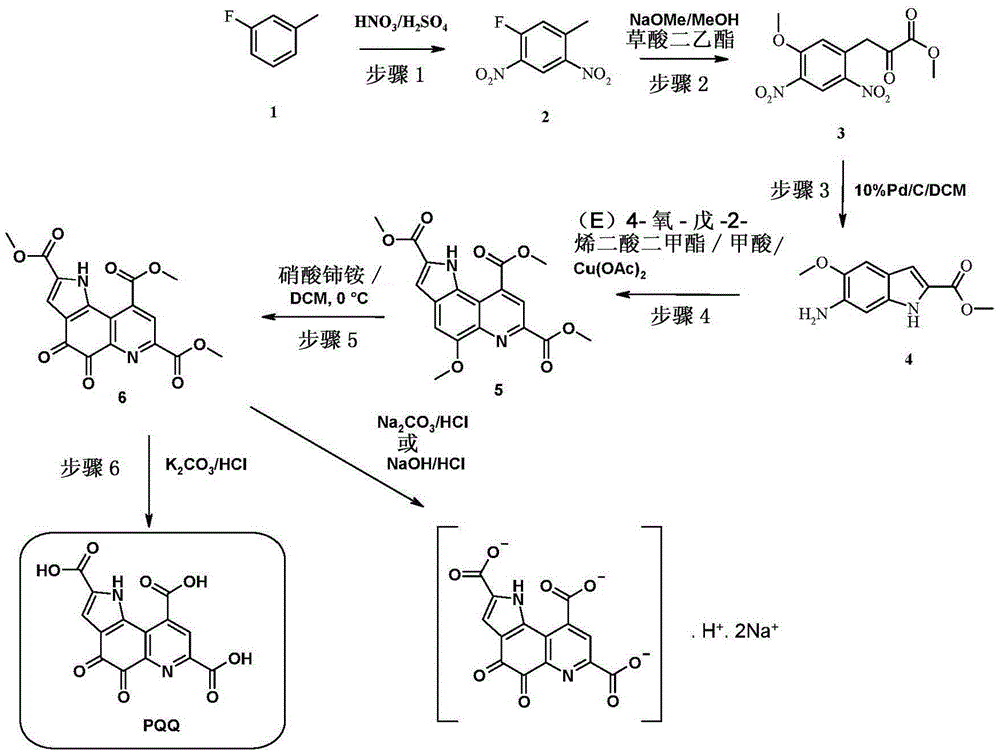

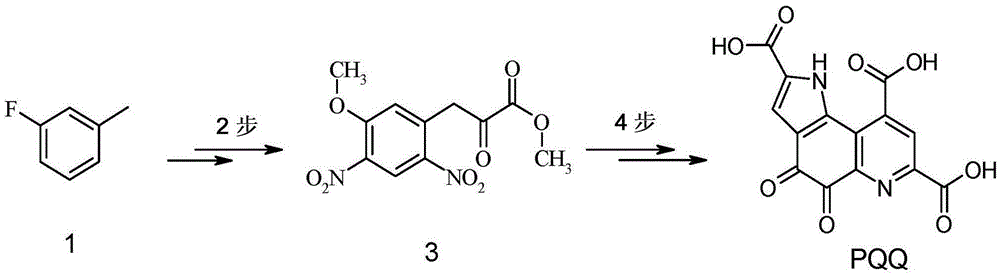

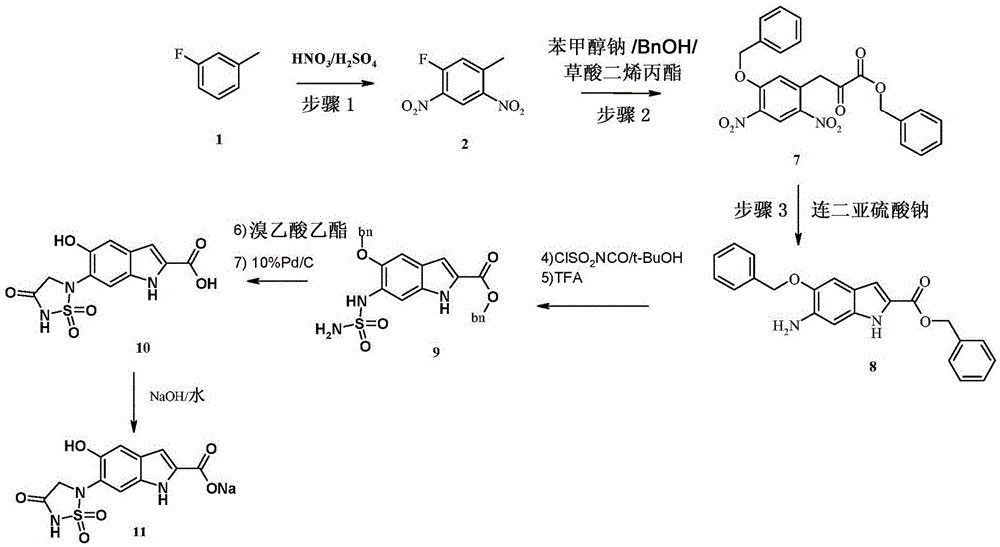

Compounds of '3-(5-sustituted oxy-2,4-dinitro-phenyl)-2-oxo-propionic acid ester', process and applications thereof

The present disclosure relates to compounds of Formula (I) and process of obtaining the same. Said compounds of Formula (I) is employed in the syntheses of pyrroloquinoline quinone (PQQ), 4,5-dioxo-4,5-dihydro-1H-pyrrolo[2,3-f]quinoline-2,7,9-tricarboxylic acid 2-allyl ester, 5-ethoxy-5-hydroxy-4-oxo-4,5-dihydro-1H-pyrrolo[2,3-f]quinoline-2,7,9-tricarboxylic acid, 5-hydroxy-6-(1,1,4-trioxo-1 lambda*6*-1,2,5-thiadiazolidin-2-yl)-1H-indole-2-carboxylic acid and its pharmaceutically acceptable salts. Said syntheses of compounds via compounds of Formula (I) as intermediates employ minimum number of steps resulting in a shorter process and has improved efficiency along with many other advantages.

Owner:ANTHEM BIOSCI PVT

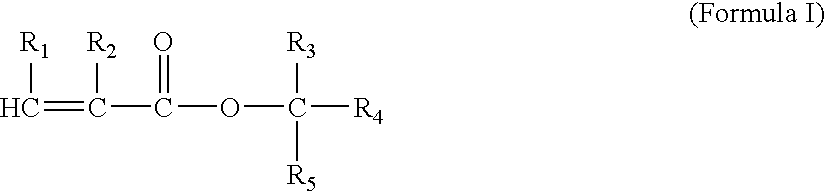

Method of preparing propionic acid-terminated polymers

ActiveUS20050171291A1Avoid adjustmentOrganic compound preparationCarboxylic acid esters preparationPropanoic acidStrong acids

The invention provides methods for preparing polymers bearing a terminal propionic acid. The method involves first reacting a water soluble and non-peptidic polymer comprising at least one hydroxyl group with a tertiary alkyl acrylate in the presence of a catalyst to form a propionic acid ester of the polymer, wherein the polymer has a weight average molecular weight of at least about 10,000 Da; and then treating the propionic acid ester of the polymer with a strong acid to form a propionic acid of the polymer.

Owner:NEKTAR THERAPEUTICS INC

Preparation method of nano coating

ActiveCN101597448AReduce pollutionKeep it clean for a long timeAntifouling/underwater paintsPaints with biocidesPolymer scienceEmulsion

The invention provides a preparation method of a nano coating. In the method, nano-composite size is adopted and added with fillers and various auxiliary agents; the mixture is mixed and reacts in a reaction kettle, sheared, emulsified, milled and dispersed in a sand mill, concocted in a paint mixing kettle and filtered in a filter so as to prepare the nano coating. The method comprises the following steps: step 1: concocting nano calcium carbonate size; step 2: preparing nano-composite size; step 3: employing the reaction kettle for mixing and reaction; step 4: employing a high-speed shear emulsifying machine for shearing and emulsifying for 30min; step 5: transferring the size to the sand mill for milling and dispersion for 2-3 times, with 30-50min per times; step 6: transferring the size to the paint mixing kettle to be stirred, adding phenylethylene-propyl ethylene acid ester emulsion, a film forming auxiliary agent and a defoamer while stirring and finally adding propylene glycol and a bactericide; step 7: adjusting the pH value to 8-9; step 8: adding a thickener to ensure the viscosity to be 3000-4000 MPa.S; step 9: adopting a coating filter for filtering and preparing the finished product after filtering. The coating is bactericidal, nontoxic, tasteless and resistant to 300000 times of washing.

Owner:马秀荣

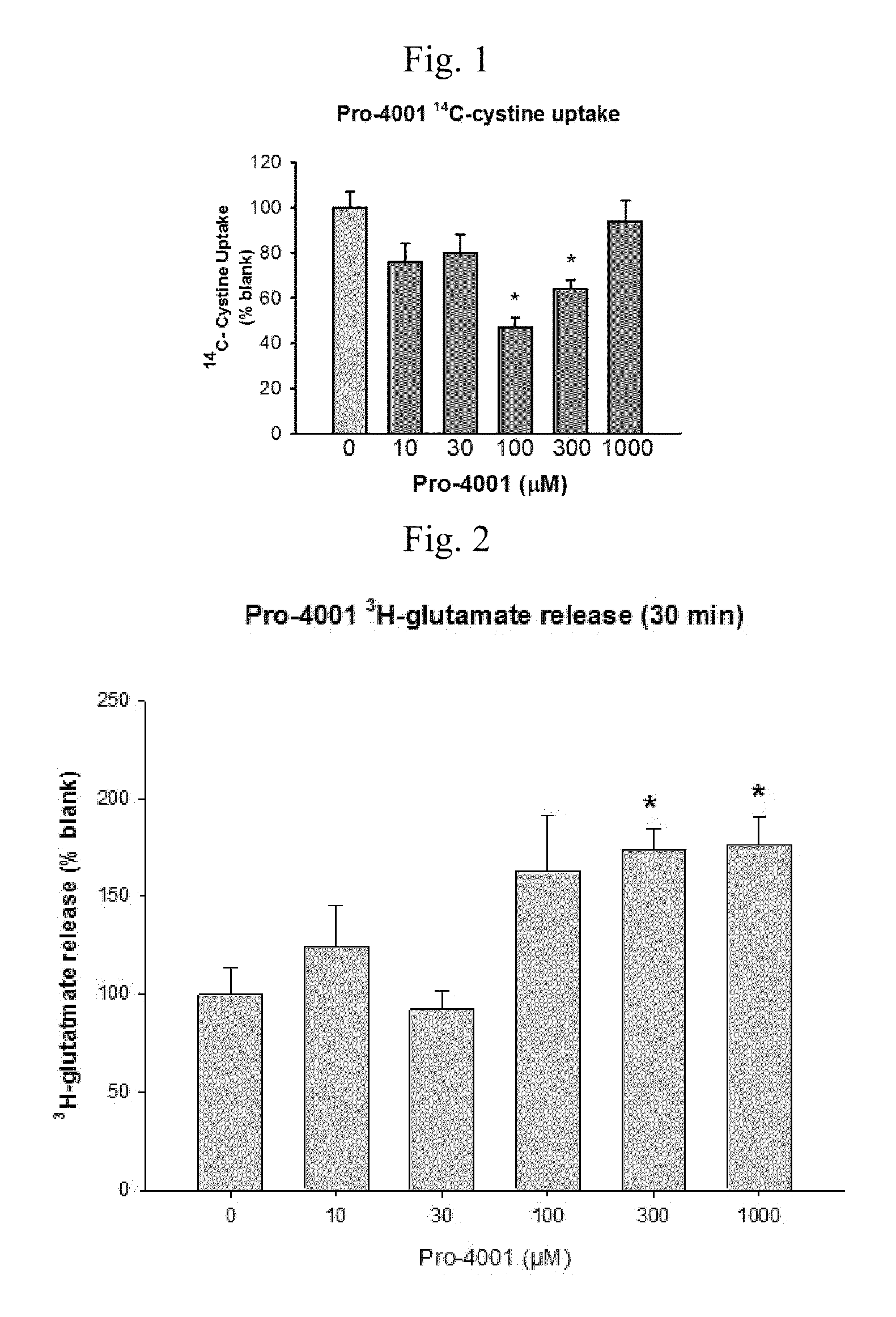

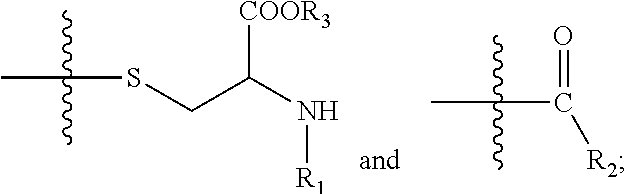

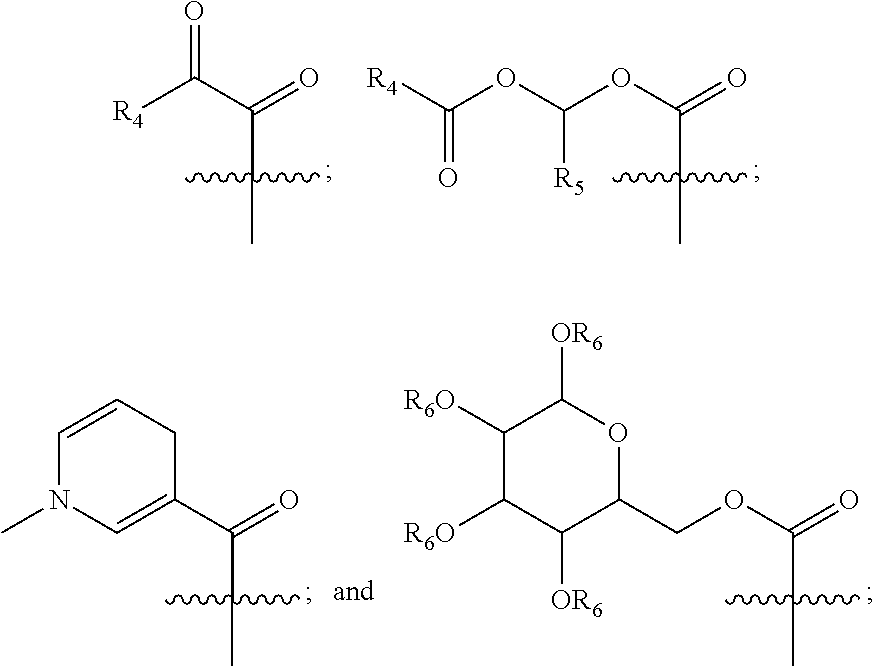

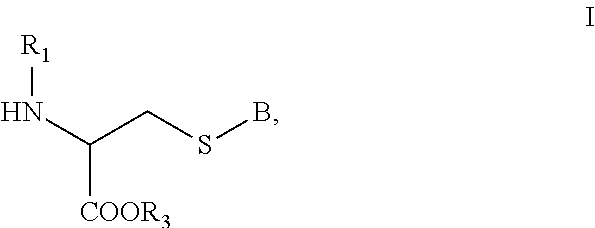

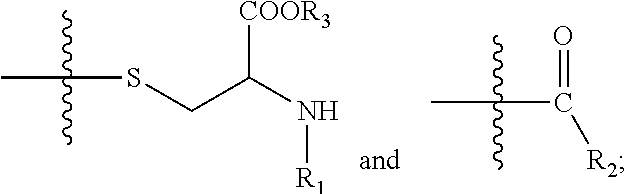

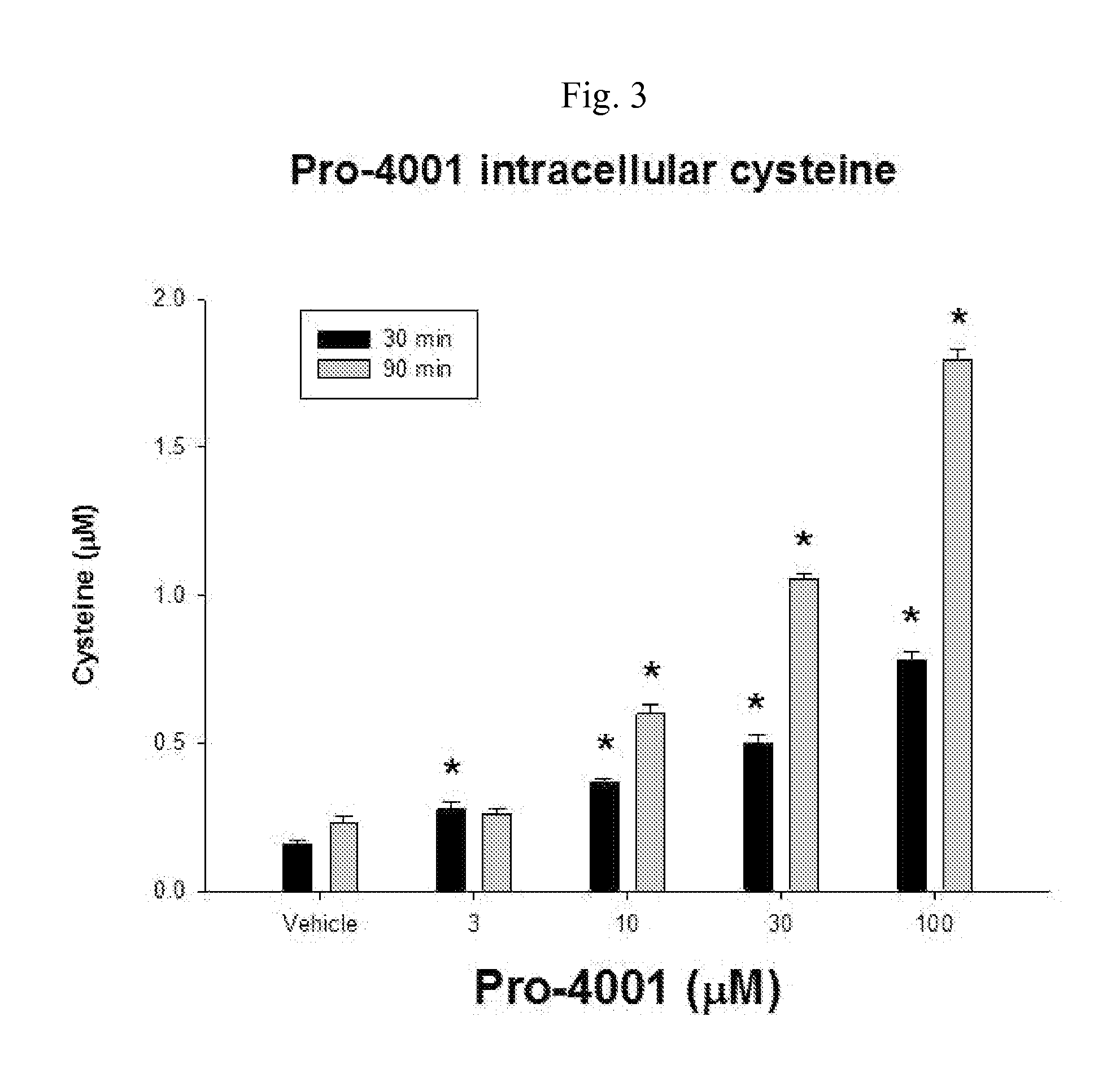

Propionic acids, propionic acid esters, and related compounds

The invention relates to propionic acids, propionic acid esters, and related compounds, pharmaceutical compositions containing these compounds, and methods of using these compounds for the treatment of various diseases or conditions, including but not limited to diseases and / or conditions of Central Nervous System (CNS).

Owner:PROMENTIS PHARMA

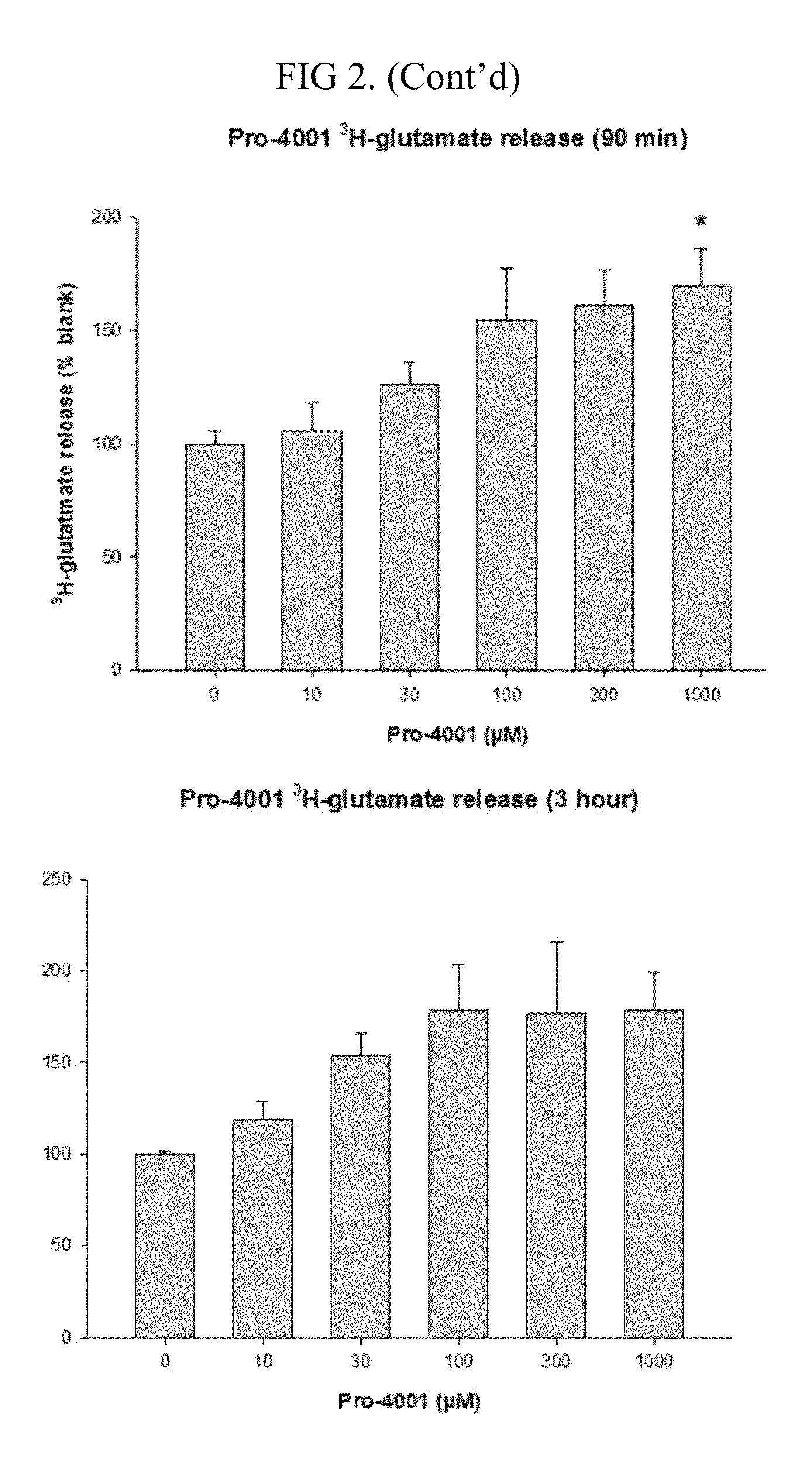

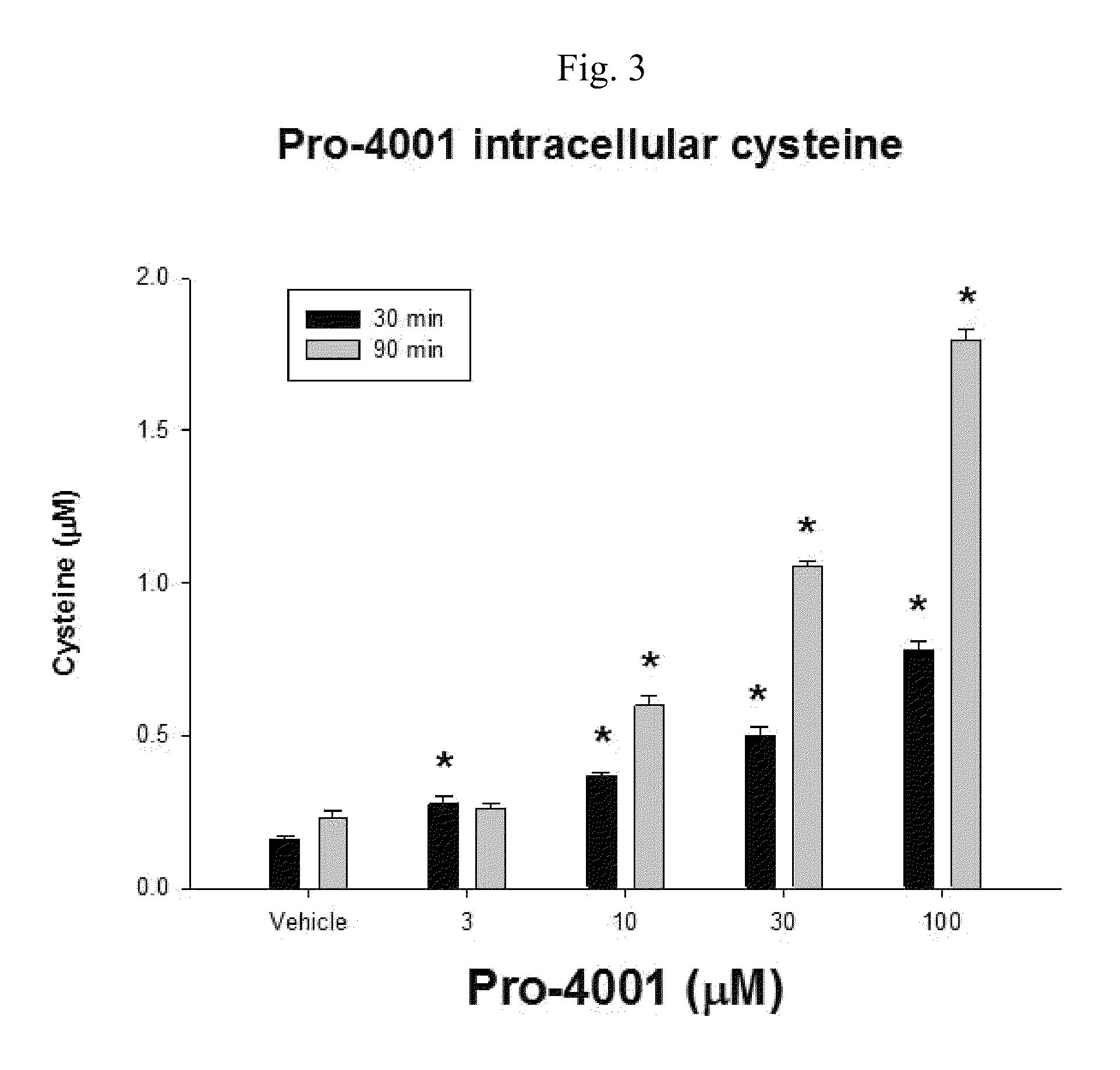

Propionic Acids, Propionic Acid Esters, and Related Compounds

The invention relates to propionic acids, propionic acid esters, and related compounds, pharmaceutical compositions containing these compounds, and methods of using these compounds for the treatment of various diseases or conditions, including but not limited to diseases and / or conditions of Central Nervous System (CNS).

Owner:PROMENTIS PHARMA

Method of Preparing Propionic Acid-Terminated Polymers

InactiveUS20100004428A1Avoid adjustmentPeptide/protein ingredientsOrganic compound preparationPropionatePropanoic acid

The invention provides methods for preparing polymers bearing a terminal propionic acid. The method involves first reacting a water soluble and non-peptidic polymer comprising at least one hydroxyl group with a tertiary alkyl acrylate in the presence of a catalyst to form a propionic acid ester of the polymer, wherein the polymer has a weight average molecular weight of at least about 10,000 Da; and then treating the propionic acid ester of the polymer with a strong acid to form a propionic acid of the polymer.

Owner:NEKTAR THERAPEUTICS INC

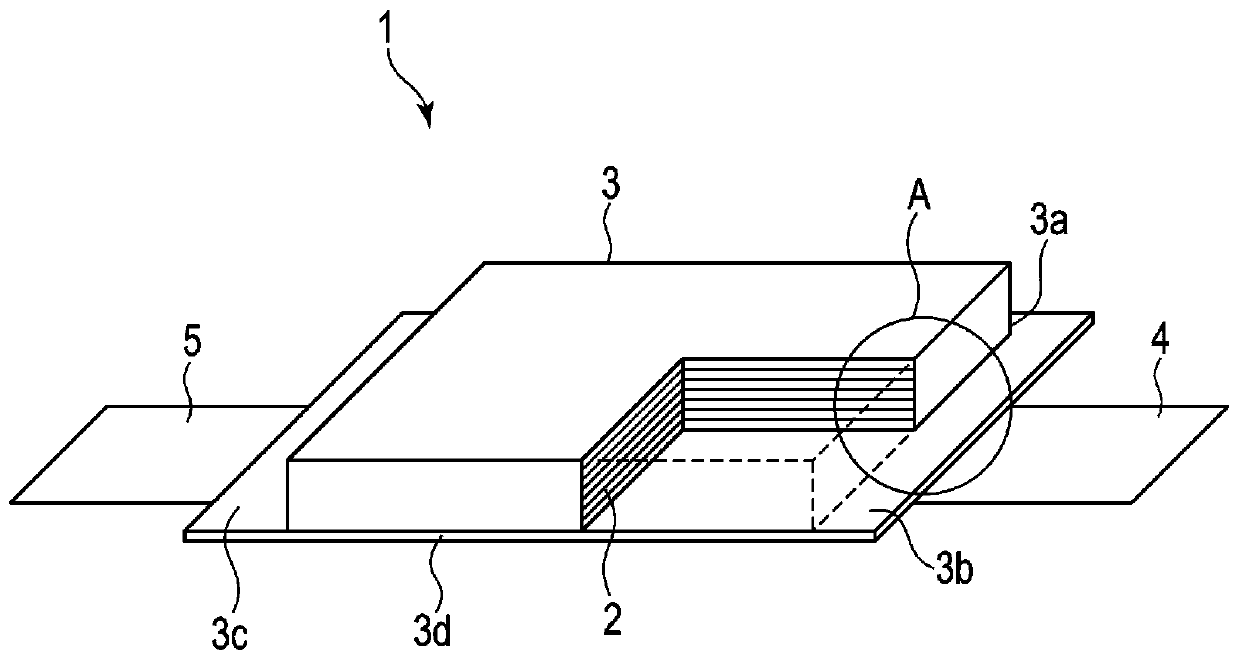

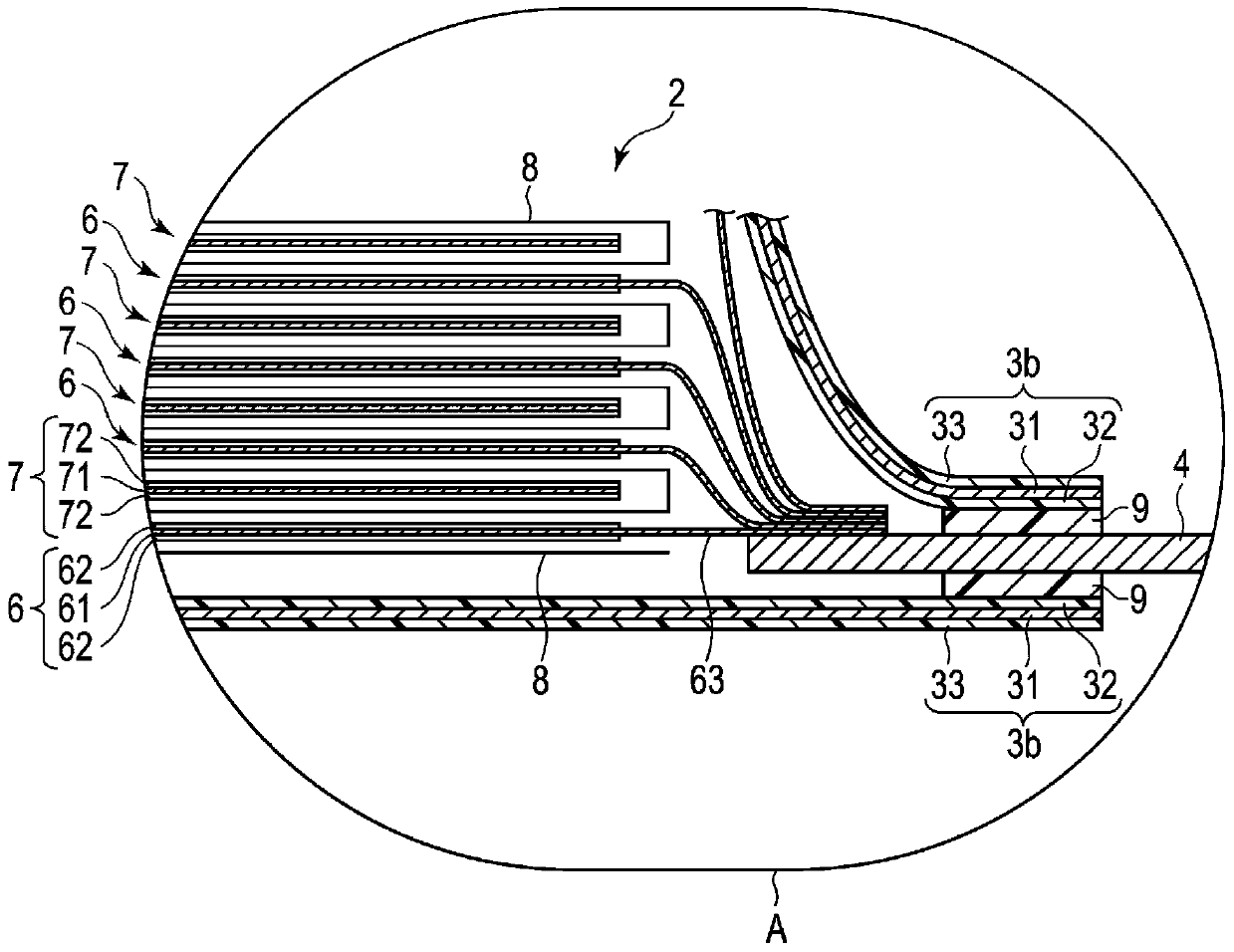

Nonaqueous electrolyte battery and battery pack

ActiveCN111164819ALower the resistance valueInhibitionNegative electrodesPositive electrodesPropanoic acidManganese

According to one embodiment, a nonaqueous electrolyte battery is provided and the nonaqueous electrolyte battery comprises a positive electrode, a negative electrode, and a nonaqueous electrolyte. Thepositive electrode includes a layer containing a positive electrode active substance, the layer containing the positive electrode active substance contains lithium-manganese compound oxide particleshaving a spinel-type crystal structure and the lithium-cobalt compound oxide particles, and the negative electrode contains a titanium-containing oxide. The nonaqueous electrolyte contains a propionicacid ester and satisfies the formulas 0.8 <= p / n < =1.2 and 1< =w / s <= 60, wherein p is the capacity per unit surface area [mAh / cm2] of the positive electrode; n is the capacity per unit surface area[mAh / cm2] of the negative electrode; w is the propionic acid ester content of the nonaqueous electrolyte and is within a range of 10 to 60 wt%; and s is the average particle diameter [Mu m] of the lithium-manganese compound oxide particles.

Owner:KK TOSHIBA

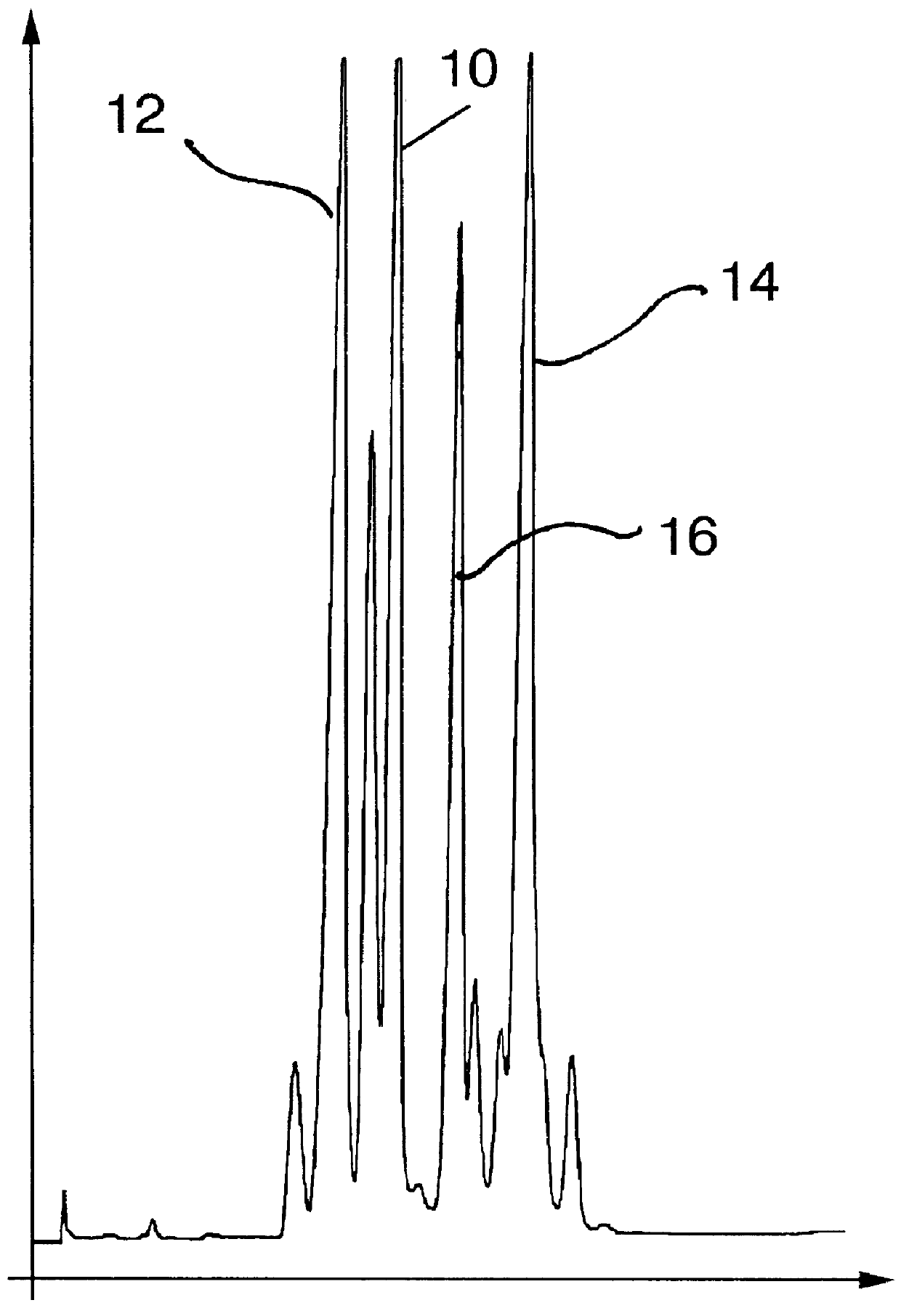

Trimethylcyclohexenylcyclopropyl ketones, process for producing same, and uses thereof in perfumery

InactiveUS6025527AIncrease aromaReduce the amount requiredOrganic compound preparationEssential-oils/perfumesPropionateAcetic acid

Described are trimethylcyclohexenylcyclopropyl ketones having the structure: wherein one of the dashed lines is a carbon-carbon double bond and the other of the dashed lines is a carbon-carbon single bond, uses thereof in augmenting, enhancing or imparting aromas in or to perfume compositions, colognes and perfumed articles, and mixtures of same with 3-methyl-1-phenylpentanol-5 and / or butanoylcyclohexane derivatives and / or acetic or propionic acid esters of o-methylphenyl isopropanol.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

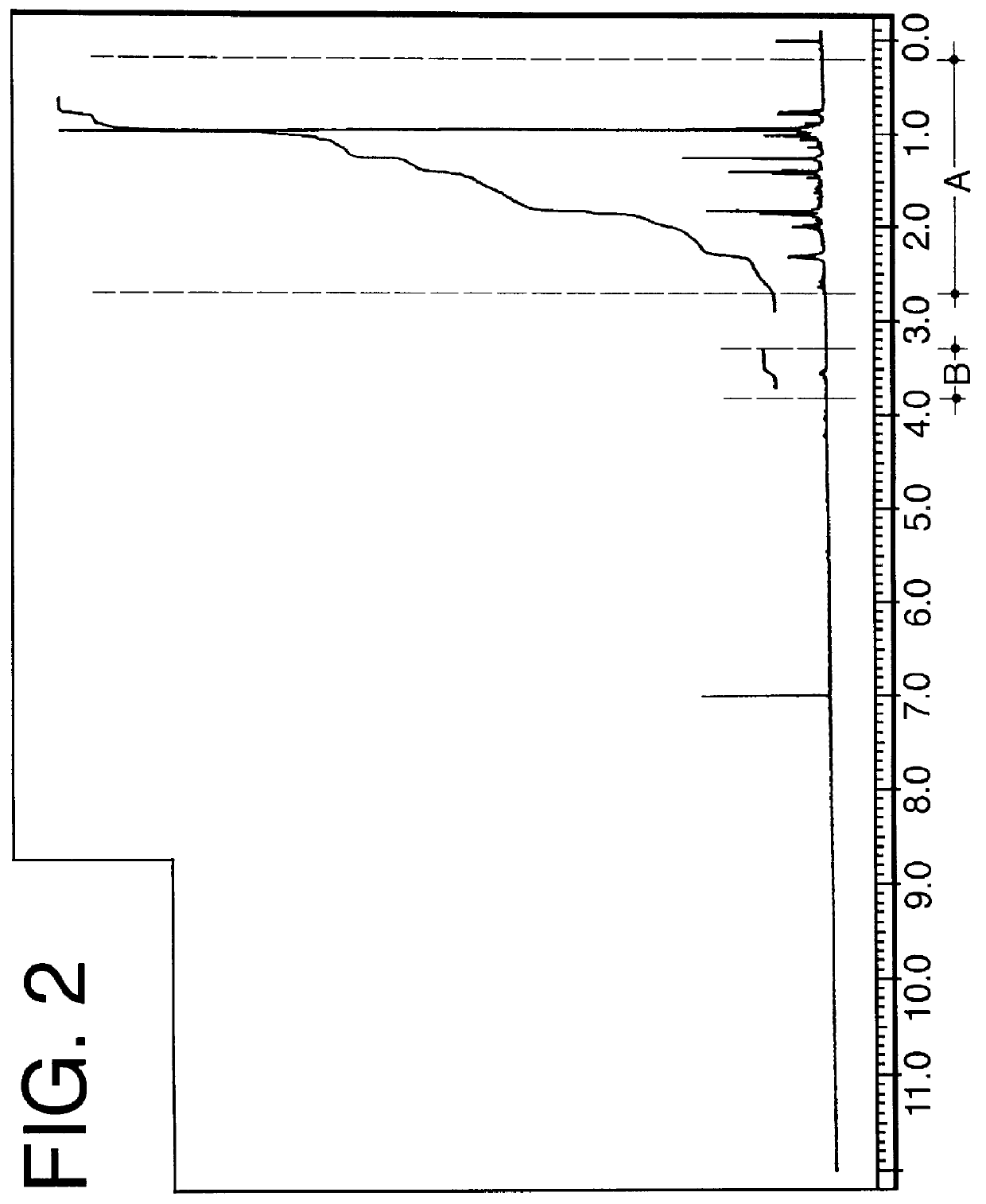

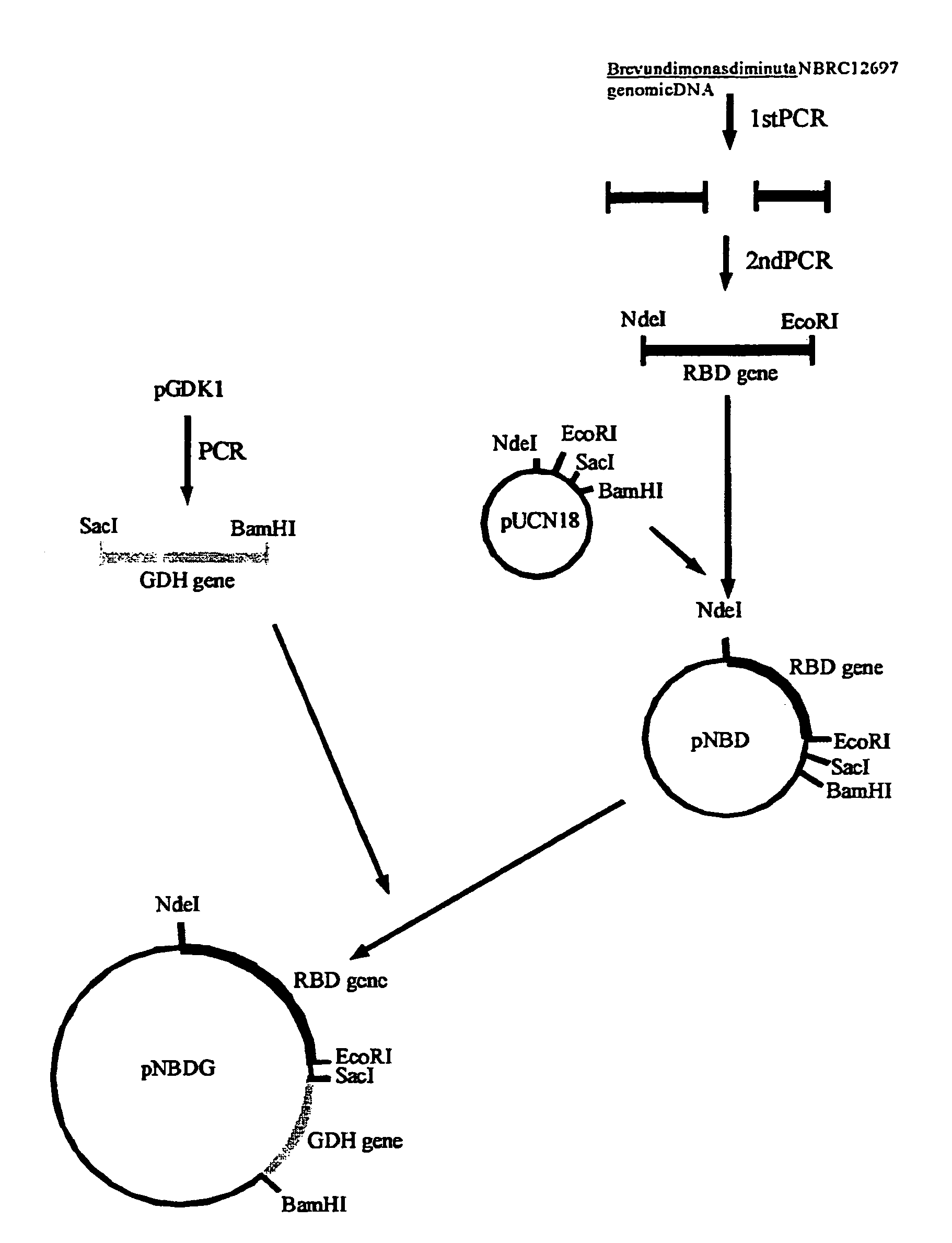

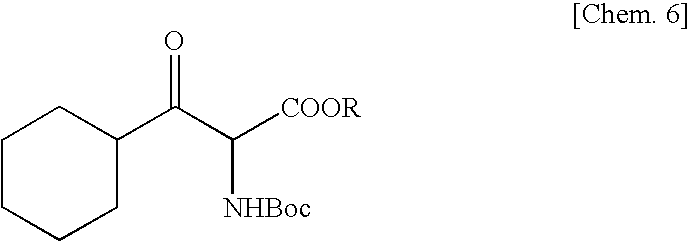

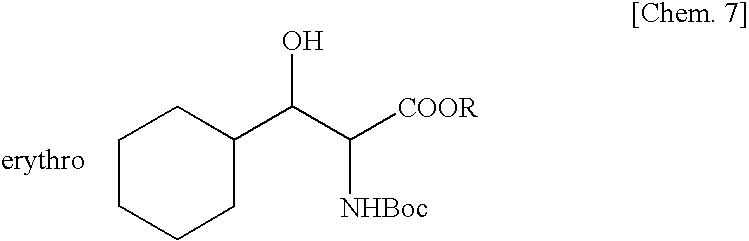

Method for production of erythro-or threo-2-amino-3-hydroxypropionic acid ester, novel carbonyl reductase, gene for the reductase, vector, transformant, and method for production of optically active alcohol using those

ActiveUS8304216B2Reduce usageEfficient executionSugar derivativesOxidoreductasesPropanoic acidCarbonyl Reductase

The present invention has its object to provide a method of producing an erythro- or threo-2-amino-3-hydroxypropionic acid ester, and so forth. The present invention relates to: a method of asymmetrically reducing an N-2-amino-3-oxopropionic acid ester by allowing cells of a microorganism to act thereon; a polypeptide having an activity of asymmetrically reducing a carbonyl compound to give an optically active alcohol, which is isolated from a microorganism belonging to genus Brevundimonas; a DNA coding for the polypeptide; and a transformant producing the polypeptide. The invention also relates to a method of producing an optically active alcohol by reducing a carbonyl compound with the help of the polypeptide or the transformant.

Owner:KANEKA CORP

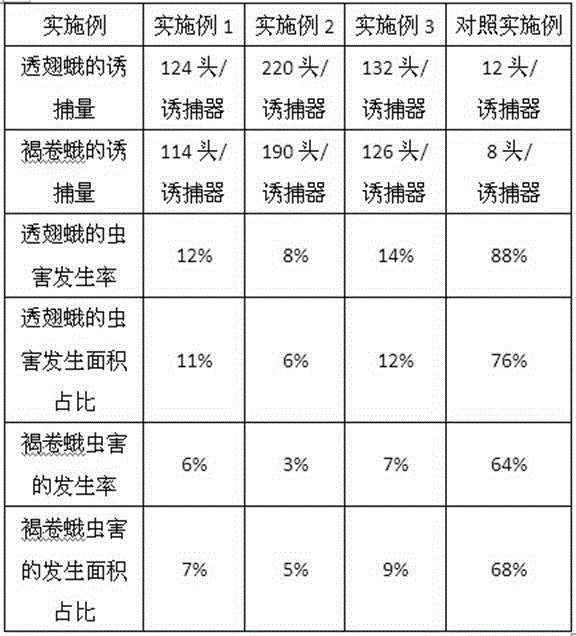

Injurious insect attractant and application thereof in cape gooseberry saline-alkali soil planting

InactiveCN104982433AGood booby effectReduce incidenceBiocidePest attractantsPropanoic acidAlkali soil

The invention provides injurious insect attractant. The attractant comprises, by mass, 12-15 parts of cetene, 10-13 parts of 9-enol, four to eight parts of carveol acetate, three to seven parts of 3-phenylacrolein, two to four parts of 1-acetyl oxide eugenol acetate, four to seven parts of anti-9, cis-11-16 carbon diene aldehyde, four to eight parts of cis-9, anti-12-14 carbon enol propionic acid ester, two to six parts of butylated hydroxytoluene, three to five parts of pyrogallol and four to eight parts of phenyl salicytate. The invention further provides the application of the attractant in cape gooseberry saline-alkali soil planting. The injurious insect attractant and the application have the advantages that within 30 days, the trapping number of clearwings is 124-220 per trap, and the trapping number of pandemis heparanas is 114-190 per trap.

Owner:WEIFANG YOURONG IND

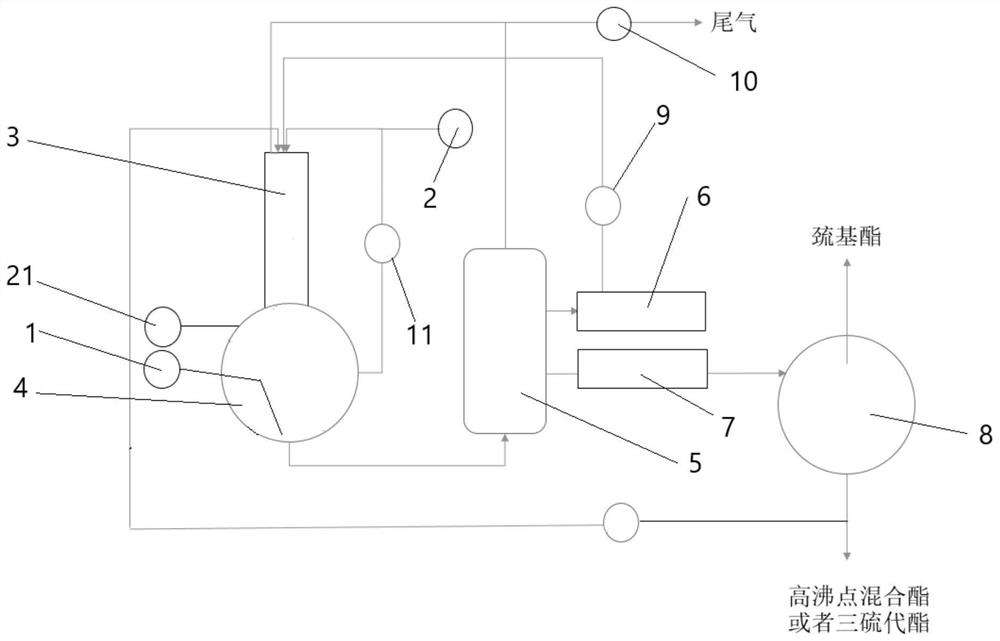

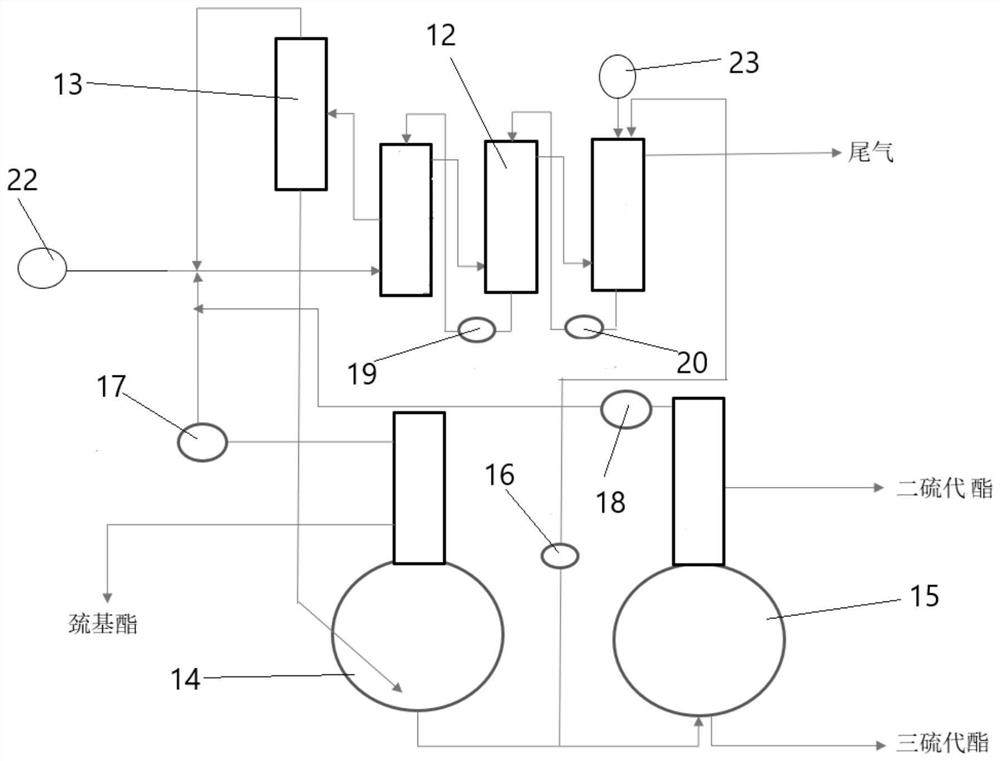

Continuous production method of 3-mercaptopropionic acid alkyl ester and 3, 3'-trithiodipropionic acid dialkyl ester

PendingCN113004177AReduce usageRealize value-added designOrganic compound preparationThiol preparationInorganic saltsPropanoic acid

The invention discloses a continuous production method of 3-mercaptopropionic acid alkyl ester and 3, 3'-trithiodipropionic acid dialkyl ester. The method comprises the following steps: reacting 3, 3'-dithiodipropionic acid dialkyl ester with hydrogen sulfide to generate 3-mercaptopropionic acid alkyl ester and 3, 3'-trithiodipropionic acid dialkyl ester; 3-alkyl mercaptopropionate is easy to separate and purify in a reduced pressure distillation mode; continuously reacting the residual 3, 3'-dithiodipropionic acid dialkyl ester with hydrogen sulfide, and continuously converting the residual 3, 3'-dithiodipropionic acid dialkyl ester into 3, 3'-trithiodipropionic acid dialkyl ester, and therefore, the continuous production process of 3-mercaptopropionate and 3, 3'-dialkyl trithiodipropionate is realized through continuous enhanced mass transfer feeding and reaction units of hydrogen sulfide raw materials and liquid raw materials, continuous phase separation units, distillation separation units and feedback control of process products to the reaction units. The synthesis method does not adopt an organic solvent, does not generate inorganic salt byproducts, has no strict requirements on the purity of raw materials, and is easy to industrialize.

Owner:靳浩田

Preparation method of high-performance acrylate-type resin

The invention relates to a preparation method of high-performance acrylate-type resin. The preparation method includes the steps of (1) adding water, sodium dodecyl benzene sulfonate, fatty alcohol-polyoxyethylene ether and 2-acrylamide-2-methylpropanesulfonic acid; (2) increasing the temperature and stirring the materials and adding a monomer A; (3) performing emulsification for 40 min, increasing the temperature to 70 DEG C and feeding backflow water; (4) increasing the temperature to 85 DEG C and adding a potassium persulfate solution; (5) performing a reaction for 2 h, adding fluticasone propionic ester, performing stirring reaction to obtain a core-layer emulsion; (6) adding dropwisely a monomer B and the potassium persulfate solution to the core-layer emulsion, and performing a stirring reaction after dropwise addition; (7) decreasing the temperature to 50 DEG C, adding the sodium dodecyl benzene sulfonate and the fatty alcohol-polyoxyethylene ether, and performing the reaction for 70 min; and (8) performing a reaction at 70 DEG C for 1 h and adding ammonia water to regulate the pH value to 7-8 to prepare the acrylate-type resin. The preparation method not only greatly improves wear resistance of the acrylate-type resin but also improves the defect of yellowing of a film formed by an emulsion of the acrylate-type resin.

Owner:珠海市卓和化工科技有限公司

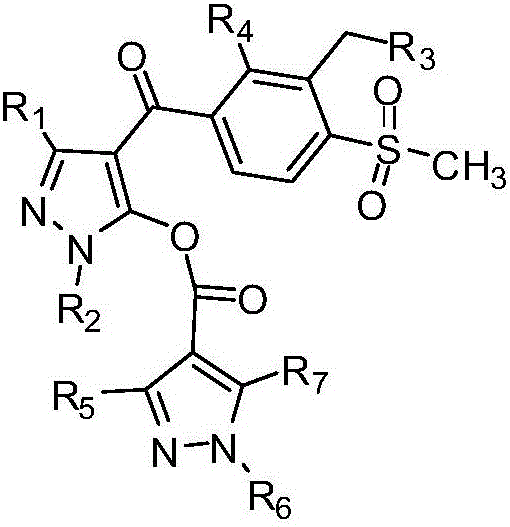

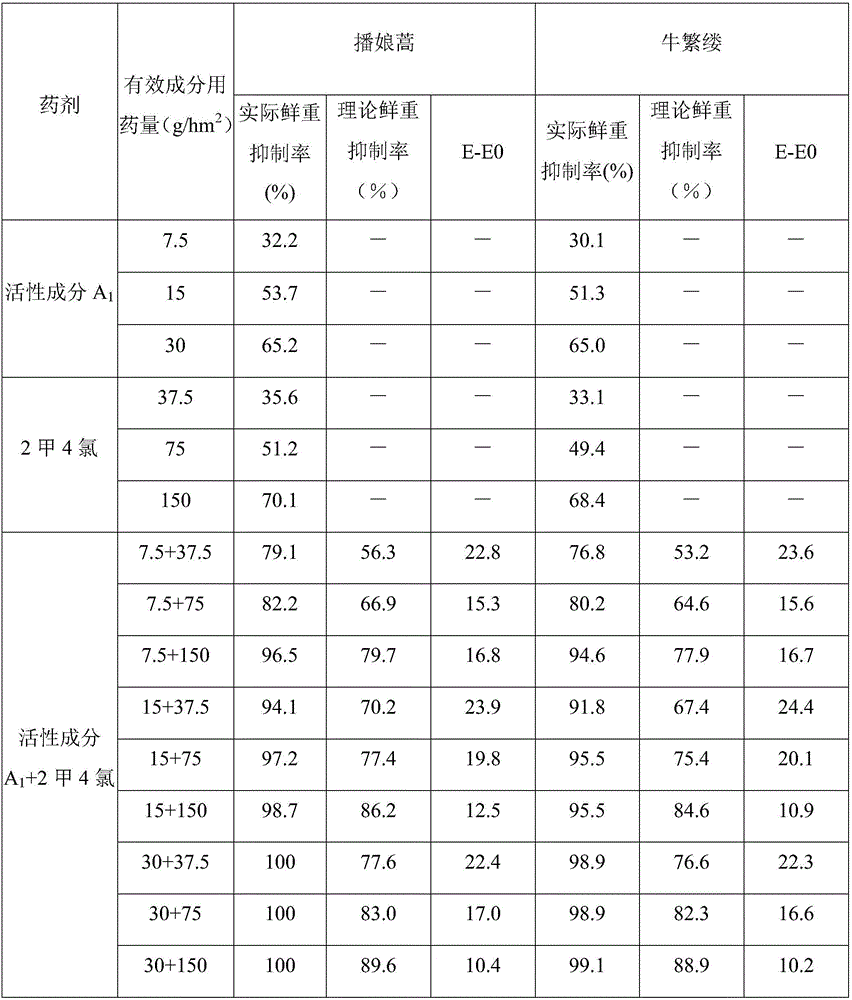

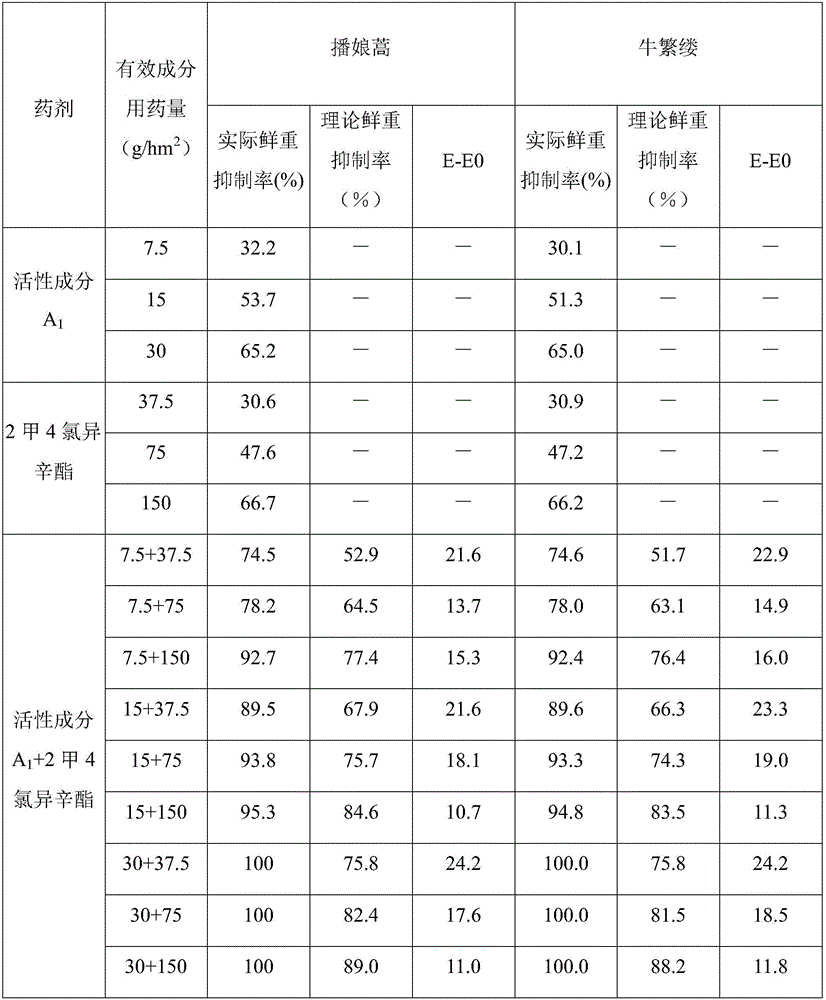

Wheat field weeding composite and application thereof

Owner:JIANGSU KINGAGROOT WEED MANAGEMENT CO LTD

Method for stereoselective resolution of 2-(4-methylphenyl)propionic acid enantiomer catalyzed by candida rugosa lipase

The invention discloses a novel chiral resolution method for obtaining a single enantiomer of 2-(4-methylphenyl)propionic acid, namely a method for synthesizing a single enantiomer of 2-(4-methylphenyl)propionic acid by enzymatically catalyzed stereoselective hydrolysis of 2-(4-methylphenyl)propionate enantiomers. Based on high selectivity and high catalytic efficiency of candida rugosa lipase, 2-(4-methylphenyl)propionate enantiomers are hydrolyzed to obtain (+)-2-(4- methylphenyl)propionic acid with high optical purity; based on the interaction of cyclodextrin to 2-(4-methylphenyl)propionateenantiomers, the conversion rate of 2-(4-methylphenyl)propionate is improved; the conversion rate of a substrate and the optical purity of the product can be as high as 40.76% and 96.24%, respectively, and the stereoselectivity E is as high as 145; the method overcomes the problems of low optical purity, low yield, environmental pollution and the like of general resolution technology, and can achieve high conversion rate and high selectivity of hydrolysis of 2-(4-methylphenyl)propionate enantiomers, so as to realize non-toxic, harmless and environmental-friendly resolution of chiral compoundsand mild reaction conditions; and the aims of simple equipment, easy operation, low cost and the like are achieved.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

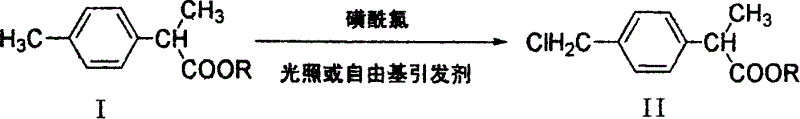

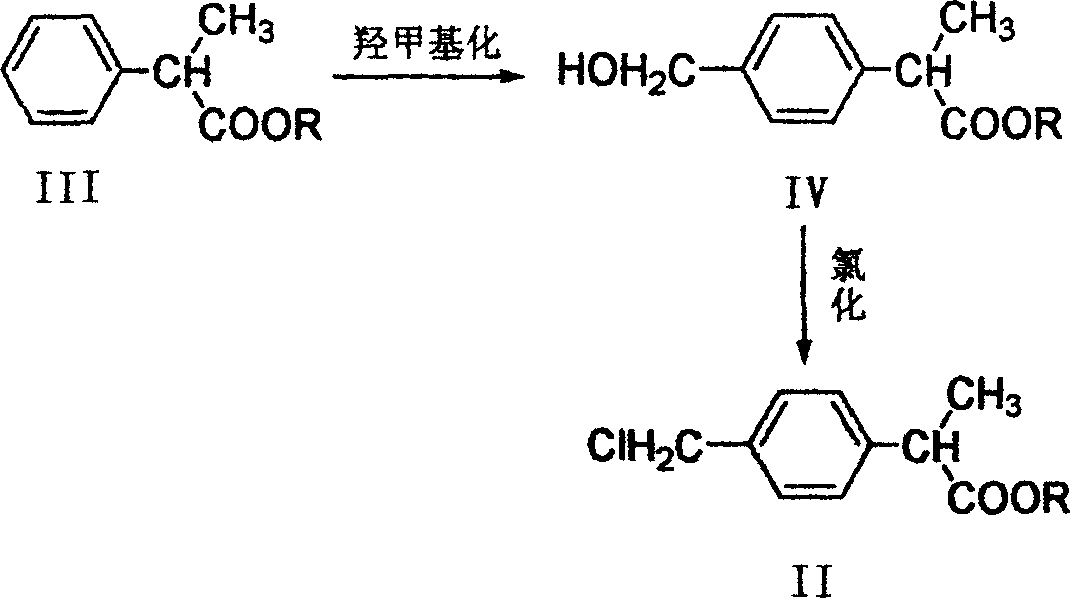

Method for preparing 2-(P-chloromethyl phenyl) propionic acid/ester

InactiveCN1757628AHigh yieldLow equipment requirementsOrganic compound preparationCarboxylic acid esters preparationPropanoic acidDistillation

This invention discloses a reaction thermal balance regulation method in acetic acid production process through carbonyl synthesis with methanol under low pressure and liquid phase. In the production process of acetic acid synthesized with methanol and carbon monoxide, recirculating flash distillation mother liquor which has lower temperature than reaction temperature with a recirculating mother liquor pump to balance the thermal quantity of synthesis reactor, it is characterized by setting a heat exchanger after recirculating mother liquor pump, to decrease the temperature of mother liquor from 124 DEG C ¿C 126 DEG C to 80 DEG C ¿C 110 DEG C, to balance reaction heat of reaction system through decreasing the temperature of recirculating mother liquid. Compared with the heat exchange method through outside-recirculating of reactor, the invention avoids catalyst deposits in heat exchanger under high temperature because of insufficient carbon monoxide, and avoids corrosion of recirculating pump under high temperature medium as well.

Owner:XIAMEN UNIV

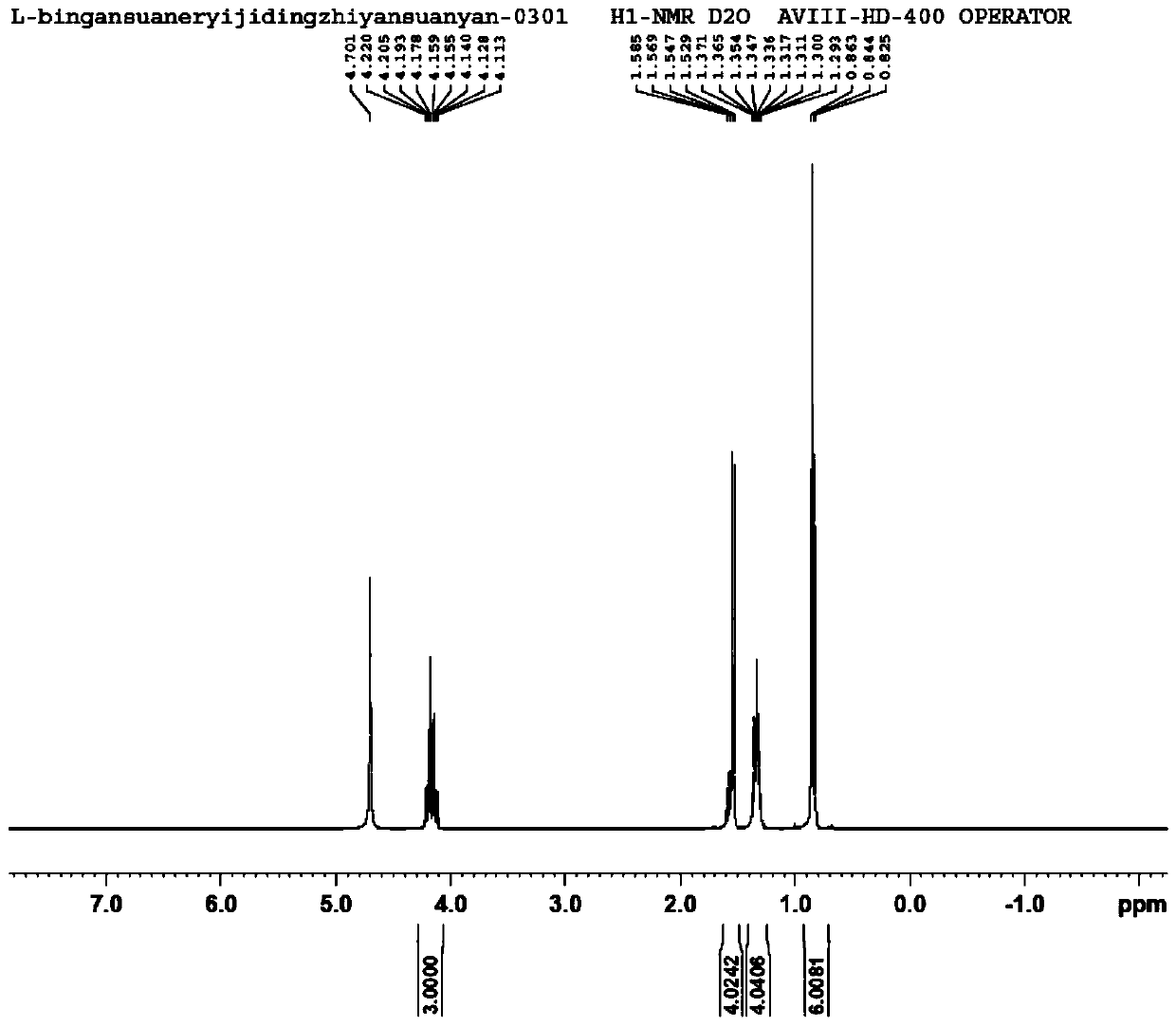

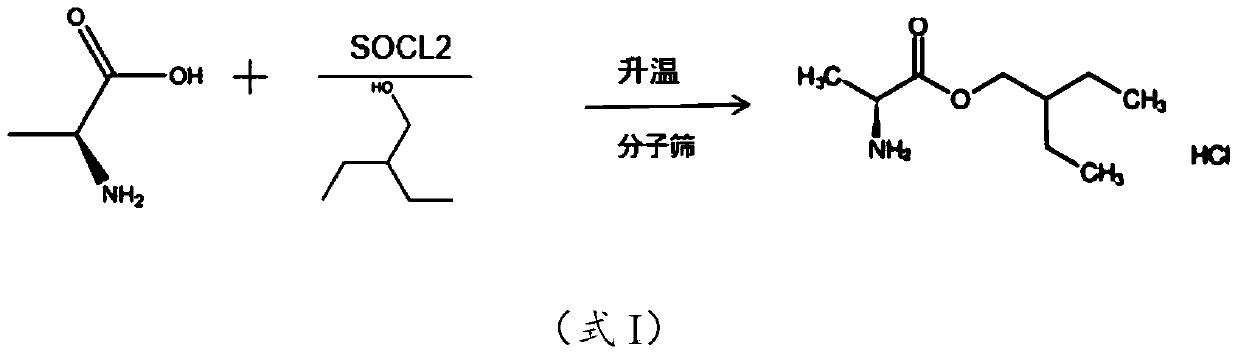

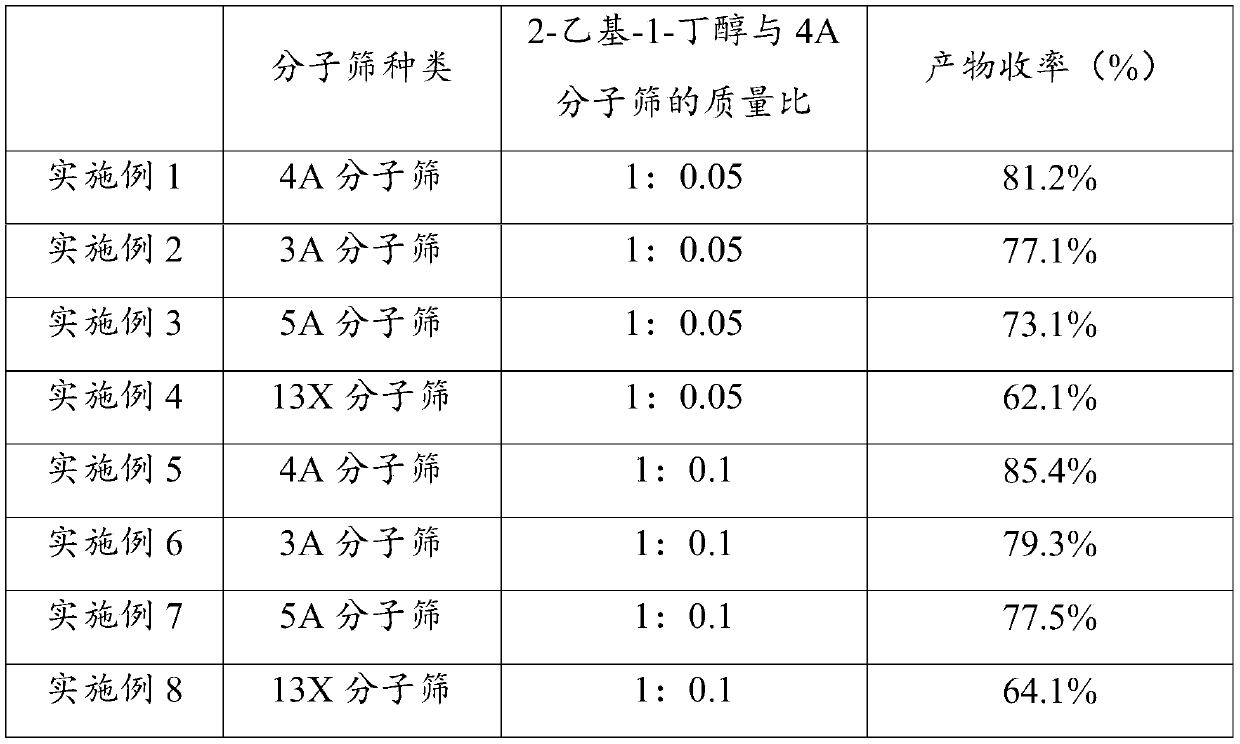

Preparation method of 2-alkyl-2-aminopropionate hydrochloride

PendingCN111393314ALow priceSustained Positive ResponseOrganic compound preparationAmino-carboxyl compound preparationPropanoic acidPharmacology

The invention provides a preparation method of 2-alkyl-2-aminopropionate hydrochloride, and belongs to the technical field of synthesis of medical intermediates. The preparation method of the 2-alkyl-2-aminopropionate hydrochloride comprises the following steps: adding thionyl chloride into a mixed solution of L-alanine and alkyl alcohol dropwise at a temperature ranging from -10DEG C to 5DEG C, and carrying out heat preservation treatment for hydrochlorination of the amino of L-alanine to obtain a reaction stock solution; and heating the reaction stock solution to 75-85DEG C in the presence of a molecular sieve, and carrying out esterification reaction to obtain a reaction solution containing 2-alkyl-2-aminopropionate hydrochloride. In the preparation method, the price of the raw materials is low and the yield of the product is high.

Owner:安徽红杉生物医药科技有限公司

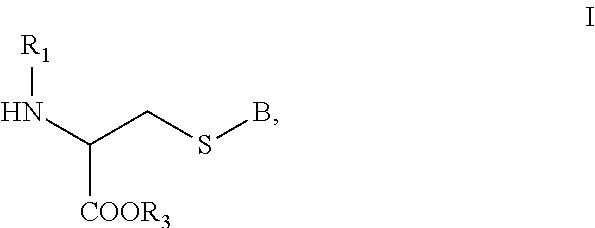

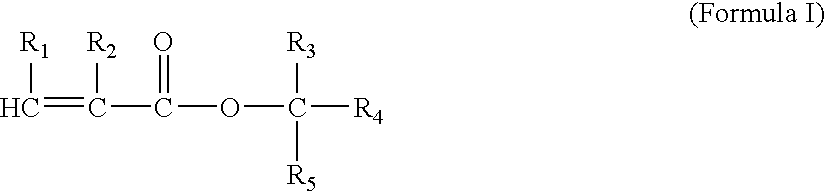

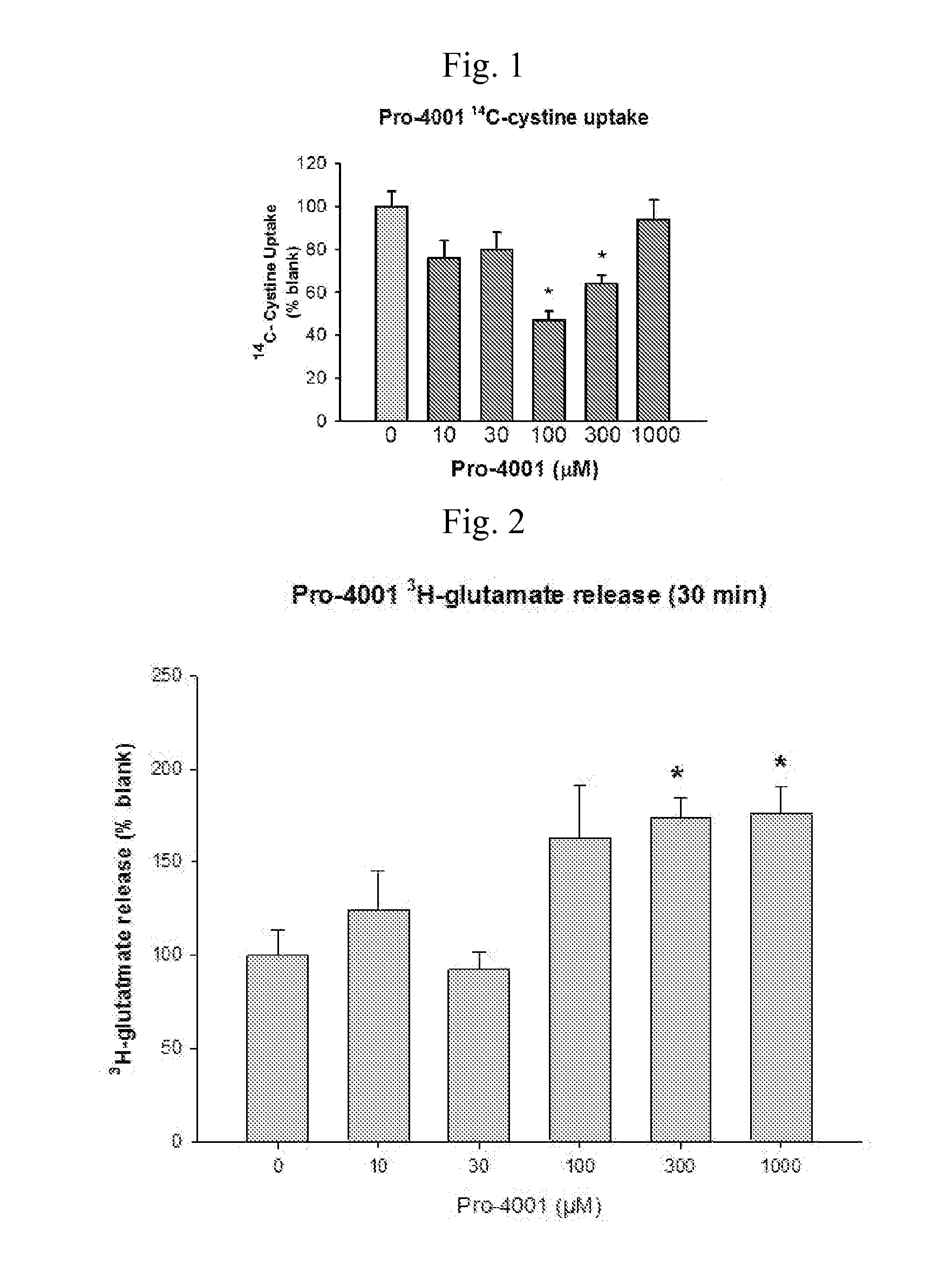

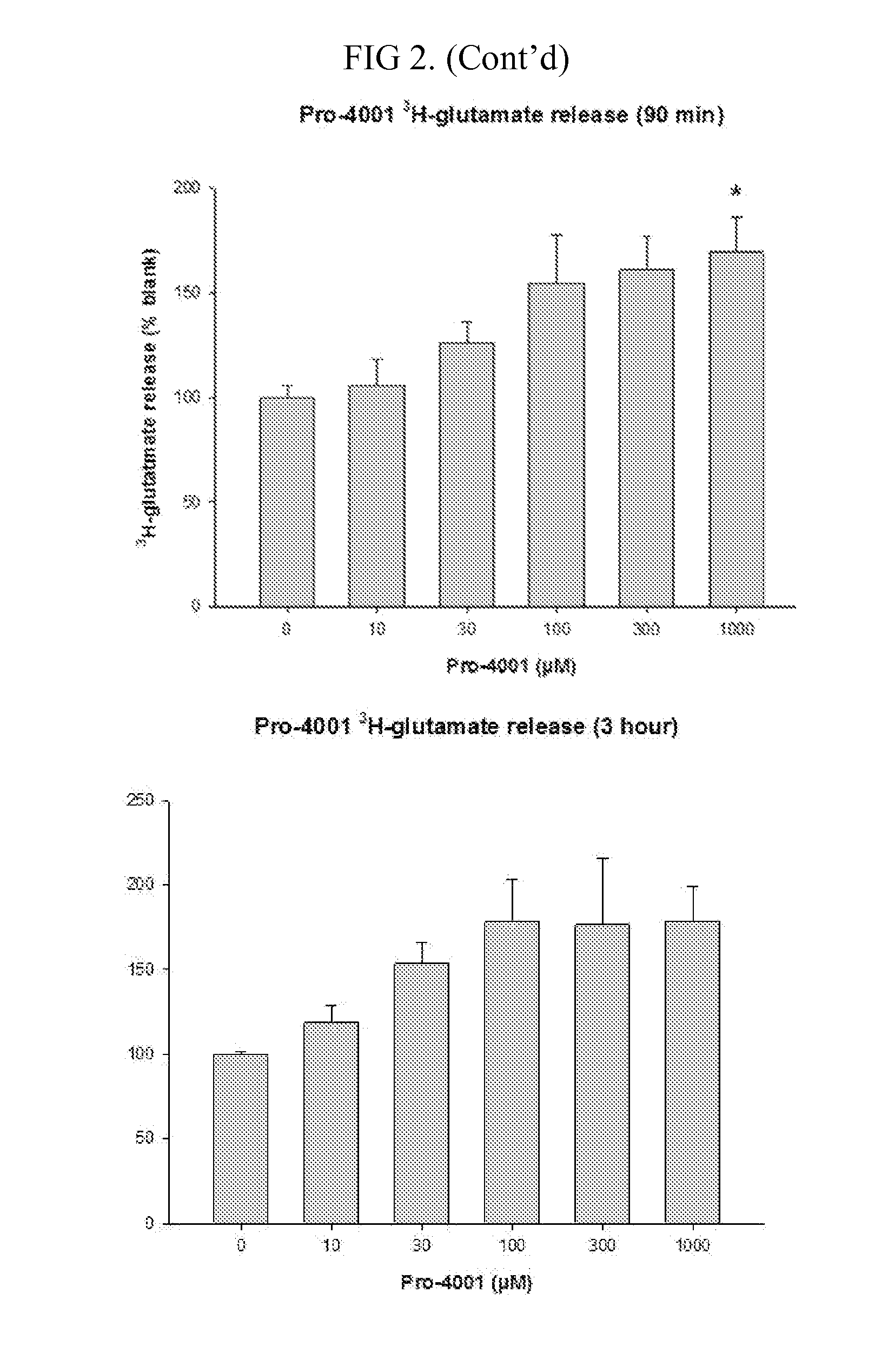

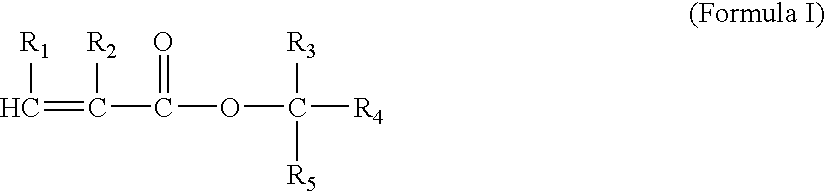

Propionic acids, propionic acid esters, and related compounds

The invention relates to compounds of the following formula:and their pharmaceutically acceptable salts, pharmaceutical compositions containing this compounds, and methods of using this compound for the treatment of various diseases or conditions, including but not limited to diseases and / or conditions of, or involving, the Central Nervous System (CNS), including schizophrenia adrenoleukodystrophy, mitochondrial diseases (e.g. Leigh syndrome, Alpers' disease, and MELAS), Huntington's disease, trichotillomania, HIV-associated neurocognitive disorder, hypoxic-ischemic encephalopathy, drug craving, and drug addiction.

Owner:PROMENTIS PHARMA

Method of preparing propionic acid-terminated polymers

ActiveUS7608663B2Avoid adjustmentOrganic compound preparationCarboxylic acid esters preparationPropionatePropanoic acid

The invention provides methods for preparing polymers bearing a terminal propionic acid. The method involves first reacting a water soluble and non-peptidic polymer comprising at least one hydroxyl group with a tertiary alkyl acrylate in the presence of a catalyst to form a propionic acid ester of the polymer, wherein the polymer has a weight average molecular weight of at least about 10,000 Da; and then treating the propionic acid ester of the polymer with a strong acid to form a propionic acid of the polymer.

Owner:NEKTAR THERAPEUTICS INC

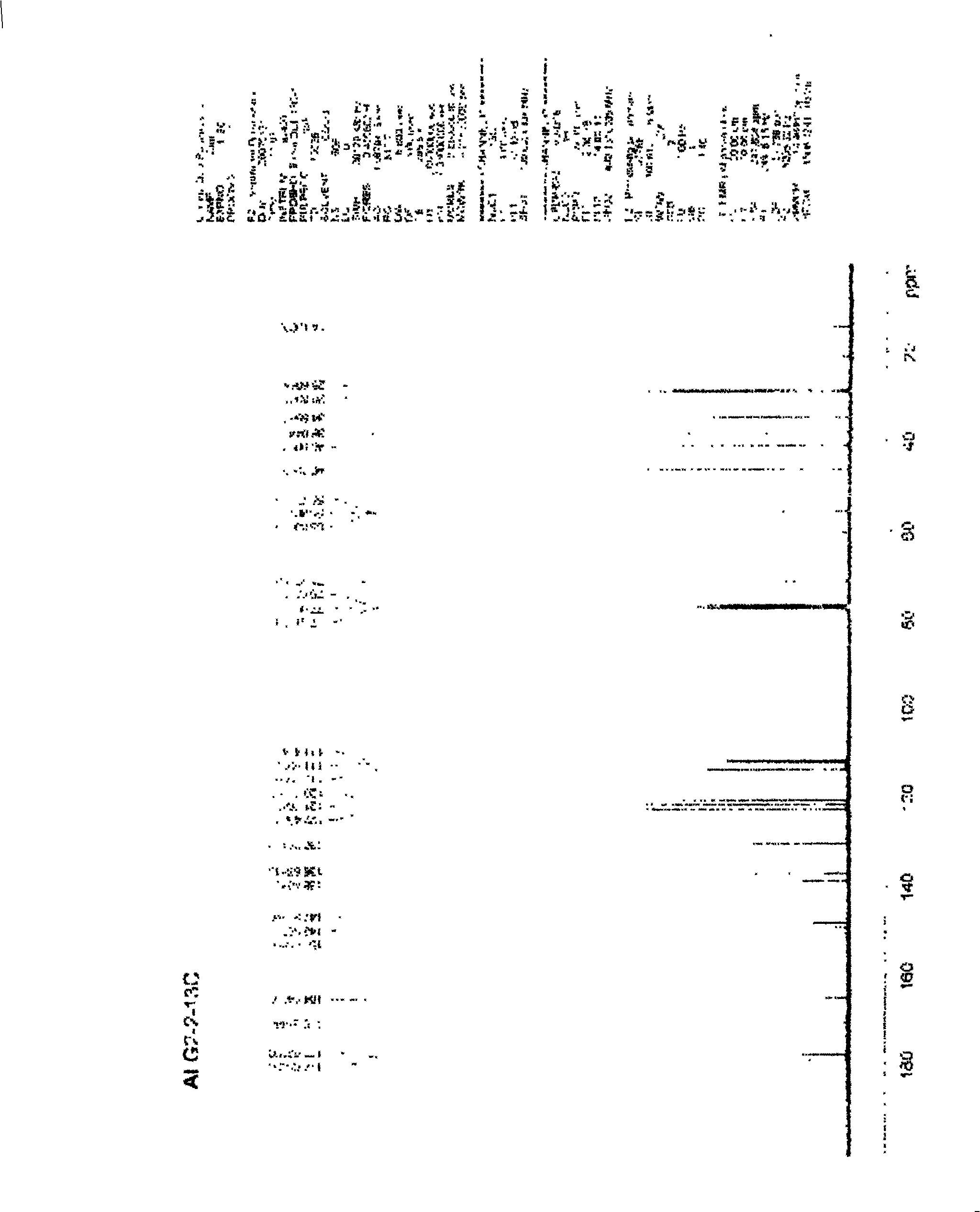

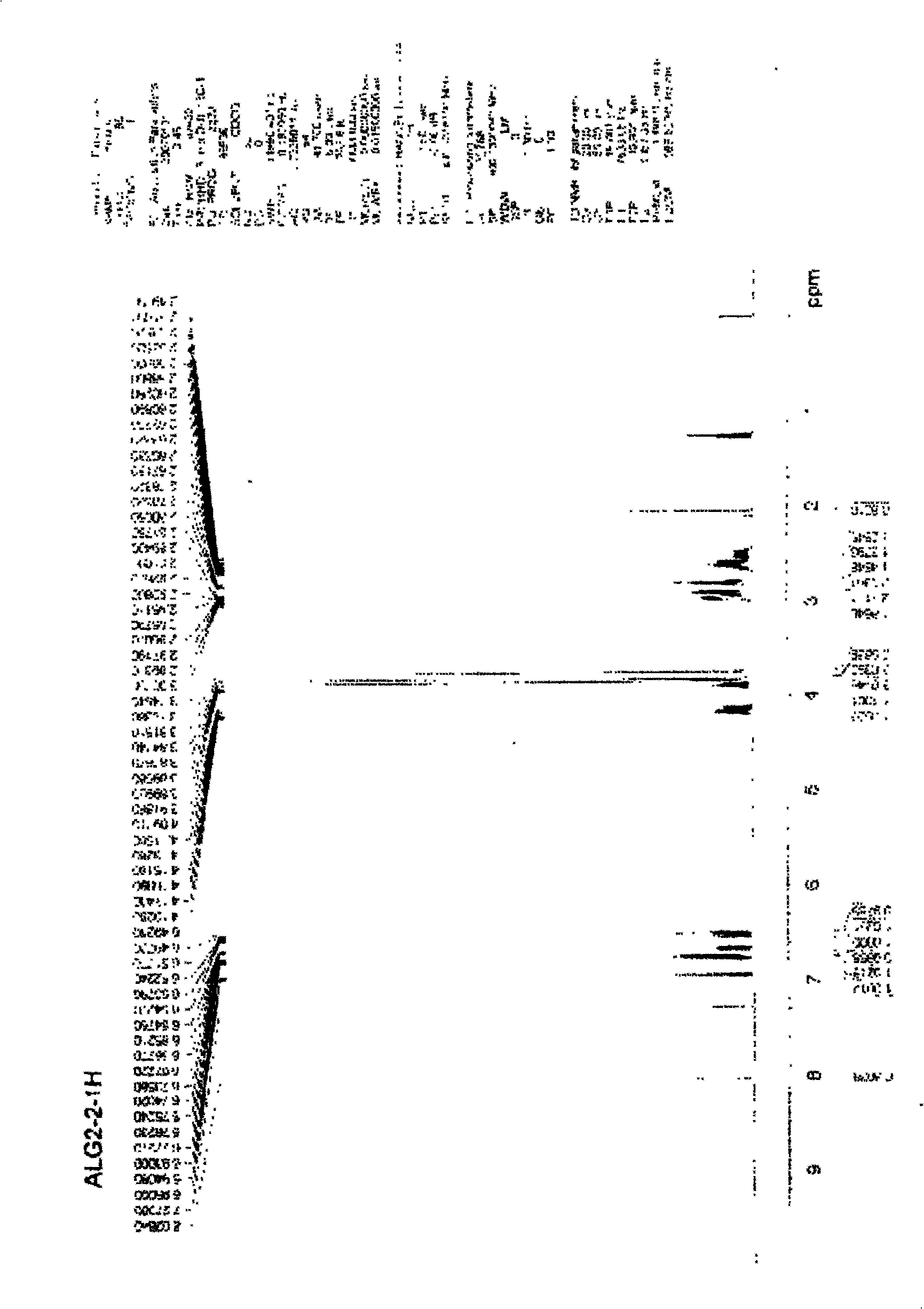

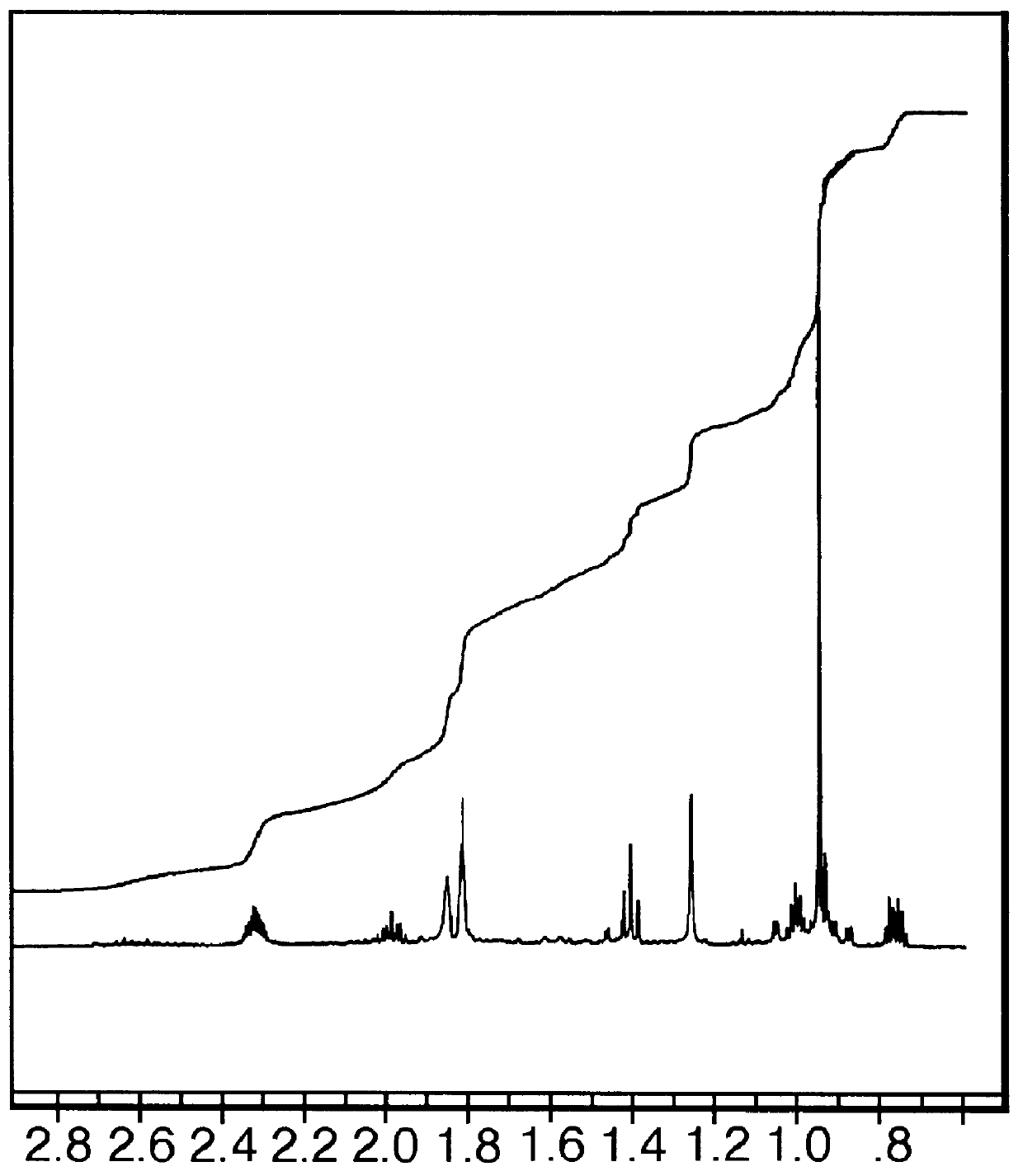

Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]

ActiveCN114213291AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationTert butyl phenolPropanoic acid

The invention relates to a synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]. The method comprises the following steps: enabling 2, 6-di-tert-butylphenol to react with acrylate, and continuing to react with 2-chloroethanol, so as to obtain an intermediate 3-(3, 5-di-tert-butyl-4-tetrahydroxyphenyl) propionic acid 2-chloroethyl ester; and reacting with sodium sulfide in the presence of quaternary ammonium salt to obtain a target product. The synthesis method disclosed by the invention has the advantages of simple process, high product yield and high purity, and is particularly suitable for being applied to industrial production.

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

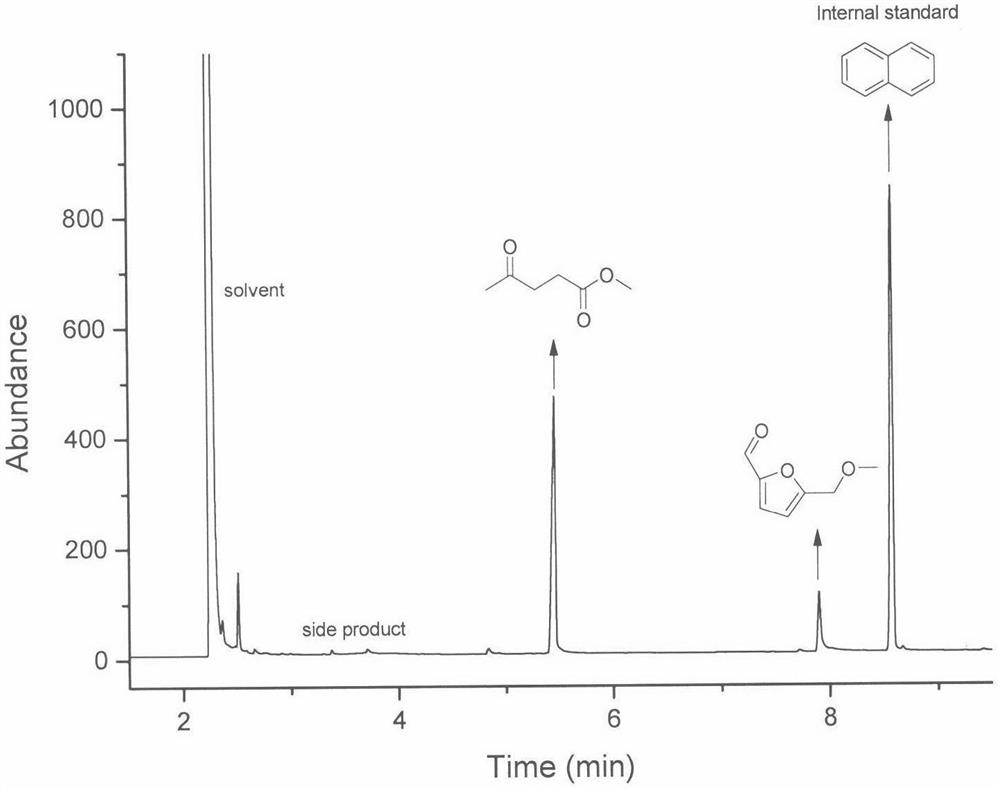

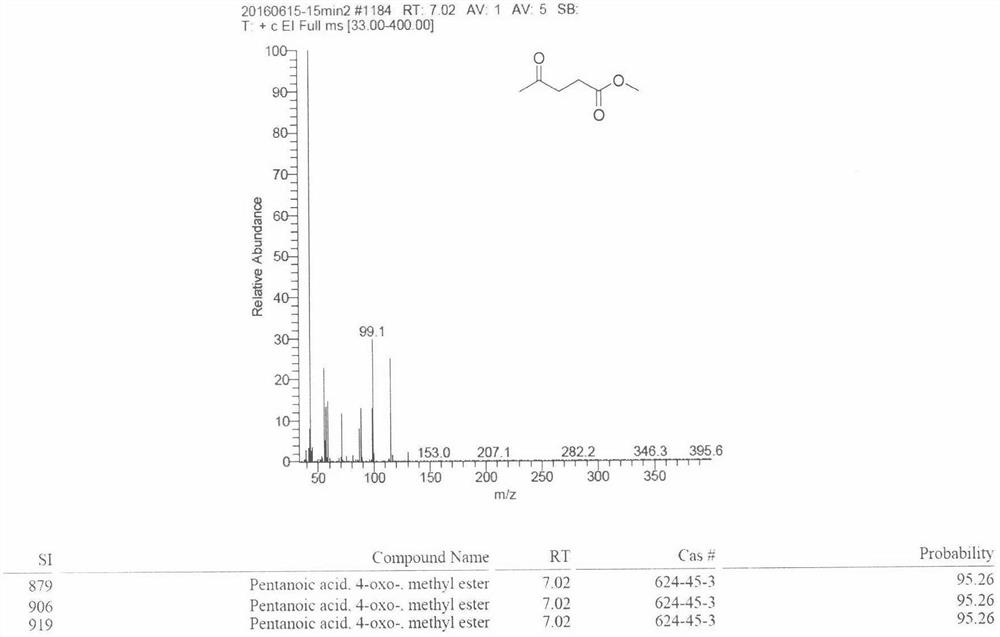

A kind of method that metal salt catalyzes cellulose to prepare levulinic acid ester

ActiveCN107759469BHigh selectivityEasy to recycleOrganic compound preparationCarboxylic acid esters preparationCellulosePtru catalyst

The invention provides a method for directly preparing levulinate from cellulose, the main steps of which are: under the action of a metal salt catalyst, cellulose is subjected to alcoholysis in a mixed solvent of alcohol and water to directly obtain levulinic acid ester. The metal cation of the metal salt used in this method is Al 3+ , Sn 4+ or Fe 3+ At least one of them; the heating methods involved in the method include microwave heating and oil bath heating. The method provided by the invention can efficiently and selectively convert cellulose into levulinate, not only has mild reaction conditions, short reaction time, and easy recovery of the catalyst, but also avoids the use of liquid acid or solid acid catalysts, and has few side reactions. Low cost and friendly to the environment.

Owner:NANJING FORESTRY UNIV

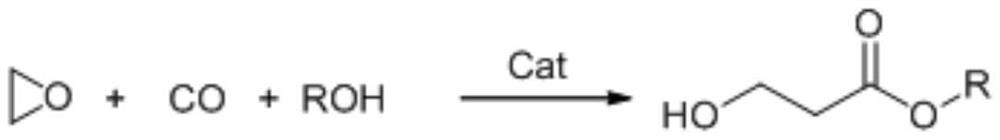

The production method of 3-hydroxypropionate

ActiveCN109678708BLow priceStable in natureOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionPropanoic acidPtru catalyst

The invention relates to a production method of 3-hydroxypropionate, which mainly solves the problems of complex catalyst preparation and low activity in the prior art. The present invention is by adopting the method for producing 3-hydroxypropionate, under the presence of cobalt salt, ligand and cocatalyst, ethylene oxide, synthesis gas and alcohol, reaction obtains 3-hydroxypropionate; Wherein, described cobalt salt It is one of cobalt phosphate, cobalt sulfate, cobalt acetate, cobalt chloride, cobalt carbonate, cobalt nitrate, cobalt hydroxide, cobalt oxide, cobalt oxalate, the ligand is an N-containing ligand, and the cocatalyst is a metal The technical solution of powder or carrier loading metal element better solves this technical problem and can be used in the industrial production of 3-hydroxypropionate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for selectively synthesizing N-alkylaminopropionate solution

ActiveCN111848425AReduce generationAvoid gatheringOrganic compound preparationAmino-carboxyl compound preparationPropionatePropanoic acid

The invention belongs to the technical field of organic synthesis and particularly discloses a method for selectively synthesizing an N-alkylaminopropionate solution. The method comprises the following steps: with akyl primary amine and acrylate as raw materials, dropwise adding acrylate into excessive alkyl primary amine and carrying out stirring for a reaction to allow the reaction to be implemented in the direction of generating N-alkylamino propionic ester, then adding an aqueous solution of alkali metal hydroxide to convert N-alkylamino propionic ester into N-alkylaminopropionate, and removing excessive alkyl primary amine through extracting via an organic solvent, thereby realizing selective synthesis of N-alkylaminopropionate. According to the method, high-purity N-alkylaminopropionate can be obtained, and an impurity content can be reduced to 5% or below; high temperature, high pressure and complex crystallization and purification steps are not needed, so the method is simple and feasible; and the used raw materials and solvents can be recycled, so the method is very energy-saving and environment-friendly.

Owner:WENZHOU INST UNIV OF CHINESE ACAD OF SCI

Propionic acids, propionic acid esters, and related compounds

The invention relates to compounds of the following formula:and their pharmaceutically acceptable salts, pharmaceutical compositions containing this compounds, and methods of using this compound for the treatment of various diseases or conditions, including but not limited to diseases and / or conditions of, or involving, the Central Nervous System (CNS), including schizophrenia adrenoleukodystrophy, mitochondrial diseases (e.g. Leigh syndrome, Alpers' disease, and MELAS), Huntington's disease, trichotillomania, HIV-associated neurocognitive disorder, hypoxic-ischemic encephalopathy, drug craving, and drug addiction.

Owner:PROMENTIS PHARMA

Multifunctional coating and preparation method thereof

PendingCN114213887AFormaldehyde freeNo heavy metalsFireproof paintsAnti-corrosive paintsIsooctyl acrylatePotassium persulfate

The invention discloses a multifunctional coating which comprises a component A and a component B. The component A comprises 1-6 parts of plant methyl acrylate, 10-60 parts of plant phosphate ester, 10-60 parts of plant polypropyl ether, 1-6 parts of plant butyl methacrylate, 1-6 parts of plant 2-ethylhexyl acrylate, 1-6 parts of plant 2-ethylhexyl methacrylate and 1-6 parts of plant acrylic acid. 1-6 parts of plant allyl polyoxyethylene ether ammonium sulfate, 1-6 parts of plant potassium persulfate, 1-6 parts of plant ammonia water, 1-6 parts of plant isomeric alcohol polyoxyethylene ether, 1-6 parts of plant lauryl sodium sulfate, 1-6 parts of mineral acrylic copolymer, 1-6 parts of plant triethylene glycol ether-di (3-tertiary butyl-4-hydroxyl-5-methyl phenyl) propionate and 100-600 parts of water. The component B is prepared from 100 to 600 parts of mineral iron aluminate cement, 100 to 600 parts of 200-mesh magnesium oxide 85 powder, 100 to 600 parts of 50-mesh quartz sand, 10 to 60 parts of mineral heavy calcium carbonate powder, 10 to 60 parts of mineral kaolin and 1 to 6 parts of mineral sodium lignin sulfonate. The coating is safe and can be widely applied to the technical field of coatings.

Owner:深圳阿米防火防水高科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]](https://images-eureka.patsnap.com/patent_img/060a5ccc-863b-4a93-8780-23f60355d765/FDA0003448855290000011.png)

![Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]](https://images-eureka.patsnap.com/patent_img/060a5ccc-863b-4a93-8780-23f60355d765/BDA0003448855300000011.png)

![Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] Synthesis method of thiodiethylene bis [3-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate]](https://images-eureka.patsnap.com/patent_img/060a5ccc-863b-4a93-8780-23f60355d765/BDA0003448855300000021.png)