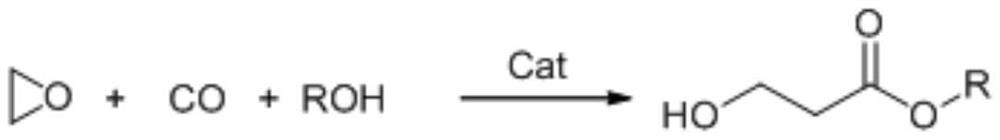

The production method of 3-hydroxypropionate

A hydroxypropionate, production method technology, applied in chemical instruments and methods, carbon monoxide or formate reaction preparation, physical/chemical process catalysts, etc., can solve problems such as poor reaction performance, complex catalyst preparation, etc., to achieve stable properties , low price, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 100mL autoclave, add 4.0mmol cobalt chloride, 2.0mmol triethylamine, 0.4mmol magnesium powder, 100.0mmol ethylene oxide, and 750.0mmol ethanol in sequence. The kettle body was fully cooled to 0°C, the air in the kettle was replaced with nitrogen three times, and synthesis gas (H 2 / CO=0.2:1), make the system pressure 10MPa, and react at 70°C for 20 hours. After the reaction was completed, the reactor body was cooled to 0° C., and the pressure was slowly released to normal pressure. The reactor was purged three times with nitrogen, and samples were taken for analysis. The experimental results are shown in Table 1.

Embodiment 2

[0034] In a 100mL autoclave, add 4.0mmol cobalt phosphate, 6.0mmol pyridine, 0.8mmol aluminum powder, 40.0mmol ethylene oxide, and 750.0mmol methanol in sequence. The kettle body was fully cooled to 0°C, the air in the kettle was replaced with nitrogen three times, and synthesis gas (H 2 / CO=0.5:1), make the system pressure 9MPa, and react at 60°C for 24 hours. After the reaction was completed, the reactor body was cooled to 0° C., and the pressure was slowly released to normal pressure. The reactor was purged three times with nitrogen, and samples were taken for analysis. The experimental results are shown in Table 1.

Embodiment 3

[0036] In a 100mL autoclave, add 4.0mmol cobalt acetate, 4.0mmol quinoline, 0.27mmol zinc powder, 20.0mmol ethylene oxide, and 1000.0mmol methanol in sequence. The kettle body was fully cooled to 0°C, the air in the kettle was replaced with nitrogen three times, and synthesis gas (H 2 / CO=1:1), make the system pressure 8MPa, and react at 90°C for 20 hours. After the reaction was completed, the reactor body was cooled to 0° C., and the pressure was slowly released to normal pressure. The reactor was purged three times with nitrogen, and samples were taken for analysis. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com