Patents

Literature

49results about How to "No icing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

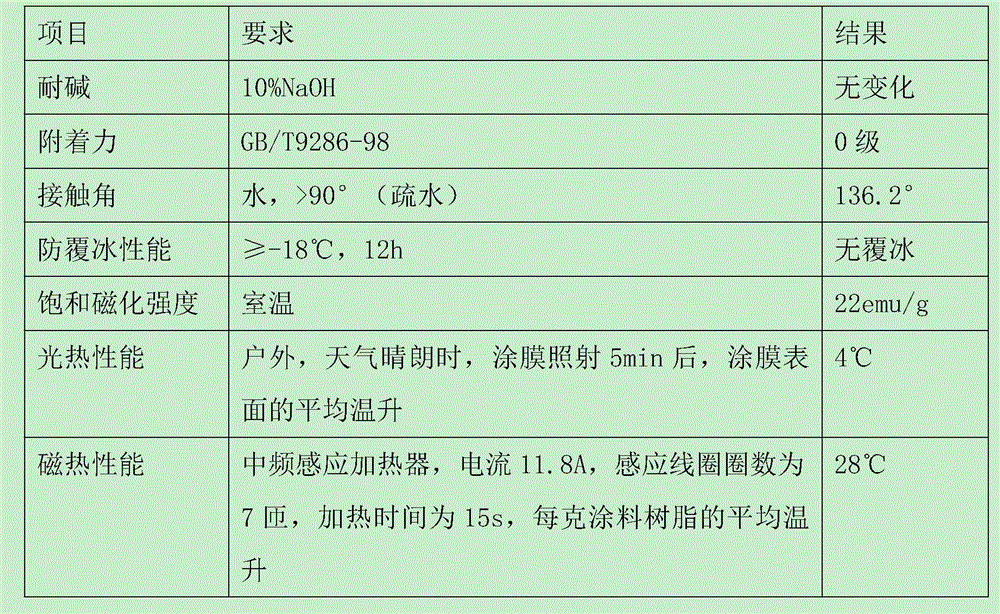

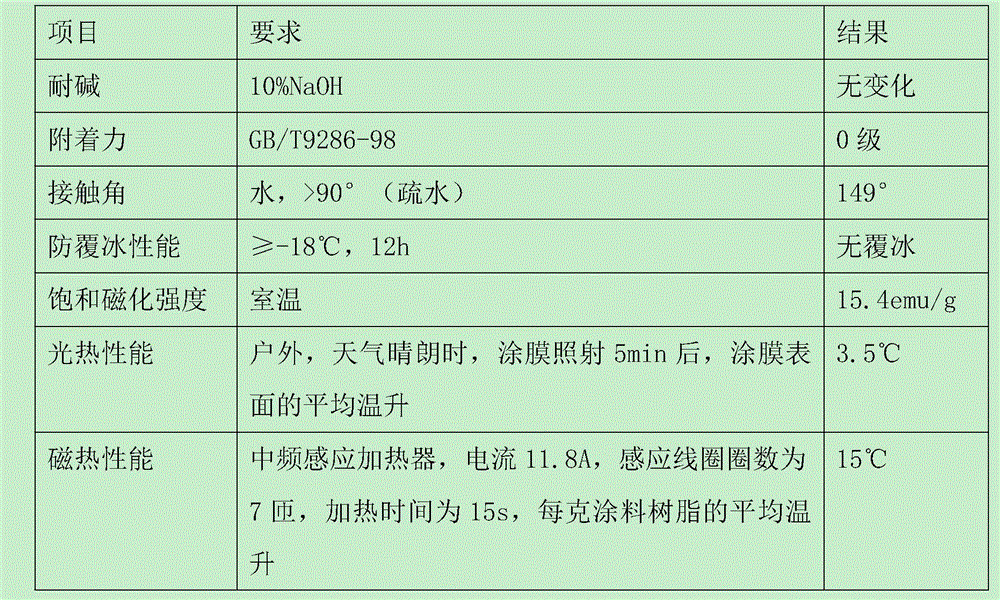

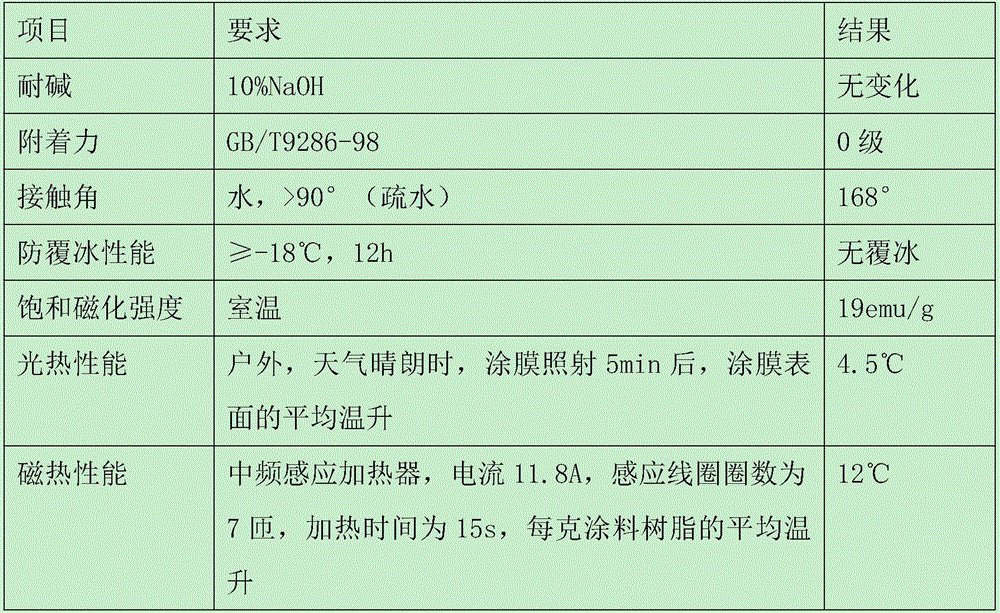

Super-hydrophobic ice-over resistant coating with thermomagnetic property and preparation method of super-hydrophobic ice-over resistant coating

ActiveCN104804603AExcellent magnetocaloric performanceDelayed icingCoatingsWeather resistanceHydrocarbon

The invention discloses a super-hydrophobic ice-over resistant coating with a thermomagnetic property and a preparation method of the super-hydrophobic ice-over resistant coating. The super-hydrophobic ice-over resistant coating comprises the following components by mass percent: 20-68% of fluorine-containing acrylic acid epoxy resin, 19-69% of an organic solvent, and 10-50% of inorganic particles which are magnetic particles or mixture of magnetic particles and nonmagnetic particles, wherein the fluorine-containing acrylic acid epoxy resin is obtained through reaction of two components; one component is obtained through free radical polymerization of a fluorine-containing acrylate monomer, a hydrocarbon chain acrylate monomer and an expoxy group-containing acrylic acid ester monomer; the other component belongs to polyamines or acid anhydrides. The coating provided by the invention is environmentally friendly, and excellent in weather resistance and chemical resistance, has excellent adhesion with a base material, can be heated in the external alternating magnetic field or light condition, and can be used for preventing and controlling icing on the surfaces of telecommunication lines and the like; the preparation method is simple in process and convenient to operate.

Owner:ZHEJIANG UNIV

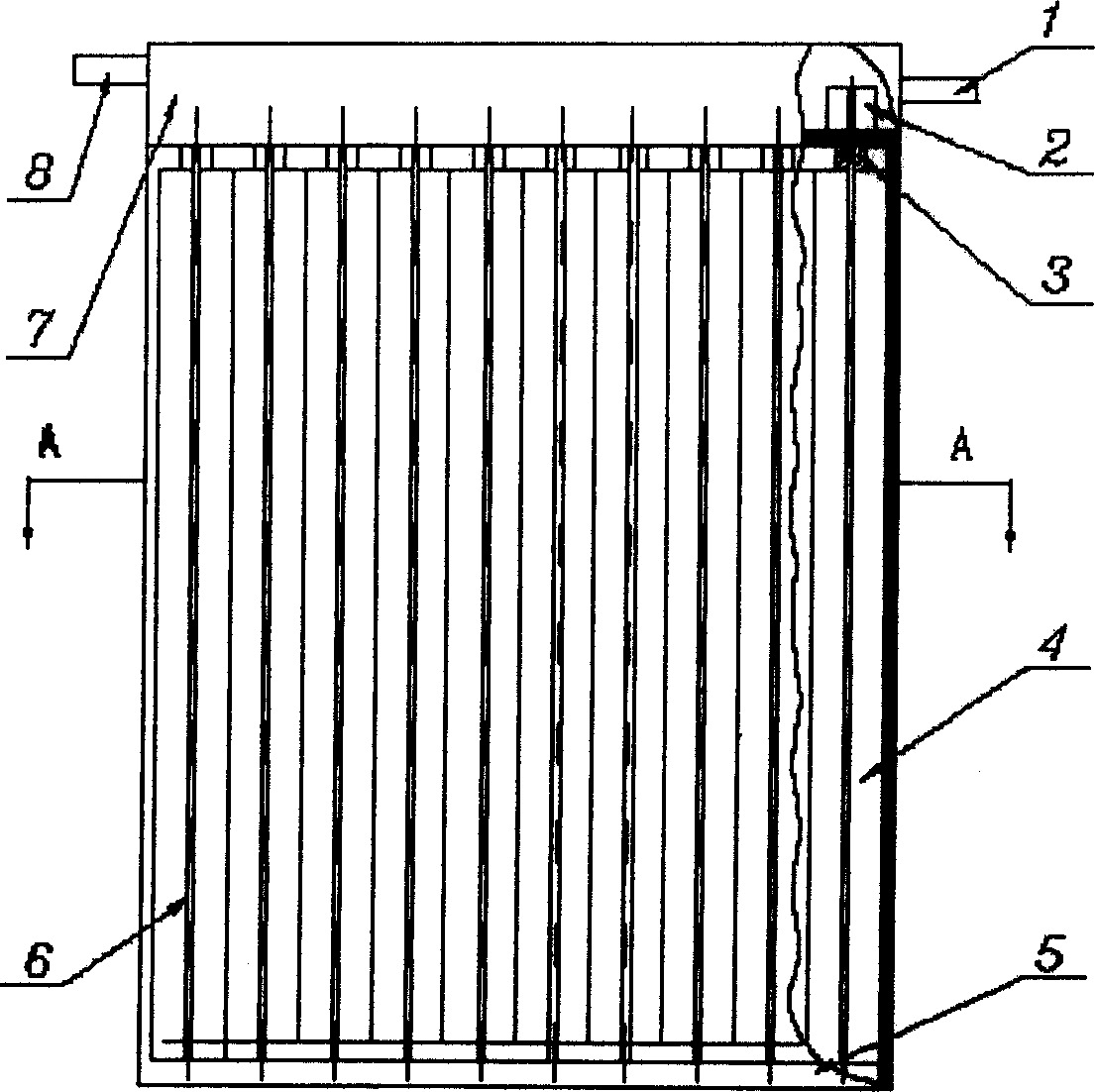

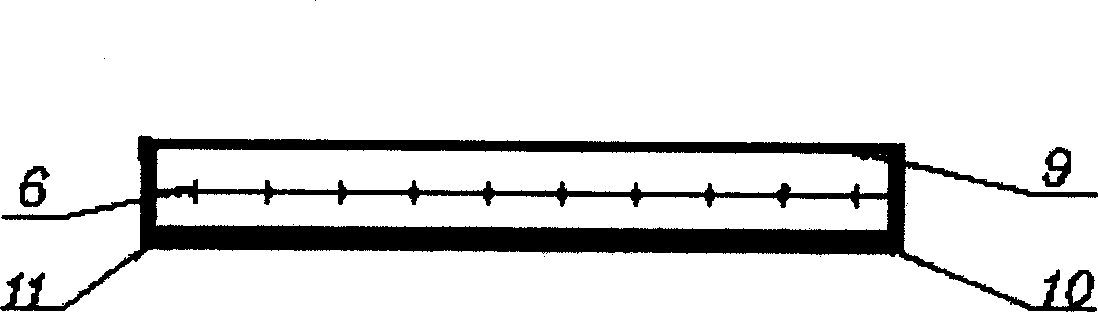

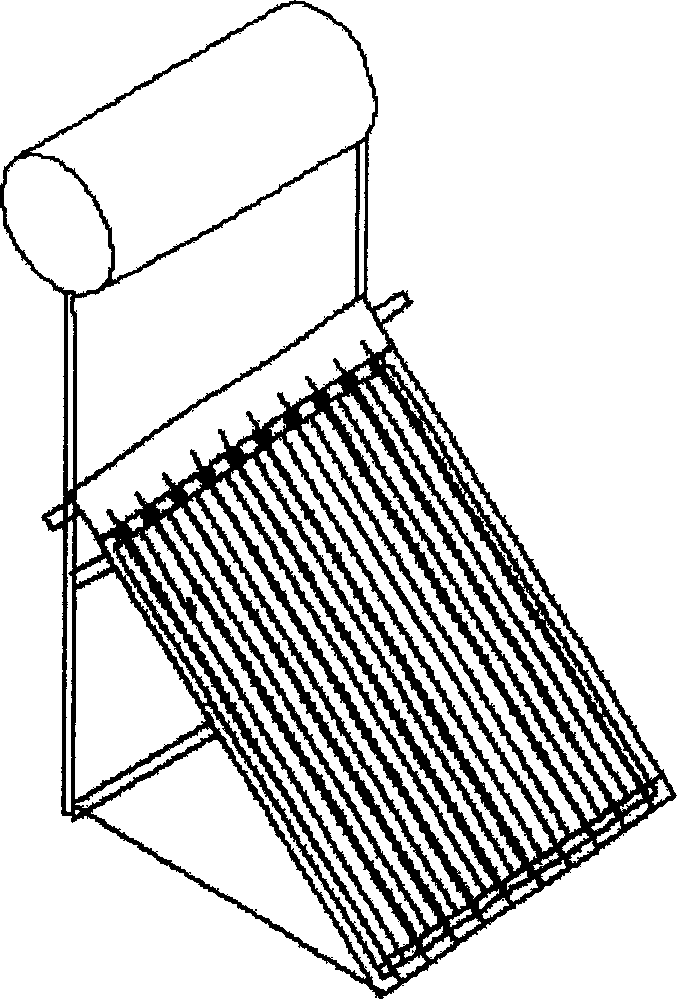

Flat-type solar water heater with vacuum glass cover plate heating tubes

InactiveCN1595010AStart fastHigh sensitivitySolar heating energySolar heat devicesFlat glassEngineering

Disclosed is a solar energy water heater of vacuum glass cover heat pipe plane type, comprising tank consisted of thermal insulating material and outer gimbal, vacuum plane glass above the tank, absorber plate consisted of heating pipe and fin, condensing zone of the heat pipe and recycling water tank are connected, the water tank and water storage are connected or the condensing zone of heat pipe is directly connected to water storage, and absorber plate is under the vacuum plane glass. The invention has no problems of icing, scale formation and atmospheric corrosion, fairly good red flared radiation can be emitting from heat collector inside because of high level of transparency of the vacuum plane glass to sun radiation but opaque to red flared radiation, decreasing radiation heat loss to absorber plate. Besides, heat pie has fast start-up, high sensitiveness, wide work range, fast heat transfer, only oneway heat exchange between heat collecting pie, and when the sun radiation is fairly low, heat elimination of heating working substance to environment can be reduced.

Owner:ZHEJIANG UNIV

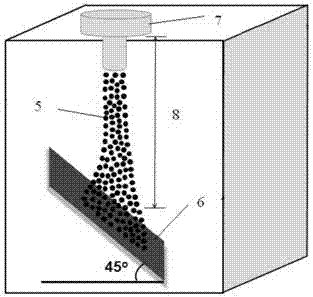

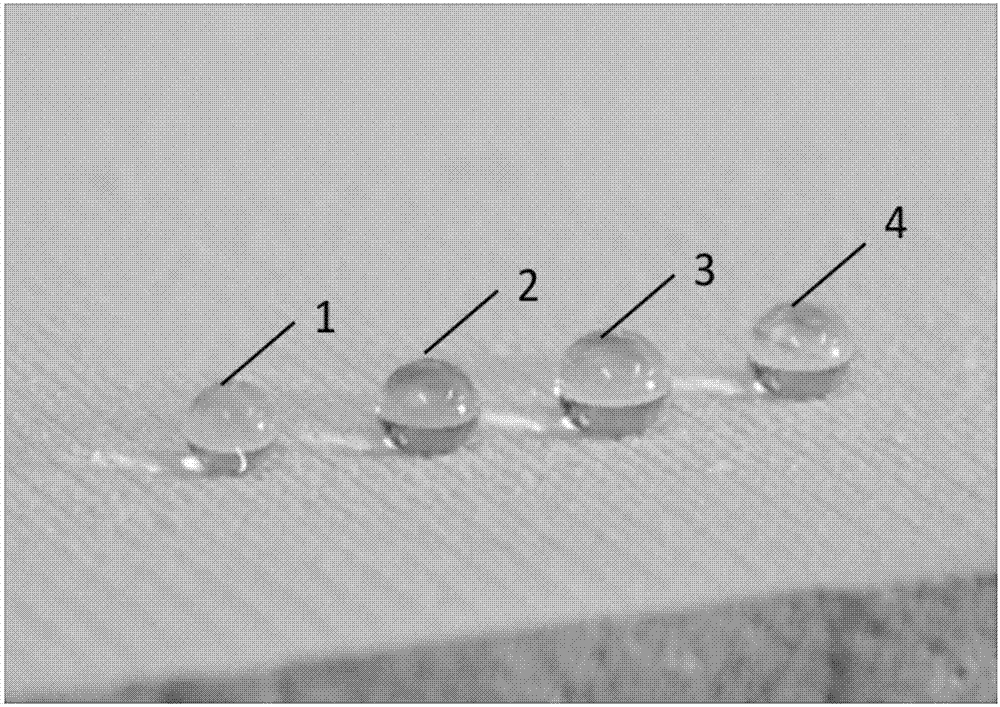

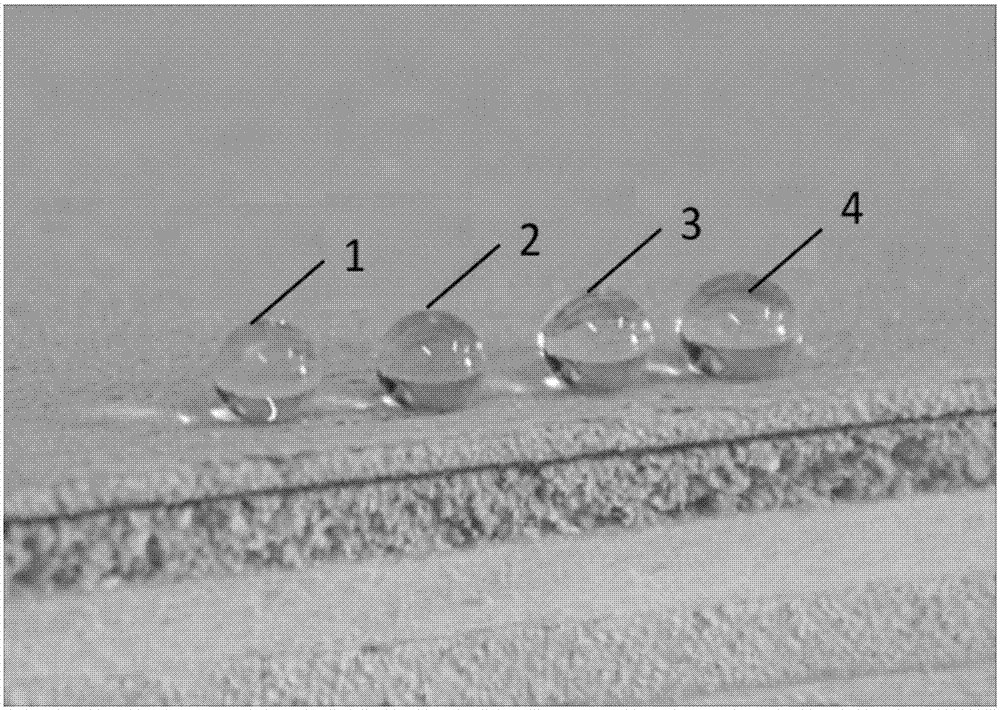

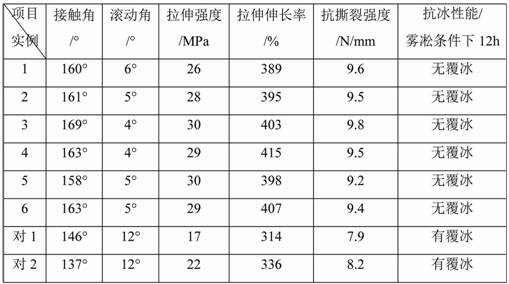

Preparation method of sustainable anti-icing super-amphiphobic coating

ActiveCN107116017AImproved long-lasting anti-icing performanceLong-lasting anti-icing performancePretreated surfacesAnti-corrosive paintsEpoxySilanes

The invention relates to the field of preparation of super-hydrophobic or super-amphiphobic coatings, in particular relates to a preparation method of a sustainable anti-icing super-amphiphobic coating. The method comprises the following steps: 1, cleaning a substrate surface and carrying out sand-blasting roughening treatment; 2, blending epoxy resins, epoxy resin curing agents and a first solvent to obtain an epoxy resin solution; 3, dispersing submicron particles and nanoparticles into a second solvent, and then adding fluoroalkyl silane to obtain particle composite suspension liquid; 4, spraying substrate surface subjected to the treatment in step 1 with the epoxy resin solution obtained in step 2, and carrying out semi-curing on the epoxy resin adhesive; 5, spraying the substrate surface subjected to the treatment in step 4 with the particle composite suspension liquid obtained in step 3, and carrying out complete curing; 6, obtaining the sustainable anti-icing super-amphiphobic coating. The method has the advantages that the super-amphiphobic coating prepared on all substrate surfaces has good durability and fastness, and has sustainable anti-icing performance.

Owner:哈尔滨毓干科技有限公司

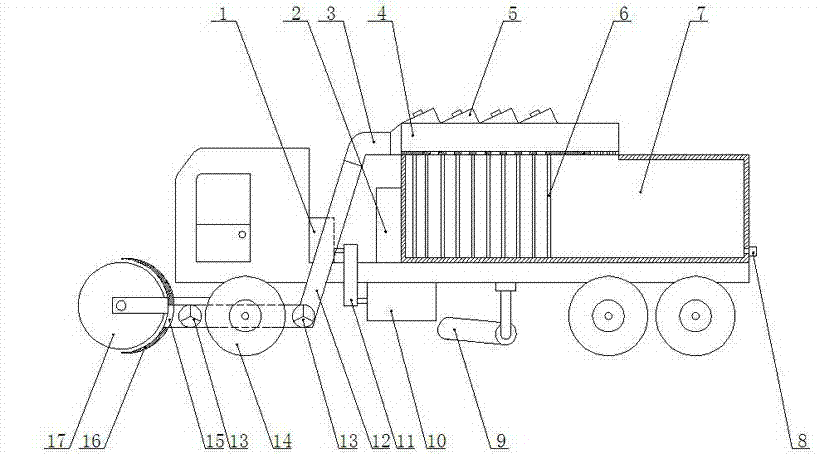

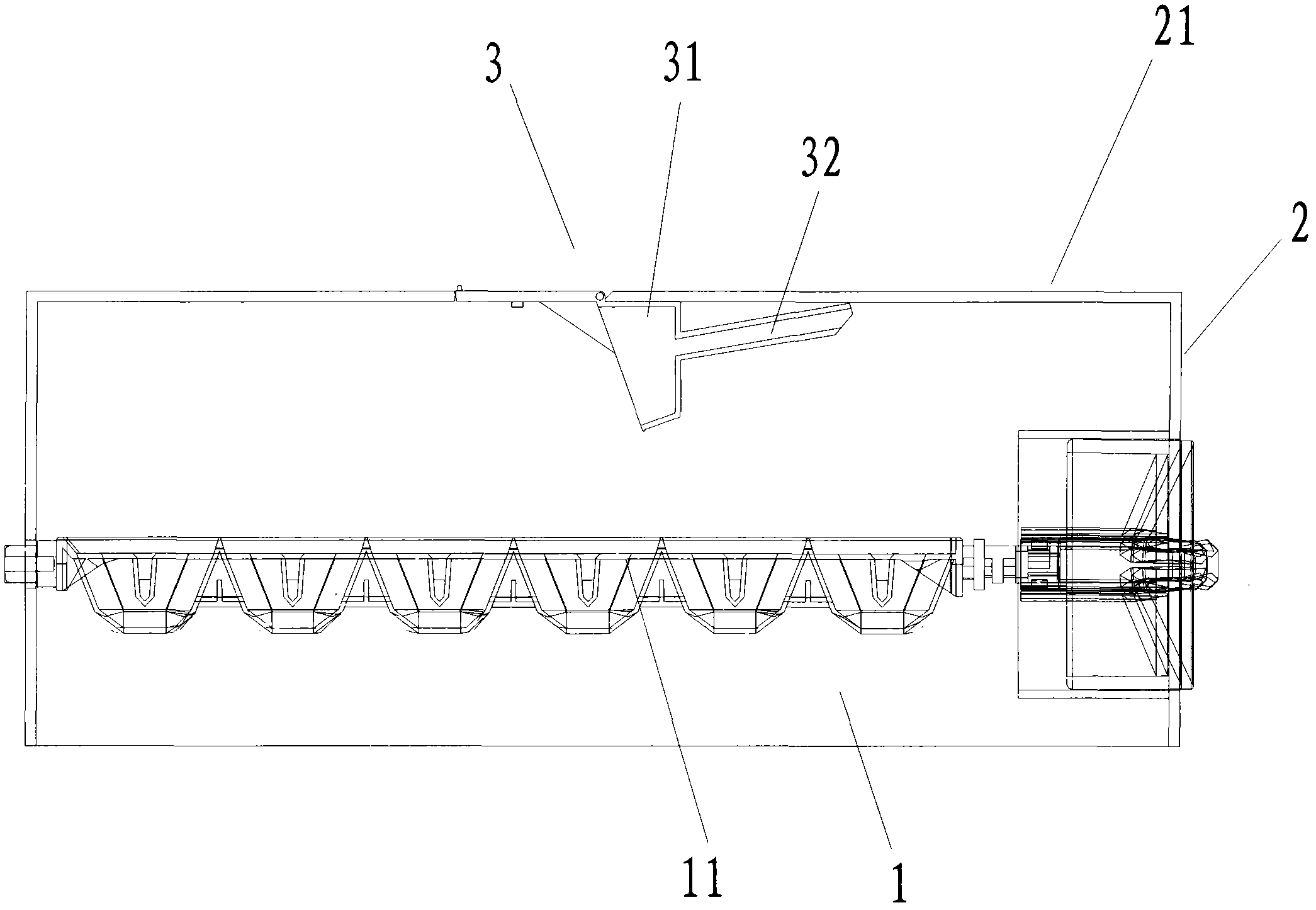

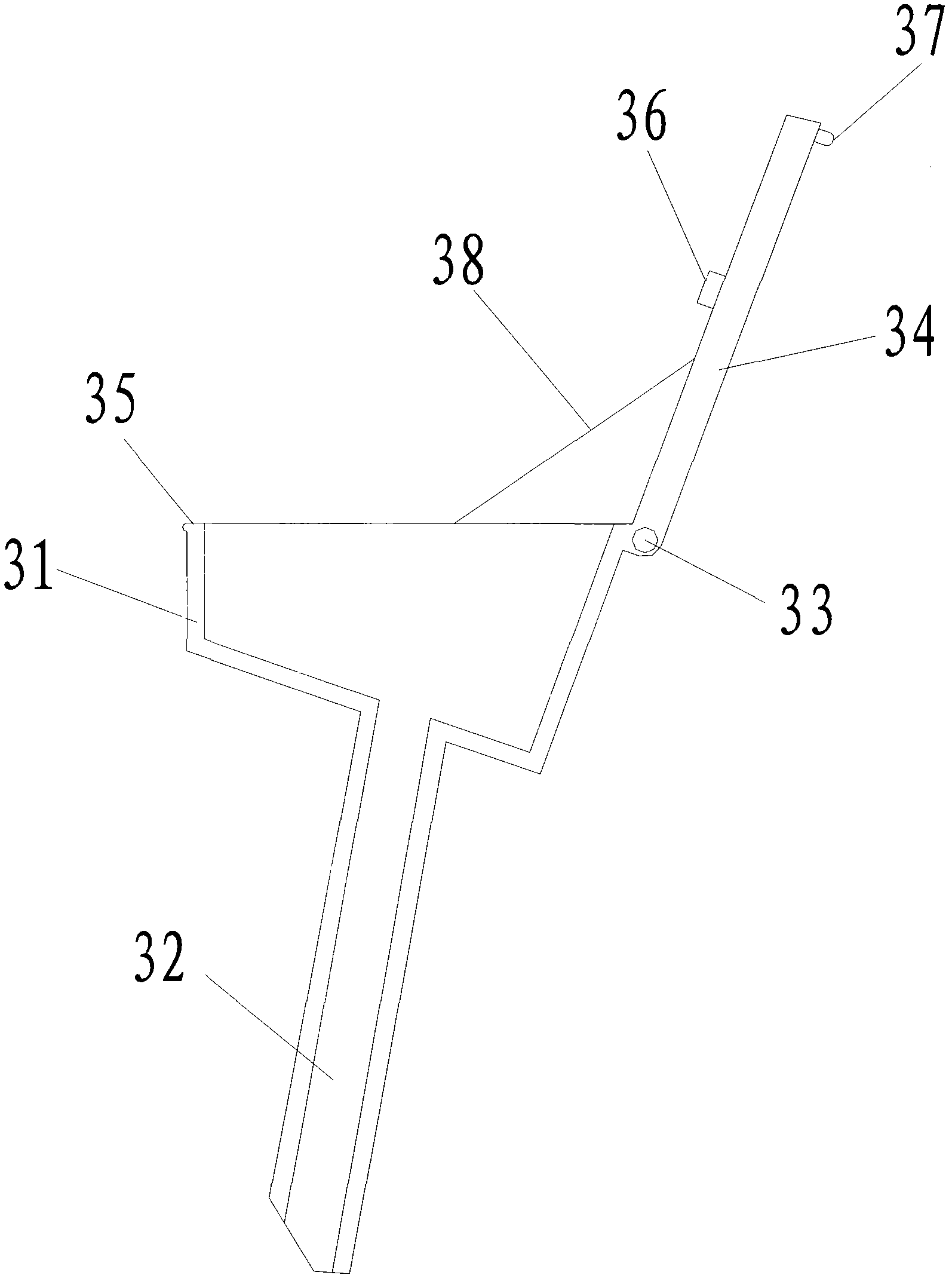

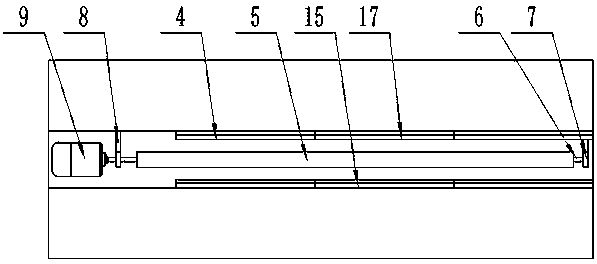

Drag suction type road surface cleaning device for sanitation truck

InactiveCN104343096AEasy to cleanIncrease the lengthTransmissivity measurementsCleaning using toolsRoad surfaceTruck

The invention discloses a drag suction type road surface cleaning device for a sanitation truck. The drag suction type road surface cleaning device comprises a road surface drag-cleaning device, a sundry separation device and a drag roller flushing device, wherein the road surface drag-cleaning device is connected with the sundry separation device and the drag roller flushing device. The drag suction type road surface cleaning device uses drag rollers to replace sweeping rollers so as to realize sorting treatment of dust and sundries, uses a conveyable barrel to replace a fixed box so as to effectively simplify and shrink the structure of a cleaning system, and uses wet method operation to replace dry method operation so as to avoid secondary blowing dust and flexibly deal with all kinds of road conditions.

Owner:XI'AN POLYTECHNIC UNIVERSITY

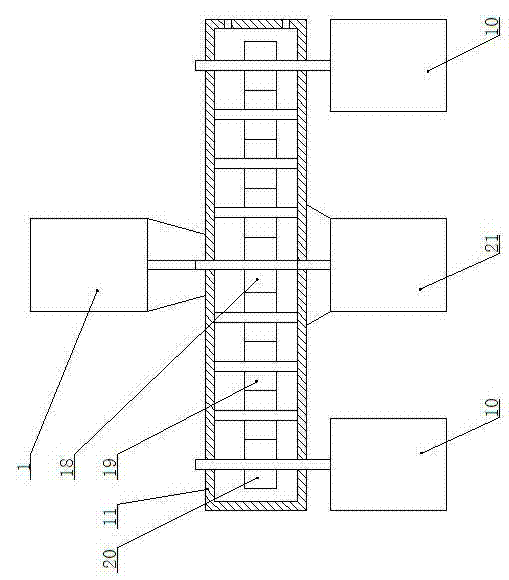

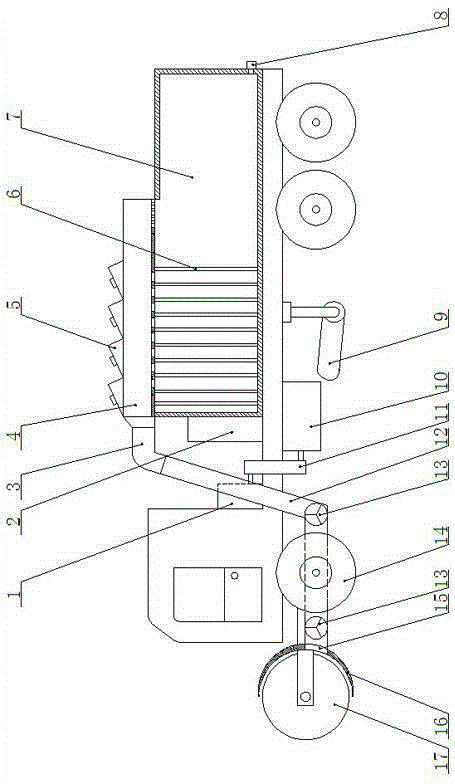

Movable electric heating high temperature snow melting and sweeping vehicle

InactiveCN103046511ALarge amount of stored snow waterNo icingSnow cleaningElectricityWinding machine

The invention relates to a movable electric heating high temperature snow melting and sweeping vehicle. The movable electric heating high temperature snow melting and sweeping vehicle comprises a driving cab of the vehicle, a water collection box arranged on a cross beam of the vehicle, and a snow melting box arranged on the water collection box. The crossbeam between the driving cab and the water collection box is provided with a soft start cabinet, the soft start cabinet is connected with a generator circuit, generators are arranged on the two sides of the lower end face of the crossbeam, and the generators are driven by a vehicle-mounted engine through a power transmission box. A horizontal vehicle beam on the front side of the driving cab is connected with a snow shoveling plate, two ends of the snow shoveling plate are provided with connecting plates, a shaft is arranged between the two connecting plates, and the shaft is provided with snow rolling wheels. The snow shoveling plate is provided with a snow discharge port, the snow discharge port is connected with a snow transport pipe, and the other end port of the snow transport pipe is connected with a snow inlet port of the snow melting box. The bottom face of the snow melting box is an electric heating plate, the electric heating plate is provided with a water drain hole, and the wall of the box body of the snow melting box is provided with a hot wind machine. The movable electric heating high temperature snow melting and sweeping vehicle can utilize the vehicle-mounted electric energy to heat, and has the advantages of low snow melting cost, good snow melting effect, large melt snow storage and long continuous operating time.

Owner:STATE GRID XINJIANG ELECTRIC POWER CORP

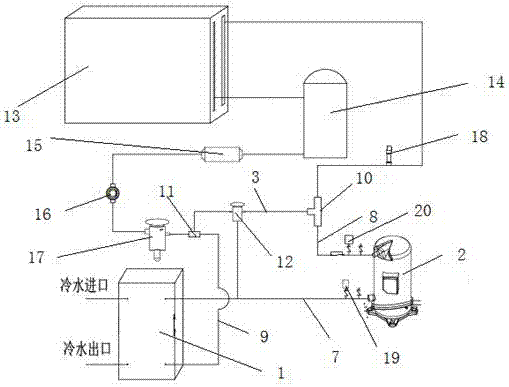

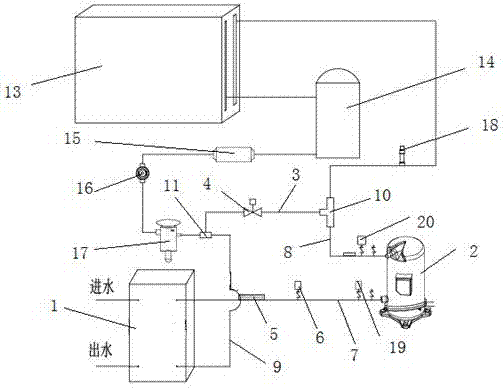

Cold water air conditioner system

InactiveCN107131598AEffect of heat transfer efficiencyThe heat transfer efficiency will not affect theSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringPressure balance

The invention discloses a cold water air conditioner system comprising a plate-type evaporator, a compressor and a condenser. The plate-type evaporator, the compressor and the condenser are connected through a pipeline. A temperature sensor and a pressure sensor are mounted on an air suction pipeline of the compressor. A bypass pipeline is connected on an outlet pipeline of the compressor. The other end of the bypass pipeline communicates with an inlet pipeline of the plate-type evaporator. An electromagnetic valve is mounted on the bypass pipeline. When the actual superheat degree is smaller than the standard superheat degree and the air suction pressure is smaller than the standard air suction pressure, the electromagnetic valve is opened. When the actual superheat degree is larger than or equal to the standard superheat degree or the air suction pressure is larger than or equal to the standard air suction pressure, the electromagnetic valve is opened. A pressure balancing valve is not adopted to preventing ice blockage any more but a common electromagnetic valve is adopted to achieve the ice blockage preventing effect, so that the ice blockage preventing cost is reduced greatly. Compared with the pressure balancing valve, the electromagnetic valve is higher in precision, smaller in weight and more precise in controlling, it is guaranteed that the interior of the evaporator is free from icing, and the ice blockage phenomenon of the plate-type evaporator is removed thoroughly.

Owner:YIMIKANG TECH GRP CO LTD

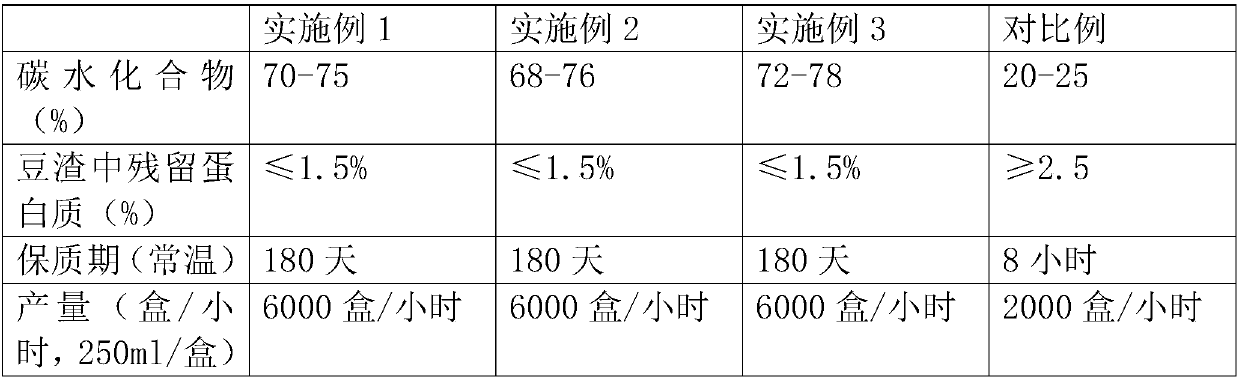

Soybean milk production technology and soybean milk

InactiveCN107771951AExtended shelf lifeAvoid damageMilk substitutesFood scienceBiotechnologyMilk production

The invention provides a soybean milk production technology and soybean milk produced through the technology. The soybean milk production technology is characterized by comprising the following stepsof soaking soybeans; performing grinding to obtain primary soybean milk; performing soybean dreg separation on the primary soybean milk for the first time so as to obtain first-time soybean dregs andfirst-time raw soybean milk; adding water to the first-time soybean dregs, performing boiling over, performing separation to obtain second-time soybean dregs and second-time boiled soybean milk, mixing the first-time raw soybean milk with the second-time boiled soybean milk, performing boiling over so as to obtain soybean milk, and then cooling the soybean milk; performing high-pressure homogenizing: performing homogenizing on the cooled soybean milk; performing ultrahigh-temperature instantaneous sterilization: sterilizing the homogenized soybean milk; and performing cooling, and performing sterile filling so as to obtain packaged soybean milk. Through the adoption of the technology, original flavor of the soybean milk is not destroyed, besides, the soybean milk is good in mouth feel, rich in nutrition and long in quality guarantee period, the protein of the soybean milk is not destructed, residual protein in the soybeans can be sufficiently extracted, the protein content can reach the demand of filled soybean milk, and besides, the input-output ratio of the soybeans and the soybean milk is reduced.

Owner:四川南溪庶人食品有限公司

Ice making device and refrigerator with same

ActiveCN102435029AAvoid it happening againGuaranteed purityDomestic cooling apparatusLighting and heating apparatusForeign matterWater flow

The invention provides an ice making device and a refrigerator with the same. The ice making device comprises an ice making tray, an ice making tray support and a water injection funnel, wherein a plurality of ice making grids are limited in the ice making tray, the ice making tray is matched in the ice making tray support, the ice making tray support comprises a top plate covered above the ice making tray, and the top plate is provided with a water injection port; and the water injection funnel is arranged at the water injection port and used for injecting water to the plurality of ice making grids. According to the ice making device of the embodiment, the water injection height can be shortened, and the water is prevented from splashing from the ice making grids to generate bubbles in ice cubes; through the top plate, the probability that dust, foreign matter and food smell enter the ice making tray support can be effectively reduced, and the purity of the ice cubes is ensured; the water injection funnel can retard the water flow rate, so that water injection is more stable, and the water is further prevented from splashing; and finally, the ice making device of the embodiment is simple in structure and convenient to manufacture.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

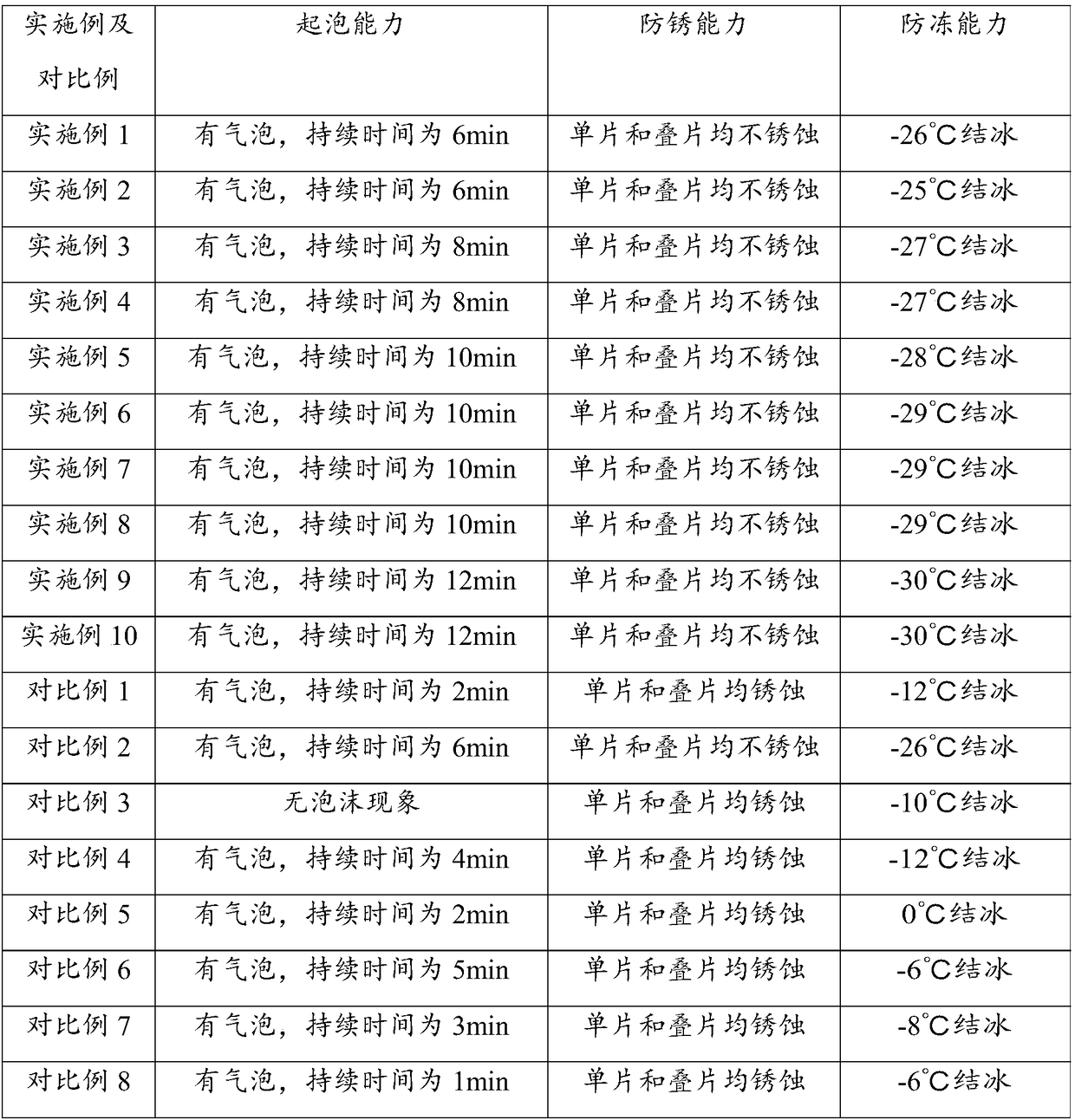

Leakage detection solution as well as preparation method and application thereof

InactiveCN108489682AGood foaming effectImprove rust resistanceDetection of fluid at leakage pointAnti freezingAir tightness

The invention provides leakage detection solution as well as a preparation method and application thereof and relates to the technical field of air tightness tests. The leakage detection solution comprises the following components by weight percent: 0.5-22.5% of a surfactant, 0.08-4% of a thickening agent, 0.2-18.5% of an antirust agent, 30-55% of an antifreezing agent and the balance of water; preferably, the leakage detection solution comprises the following components by weight percent: 5.5-16.5% of a surfactant, 0.3-2% of a thickening agent, 4.5-13.5% of a antirust agent, 35-50% of an antifreezing agent and the balance of water; and more preferably, the leakage detection solution comprises the following components by weight percent: 6.5-11.5% of a surfactant, 0.5-0.6% of a thickening agent, 5.5-9.5% of an antirust agent, 40-45% of an antifreezing agent and the balance of water. The leakage detection solution provided by the invention has better foamability, anti-rust performance and anti-freezing performance.

Owner:韩新民 +1

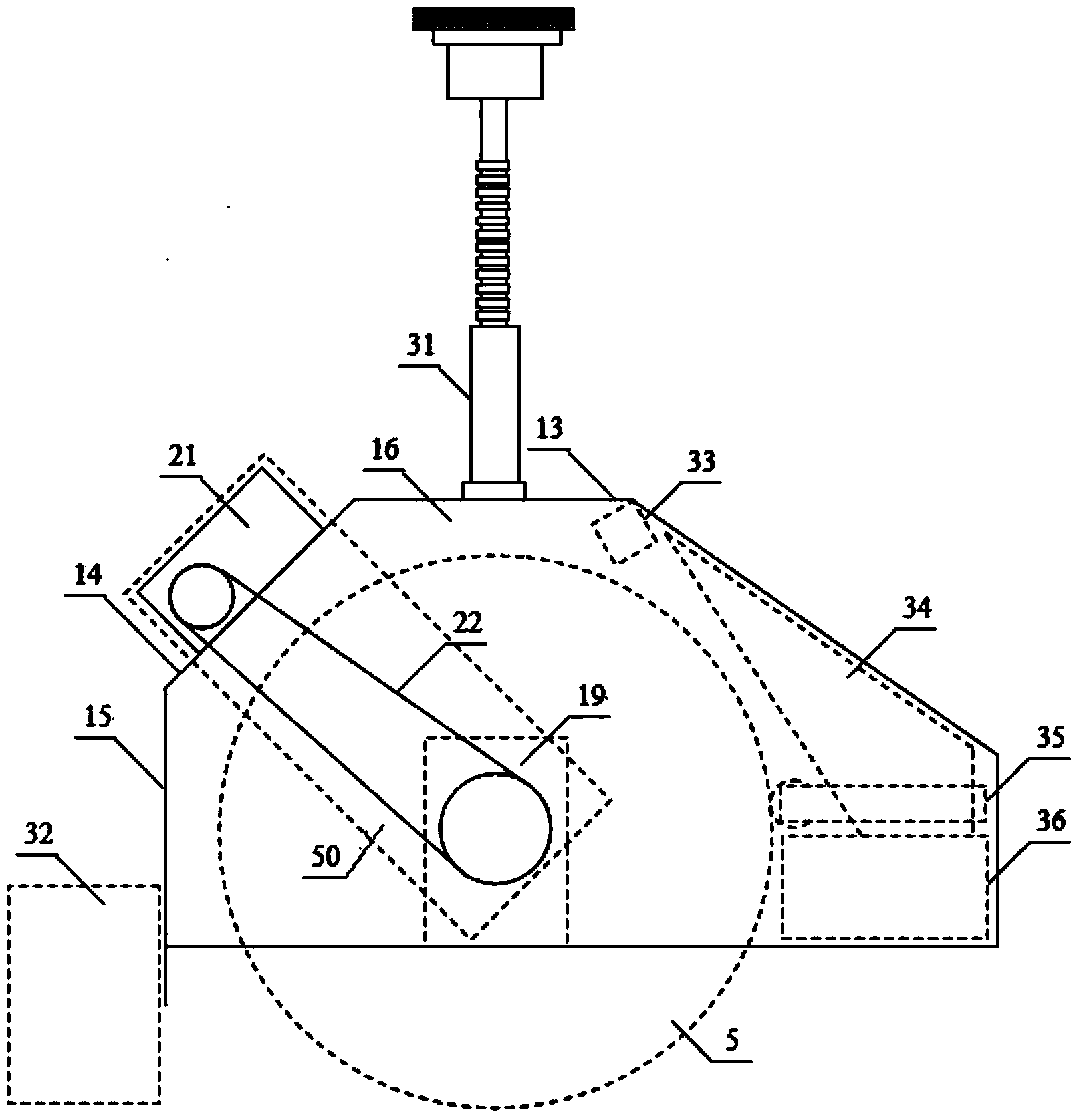

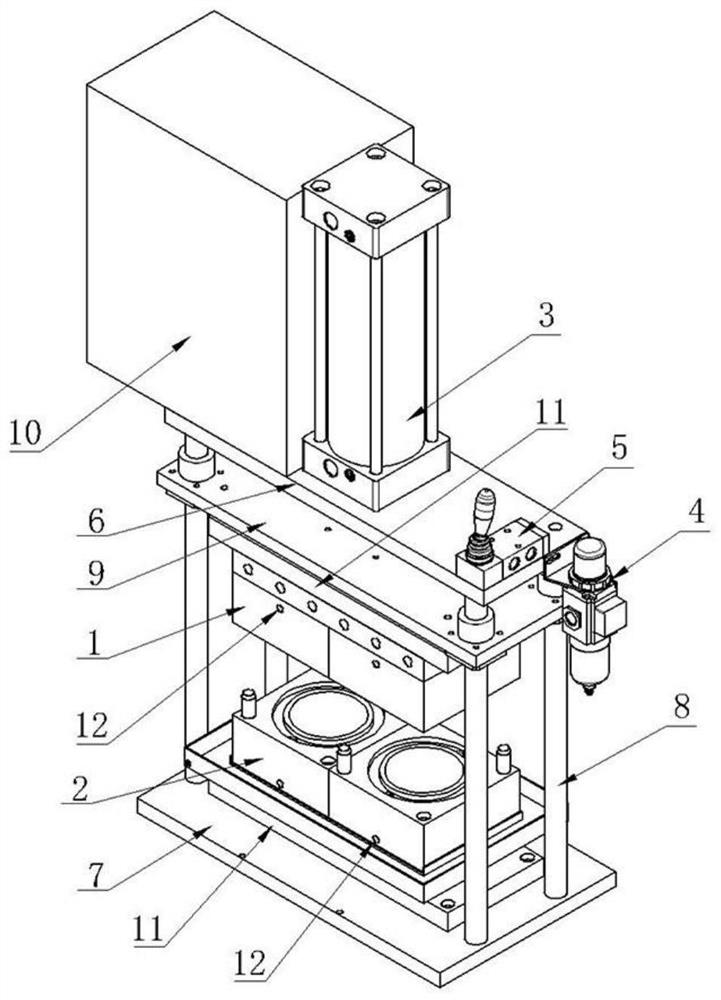

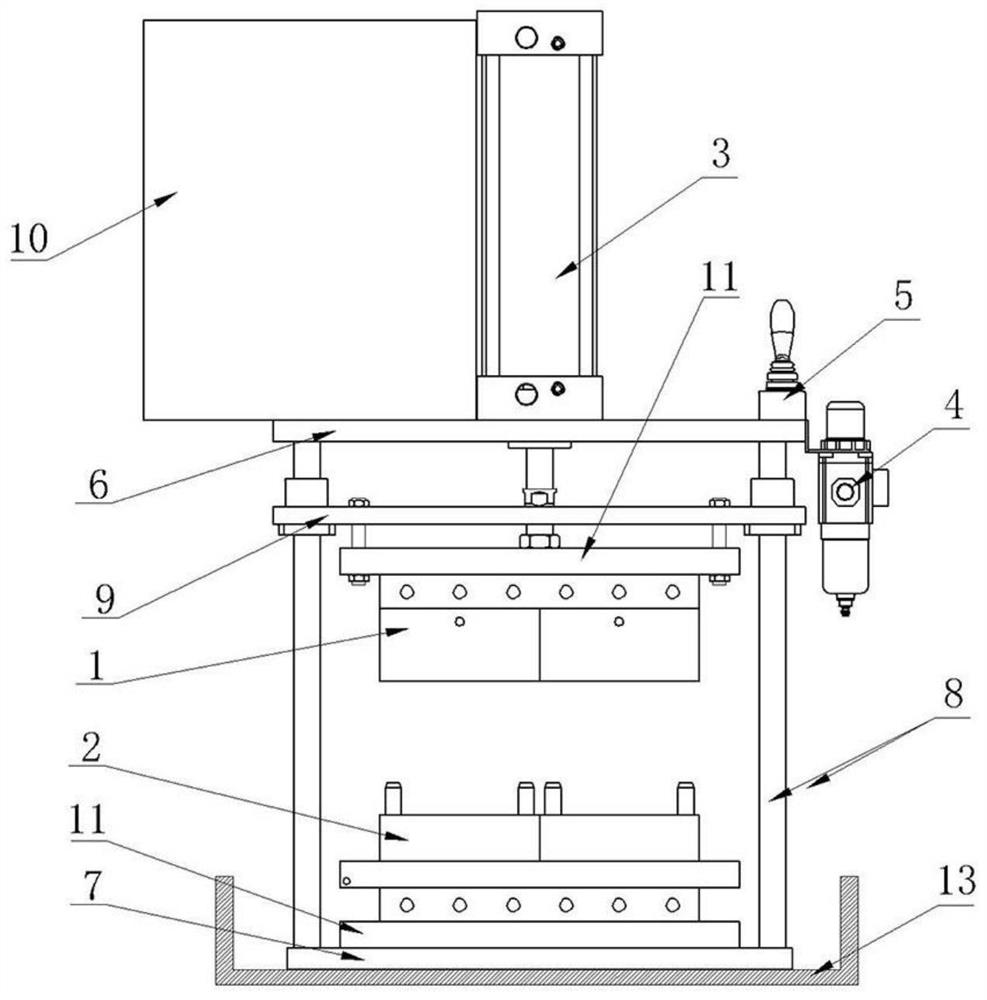

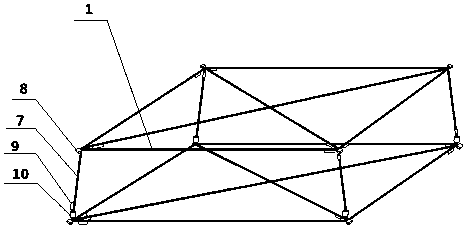

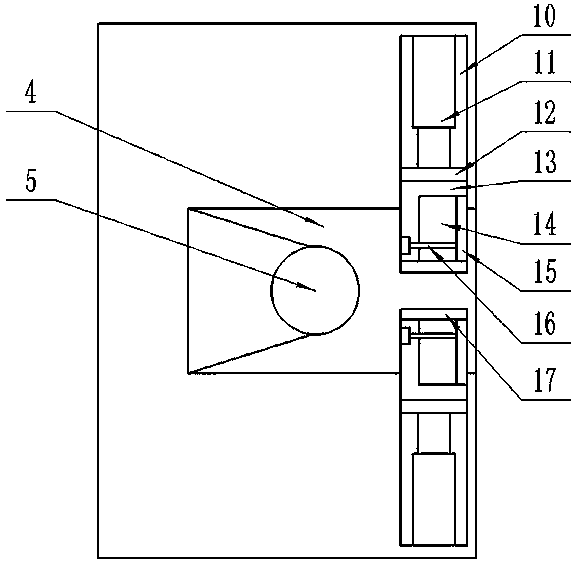

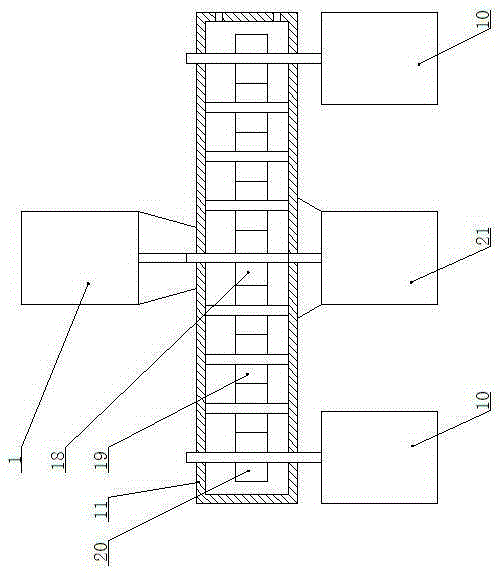

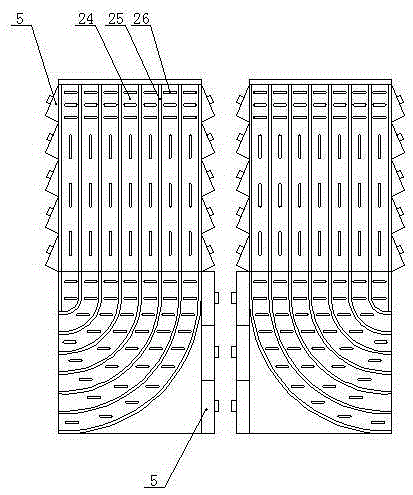

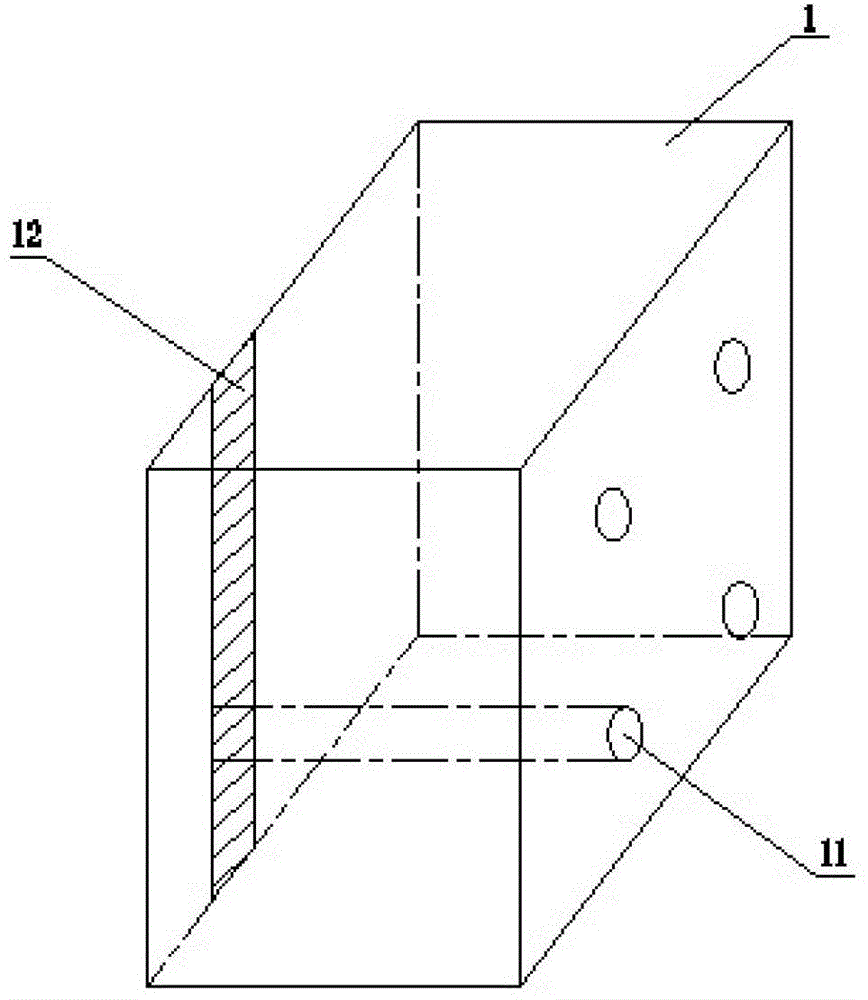

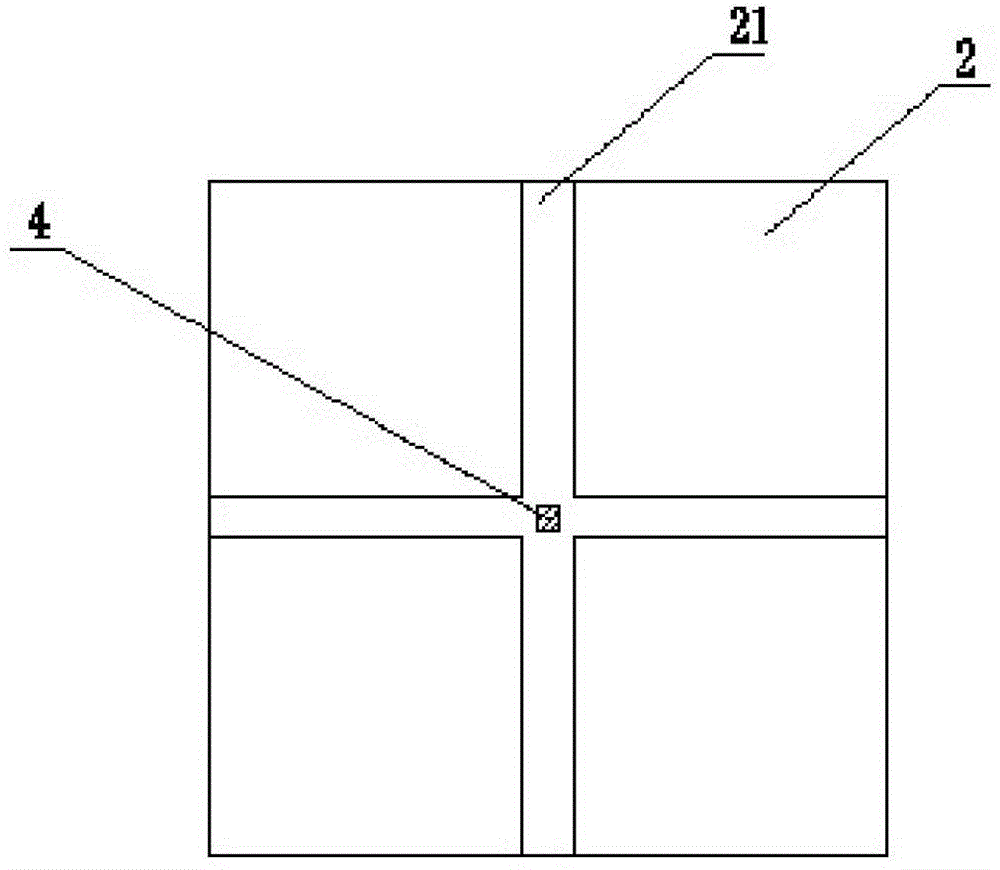

Air pressure drive type ice ball machining device

PendingCN111829243ANo bubblesNo icingLighting and heating apparatusIce storing/distributionPressure.driveAir brake

The invention relates to the field of ice breaking equipment, in particular to an air pressure drive type ice ball machining device. The air pressure drive type ice ball machining device comprises anupper extrusion die, a lower extrusion die, a pneumatic part and a die frame. The upper extrusion die and the lower extrusion die are supported by the die frame. The pneumatic part comprises a drive air cylinder, an air pressure meter and an air brake switch. The die frame comprises a top plate, a bottom plate, a sliding rail frame and an upper die sliding plate. The sliding rail frame is vertically fixed to the bottom plate, the top plate is mounted at the top end of the sliding rail frame, the upper die sliding plate movably sleeves the sliding rail frame through a sliding sleeve block, thedrive air cylinder is fixed to the top plate in a reversely-buckled manner, a cylinder shaft of the drive air cylinder penetrates through the top plate to be connected to the upper die sliding plate,the upper extrusion die is fastened at the lower end of the upper die sliding plate, the lower extrusion die is fastened on the bottom plate, and at least one semispherical die cavity is formed in each of the upper extrusion die and the lower extrusion die. According to the device, irregular ice blocks can be extruded into spherical ice blocks, the machining rate is high, the device is suitable for volume production in places such as factories, and the machined ice balls are smoother in shape and are not prone to melt.

Owner:重庆机电职业技术大学

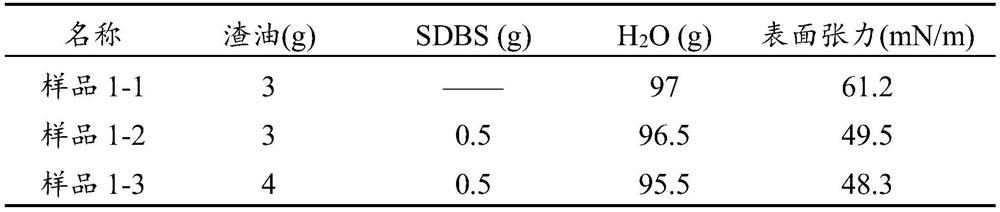

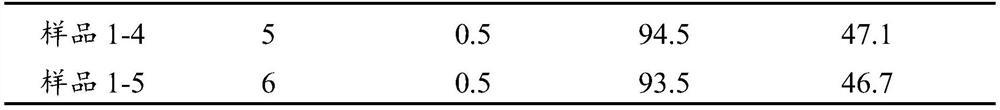

Composite dust suppressant as well as preparation method and application thereof

ActiveCN113512405AIncrease stickinessGood evaporation resistanceOther chemical processesDust removalPhysical chemistryEnvironmental engineering

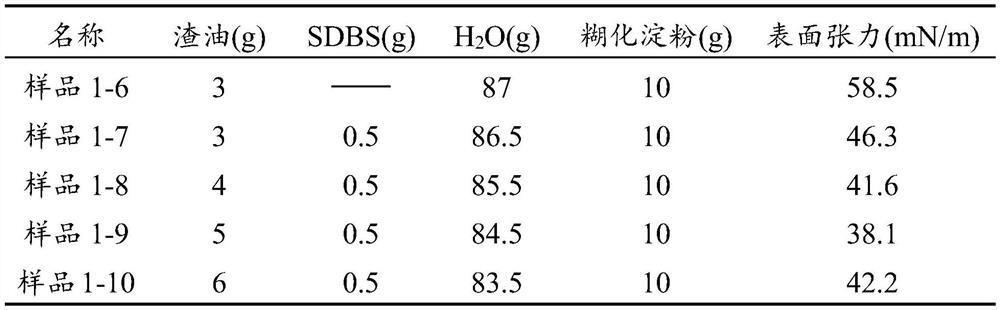

The invention relates to the technical field of dust suppressants, and provides a composite dust suppressant. According to the composite dust suppressant provided by the invention, the evaporation resistance of the composite dust suppressant is improved by adding the residual oil, the gelatinized starch and the non-cationic water-soluble polymer; through multiple cooperation of the strong electrolyte, the non-cationic water-soluble polymer, the non-cationic surface active agent and the chelating agent, the surface tension of the dust suppressant is reduced to about half of that of water, so that the dust suppressant has excellent wettability to dust; by adding halide, the freezing resistance of the dust suppressant is improved, and the dust suppressant cannot be frozen at the temperature of -26.6 DEG C to-20.3 DEG C. The composite dust suppressant obtained by the invention has a good dust suppression effect, and can effectively reduce the dust concentration in the open pit coal mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

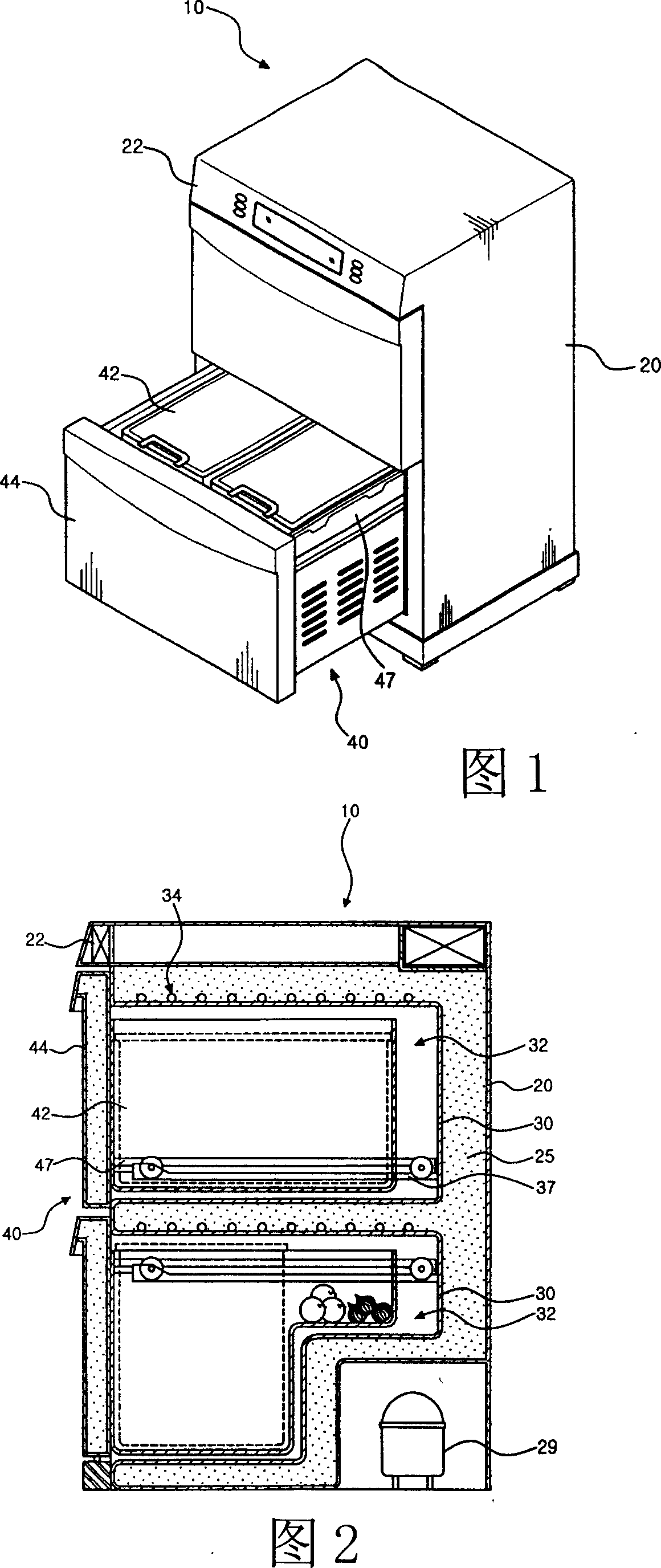

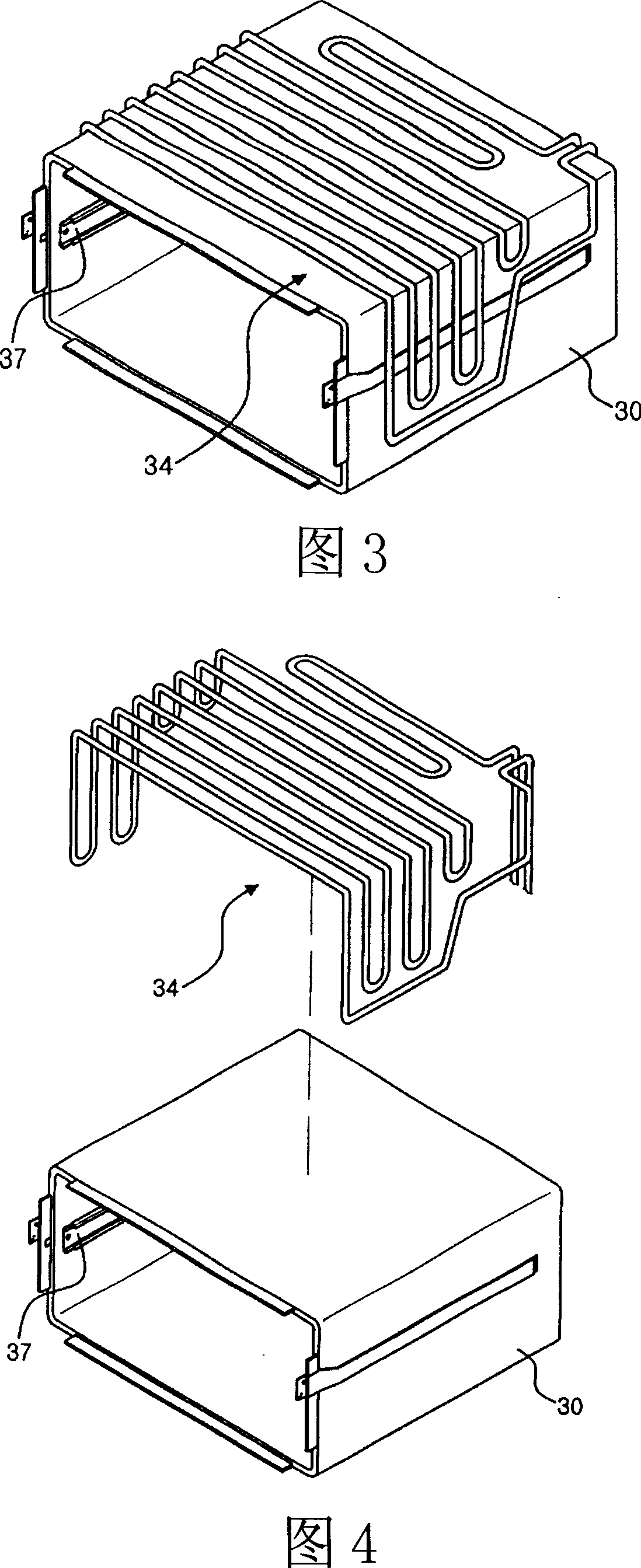

Anti-icing evaporator pipe structure for drawer type kraut refrigerator

InactiveCN1952539ASimple structureEfficient heat exchangeDomestic refrigeratorsEvaporators/condensersEngineeringRefrigerated temperature

The invention relates to a pipe structure of anti-icing evaporator for drawer pickle refrigerator, comprising bending pipe part set on two sides of said shell; straight pipe part set on the upper of said shell and connecting said bending pipe part at two sides. In the invention by improving the structure of evaporator pipe in the shell, icing on the top of said shell is prevented so as to prevent food deteriorating because of overcooling or water changed by ice. The opening-closing of said drawer container is smooth.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Anti-icing coating for power transmission cables and preparation method of anti-icing coating

InactiveCN111471396AImprove temperature resistanceGood anti-adhesionFireproof paintsAntifouling/underwater paintsTetrafluoroethyleneEngineering

The invention discloses an anti-icing coating for power transmission cables. The anti-icing coating is prepared from the following raw materials in parts by weight: 30-45 parts of fluorosilicone resin, 20-30 parts of phosphate modified acrylic emulsion, 5-15 parts of tetrafluoroethylene-ethylene copolymer, 5-10 parts of hollow glass beads, 1-3 parts of a dispersing agent, 0.5-1 part of a levelingagent, 0.1-0.5 part of an antifoaming agent, 1-2 parts of a coupling agent and 20-40 parts of a solvent. The anti-icing coating disclosed by the invention is excellent in hydrophobic property and goodin adhesion property with a power transmission cable, so that the anti-icing property of the cable is excellent.

Owner:国网河南省电力公司南召县供电公司

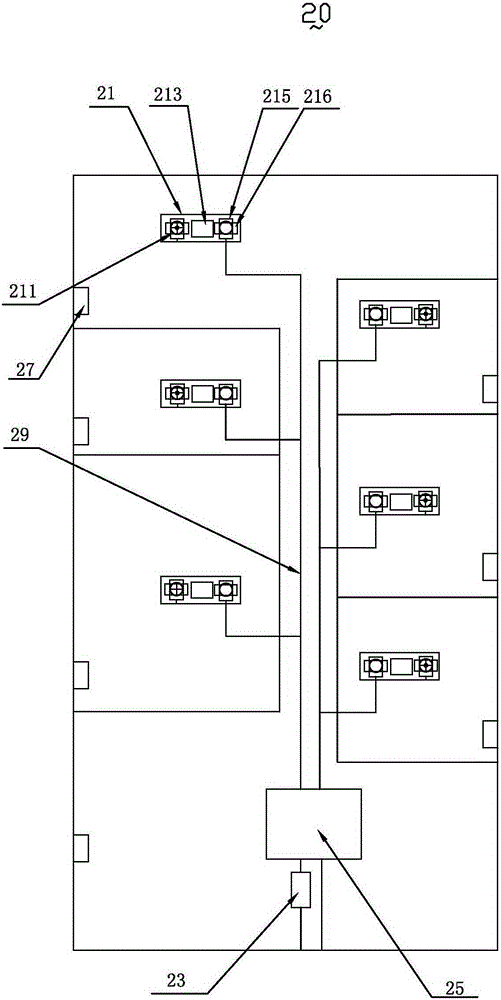

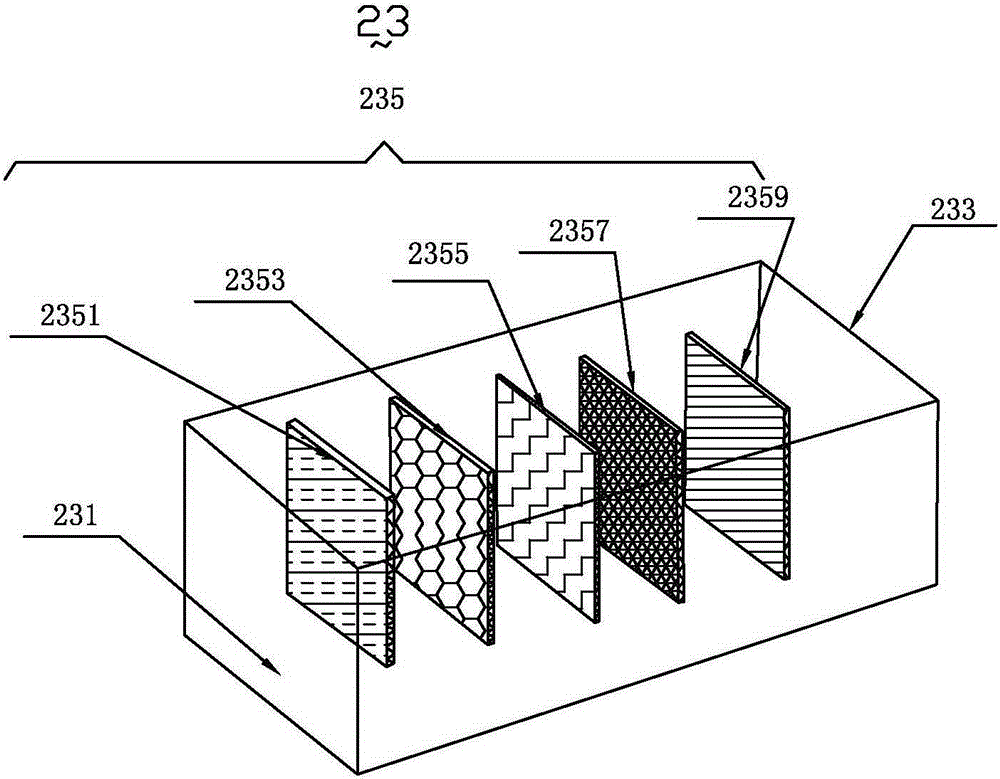

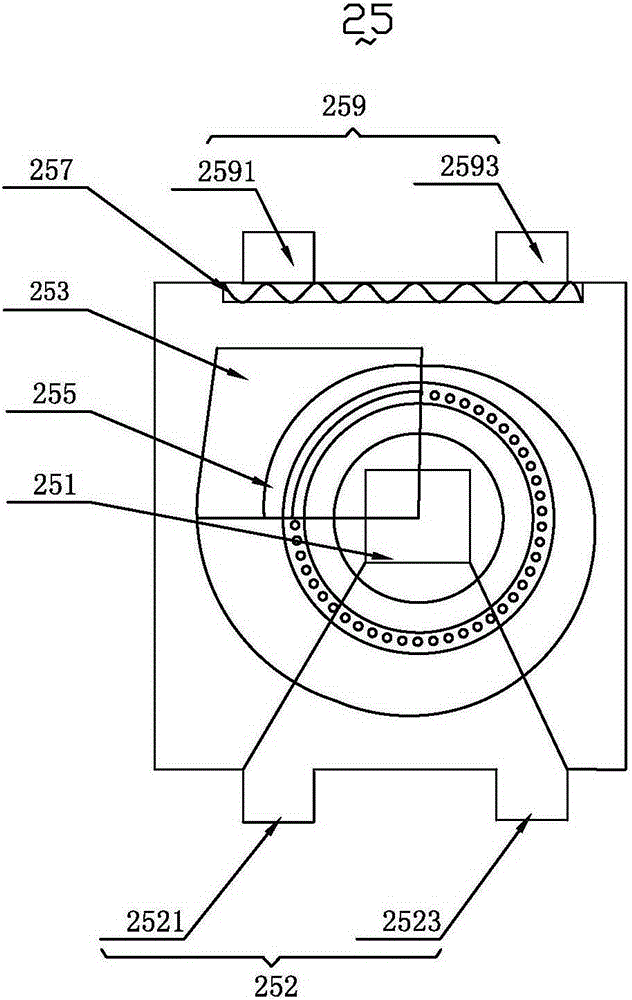

Multifunctional suspended ceiling system

InactiveCN106705291AImprove air supply capacityImprove filtering effectMechanical apparatusSpace heating and ventilation safety systemsAtmospheric airAir filter

The invention provides a multifunctional suspended ceiling system. A keel structure which is connected with a wall body is provided. The multifunctional suspended ceiling system comprises a purifier, an intelligent fan, suspended ceiling integration modules, a pipeline and control modules. One or more suspended ceiling integration modules are connected with the keel structure and arranged on ceilings of indoor spaces. The purifier, the intelligent fan and the suspended ceiling integration modules are communicated in sequence through the pipeline, one end of the pipeline is communicated with the outdoor atmosphere, and the other end of the pipeline is communicated with the indoor spaces through the suspended ceiling integration modules. The control modules are arranged on the wall of a room, and the control modules, the intelligent fan and the suspended ceiling integration modules are electrically connected to form a control loop. The multifunctional suspended ceiling system has a good air filtering effect, can provide the real healthy fresh air environment for a user, has the strong air supply capacity, takes silence into account, and provides more comfortable and easeful living and working environments for the user.

Owner:深圳市西澳实业有限公司

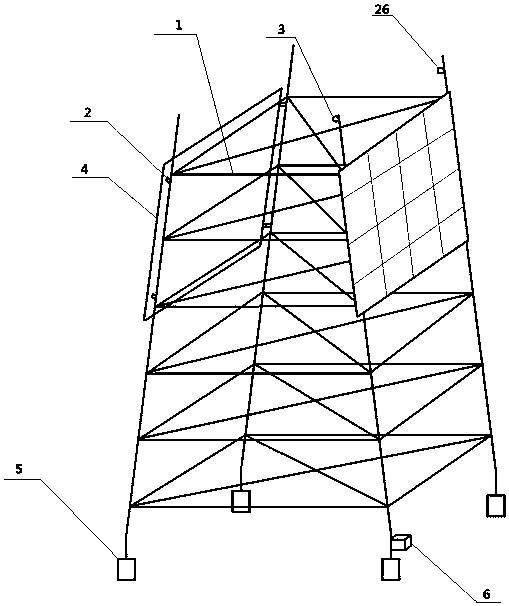

Novel monitoring and deicing iron tower

PendingCN108533051ALower resistanceReduce workloadTowersPhotovoltaic energy generationEngineeringControl room

The invention discloses a novel monitoring and deicing iron tower. The novel monitoring and deicing iron tower comprises a tower body which is mainly constituted by four main supporting rods and a plurality of cross arms. Each main supporting rod is mainly formed by a plurality of vertical rods which are connected. The two ends of each cross arm are mounted on the connecting position of every twovertical rods on the two corresponding sides correspondingly. The novel monitoring and deicing iron tower further comprises a stress detecting device, a gravity detecting device and a control chamber.The stress detecting device is mounted on the outer side faces of the connecting positions of the vertical rods and the cross arms. The gravity detecting device is mounted between the vertical rods connected in pairs. Retractable heating devices are mounted on the cross arms and the vertical rods correspondingly, and the control chamber is formed in the tower body. A temperature sensor and an icing sensor are mounted on the tower body, and a solar panel is arranged on the tower body. According to the novel monitoring and deicing iron tower, the structural design is ingenious, by arranging theretractable heating devices, the stress detecting device and the gravity detecting device on the tower body, ice covering the iron tower can be effectively removed, and loosening and inclination situations of the connecting positions of the iron tower are effectively monitored to avoid collapse accidents.

Owner:梁雪 +1

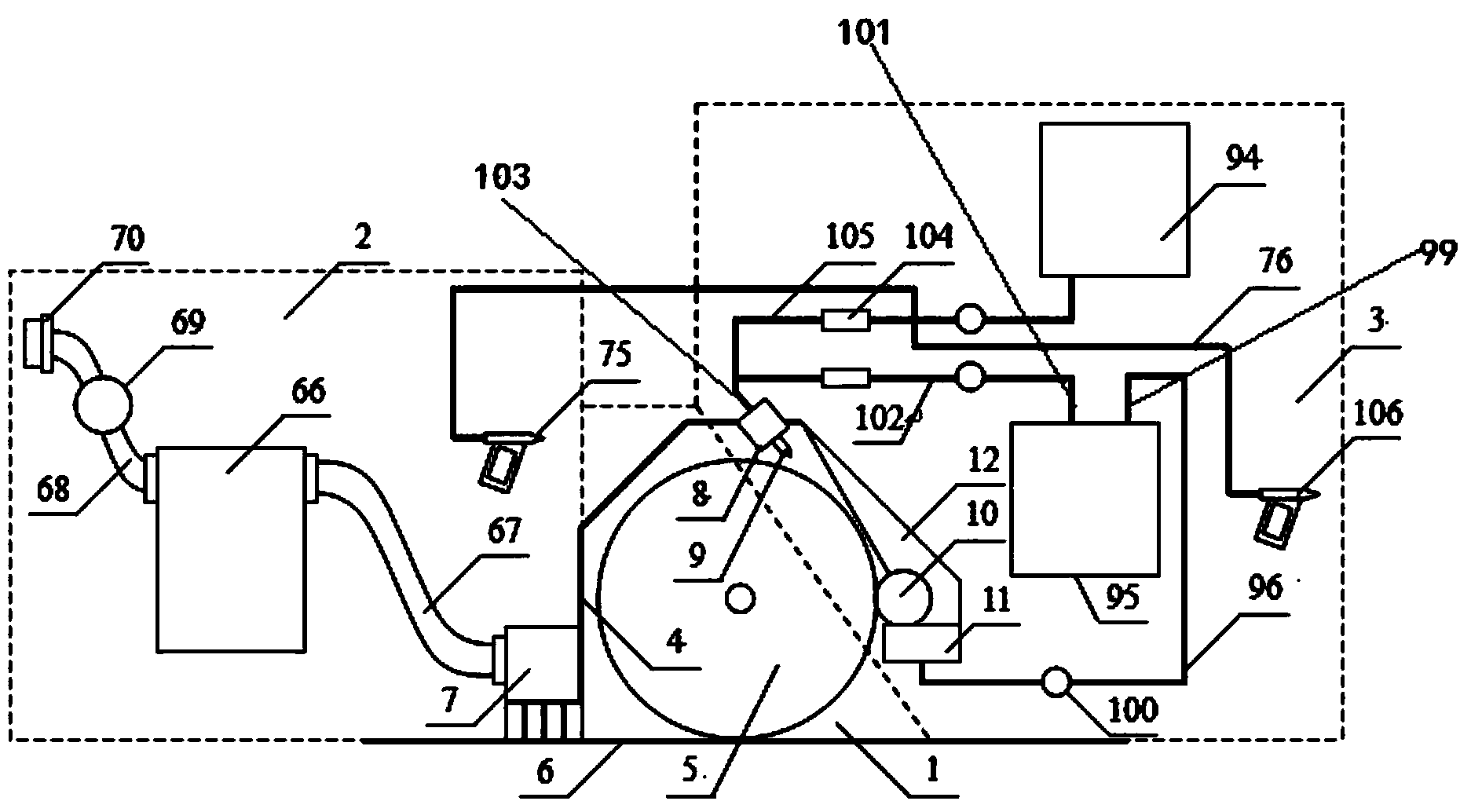

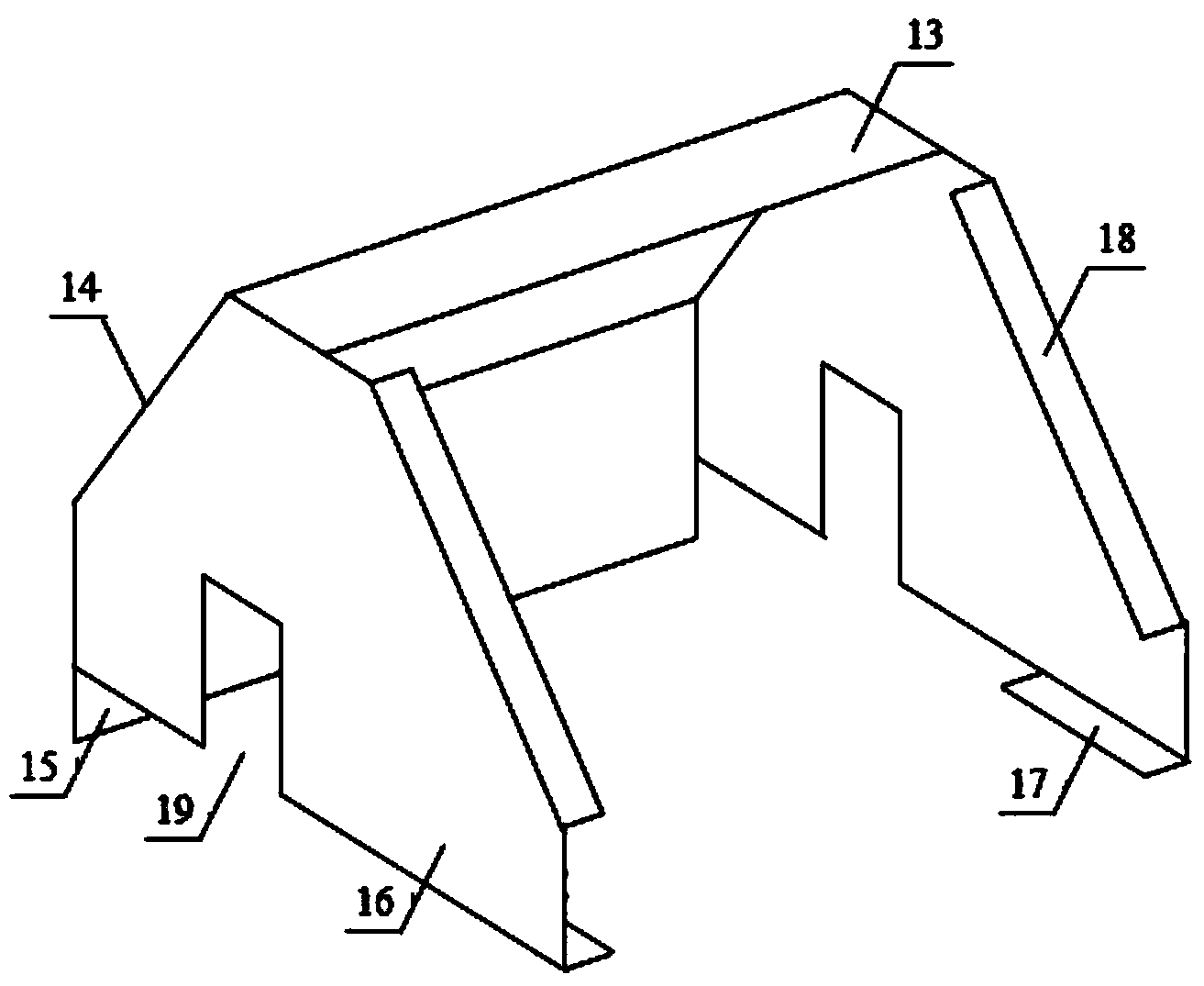

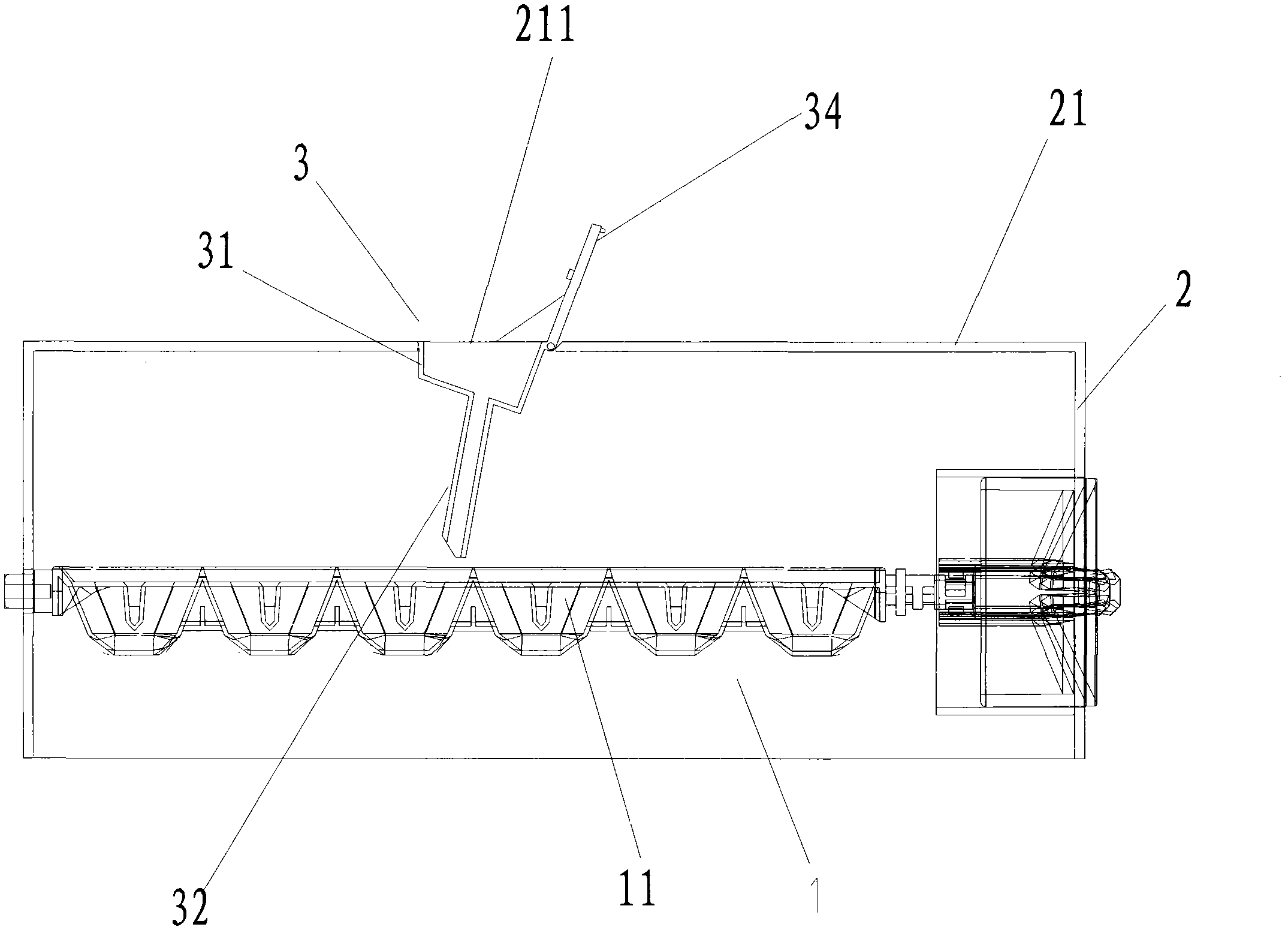

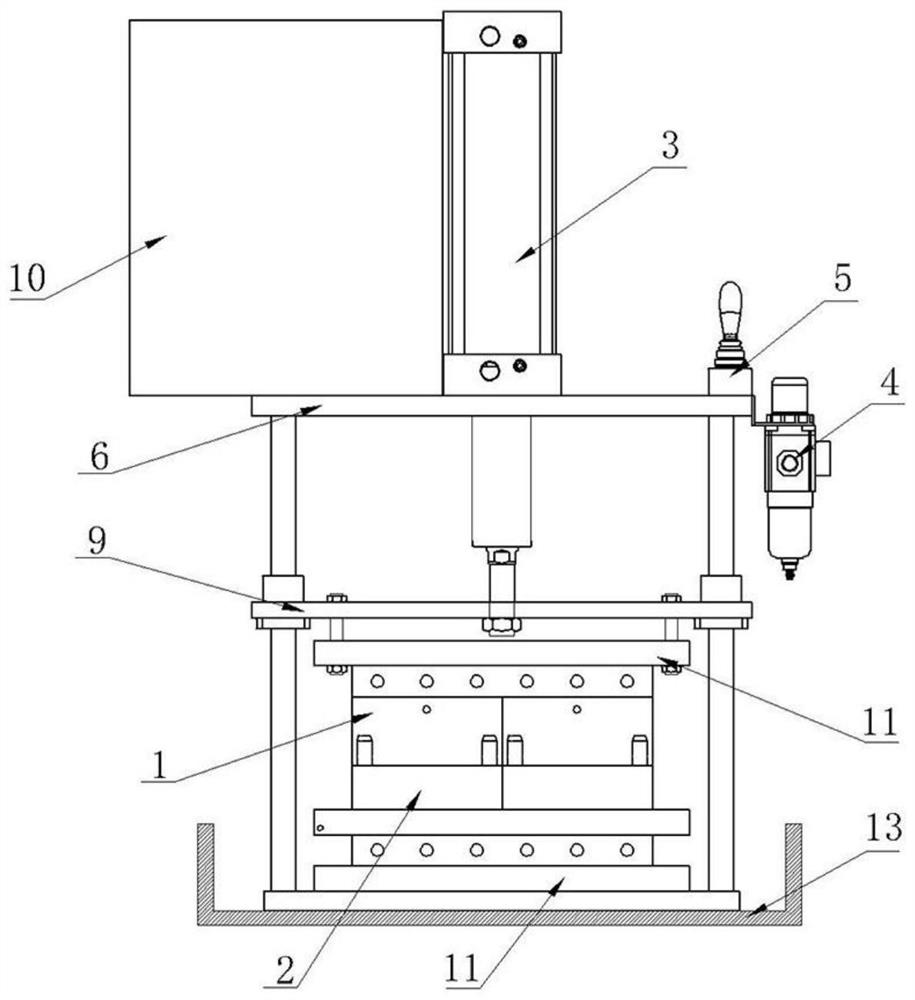

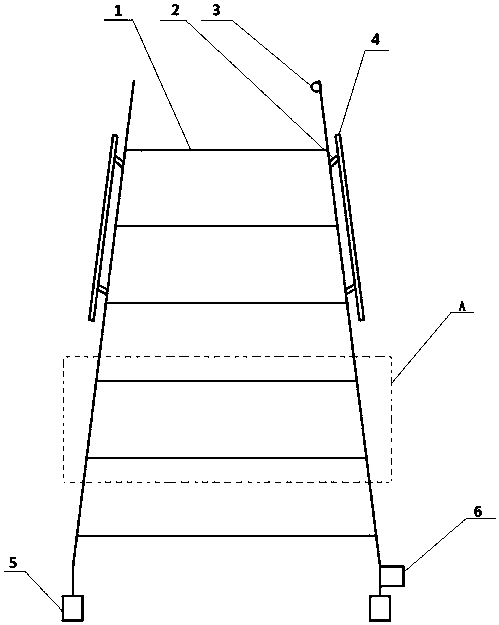

Gravity extrusion type single-ball ice press

PendingCN111947365ANo bubblesNo icingLighting and heating apparatusIce storing/distributionEngineeringMechanical engineering

The invention relates to the field of ice crushing equipment, in particular to a gravity extrusion type single-ball ice press. The gravity extrusion type single-ball ice press comprises an upper extrusion die, a lower extrusion die, two lifting frames, a base groove, a pressing hammer and a top cover plate, wherein the top cover plate and the base groove are installed at the upper ends and the lower ends of the lifting frames, the upper extrusion die is fixed to the lower bottom surface of the top cover plate, the lower extrusion die is fixed inside the base groove, the upper extrusion die andthe lower extrusion die are opposite to each other up and down and are fixed between the two lifting frames, and in addition, hemispherical die cavities are formed in the upper extrusion die and thelower extrusion die correspondingly; and the two lifting frames are extendable sleeves, and when the pressing hammer is placed on the top cover plate, the extendable sleeves contract under extrusion of the pressing hammer, and the upper extrusion die of the gravity extrusion type single-ball ice press moves towards the direction of the lower extrusion die. The gravity extrusion type single-ball ice press is simple in structure, and small in size, when ice balls are made, eat-and-make is achieved, the efficiency is high, the made ice balls have the characteristics of being free of bubbles and ice residues, high in ornamental value, edible, slow in melting and the like, ice blocks in irregular shapes can be extruded into spherical ice blocks, and the gravity extrusion type single-ball ice press is suitable for dining halls, and restaurants for use.

Owner:重庆机电职业技术大学

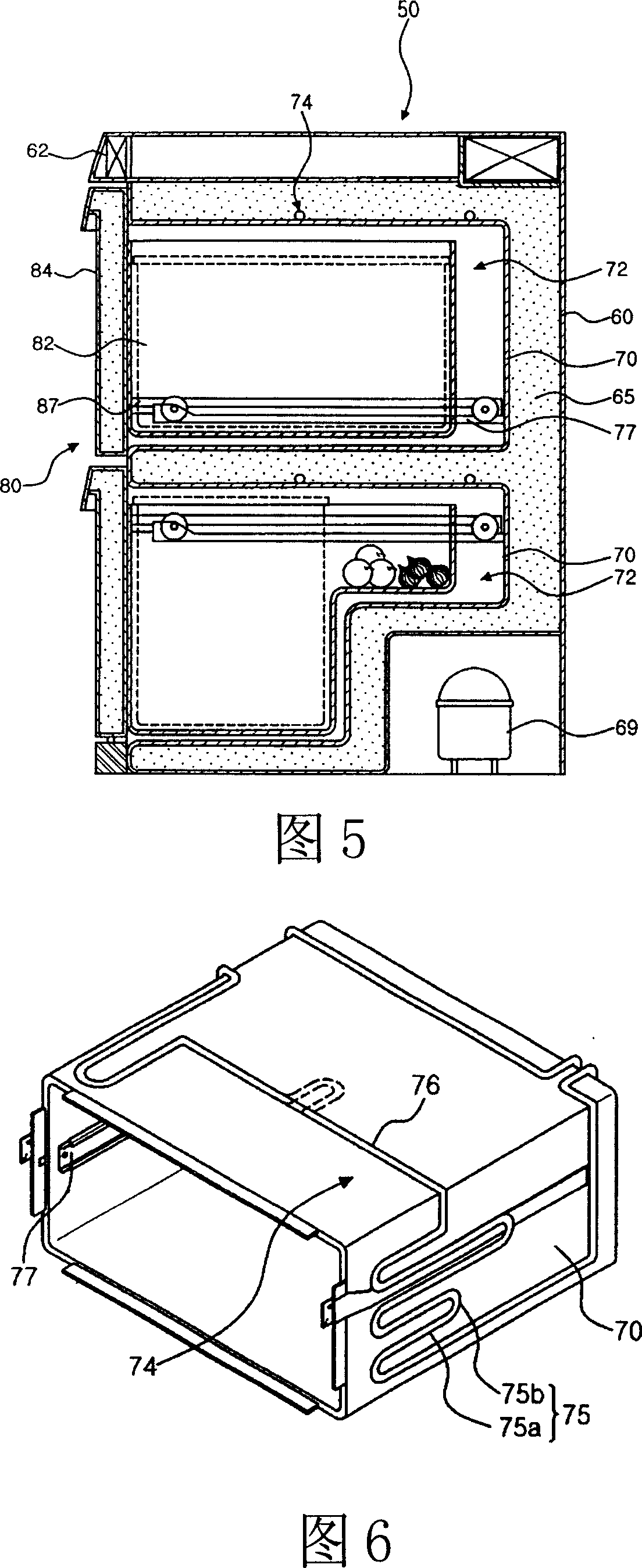

Container device with internal environment capable of being adjusted

The invention discloses a container device with the internal environment capable of being adjusted. The container device comprises a container body, sliding groove sealing devices are arranged on thetwo sides of the container body, an automatic baffle adjusting device is arranged in the container body and provided with an intelligent refrigeration device, the container body is provided with a container door sealing device, a refrigeration space in the container body is adjusted through a baffle for refrigeration of objects, and thus electric energy consumption is reduced. Sliding grooves aresealed through the sliding groove sealing devices, and the situation that the sliding grooves are frozen to hinder moving of the baffle. The container device has the beneficial effects of simple structure and high practicability.

Owner:山东鹤鹏技术有限公司

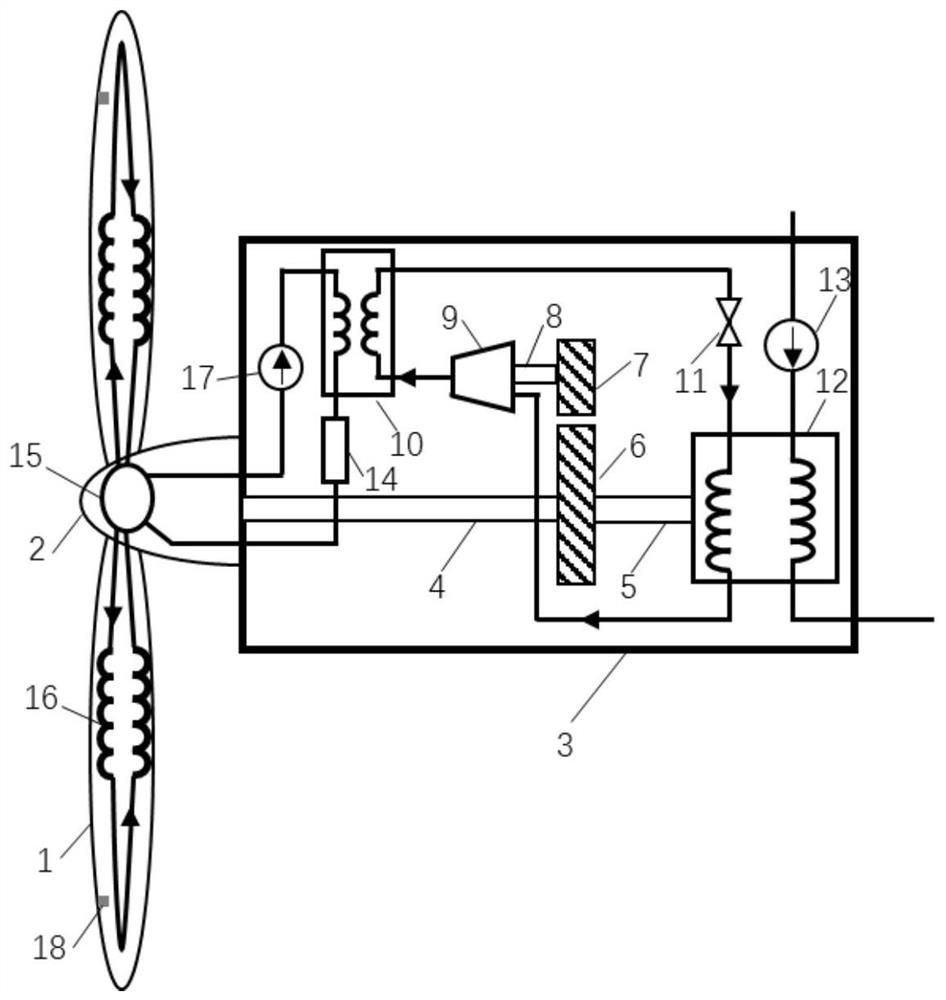

Wind generating set with heat pump self-deicing system and working method of wind generating set

The invention discloses a wind generating set with a heat pump self-deicing system and a working method of the wind generating set, and belongs to the technical field of wind power generation. Blades are connected with a hub, the hub is connected with a low-speed shaft, the low-speed shaft is connected with a gear transmission system, and the gear transmission system is connected with a generator high-speed shaft and a heat pump loop high-speed shaft. The generator high-speed shaft is connected with a generator, and a generator cooling heat exchanger is arranged in the generator. The heat pump loop high-speed shaft is connected with a compressor of the heat pump circulation loop. A heater and a deicing fan are arranged on a blade deicing circulation loop, and the blade deicing circulation loop communicates with a blade deicing device. A blade tip thermodetector is arranged on each blade. The heat pump circulation loop and the blade deicing circulation loop exchange heat in a blade deicing heat exchanger in an alternating mode, and the heat pump circulation loop and an external cooling loop exchange heat in the generator cooling heat exchanger in an alternating mode. According to the wind generating set with the heat pump self-deicing system and the working method of the wind generating set, the overall energy utilization rate of the wind generating set can be increased, the power generation efficiency of the wind generating set is improved, and good application prospects are achieved.

Owner:HUANENG CLEAN ENERGY RES INST

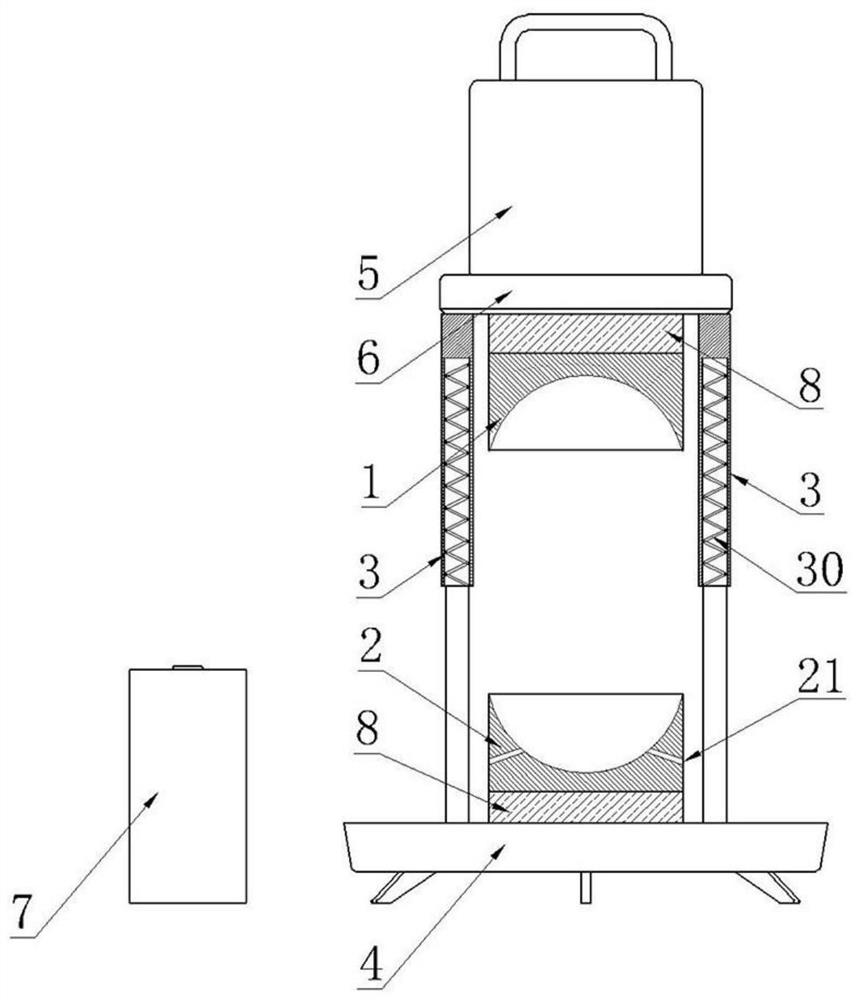

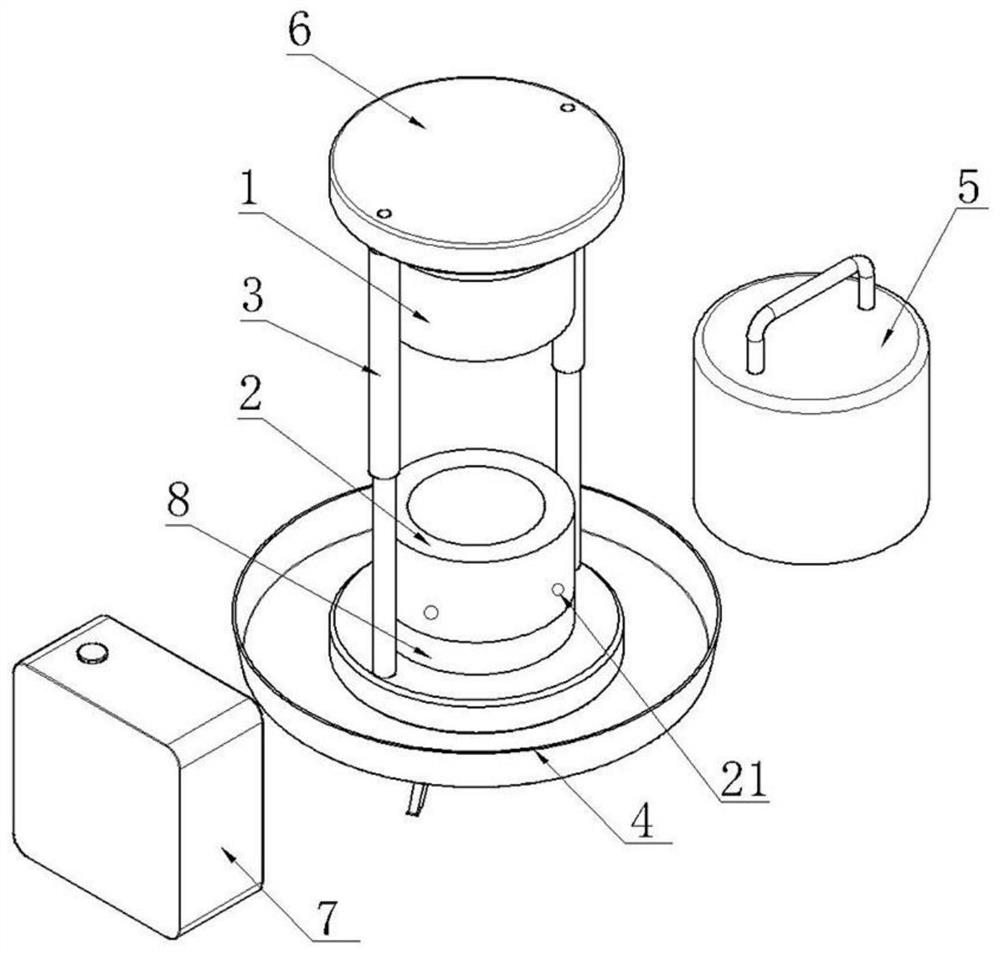

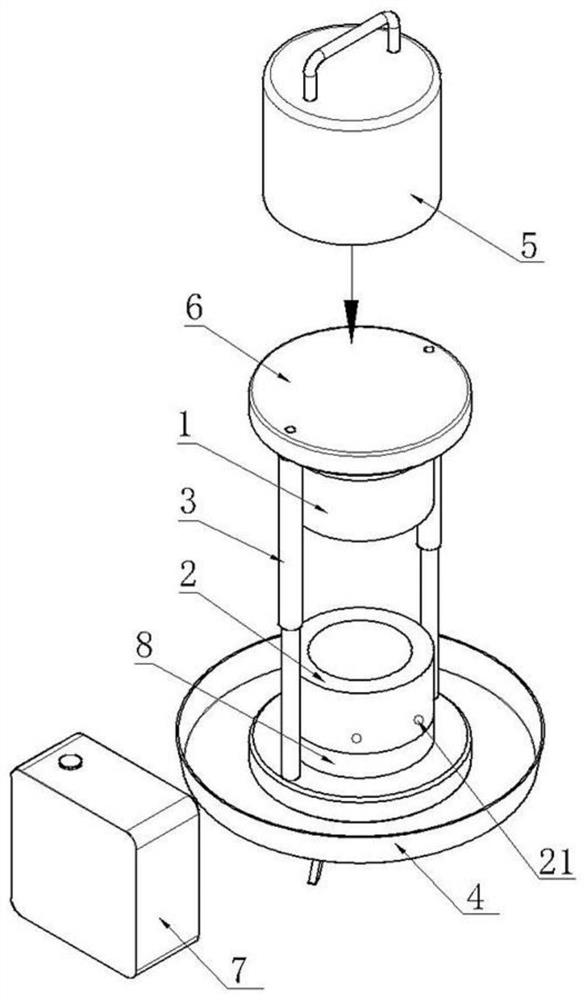

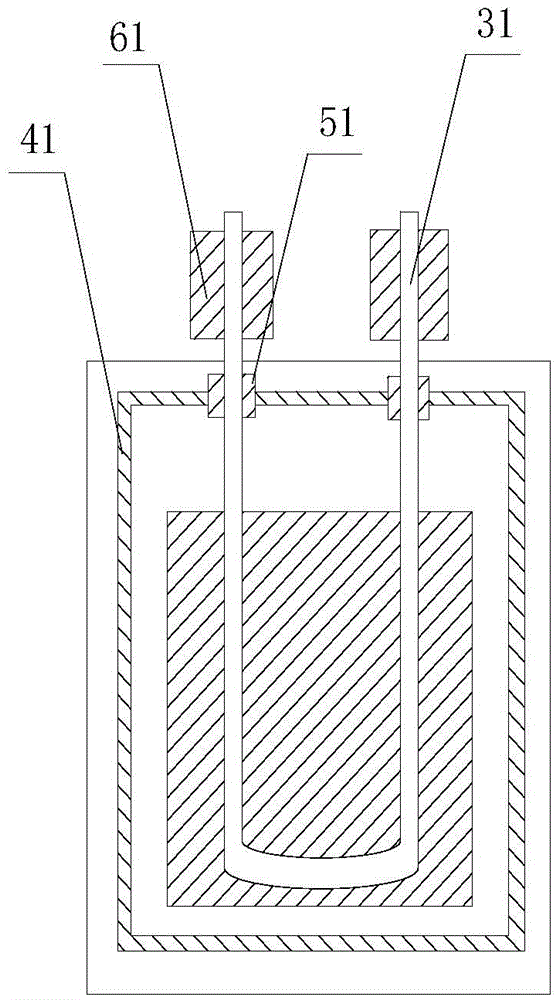

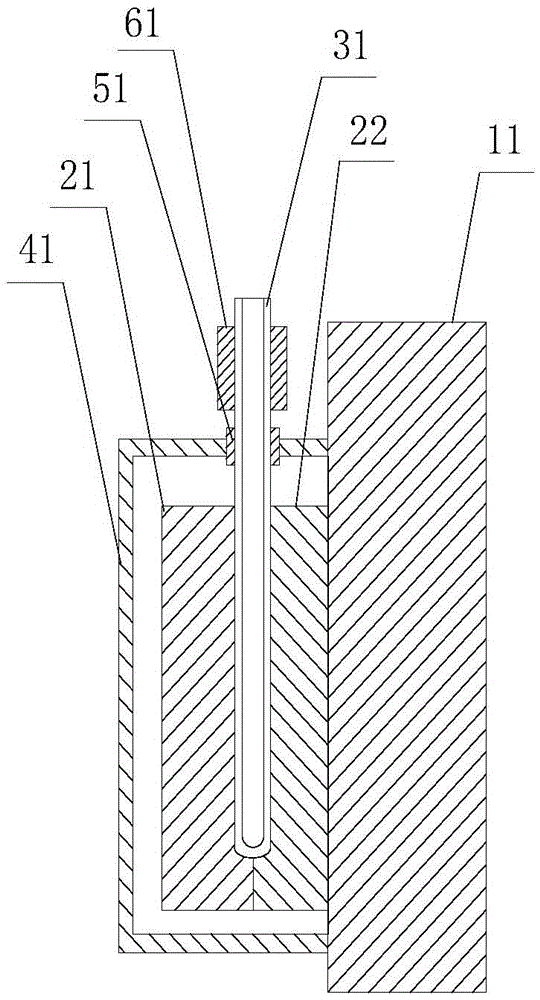

Adsorption heat desorption device

InactiveCN105466756AEasy maintenanceReduced disassembly workloadComponent separationPreparing sample for investigationHeat conductingDesorption

The invention provides an adsorption heat desorption device. The adsorption heat desorption device comprises a refrigerator and an enrichment pipe and further comprises heat conducting bodies and a heat insulation cover, wherein the heat conducting bodies are installed on the refrigerating surface of the refrigerator, the enrichment pipe is buried in the heat conducting bodies in a bent mode, the heat insulation cover is arranged on the periphery of the first heat conducting body and the second heat conducting body and fixed to the refrigerator, and an air inlet and an air outlet are formed in the heat insulation cover. The adsorption heat desorption device has the advantages of being small in size, convenient to dismount and the like.

Owner:FOCUSED PHOTONICS

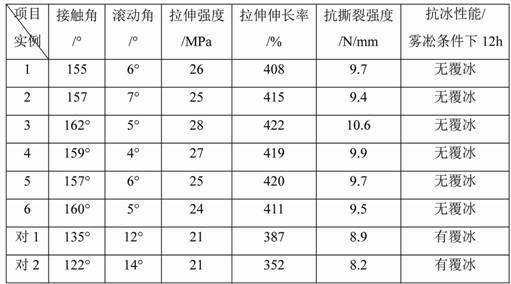

High-toughness ice-covering-resistant cable

ActiveCN111681823AImprove hydrophobicityImprove antifouling performancePower cables with screens/conductive layersInsulated cablesLinear low-density polyethyleneStearic acid

The invention discloses a high-toughness ice-covering-resistant cable, which comprises a core body, a shielding layer and an ice-covering-resistant layer, wherein the ice-covering-resistant layer is prepared from the following raw materials in parts by weight: 40-50 parts of a fluorosilicone resin, 25-35 parts of linear low-density polyethylene, 10-20 parts of maleic anhydride grafted polyethylene, 1-3 parts of stearic acid, 5-10 parts of magnesium hydroxide, 3-8 parts of modified Co3O4, 10-15 parts of hydroxyl silicone oil, 1-2 parts of an anti-aging agent, 0.5-2 parts of a silane coupling agent and 1-3 parts of an accelerant. The ice-covering-resistant cable is excellent in hydrophobic performance, excellent in low temperature resistance and ice-covering-resistant effect, high in strength and good in toughness.

Owner:国网河南省电力公司新野县供电公司

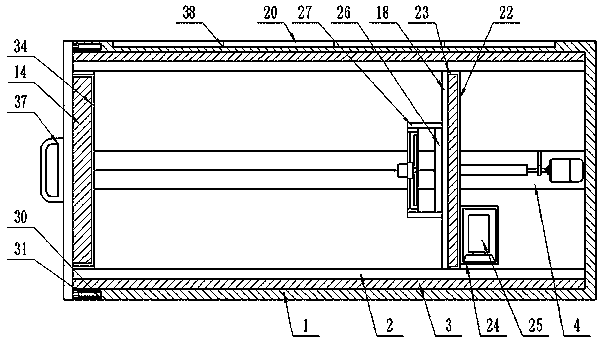

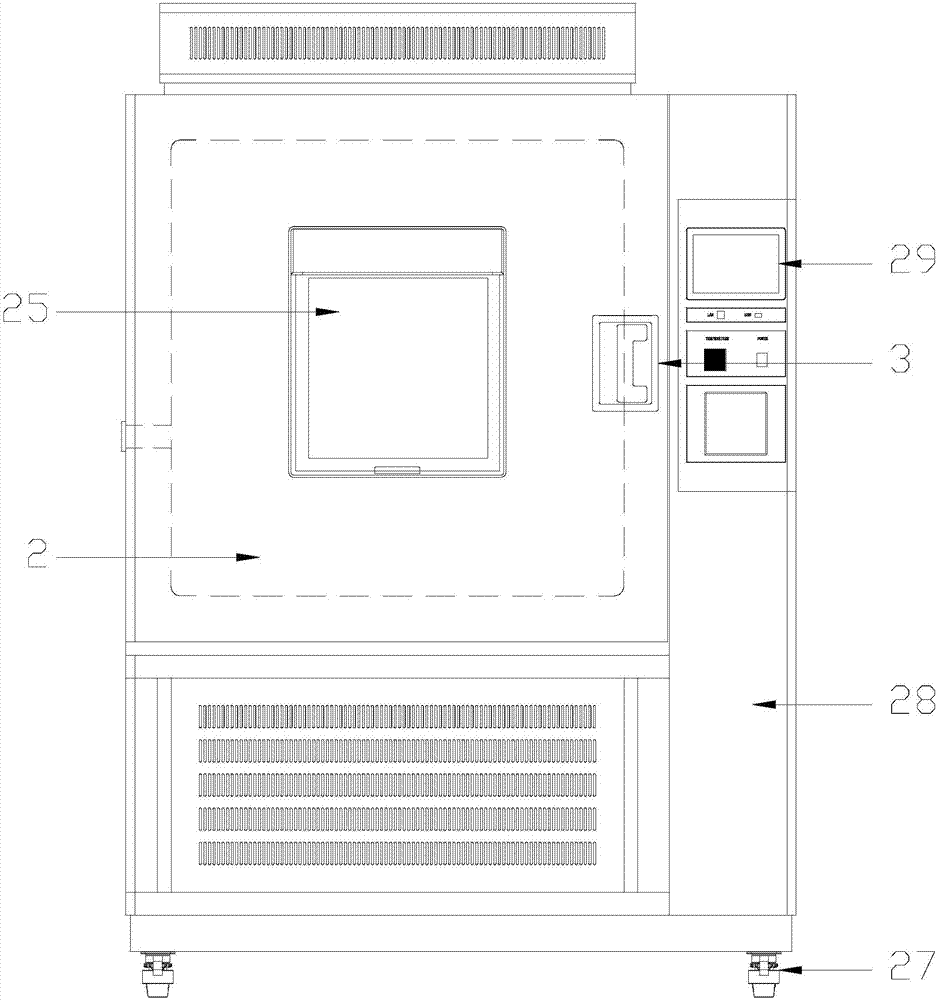

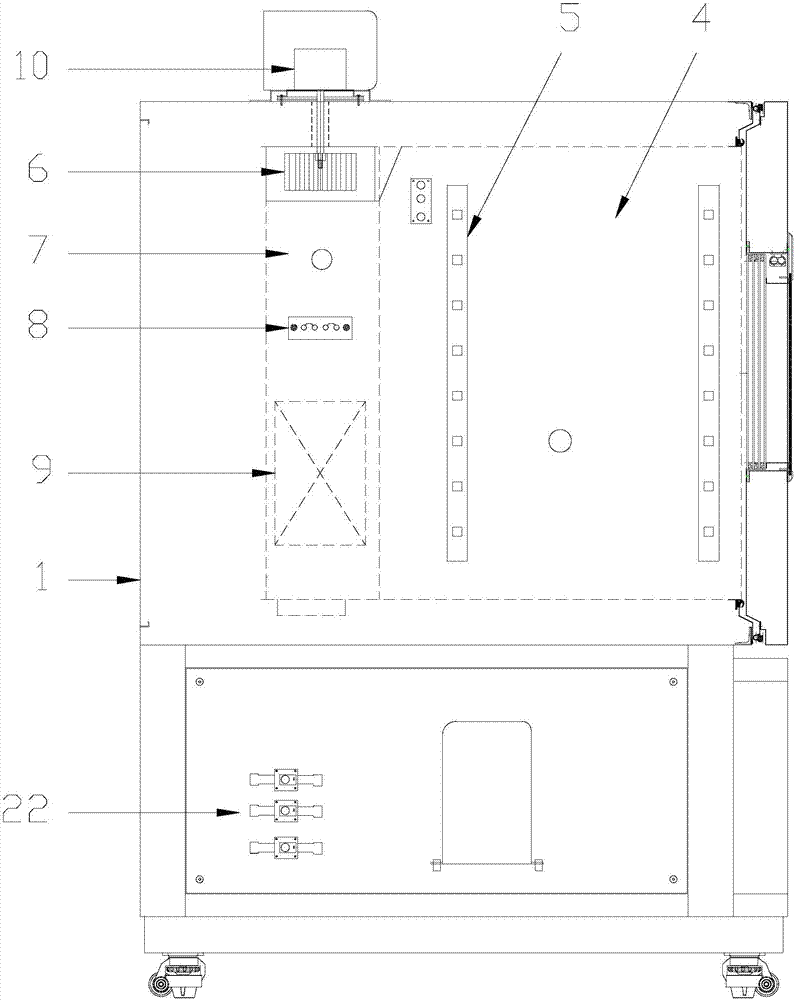

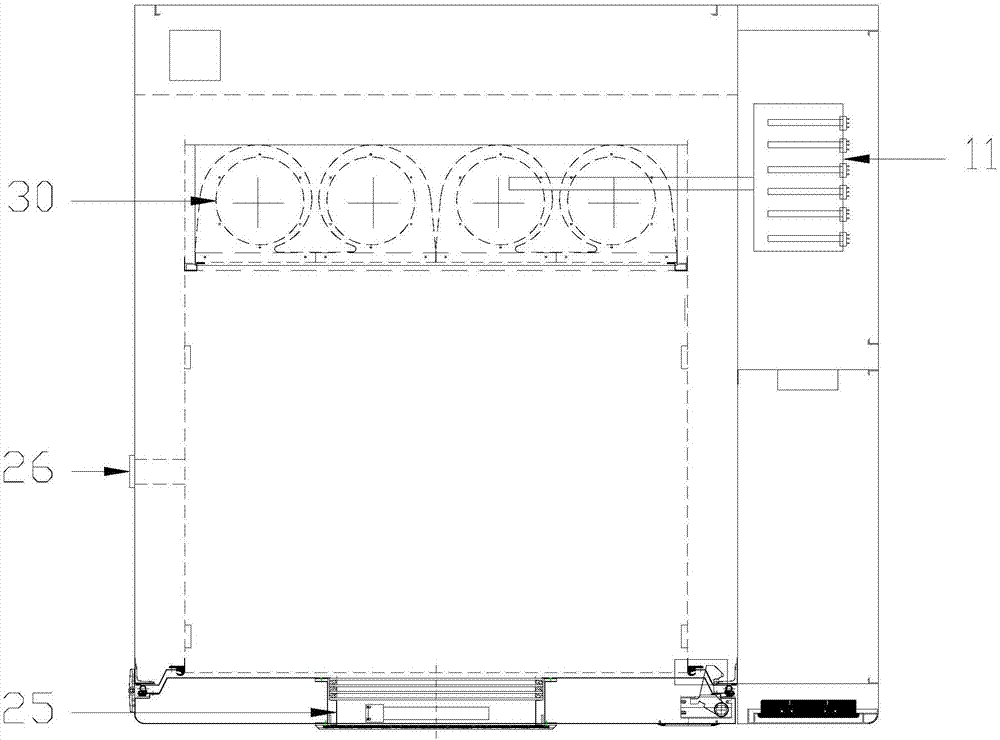

Low-humidity temperature and humidity test tank

InactiveCN107051595AWon't freezeRaise the dew point temperatureHeating or cooling apparatusAir-pressure/air-lock chambersTest chamberEngineering

The invention relates to a low-humidity temperature and humidity test box, which comprises a box body, a box door is arranged on the front surface of the box body, a door handle is installed on the box door, a test room is arranged in the front part of the box body, a sample rack is installed in the test room, the box The rear part of the body is equipped with circulating fan blades, steam pipes, heaters, and evaporators in sequence from top to bottom. On the outer top, the steam pipe is connected to the humidifying boiler, the inlet end of the evaporator is connected to the condenser through a pipe, a filter is arranged between the evaporator and the condenser, the inlet end of the condenser is connected to the compressor, and the outlet end of the evaporator is respectively passed through a pipe Connect the evaporating pressure regulating valve and the four solenoid valves, and the evaporating pressure regulating valve and the four solenoid valves are set in parallel; the invention realizes that the evaporator will not freeze during long-term operation, and at the same time achieves the effect of saving energy and reducing consumption, and solves the problem that the air in the box is The problem of the effect of drying on the temperature of the laboratory.

Owner:SHANGHAI LINPIN INSTR

Mobile electric heating high temperature medium snow melting vehicle

InactiveCN103046511BLarge amount of stored snow waterNo icingSnow cleaningWinding machineElectricity

Owner:STATE GRID XINJIANG ELECTRIC POWER CORP

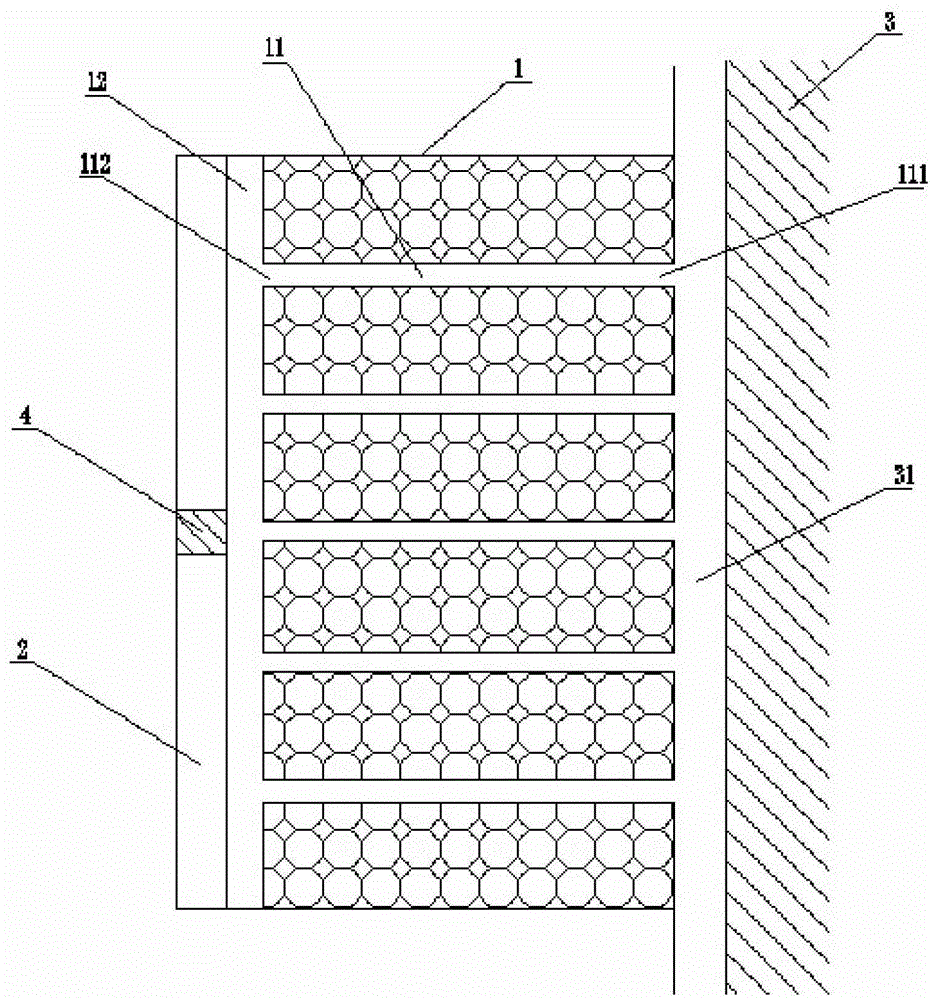

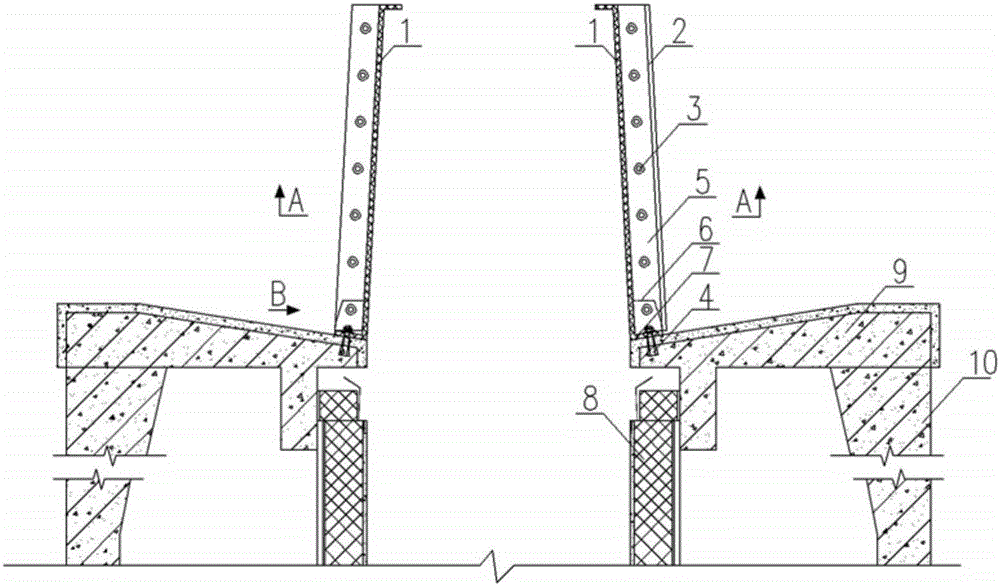

Heat preservation decorating integrated plate and manufacturing method thereof

ActiveCN103184789BImprove breathabilityImprove insulation effectCovering/liningsWater vaporProcess engineering

The invention discloses a heat preservation decorating integrated plate. The heat preservation decorating integrated plate comprises a plurality of heat preservation plates which are continuously arranged on a wall, wherein a plurality of decorating plates are continuously arranged on the outer surfaces of the plurality of heat preservation plates, a buffering cavity is formed between the wall and each heat preservation plate, a water vapor diffusion channel is formed in each of the plurality of heat preservation plates, ventilating parts are arranged at the connecting parts of the plurality of decorating plates, an inlet of each water vapor diffusion channel is communicated with each buffing cavity, and an outlet of each water vapor diffusion channel is communicated with the atmosphere through the ventilating part. The invention relates to the technical field of heat preservation materials for wall buildings, and provides the heat preservation decorating integrated plate with two functions of heat preservation and ventilation and a manufacturing method thereof, and the service life of the heat preservation system on the outer wall can be prolonged by adopting the heat preservation decorating integrated plate.

Owner:山东斯蒙特新材料有限公司

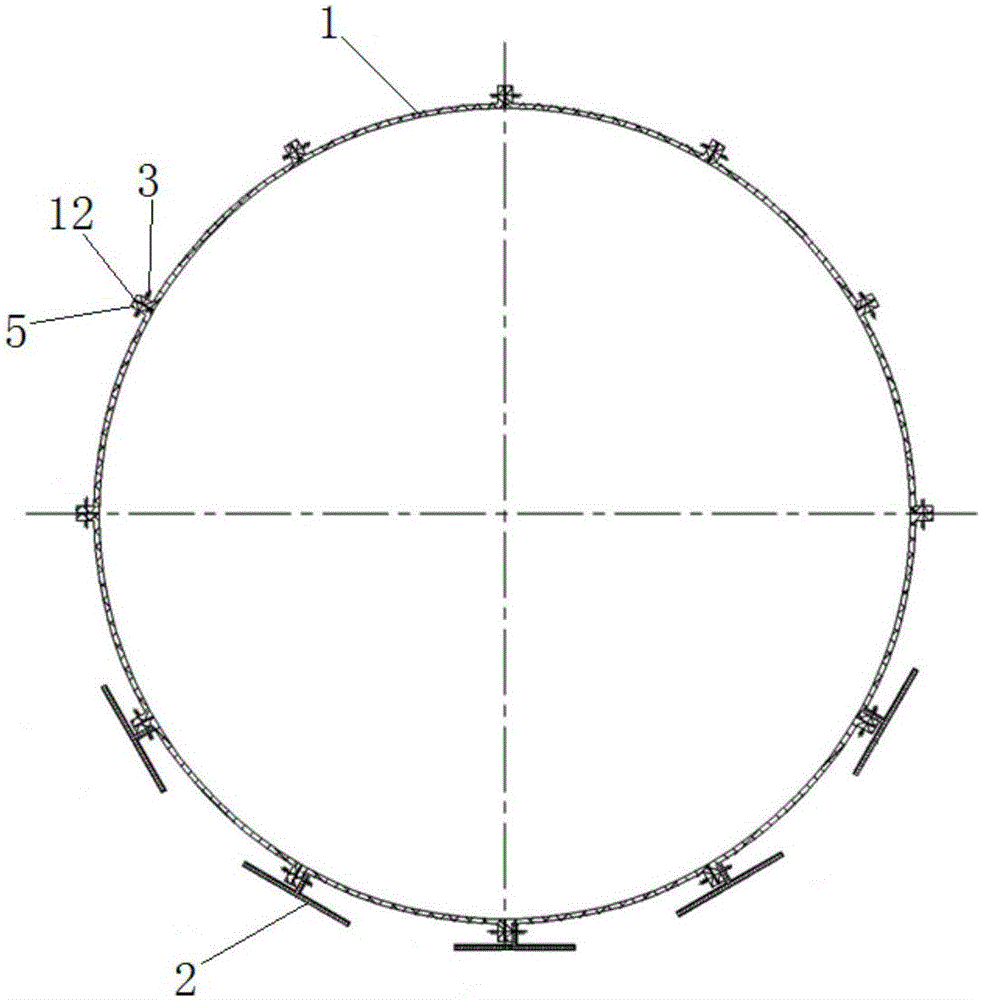

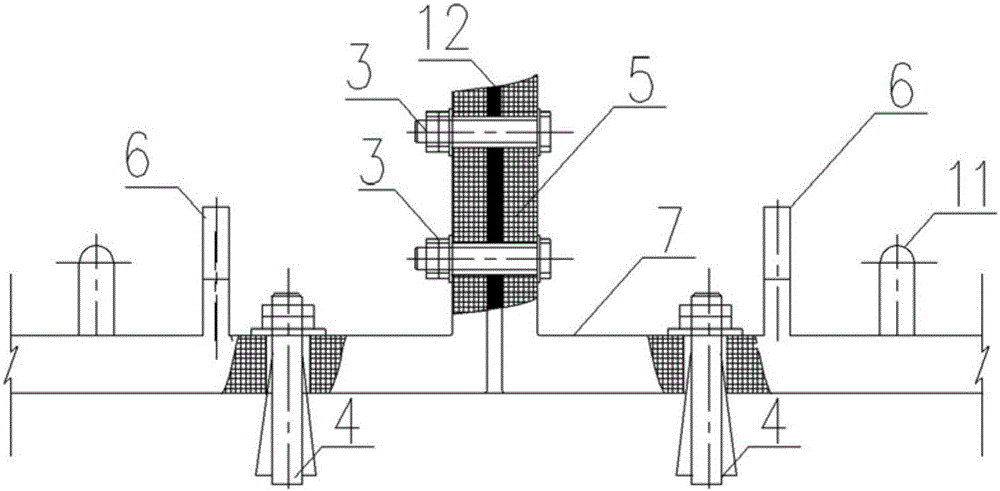

Device for preventing downwash of smoke plume for chimney

ActiveCN106765240AIncrease export speedIncrease vertical wind speedHuman health protectionChimneysGlass fiberBrick

The invention discloses a device for preventing downwash of smoke plume for a chimney. The device is characterized in that through CDF fluid dynamics analogue simulation design, a shrink mouth is formed in the top of the chimney, and air baffles are arranged on the outer wall of the shrink mouth, so that smoke is exhausted from the shrink mouth, and the flow speed at a smoke outlet is increased; and besides, through the arranged air baffles, local vertical air speed on the outer wall of the shrink mouth can be increased; through the combination of the shrink mouth and the air baffles, the height of the smoke plume is increased, so that the phenomenon that smoke plume washes down can be avoided. Through the adoption of the device, the contact of smoke plume and a chimney body can be avoided, so that the hidden danger that the chimney is frozen can be fundamentally eliminated. Compared with a conventional electric heating device, the device can thoroughly solve the problem that the chimney is frozen due to the downwash of smoke plume; besides, the device disclosed by the invention is simple in structure, and modular design and mounting are adopted; and the device is low in cost, safe and reliable, and basically no maintenance cost is needed for later periods. The device disclosed by the invention is applicable to various chimneys of thermal power plants, such as concrete single-tube chimneys, brick sleeve chimneys, steel sleeve chimneys and glass fiber reinforced plastic chimneys.

Owner:SHANGHAI DEFOG ENVIRONMENTAL SCI & TECH

A kind of anti-icing cable outer sheath and preparation method thereof

ActiveCN111675911BImprove hydrophobicityImprove antifouling performancePlastic/resin/waxes insulatorsInsulated cablesFiberPolymer science

The invention discloses an anti-icing cable outer sheath and a preparation method thereof. The anti-icing cable outer sheath is made of the following raw materials in parts by weight: 30-40 parts of fluorosilicone resin, vinyl chloride-acrylate 20-30 parts of copolymer, 5-12 parts of butadiene rubber, 5-10 parts of polyimide fiber, 2-4 parts of stearic acid, 5-10 parts of magnesium hydroxide, modified Co 3 o 4 5-10 parts, 2-5 parts of liquid coumarone, 1-2 parts of anti-aging agent, 0.5-2 parts of silane coupling agent and 1-3 parts of accelerator. The outer sheath of the anti-icing cable obtained by the invention has excellent hydrophobicity, high strength, good toughness and excellent anti-icing effect.

Owner:国网河南省电力公司新野县供电公司

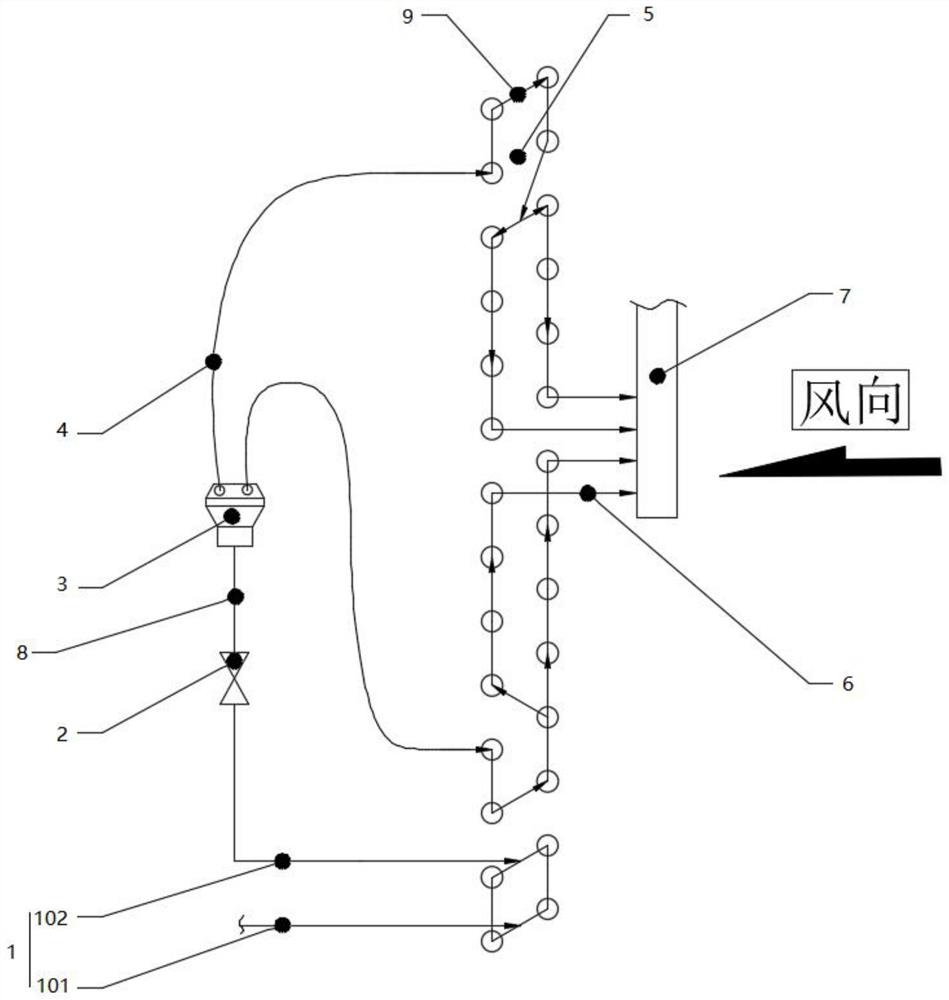

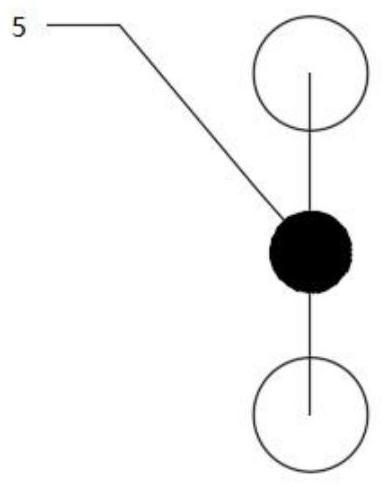

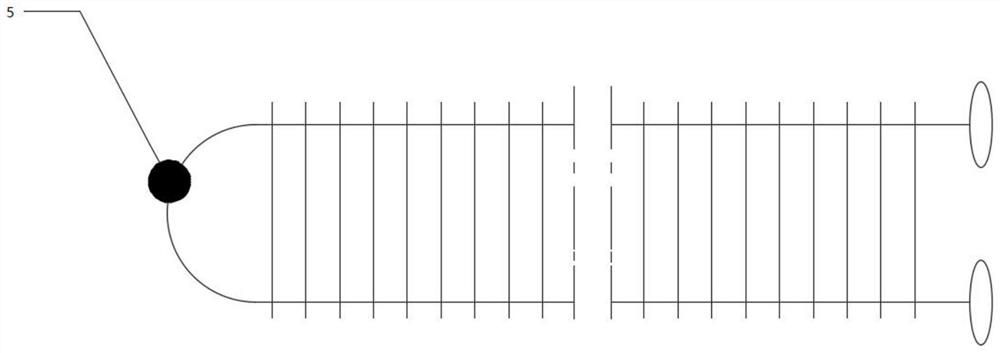

Evaporator heat exchange system applicable to heating in northern areas

InactiveCN112856565AReduce drag along the waySmall pressure dropMechanical apparatusHeat pumpsCounter flowFluid phase

The invention discloses an evaporator heat exchange system suitable for heating in northern areas, and relates to the technical field of evaporators. The system comprises a supercooling pipe, a throttle valve, a liquid distribution head, flow distribution capillary tubes, a finned sleeve heat exchanger, a gas collection branch pipe, a gathering pipe and a pipeline; the throttle valve and the liquid distribution head are fixedly mounted on the supercooling pipe in sequence through the pipeline; the liquid distribution head is fixedly connected with the two flow distribution capillary tubes; the two flow distribution capillary tubes both communicate with the finned sleeve heat exchanger; the finned sleeve heat exchanger communicates with the gathering pipe through the gas collection branch pipe; and the gathering pipe communicates with the supercooling pipe. According to the system, a gas-liquid phase refrigerant passing through the flow distribution capillary tubes is guided to the evaporator, and the refrigerant subjected to heat exchange is distributed into two parallel paths, so that the on-way resistance of a gaseous refrigerant is reduced, and the overall pressure drop of the path is reduced; a counter-current flow heat exchange mode is formed by the overall distribution trend and the air direction; and the low-temperature heating capacity and the low-temperature heating reliability and stability of a unit are improved.

Owner:KOCHEM ELECTRICAL

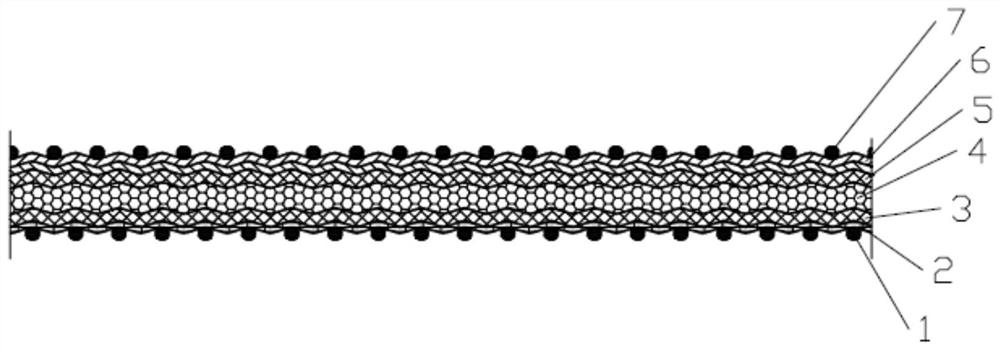

Low-temperature pipeline with inner-outer spring framework structure

PendingCN112377684AHigh tensile strengthResistance to torsional deformationThermal insulationPipe protection by thermal insulationThermodynamicsInsulation layer

The invention relates to a low-temperature pipeline with an inner-outer spring framework structure. The low-temperature pipeline comprises an inner framework layer, a wear-resistant layer, a sealing film layer, a heat preservation layer, a circumferential reinforcing layer, a longitudinal reinforcing layer and an outer framework layer which are coaxially arranged from inside to outside and are sequentially wound layer by layer. All layers of the low-temperature pipeline with the inner and outer spring framework structure belong to non-bonding structures, an outer framework layer spiral line and an inner framework layer spiral line are staggered by a half screw pitch to be wound, and the inner framework layer has spiral outward tension, the outer framework layer has spiral inward tension, the inner and outer interact to extrude the wear-resistant layer, the sealing film layer, the heat preservation layer, the circumferential reinforcing layer and the longitudinal reinforcing layer; andsliding of all layers is limited. The low-temperature pipeline is better in sealing and pressure-resisting effect, excellent in ultralow-temperature impact resistance, not prone to radial buckling andlateral buckling and capable of being widely applied to the technical field of low-temperature pipelines.

Owner:WEIHAI HONGTONG PIPING MATERIALS CO LTD

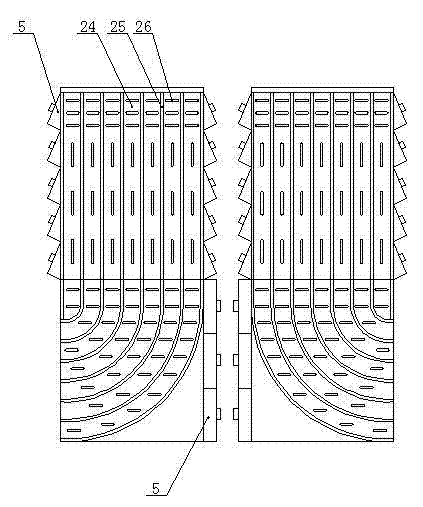

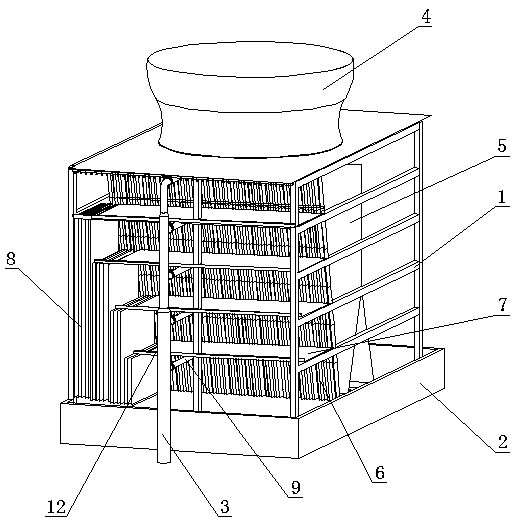

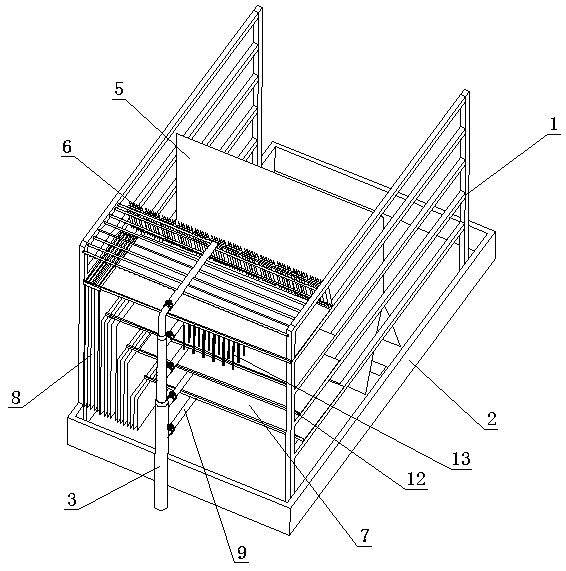

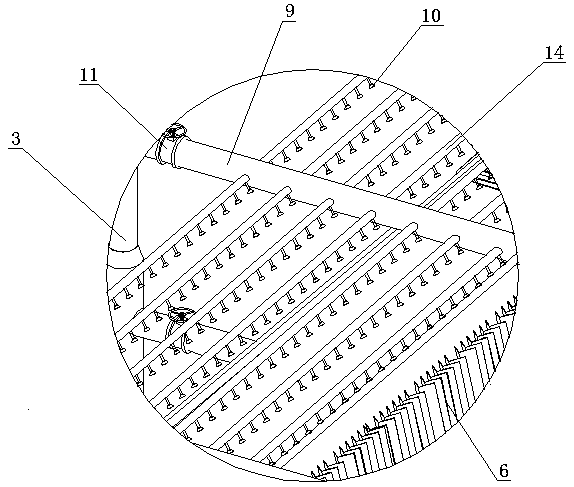

Anti-icing and anti-fogging multilayer water distribution efficient water cooling tower

ActiveCN110375560AReasonable structural designLarge contact surface areaTrickle coolersWater flowEngineering

The invention discloses an anti-icing and anti-fogging multilayer water distribution efficient water cooling tower, and relates to the water cooling tower field. The anti-icing and anti-fogging multilayer water distribution efficient water cooling tower is composed of a water cooling tower frame, a tower pool, a water distribution pipe and an air cylinder, wherein the water cooling tower frame isprovided with a square outer frame body formed by hinging vertical and horizontal lattice bars, a middle dummy plate is erected in the middle of the tower outer frame body, water collection barrier grids slightly inclined are oppositely erected on two sides of the middle dummy plate, more than one layer of water collection deflector is transversely arranged in the square frame body, heat exchangefillers vertically arranged are connected with the lower end of each water collection deflector, the water distribution pipe is erected on the outer side of the tower pool and reaches the top layer ofthe water cooling tower, a side branch water pipe is arranged on a part, located above each layer of the water collection deflector, of the water distribution pipe, cold water spray heads are arranged on end heads of the side branch water pipes and distributed in the direction of the water collection deflectors, the tower pool is located at the bottom of the water cooling tower frame, and the aircylinder is arranged at the top of the water cooling tower frame. According to the anti-icing and anti-fogging multilayer water distribution efficient water cooling tower, water streams sprayed by spray heads make full contact with air so as to be fully cooled, wind resistance in a water sprinkling area is low, the superficial area of the water and the air is large, water consumption is low, andtherefore cooling efficiency is high.

Owner:曹伟

Anti-icing outer sheath for cable and preparation method thereof

ActiveCN111675911AImprove hydrophobicityImprove antifouling performancePlastic/resin/waxes insulatorsInsulated cablesFiberEngineering

The invention discloses an anti-icing outer sheath for a cable and a preparation method thereof. The anti-icing outer sheath for the cable is prepared from the following raw materials in parts by weight: 30-40 parts of fluorosilicone resin, 20-30 parts of a vinyl chloride-acrylate copolymer, 5-12 parts of butadiene rubber, 5-10 parts of polyimide fibers, 2-4 parts of stearic acid, 5-10 parts of magnesium hydroxide, 5-10 parts of modified Co3O4, 2-5 parts of liquid coumarone, 1-2 parts of an anti-aging agent, 0.5-2 parts of a silane coupling agent and 1-3 parts of an accelerant. The anti-icingouter sheath for the cable is excellent in hydrophobic performance, high in strength, good in toughness and excellent in anti-icing effect.

Owner:国网河南省电力公司新野县供电公司

Leakage testing liquid preventing low-temperature icing and preparation method

ActiveCN101230246BProduce corrosionNo icingDetection of fluid at leakage pointProductsAlcoholFoaming agent

The invention provides a low-temperature icing preventing leakage detecting solution and the preparing method. The invention aims at solving the problem that leakage detecting solution ices. The invention is prepared by the matters of the following weight units: anhydrous calcium chloride 4-7, vesicant 5-7, distilled water 50-60. The vesicant is one or multifold combination which are selected fromcoconut oleic acid diethyl alcohol amide, cherry bay radical acylamide propyl lycine, coconut oleic radical acylamide propyl lycine, dodecyl dimethyl betaine and dodecyl dimethyl amine oxide. The invention does not ice within 3 hours at 18 DEG C below zero, has fine foaming effect, can meet the requirements on the leakage detecting solution in field task or in the condition of 18 DEG C below zero.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com