Low-humidity temperature and humidity test tank

A humidity test, humidity temperature technology, applied in laboratory utensils, supporting utensils, shells or chambers, etc., can solve the problems of consuming gas energy, supporting a lot of work, and not being able to work for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

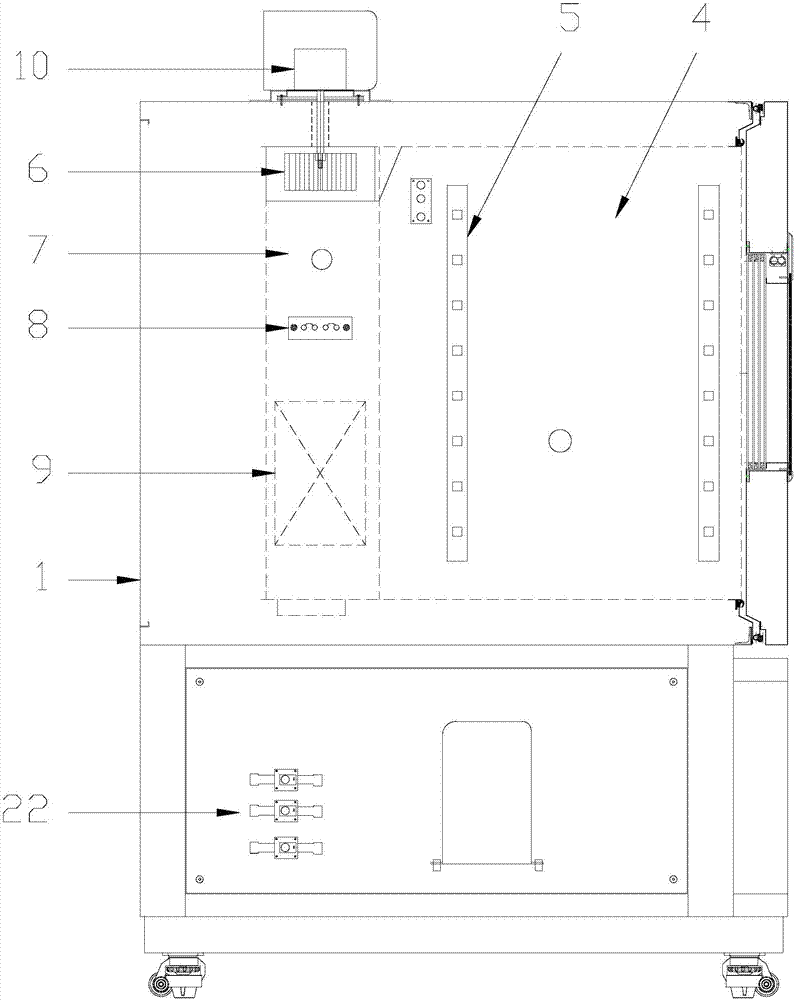

[0031] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

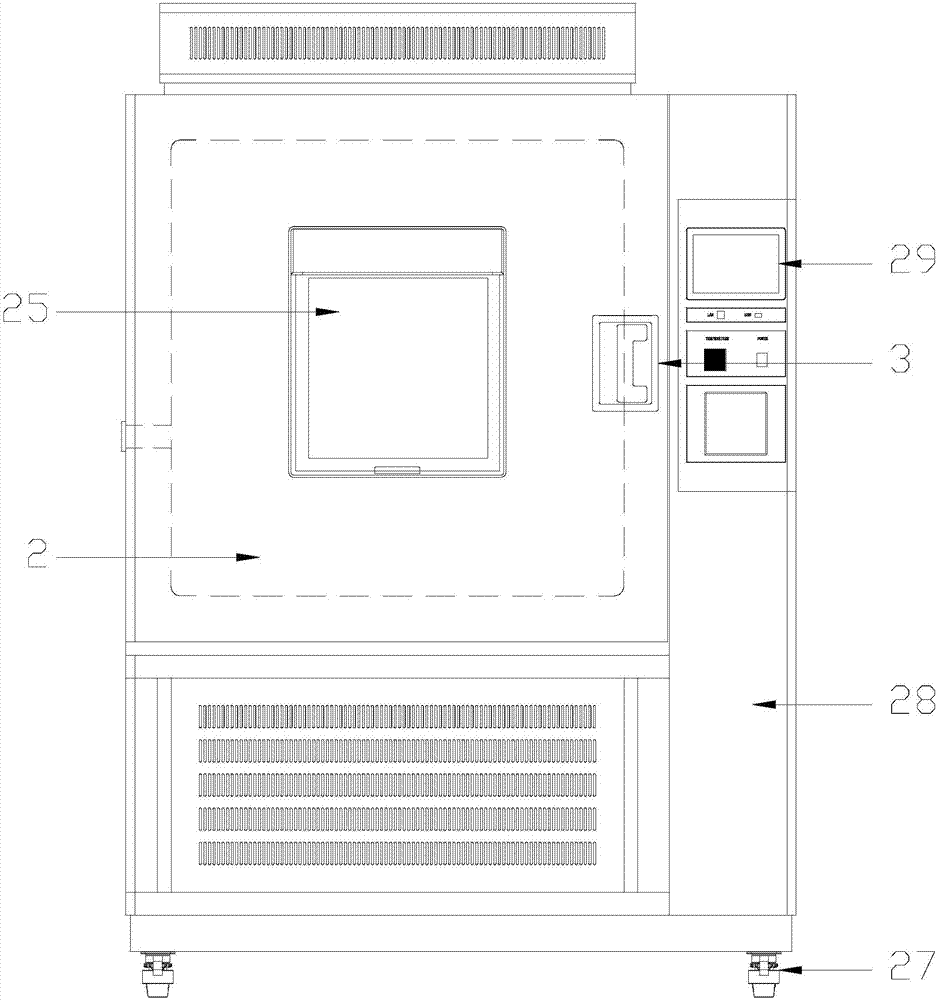

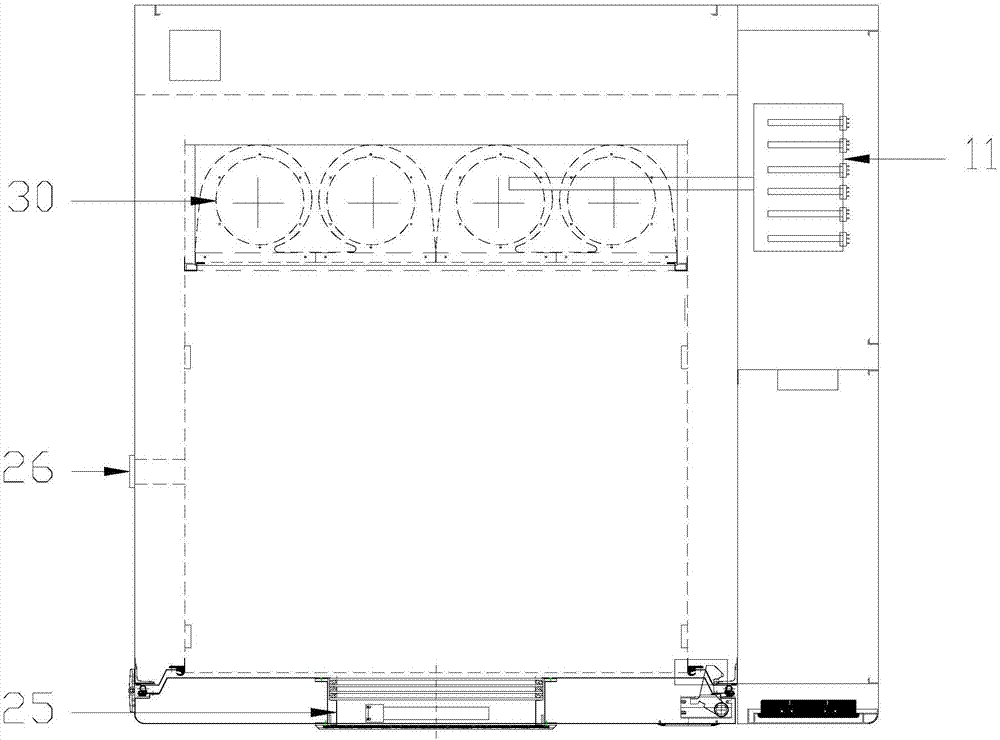

[0032] As shown in the drawings, the present invention includes: a box body 1, a box door 2 is arranged on the front end of the box body 1, a door handle 3 is installed on the box door 2, a test room 4 is provided at the front of the box body 1, and the test room 4 is equipped with a sample rack 5, and the rear of the box body 1 is provided with a circulating fan 6, a steam pipe 7, a heater 8, and an evaporator 9, and a circulating fan 6, a steam pipe 7, a heater 8, and an evaporator 9. Arranged in order from top to bottom, the circulation vane 6 is installed inside the fan volute 30, the circulation vane 6 is installed at the output end of the circulation motor 10, the circulation motor 10 is installed on the outer top of the box body 1, and the steam pipe 7 is connected to the humidification boiler 11 , the inlet end of the evaporator 9 is connected to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com