Adsorption heat desorption device

A technology of adsorption heat and desorption, which is applied in the field of chromatographic analysis, can solve the problems of short circuit of the heating wire of the enrichment tube, inaccurate temperature measurement of thermocouples, and enlarged volume of the instrument, so as to reduce the workload of disassembly and solve the problem of inaccurate temperature measurement , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

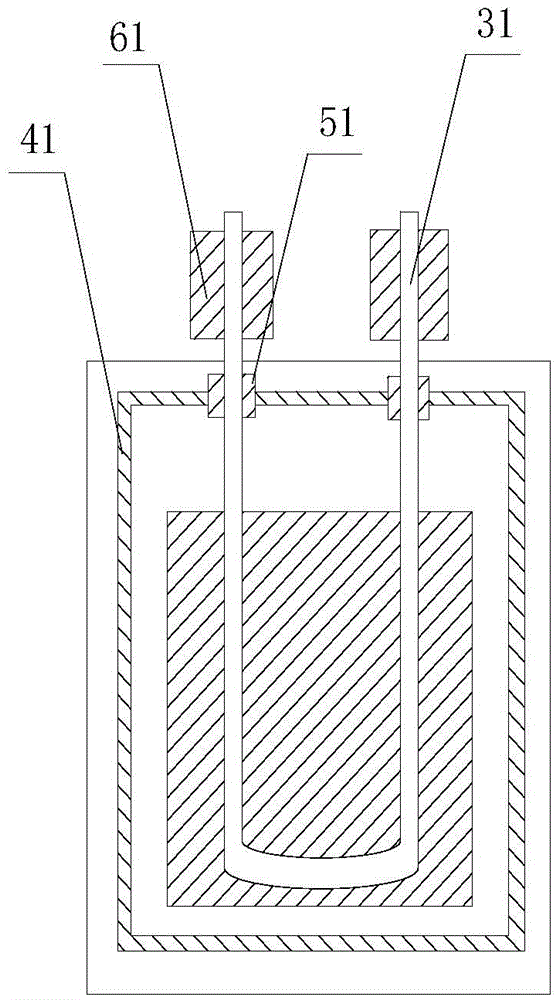

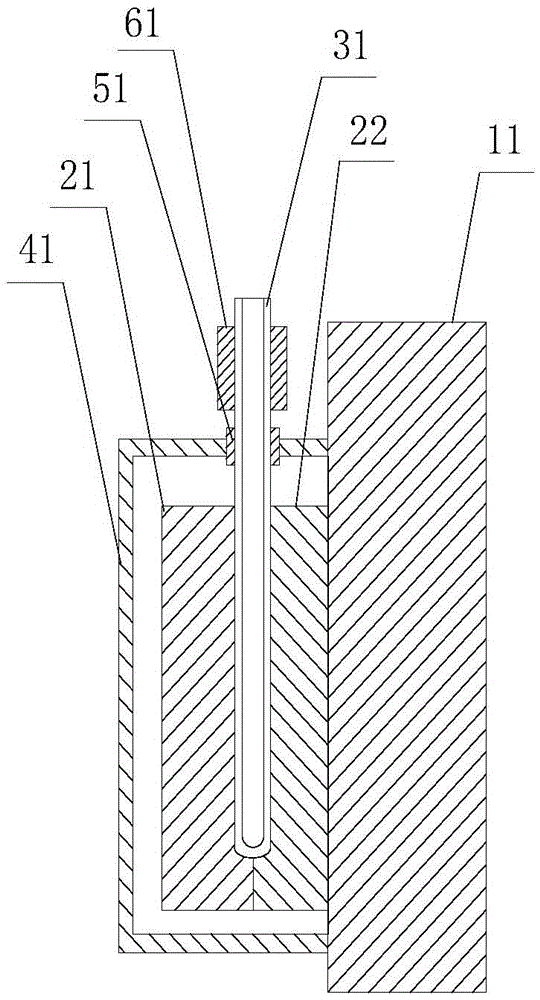

[0031] figure 1 , 2 Schematically provides the structural diagram of the adsorption thermal desorption device of the embodiment of the present invention, as figure 1 , 2 As shown, the adsorption thermal desorption device includes:

[0032] The heat conductor is installed on the cooling surface 11 of the refrigerator, and the enrichment pipe 31 is buried in the heat conductor in a curved manner; the heat conductor specifically includes: a first heat conductor 21, the first heat conductor One side of the body is installed on the cooling surface of the refrigerator, and the other side facing away from the cooling surface has a curved first installation groove; the second heat conductor 22, the second heat conductor is opposite to the first One side of the heat conductor has a second installation groove matching the first installation groove; the enrichment pipe is installed in the space formed by the first installation groove and the second installation groove, and the inlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com