Soybean milk production technology and soybean milk

A production process, soy milk technology, applied in the soy milk production process, soy milk field, can solve the problems of incomplete removal of beany smell, lower input-output ratio, reduced dosage, etc. The effect of high output ratio and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

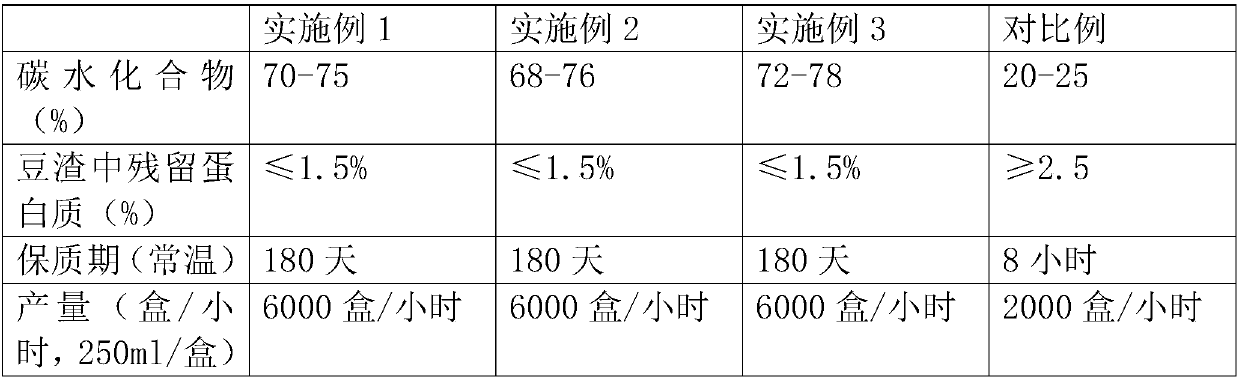

Examples

Embodiment 1

[0033] The production of soybean milk comprises the following steps;

[0034] The soybeans are soaked and pulped to obtain the puree.

[0035] In the first separation, the original pulp is subjected to the first okara separation, and the primary okara and the primary raw pulp are obtained after separation.

[0036] For secondary separation, the primary bean dregs is boiled with water to separate the second bean dregs to obtain secondary bean dregs and secondary cooked pulp.

[0037] The primary raw milk and the secondary cooked milk are mixed, boiled to obtain soybean milk, and then the soybean milk is cooled. The temperature of the plate heat exchanger is lowered to below 10°C, so that the soybean milk is cooled, and the blending tank is added with essence and water to adjust the temperature to below 10°C, and the soybean milk is temporarily stored in the blending tank.

[0038] High-pressure homogenization, high-temperature instantaneous sterilization equipment and high-pr...

Embodiment 2

[0042] The production of soybean milk comprises the following steps;

[0043] The soybeans are soaked and pulped to obtain the puree.

[0044] In the first separation, the original pulp is subjected to the first okara separation, and the primary okara and the primary raw pulp are obtained after separation.

[0045] For secondary separation, the primary okara is boiled with water for secondary okara separation to obtain secondary okara and secondary cooked pulp.

[0046] The primary raw milk and the secondary cooked milk are mixed and boiled to obtain soybean milk.

[0047] In order to make the soy milk have a good flavor, add stabilizers, white sugar and other auxiliary materials to the soy milk, so add a mixing step before cooling, first dry mix the auxiliary materials in the shear tank, disperse and stir for 5-10 minutes, and then add to the soy milk and stir 10-15min. The adjuvant can also be any other adjuvant such as fruit juice / powder for seasoning or increasing stabi...

Embodiment 3

[0053] The production of soybean milk comprises the following steps;

[0054] The soybeans are soaked and pulped to obtain the puree.

[0055]In the first separation, the original pulp is subjected to the first okara separation, and the primary okara and the primary raw pulp are obtained after separation.

[0056] For secondary separation, the primary okara is boiled with water for secondary okara separation to obtain secondary okara and secondary cooked pulp.

[0057] The primary raw milk and the secondary cooked milk are mixed and boiled to obtain soybean milk.

[0058] In order to make the soy milk have a good flavor, add stabilizers, white sugar and other auxiliary materials to the soy milk, so add a mixing step before cooling, first dry mix the auxiliary materials in the shear tank, disperse and stir for 5-10 minutes, and then add to the soy milk and stir 10-15min.

[0059] In order to make the soymilk more delicate, the soymilk mixed with auxiliary materials is finely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com