Low-temperature pipeline with inner-outer spring framework structure

A skeleton structure and inner skeleton technology, applied in the direction of pipeline protection, protection of pipelines by thermal insulation, and prevention of damage/wear of pipelines, etc., can solve the problems of troublesome production, complex structure, poor low temperature sealing effect, etc., to achieve good resistance to torsional deformation, Wide range of applications, the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments, so as to help understand the content of the present invention. The methods used in the present invention are conventional methods unless otherwise specified; the raw materials and devices used are conventional commercially available products unless otherwise specified.

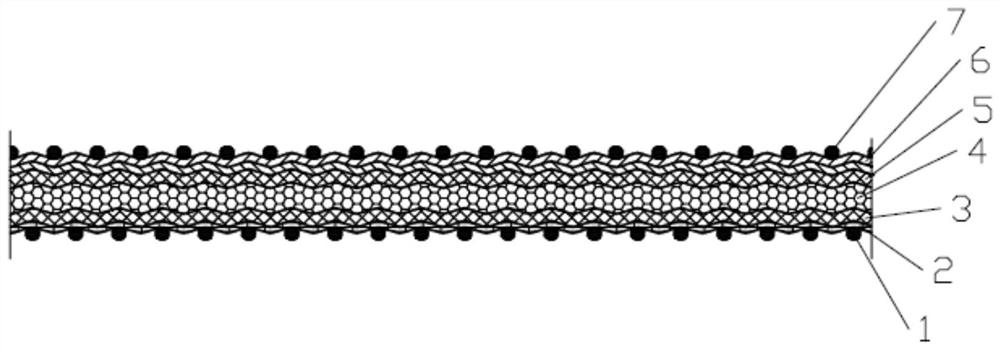

[0023] Such as figure 1 As shown: the present invention provides a low-temperature pipeline with an inner and outer spring frame structure, which includes an inner frame layer 1 coaxially arranged from inside to outside, a wear-resistant layer 2, a sealing film layer 3, an insulation layer 4, a circumferential reinforcement layer 5, a longitudinal The reinforcement layer 6 and the outer skeleton layer 7, the wear-resistant layer 2 is coated on the outer peripheral surface of the inner skeleton layer 1, the sealing film layer 3 is coated on the outer peripheral surface of the wear-resistant layer 2, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com