Anti-icing outer sheath for cable and preparation method thereof

An outer sheath and anti-icing technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor low temperature resistance, general hydrophobicity and elasticity, and poor toughness of cable insulation, so as to achieve good cold resistance and anti-icing performance. Excellent icing effect and good cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

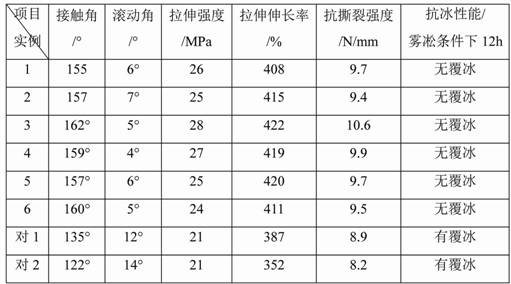

Examples

Embodiment 1

[0020] An outer sheath of an ice-coated cable, made of the following raw materials in parts by weight: 30 parts of fluorosilicone resin, 20 parts of vinyl chloride-acrylate copolymer, 5 parts of butadiene rubber, 5 parts of polyimide fiber, 2 parts of stearic acid, 5 parts of magnesium hydroxide, modified Co 3 o 4 5 parts, 2 parts of liquid coumarone, 1 part of anti-aging agent, 0.5 part of silane coupling agent and 1 part of accelerator.

[0021] The modified Co 3 o 4 The preparation method comprises the following steps:

[0022] Cobalt subcarbonate 2CoCO 3 3Co(OH) 2 ·H 2 O was calcined in a muffle furnace at 490 °C for 3 h and cooled to room temperature to obtain Co 3 o 4 film, then soaked in 0.5wt% stearic acid absolute ethanol solution for 2h, removed, and finally dried in an oven at 60°C for 24h to obtain the modified Co 3 o 4 .

[0023] Described anti-aging agent is anti-aging agent 4010NA.

[0024] The silane coupling agent is vinyltriethoxysilane.

[0025...

Embodiment 2

[0030] An anti-icing cable outer sheath, made of the following raw materials in parts by weight: 32 parts of fluorosilicone resin, 24 parts of vinyl chloride-acrylate copolymer, 8 parts of butadiene rubber, 7 parts of polyimide fiber, 3 parts of stearic acid, 6 parts of magnesium hydroxide, modified Co 3 o 4 6 parts, 2.5 parts of liquid coumarone, 1.2 parts of anti-aging agent, 0.6 parts of silane coupling agent and 1.5 parts of accelerator.

[0031] The modified Co 3 o 4 The preparation method comprises the following steps:

[0032] Cobalt subcarbonate 2CoCO 3 3Co(OH) 2 ·H 2 O was calcined in a muffle furnace at 450 °C for 2 h and cooled to room temperature to obtain Co 3 o 4 film, then soaked in 1wt% stearic acid absolute ethanol solution for 2h, removed, and finally dried in an oven at 70°C for 12h to obtain the modified Co 3 o 4 .

[0033] The anti-aging agent is anti-aging agent RD.

[0034] The silane coupling agent is methacryloxypropyltrimethoxysilane.

...

Embodiment 3

[0038] An anti-icing cable outer sheath, made of the following raw materials in parts by weight: 34 parts of fluorosilicone resin, 25 parts of vinyl chloride-acrylate copolymer, 10 parts of butadiene rubber, 8 parts of polyimide fiber, 2.4 parts of stearic acid, 7.5 parts of magnesium hydroxide, modified Co 3 o 4 7 parts, 3 parts of liquid coumarone, 1.5 parts of anti-aging agent, 1 part of silane coupling agent and 2 parts of accelerator.

[0039] The modified Co 3 o 4 The preparation method comprises the following steps:

[0040] Cobalt subcarbonate 2CoCO 3 3Co(OH) 2 ·H 2 O was calcined in a muffle furnace at 450 °C for 3 h and cooled to room temperature to obtain Co 3 o4 film, then soaked in 1wt% stearic acid absolute ethanol solution for 1h, removed, and finally dried in an oven at 80°C for 24h to obtain the modified Co 3 o 4 .

[0041] The anti-aging agent is anti-aging agent MB.

[0042] The silane coupling agent is aminopropyltriethoxysilane.

[0043] The ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com