Gravity extrusion type single-ball ice press

An extruded, single-ball technology, which is applied in the manufacture of ice, ice storage/distribution, lighting and heating equipment, etc., can solve the problems of poor practicability, high risk, complex structure, etc., and achieve simple structure, labor-saving manual operation, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

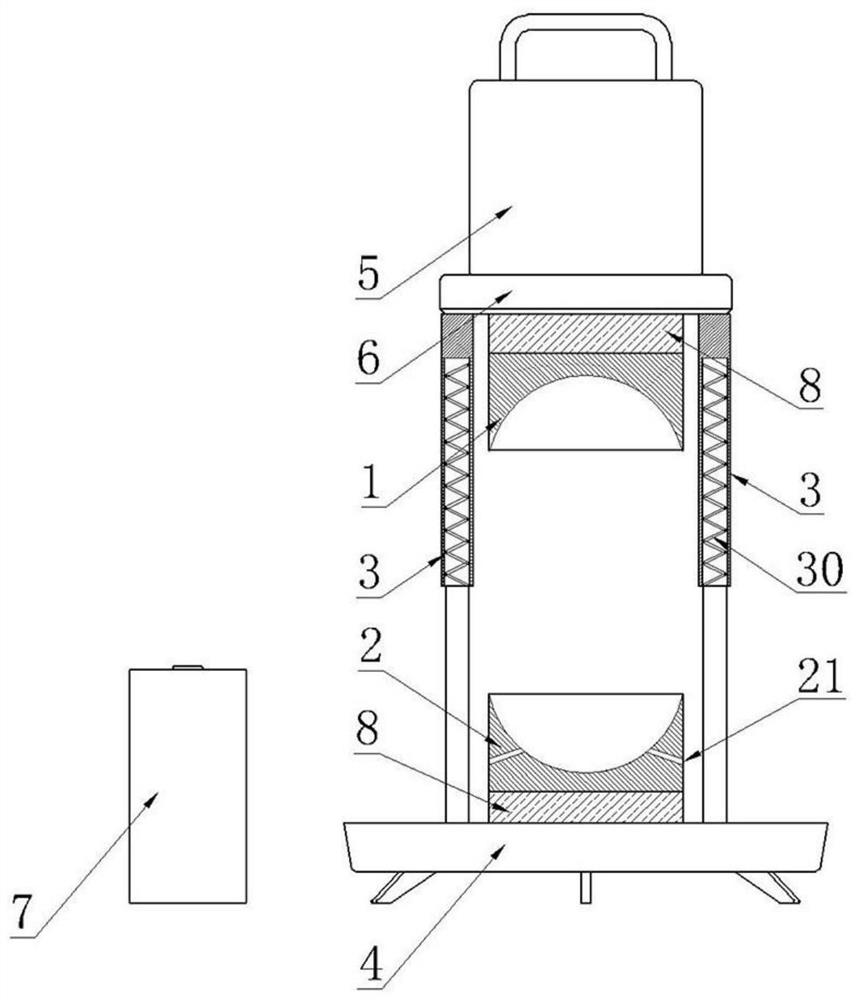

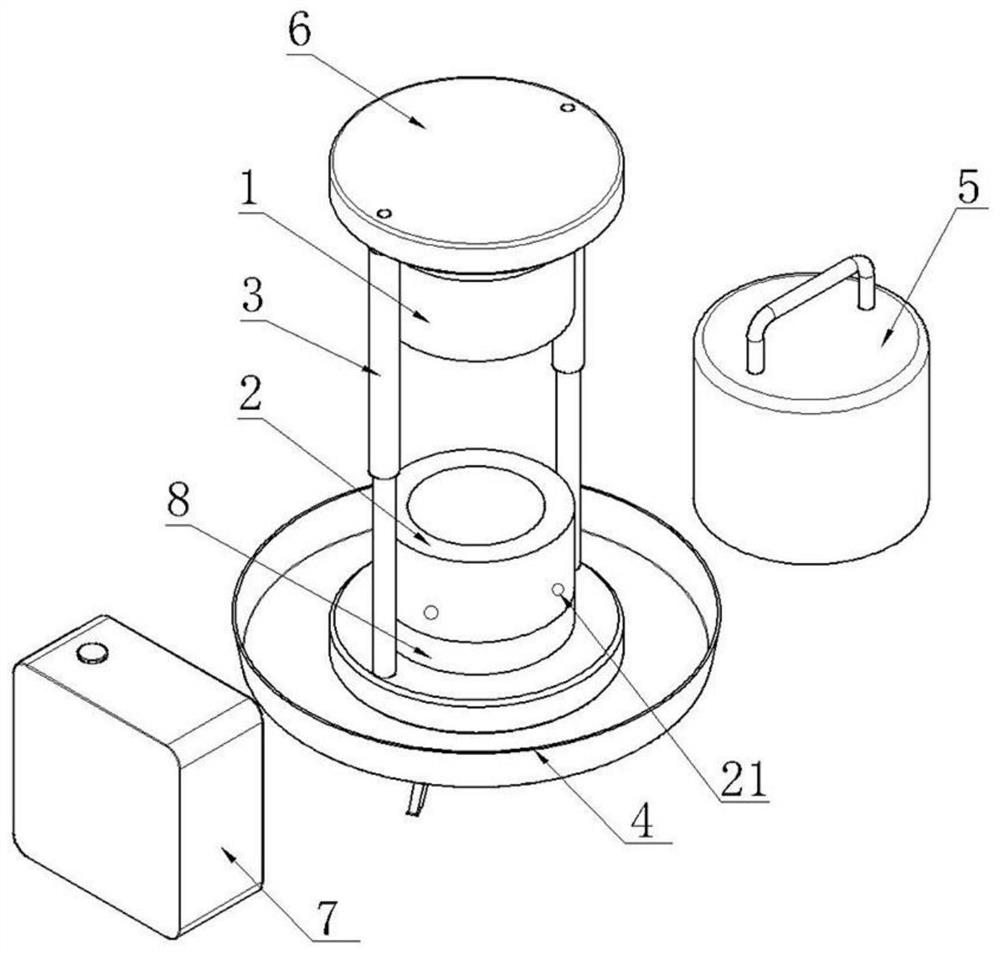

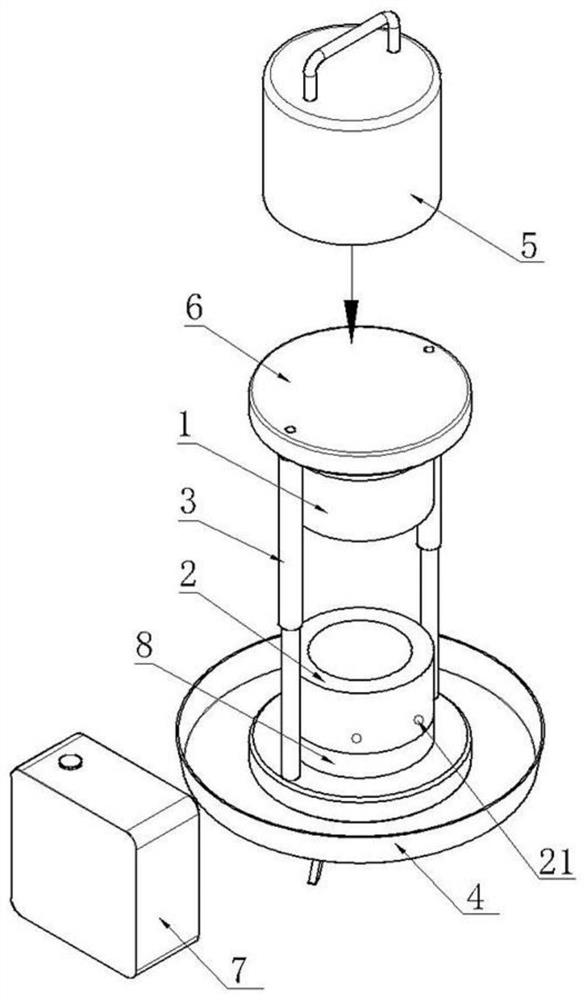

[0018] Such as figure 1 , figure 2 , image 3 A gravity extrusion type single-ball ice compactor shown includes an extrusion upper die 1, an extrusion lower die 2, two lifting frames 3, a base groove 4, a pressure hammer 5 and a top cover plate 6. The cover plate 6 and the base groove 4 are installed on the upper and lower ends of the lifting frame 3, the extrusion upper die 1 is fixed on the lower bottom surface of the top cover plate 6, the extrusion lower die 2 is fixed in the base groove 4, and the extrusion The upper die 1 and the lower extrusion die 2 are opposite up and down and fixed in the middle of the two elevating frames 3. In addition, the upper extruding die 1 and the lower extruding die 2 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com