Leakage detection solution as well as preparation method and application thereof

A technology of leak detection and mass percentage, which is applied in the field of air tightness inspection, can solve problems such as difficulty in air tightness inspection and failure to use normally, and achieve the effects of good foaming performance, good antirust performance and good antifreeze performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

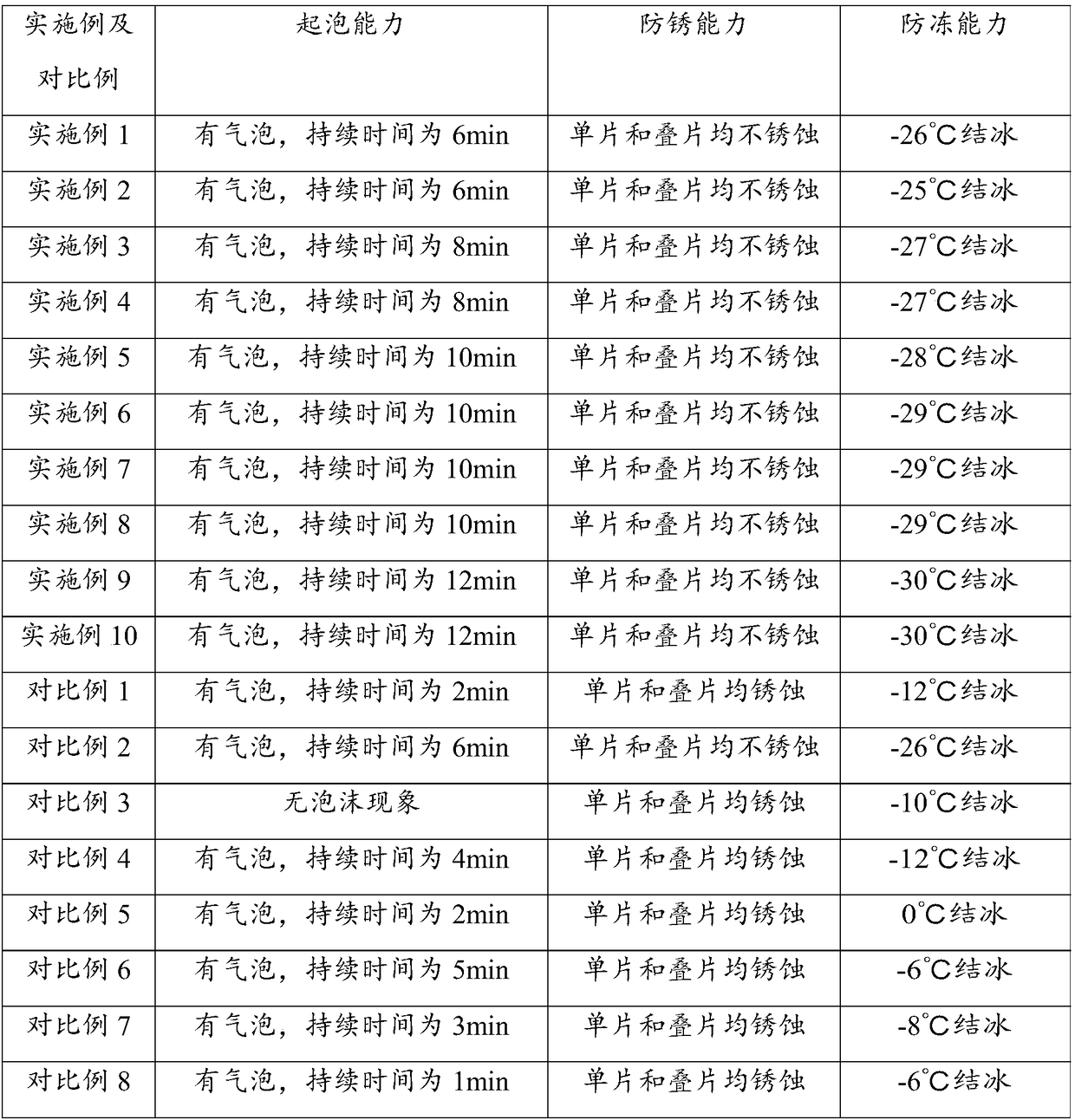

Examples

preparation example Construction

[0066] According to a second aspect of the present invention, there is provided a method for preparing the above-mentioned leak detection liquid, which includes the following steps: fully mixing a surfactant, a thickener, an antifreeze, a rust inhibitor and water to obtain a leak detection liquid.

[0067] In a preferred embodiment, the preparation of the leak detection liquid includes the following steps:

[0068] (a) Dissolve the thickener in water.

[0069] (b) The surfactant, antifreeze and rust inhibitor are thoroughly mixed with the solution obtained in step (a) to obtain a leak detection liquid.

[0070] In a preferred embodiment, the preparation of the leak detection liquid includes the following steps:

[0071] (a) Dissolve xanthan gum in dewatered water.

[0072] (b) Cocoyl diethanolamide, oleoyl sarcosine ethanol, cocoyl acid ethanolamine, fatty acid sodium soap and glycerol are thoroughly mixed with the solution obtained in step (a).

[0073] According to the third aspect of t...

Embodiment 1

[0076] A leak detection liquid includes the following components according to mass percentage: 0.5% of oleoyl sarcosinate sodium, 4% of xanthan gum, 0.2% of coco diethanolamide, 55% of triethanolamine, and 40.3% of water.

Embodiment 2

[0078] A leak detection liquid comprises the following components according to mass percentage: 22.5% of fatty acid potassium soap, 0.08% of polyvinyl alcohol, 18.5% of oleoyl sarcosine ethanolamine, 30% of triethanolamine, and 28.92% of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com