Movable electric heating high temperature snow melting and sweeping vehicle

A mobile, electric heating technology, used in snow surface cleaning, cleaning methods, construction, etc., can solve the problems of uncontinuous snow clearing work, unsatisfactory snow melting efficiency, and small size of the water collecting tank, saving snow melting operation time and continuous work. The effect of long time and large amount of snow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

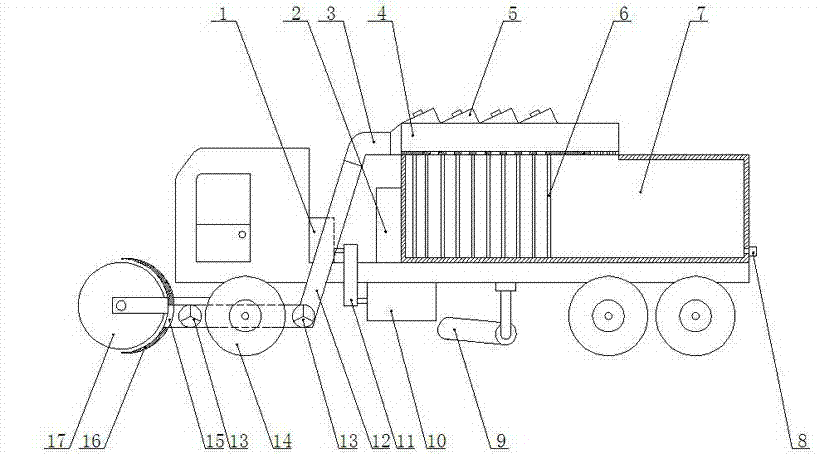

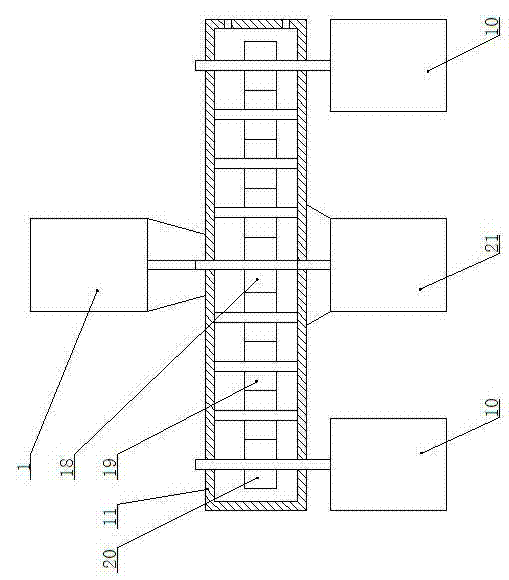

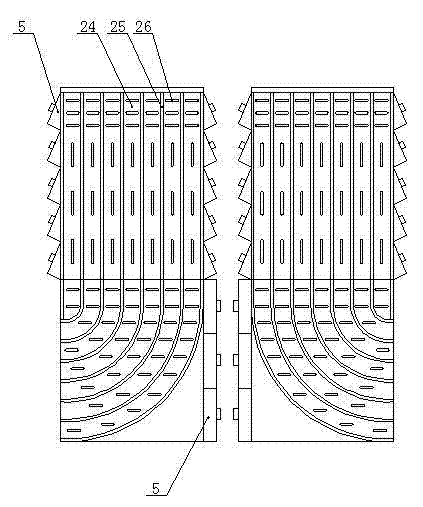

[0013] Example: such as figure 1 As shown, the mobile electric heating high temperature snow melting vehicle includes a vehicle cab, a water collecting tank 7 is installed on the vehicle girder 22 on the rear side of the cab, and two parallel snow melting boxes 4 are installed on the front side of the water collecting tank 7 upper ends. A soft starter cabinet 2 is arranged on the vehicle frame 22 between the driver's cab and the water collection tank 7. The soft starter cabinet 2 is connected to the generator 10 circuit. The generator 10 is installed on both sides of the lower end surface of the vehicle frame 22. The transfer box 11 is driven by the onboard engine 1 . A middle sweep 9 is installed at the lower end of the middle part of the vehicle girder 22, and the middle sweep 9 is used to sweep a small amount of residual snow on the road surface to the curb, so as to ensure that there is no residual snow on the road after the snow melting vehicle is driven. The middle sweep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com