Hanging curtain type biological filtering pool and application thereof to recirculating aquaculture

A recirculating water aquaculture, biological filter technology, applied in biological water/sewage treatment, sustainable biological treatment, water distribution, etc. The effect of attachment and growth, simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

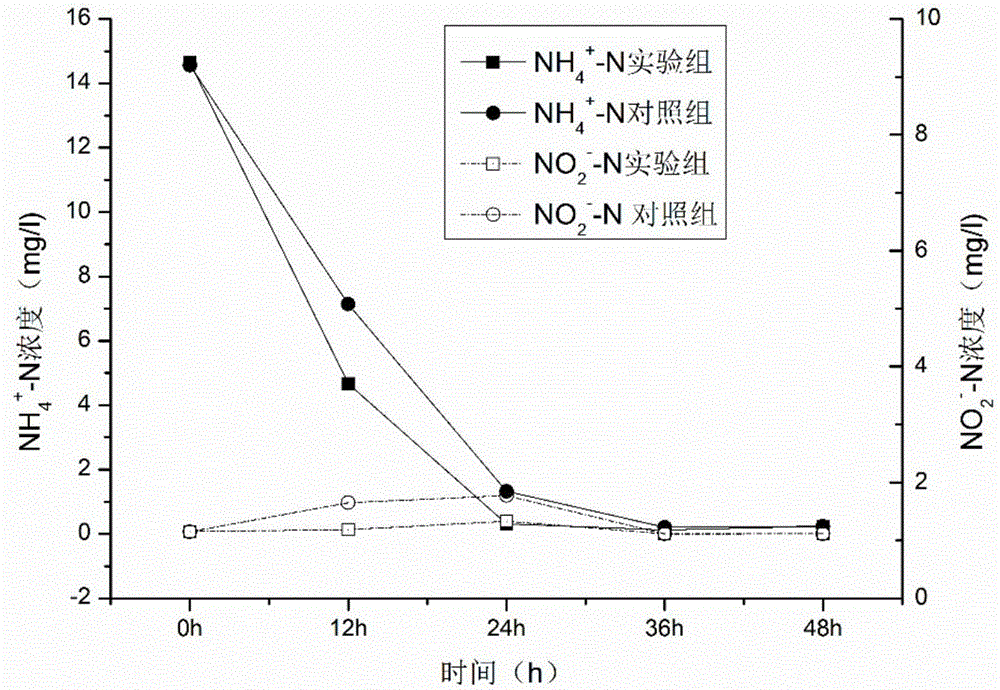

[0042] Embodiment 1 curtain type biofilter test stage is to NH 4 + -N and NO 2 - -N degradation

[0043] The experimental group is a curtain-type biofilter reactor, which is a cuboid with 4 carbon fiber felts inserted inside, and the control group is a suspension filler with a large particle size (the filler is commercially available, its diameter is 1.5cm, and its height is 1cm ) constitutes the same reactor volume as that of the experimental group. Configure 6L of simulated sewage in the experimental group and the control group respectively, and the influent formula is: C 6 h 12 o 6 :33.3mg / L, NH 4 Cl: 57.3mg / L (NH 4 + -N:15mg / L), NaHCO 3 :71.4mg / L, NaHPO 4 : 18.85mg / L, mixed trace elements 1mg / L. Take the sludge from the aquaculture biological filtration system, dilute it until the solid content TS is 4500mg / L, inoculate 6ml of the diluted sludge into a 3L reactor at 1‰ (V:V), adjust the pH to 7.5, and wait for the film to mature NH 4 + -N removal experiment....

Embodiment 2

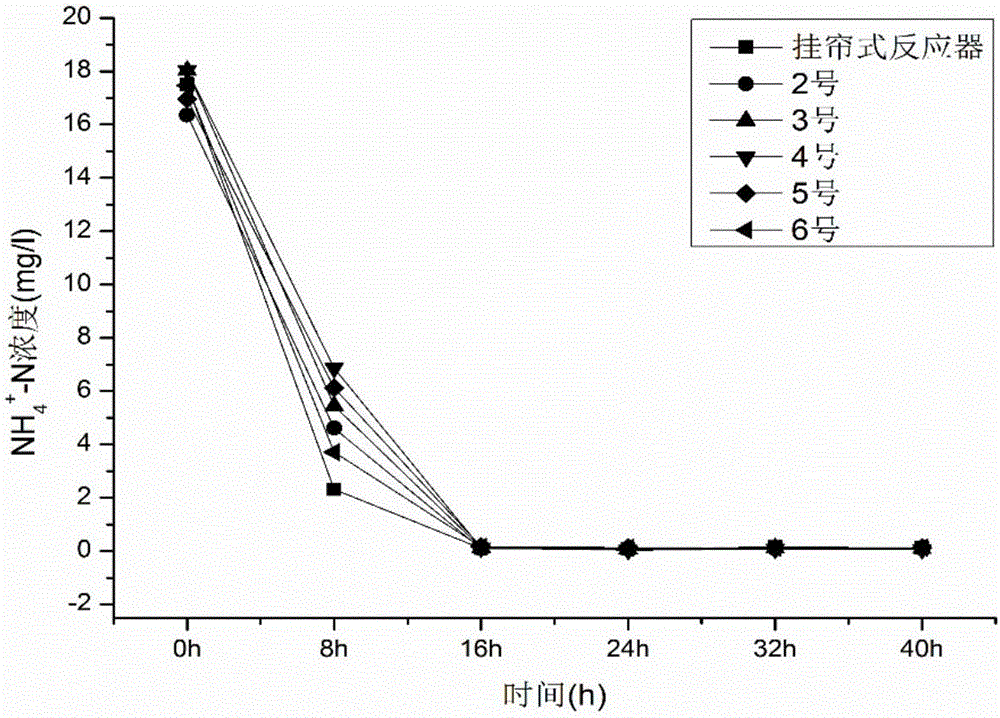

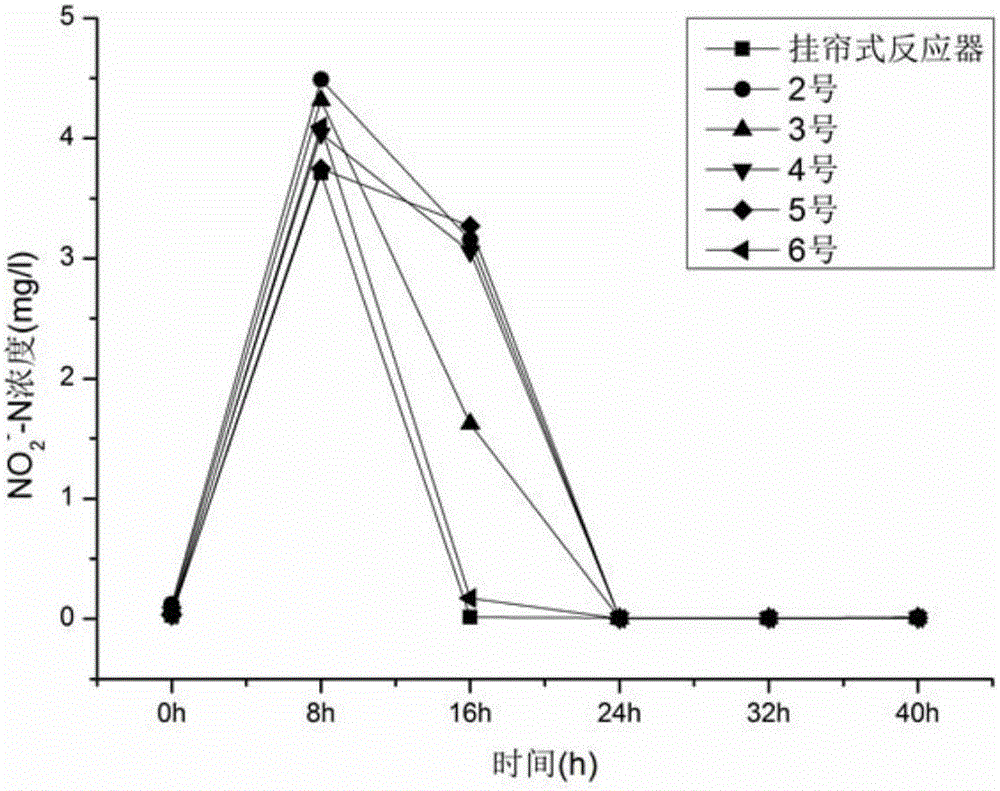

[0048] Embodiment 2: Contrast experiment between hanging curtain type biofilter and other reactors

[0049] A total of 6 barrels of 6L simulated sewage are configured, and the water intake formula is: C 6 h 12 o 6 :33.3mg / L, NH 4 Cl:68.76mg / L (NH 4 +-N: 18mg / L), NaHCO 3 :71.4mg / L, NaHPO 4 : 18.85mg / L, mixed trace element 1ml / L, joins respectively in hanging curtain type biofilter and other No. 2, 3, 4, 5, 6 reactors (volume is all 3L), in No. 2 reactors Large particle size three-dimensional hollow filler (commercially available, cylindrical shape, 1.5cm in diameter, 1cm high, and the material is high-density polyethylene), and in the No. 3 reactor is a disc hollow filler (commercially available, 2.5cm in diameter, with a height of 1cm 0.4cm, the material is high-density polyethylene), in the No. 4 reactor, it is a small particle size three-dimensional hollow filler (commercially available, with a diameter of 1cm, and a height of 0.7cm, and the material is high-density po...

Embodiment 3

[0055] see Figure 4 , a curtain type biofilter, comprising a container, carbon fiber felt 5, inlet pipe 1 and outlet pipe 6; the container is a cuboid, 100cm long, 50cm wide, and 75cm high. Insert 20 sheets of carbon fiber felts side by side in the container, and a water inlet pipe 1 is arranged above the container, and the water inlet pipe is connected with a water distribution pipe 2, and the water distribution pipe 2 is connected with a perforated pipe-type water distributor 3, and the water distributor is located above the carbon fiber felt 5 ; Outlet pipe 6 is located at the bottom of the container.

[0056] Wherein, the specific surface area of the carbon fiber felt 5 is 1300~1500m 2 / m 3 , the thickness is 3mm. Support with hanging curtain support plate 4.

[0057] see Figure 5 , form the circulating aquaculture system with the curtain-type biofilter 7 of the present embodiment, and the recirculating aquaculture system also includes a culture pond 8, a water st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com