Constructed wetland padding brick and preparation method thereof

A technology of artificial wetland filler and artificial wetland, which is applied in the field of artificial wetland filler bricks and its preparation, to achieve the effects of facilitating attachment and growth, improving the effect of sewage treatment, and avoiding plugging of fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

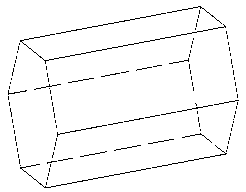

[0011] Such as figure 1 As shown, an artificial wetland filler brick is a regular hexagonal prism structure, and its specific dimensions are as follows: the side length is 8-12cm, and the height is 40-50cm. In order to avoid clogging, provide an environment more conducive to the growth of microorganisms, and improve the sewage treatment effect of wetlands, the porosity of the filler is determined to be ≥ 30%, and the bulk density is 1.2×10 3 —1.5×10 3 Kg / m 3; , the water permeability rate is 15-20m / h, the mass ratio of filler bricks is limestone with a particle size of 2-8mm, 30-40% of cinder with a particle size of 3-10mm, 5-10% of fly ash with a particle size of <2mm, and 15-20 % clay with particle size <2mm, 15-25% volcanic rock with particle size 3-8mm, 5-10% modified diatomite with particle size 2-8mm and 10-15% water.

[0012] Preparation method: (1) At room temperature, add limestone, coal cinder, fly ash, clay, volcanic rock, modified diatomite and water in propo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com