Patents

Literature

167results about How to "Guaranteed removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

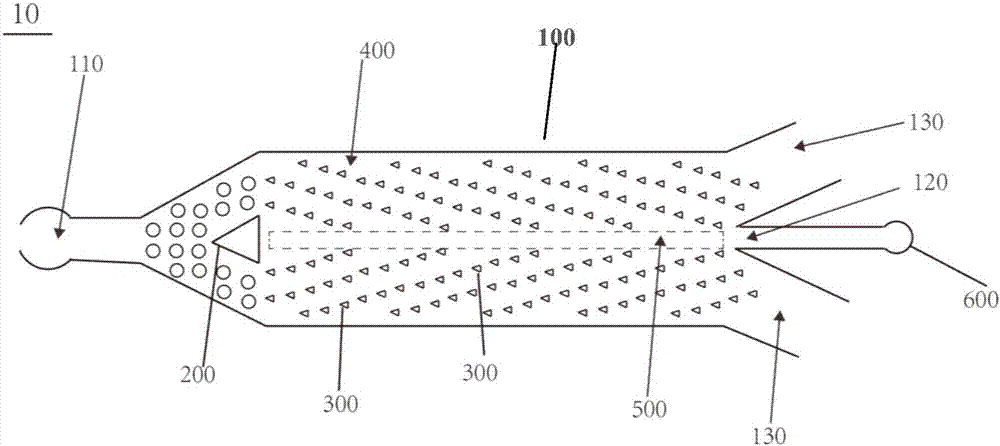

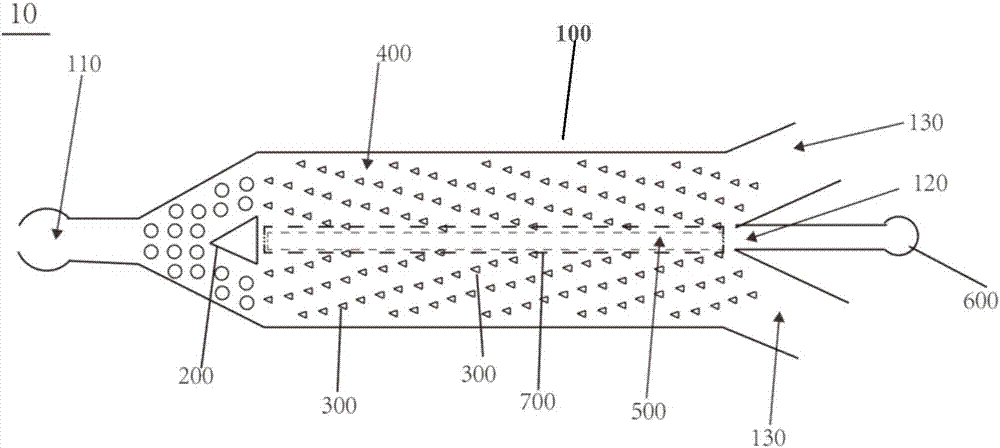

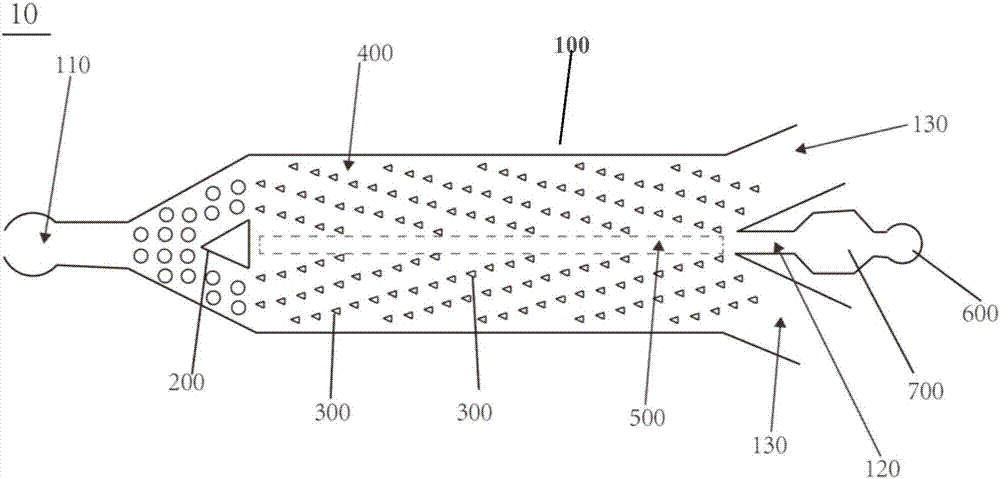

Circulation tumor cell automatic separation and purification micro-fluidic chip and separation and purification method thereof

ActiveCN107402295AHigh purityAvoid spurious resultsMaterial analysisPurification methodsMicro column

The invention discloses a circulation tumor cell automatic separation and purification micro-fluidic chip and a separation and purification method thereof. The circulation tumor cell automatic separation and purification micro-fluidic chip comprises a separation and purification chamber, a diversion column and micro columns, wherein a sample inlet, a first outlet from which target cells flow out, and a plurality of second outlets from which non-target cells flow out are formed in the separation and purification chamber; the separation and purification chamber is internally provided with two micro column arrays; each micro column array consists of a plurality of micro column rows; each micro column row comprises a plurality of micro columns; a gap is formed between every two adjacent micro columns of one micro column row; the gap forms a non-target cell channel; a gap is formed between two micro column arrays; the gap forms a target cell channel from which the target cells pass; the width of the target cell channel is greater than that of the non-target cell channel; an acute angle is formed between the micro column rows and the target cell channel; and the acute angle faces to the sample inlet. The circulation tumor cell automatic separation and purification micro-fluidic chip is high in separation and purification degree.

Owner:SUREXAM BIO TECH

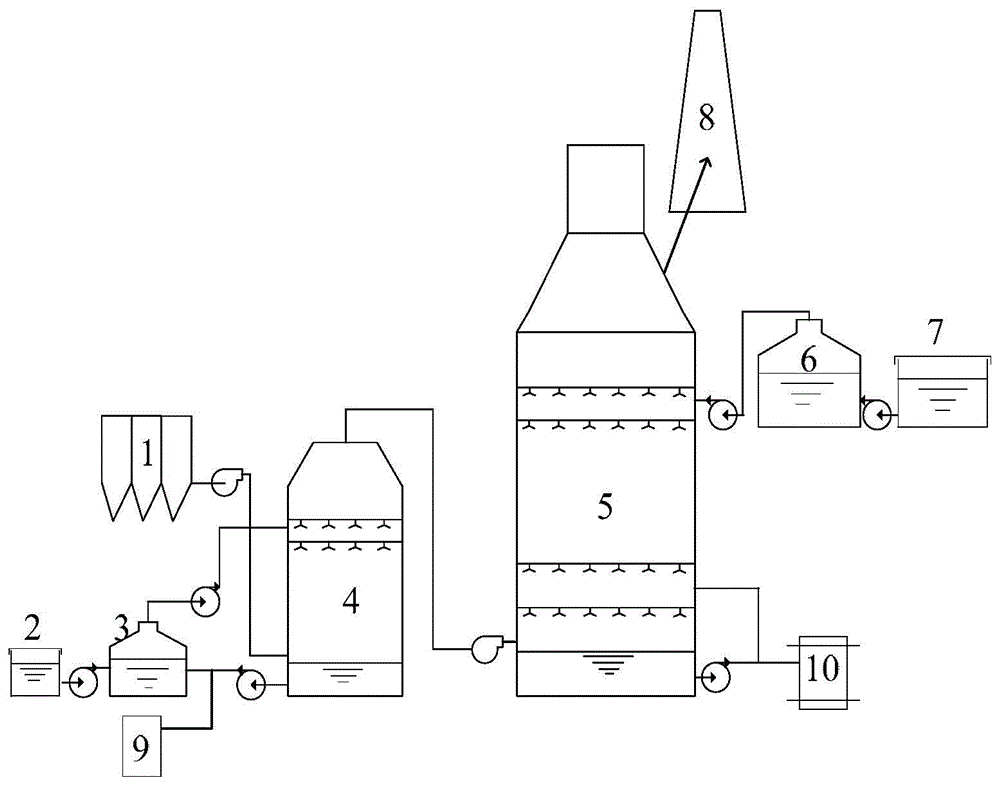

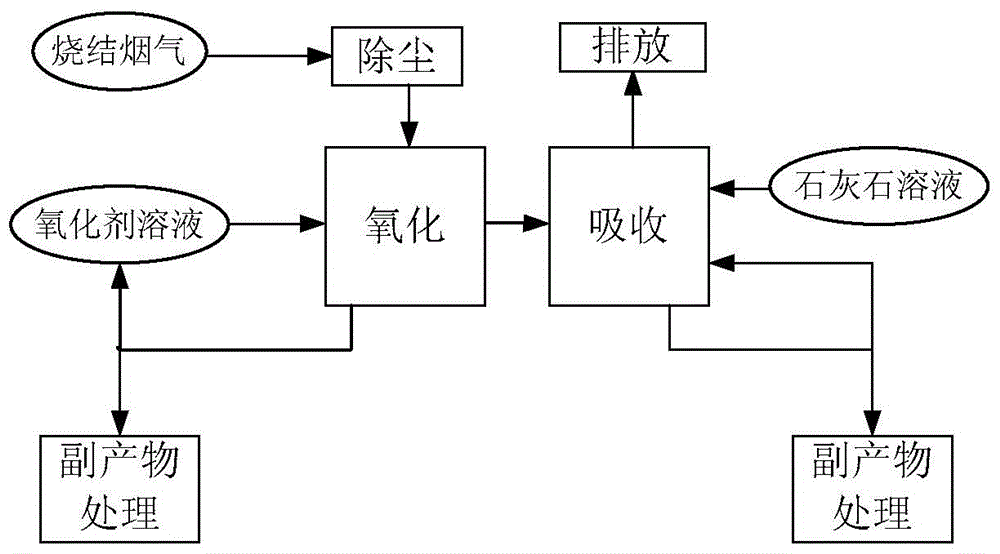

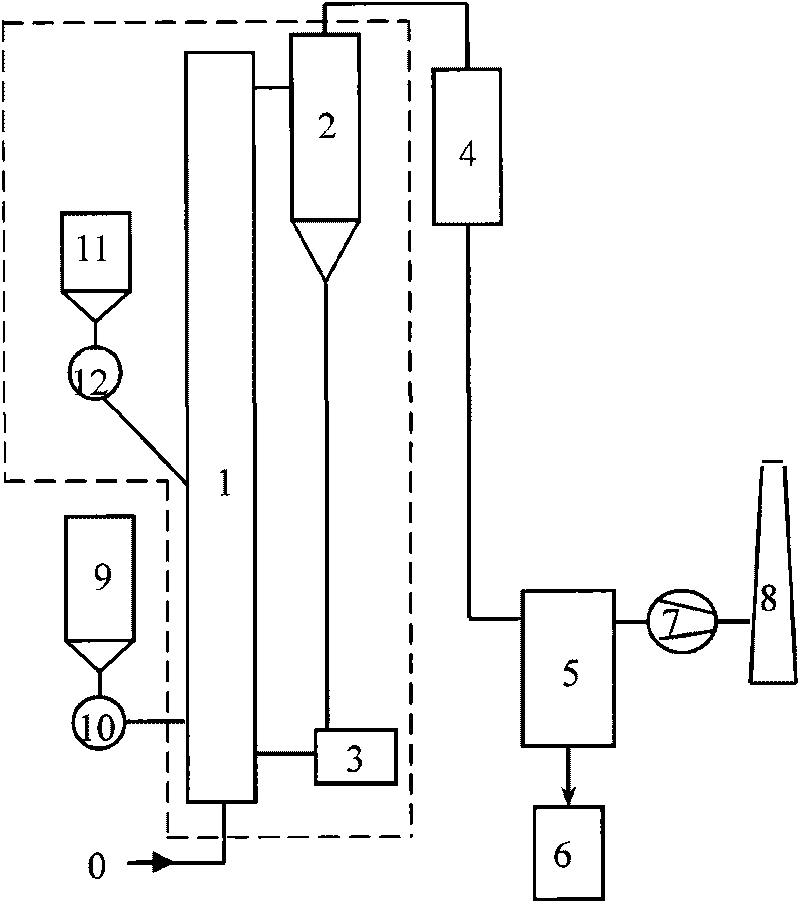

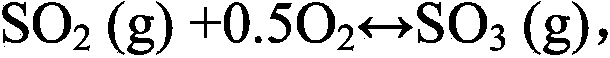

Grading oxidation and absorption type method for simultaneous desulphurization and denitration of sintering flue gas, and system

InactiveCN103977679ALow costRapid responseDispersed particle separationAir quality improvementNitrogen dioxideFlue gas

The invention discloses a grading oxidation and absorption type method for simultaneous desulphurization and denitration of sintering flue gas, and a system. An oxidant solution is adopted in a first grade oxidation tower to spray and oxidize the sintering flue gas so that nitrogen oxides are oxidized into nitric oxide and sulfur dioxide is oxidized into sulfur trioxide. An absorbent solution is adopted in a second grade absorption tower to spray and absorb the sintering flue gas being sprayed and oxidized so that the nitric oxide and the sulfur trioxide are absorbed. Finally, the sintering flue gas after spray oxidation and spray absorption is discharged. The method and the system largely reduce the using amount of the oxidant at the same time of achieving the objectives of simultaneous desulphurization and denitration, and are efficient and energy-saving.

Owner:SOUTHEAST UNIV

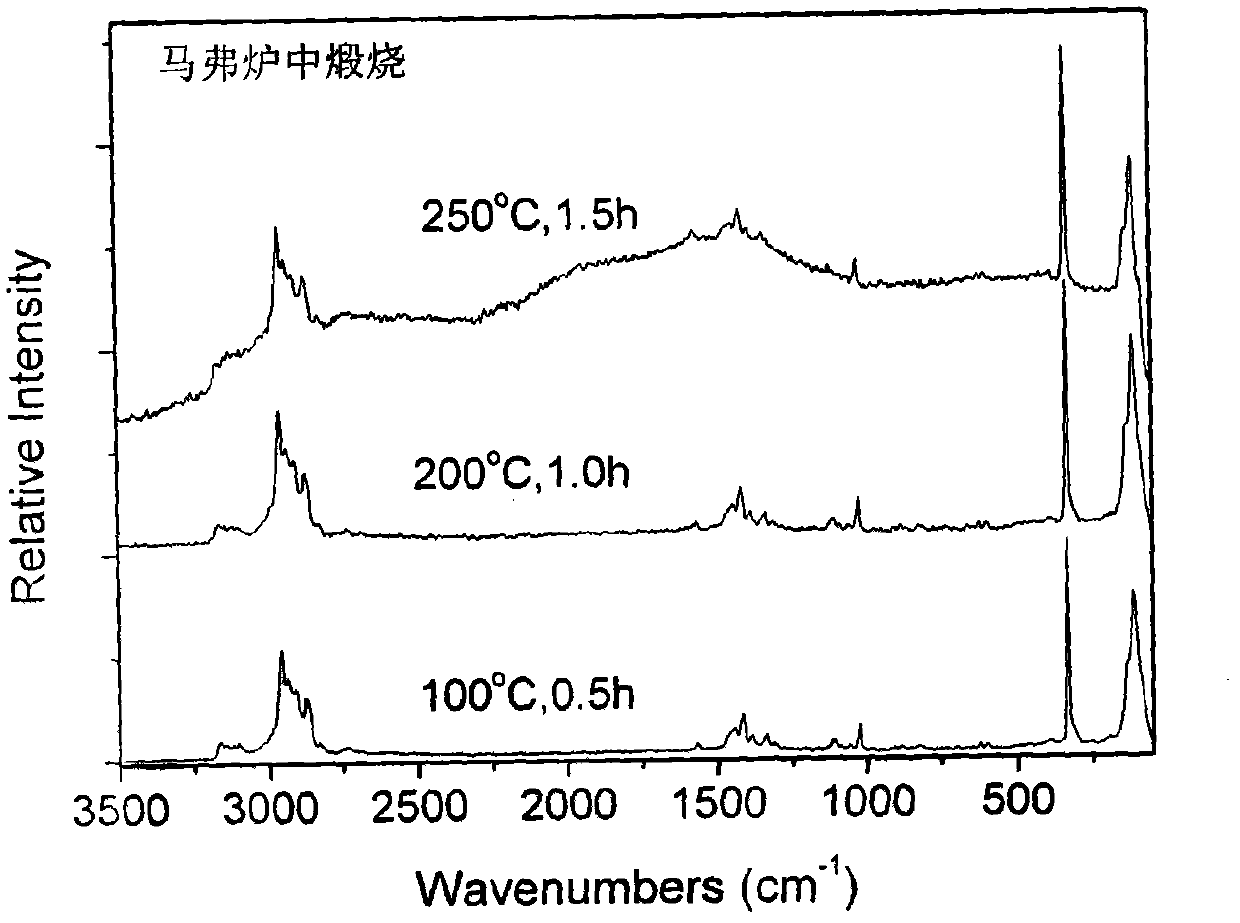

Catalytic ceramic filter tube and preparation method

ActiveCN105107310AEfficient removalExtended service lifeSemi-permeable membranesDispersed particle filtrationActive componentElemental mercury

The invention provides a catalytic ceramic filter tube which is high in dust collection efficiency, can efficiently oxidize elemental mercury, can also efficiently reduce NOx, and achieves simultaneous dust removal and SCR denitration and a preparation method. The catalytic ceramic filter tube comprises a ceramic filter tube substrate, and a catalytic active component layer and a separation membrane which sequentially coat the ceramic filter tube substrate. The preparation method comprises the following steps: step 1. preparing the ceramic filter tube substrate by isostatic pressing molding; step 2. coating the ceramic filter tube substrate with a catalytic active component membrane to obtain a catalytic ceramic filter tube substrate; and step 3. preparing the separation membrane on the catalytic ceramic filter tube substrate. The catalytic ceramic filter tube provided by the invention can achieve integrated efficient removal of dust, NOx and elemental mercury in high-temperature flue gas (>300 DEG C), the service life of the catalyst can be prolonged through protection for the catalyst by the separation membrane and the substrate, and the structure arrangement of the ceramic filter tube can reduce the occupied area and running cost of equipment.

Owner:HUANENG POWER INTERNATIONAL +2

Desulfuration method by directly utilizing magnesium slags in circulating fluidized bed boiler

ActiveCN101703886AExtended stayIncrease profitDispersed particle separationProcess efficiency improvementSmelting processFluidized bed

The invention provides a desulfuration method by directly utilizing magnesium slags in a circulating fluidized bed boiler, belonging to the technical field of flue gas desulfuration in the circulating fluidized bed boiler, in particular relating to the technical scheme in which magnesium slags are directly used as desulfurating agent for desulfuration in the circulating fluidized bed boiler. The invention directly utilizes magnesium slags and adds the magnesium slags into the hearth of the circulating fluidized bed boiler through a controllable feeding device; the magnesium slags react with the SO2 in the exhaust gas under the condition of good gas-solid contact condition in the circulating fluidized bed; and the temperature condition of 850-950 DEG C in the circulating fluidized bed is beneficial for the gas-solid desulfuration reaction. The invention can realize the desulfuration of the coal burning process by utilizing the characteristics of the magnesium slags and the special burning conditions of the circulating fluidized bed, thus solving the environmental pollution to the air and the soil by the magnesium slags generated in the magnesium smelting process, finding a way for reasonably utilizing waste slags for magnesium enterprises, realizing the purpose of utilizing waste to control waste and achieving the purpose of comprehensive utilization of resources.

Owner:TAIYUAN UNIV OF TECH

Treatment method and system for sprayed VOCs (Volatile Organic Chemicals) mixed gas

InactiveCN105964141AReduce complexityImprove processing efficiencyGas treatmentDispersed particle separationHydrogenFlue gas

The invention provides a treatment method and system for sprayed VOCs (Volatile Organic Chemicals) mixed gas. The method comprises the following steps: firstly, removing paint mist in mixed gas; then raising the temperature of the gas without the paint mist to 320 DEG C to 350 DEG C; and carrying out a catalytic oxidization reaction under a catalytic condition of a catalyst to thermally decompose the mixed gas into high-temperature flue gas containing a carbon-oxygen compound and a hydrogen-oxygen compound, and then discharging out the high-temperature flue gas. The system comprises a paint mist removing device for removing the paint mist in the sprayed VOCs mixed gas, a heating unit for heating the sprayed VOCs mixed gas, a catalytic oxidization reaction chamber and a centralized emission device, wherein the paint mist removing device is provided with a gas inlet of the sprayed VOCs mixed gas and a gas outlet of the sprayed VOCs mixed gas; the gas outlet of the paint mist removing device is connected with the gas inlet of the heating unit; the gas outlet of the heating unit is connected with the gas inlet of the catalytic oxidization reaction chamber; and the gas outlet of the catalytic oxidization reaction chamber is communicated with the centralized emission device, and the catalytic oxidization reaction chamber is internally filled with a catalyst and a heat accumulation body.

Owner:CHONGQING UNIV

Method of for desulfurization by wet oxidation of hydrogen sulfide at medium-high temperature

InactiveCN102559292AFast and efficient oxidation removalRaise the reaction temperatureGas purification by catalytic conversionIonWet oxidation

The invention relates to a new method for desulfurization by wet oxidation of hydrogen sulfide using iron-based ionic liquid at medium-high temperature. The iron-based ionic liquid is heatproof liquid with strong absorption and oxidation properties. Application of the iron-based ionic liquid can not only effectively absorb hydrogen sulfide gas within a concentration range of 0-100% at 70-240 DEG C, but also can oxidize hydrogen sulfide gas into elemental sulfur in a fast and efficient way. The sulfur is cooled and separated, and the iron-based ionic liquid is regenerated and reused after being subjected to oxygen oxidation. Adjustment of the pH of a reaction system is not needed during the process of high-temperature oxidation of hydrogen sulfide in the iron-based ionic liquid, and the acidity characteristic of the iron-based ionic liquid can avoid production of sulfur-containing by-products. Wet oxidation of hydrogen sulfide can be realized at a temperature ranging from 70 DEG C to 240 DEG C through adjustment of flow and concentration of hydrogen sulfide gas and adoption of combined process of absorption-oxidation-separation-regeneration, the desulfurization percent can reach over 99%, and no secondary pollution is produced.

Owner:BEIJING UNIV OF CHEM TECH

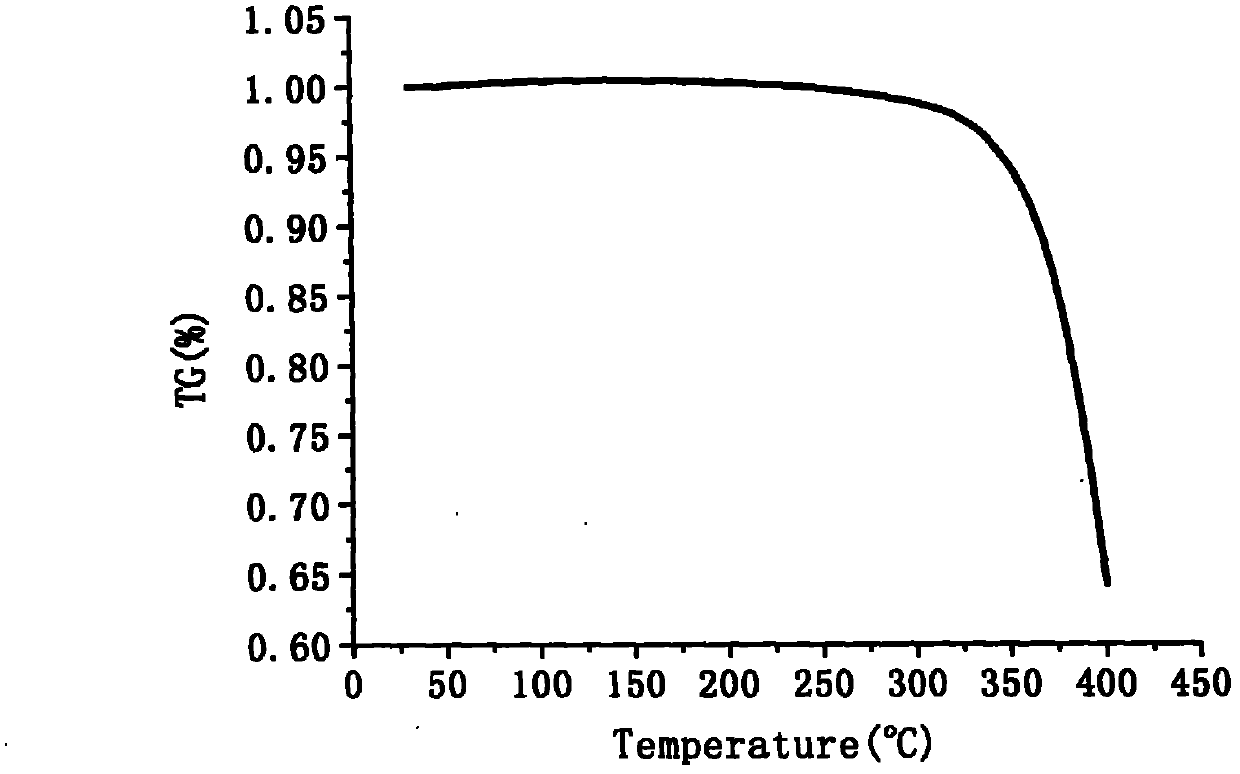

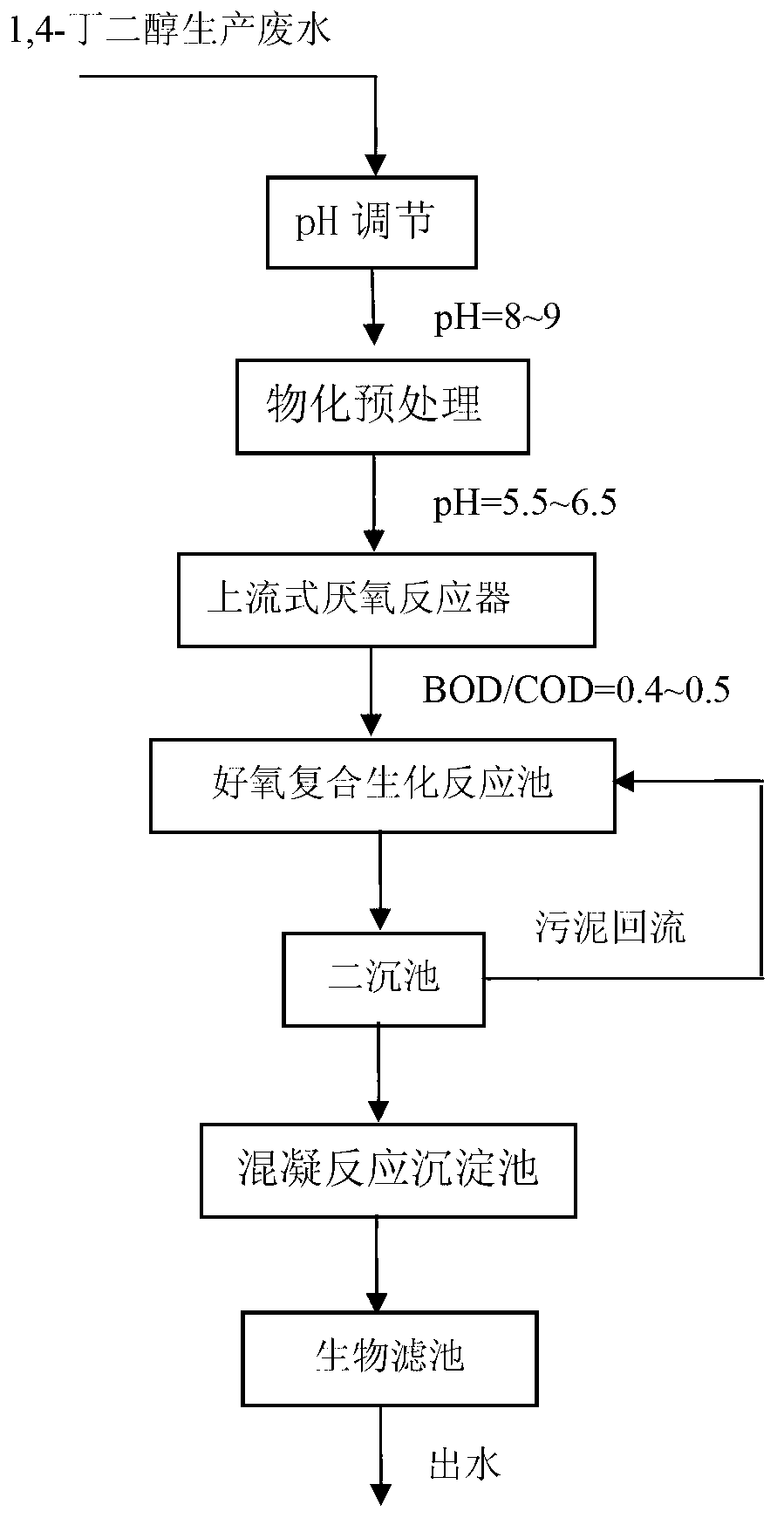

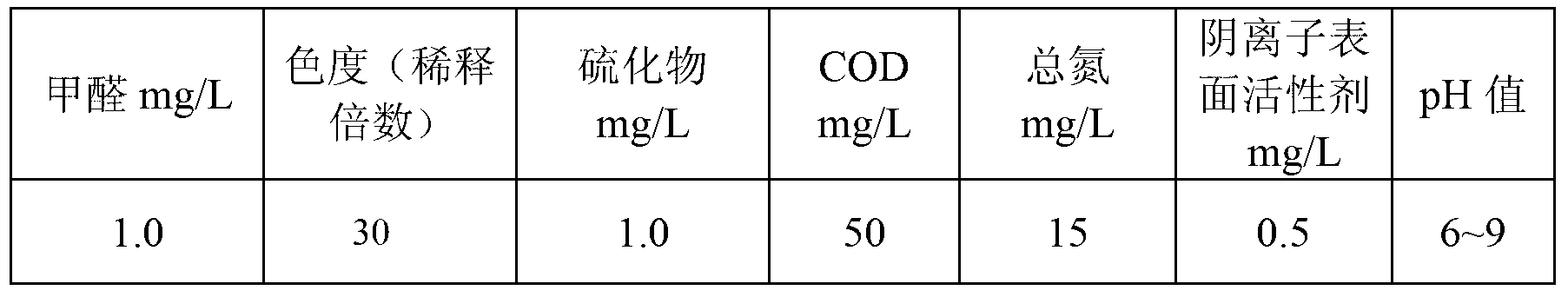

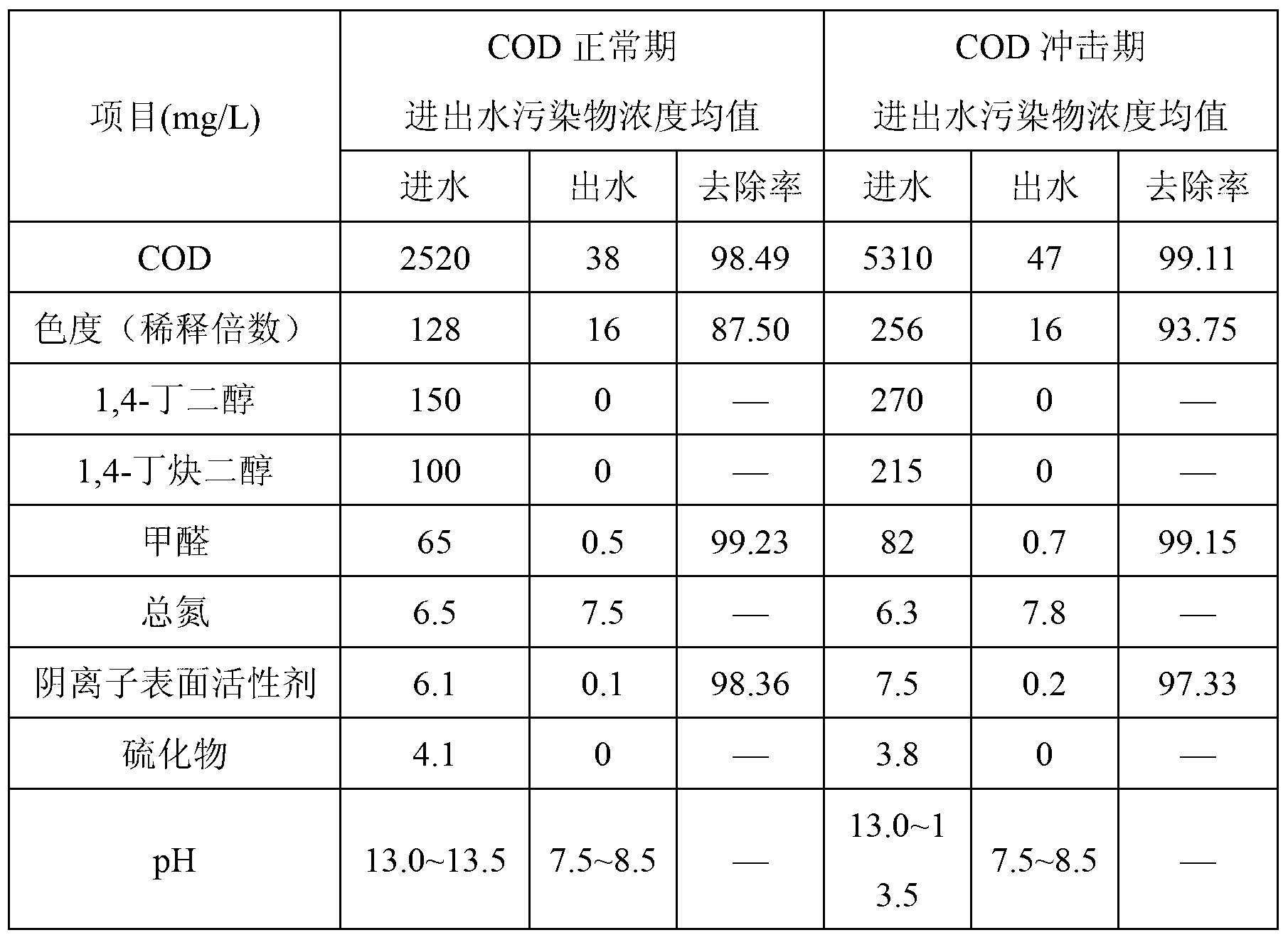

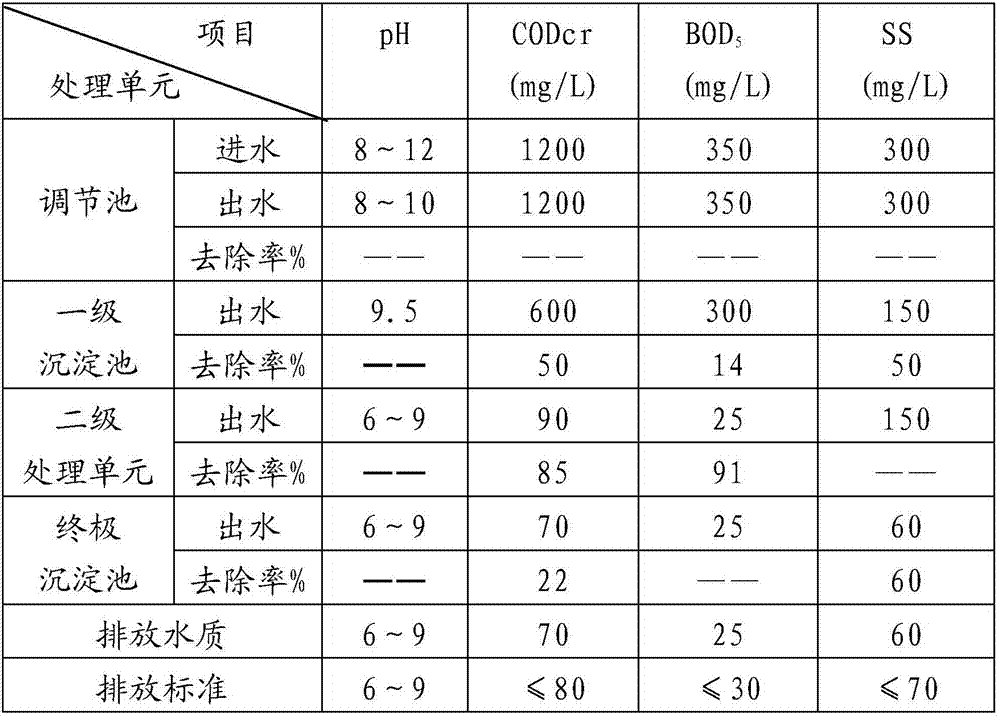

Combined treatment method of 1,4-butanediol production wastewater

InactiveCN103253827AReduce acidityWeak acidMultistage water/sewage treatmentNature of treatment waterHigh concentrationChemical oxygen demand

The invention relates to a combined treatment method of 1,4-butanediol production wastewater, which comprises the following steps: carrying out physical and chemical pretreatment on wastewater firstly so as to obtain pre-optimized wastewater; improving the biodegradability of the wastewater and further reducing the COD (chemical oxygen demand) concentration of the wastewater through an upflow anaerobic reactor and an aerobic combined biochemical reaction tank; and after the muddy water separation of the wastewater is realized through a secondary sedimentation tank, sequentially feeding the wastewater into a coagu-flocculation reaction settling pond and a biological filter, carrying out deep treatment on the wastewater, removing substances such as tiny suspended solids and colloids and the like in the wastewater through coagu-flocculation reaction and precipitation, and enabling discharged water to meet the requirements of one-class A standards in the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002) through the synergistic effect of adsorption and biodegradation of the biological filter. The method disclosed by the invention not only has a stable removal effect on COD in 1,4-butanediol production wastewater, but also can effectively resist violent water impacts; and the method has the characteristics of rapid system startup and the like. The method disclosed by the invention also can be applied to the treatment of other high-concentration toxic degradation-resistant organic wastewater with a water quality similar to that of 1,4-butanediol production wastewater.

Owner:TONGJI UNIV +1

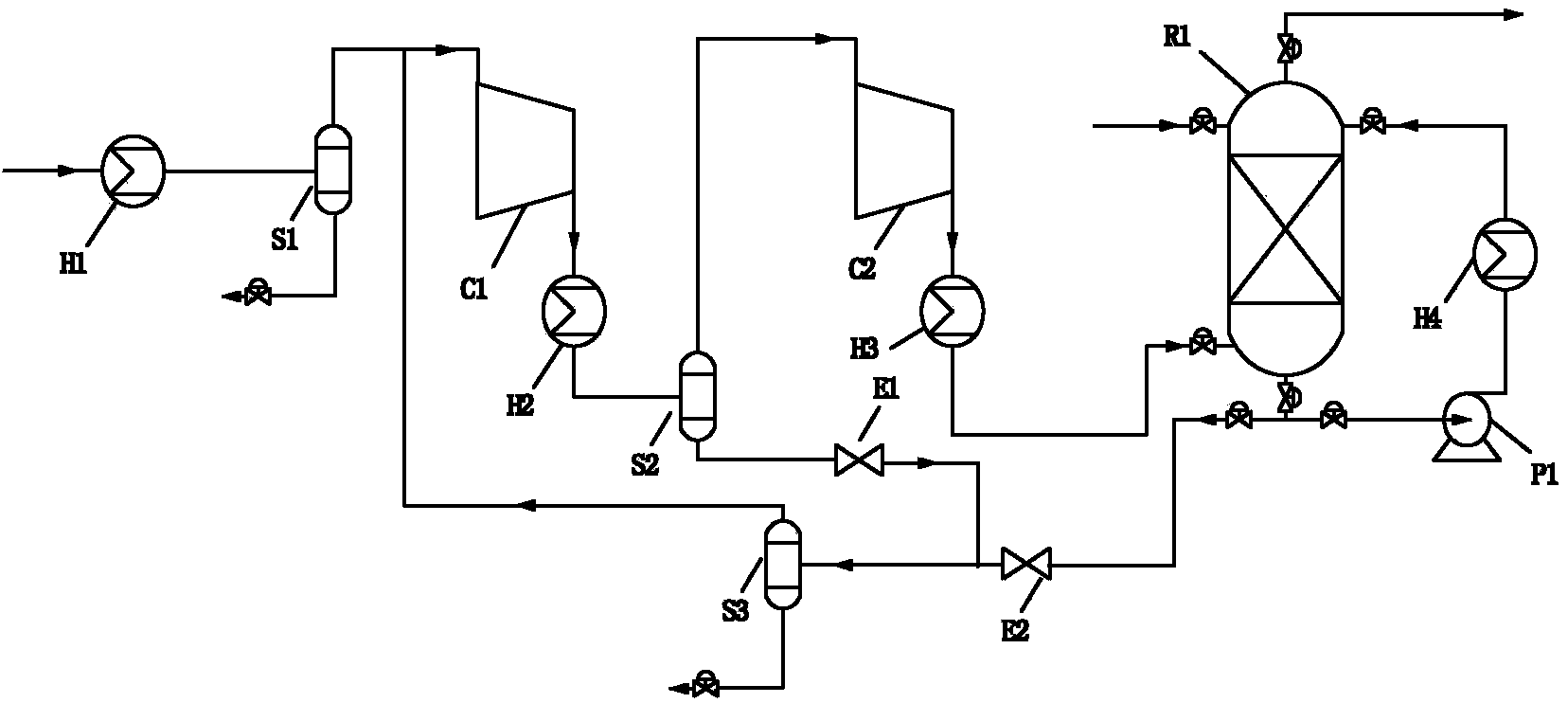

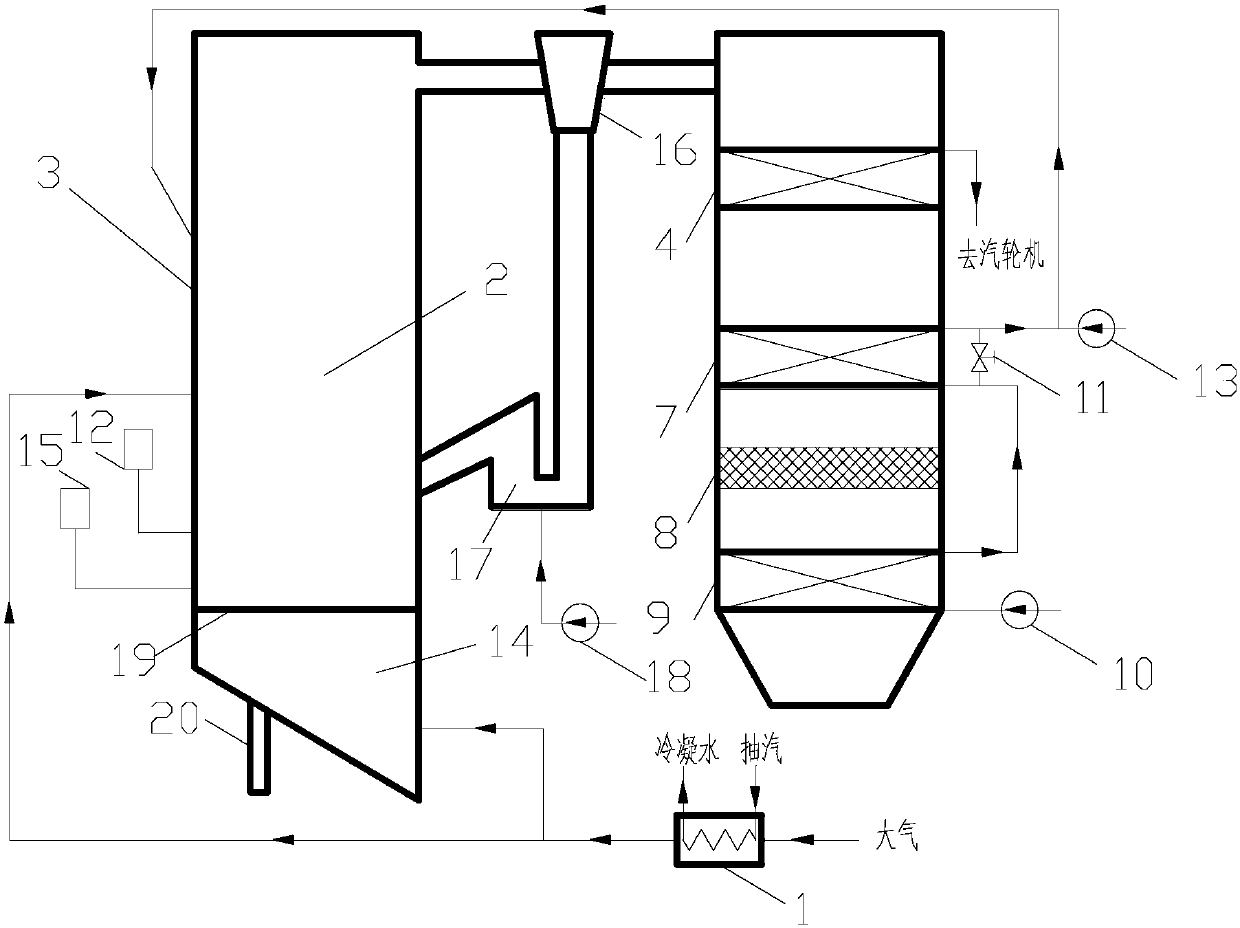

Oxygen-enriched combustion flue gas purification device

ActiveCN103363537ARapid responseSimplify multi-stage compressionLighting and heating apparatusDispersed particle separationVapor–liquid separatorFlue gas

The invention provides an oxygen-enriched combustion flue gas purification device, and belongs to a boiler flue gas purification device. The oxygen-enriched combustion flue gas purification device can simultaneously remove NOx, SO2 and Hg in tail flue gas of an oxygen-enriched combustion boiler in a compression process, is applicable to a generating station utilizing an oxygen-enriched combustion technology, and solves the problems that the existing flue gas desulfurization and denitration device is complicated in system and higher in energy consumption, the gas extraction purity is low and a high-pressure absorption liquid cannot be used conveniently. The oxygen-enriched combustion flue gas purification device comprises a first condenser, a first gas-liquid separator, a primary compressor, a second condenser, a second gas-liquid separator, a secondary compressor, a third condenser, a high pressure reaction tower, a third gas-liquid separator and a fourth condenser. With the adoption of the oxygen-enriched combustion flue gas purification device, equipment can be simplified; the running cost can be lowered; the removing efficiency can be guaranteed; the oxysulphide removing efficiency approximates to 100%; the oxynitride removing efficiency can reach 95%; and an Hg removing effect is better.

Owner:HUAZHONG UNIV OF SCI & TECH

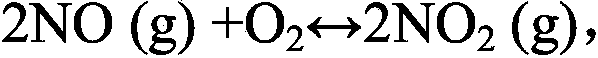

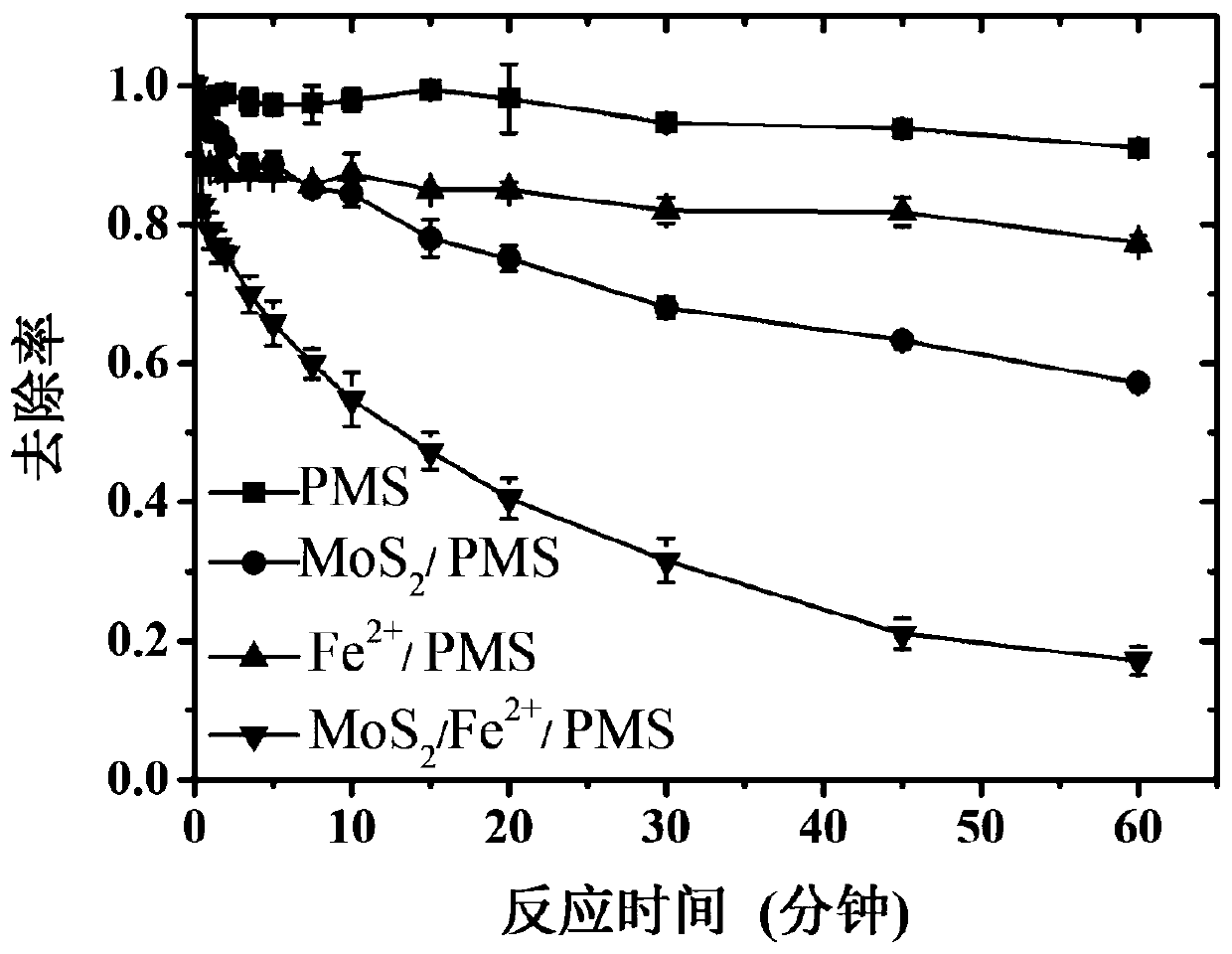

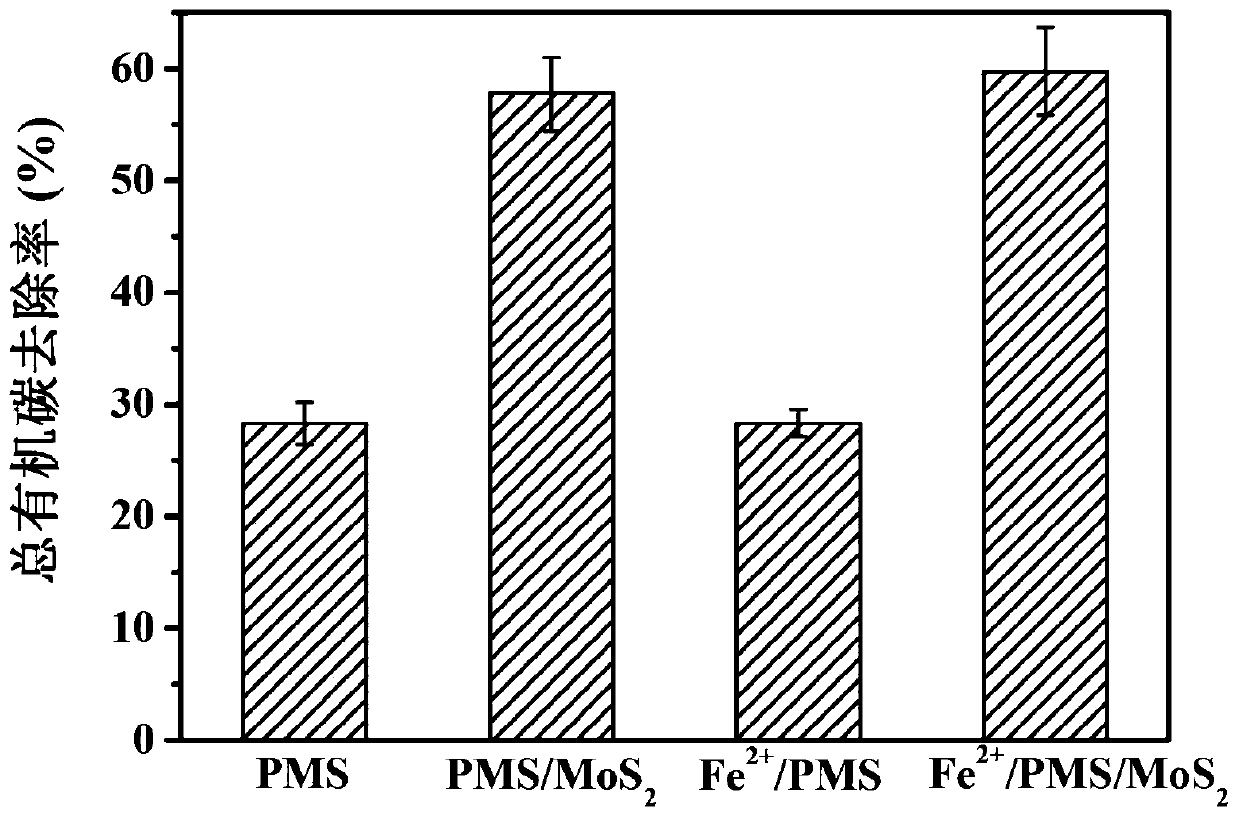

Method for degrading organic dye in water by activating persulfate by using molybdenum disulfide synergized bivalent iron

ActiveCN110227499ASolve easy precipitationSolve Fe(III)Physical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyeOperability

The invention discloses a method for degrading organic dye in water by activating a persulfate by using molybdenum disulfide synergized bivalent iron. The method comprises the following steps: addingmolybdenum disulfide into ultrapure water, carrying out ultrasonic treatment at a temperature of 15-25 DEG C, then adding organic dye wastewater, uniformly carrying out mixing, then adding ferrous iron, adjusting the pH value to 2-4, then adding a persulfate to obtain a reaction system, and carrying out stirring at normal temperature for degradation. The use amount of molybdenum disulfide in the method is low, the molybdenum disulfide can be repeatedly used, and no secondary pollution is caused. Compared with a method of activating a persulfate by single bivalent iron, the method has the advantages that the use amount of bivalent iron is lower, the reaction time is greatly shortened, and a large amount of manpower, material resources and financial resources are saved. The application rangeof a pH value of the system is wide, and the activation effect is the best under the condition that the pH value is equal to 3. The method disclosed by the invention has a very simple process flow and does not need a complex device, the reaction conditions are mild, and a reaction can be carried out quickly at normal temperature and normal pressure. Operability is high, and the method has a widepractical application prospect.

Owner:ZHEJIANG UNIV OF TECH

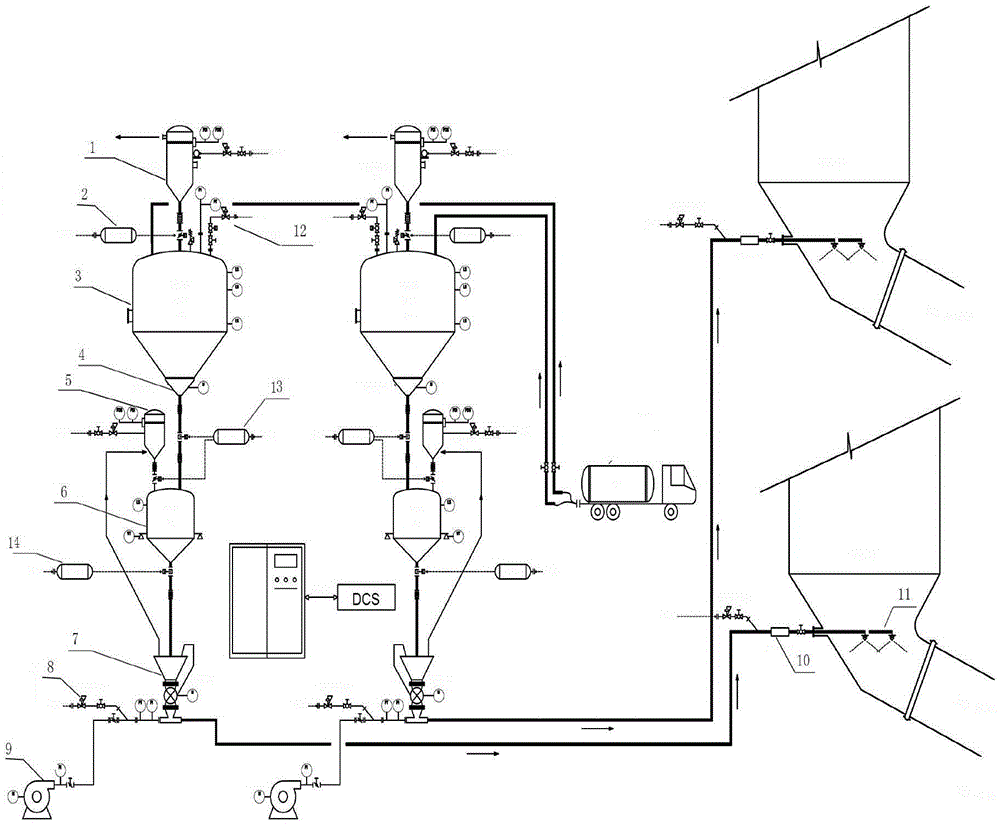

Device for removing SO3 through flue injection of dry powder adsorbent

ActiveCN105617861AImprove performanceSmooth moisture resistanceGas treatmentDispersed particle separationSorbentFlue gas

The invention relates to the technical field of coal-fired flue gas pollutants and specifically relates to a device for removing SO3 through flue injection of a dry powder adsorbent. The device comprises a storage tank used for storing the dry powder alkaline adsorbent, wherein a feeding hole and an exhaust hole are formed in the top of the storage tank; the exhaust hole is connected with a gas inlet of a storage tank filter through a storage tank gas conveying pipe; the middle part of the storage tank gas conveying pipe is connected with a first pressure gas source through a pipeline with a first pneumatic stop valve; a micro positive pressure device used for keeping micro positive pressure in the storage tank is mounted on the upper part of the storage tank; the lower part of the storage tank is of conical hopper shape with downward taper angle; a storage tank discharging hole is arranged at the bottom of the storage tank; a pneumatic feeder is arranged at the storage tank discharging hole; a weighting tank is arranged under the pneumatic feeder; a discharging hole of the pneumatic feeder is connected with a feeding hole at the top of the weighting tank through a pneumatic feeder delivery pipe; the pneumatic feeder delivery pipe is connected with a second pressure gas source through a pipeline with a stop valve; a weighting tank exhaust hole is arranged at the top of the weighting tank.

Owner:中国大唐集团科学技术研究总院有限公司

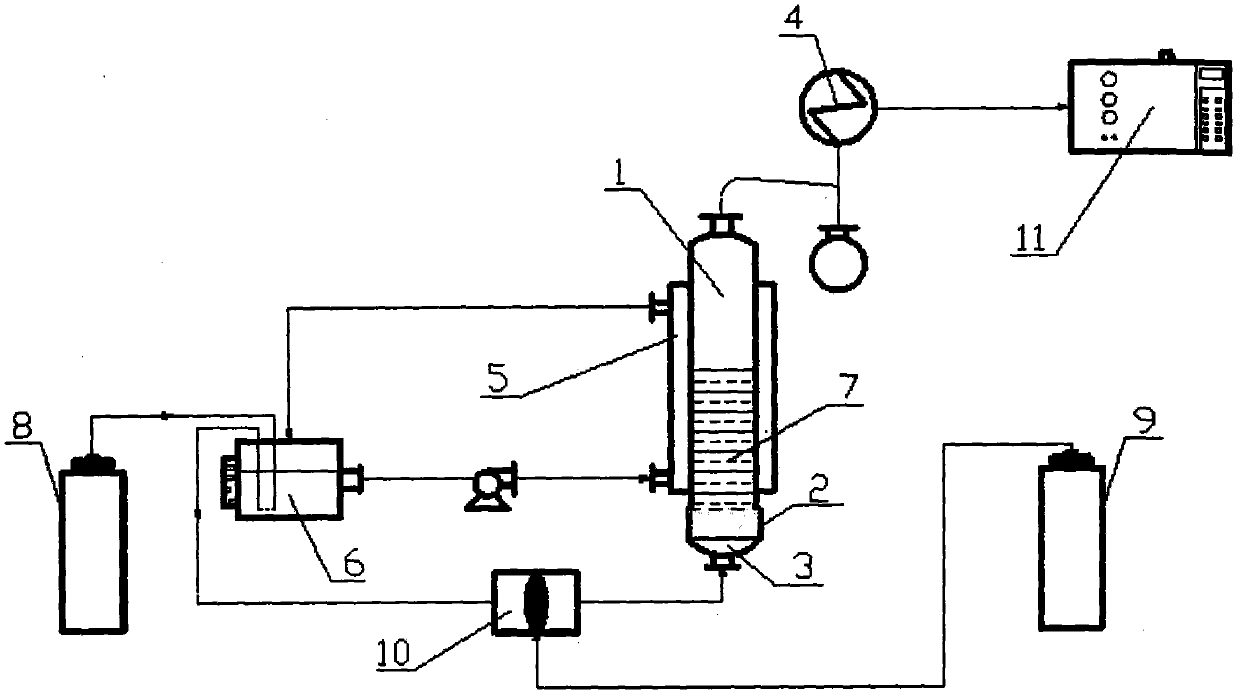

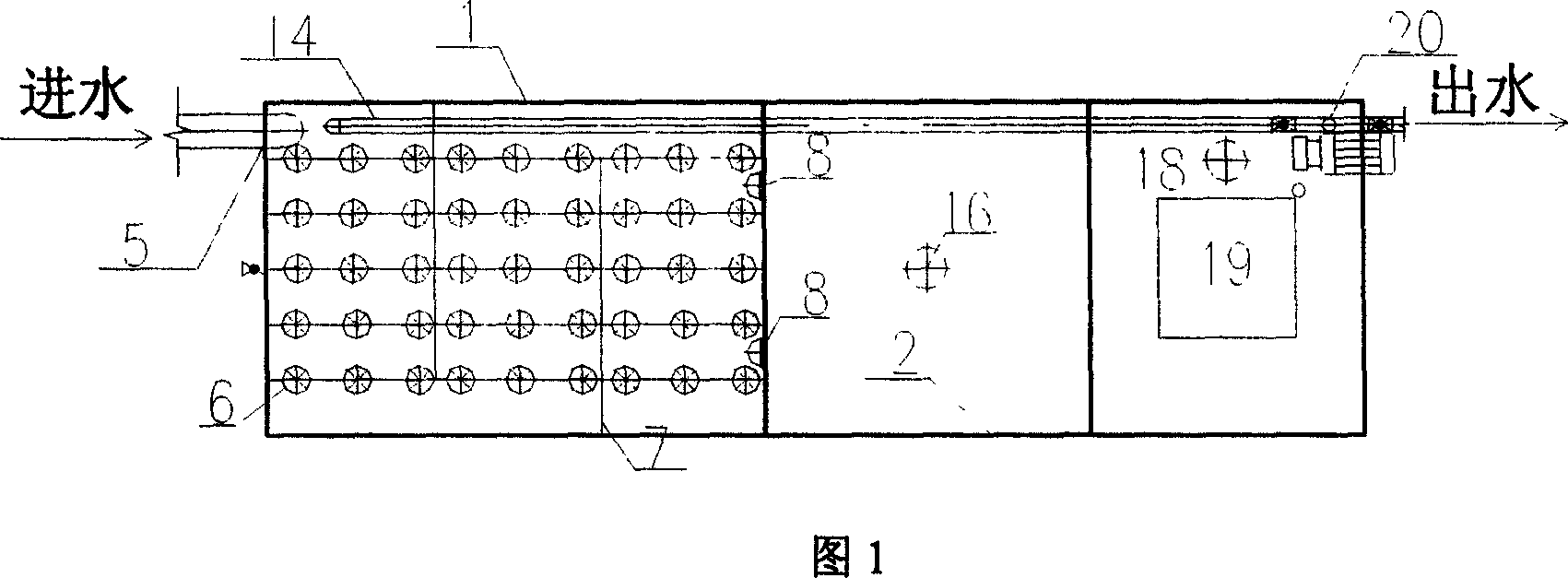

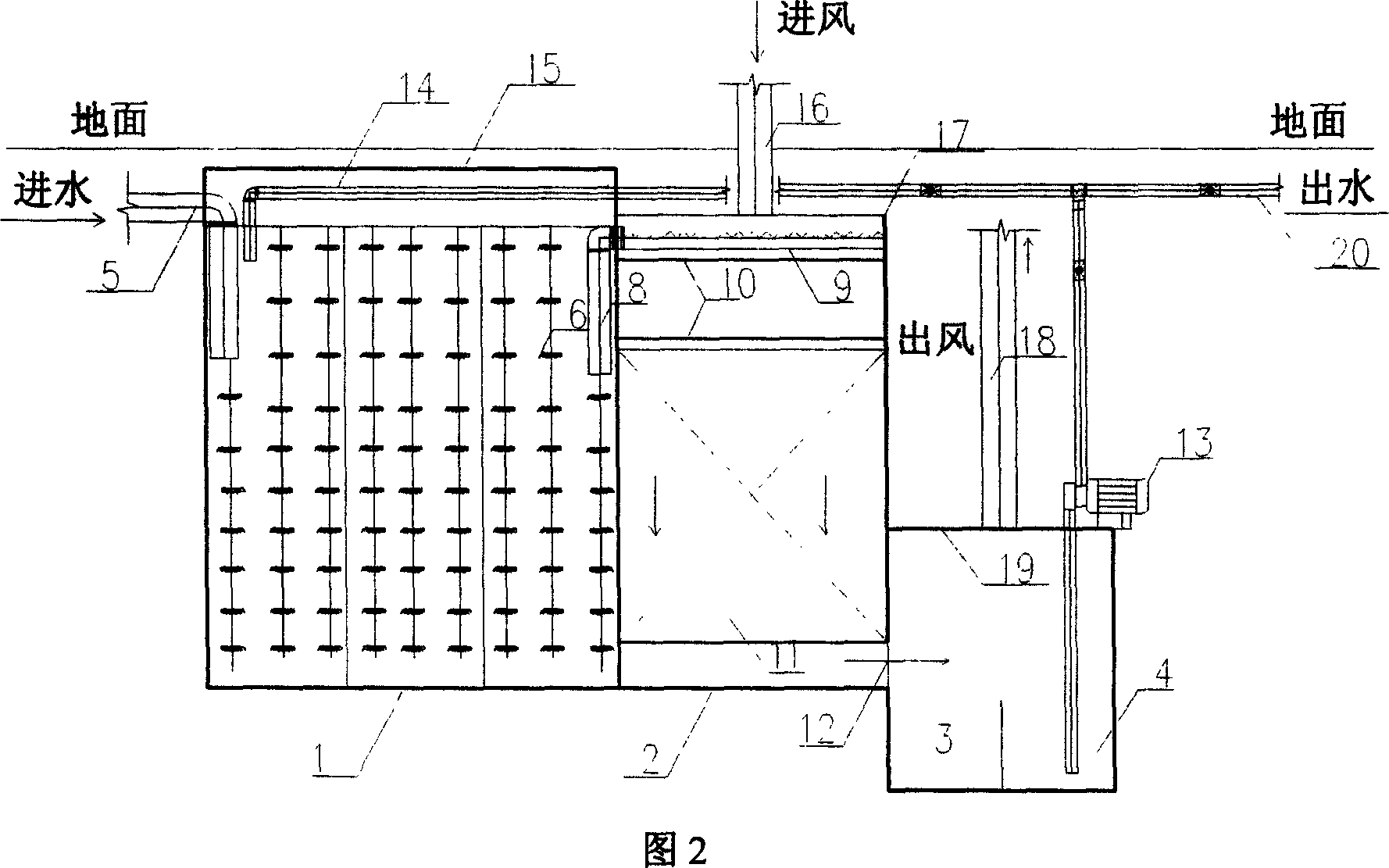

Integral sputtering-oxygenating-biofiltering waste water purifying apparatus and process

InactiveCN1931743AGood removal effectImprove denitrification effectTreatment with aerobic and anaerobic processesSustainable biological treatmentBio filtrationSewage

The present invention is integral sputtering, oxygenating and biofiltering waste water purifying apparatus and process, and belongs to the field of sewage treating technology in environmental engineering. The advanced sewage treating technology is for use in subzone, school and countryside. The sewage purifying apparatus includes parallel anaerobic denitrogenating reactors, sputtering, oxygenating and biofiltering reactor and precipitating area. Sewage is treated in the anaerobic denitrogenating reactors, the sputtering, oxygenating and biofiltering reactor and the precipitating area successively, and part of the output water is returned to the anaerobic denitrogenating reactors. The present invention has high organic matter and nitrogen eliminating efficiency.

Owner:SOUTHEAST UNIV

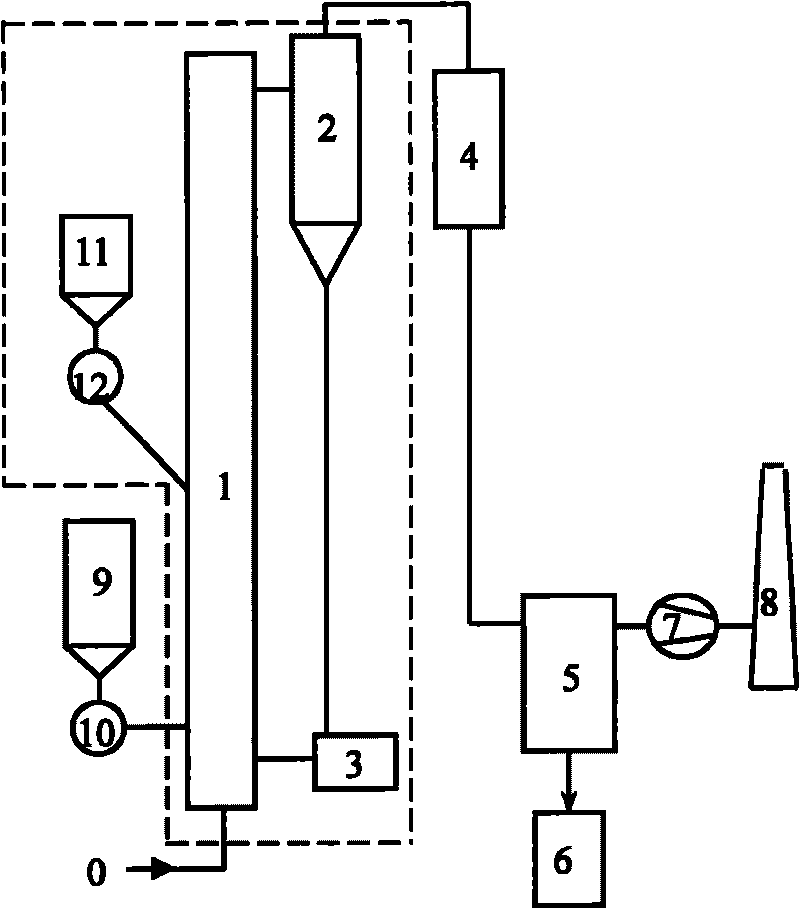

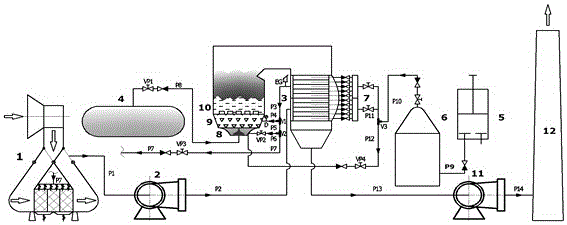

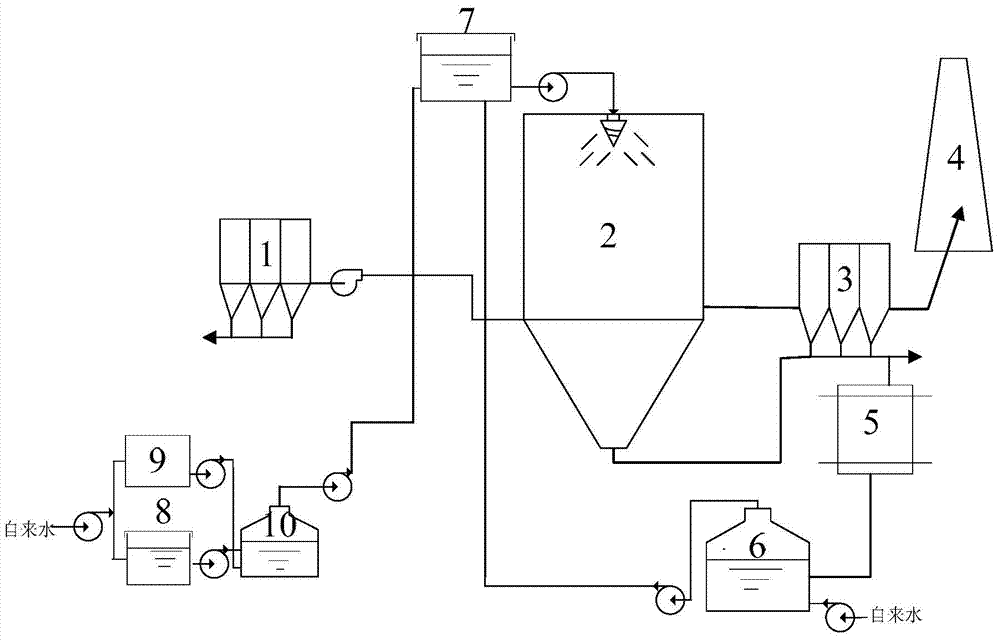

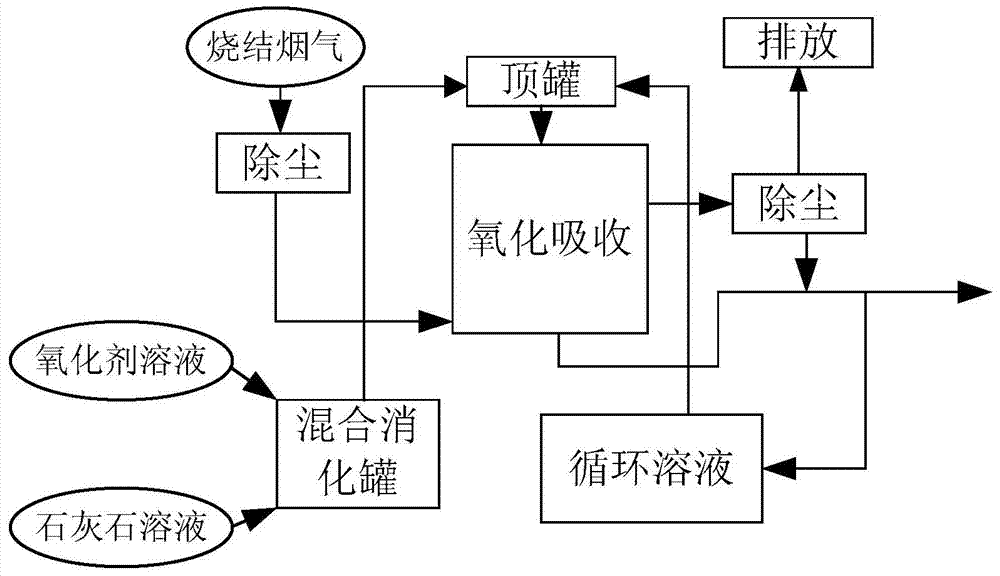

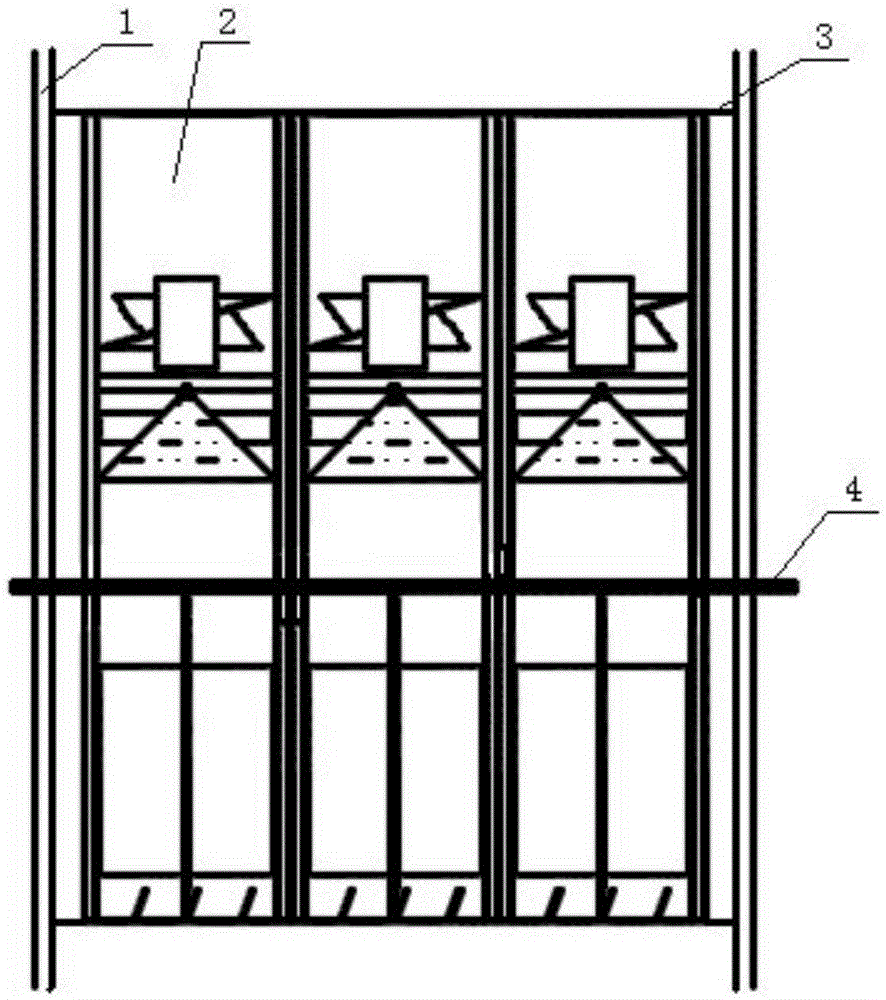

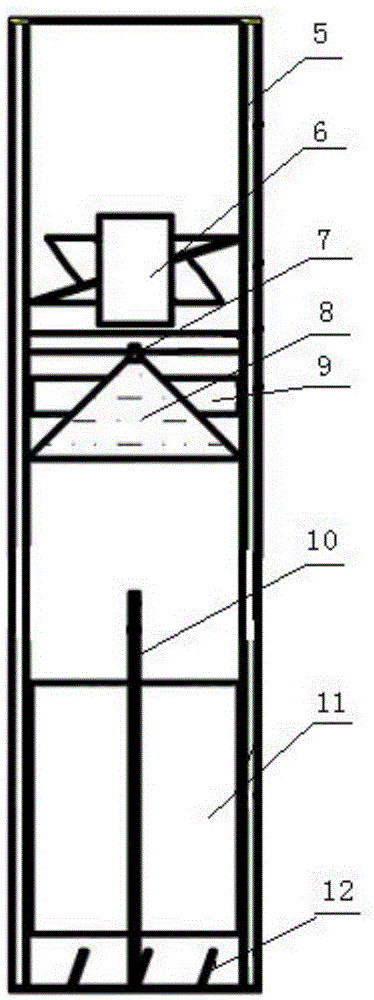

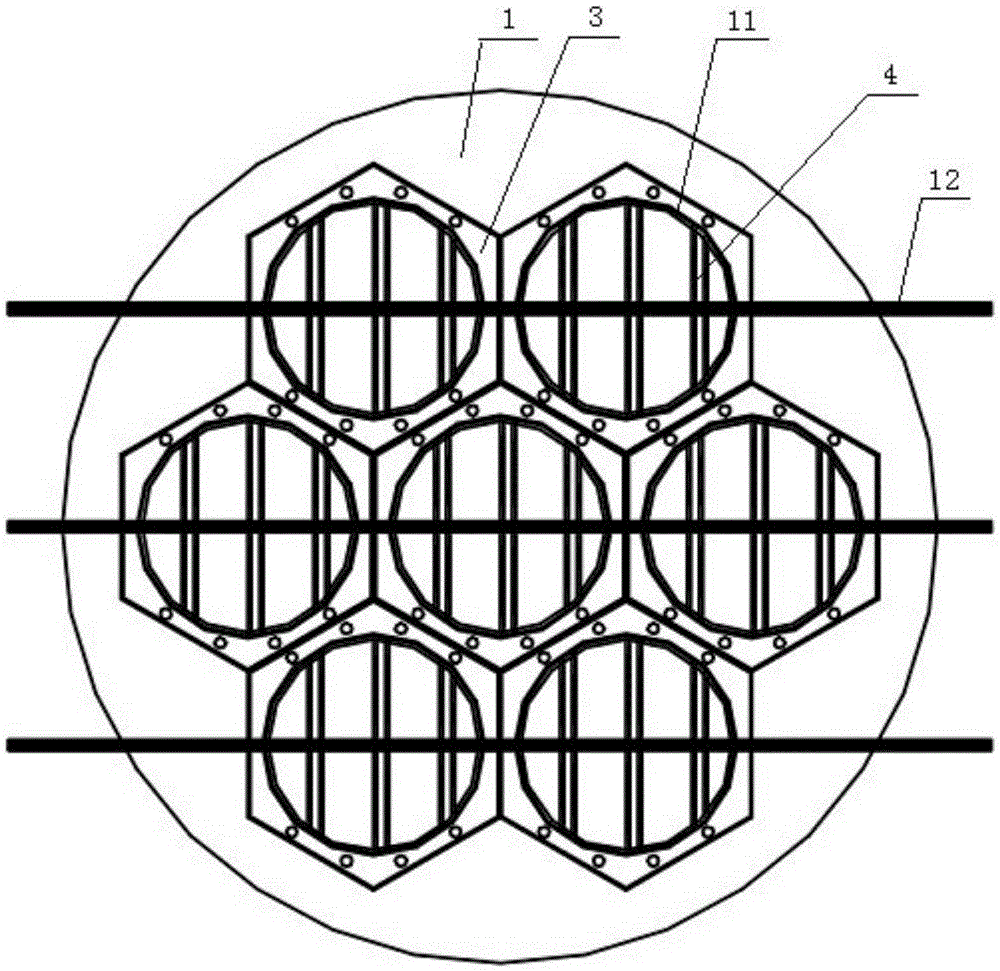

Spray absorption type system for simultaneous desulphurization and denitration of sintering flue gas

ActiveCN104324575ASolve the problems of large initial investment and occupied spaceLow costCombination devicesAir quality improvementNitrogen oxidesFlue gas

The invention discloses a spray absorption type system for simultaneous desulphurization and denitration of sintering flue gas; the system includes a flue gas reaction and purification system, a new solution adding system and a recirculation solution system, the flue gas reaction and purification system comprises a first cloth bag dust collector, a spray absorption tower, a second bag dust collector and a chimney, the new solution adding system comprises a sintering lime solution tank, an oxidant solution tank and a mixing digestion tank, and the recirculation solution system includes a recirculation desulfurization denitration slag filtering device, a recirculation oxidation absorption liquid pool and an oxidation absorption liquid tank. The system aims to use lime produced in sintering process for desulfurization and meanwhile removal of nitrogen oxides in the sintering flue gas, and is a high-efficiency energy-saving cost-saving flue gas purification system and method.

Owner:SOUTHEAST UNIV

Electrostatic agglomeration cyclone demisting device and application

ActiveCN105251304AReduce the critical particle sizeReduce outlet droplet concentrationCombination devicesSpray nozzleEngineering

The invention relates to an electrostatic agglomeration cyclone demisting device. The device comprises electrostatic agglomeration cyclone demisting units which are tightly arranged in a tower, wherein each electrostatic agglomeration cyclone demisting unit comprises a cylinder, a guide plate, a metal discharge wire, a lower cylinder, an upper cylinder, a high compression ring, a nozzle and guide blades. According to the device, the ultimate grain size of the demister can be reduced, an effect of reducing the droplet concentration at the outlet of the demister is achieved, to-be-treated flue gas enters the device from bottom to top, and dust droplets in the flue gas are negatively charged while passing through the lower cylinder and agglomerate and grow up with positively charged spray mist while passing through the upper cylinder, so that the droplets in the flue gas are separated from the flue gas while passing through the guide blades according to the pneumatic cyclone principle.

Owner:AEROSPACE ENVIRONMENTAL ENG

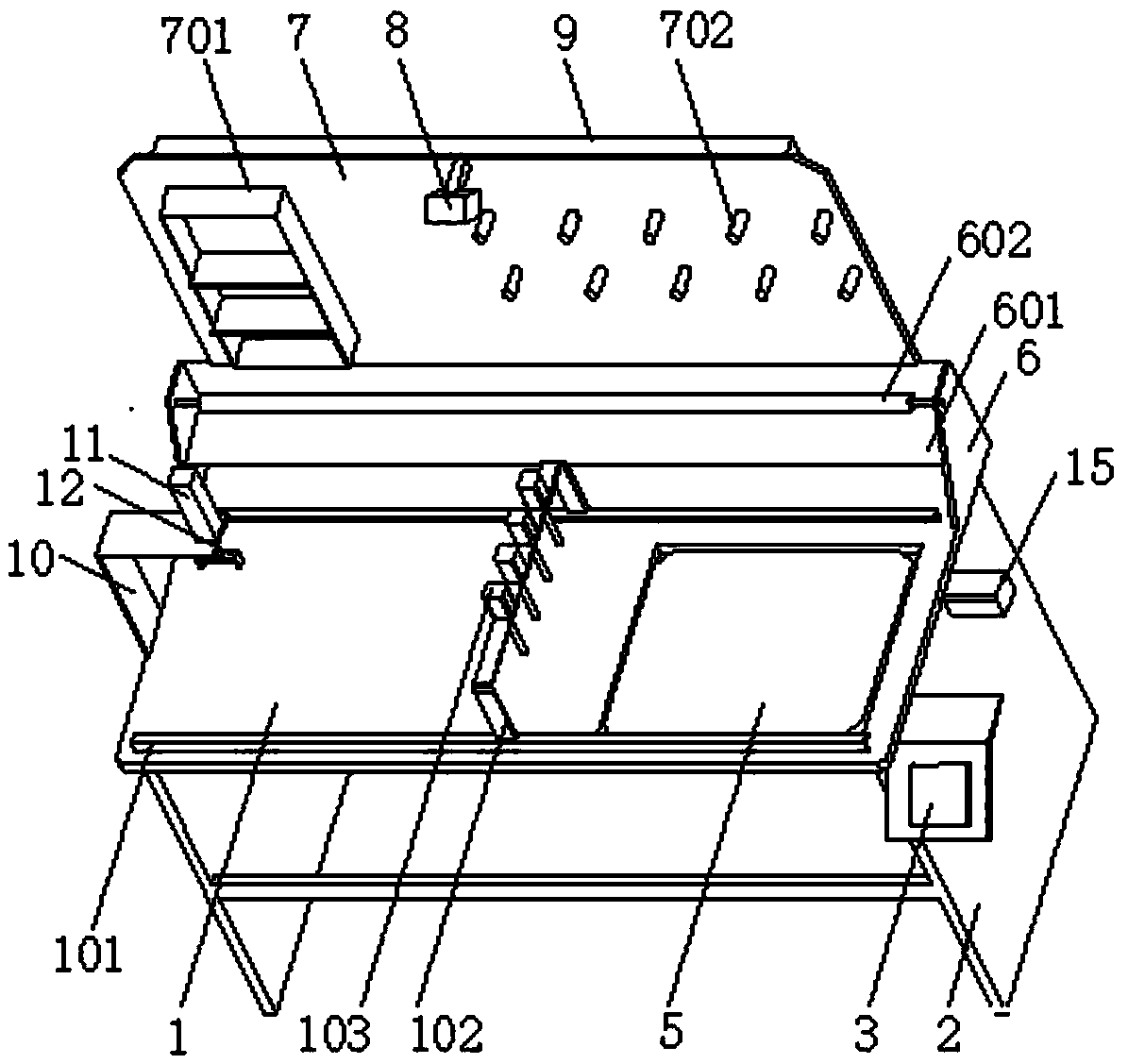

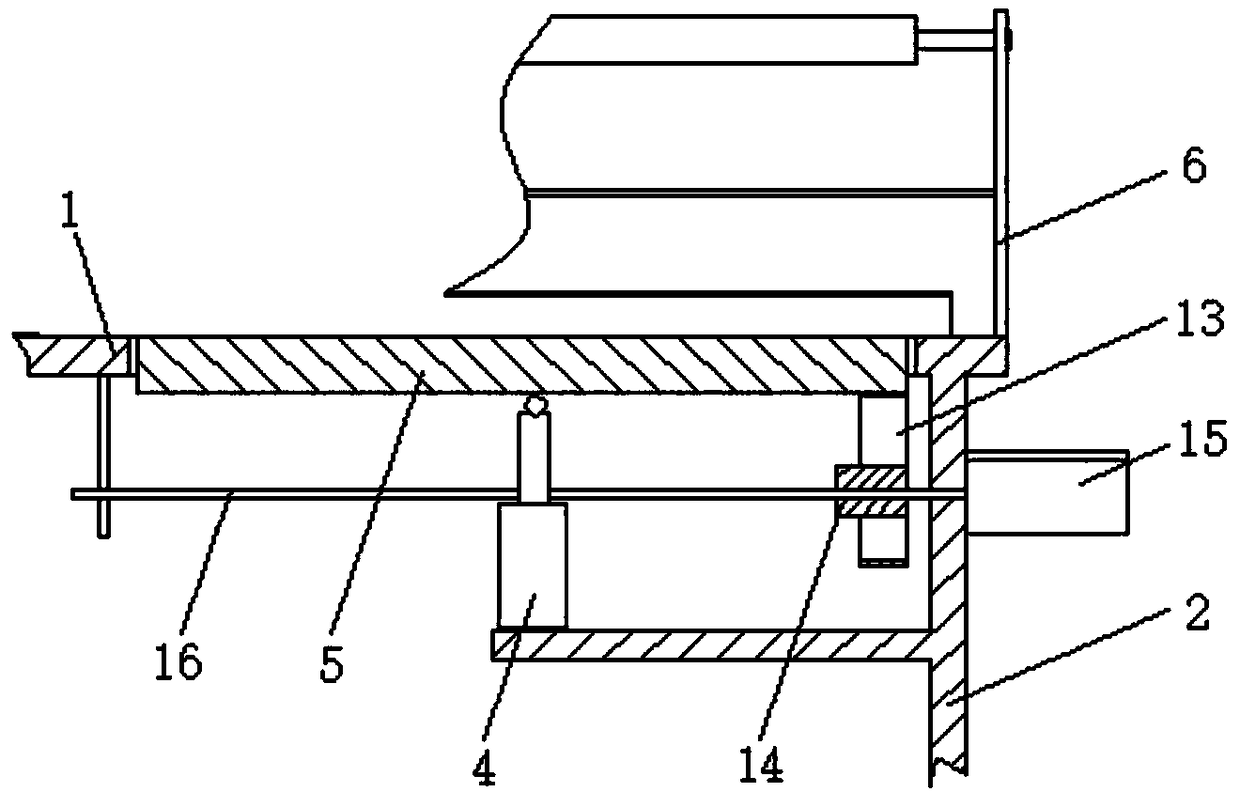

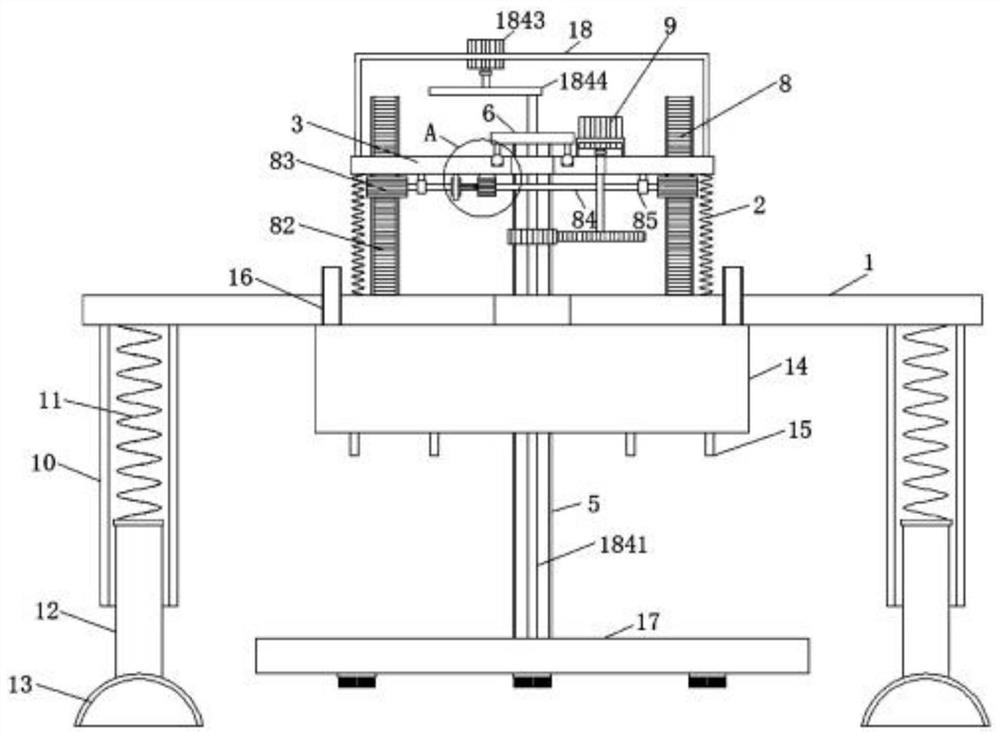

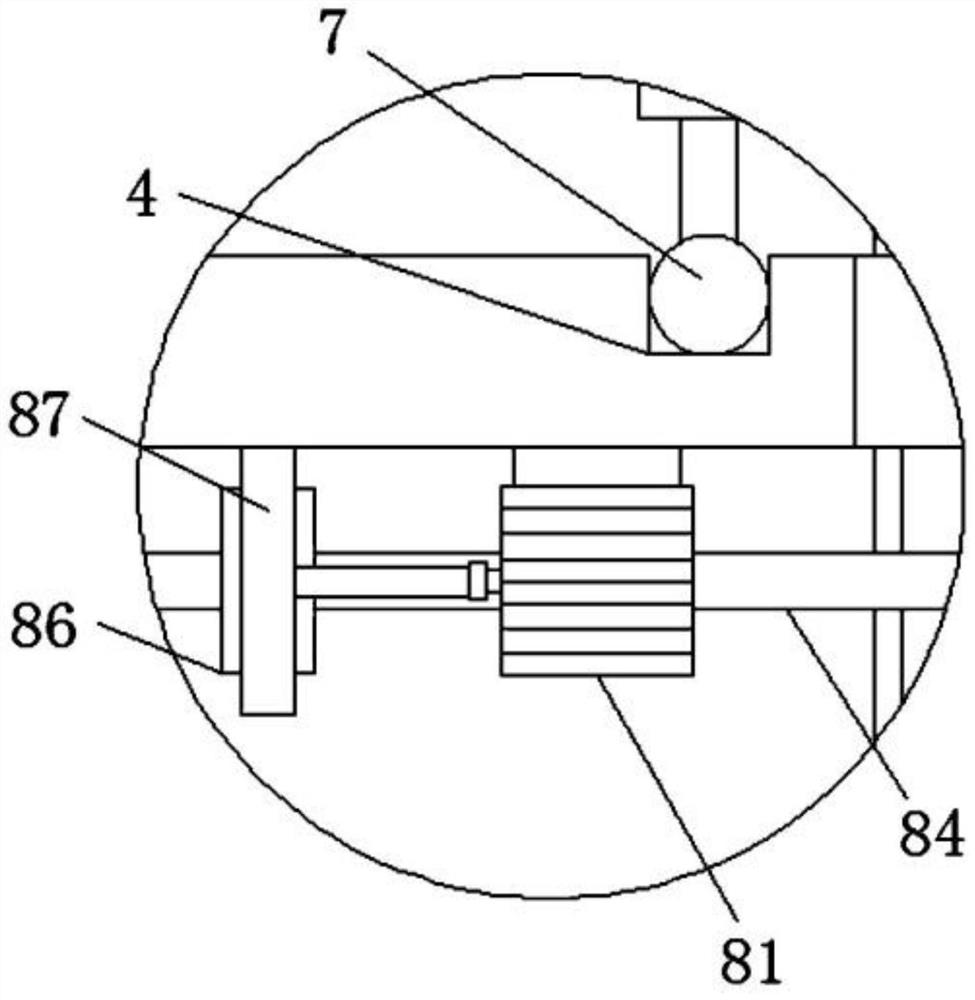

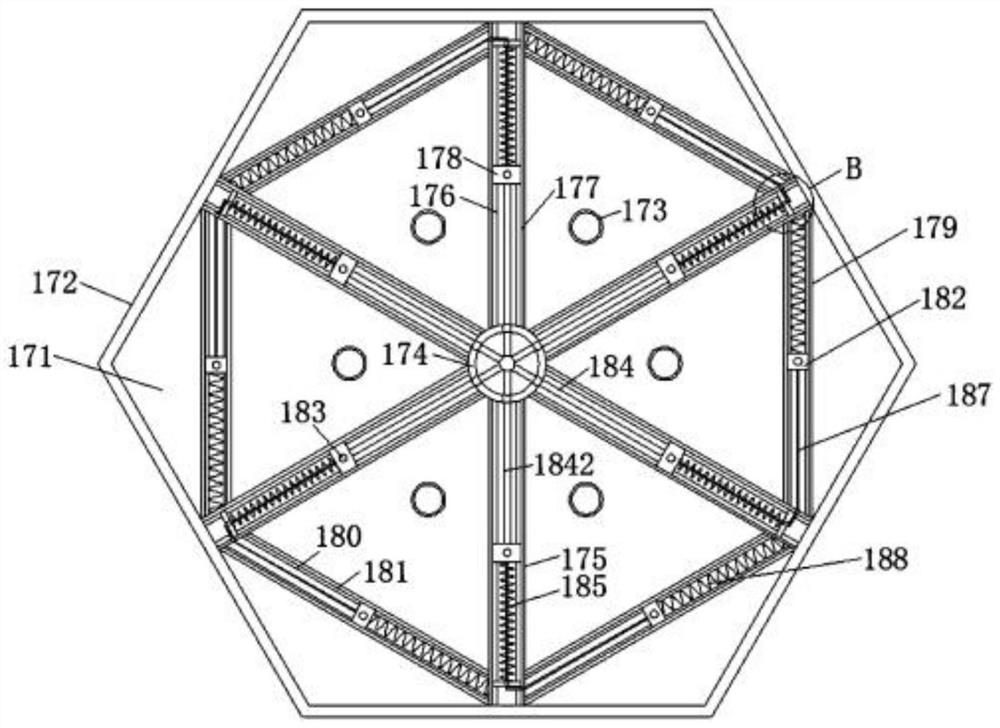

Novel detachment table for machinery teaching

ActiveCN108376507ASimple structureGuaranteed stabilityEducational modelsFixed frameSoftware engineering

The invention discloses a novel detachment table for machinery teaching. The detachment table comprises a worktable. The upper surface of the worktable is provided with a slide rail. The slide rail isslidably connected with a slide carriage. The horizontal part of the slide carriage is provided with a first electric telescopic rod. A fixing frame is fixed to the left end of the upper surface of aworktable. A third electric telescoping rod in a vertical direction is fixed to the fixing frame. The detachment table for machinery teaching realizes a simple structure. The detachment table is provided with the slide carriage and the first electric telescopic rod for clamping components, thereby ensuring high stability of the components in detachment, and ensuring high detachment efficiency. The components are lifted in the vertical direction through matching between the third electric telescopic rod and a clamp, thereby facilitating component separation. An insertion plate can perform horizontal movement, thereby facilitating movement of the components to appropriate detachment distribution positions, and reducing physical power of a teacher. A detachment process is recorded and projected to a display screen through a camera, thereby facilitating viewing of all students, improving teaching effect and realizing higher convenience in use.

Owner:ZIBO VOCATIONAL INST

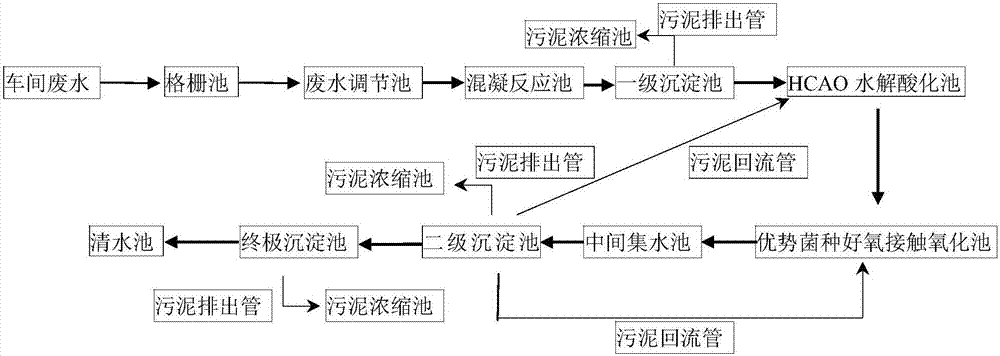

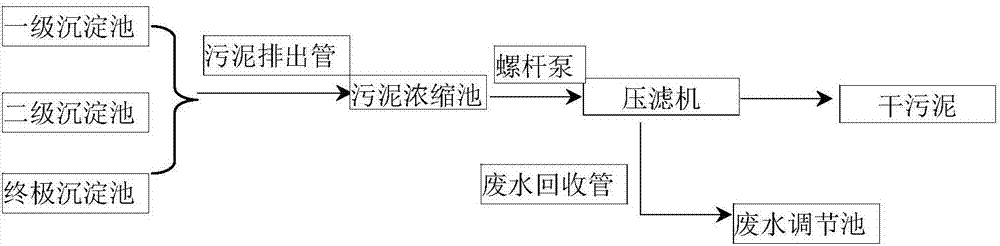

Printing and dyeing wastewater treatment system and technology

PendingCN107512833AFully removeAvoid cloggingSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesHigh concentrationSludge

The invention discloses a printing and dyeing wastewater treatment system and technology. An HCAO (hydrolytic acidification dominant bacterial strain aerobic contact oxidation) system which is summarized and developed by the applicant according to many years of practical experience in the printing and dyeing wastewater engineering is used for treating high-concentration printing and dyeing wastewater, the content of SS (suspended solids) and BOD in recycled water can meet discharge requirement, sludge activity is good, and settling property is good. The printing and dyeing wastewater treatment technology disclosed by the invention has the advantages that the printing and dyeing wastewater can be deeply treated, and the standards of recycled water are met, so that pure investment on wastewater treatment is changed into investment with output, the multiple effects of reducing discharge amount of wastewater, saving water resource and protecting the environment are achieved, and the market demand of the spinning, dyeing and finishing industry can be met.

Owner:福建省万德环境工程有限公司

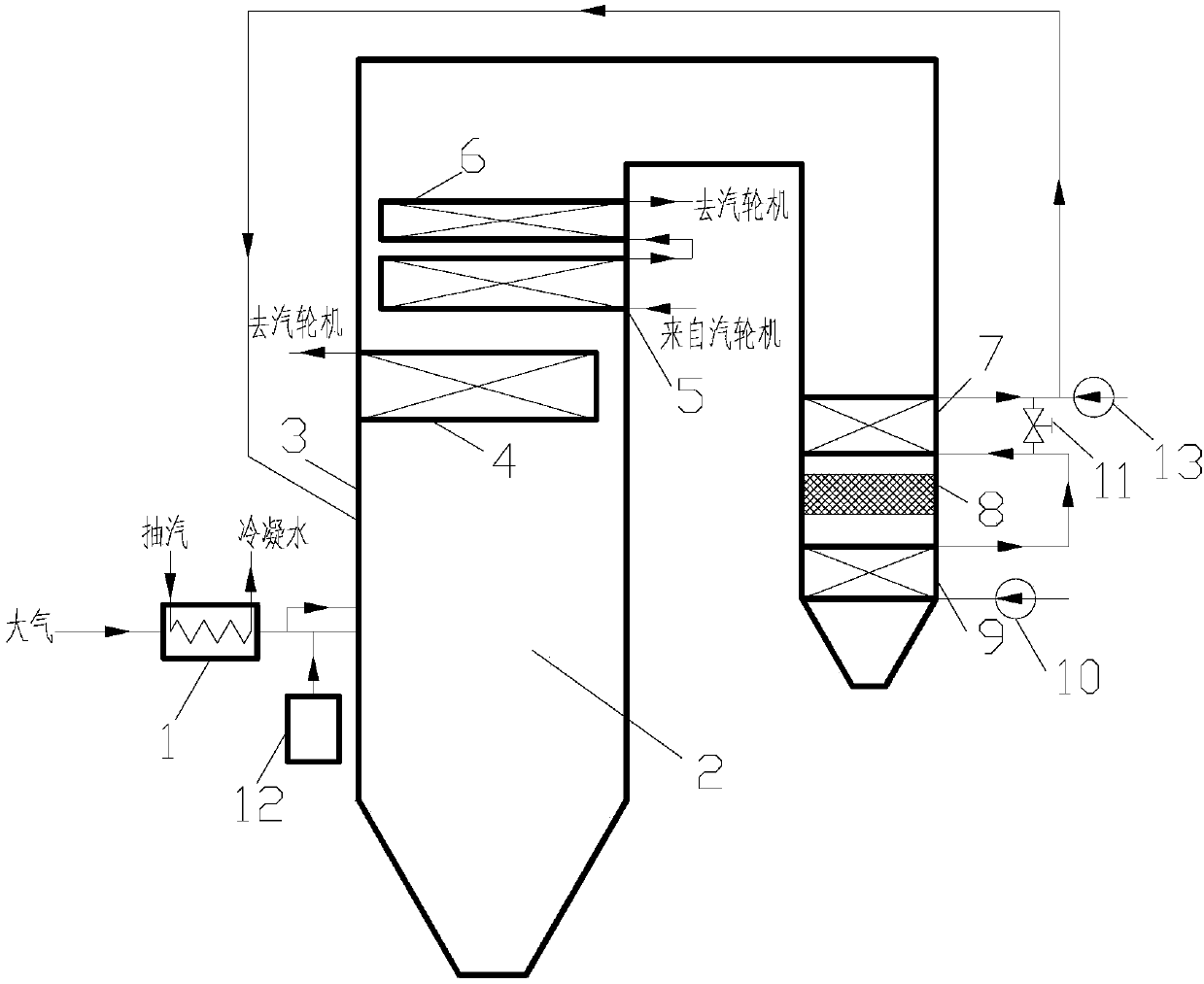

Boiler suitable for full load SCR denitration and working method

ActiveCN107726305AOvercoming the inherent defect of different heat capacity flow ratesTemperature controlIndirect carbon-dioxide mitigationCombustion apparatusAir preheaterHearth

The invention discloses a boiler suitable for full load SCR denitration. Water-cooled walls and superheaters are arranged at a hearth and a boiler high-temperature flue gas section; a first flue gas condensation water heat exchanger, an SCR denitration device and a second flue gas condensation water heat exchanger are arranged at the tail of the boiler; the SCR denitration device is arranged between the first flue gas condensation water heat exchanger and the second flue gas condensation water heat exchanger; a condensation water outlet of the second flue gas condensation water heat exchangeris connected with a condensation water inlet of the first flue gas condensation water heat exchanger; a condensation water inlet of the second flue gas condensation water heat exchanger is connected with a condensation water pump; a by-pass is arranged at the condensation water inlet of the first flue gas condensation water heat exchanger and is connected with a condensation water outlet of the first flue gas condensation water heat exchanger; a bypass valve is arranged on the by-pass; and an outlet of a feed pump and an outlet of the first flue gas condensation water heat exchanger are connected with the water-cooled walls. The disadvantages arising from the arrangement of a traditional boiler economizer and an air preheater are overcome, and the stabilization of an SCR flue gas inlet temperature and a high-temperature air temperature can be realized.

Owner:XI AN JIAOTONG UNIV

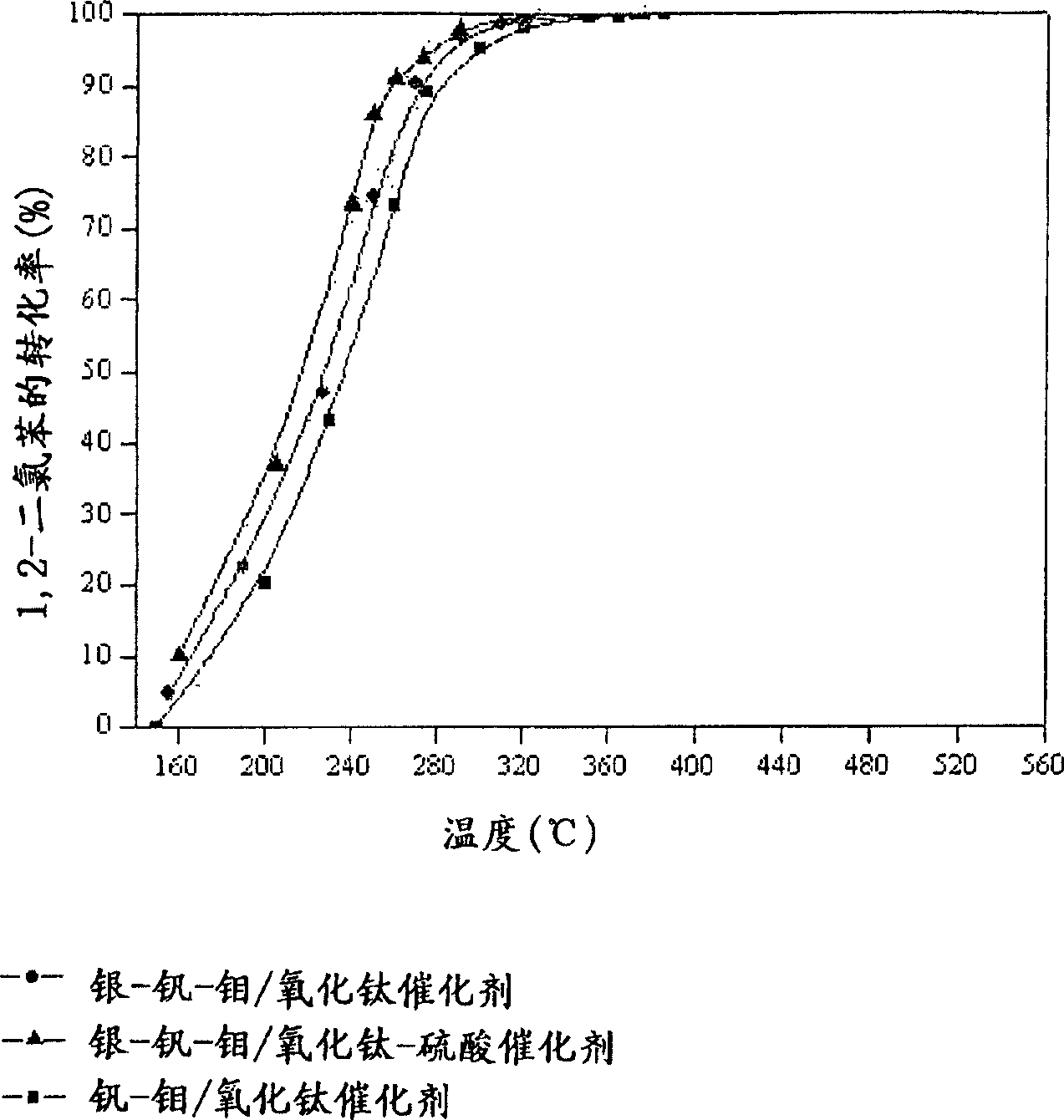

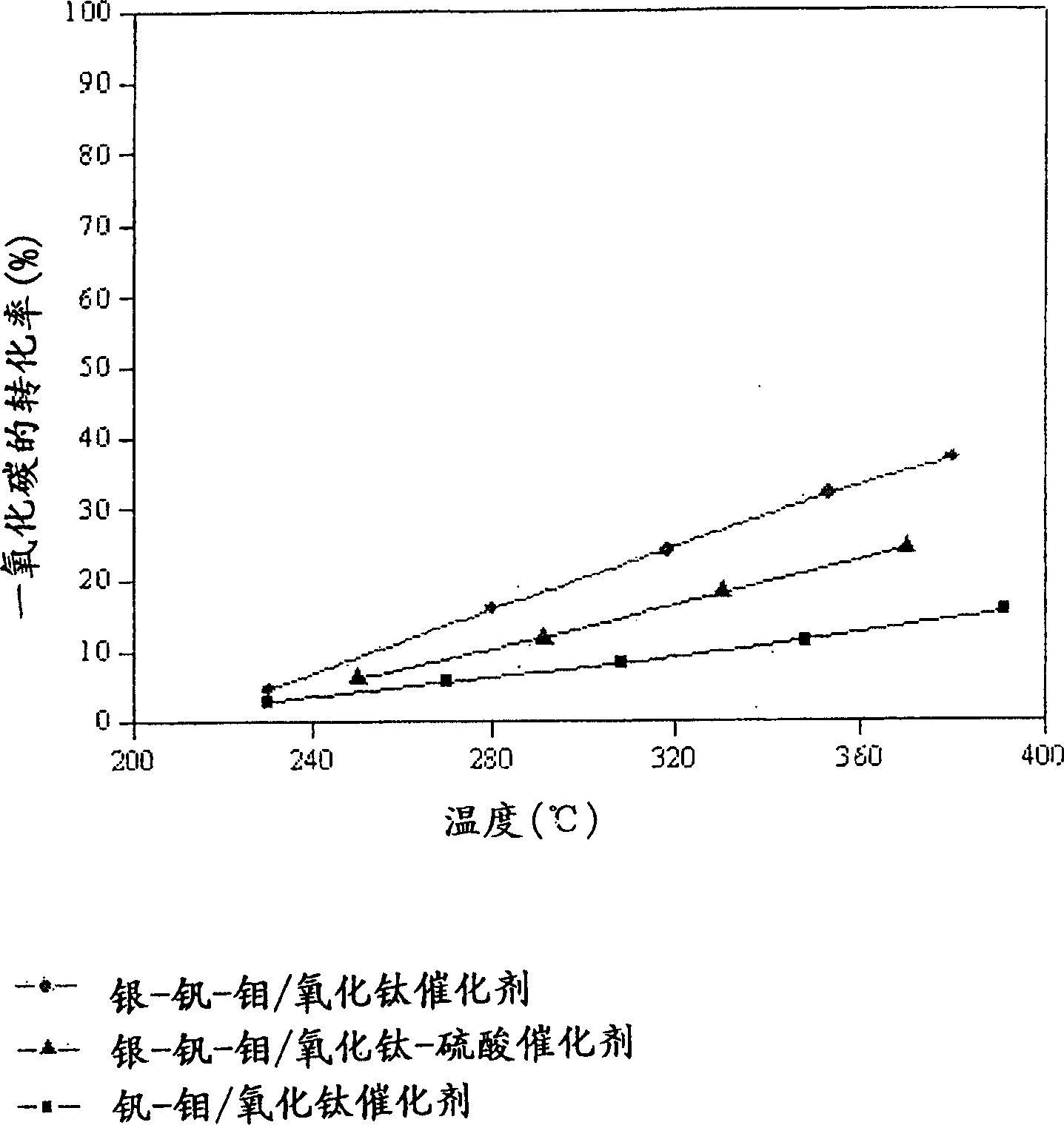

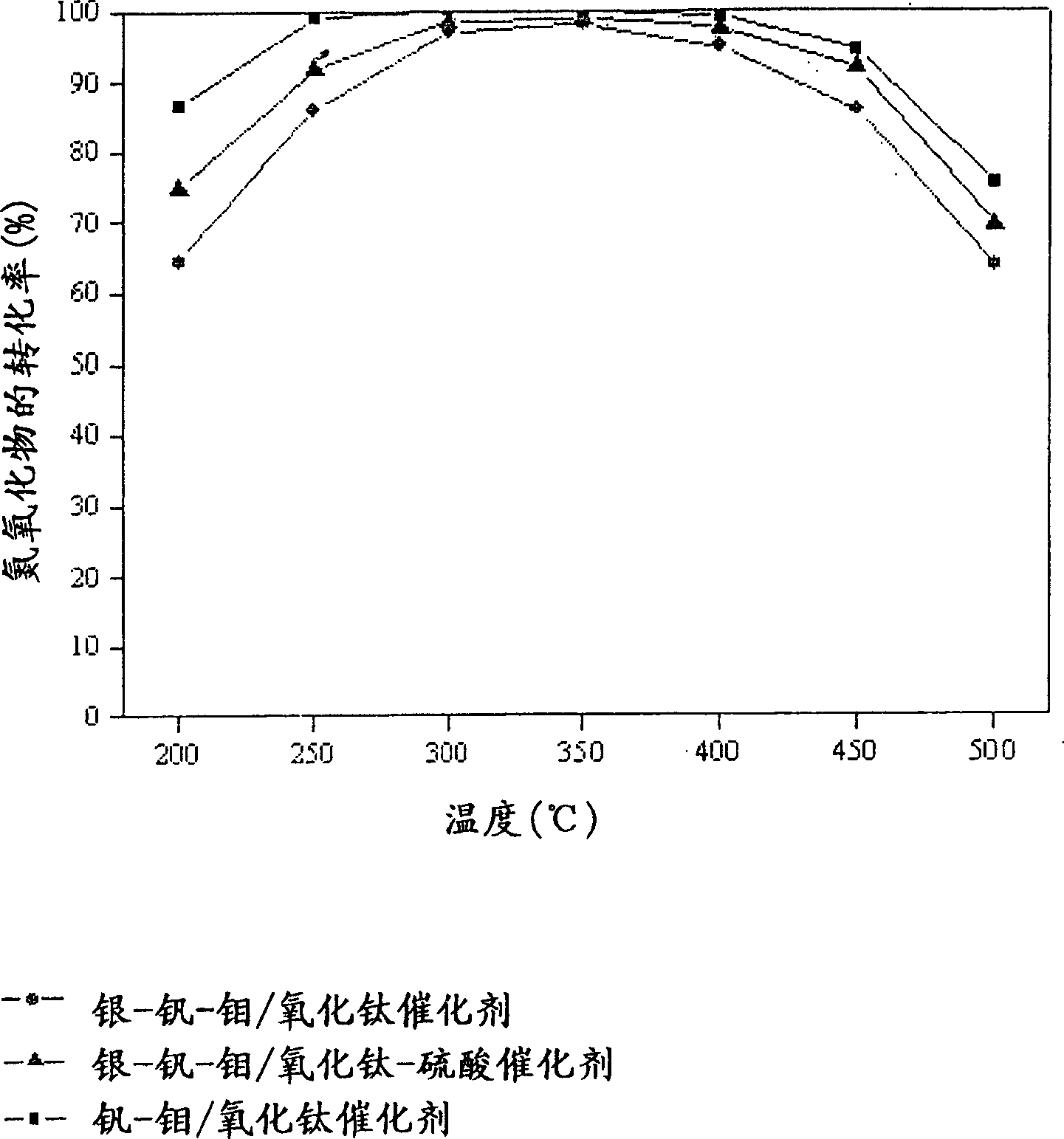

Catalyst for de-aromatic halogeno compound containing dioxina, carbon monoxide and nitrogen oxide and its use

InactiveCN1623632AGuaranteed removal efficiencyImprove the level ofDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAcid treatmentSulfuric acid

A catalyst for removing the aromatic halogenated compounds including dioxin, CO and NOx is composed of titanium oxide as carrier, the metal element chosen from the metals in 6A family, and Ag. It may be treated by acid in such manner that it is immersed in the solution of sulfuric acid. Its advantage is high efficiency.

Owner:KOCAT +1

A catalytic ceramic filter tube and its preparation method

ActiveCN105107310BEfficient removalExtended service lifeSemi-permeable membranesDispersed particle filtrationPtru catalystFlue gas

The invention provides a catalytic ceramic filter tube which is high in dust collection efficiency, can efficiently oxidize elemental mercury, can also efficiently reduce NOx, and achieves simultaneous dust removal and SCR denitration and a preparation method. The catalytic ceramic filter tube comprises a ceramic filter tube substrate, and a catalytic active component layer and a separation membrane which sequentially coat the ceramic filter tube substrate. The preparation method comprises the following steps: step 1. preparing the ceramic filter tube substrate by isostatic pressing molding; step 2. coating the ceramic filter tube substrate with a catalytic active component membrane to obtain a catalytic ceramic filter tube substrate; and step 3. preparing the separation membrane on the catalytic ceramic filter tube substrate. The catalytic ceramic filter tube provided by the invention can achieve integrated efficient removal of dust, NOx and elemental mercury in high-temperature flue gas (>300 DEG C), the service life of the catalyst can be prolonged through protection for the catalyst by the separation membrane and the substrate, and the structure arrangement of the ceramic filter tube can reduce the occupied area and running cost of equipment.

Owner:HUANENG POWER INT INC +2

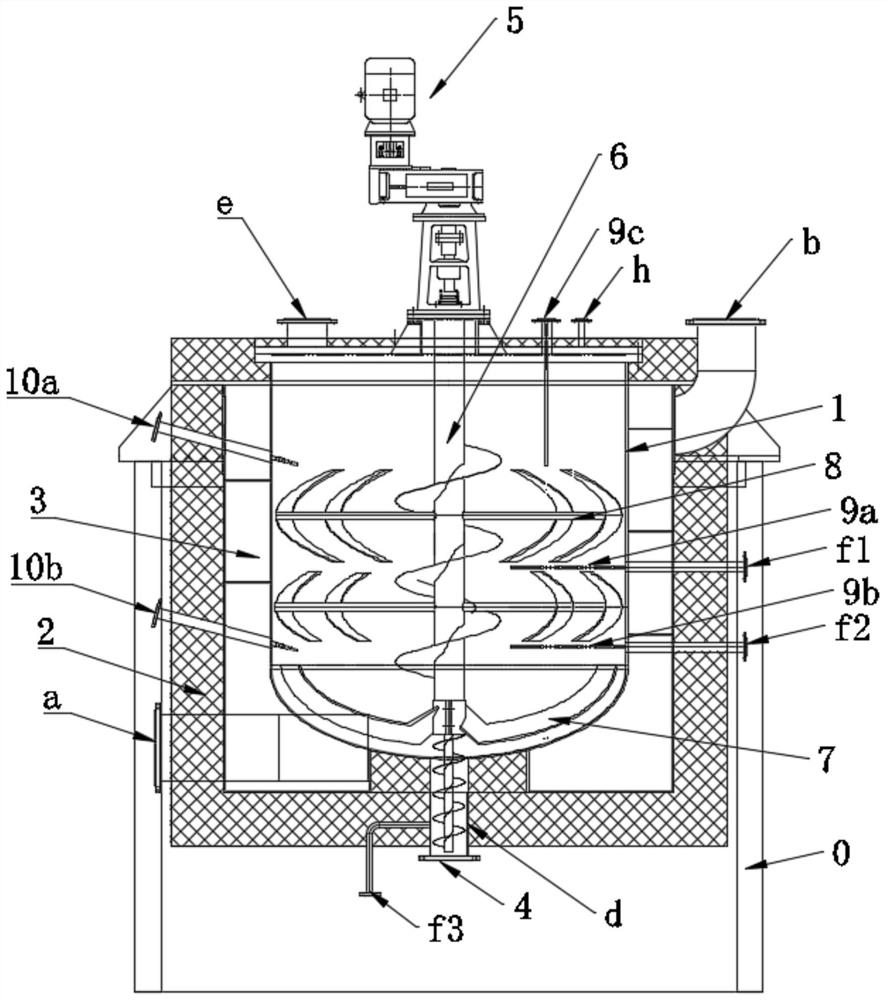

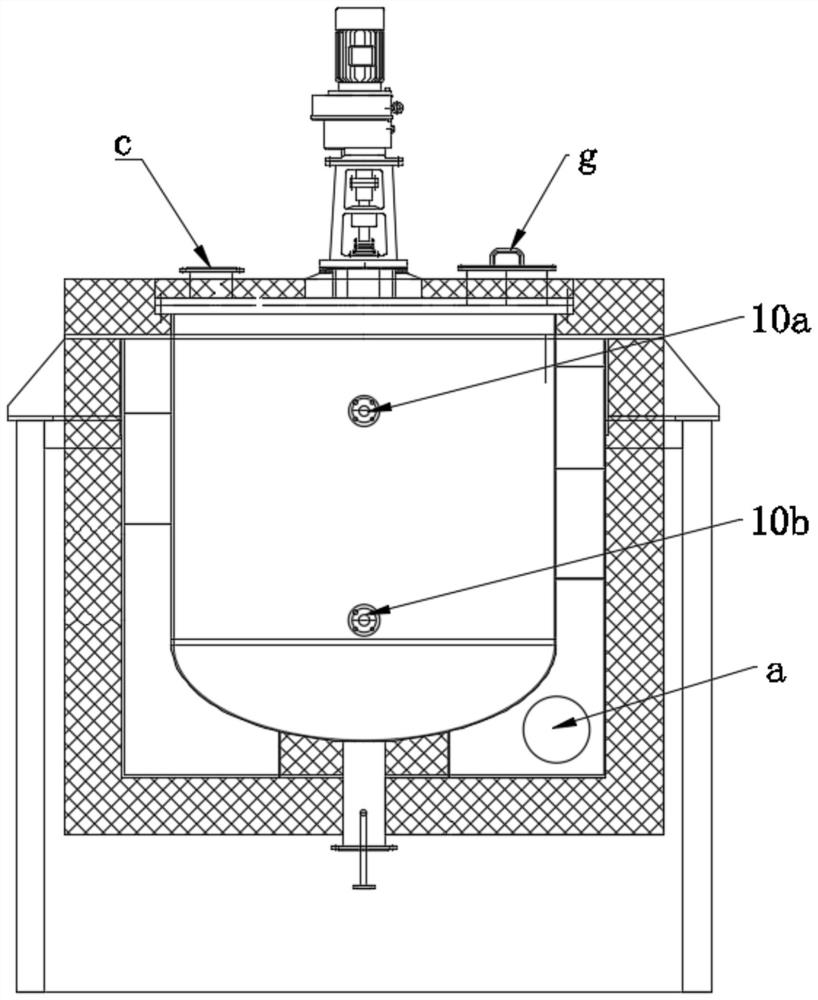

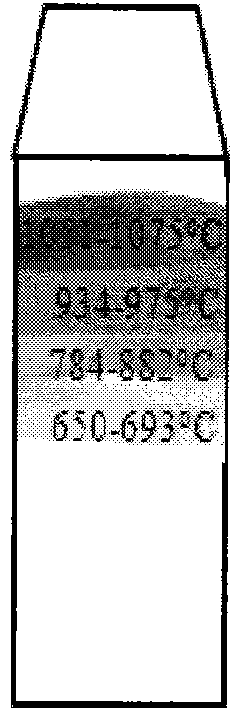

Pyrolysis furnace and pyrolysis system for treating dioxin in waste incineration fly ash

InactiveCN113102446AGuaranteed stabilityUniform temperatureSolid waste disposalTransportation and packagingThermodynamicsHearth

The invention relates to a pyrolysis furnace and a pyrolysis system for treating dioxin in waste incineration fly ash. The pyrolysis furnace comprises a hearth, the hearth is covered with a heat insulation shell in a sealing manner, a sealed flue is formed between the hearth and the heat insulation shell, and the flue is of a spiral structure extending in the axial direction of the hearth; the heat insulation shell is provided with a hot air inlet and a hot air outlet which are both communicated with the flue and located at the two ends of the flue respectively; the heat insulation shell is provided with a feeding hole and a discharging hole which are respectively used for feeding and discharging, and the feeding hole and the discharging hole are respectively communicated with the hearth; the discharging port is provided with a discharging throat pipe which is provided with a switch valve; and the heat insulation shell is provided with an exhaust port and an inert gas inlet which are communicated with the hearth. By means of the method, the dioxin in the waste incineration fly ash can be stably reduced to 50 ngTEQ / kg or below after being treated, and the problem that fly ash chlorine salt is heated and agglomerated can be avoided.

Owner:浙江京兰环保科技有限公司

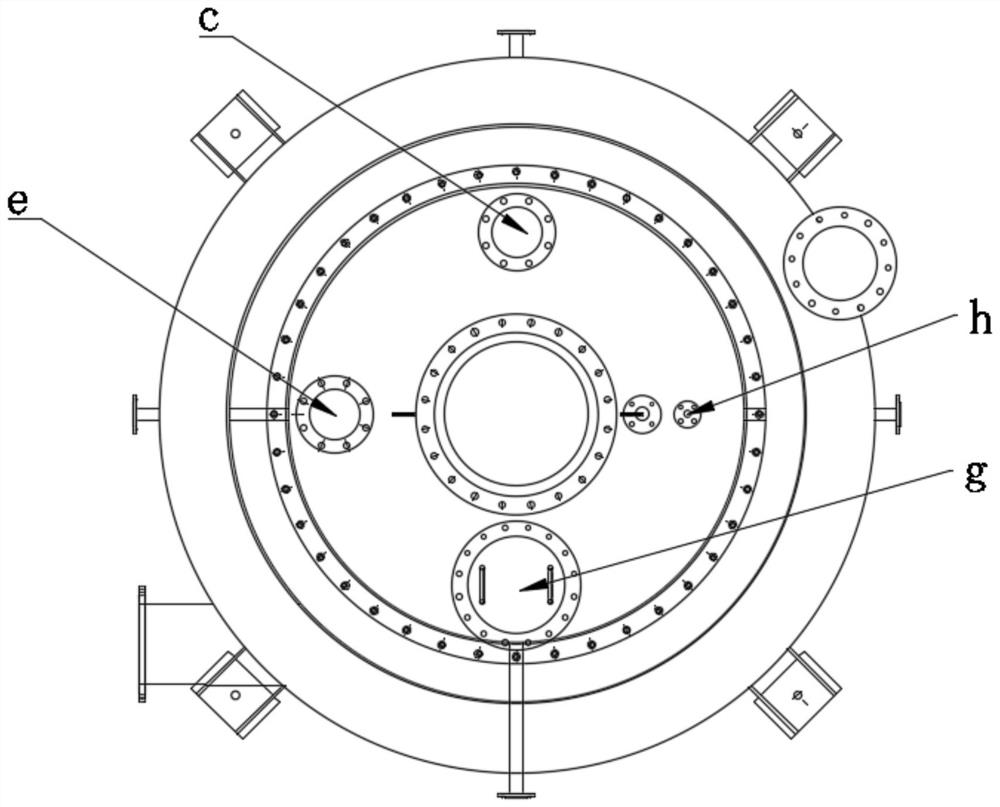

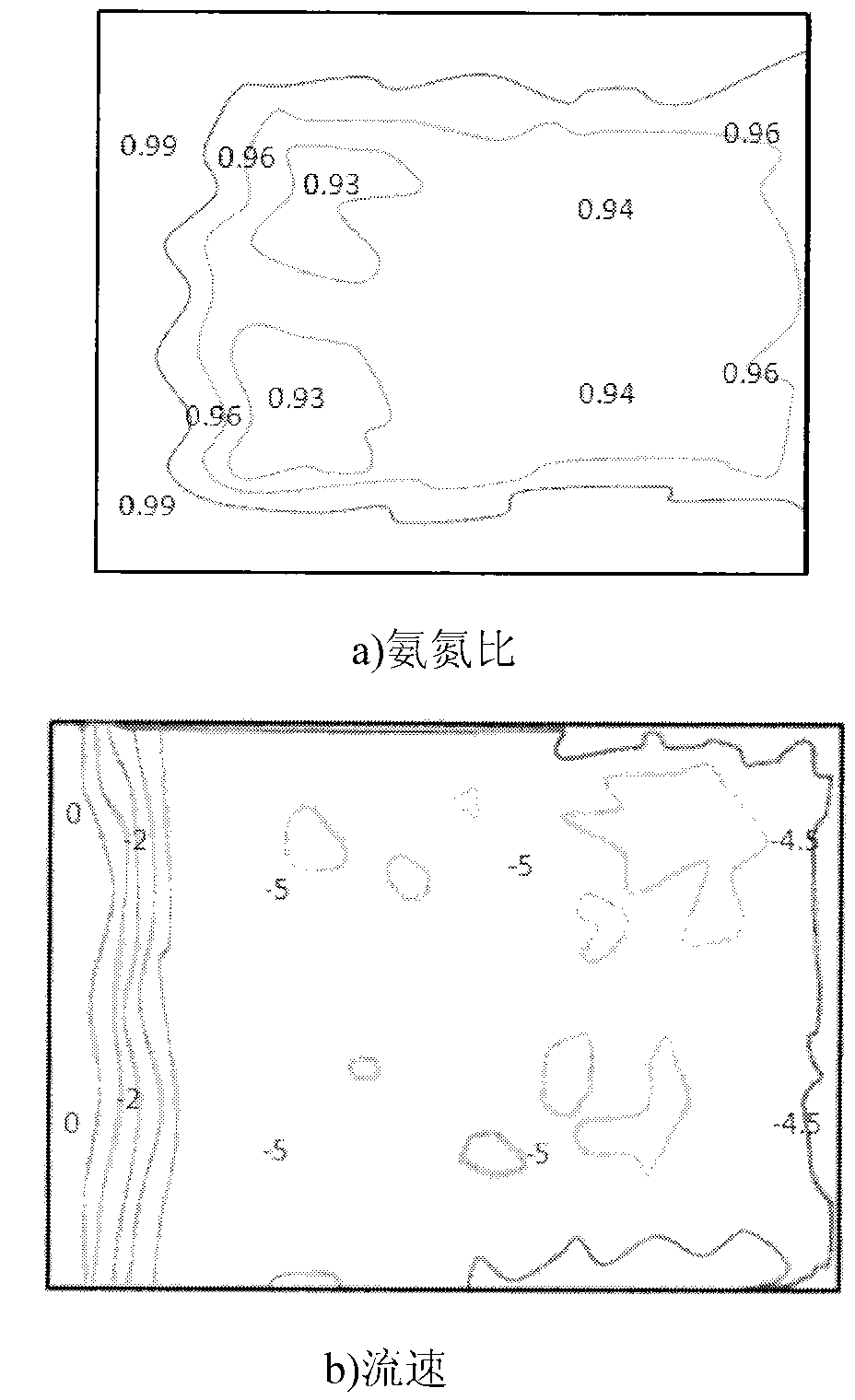

Optimization method aiming at SNCR denitration

InactiveCN103084063AReduce escape rateGuaranteed removal efficiencyDispersed particle separationAmmoniacal nitrogenThermodynamics

The invention provides an optimization method aiming at SNCR denitration, and especially relates to a method for optimizing removing efficiency of NOx in SNCR by using a fluid-mechanics-related calculation method. The method comprises the steps that: flue gas flow field variation is simulated with a fluid mechanical method, and calculation and analysis are carried out, such that a design scheme with an optimal mixing effect is obtained; and the design scheme is used for guiding equipment mounting and PLC system control, such that SNCR operation efficiency can be improved to a maximal extent. According to the invention, flue gas velocity field, flue gas temperature field, and ammonia-nitrogen ratio at an ammonia injection grid are researched with a fluid mechanical method, ammonia injection grid mounting position and structure are finally determined, and PLC system control and ammonia injection amount are guided. Therefore, ammonia is sufficiently mixed with flue gas, and complete reaction is carried out. Removing efficiency of NOx in SNCR is improved, ammonia escaping rate is reduced, SNCR technology is improved, and SNCR application range is widened.

Owner:ZHEJIANG HAILIANG ENVIRONMENTAL MATERIALS

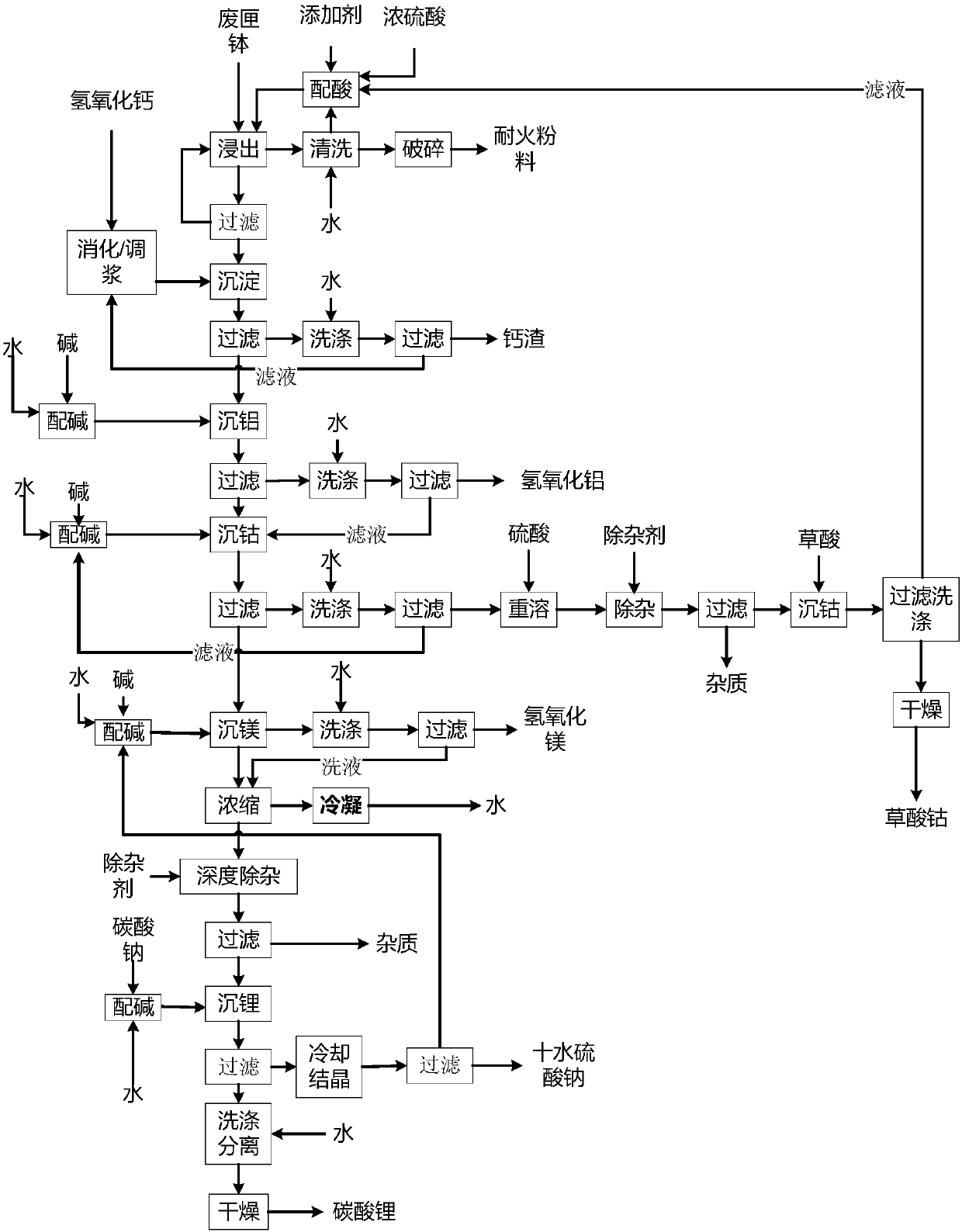

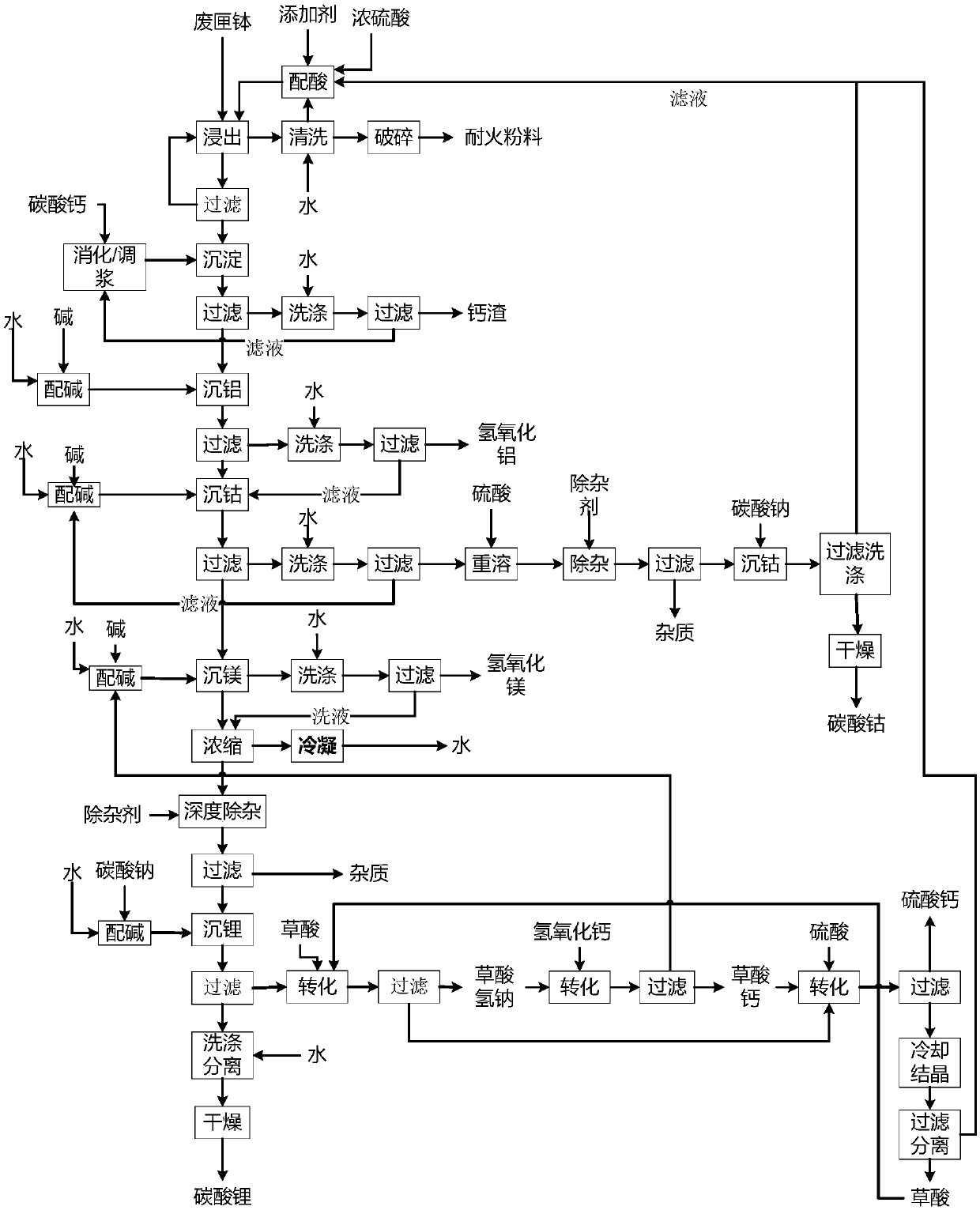

Method for carrying out recovery treatment on waste saggar in lithium cobaltate positive electrode material preparation process

ActiveCN109911909AWide variety of sourcesAchieve recyclingAlkaline-earth metal silicatesCalcium/strontium/barium sulfatesLithiumCobalt

The invention provides a method for carrying out recovery treatment on a waste saggar in a lithium cobaltate positive electrode material preparation process, wherein the waste saggar contains silicon,aluminum and magnesium impurities. The method comprises: 1) mixing a waste saggar, an acid and an additive, carrying out a leaching reaction, and separating to obtain a purified saggar and a leachate; 2) adjusting the pH value of the leachate to 2-4, and carrying out solid-liquid separating to obtain solid residue and a separated liquid; 3) adjusting the pH value of the separated liquid to 4.5-5.5, and carrying out solid-liquid separating to obtain solid residue and an aluminum removed liquid; 4) adjusting the pH value of the aluminum removed liquid to more than or equal to 8, and carrying out solid-liquid separating to obtain a cobalt-containing substance and a cobalt precipitation liquid; 5) adjusting the pH value of the cobalt precipitation liquid to more than or equal to 11, and carrying out solid-liquid separating to obtain solid residue and a magnesium removed liquid; and 6) adding a precipitating agent to the magnesium removed liquid, and carrying out solid-liquid separation toobtain a lithium-containing substance and a lithium precipitation liquid. According to the present invention, with the method, the recovery and utilization of cobalt and lithium in the waste saggar in the lithium cobaltate positive electrode material preparation process is achieved, the waste saggar is purified, and the method is suitable for industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

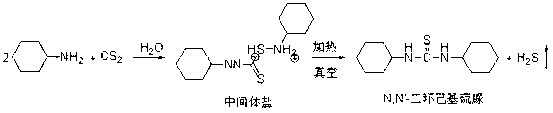

Preparation method of high purity N,N'-dicyclohexylthiourea

ActiveCN102731357AEliminate flammable and explosiveLow costOrganic chemistryOrganic solventFiltration

The invention provides a preparation method of high purity N,N'-dicyclohexylthiourea. The method comprises the following steps:1) mixing water and cyclohexylamine, then adding carbon disulfide in a dropwise manner at a temperature of 0-40 DEG C for 1-3 hours, controlling the temperature to 0-40 DEG C and continuously carrying out the reaction for 1-3 hours, wherein a weight ratio of the water to the cyclohexylamine is 2.5 to 3.8:1, and a weight ratio of the carbon disulfide to the cyclohexylamine is 0.3 to 0.45:1; 2) and carrying out filtration to remove the mother liquor to obtain an intermediate salt, and carrying out vacuum hydrogen sulfide removing on the under intermediate salt to obtain the N,N'-dicyclohexyl thiourea. With the technical scheme, disadvantages of flammability and explosiveness, and high cost of the organic solvent are avoided. Yield of the product provided in the invention is greater than 99%, and purity is greater than 99.5%. With the method, the same effect with using an organic solvent is realized, and the mother liquor can be reused, such that the organic solvent is wholly substituted and no waste liquid is discharged. According to the invention, by using the technology of vacuum hydrogen sulfide removing at the low temperature, energy consumption is lowered and removal efficiency of removing the hydrogen sulfide is guaranteed.

Owner:SHANDONG HUIHAI PHARMA & CHEM

Sewage treatment method for coping with industrial wastewater impact in municipal wastewater plant

ActiveCN104150611ALow running costLow mud productionTreatment with aerobic and anaerobic processesIndustrial effluentSludge

The invention belongs to sewage treatment and especially relates to a sewage treatment method for coping with industrial wastewater impact in a municipal wastewater plant. When degradation-resistant industrial wastewater flows into the municipal wastewater plant and causes impact on the municipal wastewater plant, according to difference of a value of a COD load of an inlet water exceeding a normal work load, a carbon source, which is composed of glucose, starch and methanol in different masses, is added to a biochemical tank correspondingly with a sludge age being adjusted correspondingly. The method can solve problems of a long recovering time after sludge being impacted and a poor degradation effect on COD in the prior art, and has advantages of being short in recovering time of a sludge system, being good in degradation effect on COD and being stable in microbial communities required in sewage treatment.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

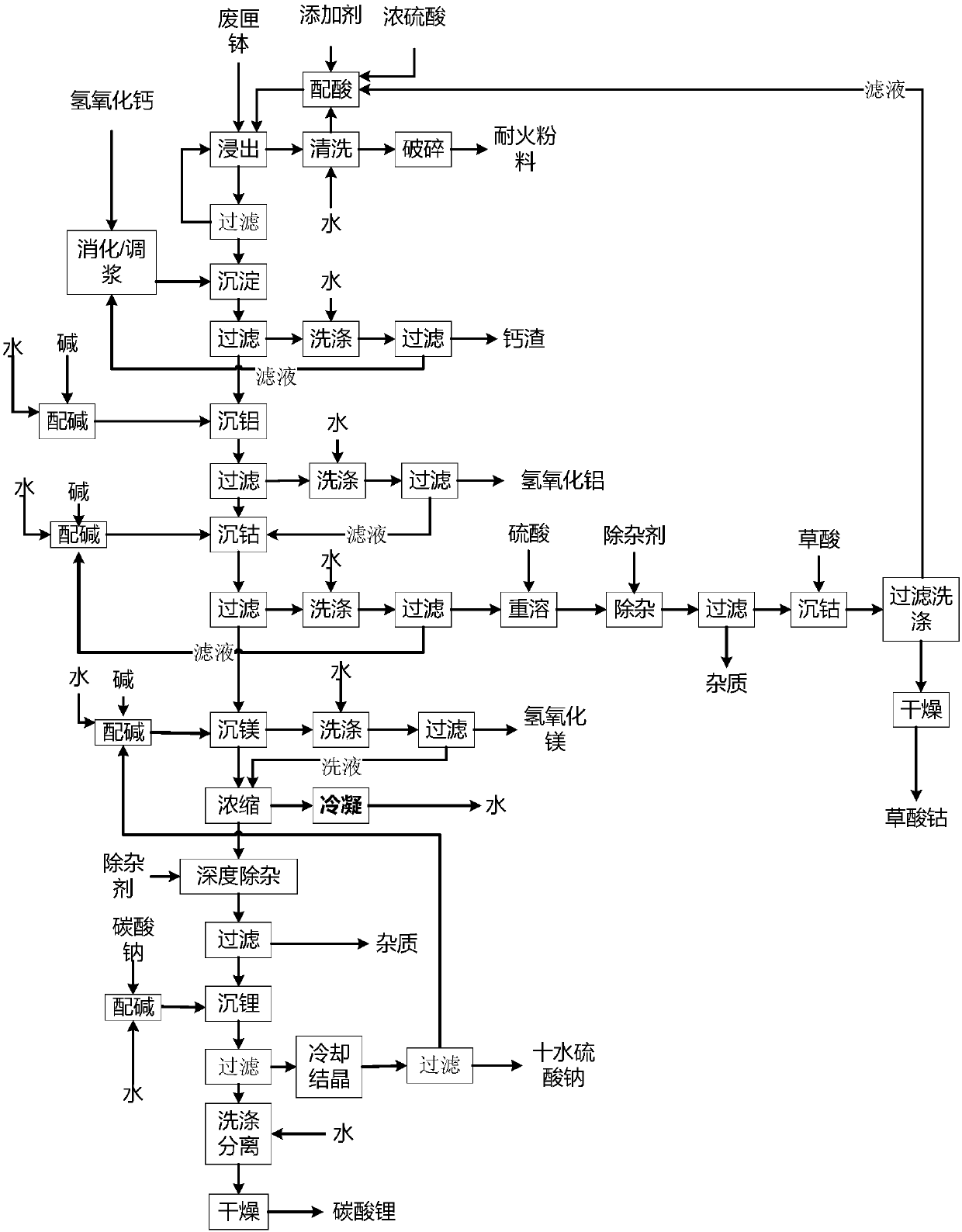

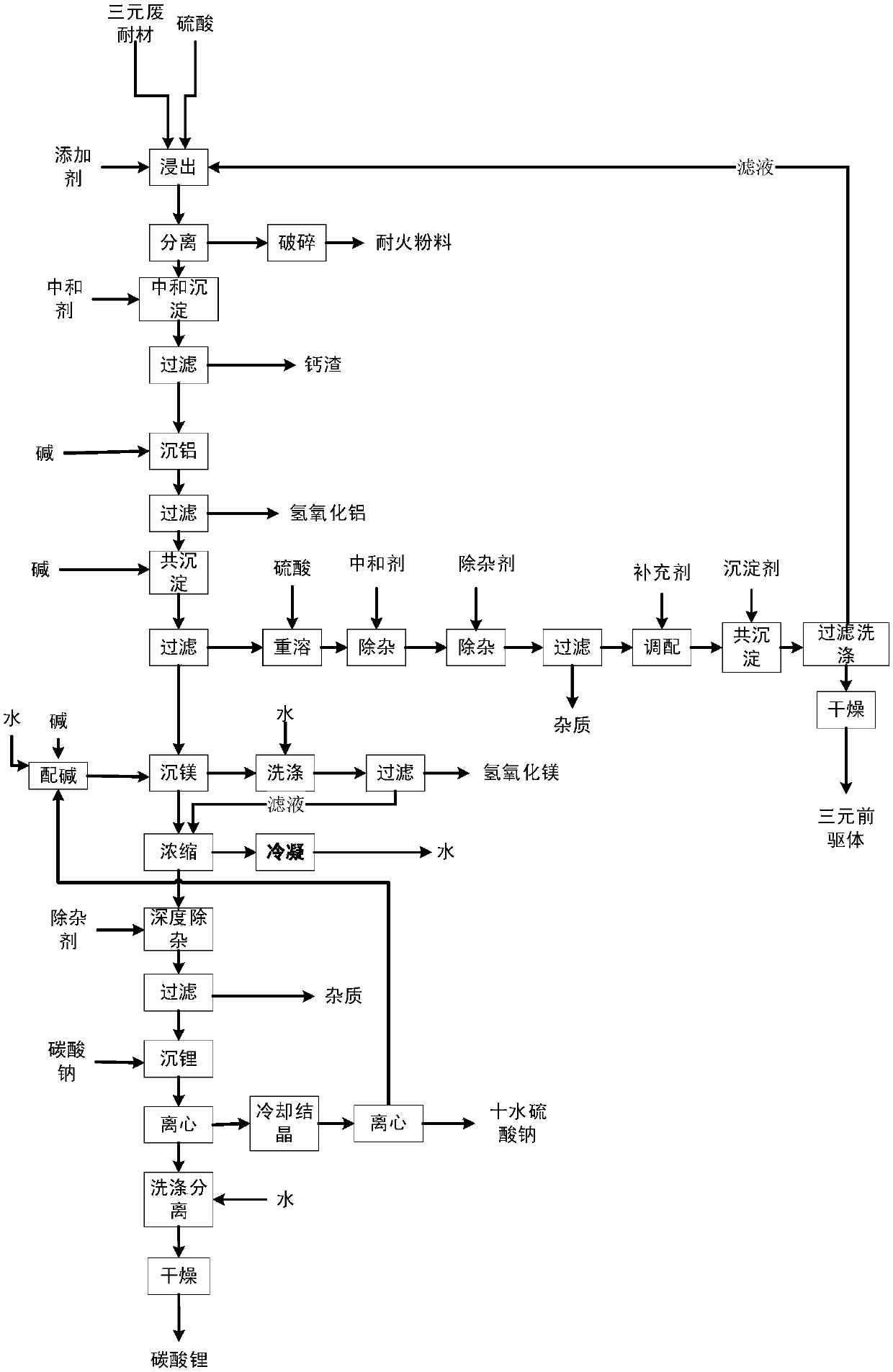

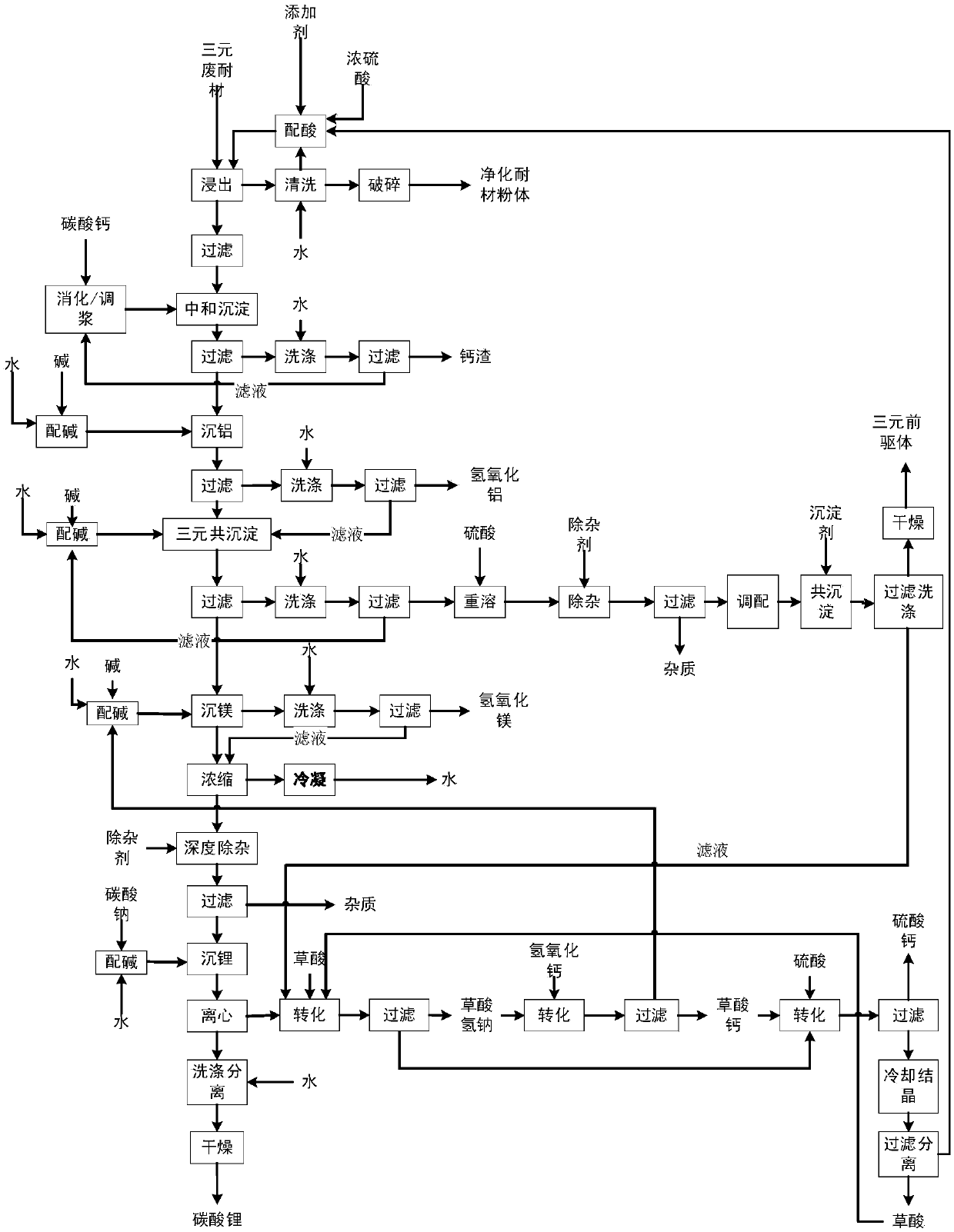

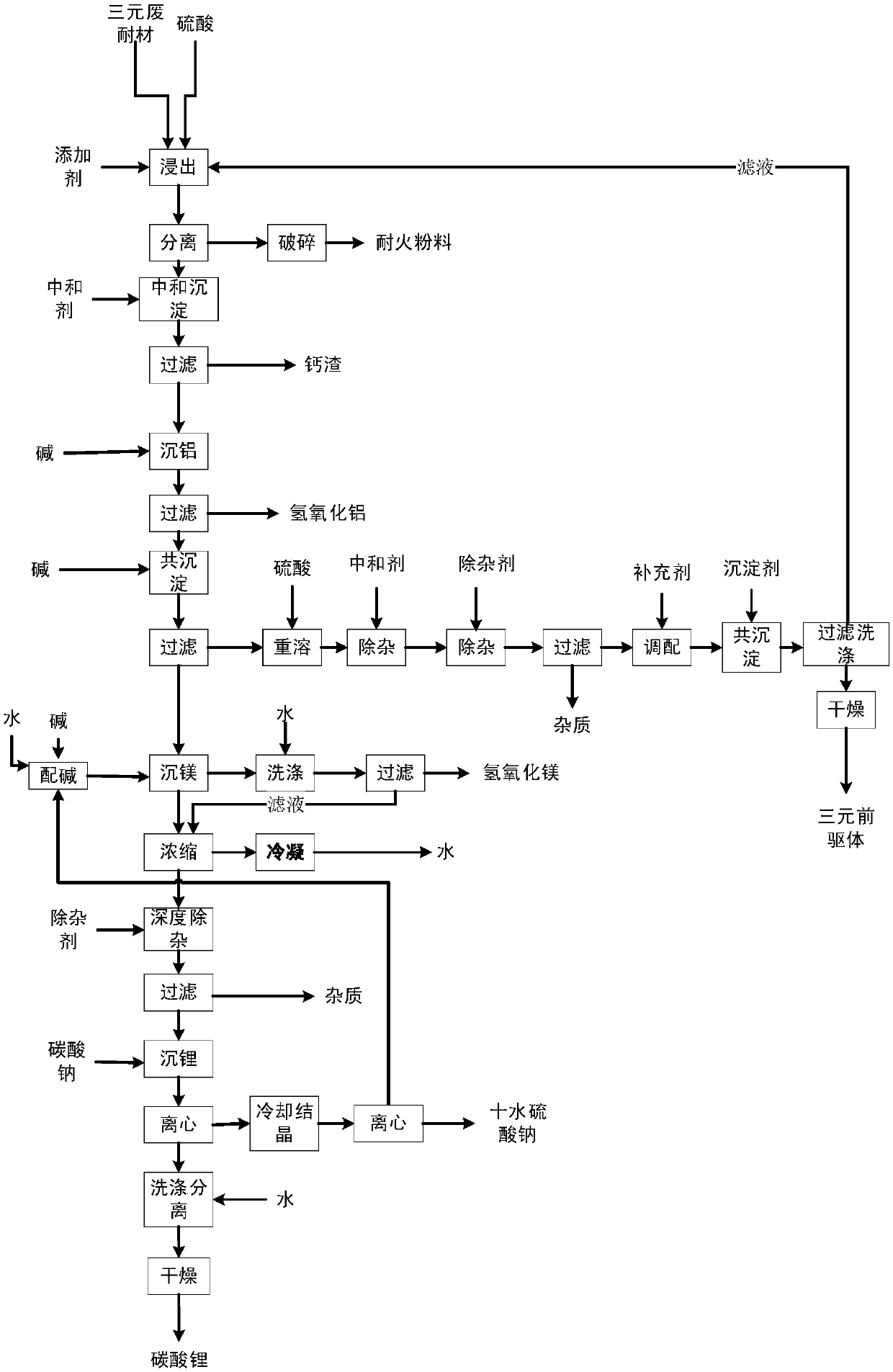

Comprehensive treatment method of waste refractory materials in ternary anode material preparation process

ActiveCN109913652AAchieve recyclingImprove recycling ratesProcess efficiency improvementSlagManganese

The invention provides a comprehensive treatment method for waste refractory materials in the ternary anode material preparation process. The waste refractory material comprises silicon, aluminum andmagnesium impurities, and the method comprises the following steps that 1) the waste refractory material, the acid and the additive are mixed, leaching reaction and then separation process are carriedout to obtain a purified refractory material and a leachate; 2), the pH value of the leachate is adjusted to be 2-4, and solid-liquid separation is carried out to obtain solid slag and a separation solution; 3) the pH value of the separation liquid is adjusted to be 4.5-5.5, and solid-liquid separation is carried out to obtain solid slag and an aluminum removal solution; 4) the pH value of the aluminum removal solution is adjusted to be more than or equal to 9, and solid-liquid separation is carried out to obtain a ternary mixture and a co-precipitation separation solution; 5) magnesium is removed, specifically, the pH value of the co-precipitation separation solution is adjusted to be more than or equal to 11, and solid-liquid separation is carried out to obtain solid slag and a magnesium removal solution; and 6) lithium is precipitated, specifically, a precipitant is added into the magnesium removal solution, and solid-liquid separation is carried out to obtain a lithium-containingsubstance and a lithium precipitation solution. According to the method, recycling of nickel, cobalt, manganese and lithium in the waste refractory material is realized, the waste refractory materialis purified, and the industrial production is facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

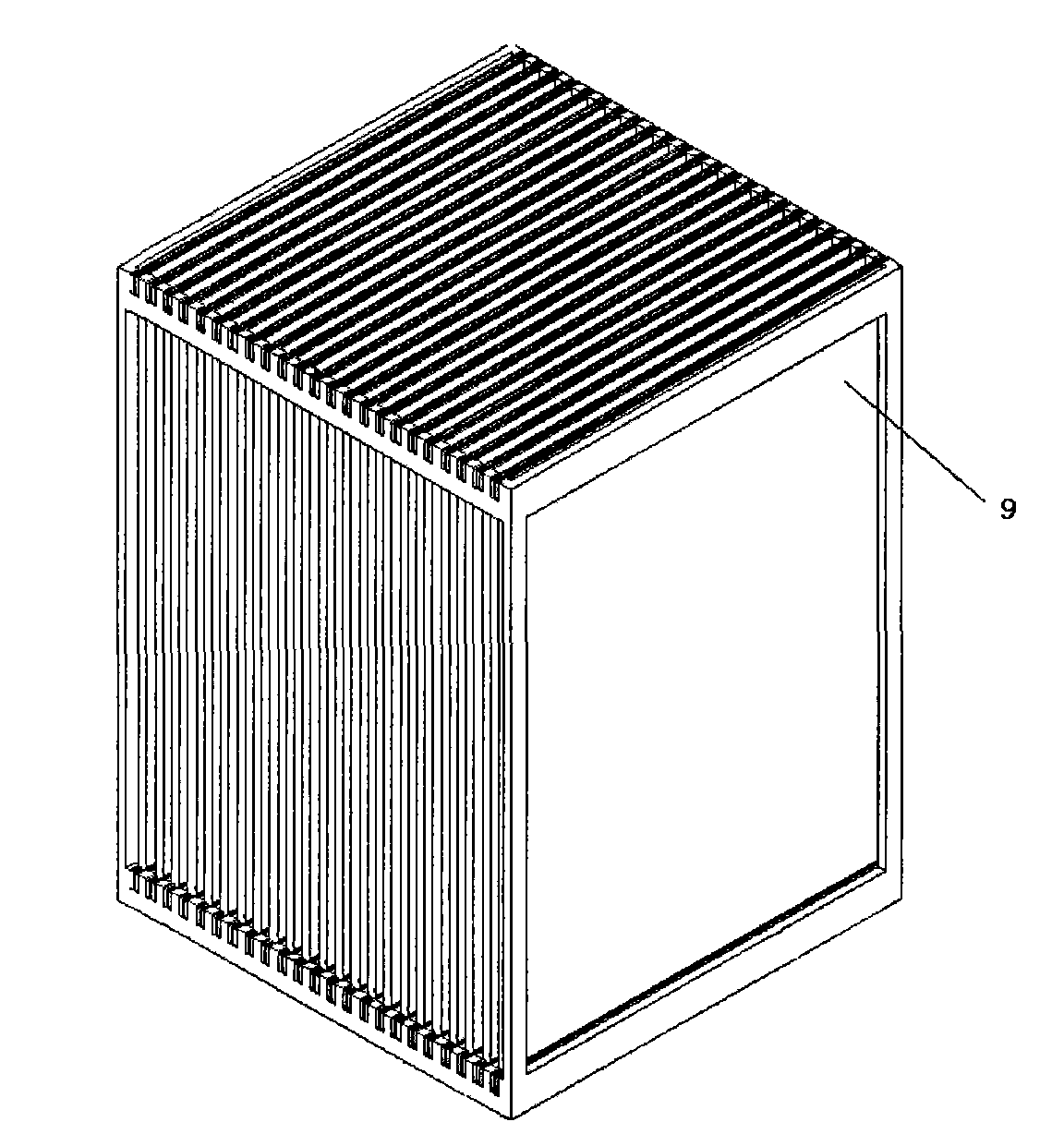

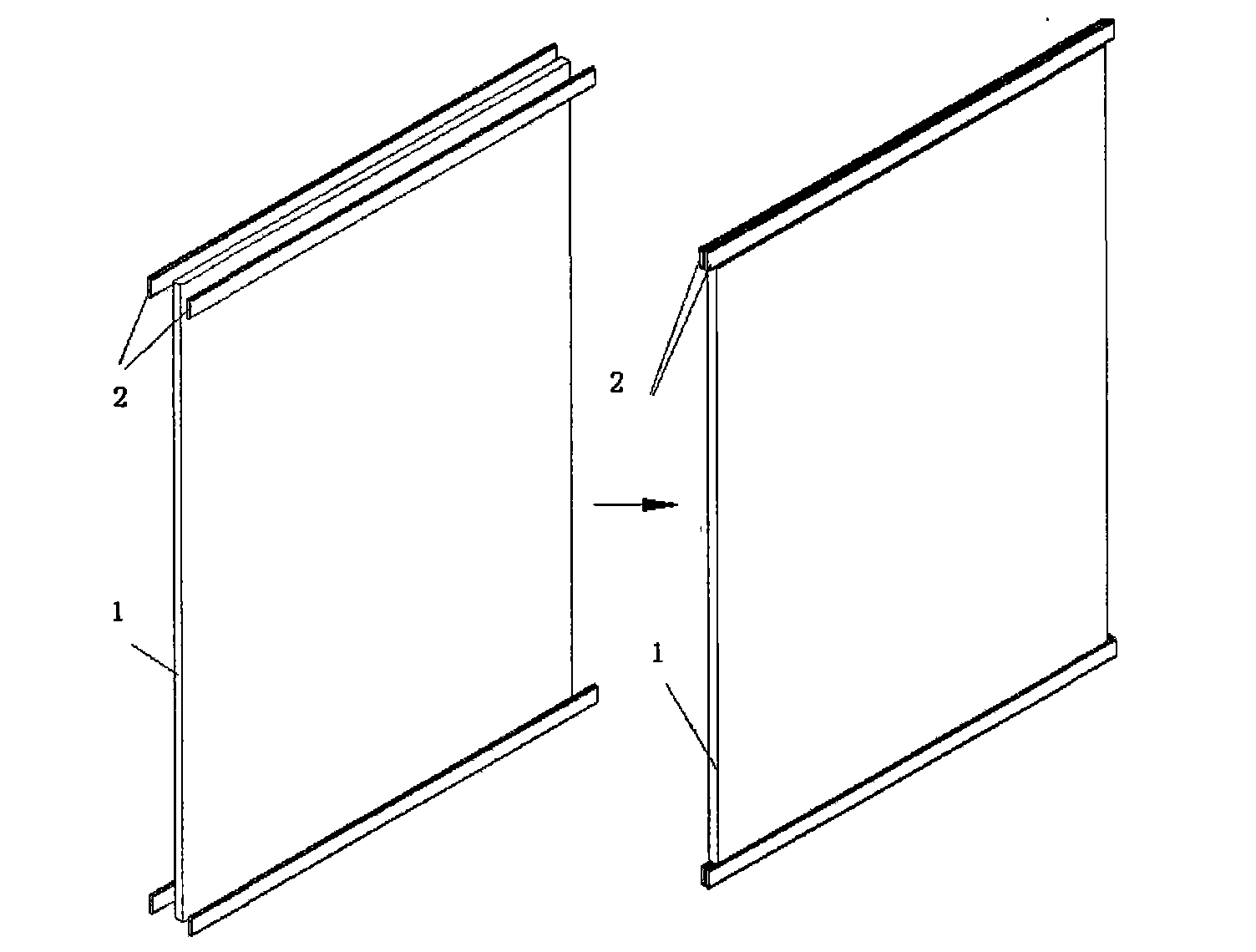

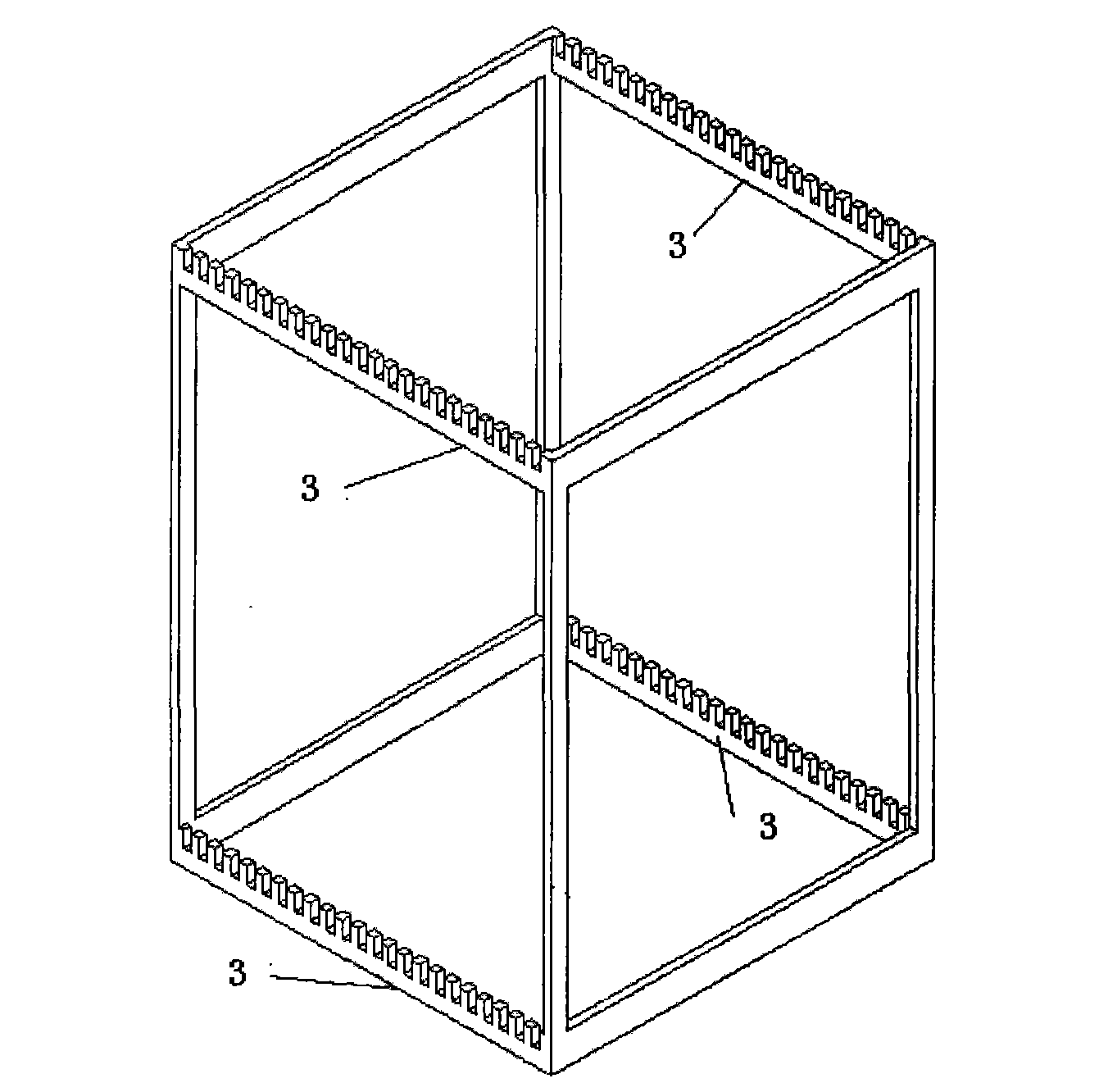

Flue gas purifying device for fixed-bed

The invention discloses a flue gas purifying device for a fixed-bed, which is filled with activated carbon fiber. The top part of a shell of the device is provided with an exhaust inlet and the bottompart is provided with an air outlet; the inner cavity of the shell is divided into a diversion section, a purification section and an air collection section from top to bottom; the diversion sectionis provided with a plate rectifier with holes and a diversion plate is arranged on the plate rectifier; and the purification section is provided with an activated carbon fiber filling cell. The upperend and the lower end of a fixed frame of the activated carbon fiber filling cell are provided with two parallel comb plates respectively; upper clamping plates and lower clamping plates are respectively inserted in various comb openings of the upper comb plate and the lower comb plate; sheet-shaped activated carbon fibers are fixed between the upper clamping plates and between the lower clampingplates; and the width of the spacing between the adjacent two activated carbon fibers is between 0.5 mm and 10 mm. In the invention, the activated carbon fiber can be tightly, reliably and fixedly installed in the purifying device for a long time. The device has the advantages of compact structure, high filling efficient of activated carbon fiber, low consumption of a reactor, convenient repair, installation, replacement and reproduction and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

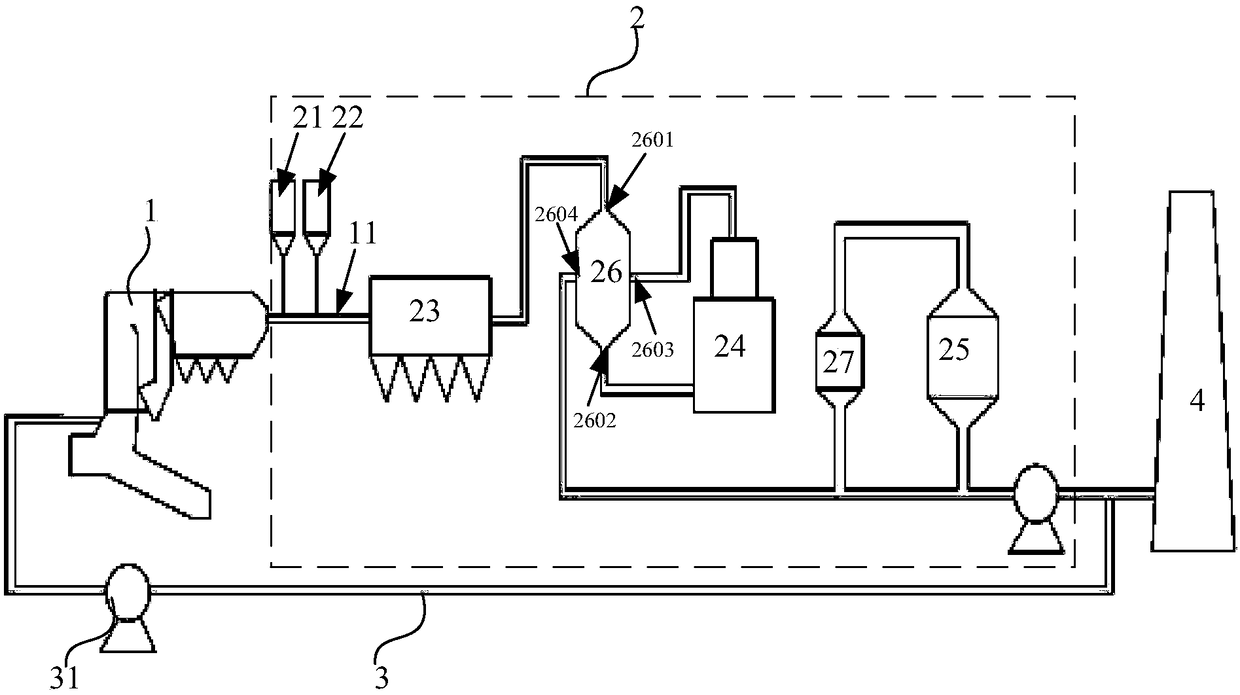

Waste incineration system

PendingCN108543419AReduce processShorten the lengthGas treatmentDispersed particle filtrationLitterFlue gas

The invention provides a waste incineration system. The waste incineration system comprises: an incinerator; a flue gas treatment system, which is used for purifying flue gas generated by incinerationin the incinerator to obtain dischargeable flue gas; and a flue gas recirculation system, which is used for introducing the dischargeable flue gas into the incinerator; wherein the flue gas treatmentsystem comprises an active carbon injection device, a dry deacidification device, a dust remover, a wet deacidification device and an SCR denitration device which are successively arranged along theflowing direction of the flue gas. According to the waste incineration system provided by the invention, the dischargeable flue gas undergone purification treatment of the flue gas treatment system isintroduced into the incinerator through arrangement of the flue gas recirculation system, so the oxygen content and temperature of the interior of the incineration chamber of the incinerator are adjusted, and the flue gas temperature of the outlet of the incinerator is reduced; thus, the thermal efficiency of the incinerator is significantly improved; the generating capacity of power is increased; meanwhile, process steps and process chain length in the purification process of the flue gas are significantly reduced; and equipment investment cost and operation cost are decreased.

Owner:EVERBRIGHT ENVIRONMENTAL TECH RES INST NANJING CO LTD +1

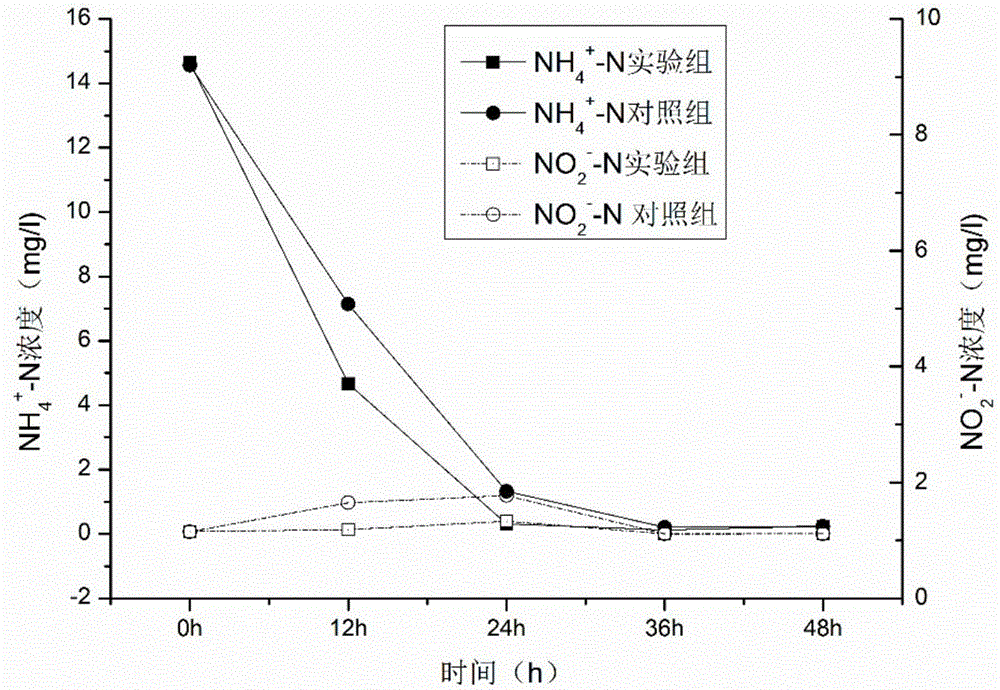

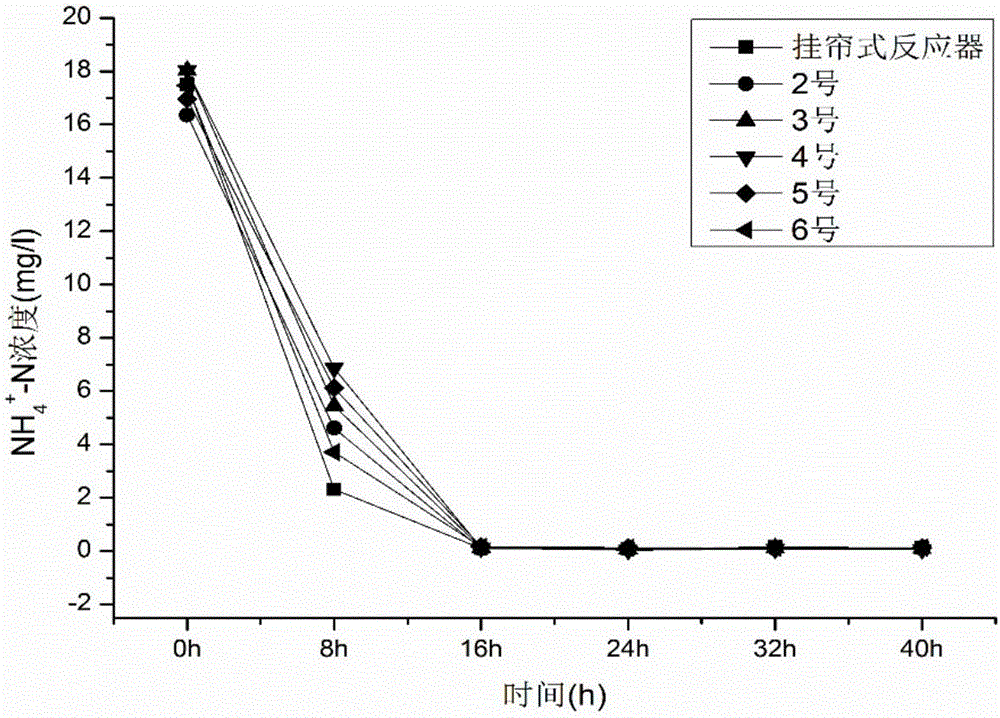

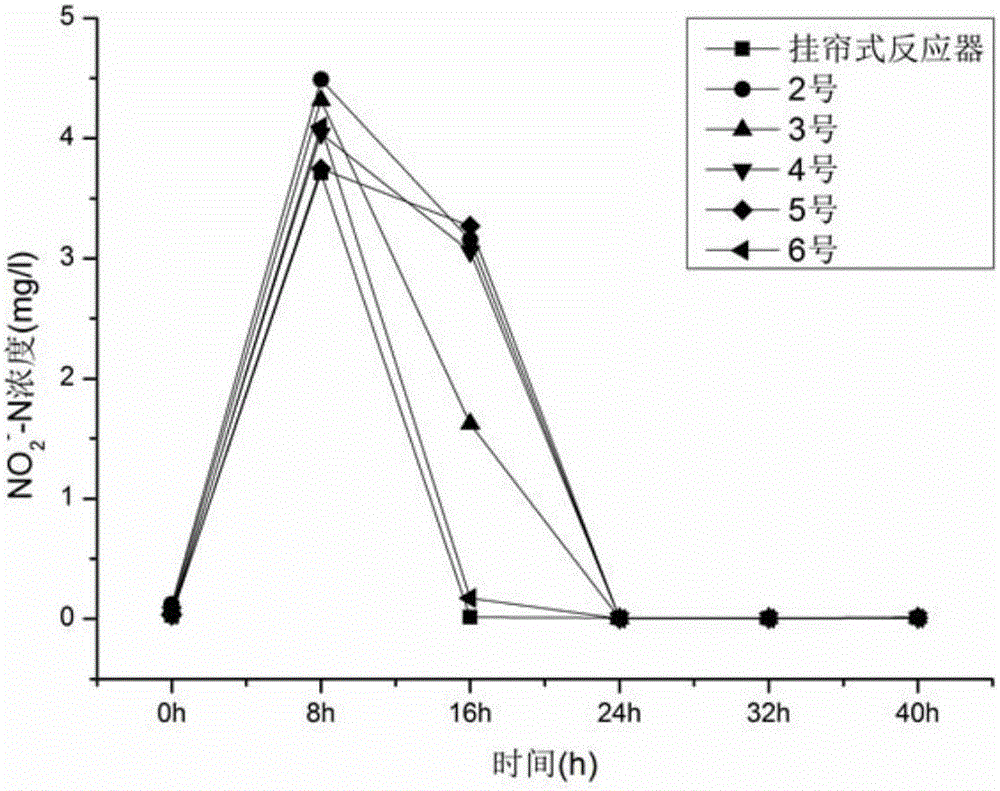

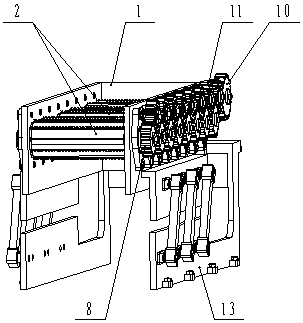

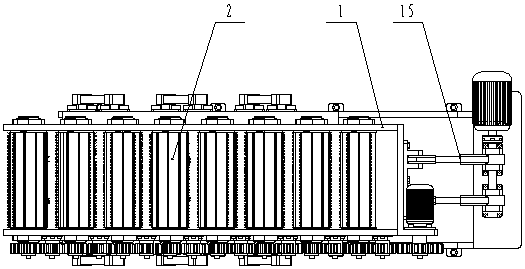

Hanging curtain type biological filtering pool and application thereof to recirculating aquaculture

ActiveCN105693022AFavorable for attachment growthLess agitationWater/sewage treatment by irradiationWater contaminantsFiberCarbon fibers

The invention provides a hanging curtain type biological filtering pool which comprises a container, carbon fiber felt, a water inlet pipe and a water outlet pipe; the carbon fiber felt is inserted into the container side by side at the interval of 2-4 cm, the water inlet pipe is arranged on the upper portion of the container, the water inlet pipe is connected with water distribution pipes, the water distribution pipes are connected with a water distribution device, and the water distribution device is located above the carbon fiber felt; the water outlet pipe is located at the bottom of the container. The invention further provides application of the hanging curtain type biological filtering pool. The hanging curtain type biological filtering pool enables microorganisms to be attached to the carbon fiber felt, stirring of water flow is reduced, the microorganisms can grow more easily in an attached mode, pollutants in water are further removed, and quality of outlet water is improved; meanwhile, an aged biological membrane falls along with water and is removed through a physical filtration system, backwash equipment is not needed, and cost is saved while removal efficiency of ammonia nitrogen and nitrite nitrogen is guaranteed.

Owner:BEIJING AGRO BIOTECH RES CENT

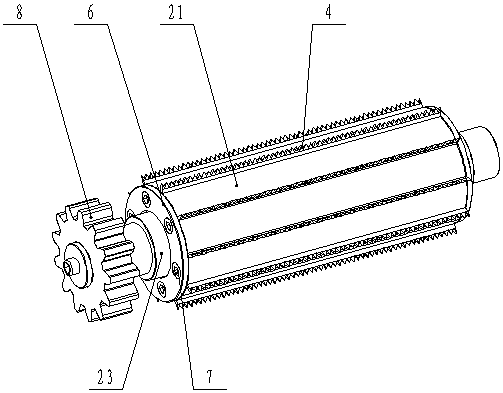

Hemp thread removal device of tobacco products

PendingCN109351586AAchieve sticky hookEfficient removal of impuritiesTobacco preparationSievingDrive wheelEngineering

The invention discloses a hemp thread removal device of tobacco products. The device comprises an impurity removal roller way arranged in a conveying groove of a vibration conveyor, an impurity removal roller is formed through combined arrangement of thread impurity removal rollers, the thread impurity removal rollers are of split type roller structures and comprise roller bodies arranged on roller shafts in a sleeving manner and each formed through abut joint of two half roller bases, multiple discharging racks made of elastic materials are evenly distributed on the roller faces of the rollerbodies in the circumference direction, the thread impurity removal rollers are arranged on the conveying groove through the corresponding roller shafts and matched bearings, transmission gears are fixedly arranged on roller shaft ends, located on the same side, of the thread impurity removal rollers, the transmission gears are in transmission connection with a drive mechanism, the drive mechanismcomprises a driving wheel and multiple driven wheels distributed on the outer wall of the conveying groove, and the driven wheels are located between two adjacent transmission gears and are in engaged connection with the transmission gears on two sides adjacent to the driven wheels. Threads such as hemp ropes and hemp browns can be subjected to efficient impurity removal and eliminating, and thedamage to the tobacco leaves can be reduced.

Owner:CHINA TOBACCO HENAN IND

Ammonia spraying device and flue gas denitration device

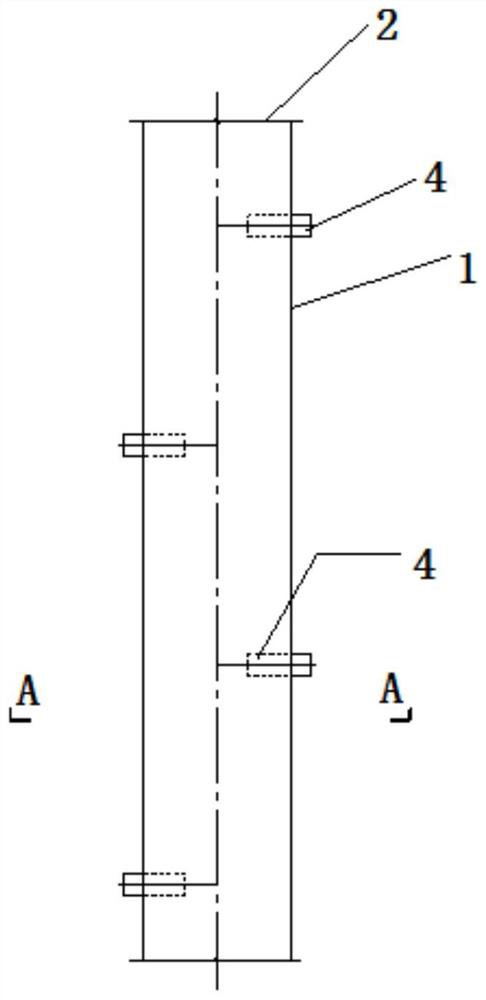

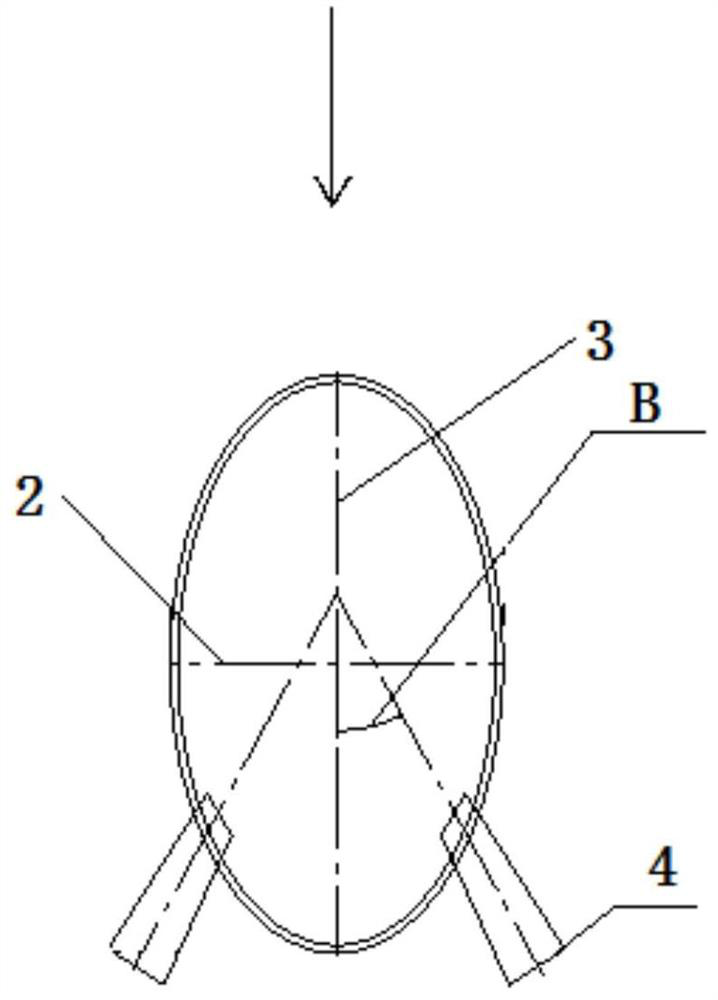

PendingCN112870960AImprove bending resistanceReduce distortionGas treatmentDispersed particle separationFlue gasProcess engineering

The invention relates to the technical field of environmental protection, in particular to an ammonia spraying device and a flue gas denitration device.The ammonia spraying device comprises an ammonia spraying pipeline suitable for being horizontally arranged in a flue, wherein the cross section of the ammonia spraying pipeline is in an oval shape, the short axis of the oval shape is perpendicular to the flowing direction of flue gas in the flue, the long axis of the oval shape is parallel to the flowing direction of flue gas in the flue; and a nozzle which is arranged on the ammonia spraying pipeline. Due to the fact that the short axis is perpendicular to the flowing direction of the flue gas, on the premise that the length of the ammonia spraying pipeline is not changed, the projection area of the ammonia spraying pipeline is the product of the length of the short axis and the length of the ammonia spraying pipeline, the flue gas blocking area can be greatly reduced, the deamination efficiency of the system is guaranteed, and the system resistance is effectively reduced. The mass transfer path and area are increased, and the deamination efficiency is improved. In addition, due to the oval shape, flowing of the smoke can be guided, the smoke flows smoothly, and abrasion to the ammonia spraying pipeline is small.

Owner:CHINA HUADIAN ENG +1

Sticker water removing mechanism for ceramic tile floor and using method

InactiveCN111938521AAffect stabilityGuaranteed removal efficiencyCarpet cleanersFloor cleanersHollow corePaper sheet

Owner:南京溧水高新产业股权投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com