Hemp thread removal device of tobacco products

A technology for tobacco products and equipment, which is applied to the field of hemp silk removing equipment for tobacco products, can solve the problems of not being able to meet the hemp rope removal requirements, inconvenient use and maintenance, affecting impurity removal efficiency, etc., so as to avoid hidden quality risks and reduce maintenance costs. , to ensure the effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

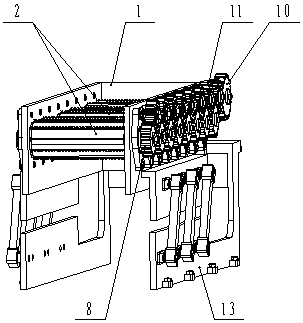

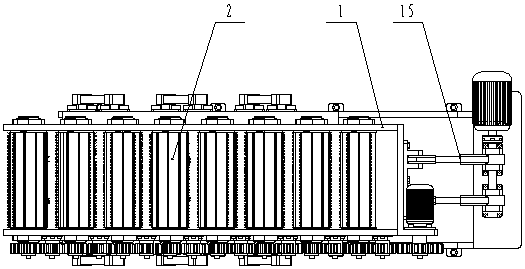

[0039] Such as Figure 1 to Figure 7 As shown, this embodiment discloses a device for removing flax from tobacco products, which includes a vibrating conveyor. A roller table for removing impurities is arranged in the conveying trough 1 of the vibrating conveyor along its conveying direction. Miscellaneous rollers 2 are arranged in combination.

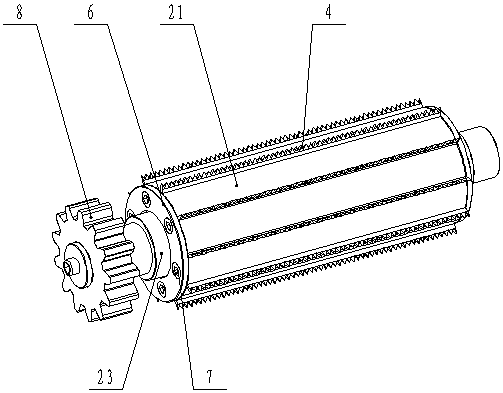

[0040]In the present invention, the rollers 2 for removing impurities from silk are installed on the conveying trough 1 through the corresponding roller shafts and the associated bearings, and the roller axles on the same side of the removing rollers 2 for silk objects pass through the conveying groove 1 outwards. And fixedly set transmission gear 8 at this piercing end; Transmission gear 8 transmission is connected with driving mechanism. The driving mechanism includes a motor 9 inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com