Patents

Literature

30results about How to "Guaranteed transmission ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

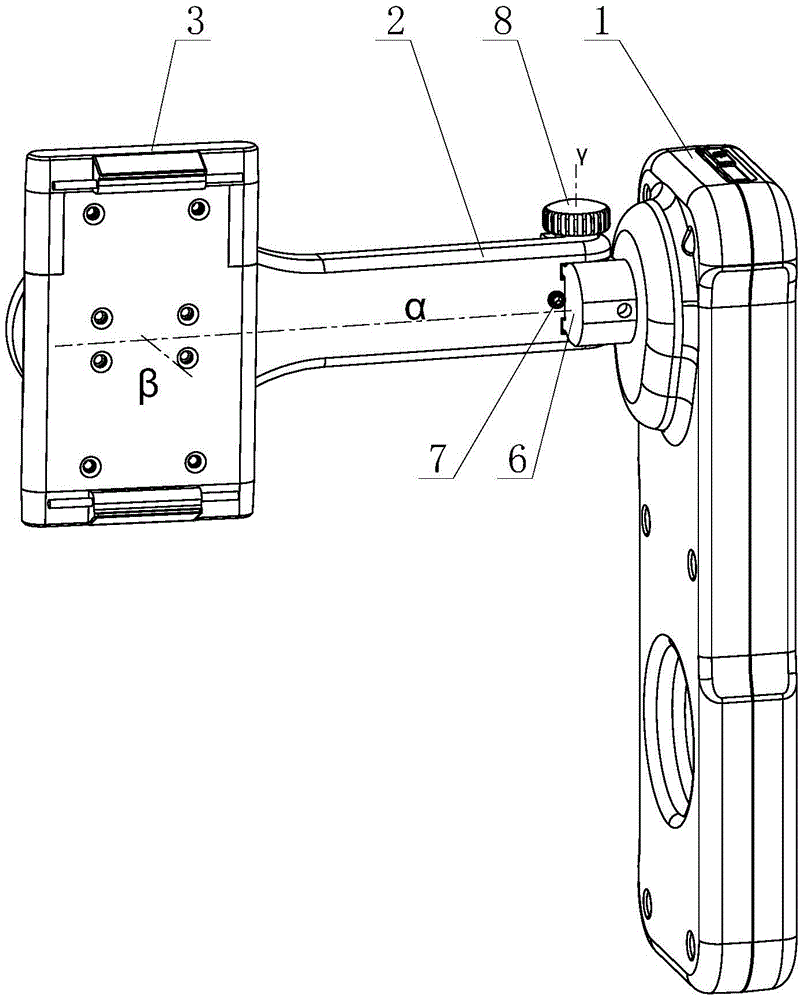

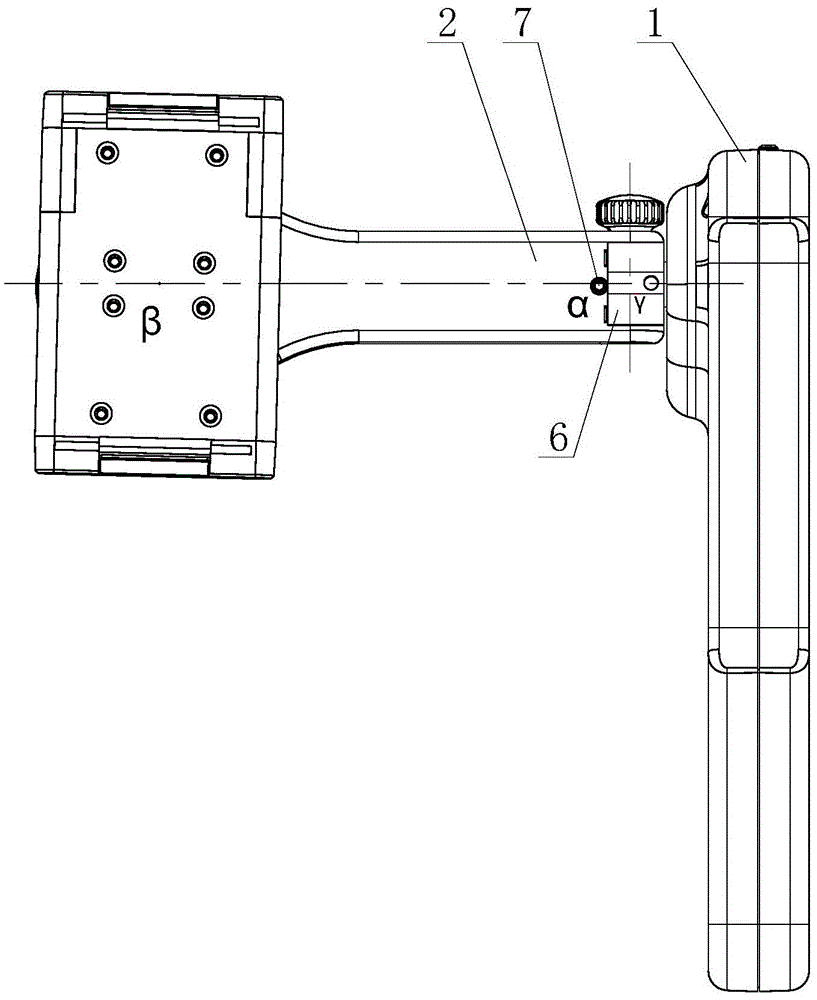

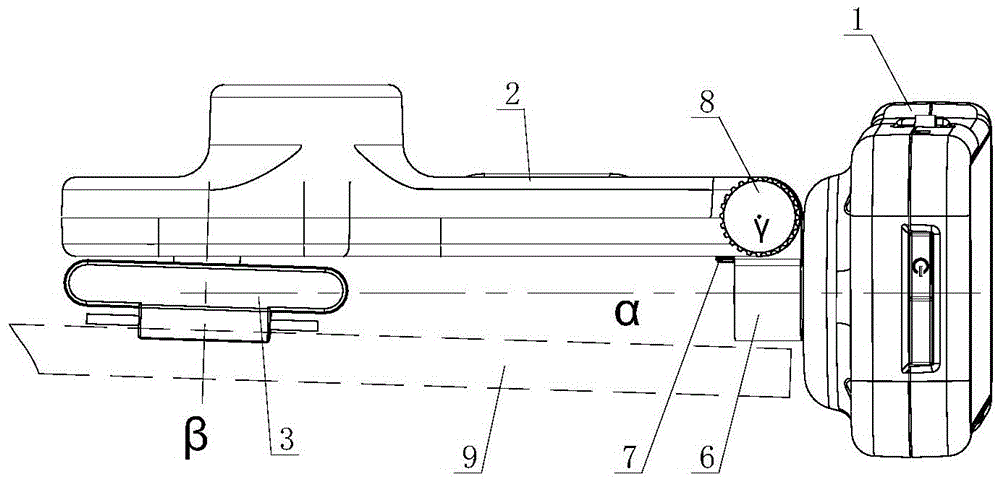

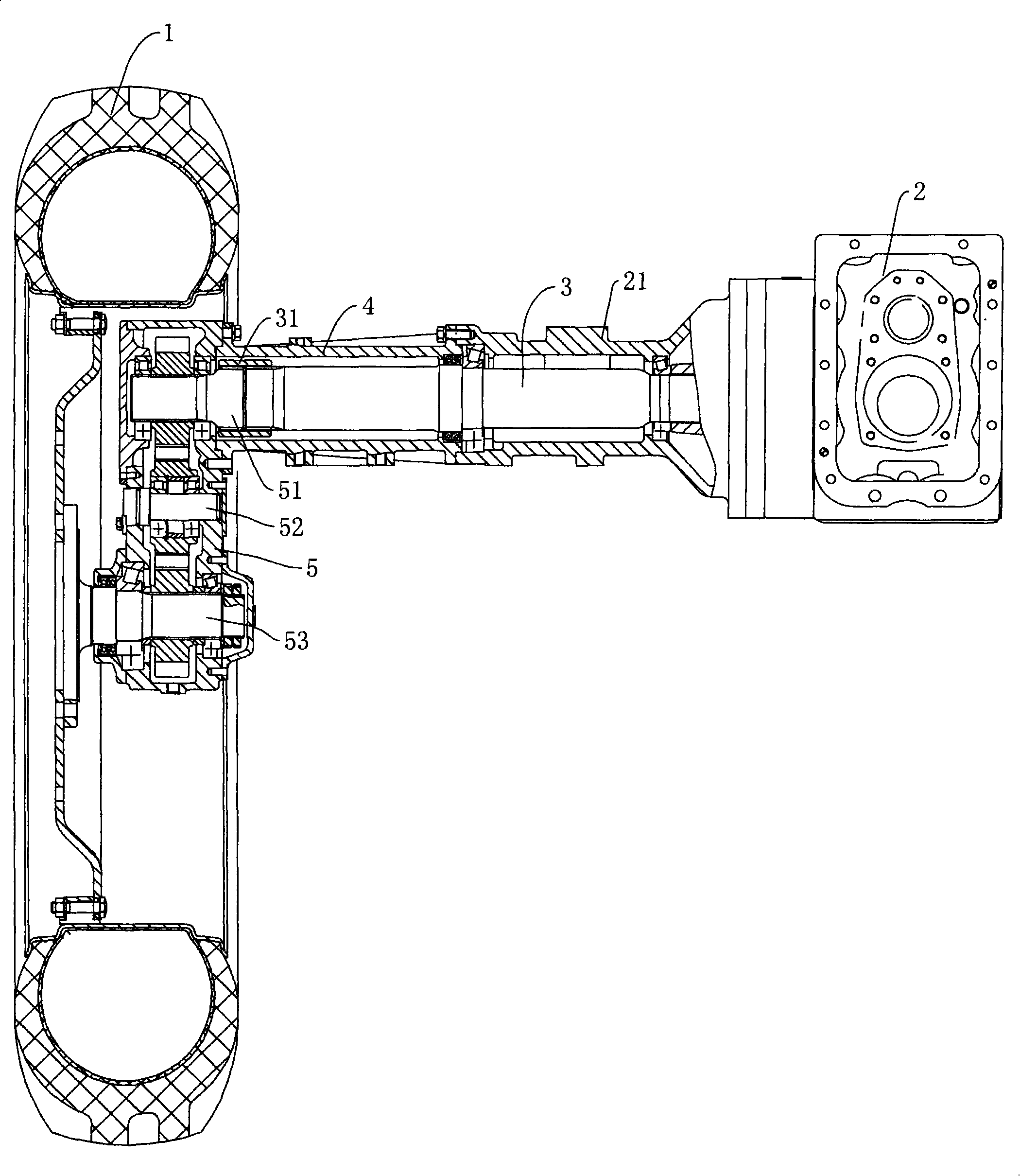

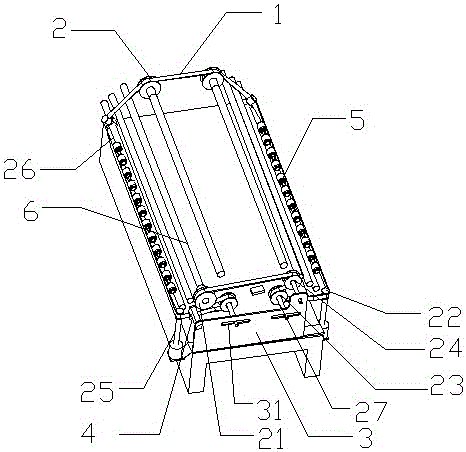

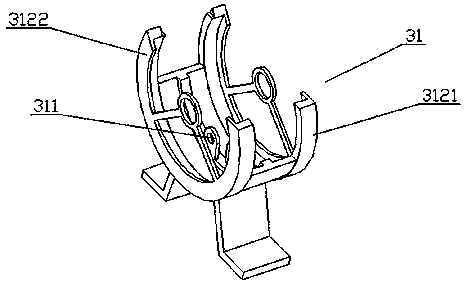

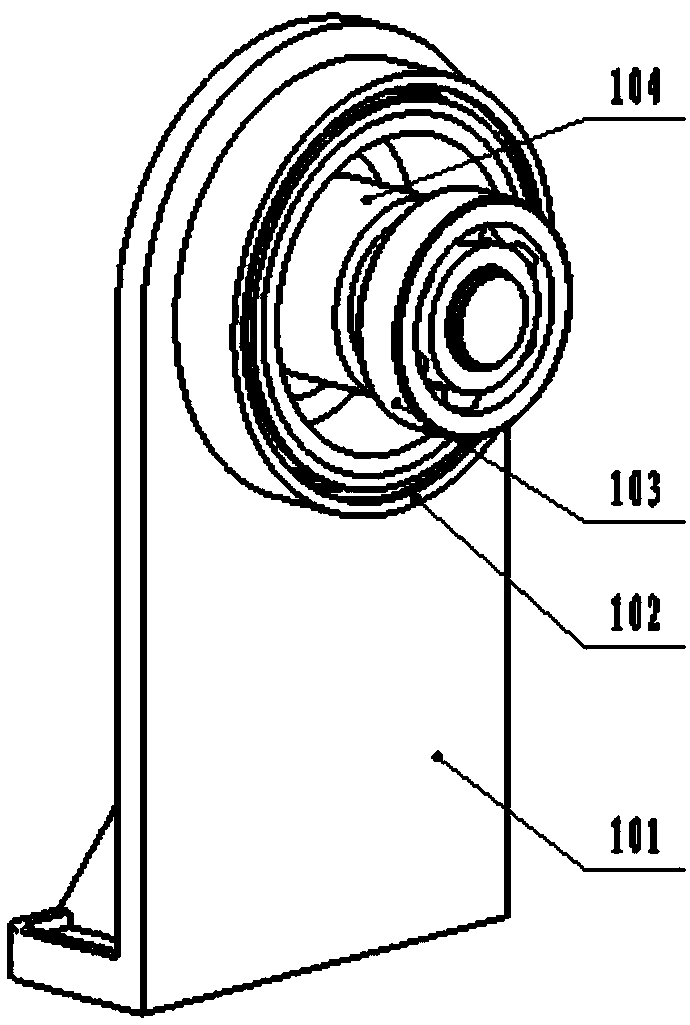

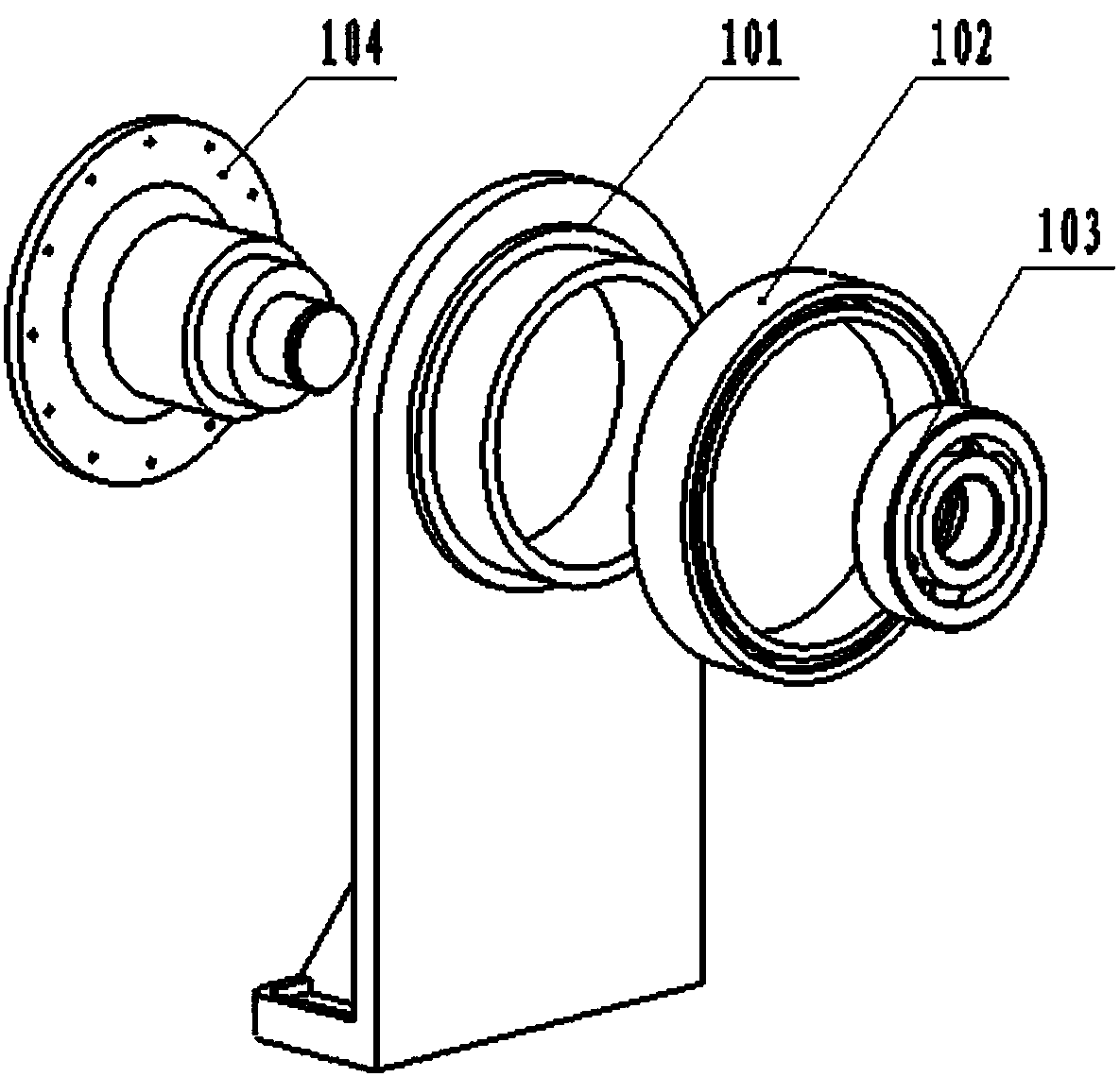

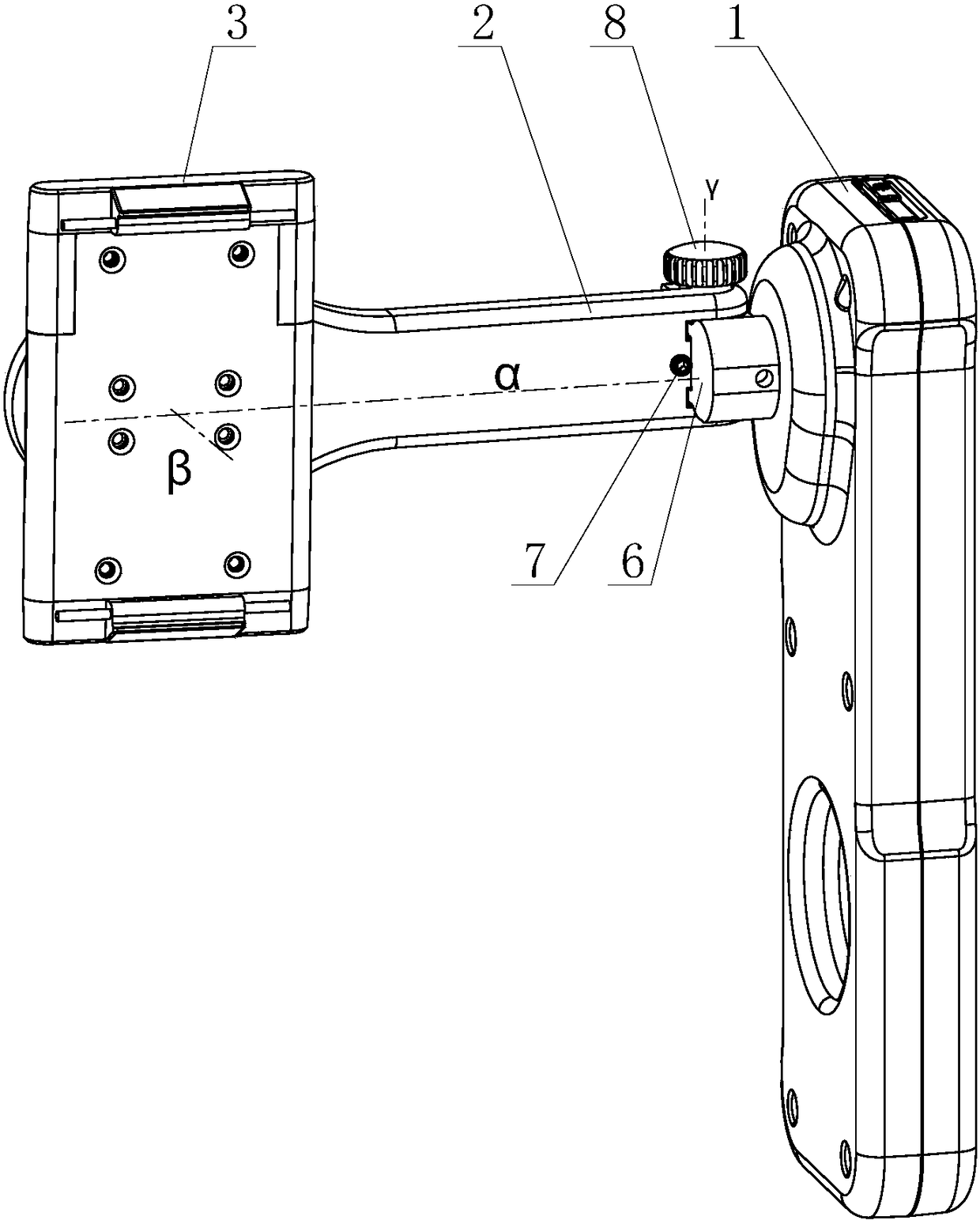

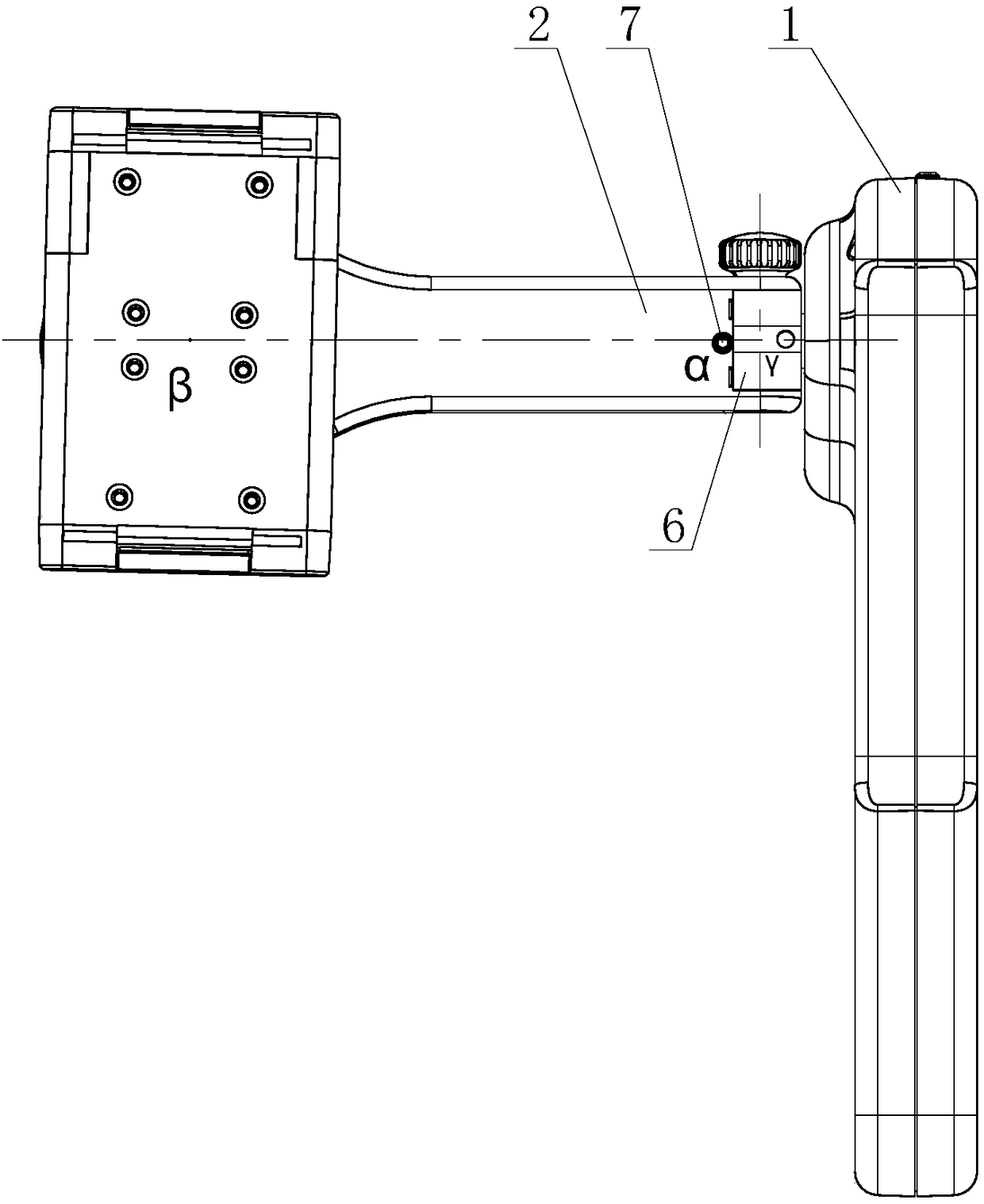

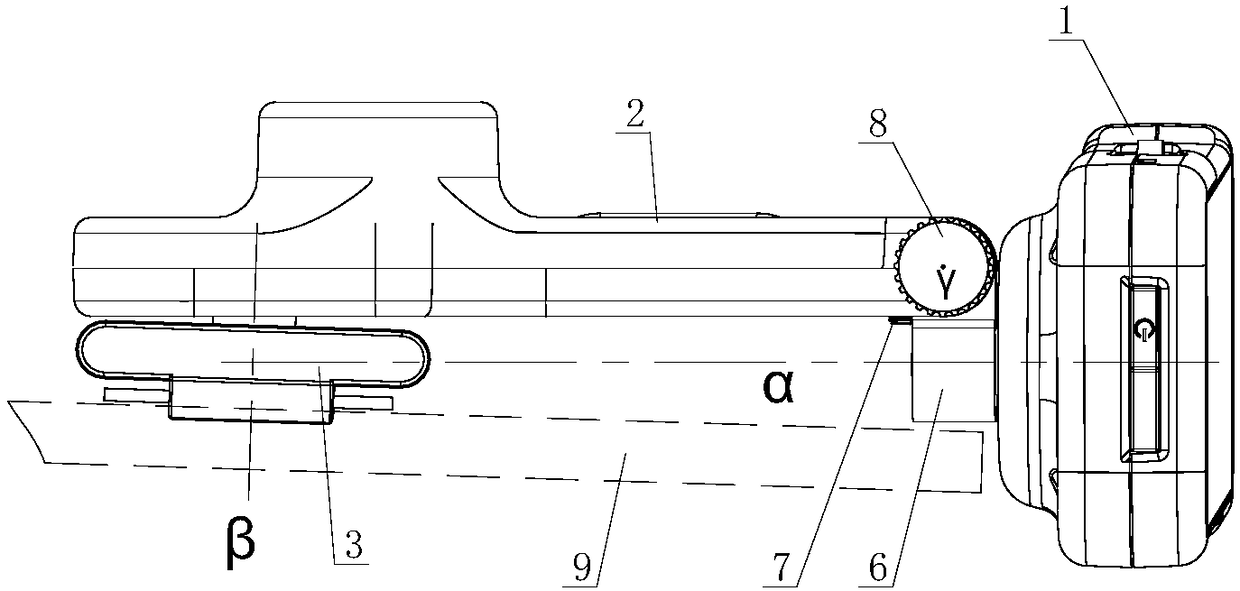

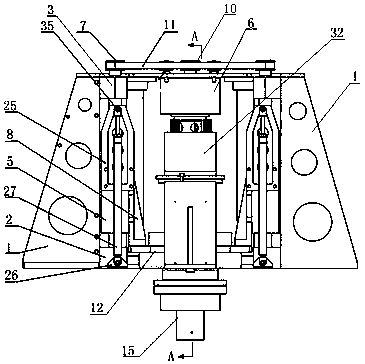

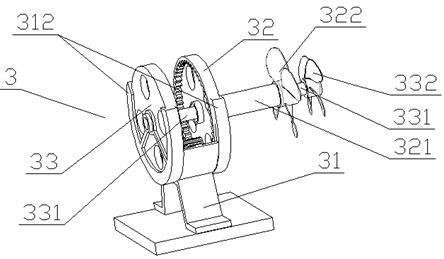

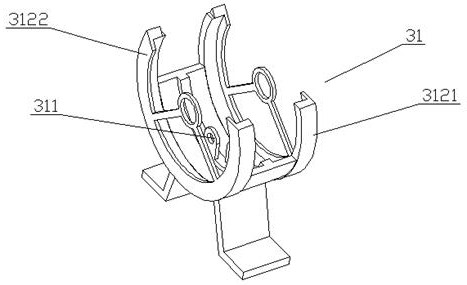

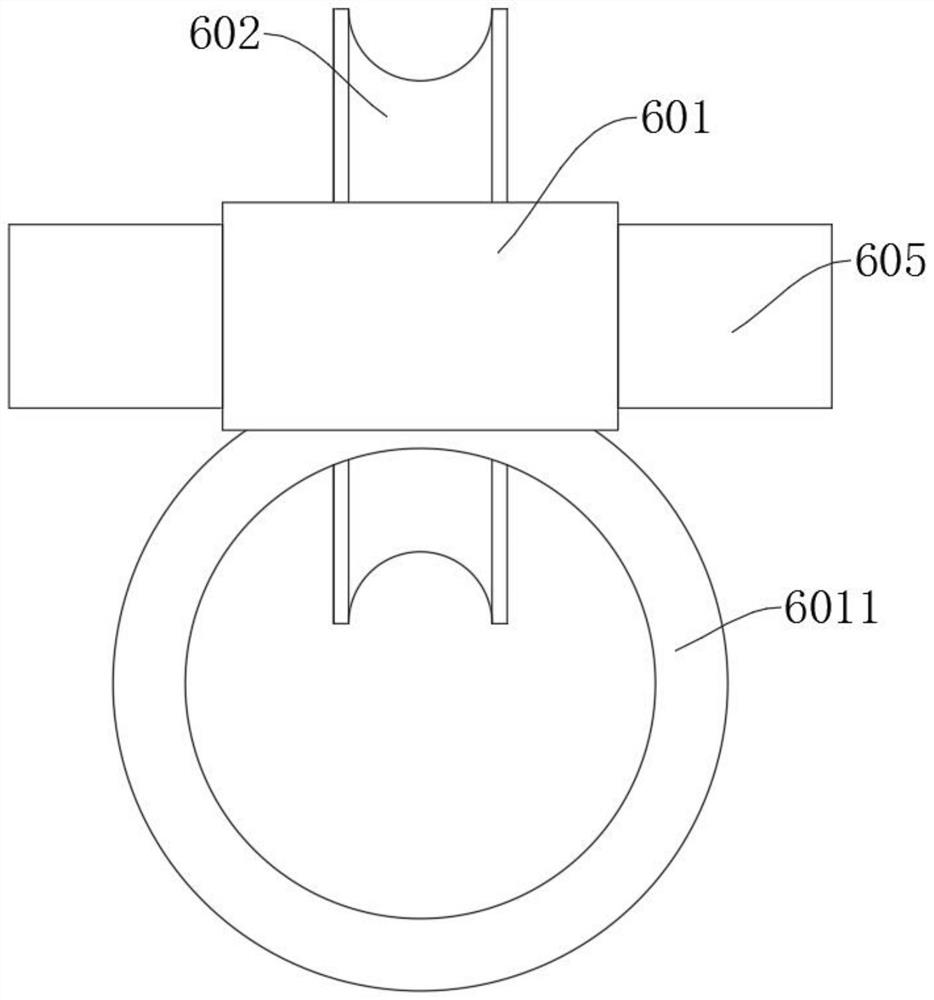

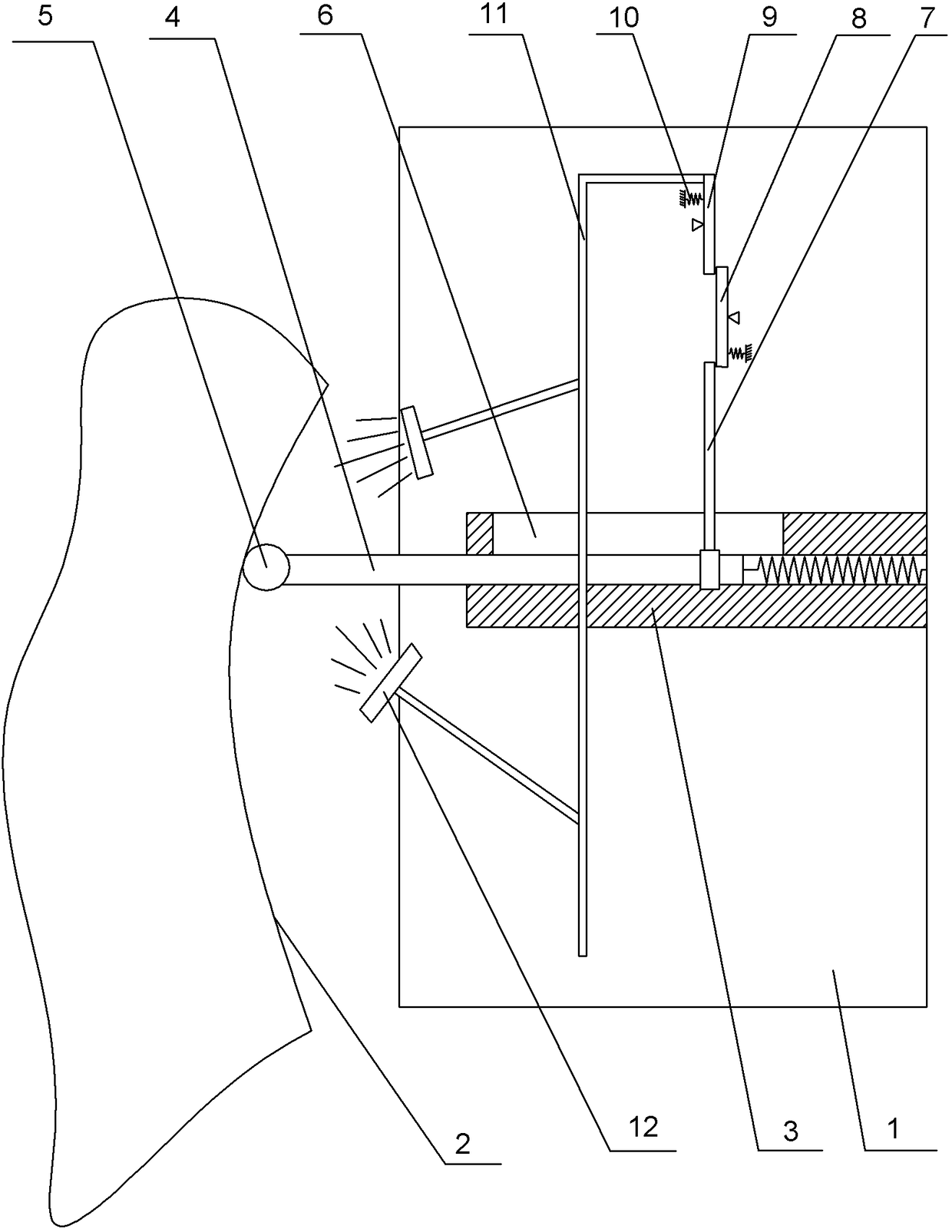

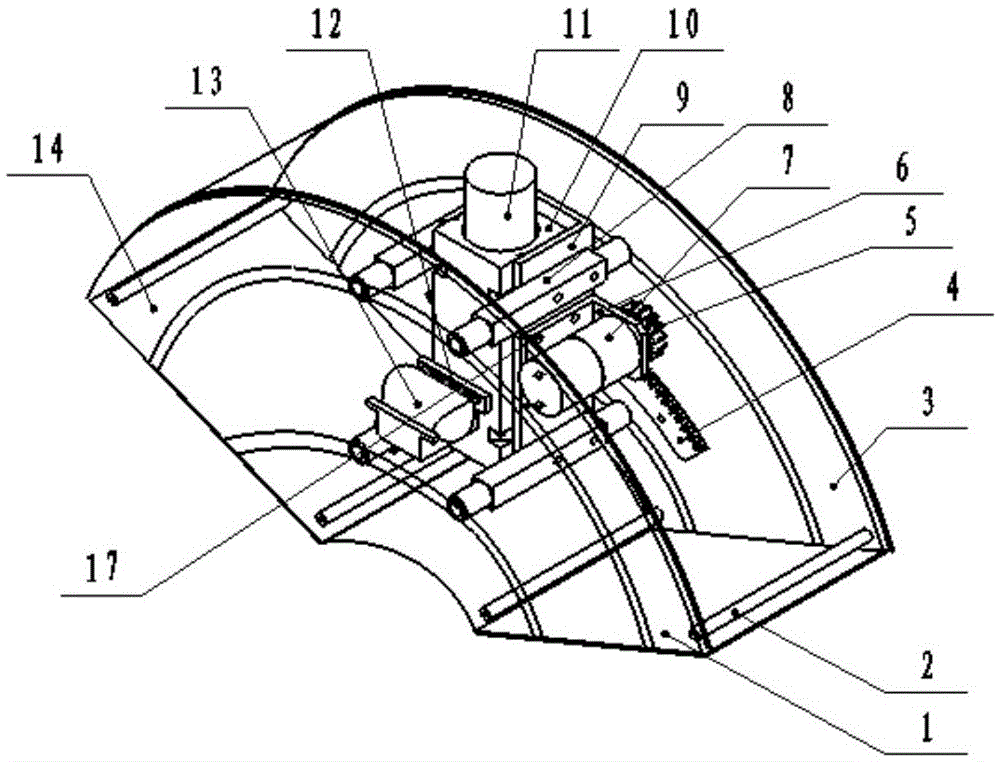

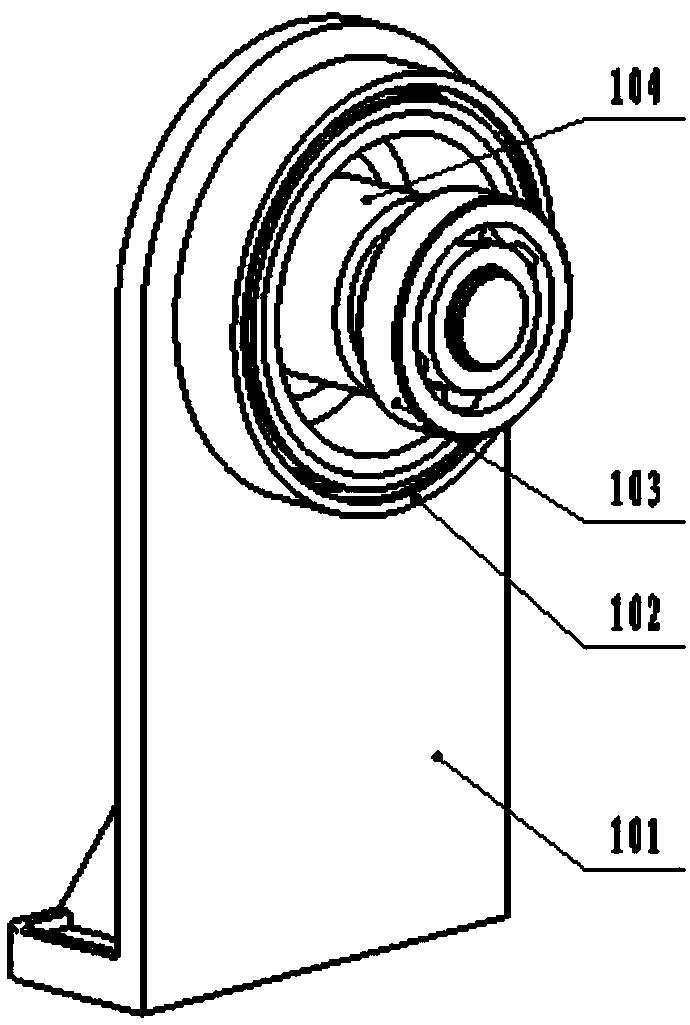

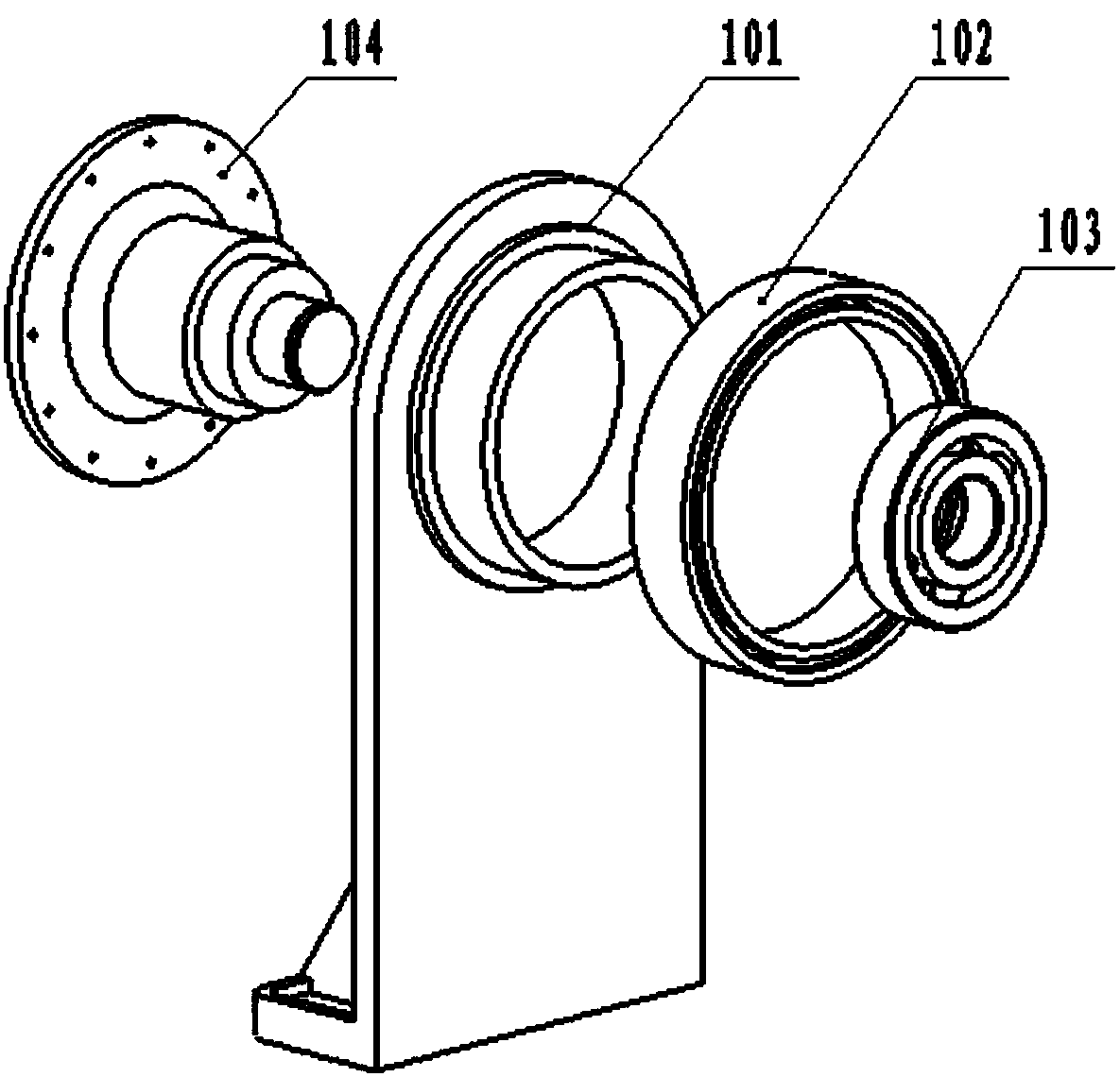

Portable auxiliary stabilizer for camera shooting and photographing

InactiveCN106764345AEfficient use ofEasy to operateStands/trestlesTelephone set constructionsCamera lensGreek letter beta

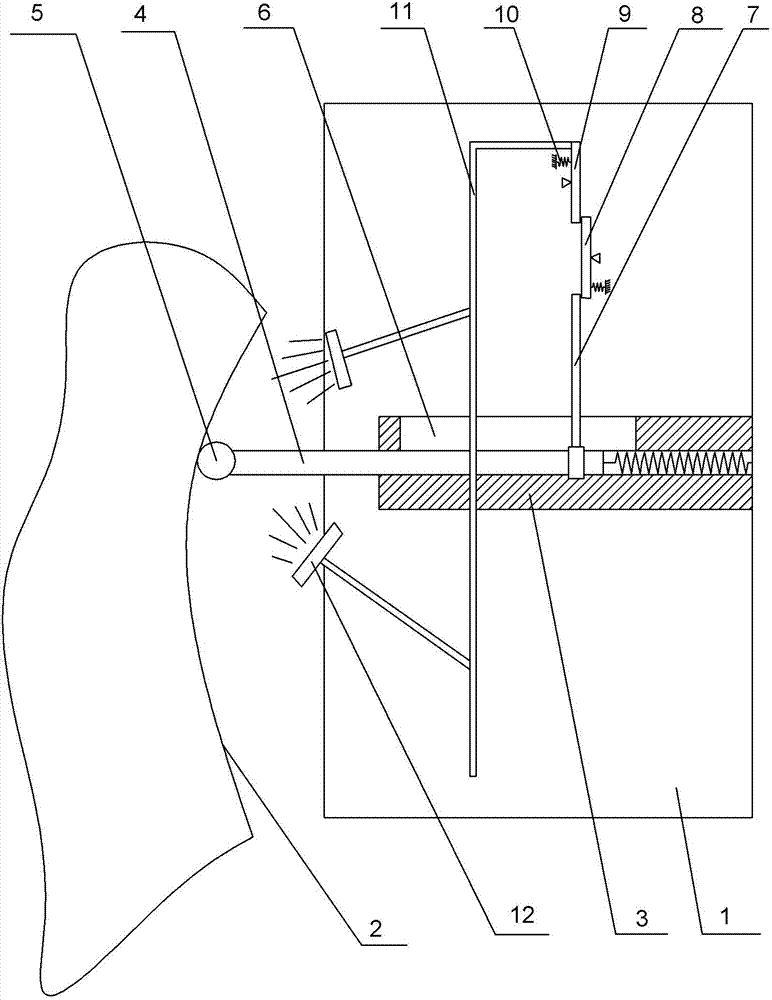

The invention relates to a portable auxiliary stabilizer for camera shooting and photographing. One end of a rolling machine arm is connected with a rolling machine arm mounting base in a rotary mode, and the rotation center line of the rolling machine arm is gamma; the rolling machine arm mounting base is connected with a pitching machine arm in a rotary mode, and the rotation center line of the rolling machine arm mounting base is alpha, and a rotating shaft of the rolling machine arm mounting base is equipped with a pitching correcting motor; a fixing base is mounted on the side surface near the other end of the rolling machine arm, the rotation center line of the fixing base is beta, and the rotating shaft is equipped with a rolling correcting motor; the rotation center line gamma is perpendicular to a plane where the rotation center line alpha and the rotation center line beta intersect; the fixing base is equipped with an accelerometer and a gyroscope, and the accelerometer and the gyroscope are connected to the pitching correcting motor and the rolling correcting motor through a control unit; and the portable auxiliary stabilizer for camera shooting and photographing is also equipped with a pitching angle adjusting switch connected with the pitching correcting motor through a control unit. The portable auxiliary stabilizer for camera shooting and photographing can be helpful for users to find the balancing positions of the gravity centers of phones rapidly and conveniently, no professional skill is needed, the system power consumption is low, heating is less, a shooting device keeps a lens stably oriented to a photographed object, and the precision of the image quality is high.

Owner:SHANGHAI RUIPAI INTELLIGENT TECH LLC

Tractor capable of realizing hi-crop working

The invention discloses a tractor capable of high-clearance cultivating, which comprises two rear wheels and two front wheels respectively arranged on a rear driving bridge and a front bridge, wherein, the rear driving bridge comprises two rear bridge shaft tubes, two driving shafts connected with a rear bridge transmission box run through and respectively and rotatably arranged on the two rear bridge shaft tubes; the front bridge comprises a bushing with both ends respectively and detachably connected with auxiliary bushings, wherein, the two auxiliary bushings are respectively connected with the two front wheels, the two driving shafts are respectively and detachably connected with transmission boxes, and the two transmission boxes are respectively connected with and drive the two rear wheels; the space between the two rear bridge shaft tubes and the two transmission boxes respectively, detachably and fixedly connected with connecting shaft tubes for sleeving the corresponding driving shafts. The tractor of the invention is enabled to realize two functions of routine work such as plowing, tilling, sowing, harvesting, etc. and cultivating work such as weeding, loosing, fertilizing, ridging, etc., thereby greatly reducing investment cost, expanding the functions of tractor and improving the utilization rate of the tractor.

Owner:LOVOL HEAVY IND

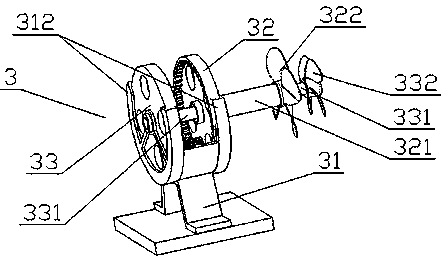

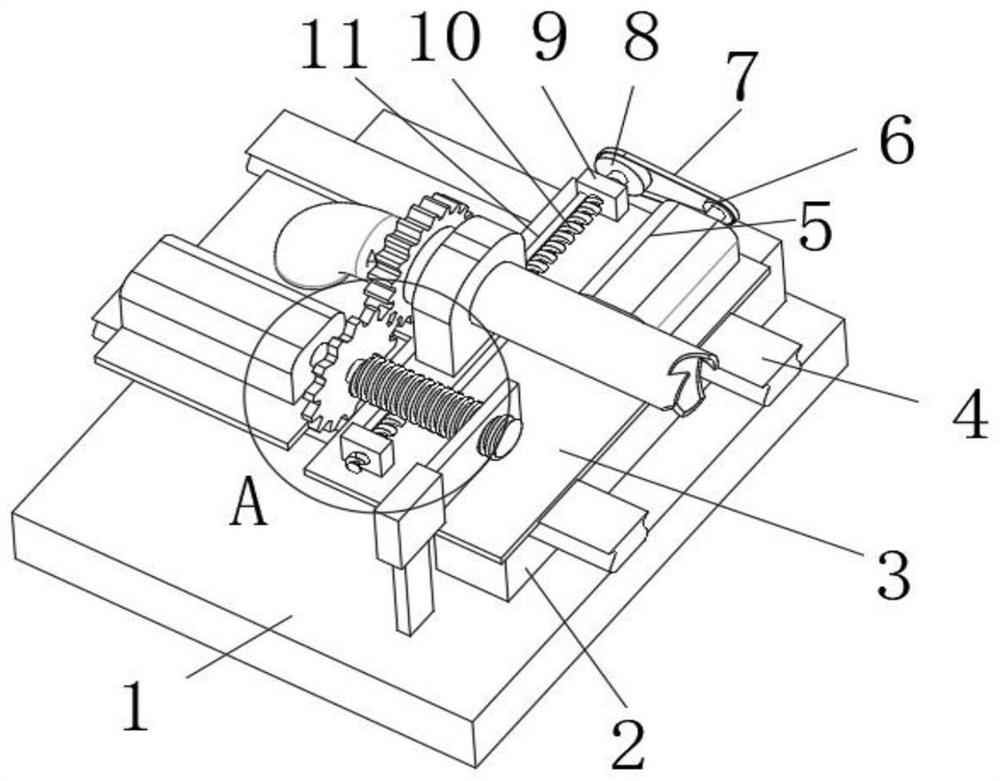

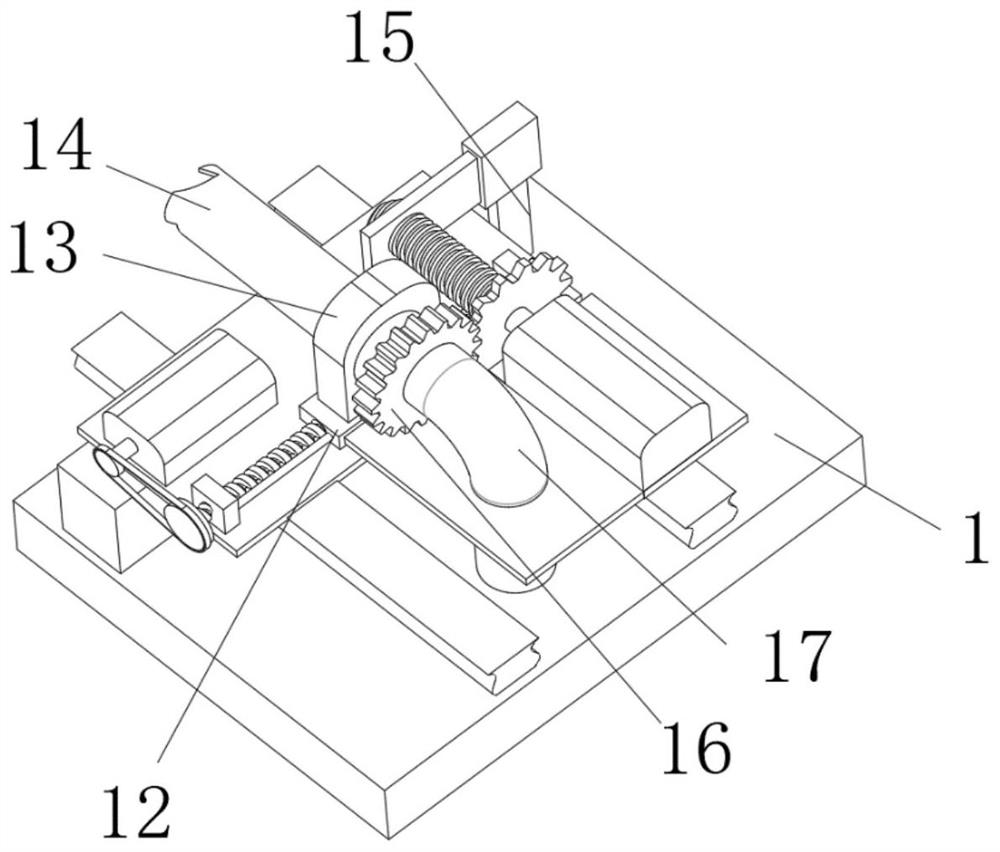

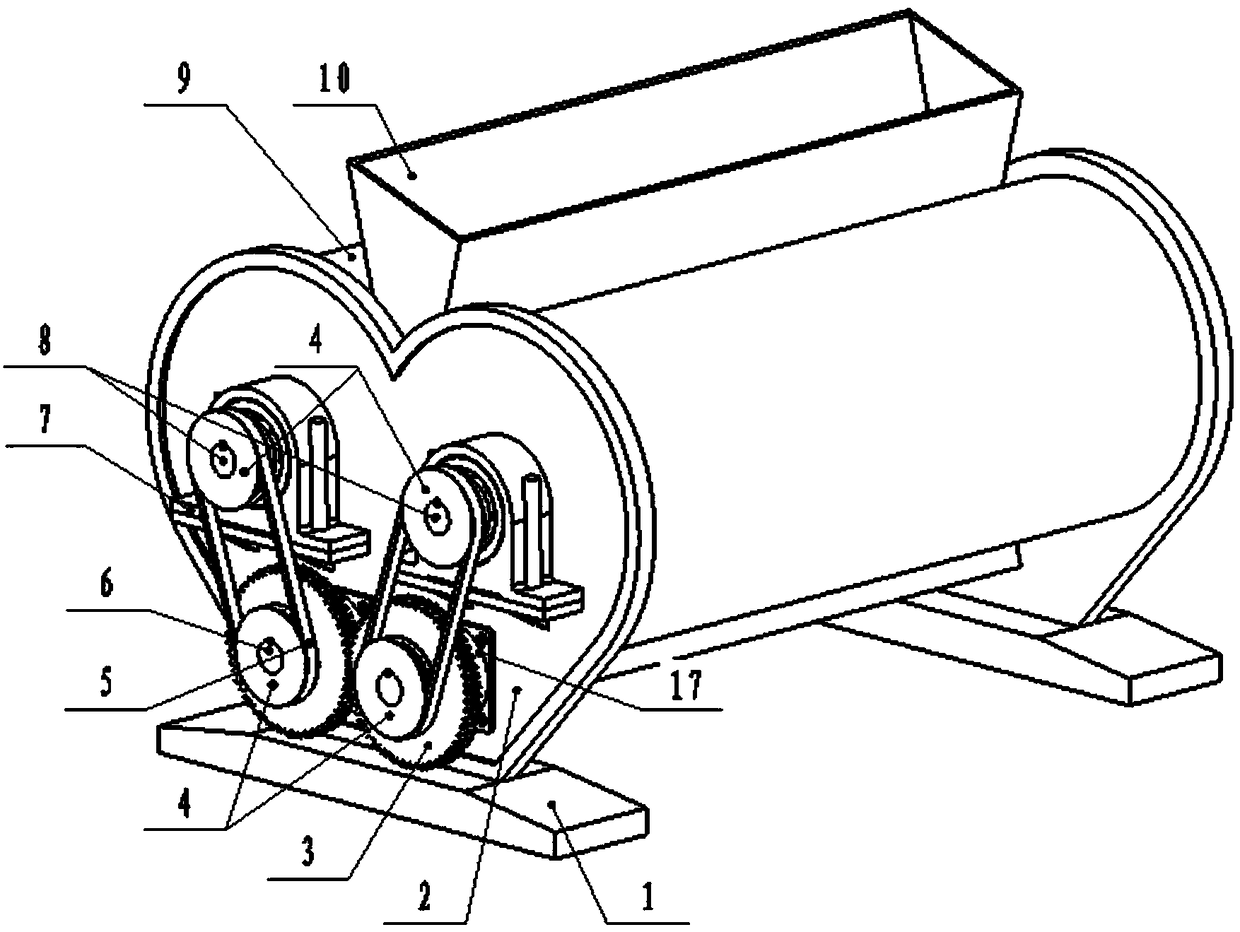

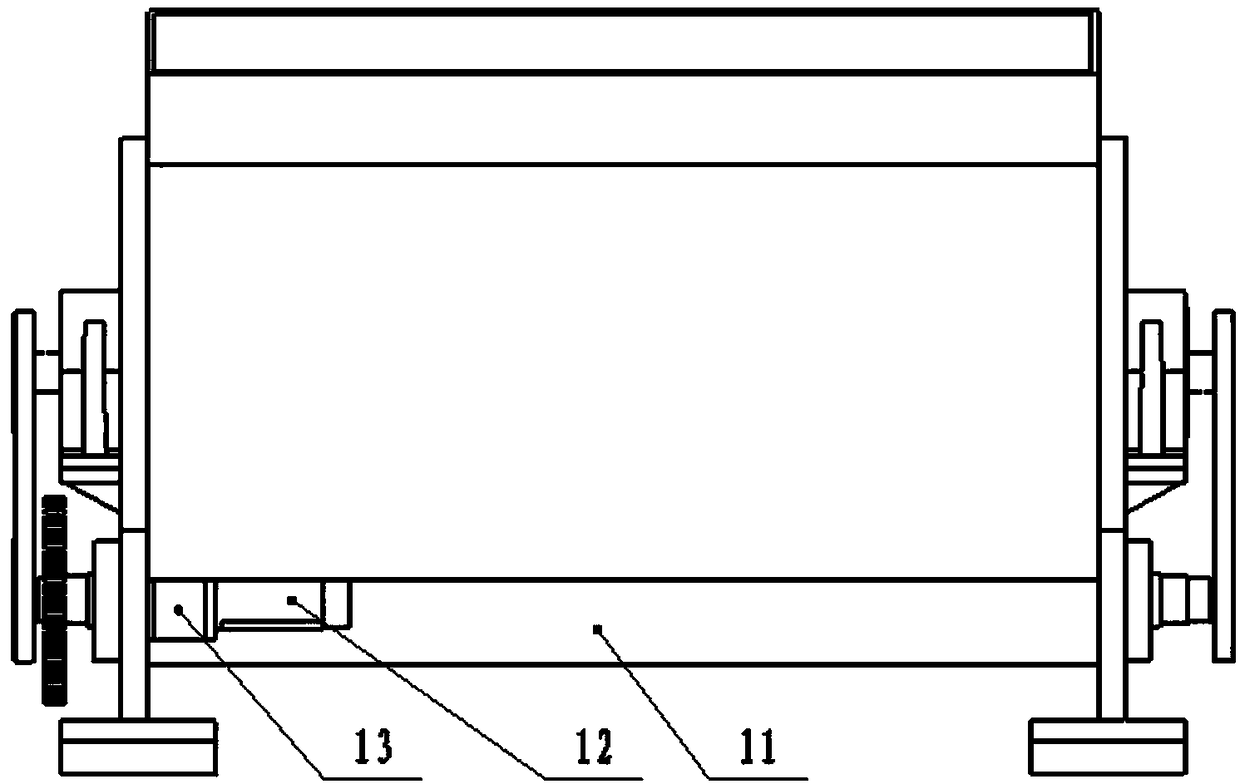

Guitar manufacturing method

ActiveCN107297293AEvenly paintedHigh efficiency of artificial paintingSpraying apparatusMotor driveSprayer

The invention belongs to the technical field of guitar production and particularly discloses a guitar manufacturing method. The method includes steps of material selection, neck manufacturing, body manufacturing, neck connection and paint spraying. At the step of paint spraying, a paint spraying device is used for paint spraying at a side plate concave position and comprises a frame, a guitar side plate is rotationally connected to the frame, a motor is arranged on the frame, the frame is provided with a guide groove and a slide rod which is slidably arranged in the guide groove, one end of the slide rod is abutted against the concave position of guitar side plate, and a reset spring is connected between the other end of the slide rod and the guide groove; the slide rod is connected with a spraying frame through a transmission mechanism in a transmission ratio of 1:1, and a pair of sprayers are arranged on the spraying frame, oppositely obliquely arranged at the concave position of the side plate and staggered in the height of the side plate; after the motor and the sprayers are switched on, the motor drives the side plate to rotate, and then the concave position of the side plate is sprayed by the sprayers. By adoption of the manufacturing method, uniformity in paint spraying at the concave position of the guitar side plate is achieved.

Owner:贵州金韵乐器有限公司

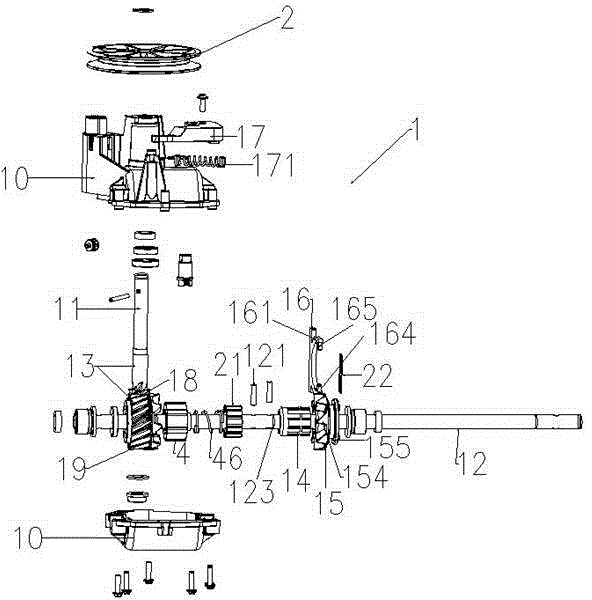

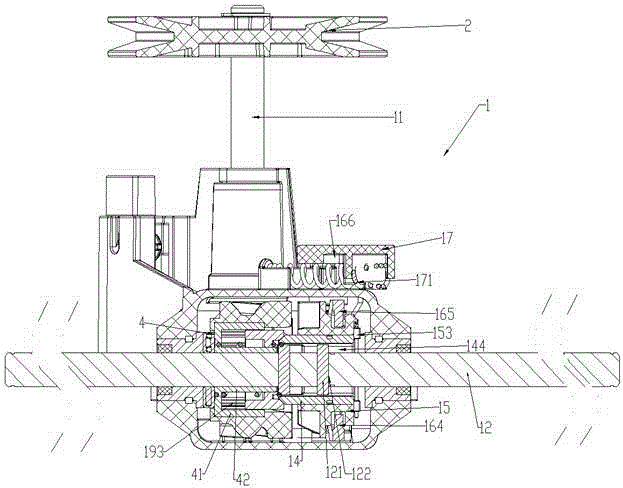

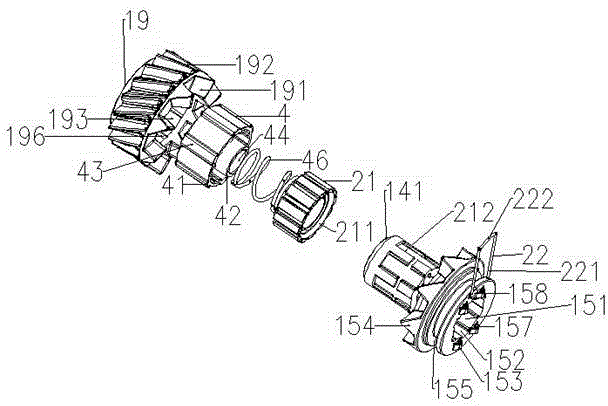

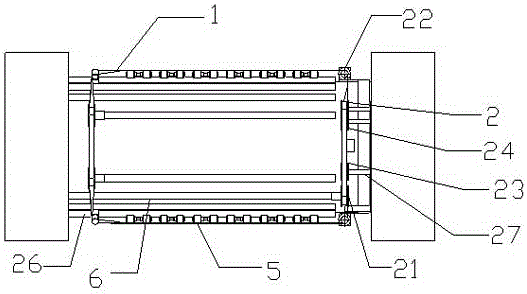

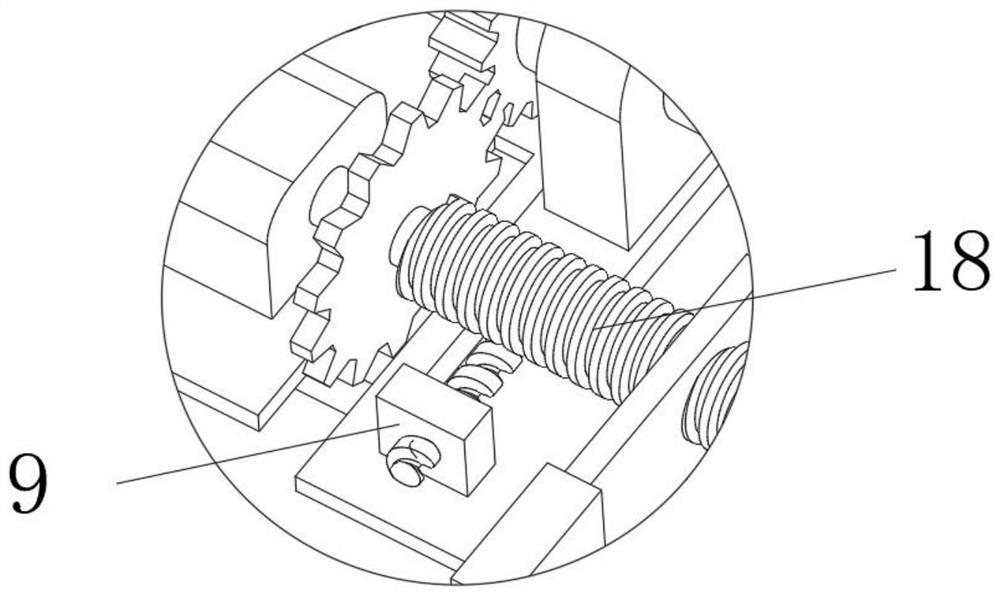

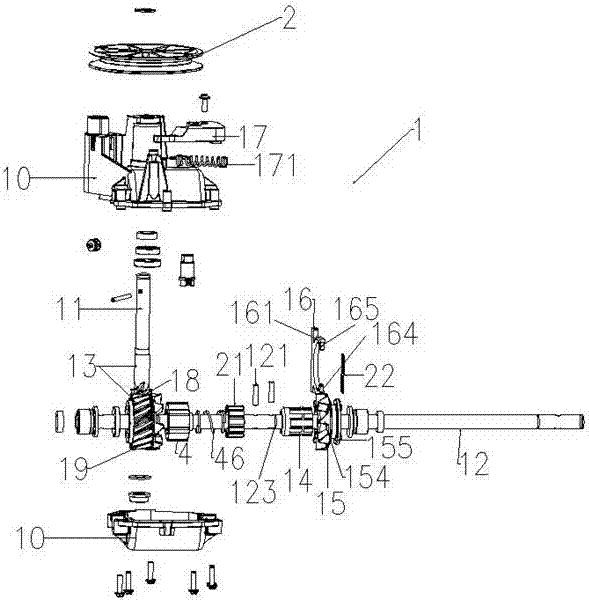

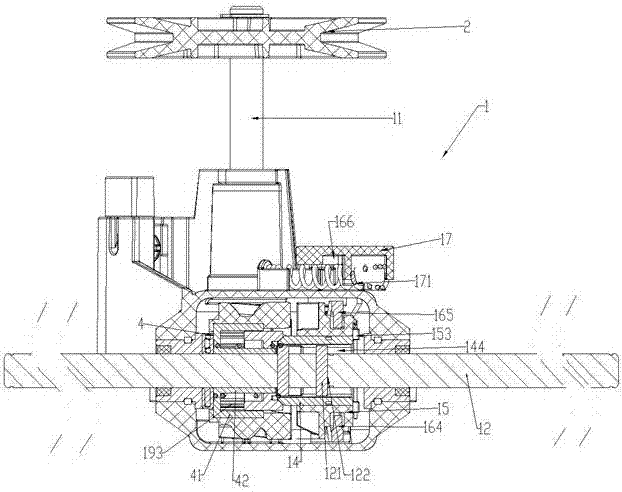

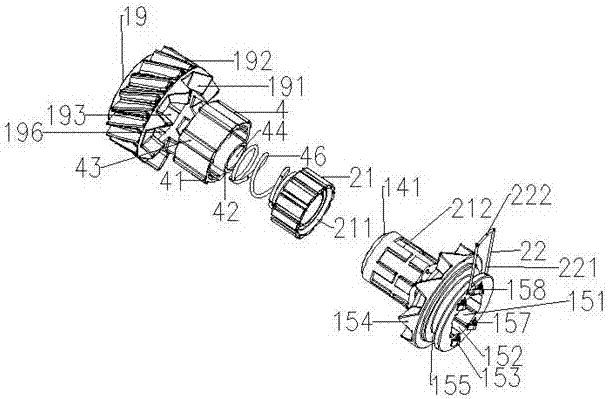

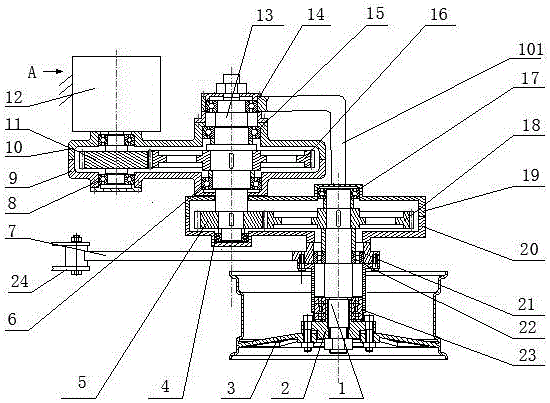

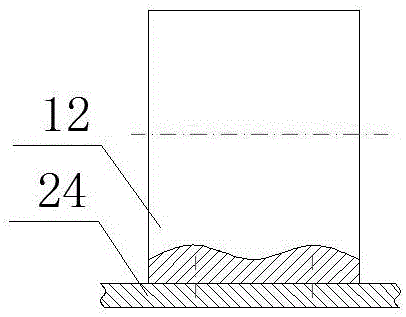

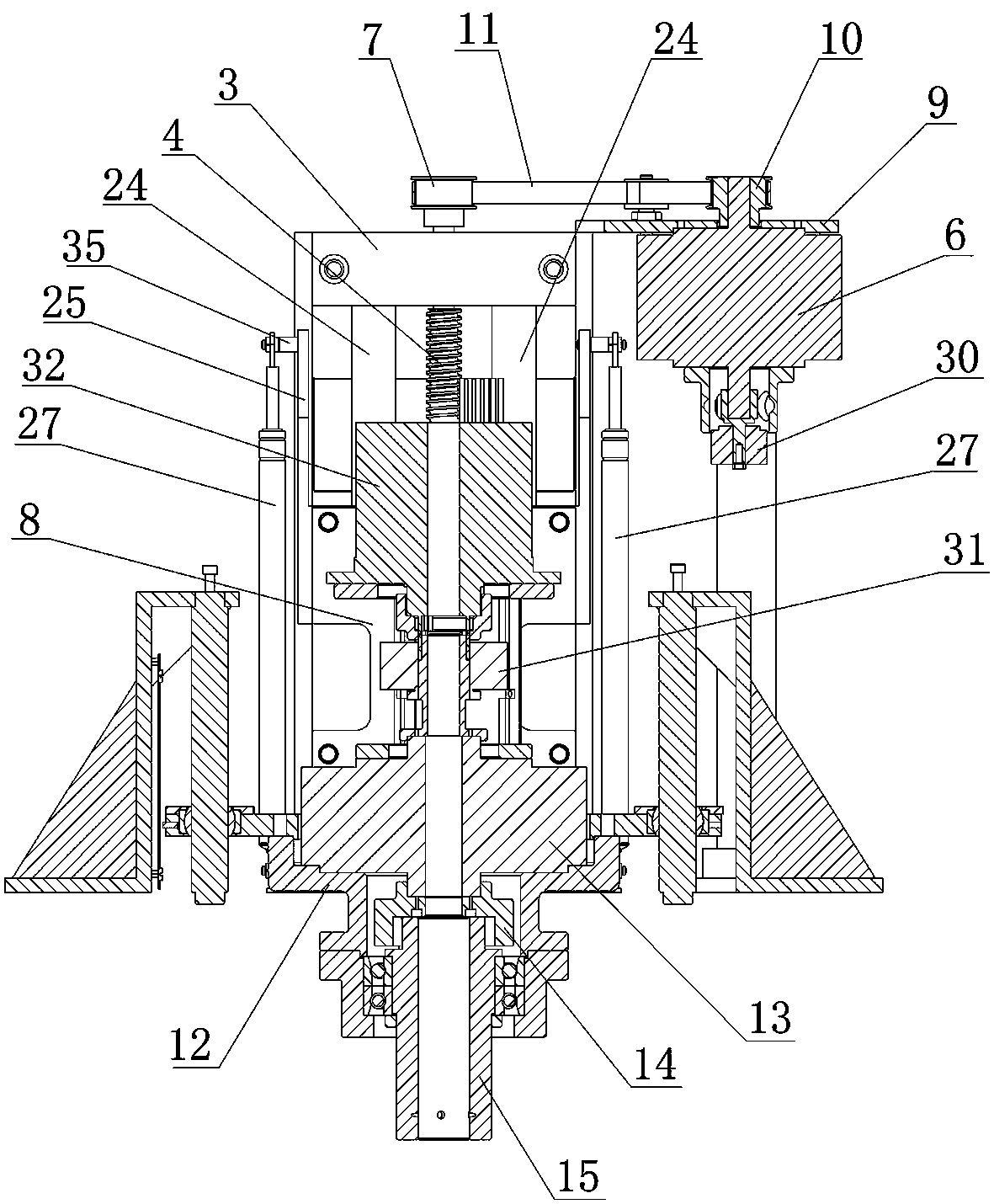

Double clutch structure reducer

ActiveCN104913010AClutch structure is simpleGuaranteed transmission ratioToothed gearingsInterengaging clutchesClutch controlReduction drive

A reducer with a double-clutch structure. The reducer is provided with a source power input shaft (11), a power output shaft (12), a first clutch device (14), a second clutch device (15) and a clutch control device (16). The first clutch device (14) and the second clutch device (15) can axially move at a disengaging position and an engaging position. The first clutch device (14) always performs engaging earlier than the second clutch device (15) and performs disengaging later than the second clutch device (15). The first clutch device (14) is axially arranged between a driven device (19) and the second clutch device (15). The first clutch device (14) and the second clutch device (15) rotate coaxially and synchronously. When the clutch control device (16) operates the second clutch device (15) to move axially to the engaging position from the disengaging position, the first clutch device (14) is axially pushed to the engaging position from the disengaging position by the second clutch device (15). The reducer has a small size, a simpler structure, stable operation, and the capability of ensuring the transmission ratio.

Owner:SKYBEST ELECTRIC APPLIANCE SUZHOU CO LTD

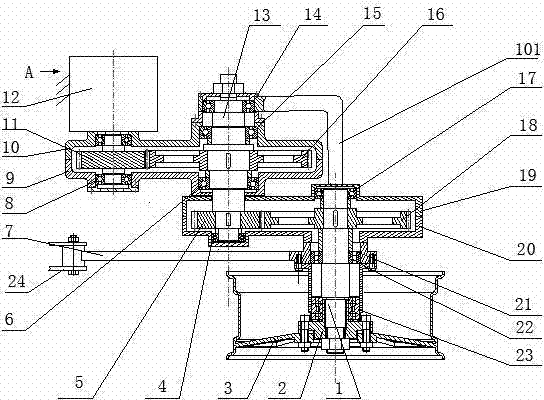

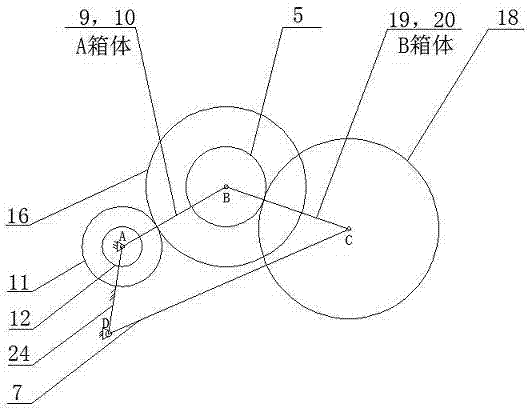

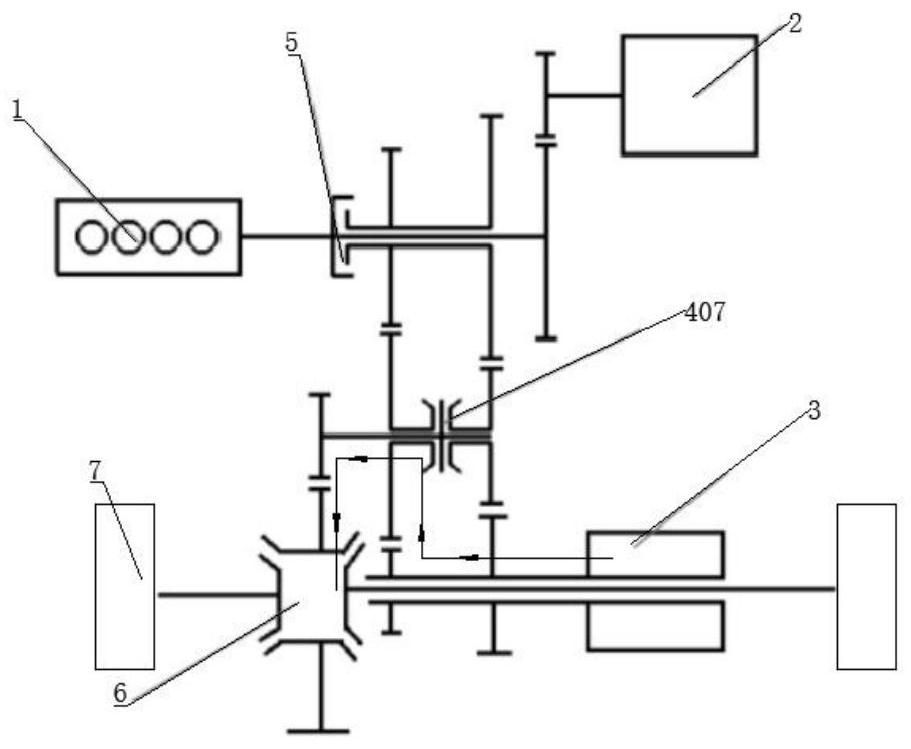

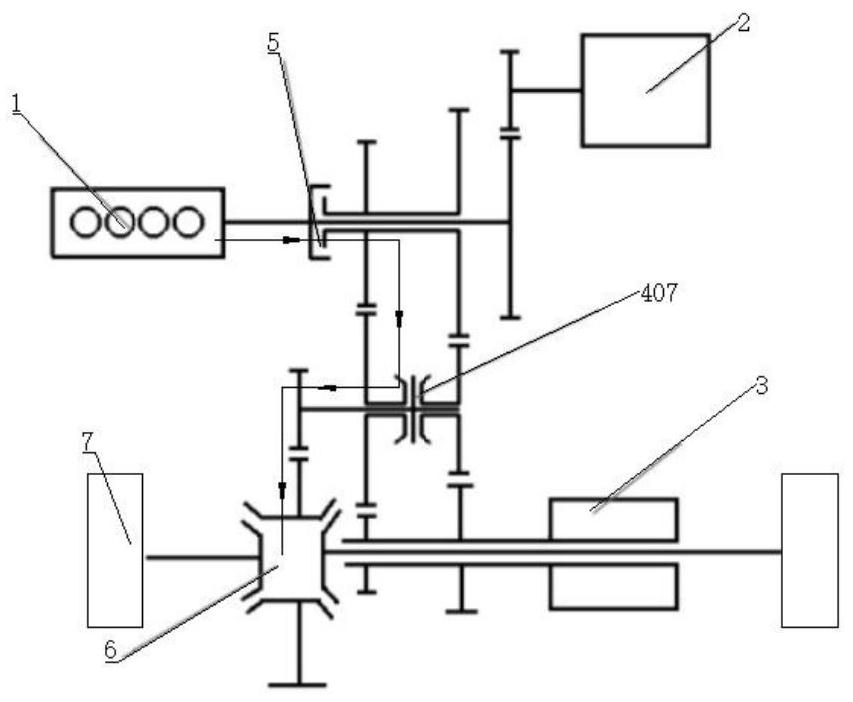

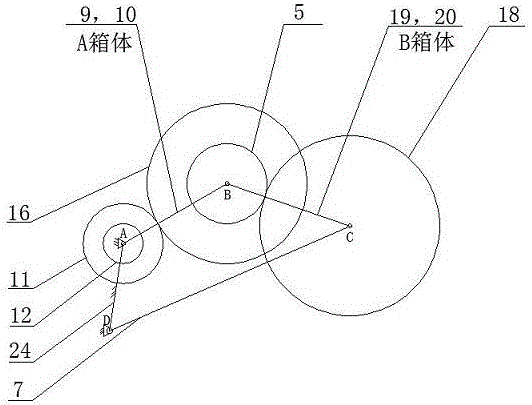

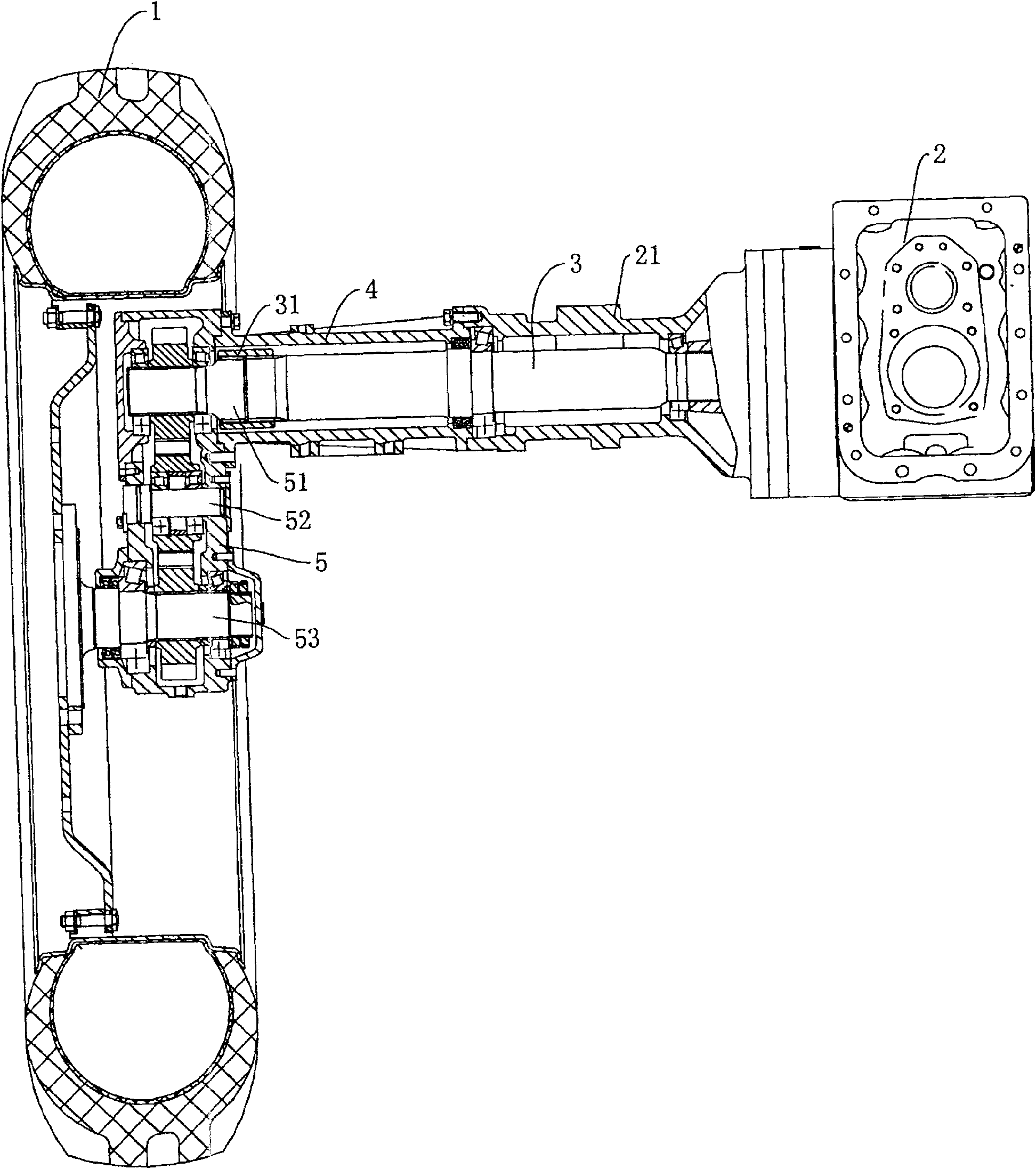

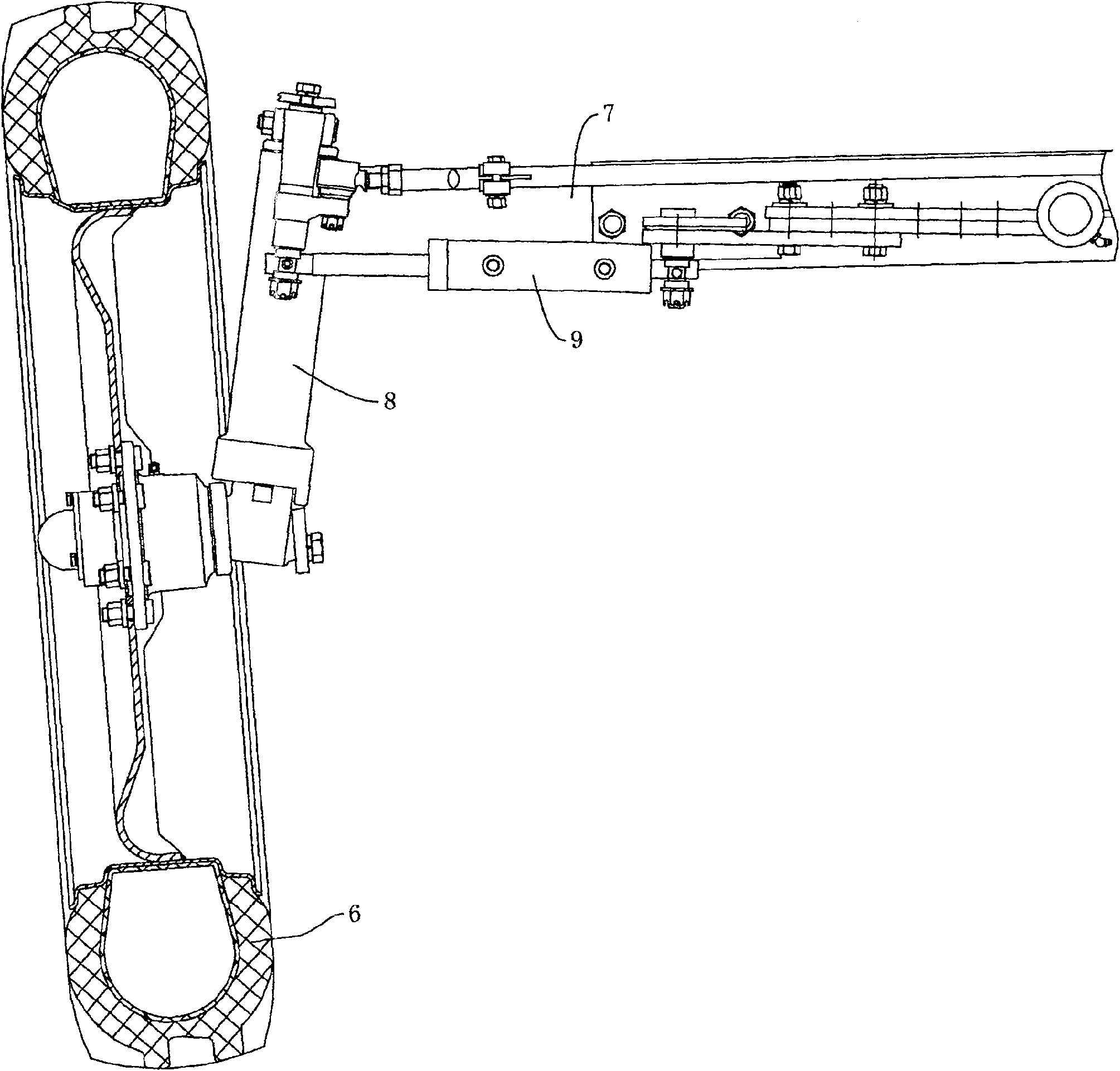

Integrated single-trailing-arm gear-reducing type electric wheel drive system

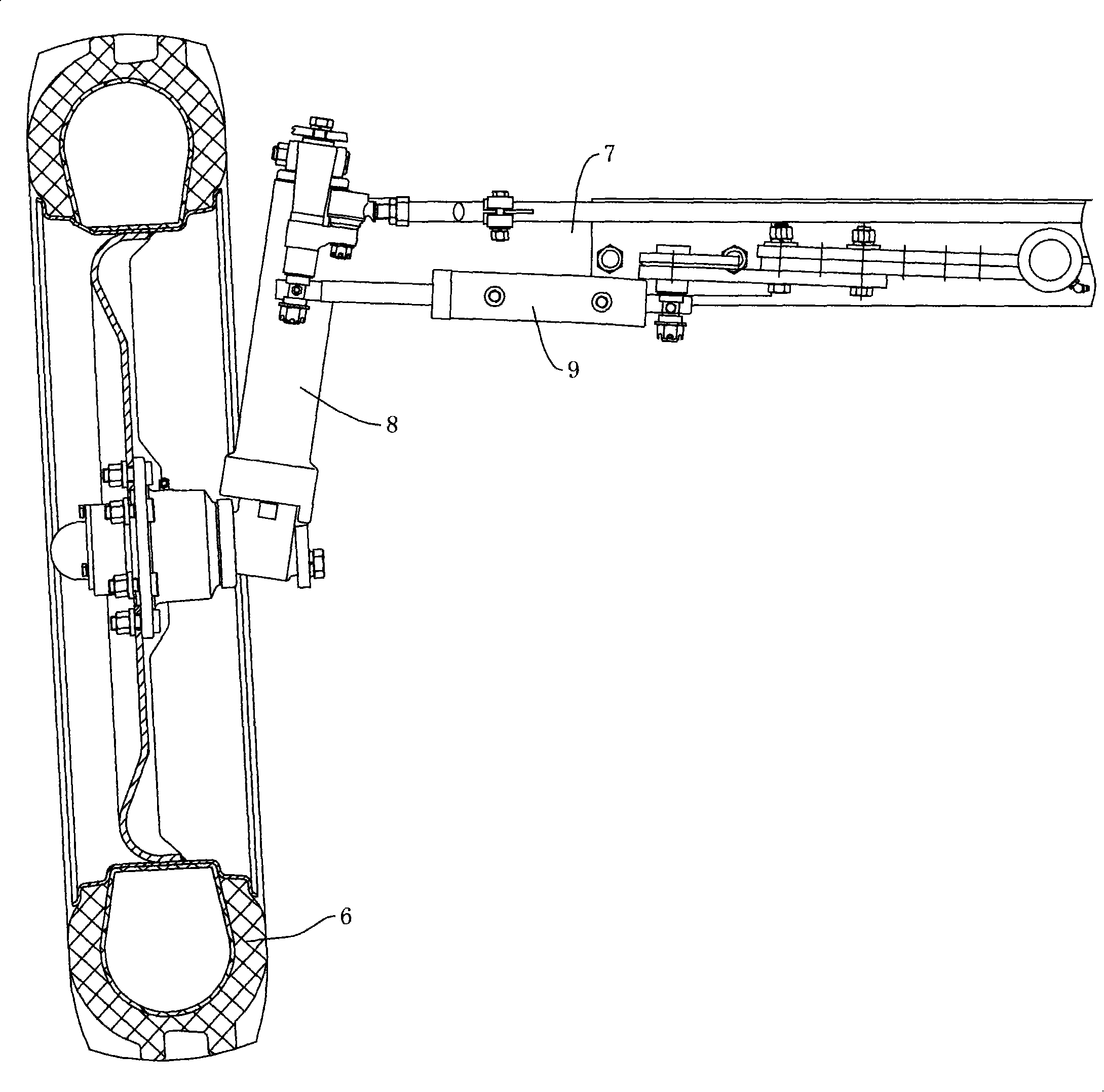

InactiveCN103707749AImprove riding performanceGood grounding effectElectric propulsion mountingControl devicesDrive wheelTrailing arm

The invention relates to an integrated single-trailing-arm gear-reducing type electric wheel drive system. A drive motor is fixed on a frame, and assembled with a drive wheel, planet gears, tanks and a single trailing arm to form an integrated structure, so that unsprung mass of an automobile is reduced. Tanks A, tanks B, the single trailing arm and the frame form an articulated four-bar mechanism, when wheels hop up and down under the action of random road excitation, the single trailing arm and the tanks A and B also rotate around respective rotation axes, and by the mechanism, transmission ratio can be ensured unchanged when the center distance between the motor and a driven planet gear changes due to road input excitation. By the novel wheel reduction and transmission mechanism transmitting motor power to the driven planet gear (wheel rim), the transmission ratio between the motor and the driven planet gear can be ensured not to change with the center distance without the help of a constant-speed universal transmission shaft device. The integrated single-trailing-arm gear-reducing type electric wheel drive system has the advantages of simplicity of the wheel reducing mechanism and high transmission efficiency.

Owner:TONGJI UNIV

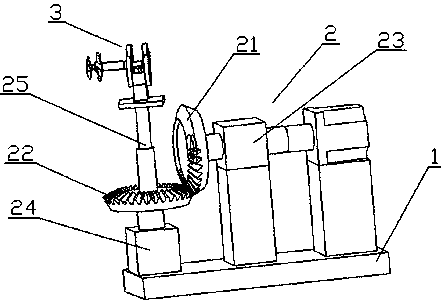

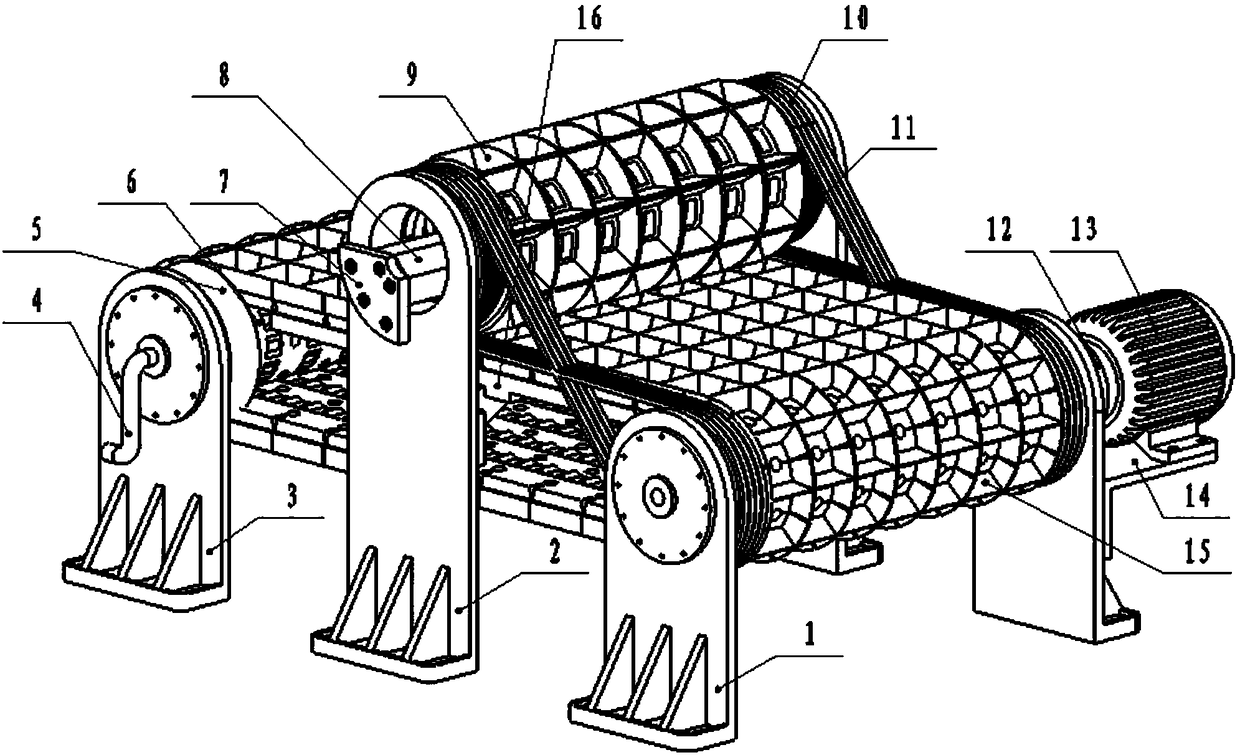

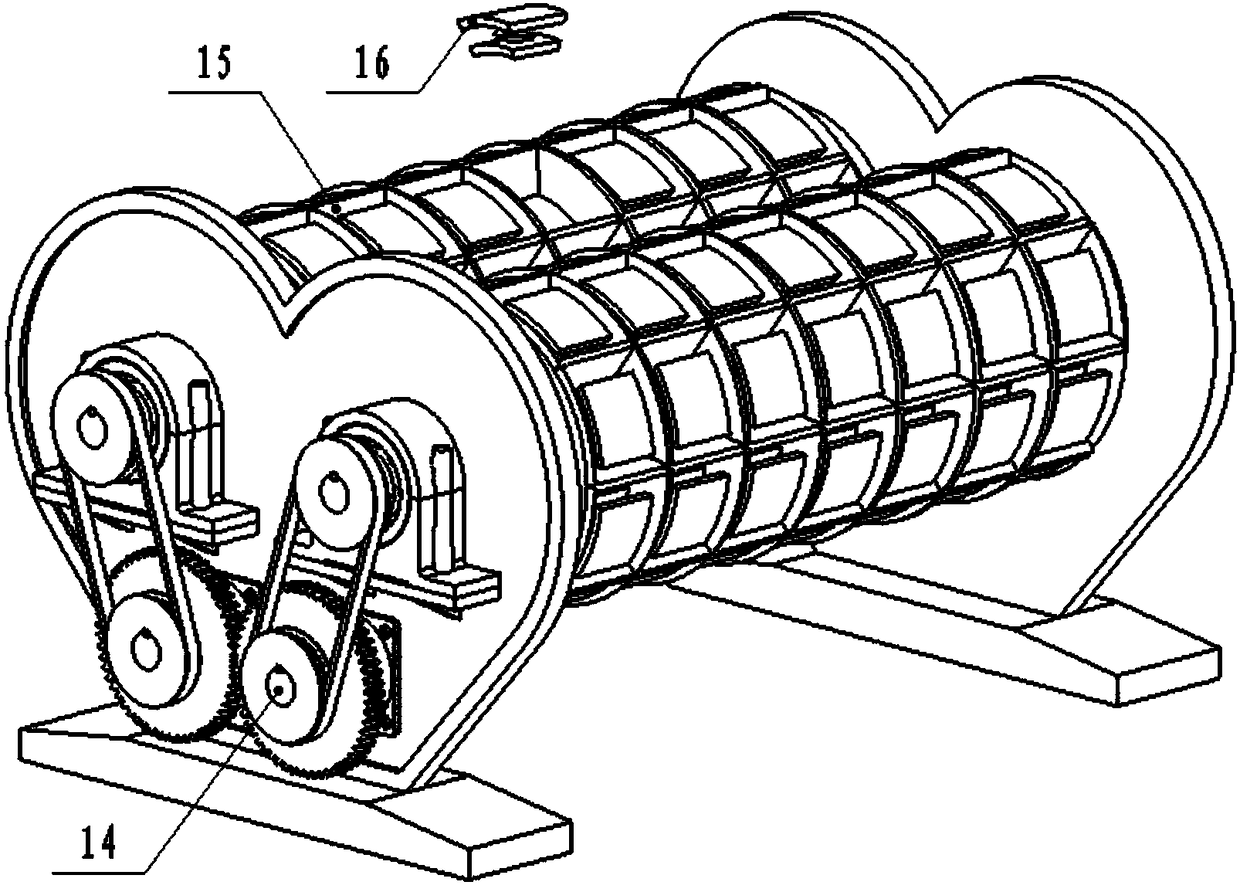

Automatic cleaning device for rubber covered rollers of spinning frame

The invention relates to an automatic cleaning device for rubber covered rollers of a spinning frame. The automatic cleaning device for the rubber covered rollers of the spinning frame is installed on the spinning frame, and a roller installation idler wheel of the spinning frame serves as a rotation drive idler wheel. The automatic cleaning device is characterized by comprising a cleaning band, the idler wheel, a tension adjusting frame and a brush; by installing the movable closed cleaning band at the position closely attached to the outer sides of the rubber covered rollers of the spinning frame, spun yarn adhering to the rubber covered roller can be cleaned away by the cleaning band in time, and the situation that a large quantity of spun yarn is accumulated on the rubber covered rollers is avoided. Compared with cleaning of felt covered rollers, the cleaning mode of the cleaning band is very high in efficiency, the rubber covered rollers of the spinning frame can be cleaned without stopping the machine, and the working efficiency of the spinning frame is improved. The automatic cleaning device is driven by roller connection, the drive ratio is guaranteed, the yarn spinning quality is improved, the cleaning and labor intensity is lowered, and the loss of spinning machine materials is reduced.

Owner:江苏凯瑞智能科技有限公司

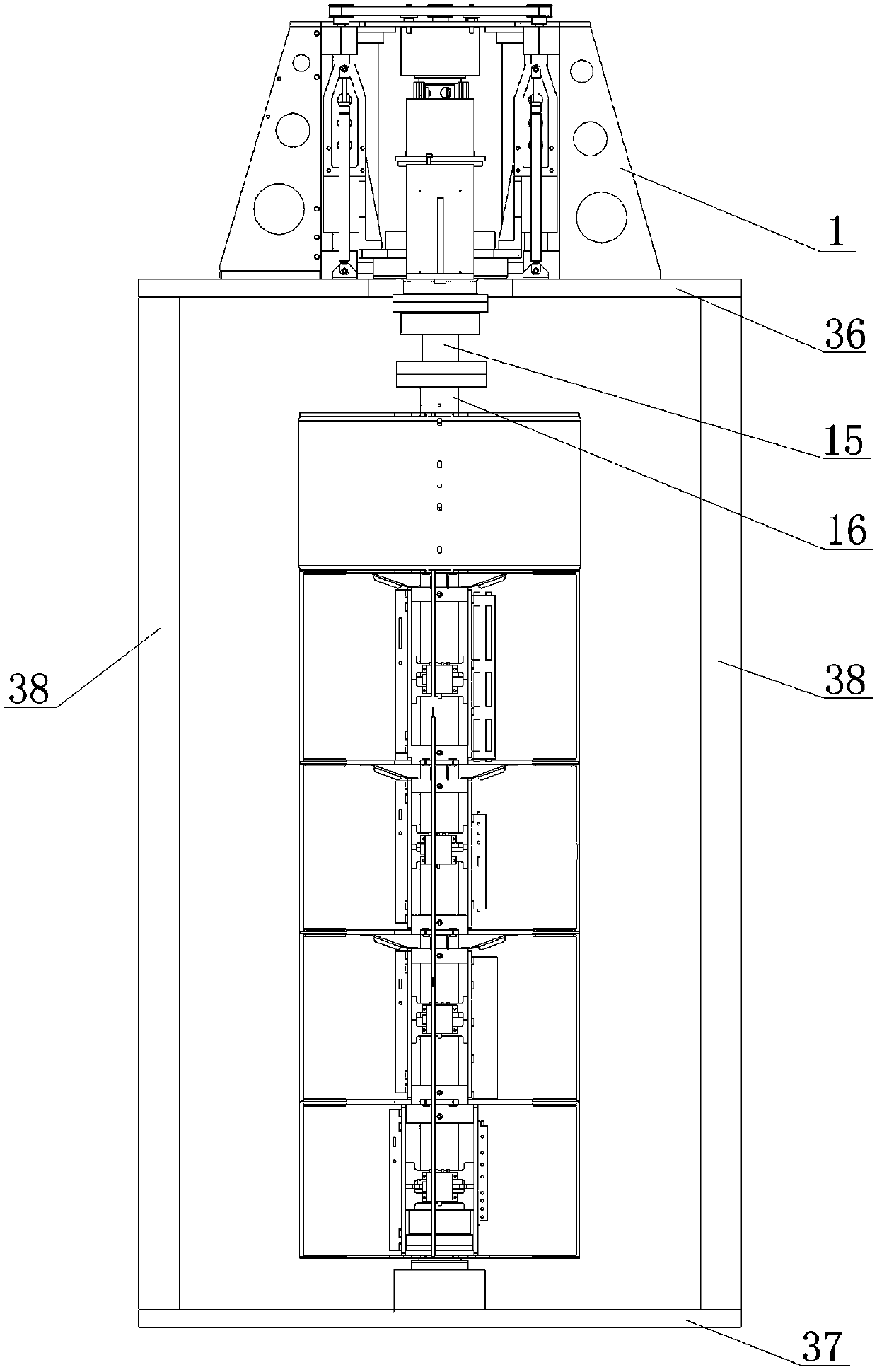

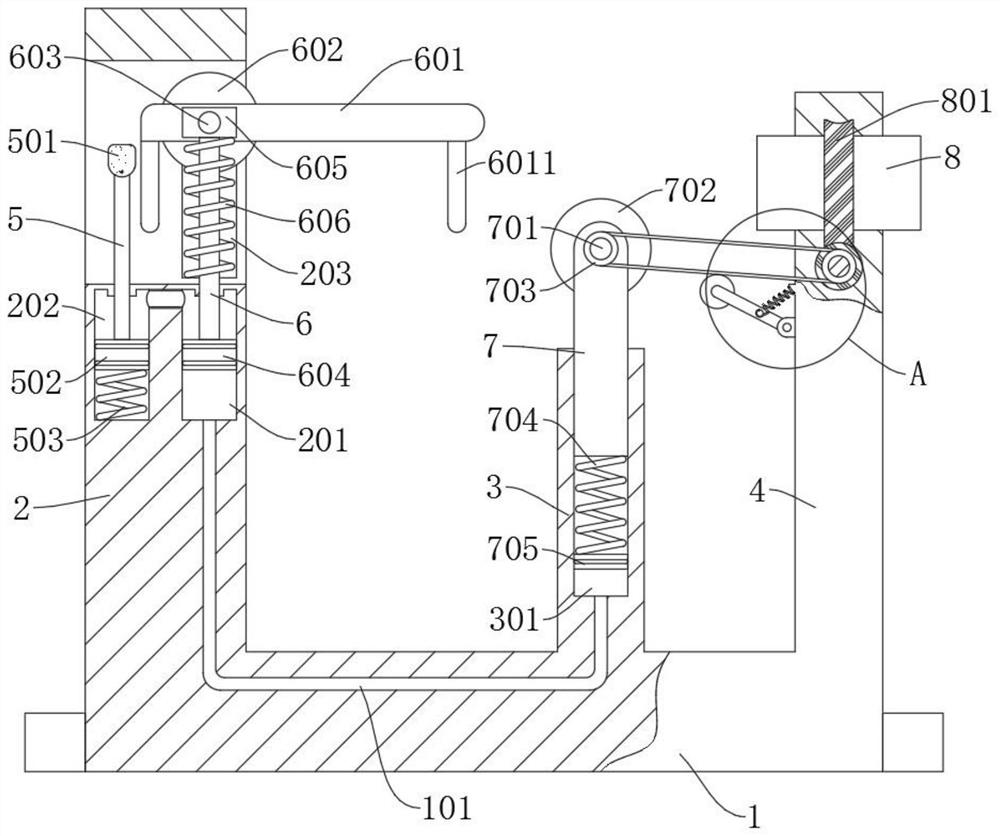

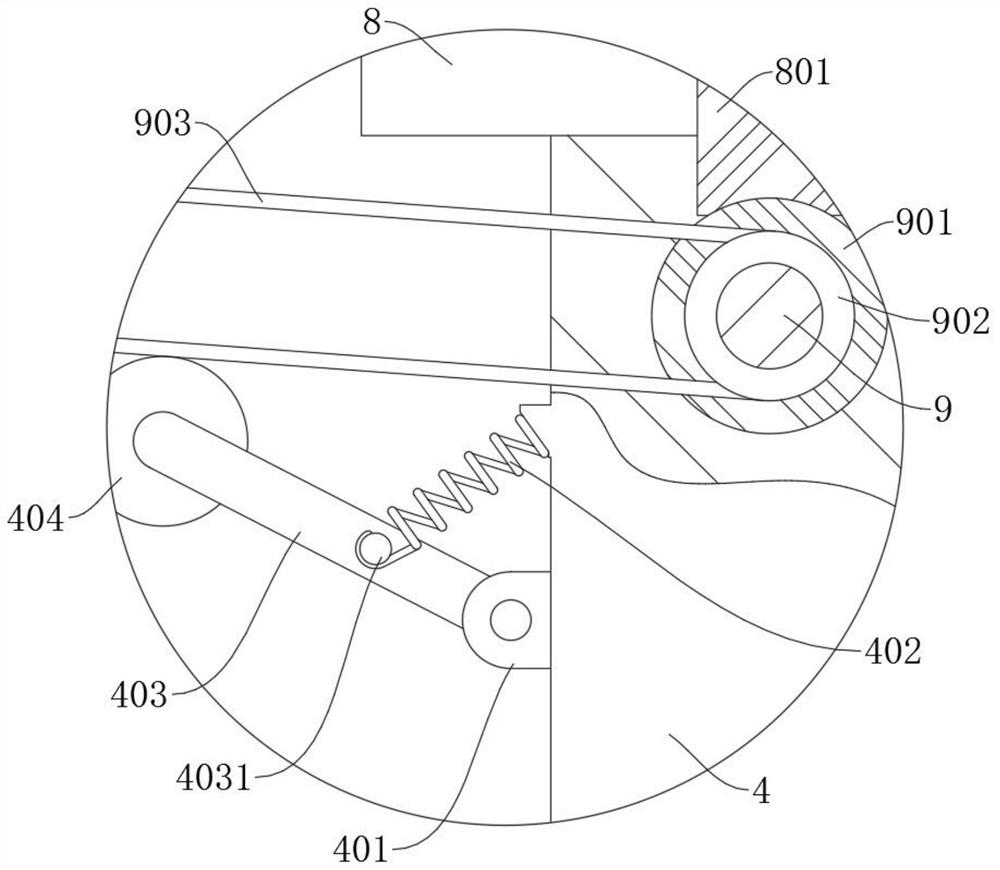

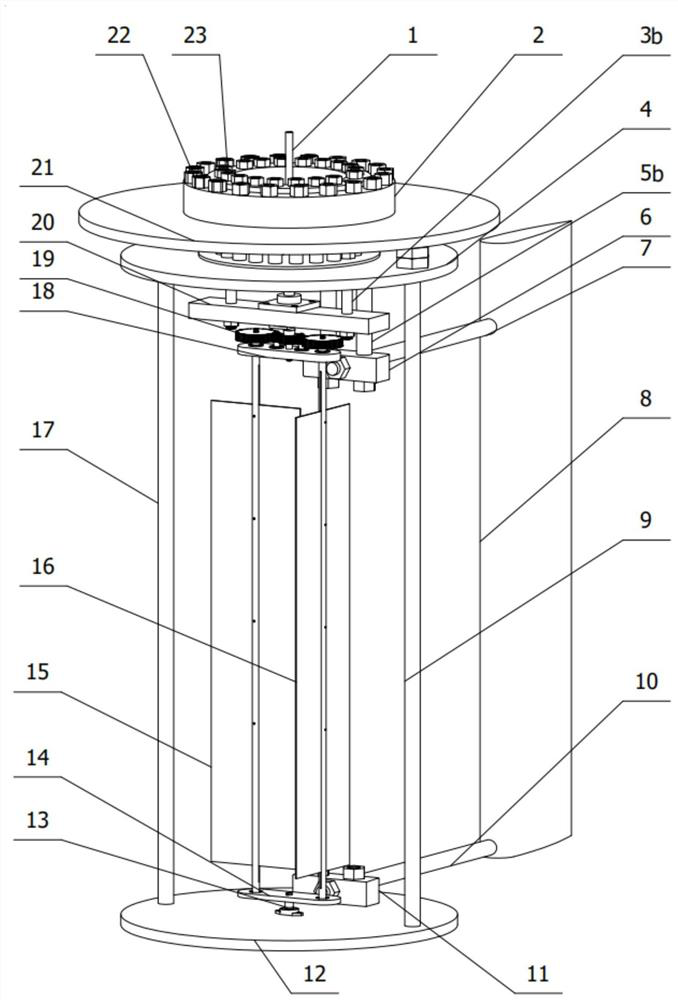

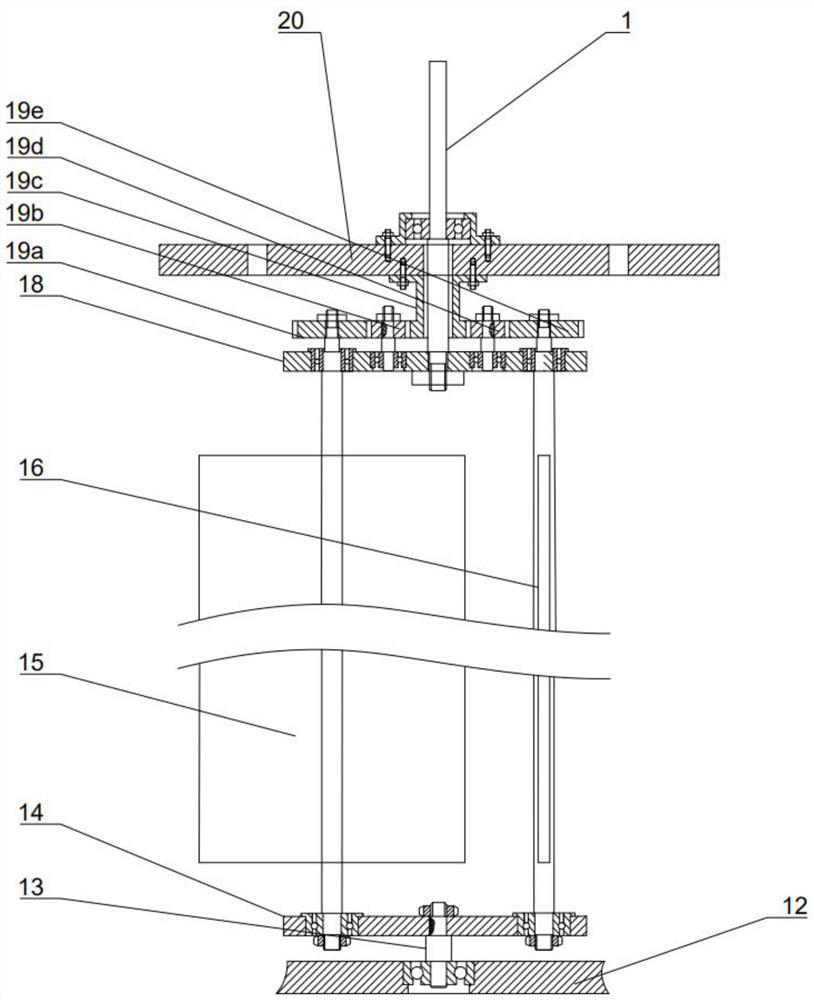

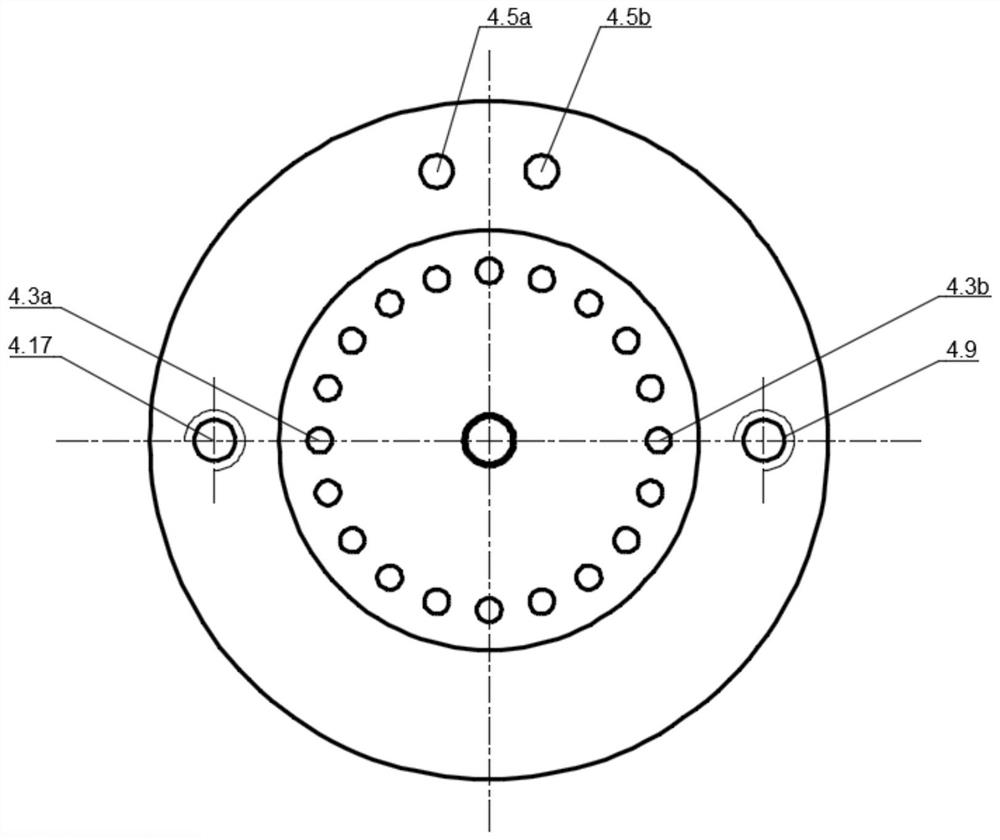

Drilling device for pipe jacking construction

ActiveCN108979655AImprove stabilityExtended service lifePipe laying and repairToothed gearingsIntermittent motionEngineering

The invention provides a drilling device used for pipe jacking construction and belongs to the technical field of municipal engineering. The technical scheme includes that the drilling device comprises a base plate, an intermittent motion mechanism is arranged on the base plate, and a drilling mechanism is arranged on the intermittent motion mechanism. The drilling device has the advantages that manual soil ploughing can be replaced, working efficiency is high, and injury to the body, caused by manually lying on front to plough can be avoided.

Owner:ZHEJIANG ZHUJI CONSTR CHAIN MFG

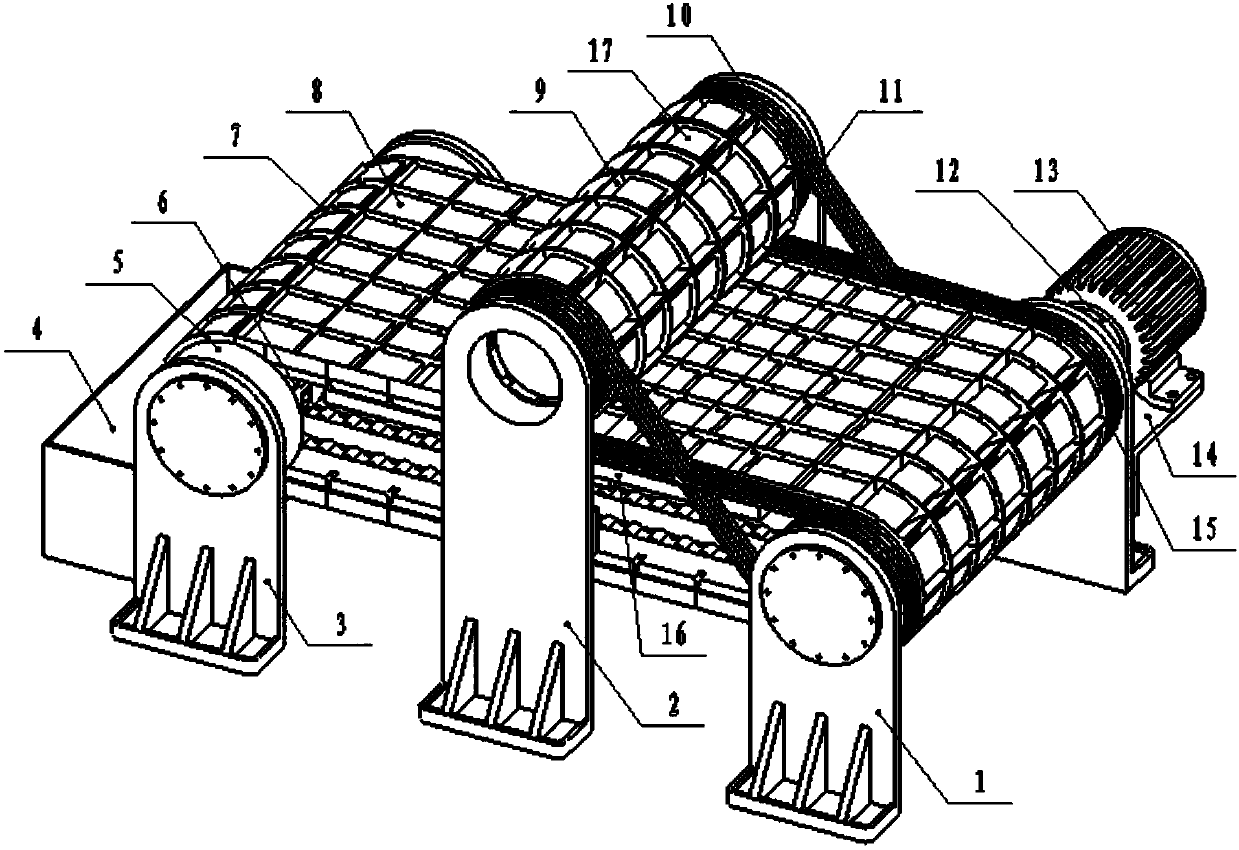

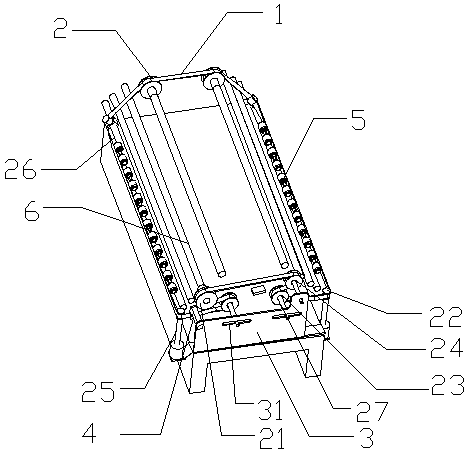

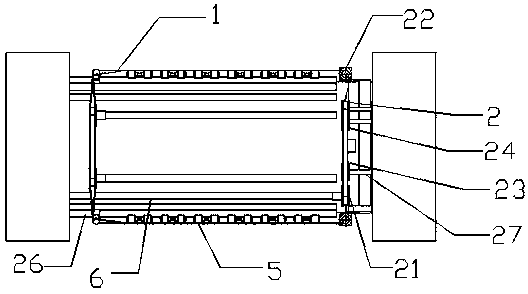

Pork rib block cutting device

The present invention discloses a pork rib block cutting device and relates to the field of food processing devices. The pork rib block cutting device comprises a front-end bracket assembly, an intermediate bracket assembly, a rear-end bracket assembly, a high-pressure gas pipeline, a rear-end pulley assembly, block cutting belts, a pork rib block pushing-out assembly, block cutting hobs, synchronous belts, synchronous wheels, a speed reducer, a motor, etc. The motor drives a front-end pulley assembly via the speed reducer, the synchronous belts and synchronous wheels are used to transmit motion to the block cutting hobs, cutting edges of the block cutting hobs can form bisection with cutting edges on the block cutting belts, and thus a whole slice of the pork ribs are cut into blocks. Inorder to avoid adhesion of the pork rib blocks, the pork rib block pushing-out assembly is arranged inside the block cutting hobs, air injection rollers are arranged at rear-ends of the belts, under functions of a cam plate, sealing roller assemblies, etc. the air injection rollers inject high-pressure gas in fixed positions, and the cut pork rib blocks adhering to the block cutting belts are blown off. The device can be applied to automatic block cutting of the whole slice of the pork ribs.

Owner:陈正康

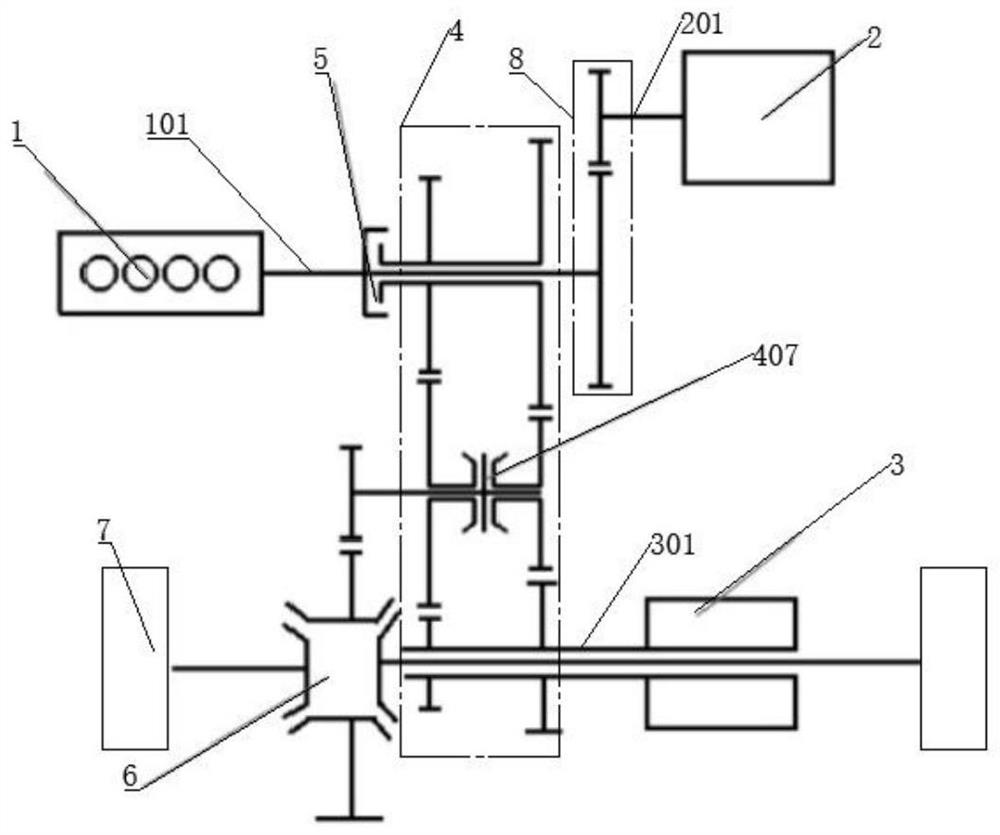

Coaxial multi-gear front-drive hybrid power system

PendingCN114475208ACompact structureReduce volumeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchElectric drive

The coaxial multi-gear front-drive hybrid power system comprises an engine, a generator, a driving motor, a gear speed change mechanism, a clutch and a differential mechanism, the clutch is arranged between an output shaft of the engine and the gear speed change mechanism, an output shaft of the gear speed change mechanism is connected with the differential mechanism, and the generator is electrically connected with the driving motor. A motor output shaft of the driving motor is of a hollow shaft structure, and an output shaft of the differential mechanism penetrates through the motor output shaft and then is connected with wheels. The system has four modes of pure electric drive, direct drive, series connection and parallel connection, the mechanical transmission efficiency is high, the wet clutch adopted by the system is good in gear shifting smoothness, the shafting arrangement is of a four-shafting structure, the arrangement position of the wet clutch and the arrangement position of a synchronizer are staggered, the size is small, a planetary gear is omitted, the cost is low, and the technical difficulty is small.

Owner:LIUZHOU WULING MOTORS +1

Full-face gear axle

InactiveCN108790807AReduce process difficulty and processing costImprove axle lifeControl devicesEngineeringPlanet

The invention relates to an automobile axle assembly, in particular to a full-face gear drive axle assembly. According to the technical scheme, the full-face gear drive axle assembly comprises a driving gear shaft, an output shaft, a differential housing, a planetary shaft, a planetary shaft sleeve, a planetary gear, a half-axle face gear and a half-axle. The half-axle face gear is installed in two transverse through holes in the inner cavity of the differential housing, and the planetary gear is installed in two longitudinal through holes in the inner cavity of the differential housing. A shoulder is arranged on the outer wall of the differential housing, a plane boss is arranged at the inner end of a planetary shaft hole, a driven face gear is installed on the shoulder through bolts anda washer, the planetary gear is limited by the planetary shaft sleeve and the plane boss in the differential housing separately, and the driving gear shaft meshes with the driven face gear to drive the differential housing to rotate. By adopting the technical scheme, the full-face gear drive axle assembly is a novel face gear drive axle main reducer assembly which is high in strength, large in drive ratio, compact in structure, low in machining cost, high in interchangeability and easy to install and maintain.

Owner:沈阳德创金属材料有限公司

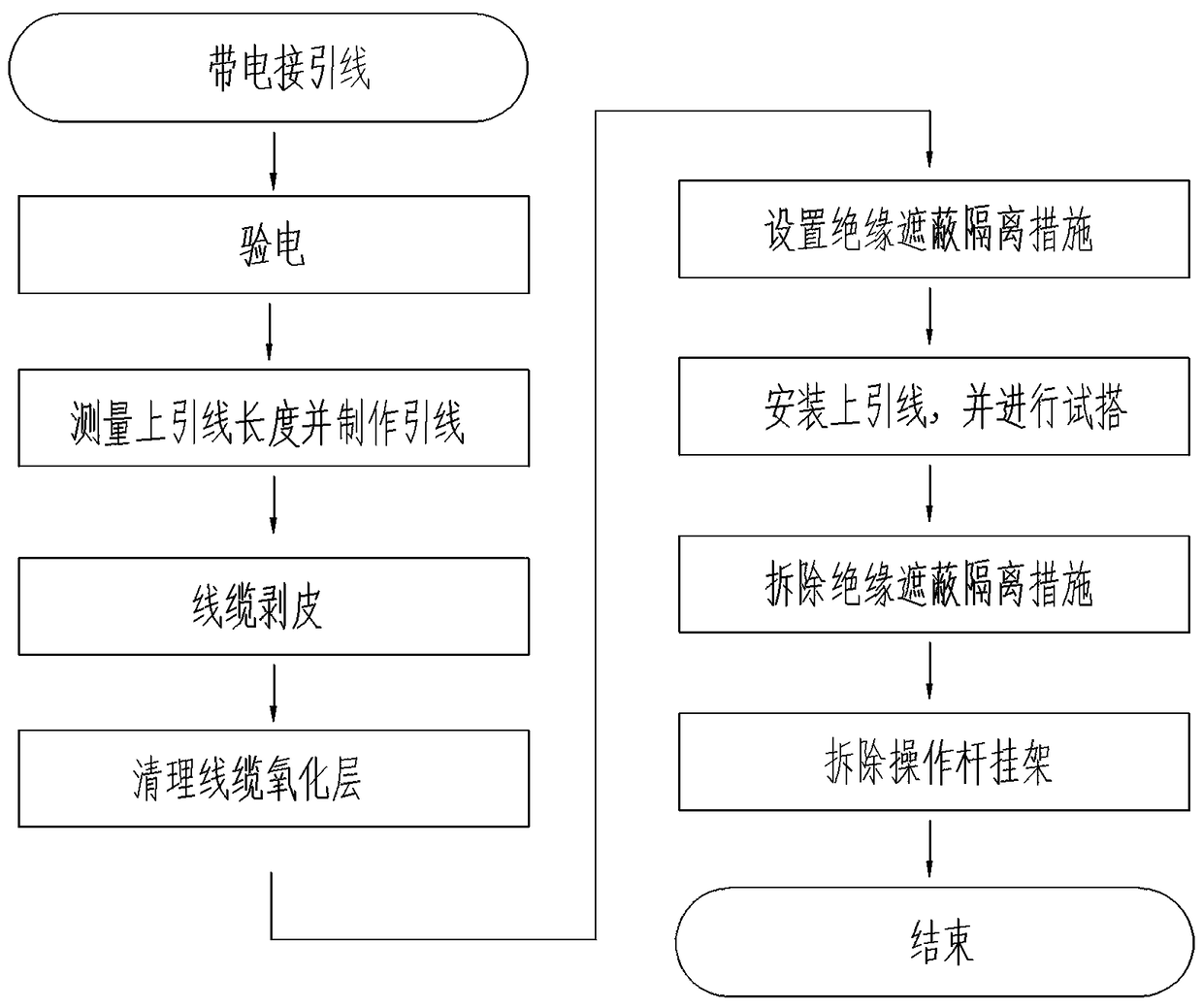

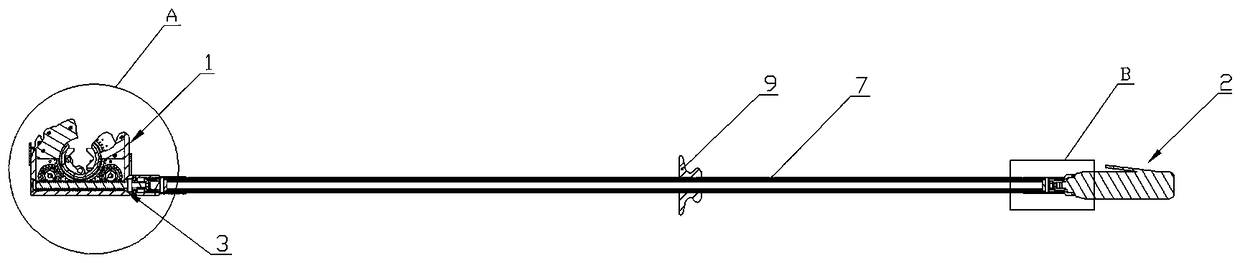

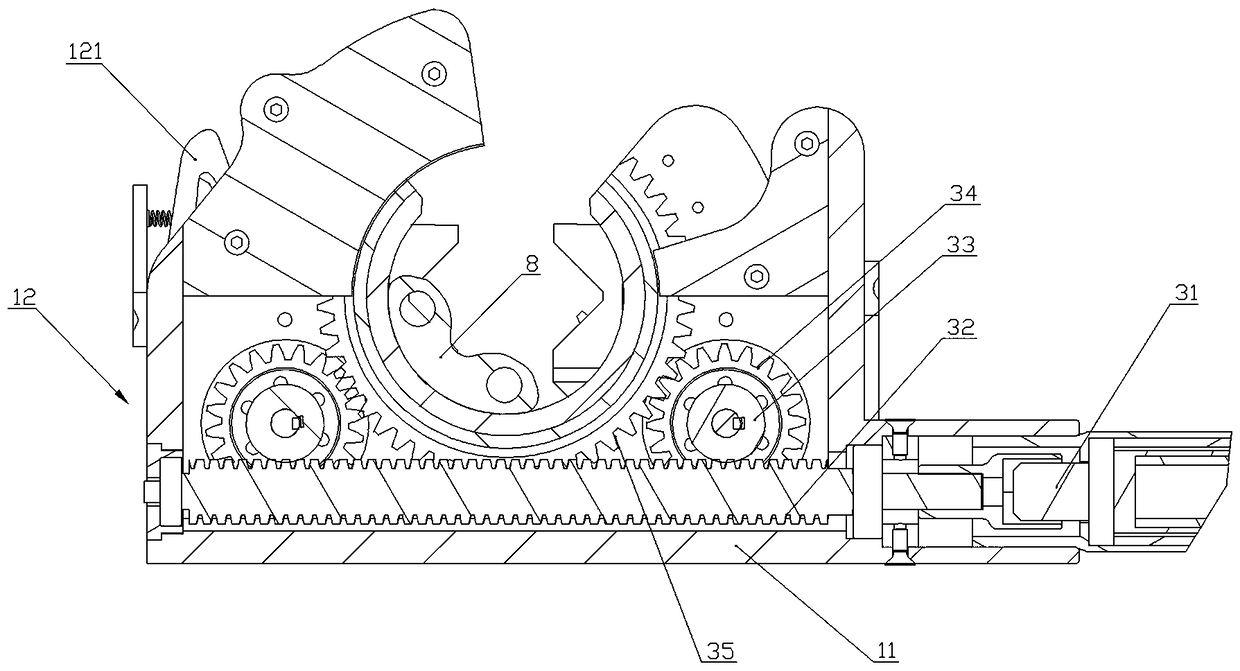

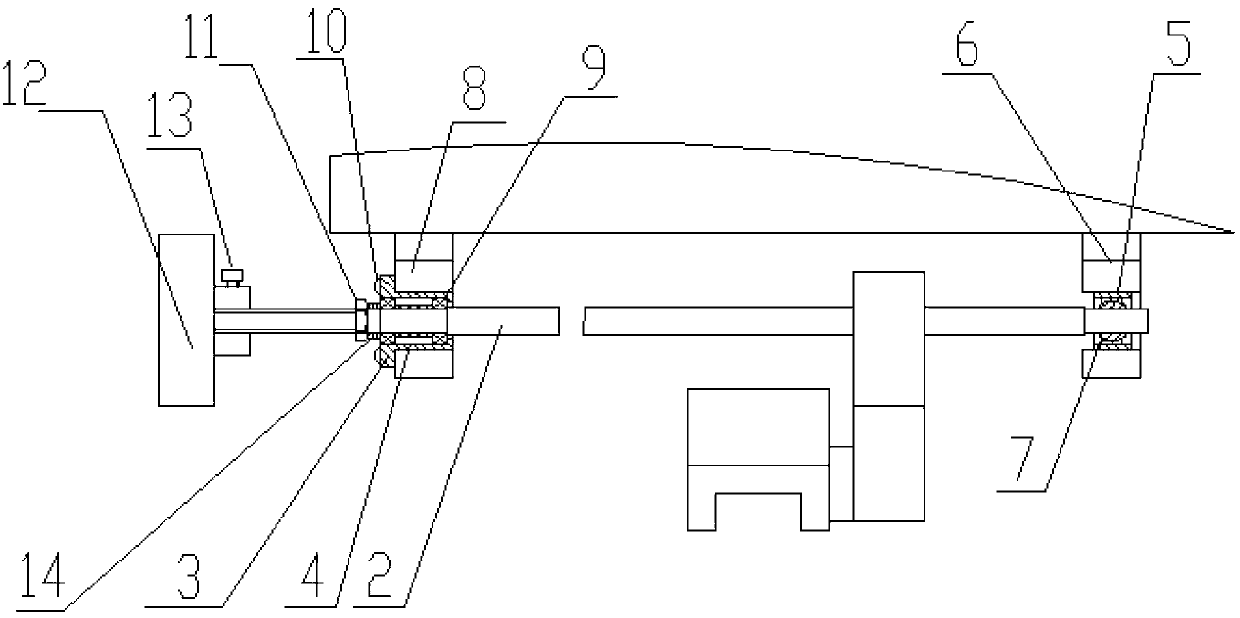

Electric cable stripper

ActiveCN106654808BGuaranteed continuityGuaranteed reliabilityLine/current collector detailsApparatus for removing/armouring cablesElectricityDrive shaft

The invention discloses a novel electrified lead connection method and an electric wire stripper for cables. The method comprises the following steps of: climbing on a pole by an electrician to affirm that no electric leakage phenomenon exists, measuring and manufacturing leads, measuring the lengths of leads on three phases by the electrician on the pole by using an insulating electricity inspection and distance measurement integrated rod, and manufacturing an upper lead by an electrician on the ground; carrying out stripping according to a sequence of A phase, B phase and C phase by using the electric wire stripper for cables, cleaning a cable oxidation layer at a hook-up wire clip, setting a three-phase insulating, shielding and isolating measure; respectively transferring an insulating operation rod and an insulating and shielding tool onto the pole by the electrician on the pole under the coordination of the electrician on the ground; carrying out insulating and shielding by the electrician on the pole by utilizing the insulating operation rod according to the sequence of B phase, C phase and B phase; mounting the upper lead on an upper pile head of a drop-out fuse, carrying out test lap joint, carrying out lap joint on branch line leads of B phase, C phase and A phase in sequence; dismantling the three-phase insulating, shielding and isolating measure, carrying out dismantling by the electrician on the pole according to the sequence of B phase, B phase and A phase; checking that operation requirements are satisfied by the electrician on the pole and then returning to the ground to complete electrified lead connection, so as to ensure the continuity and reliability of power supply.

Owner:LIVE WORKING CENT OF STATE GRID HUNAN ELECTRIC POWER +2

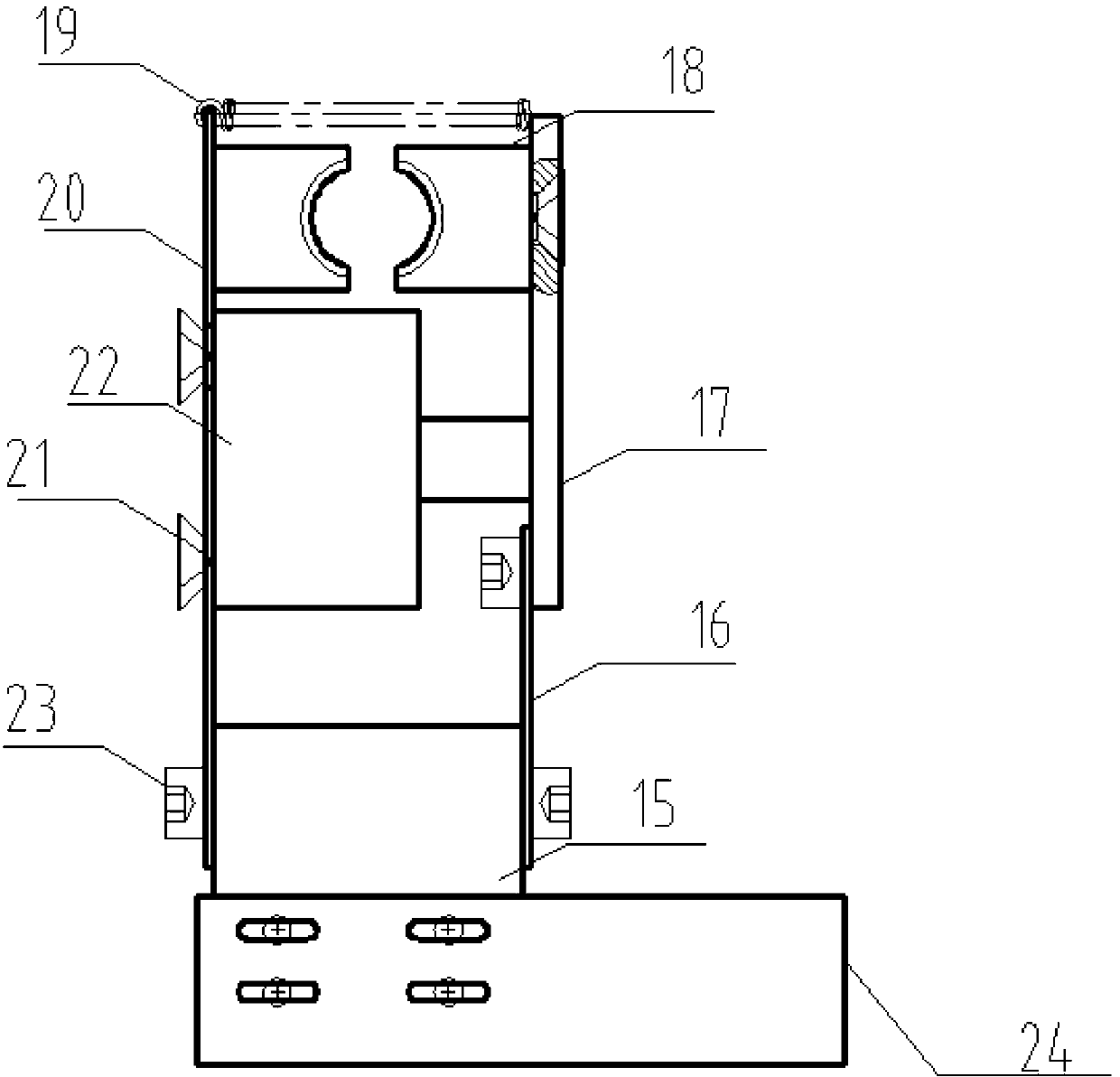

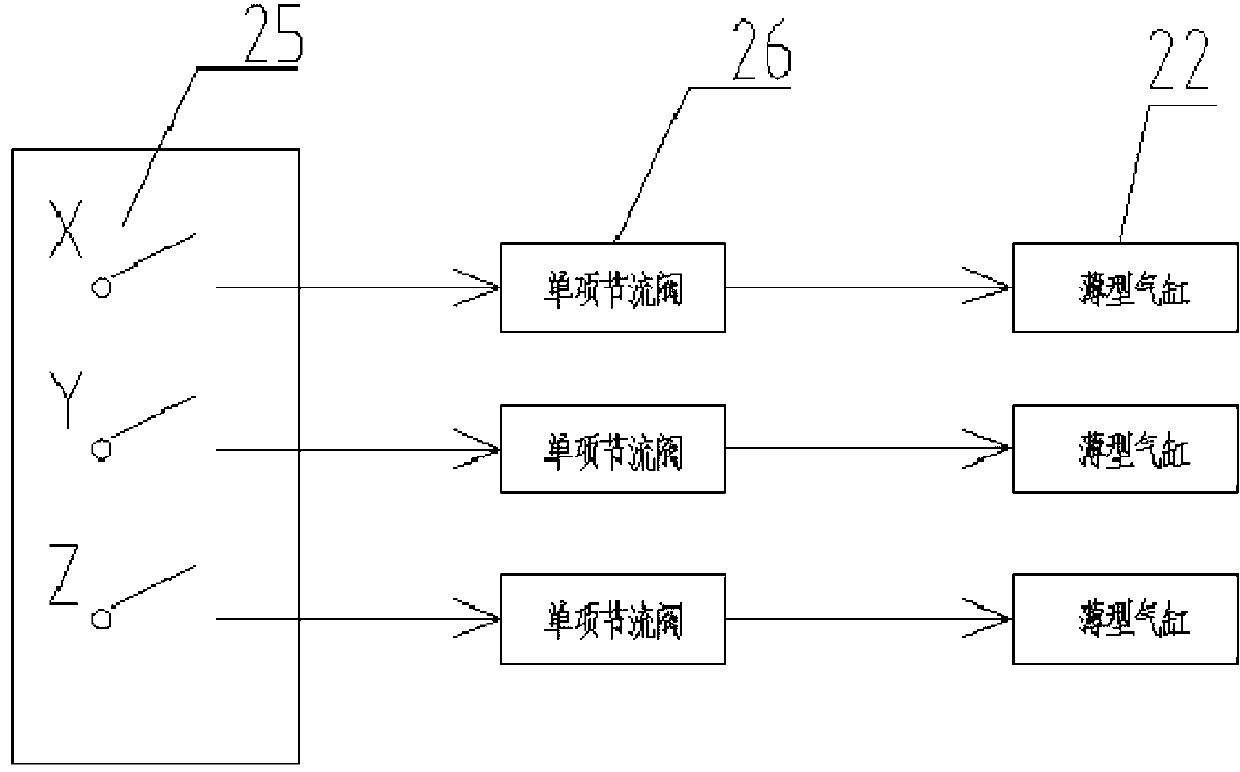

High-stability transmission device of manual three-coordinate measuring machine

The invention discloses a high-stability transmission device of a manual three-coordinate measuring machine. The high-stability transmission device comprises a screw rod transmission component and a clamping mechanism, wherein the screw rod transmission component comprises a transmission screw rod, and a net-shaped hand wheel is fixed at the front end of the transmission screw rod; the clamping component comprises a connecting block which is fixed on a connecting plate; left and right elastic plates are arranged on two sides of the connecting block respectively; a rigid plate is connected to one end of the right elastic plate; a thin type cylinder is fixed on the left elastic plate and between the rigid plate and the left elastic plate; a pair of clamping blocks are arranged between the rigid plate and the left elastic plate; the upper end part of the rigid plate is connected with the upper end part of the left elastic plate through a tension spring; the clamping blocks are clamped on the transmission screw rod; threads in match with the transmission screw rod are arranged on the inner sides of the clamping blocks. The high-stability transmission device can be arranged on X, Y and Z measurement axes of the three-coordinate measuring machine and is simple in structure, easy to produce, convenient to operate and good in use effect; the transmission efficiency is improved, and a transmission part has a stable transmission ratio; the fine tuning function of the hand machine is realized, the transmission precision is ensured, and the measurement is convenient.

Owner:青岛弗尔迪测控有限公司

Wall drilling and pre-burying auxiliary equipment for blasting

PendingCN114800887AReduce workloadSimple structureWorking accessoriesStone-like material working toolsStructural engineeringWaste material

The invention discloses wall drilling pre-burying auxiliary equipment for blasting, and relates to the field of drilling blasting, the wall drilling pre-burying auxiliary equipment for blasting comprises a base, a fixing block is fixedly mounted on the top side of the base, two sliding grooves are formed in the top side of the fixing block, two guide rails are slidably mounted in the two sliding grooves, a same supporting plate is fixedly mounted on the two guide rails, and the supporting plate is fixedly mounted on the fixing block. A first servo motor is fixedly installed on the supporting plate, and an output shaft of the first servo motor is fixedly sleeved with a small rolling wheel. According to the wall blasting, drilling and pre-burying integrated equipment, the drilling and blasting functions of walls at different angles can be achieved, under the positioning effect of the positioning block, the supporting seat is driven to do reciprocating circulating motion, and the drilling and pre-burying functions of the walls are achieved. And the horizontal and longitudinal positioning functions of the drill bit are further realized through the reciprocating circulating motion of the supporting seat. Through the design of the discharging hose, the drilling waste discharging function is achieved, through the design of the positioning block, the positioning function of the first lead screw is achieved, and the drilling blasting equipment is simple in structure and high in practicability.

Owner:ANHUI UNIV OF SCI & TECH

Double clutch structure reducer

ActiveCN104913010BClutch structure is simpleReduce volumeToothed gearingsLawn-mowersClutch controlReduction drive

The invention relates to a double-clutch structure reducer, which has a source power input shaft and a power output shaft; a first clutch device and a second clutch device; the first clutch device and the second clutch device can be axially separated and combined Position movement; the first clutch device is always combined earlier than the second clutch device, and is always separated than the second clutch device; the first clutch device is axially arranged between the driven device and the second clutch device ; The first clutch device and the second clutch device are coaxial and rotate synchronously; the clutch control device operates the second clutch device to move axially from the disengaged position to the combined position, the first clutch device is driven by the second clutch device shaft The speed reducer of the present invention has the advantages of smaller volume, simpler structure, stable operation and guaranteed transmission ratio.

Owner:SKYBEST ELECTRIC APPLIANCE SUZHOU CO LTD

A portable video camera, photography auxiliary stabilizer

InactiveCN106764345BEfficient use ofEasy to operateStands/trestlesTelephone set constructionsGyroscopeAccelerometer

A hand-held camera and photography auxiliary stabilizer, one end of the roll arm is rotatably connected to the roll arm mount, the center line of its rotation is γ, the roll arm mount is rotatably connected to the pitch arm, and its rotation The center line is α, and the pitch correction motor is arranged on the rotation shaft of the roll arm mounting seat; the fixed seat is installed by rotating near the other end of the roll arm, and the center line of its rotation is β, and the roll correction motor is arranged on the rotation shaft; The center line γ is perpendicular to the plane where the rotation center line α and the rotation center line β intersect; the accelerometer and gyroscope are arranged on the fixed seat and connected to the pitch correction motor and the roll correction motor through the control unit; the device also has a pitch correction motor connected to the control unit Motor pitch angle adjustment switch. This device can quickly and conveniently help users find the balance position of the center of gravity of the mobile phone without any professional skills; the system has low power consumption and less heat generation; the shooting device always keeps the lens facing the object stably, and the image quality is high in precision.

Owner:SHANGHAI RUIPAI INTELLIGENT TECH LLC

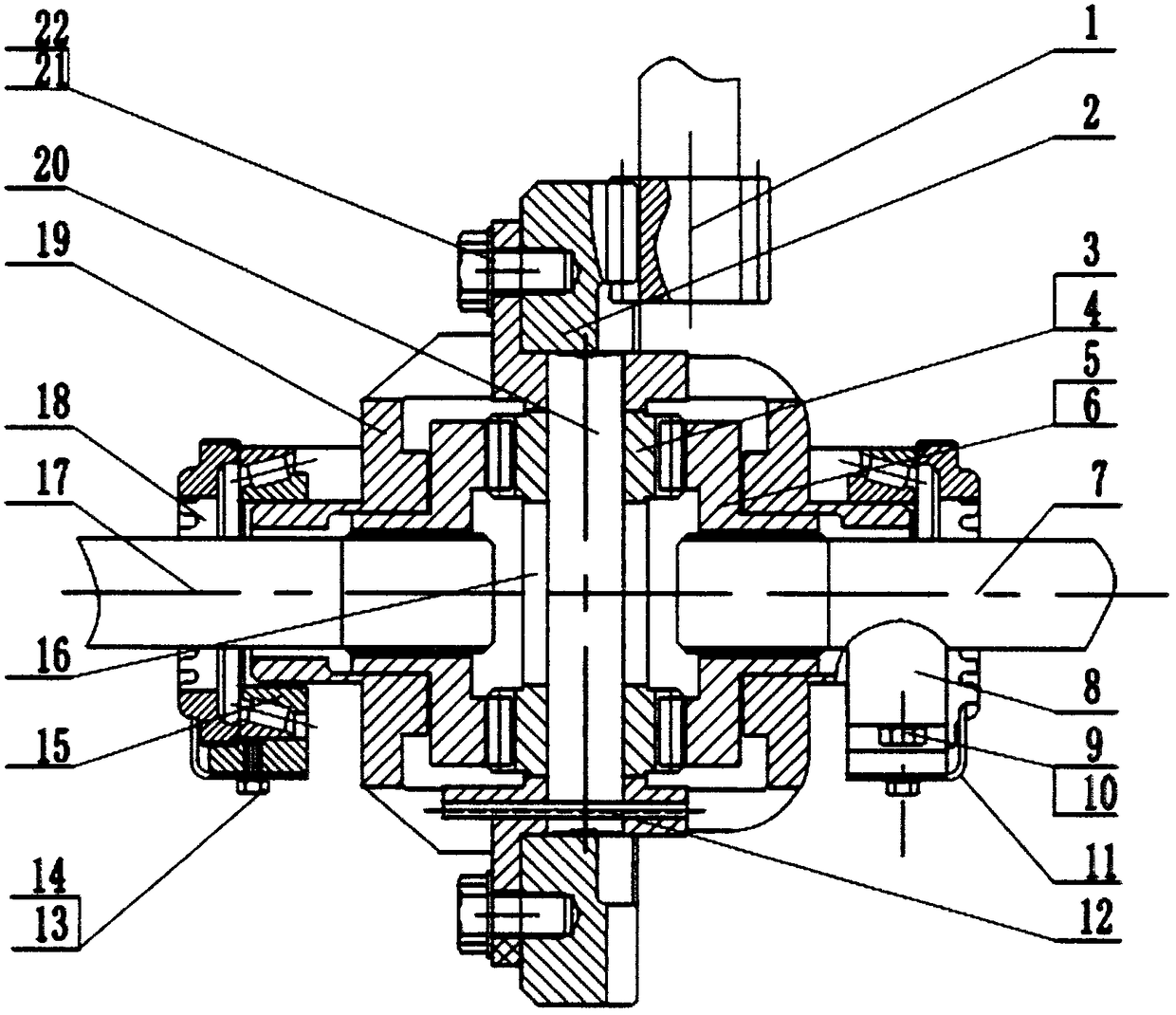

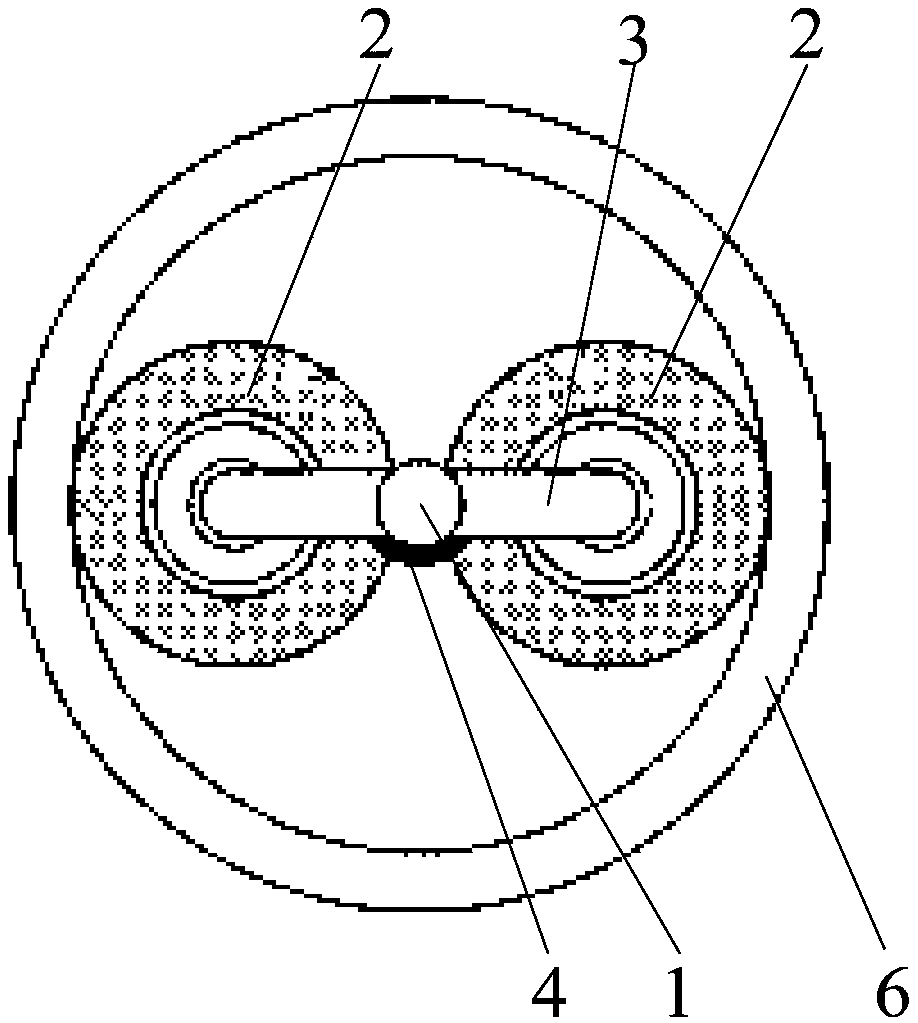

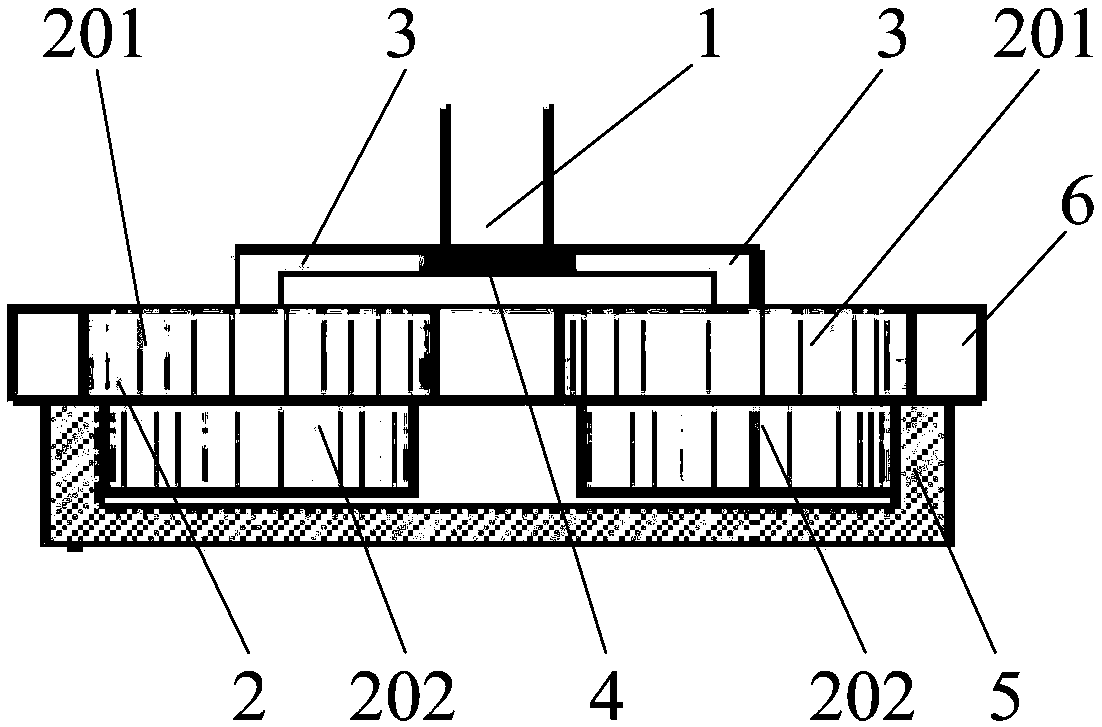

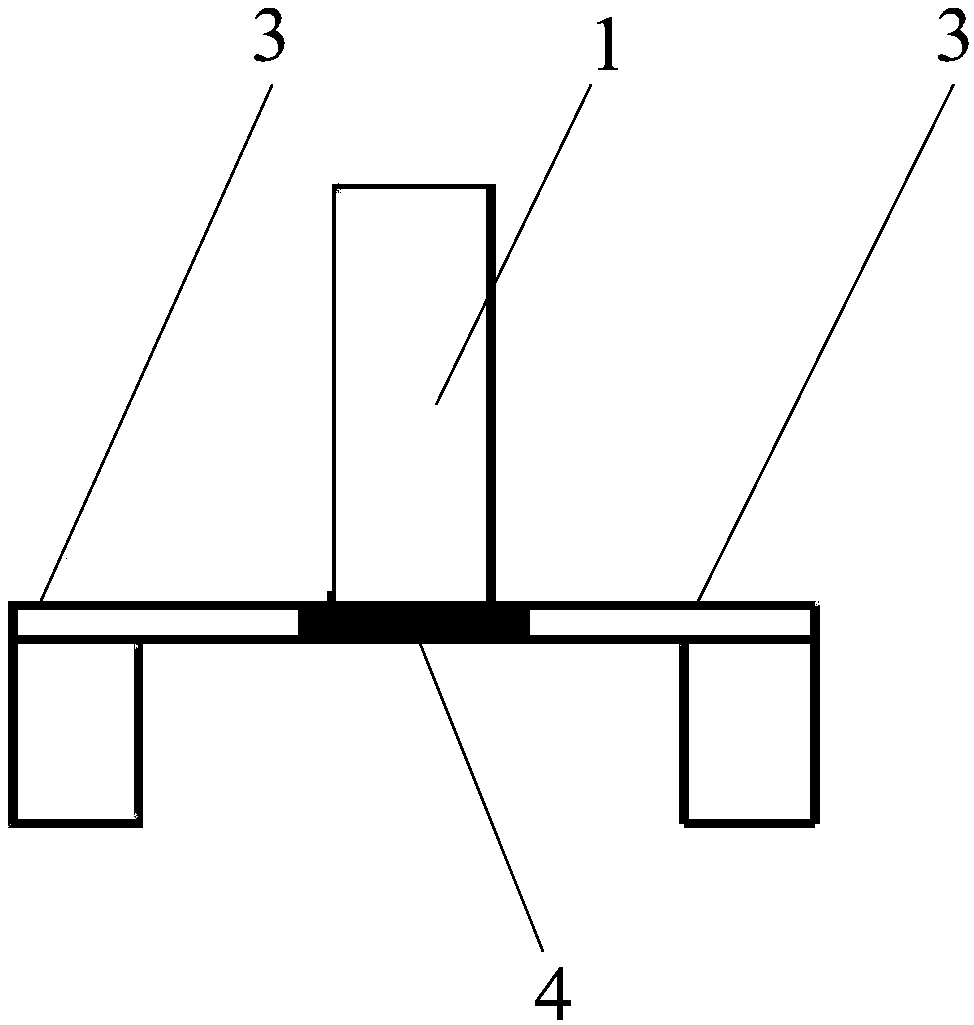

Star wheel reducer and mechatronics equipment with the star wheel reducer

InactiveCN108006164BGuaranteed transmission ratioSimple structureToothed gearingsGearing detailsLow speedReduction drive

The invention discloses a planetary wheel speed reducer. The planetary wheel speed reducer comprises a main shaft connected with a high-speed part, planetary wheels, a fixed inner tooth ring fixedly arranged, and an output inner tooth ring connected with a low-speed part. The axes of the planetary wheels are eccentric relative to the axis of the main shaft and are arranged in parallel. Center shafts in the planetary wheels are connected to the main shaft, and the planetary wheels can rotate around the respective center shafts in the planetary wheels. Each planetary wheel comprises a first-stage gear used for meshing transmission with the fixed inner tooth ring and a second-stage gear used for meshing transmission with the output inner tooth ring. In each planetary wheel, the first-stage gear is coaxially and fixedly arranged on one side of the second-stage gear. The planetary wheels in the planetary wheel speed reducer conduct a circular movement around the main shaft and a rotation movement, the two movements are superimposed and transmitted to the output inner tooth ring, and thus the planetary wheel speed reducer has a large transmission ratio, and the planetary wheel speed reducer is simple in structure and convenient to machine. The invention further discloses mechanical and electronic integration equipment comprising the planetary wheel speed reducer, and the planetary wheel speed reducer can guarantee the transmission ratio and is simple in structure.

Owner:深圳市星轮科技有限公司

An integrated single trailing arm gear reduction wheel side electric drive system

InactiveCN103707749BImprove riding performanceGood grounding effectElectric propulsion mountingControl devicesTrailing armDrive wheel

The invention relates to an integrated single-trailing-arm gear-reducing type electric wheel drive system. A drive motor is fixed on a frame, and assembled with a drive wheel, planet gears, tanks and a single trailing arm to form an integrated structure, so that unsprung mass of an automobile is reduced. Tanks A, tanks B, the single trailing arm and the frame form an articulated four-bar mechanism, when wheels hop up and down under the action of random road excitation, the single trailing arm and the tanks A and B also rotate around respective rotation axes, and by the mechanism, transmission ratio can be ensured unchanged when the center distance between the motor and a driven planet gear changes due to road input excitation. By the novel wheel reduction and transmission mechanism transmitting motor power to the driven planet gear (wheel rim), the transmission ratio between the motor and the driven planet gear can be ensured not to change with the center distance without the help of a constant-speed universal transmission shaft device. The integrated single-trailing-arm gear-reducing type electric wheel drive system has the advantages of simplicity of the wheel reducing mechanism and high transmission efficiency.

Owner:TONGJI UNIV

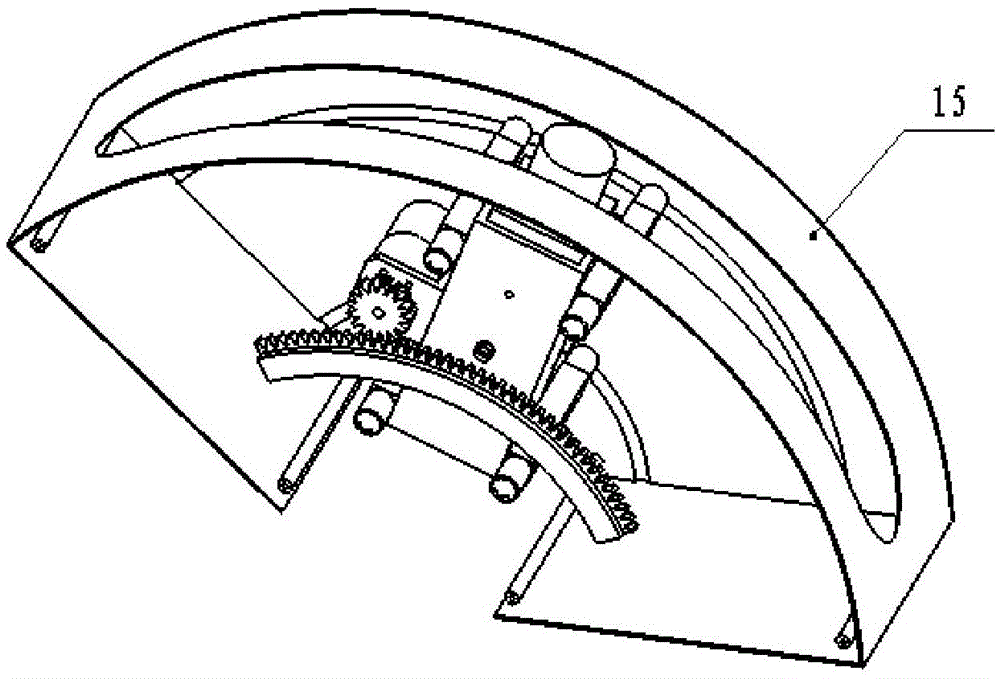

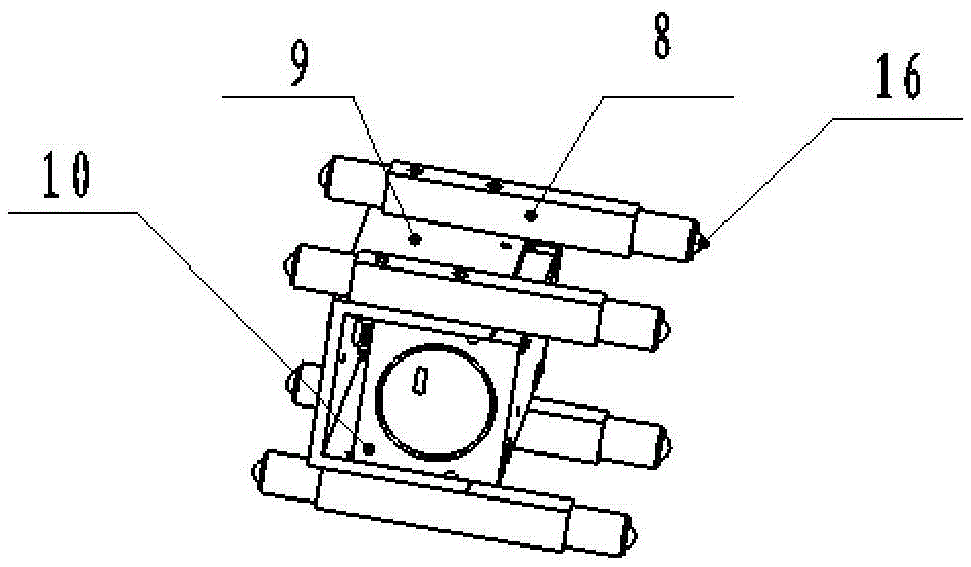

A rifled barrel scanning device

ActiveCN109521497BReduce design difficultyReduce manufacturing costOptical detectionEngineeringRadome

Owner:四川省华盾防务科技股份有限公司

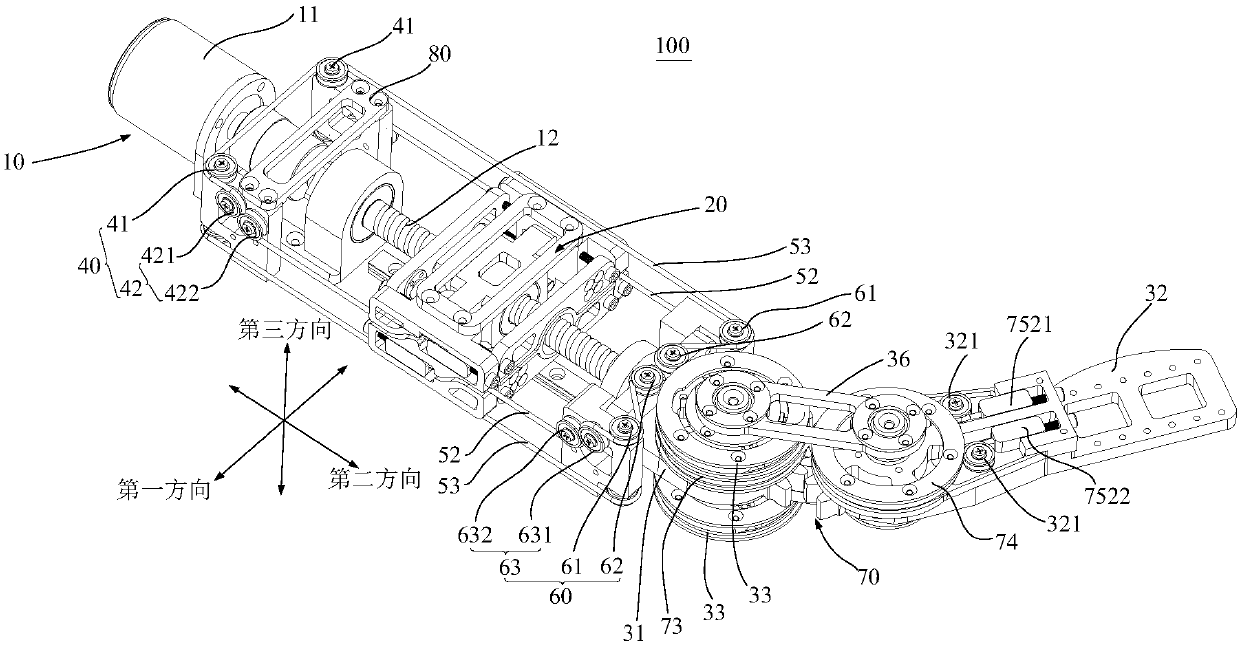

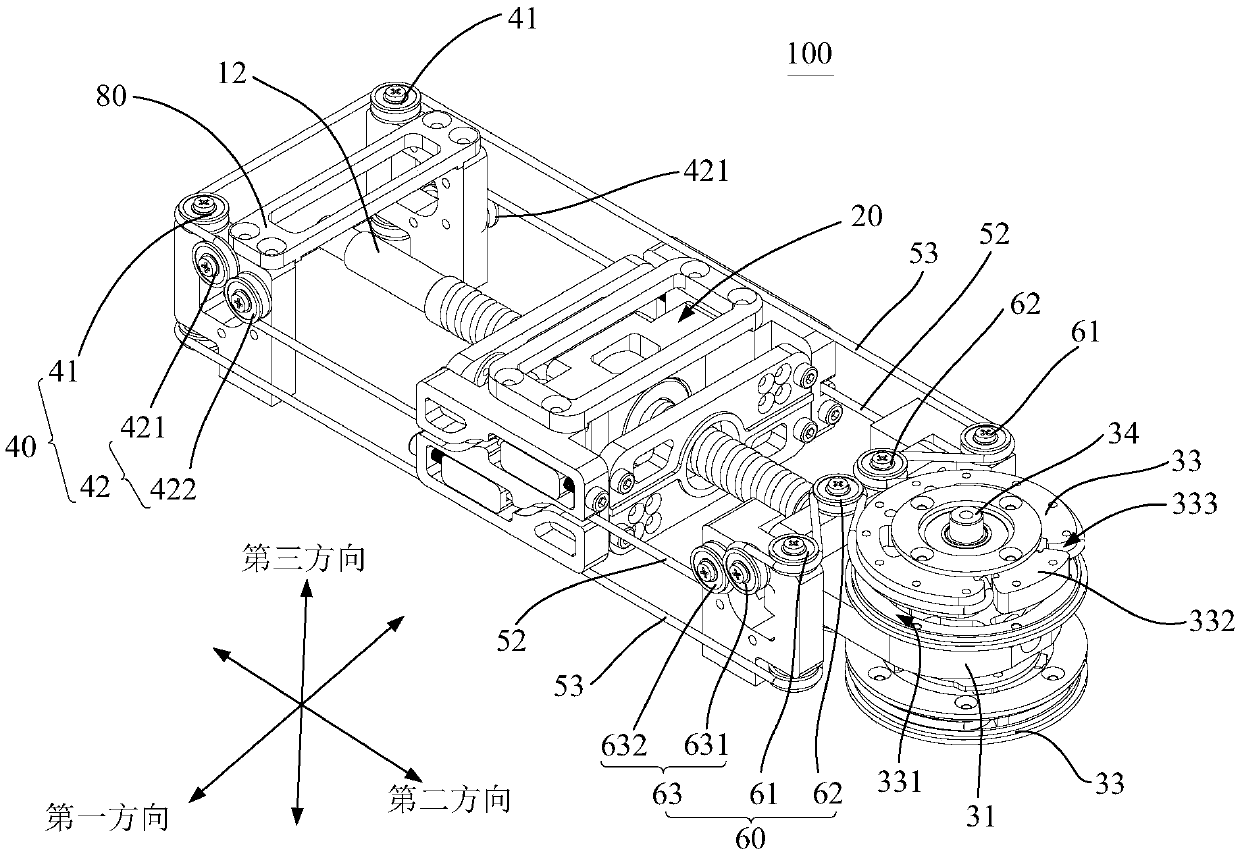

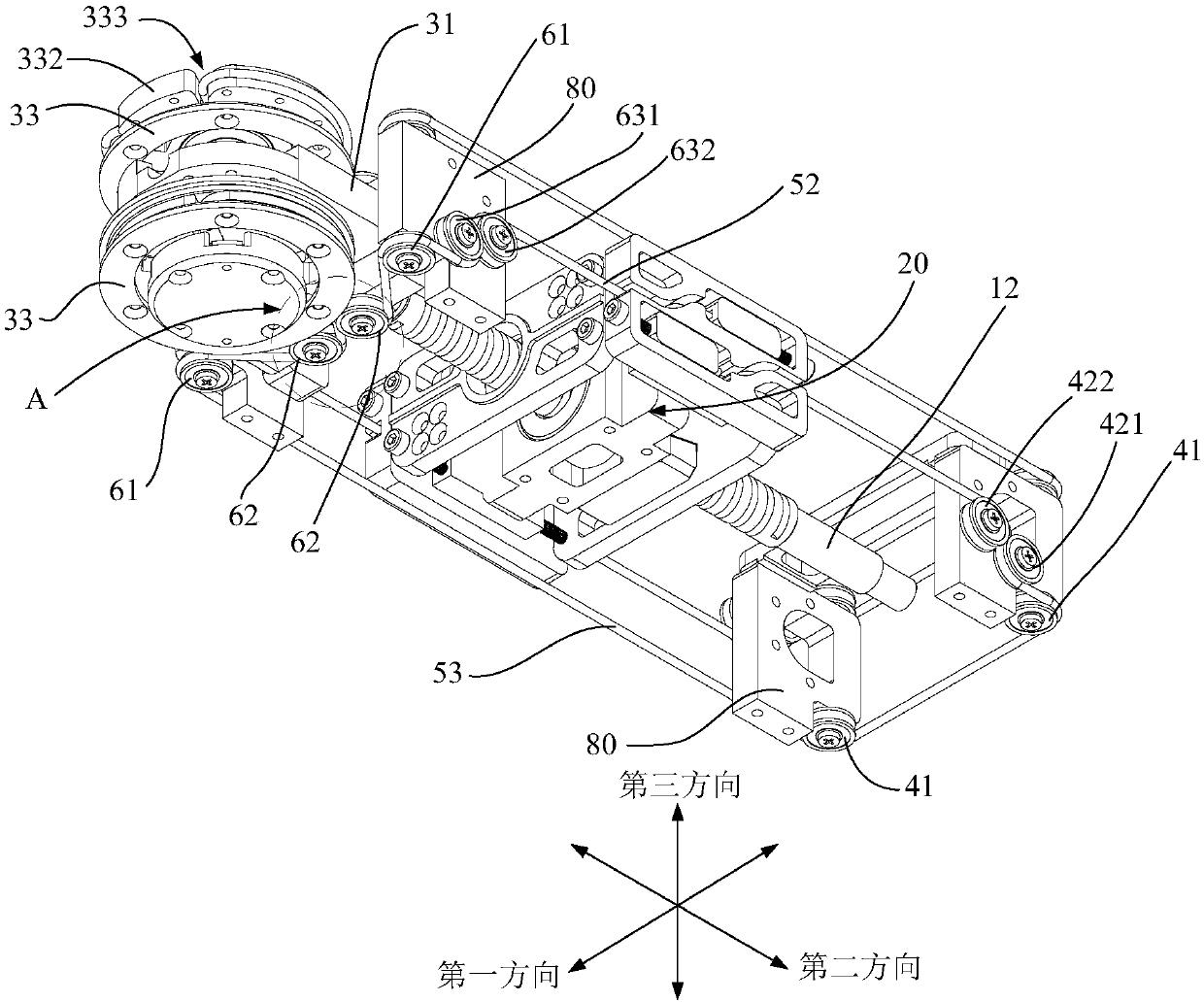

Power transmission mechanism and robot

PendingCN110524512AReduce volumeReduce quality problemsProgramme-controlled manipulatorEngineeringExoskeleton

The invention discloses a power transmission mechanism and a robot. The power transmission mechanism comprises a driving assembly and further a linkage device, wherein the driving assembly drives thelinkage device to move; a joint assembly which comprises a joint line wheel, wherein the joint line wheel is located at one side of the linkage device; a first guide assembly which is located at the side, deviating from the joint line wheel, of the linkage device; a transmission line set at least part of which is fixedly connected with the linkage device, wherein the transmission line set bypassesthe joint line wheel and the first guide assembly, the driving assembly drives the linkage device to move, the linkage device drives the transmission line set to move around the joint line wheel, andthe transmission line set drives the joint line wheel to rotate. According to the technical scheme, the overall mass of an exoskeleton is reduced, the installation space is compact, the reasonable transmission ratio configuration is achieved, the output requirements for high rotating speed and large torque are met, and the usage is convenient.

Owner:SHENZHEN CHWISHAY SMART TECH CO LTD

A drilling device for pipe jacking construction

ActiveCN108979655BImprove stabilityExtended service lifePipe laying and repairToothed gearingsArchitectural engineeringMechanical engineering

The invention provides a drilling device used for pipe jacking construction and belongs to the technical field of municipal engineering. The technical scheme includes that the drilling device comprises a base plate, an intermittent motion mechanism is arranged on the base plate, and a drilling mechanism is arranged on the intermittent motion mechanism. The drilling device has the advantages that manual soil ploughing can be replaced, working efficiency is high, and injury to the body, caused by manually lying on front to plough can be avoided.

Owner:ZHEJIANG ZHUJI CONSTR CHAIN MFG

Textile yarn guiding device for textile machine

The invention discloses a textile yarn guiding device for a textile machine, and belongs to the technical field of textile equipment. The textile yarn guiding device for a textile machine comprises abase and a yarn guiding rod; a yarn guiding ring is connected to the yarn guiding rod; a yarn guiding wheel is rotationally connected to the yarn guiding rod; a sliding groove and a first cavity are formed in a first support; a lifting rod is connected to the yarn guiding rod; the lifting rod is glidingly connected in the sliding groove; the bottom of the lifting rod extends into the first cavityto be connected with a first piston; a third cavity is formed in a second support; the first cavity communicates with the third cavity through a guiding pipe; an adjusting rod is glidingly connected in the third cavity; a first rotating shaft is rotationally connected to the top of the adjusting rod; an adjusting wheel and a first belt wheel are connected to the first rotating shaft; and the top of the third support is rotationally connected with a yarn bundling barrel matched with the adjusting wheel. According to the textile yarn guiding device, by the aid of the yarn guiding wheel, the limiting rod, the adjusting wheel and the yarn bundling barrel which restrict and promote one another, it is effectively guaranteed that the tightness of yarn is in the controllable range, output of the yarn is protected, and the yarn quality is improved.

Owner:黄时成

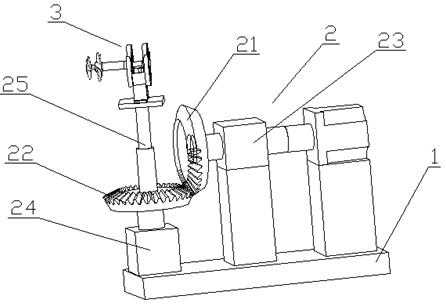

How to make a guitar

ActiveCN107297293BEvenly paintedHigh efficiency of artificial paintingSpraying apparatusMotor driveMaterial selection

The invention belongs to the technical field of guitar production and particularly discloses a guitar manufacturing method. The method includes steps of material selection, neck manufacturing, body manufacturing, neck connection and paint spraying. At the step of paint spraying, a paint spraying device is used for paint spraying at a side plate concave position and comprises a frame, a guitar side plate is rotationally connected to the frame, a motor is arranged on the frame, the frame is provided with a guide groove and a slide rod which is slidably arranged in the guide groove, one end of the slide rod is abutted against the concave position of guitar side plate, and a reset spring is connected between the other end of the slide rod and the guide groove; the slide rod is connected with a spraying frame through a transmission mechanism in a transmission ratio of 1:1, and a pair of sprayers are arranged on the spraying frame, oppositely obliquely arranged at the concave position of the side plate and staggered in the height of the side plate; after the motor and the sprayers are switched on, the motor drives the side plate to rotate, and then the concave position of the side plate is sprayed by the sprayers. By adoption of the manufacturing method, uniformity in paint spraying at the concave position of the guitar side plate is achieved.

Owner:贵州金韵乐器有限公司

Pair-rolling pork rib square-cutting machine

The invention discloses a pair-rolling pork rib square-cutting machine, and belongs to the field of food processing equipment. The pair-rolling pork rib square-cutting machine is composed of bottom brackets, vertical plates, gears, synchronous wheels, synchronous belts, drive shafts, bearing assemblies, hob shafts, an outer shell, a feeding port, a discharge port, a motor, a reducer, an interfacedisc, hobs, ejecting assemblies and a bearing seat. The outer surface of each of two hobs is provided with hob warp-wise blades and hob weft-wise blades; a grid shape is formed by the hob warp-wise blades and the hob weft-wise blades; the ejecting assemblies are arranged in the grid; the motor transfers motion to the gears through a speed reducer, and the gears are merged to transfer the motion tothe synchronous wheels and the synchronous belts, so as to drive the hobs to rotate, the reverse and bevelment of motion of the two hobs are achieved, and pork ribs at the middle of the two hobs arecut into squares. For avoiding the adhesion of the pork ribs cut into squares, the ejecting assemblies are arranged on the outer side of the hobs, the pork ribs cut into squares and attached onto thehobs are ejected out, and the device can be applied to automatically square cutting of the slicing pork ribs.

Owner:陈正康

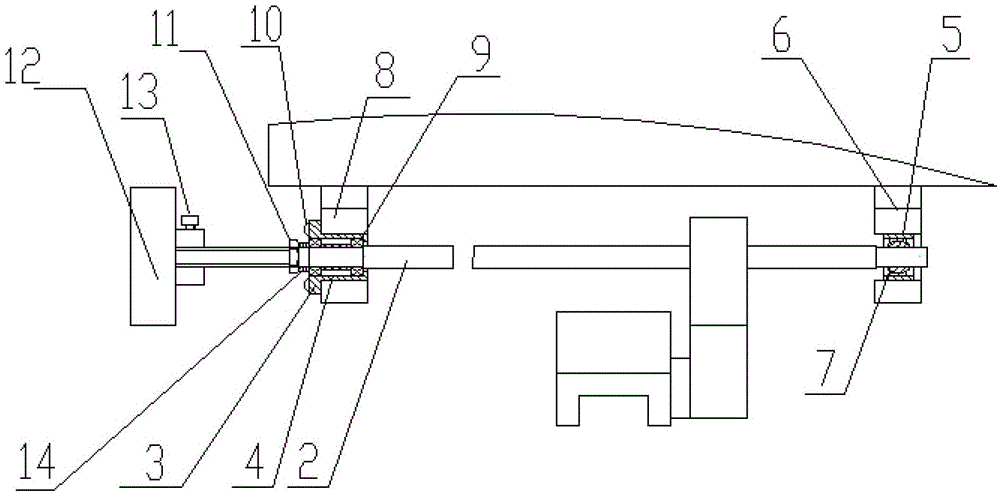

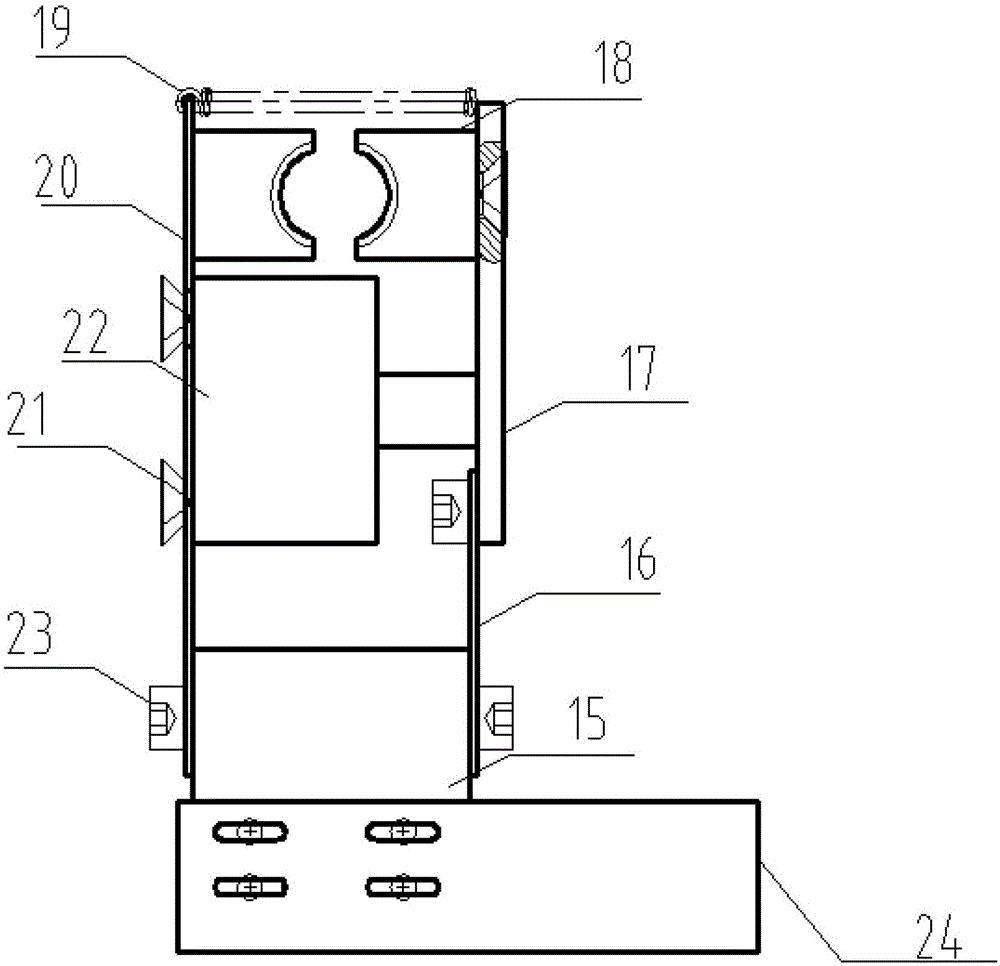

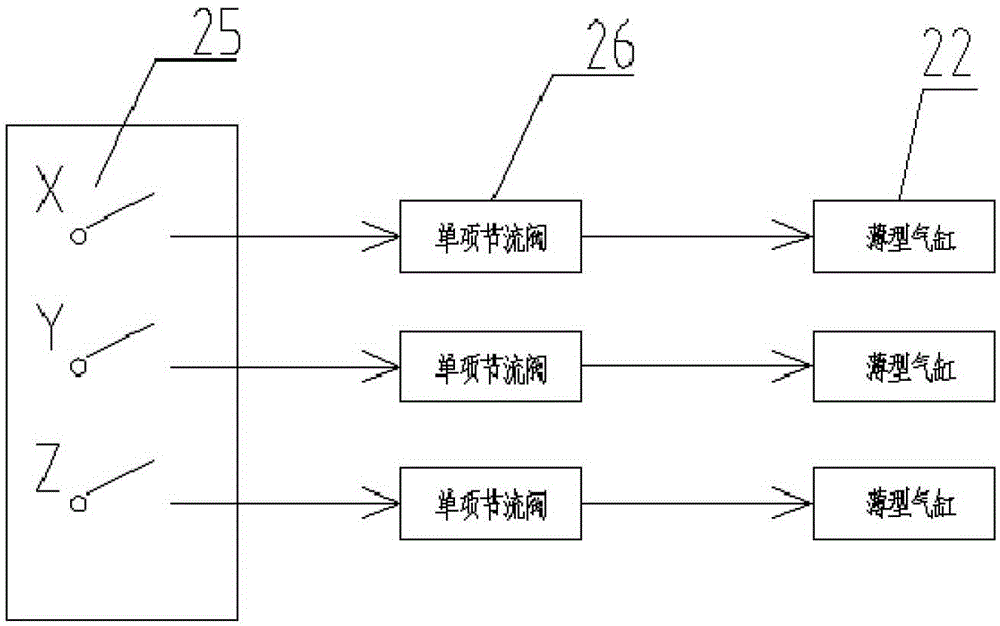

High Stability Transmission Device of Manual Coordinate Measuring Machine

ActiveCN103344204BGuaranteed accuracyStable transmission ratioMeasurement devicesEngineeringCoordinate-measuring machine

The invention discloses a high-stability transmission device of a manual three-coordinate measuring machine. The high-stability transmission device comprises a screw rod transmission component and a clamping mechanism, wherein the screw rod transmission component comprises a transmission screw rod, and a net-shaped hand wheel is fixed at the front end of the transmission screw rod; the clamping component comprises a connecting block which is fixed on a connecting plate; left and right elastic plates are arranged on two sides of the connecting block respectively; a rigid plate is connected to one end of the right elastic plate; a thin type cylinder is fixed on the left elastic plate and between the rigid plate and the left elastic plate; a pair of clamping blocks are arranged between the rigid plate and the left elastic plate; the upper end part of the rigid plate is connected with the upper end part of the left elastic plate through a tension spring; the clamping blocks are clamped on the transmission screw rod; threads in match with the transmission screw rod are arranged on the inner sides of the clamping blocks. The high-stability transmission device can be arranged on X, Y and Z measurement axes of the three-coordinate measuring machine and is simple in structure, easy to produce, convenient to operate and good in use effect; the transmission efficiency is improved, and a transmission part has a stable transmission ratio; the fine tuning function of the hand machine is realized, the transmission precision is ensured, and the measurement is convenient.

Owner:青岛弗尔迪测控有限公司

A follow-up inkjet equipment

The invention discloses a following type ink jet printing device, and belongs to the field of industrial automation devices. The following type ink jet printing device is composed of stopping edges, supporting columns, a back arc face, a gear arc, a gear, a motor installation plate, a direct-current gear motor, roller supporting columns, an ink jet printing assembly sleeve, an ink jet printing sleeve, an ink jet printing head, a CCD support, a CCD, a front arc face, an upper cover plate and rollers. The following type ink jet printing device is characterized in that the two stopping edges are arranged in the device, the back arc face and the front arc face are installed on the lateral sides of the two stopping edges, the supporting columns are installed between the front arc face and the back arc face, and the upper cover plate is installed on the front arc face and the back arc face; the gear arc is installed on the inner side of the back arc face, the four roller supporting columns are installed on the ink jet printing assembly sleeve, the ink jet printing sleeve is installed in the cold jetting assembly sleeve, the ink jet printing head is installed in the ink jet printing sleeve, the motor installation plate is installed on the ink jet printing assembly sleeve, the direct-current gear motor is installed on the motor installation plate, and the gear is installed on the motor and meshed with the gear arc; and the CCD support is installed on the lateral side of the ink jet printing sleeve, and the CCD is installed on the CCD support. By means of the following type ink jet printing device, product information can be printed to the proper position of a plastic pipe in a jetted manner.

Owner:SHANDONG JIANZHU UNIV

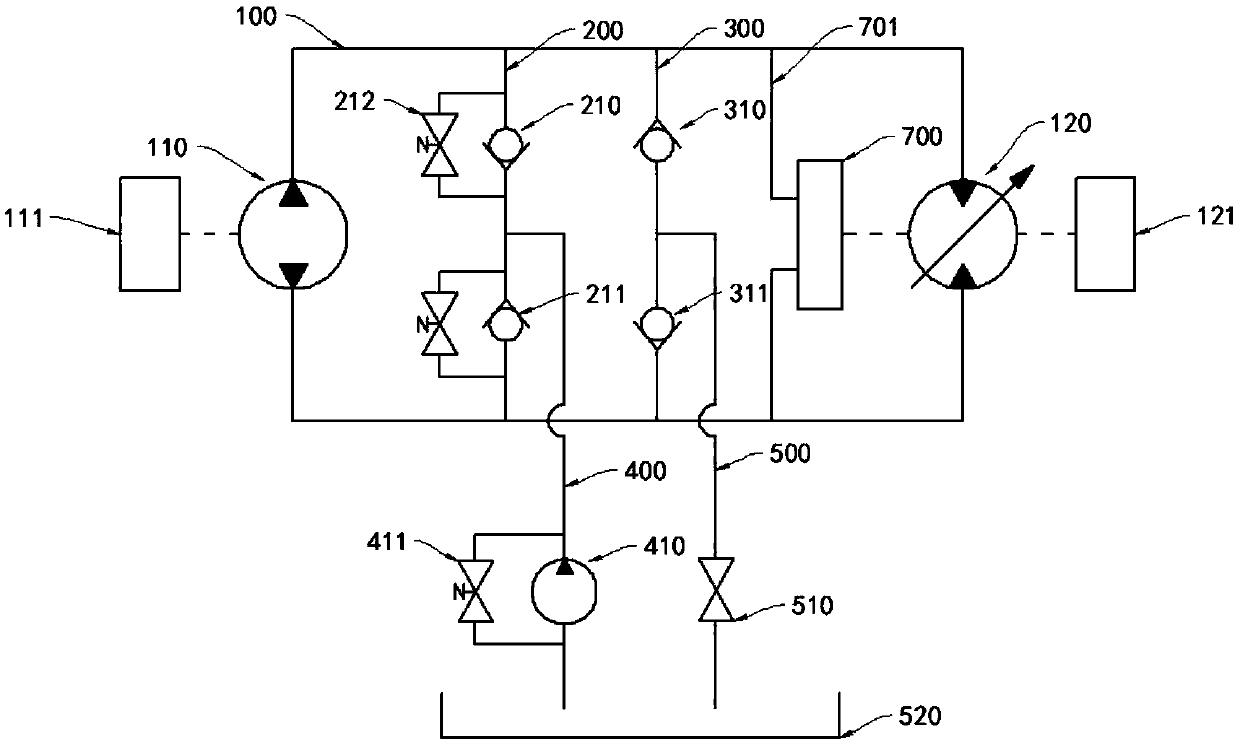

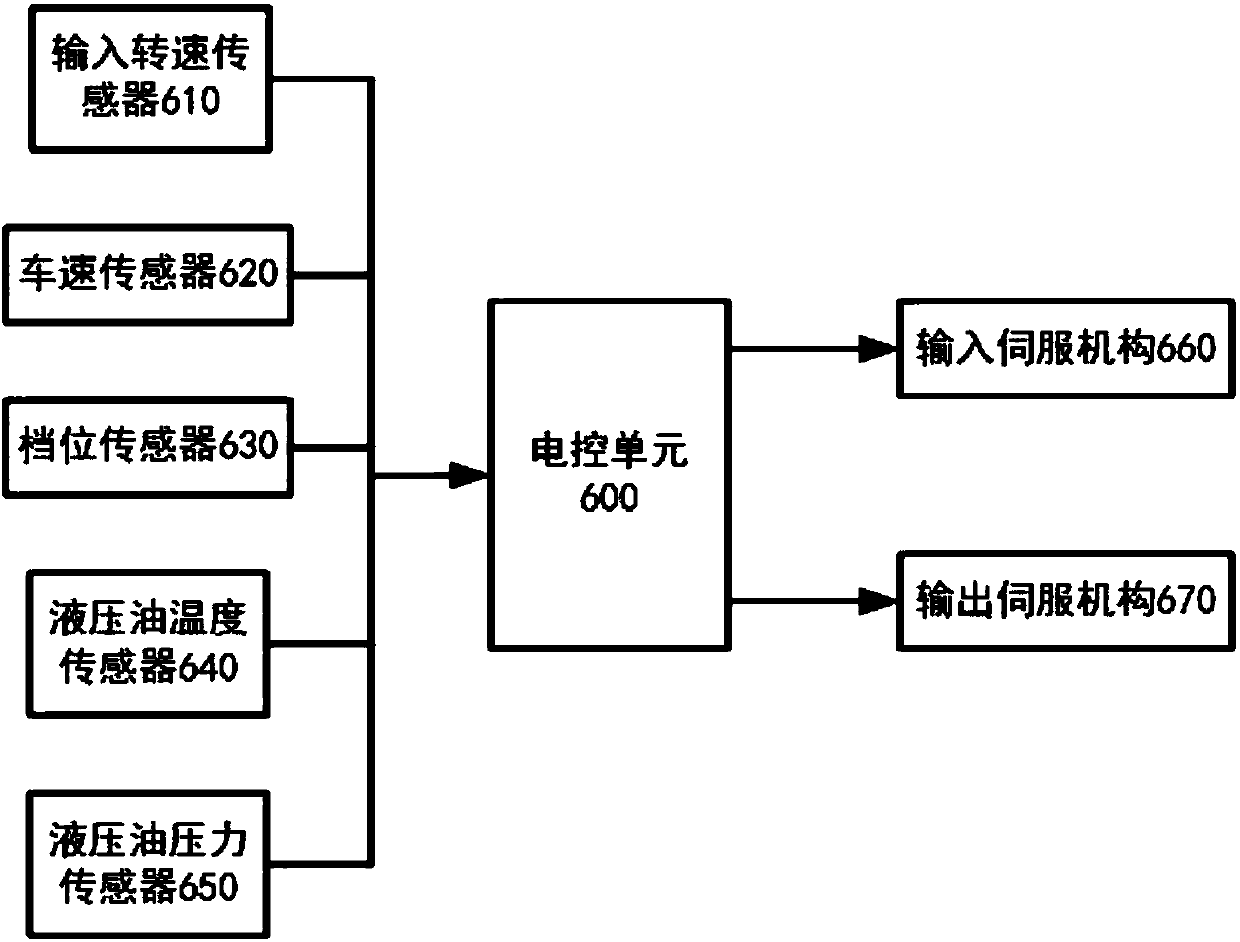

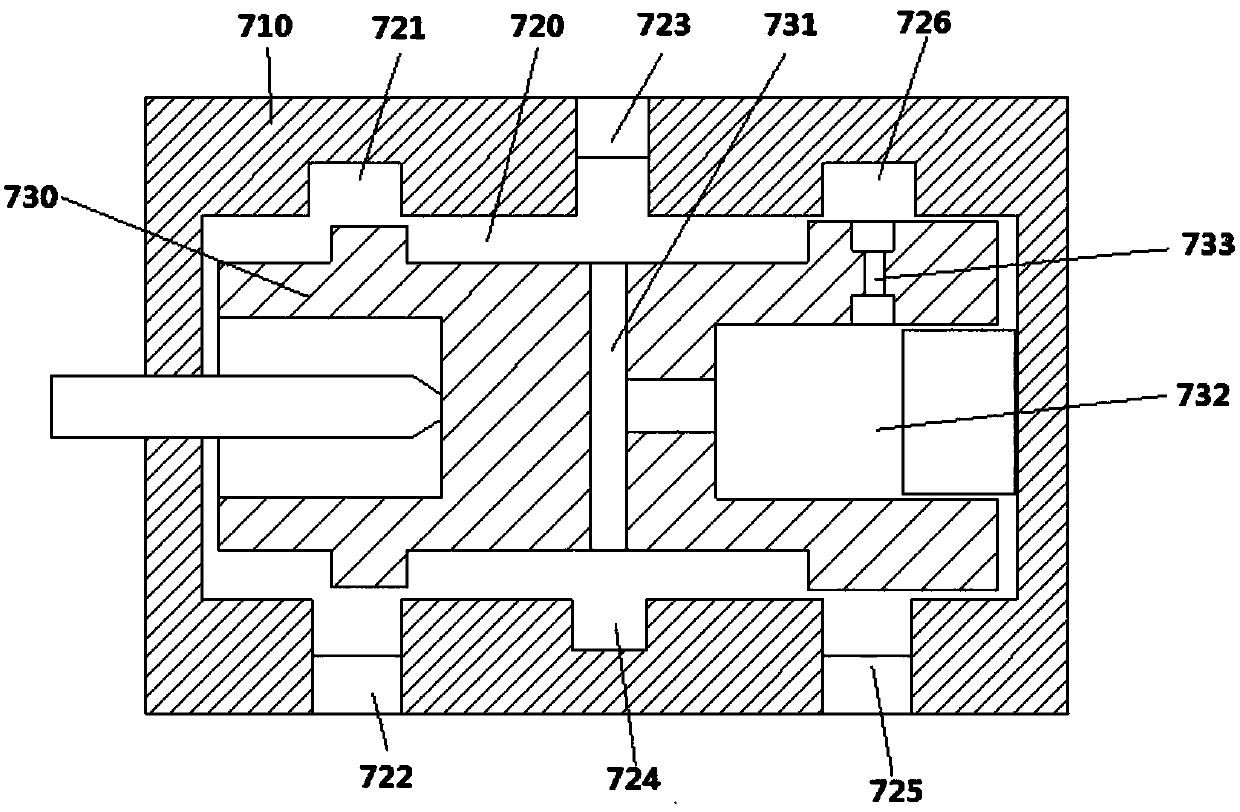

Hydraulic transmission stepless speed-changing system

ActiveCN108050225AQuick responseFully lubricatedGear lubrication/coolingFluid gearingsFriction lossSystem pressure

The invention discloses a hydraulic transmission stepless speed-changing system. The hydraulic transmission stepless speed-changing system comprises a main loop composed of a pump and a motor and further comprises an electronic control unit. The main loop is provided with a first branch circuit for oil inlet and corresponding structures and a second branch circuit of oil outlet and corresponding structures. A sliding valve connected with the motor is further connected to the main loop in parallel; the pump is connected with an input shaft, and the motor is connected with an output mechanism; the electronic control unit is connected with a plurality of sensors and further connected with an output servo mechanism; and the output servo mechanism is connected with the motor. The hydraulic transmission stepless speed-changing system has the characteristics of smooth transmission, high lubrication full response speed and relatively-simple system; in addition, the oil leakage phenomenon is not likely to occur, and the system pressure and the transmission ratio are stable; meanwhile, the performance, resistant to hydraulic pressure impact, of a pipeline of the hydraulic transmission stepless speed-changing system is good, and the oil leakage phenomenon can be further reduced; and the motor is sufficiently lubricated, the energy of the friction loss is small, and the transmission efficiency of the system is high.

Owner:ZHEJIANG UNIV CITY COLLEGE

Tractor capable of realizing hi-crop working

The invention discloses a tractor capable of high-clearance cultivating, which comprises two rear wheels and two front wheels respectively arranged on a rear driving bridge and a front bridge, wherein, the rear driving bridge comprises two rear bridge shaft tubes, two driving shafts connected with a rear bridge transmission box run through and respectively and rotatably arranged on the two rear bridge shaft tubes; the front bridge comprises a bushing with both ends respectively and detachably connected with auxiliary bushings, wherein, the two auxiliary bushings are respectively connected withthe two front wheels, the two driving shafts are respectively and detachably connected with transmission boxes, and the two transmission boxes are respectively connected with and drive the two rear wheels; the space between the two rear bridge shaft tubes and the two transmission boxes respectively, detachably and fixedly connected with connecting shaft tubes for sleeving the corresponding driving shafts. The tractor of the invention is enabled to realize two functions of routine work such as plowing, tilling, sowing, harvesting, etc. and cultivating work such as weeding, loosing, fertilizing, ridging, etc., thereby greatly reducing investment cost, expanding the functions of tractor and improving the utilization rate of the tractor.

Owner:LOVOL HEAVY IND CO LTD

A tail self-yawing semi-rotary impeller turbine

ActiveCN111120182BMinimize the impact of energy harvesting efficiencyReduce consumptionHydro energy generationMachines/enginesImpellerWater turbine

The invention discloses a tail wing self-yawing type half-rotating impeller water turbine, and belongs to the technical field of new energy. According to the water turbine, through gear transmission,the motion rule of the water turbine is kept as follows an output shaft rotates by a circle, water turbine blades rotate by half circle, the phase difference between two blades is 90 degrees, the topof an outer frame of the water turbine is connected with a bearing, the rear end of the outer frame is connected with a water drop type tail wing, along with changes of the water flow direction, force, acting on the tail wing, of the water flow generates yawing moment for the outer frame, the water turbine is driven to perform deflection, and can right face the water flow direction, and the influence of the water flow deflection on the efficiency of the water turbine is reduced. According to the tail wing self-yawing type half-rotating impeller water turbine, a tail wing self-yawing mechanismis adopted, the consumption of the electric amount of the small water turbine can be reduced, and the adaptation water area is wide.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Simple equipment capable of cutting spare ribs into blocks

The invention relates to simple equipment capable of cutting spare ribs into blocks, and belongs to the field of food processing equipment. The simple equipment consists of a front end bracket assembly, a middle bracket assembly, a rear end bracket assembly, a spare rib container, a rear end belt pulley assembly, a dicing belt, spare rib block ejecting assemblies, dicing hobs, synchronizing belts,synchronizing wheels, a speed reducer, a motor, a hob ejecting assembly, and the like, wherein the front end belt pulley assembly is driven by the motor through the speed reducer; movements are transmitted to the dicing hobs through the synchronizing wheels and the synchronizing belts; and in the movements, cutting edges of the dicing hobs and cutting edges on the dicing belt can form opposite cutting, so that sliced spare ribs can be cut into blocks. In order to avoid the situation that the spare rib blocks obtained through cutting are adhered, each hob ejecting assembly is mounted on the outer side of the corresponding dicing hob, and each spare rib block ejecting assembly is mounted on the outer side of the dicing belt, so that the spare rib blocks obtained through cutting, adhered onthe dicing hobs and the dicing belt are ejected. The simple equipment disclosed by the invention can be applied to the situation of automatically cutting the sliced spare ribs into the blocks.

Owner:重庆巴山物语食品加工有限公司

An automatic cleaning device for rubber rollers of spinning frame

Owner:江苏凯瑞智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com