Pair-rolling pork rib square-cutting machine

A technology of ribs and rolling shape, applied in slaughtering, meat processing equipment, food science and other directions, can solve the problems of time-consuming and laborious chopping, noise in shopping malls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

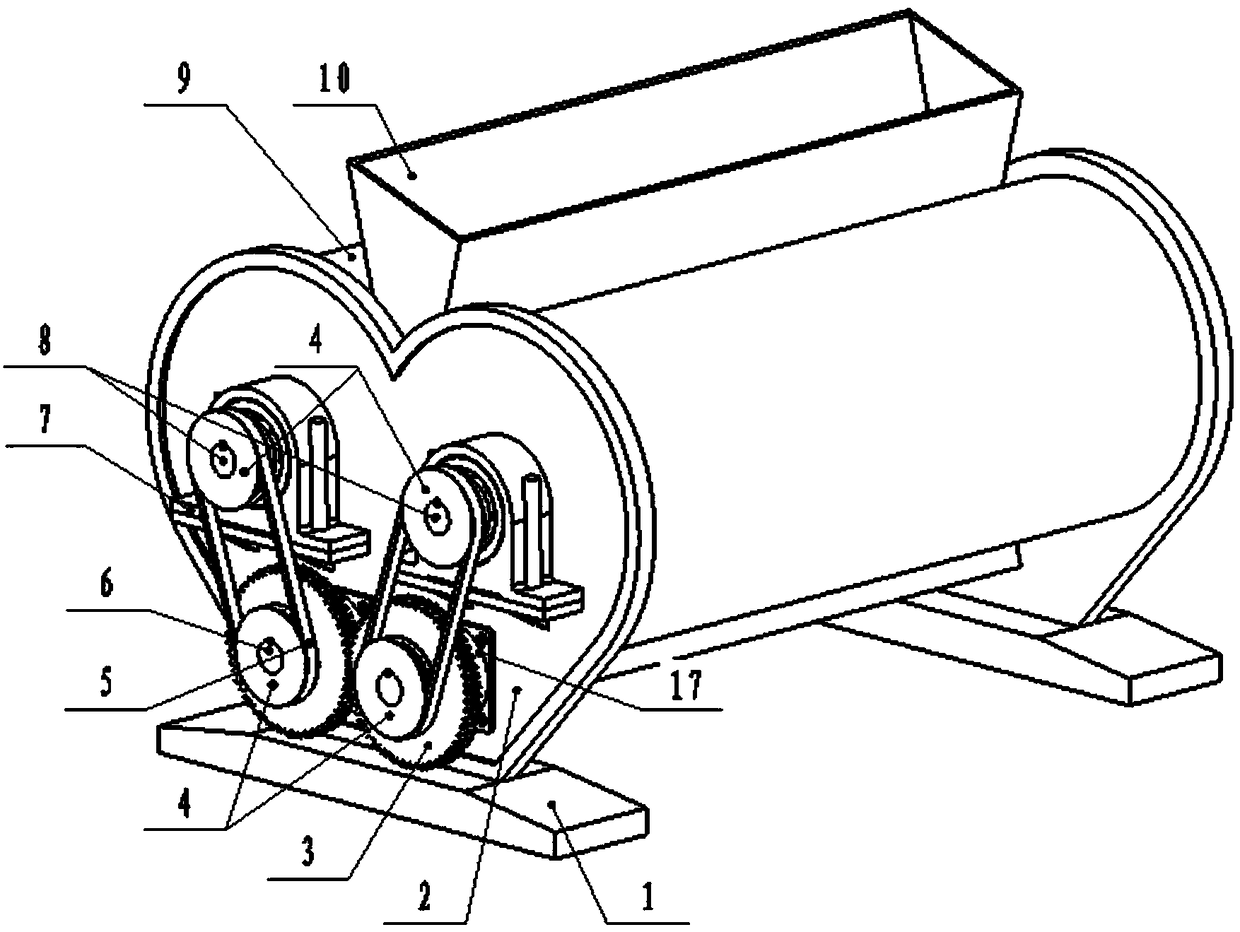

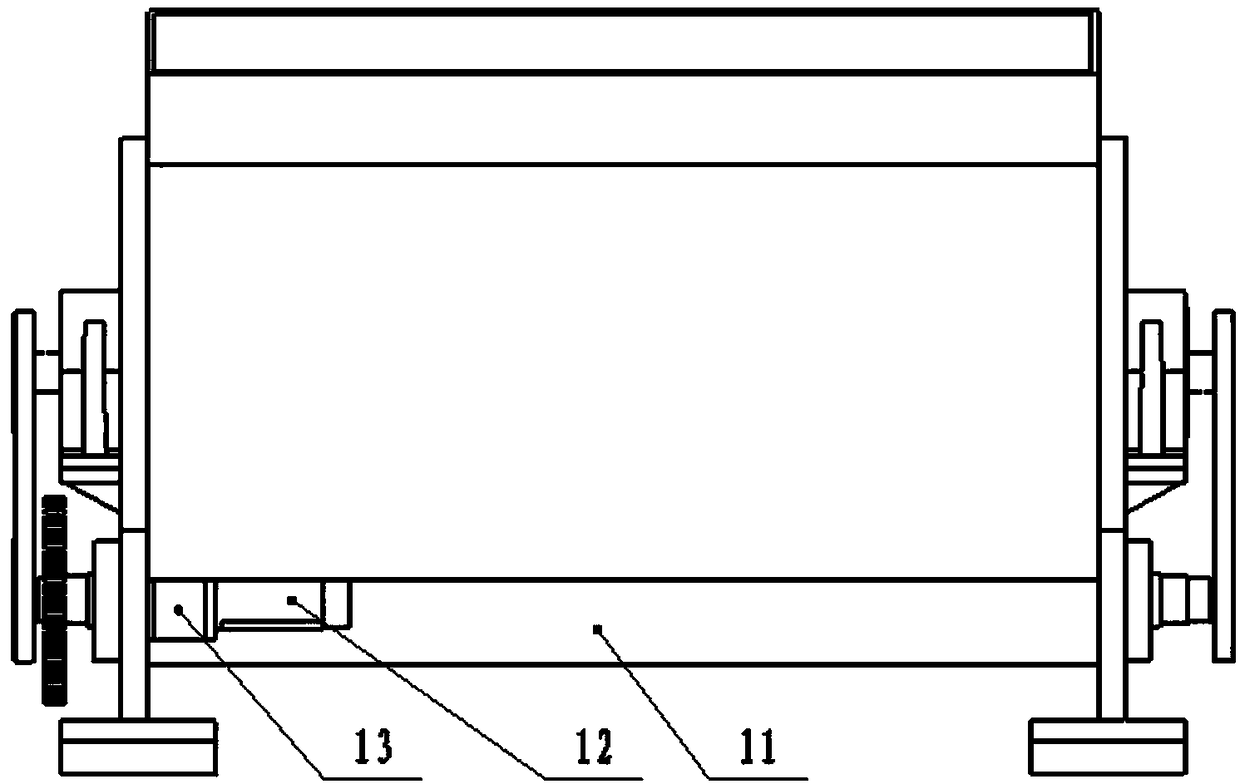

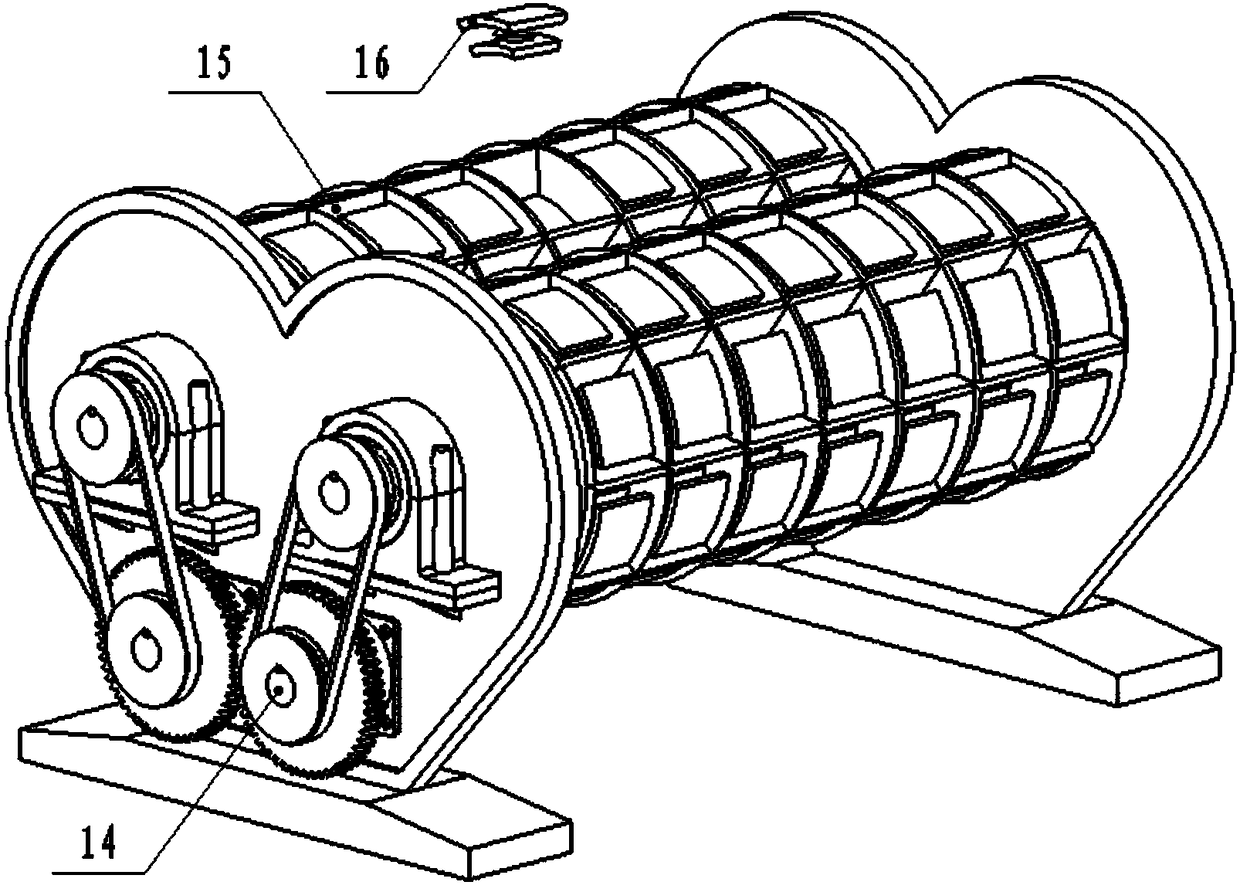

[0020] A double-rolling rib cutting machine, which consists of bottom bracket 1, vertical plate 2, gear 3, synchronous wheel 4, synchronous belt 5, drive shaft 6, bearing assembly 7, hob shaft 8, shell 9, and inlet 10. The discharge port 11, the motor 12, the reducer 13, the interface plate 14, the hob 15, the ejector assembly 16 and the bearing seat 17, the hob 15 has two, and the outer surface of the hob 15 is installed The hob warp knife edge 151 and the hob weft knife edge 152, the hob warp knife edge 151 and the hob weft knife edge 152 form a grid, and the ejector assembly 16 is installed on the hob warp knife edge 151 and the hob weft In the grid formed by the blade 152; the two bottom brackets 1 are respectively placed on the ground or the work surface, the two vertical plates 2 are respectively installed on the two bottom brackets 1, and the bearing assembly 7 with internal bearings is installed on the vertical plate 2, the hob shaft 8 is installed in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com