How to make a guitar

A production method and guitar technology, applied in spraying devices and other directions, can solve the problems of uneven spraying, poor spraying effect, low spraying efficiency, etc., achieve good spraying effect, simple structure, and avoid poor spraying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

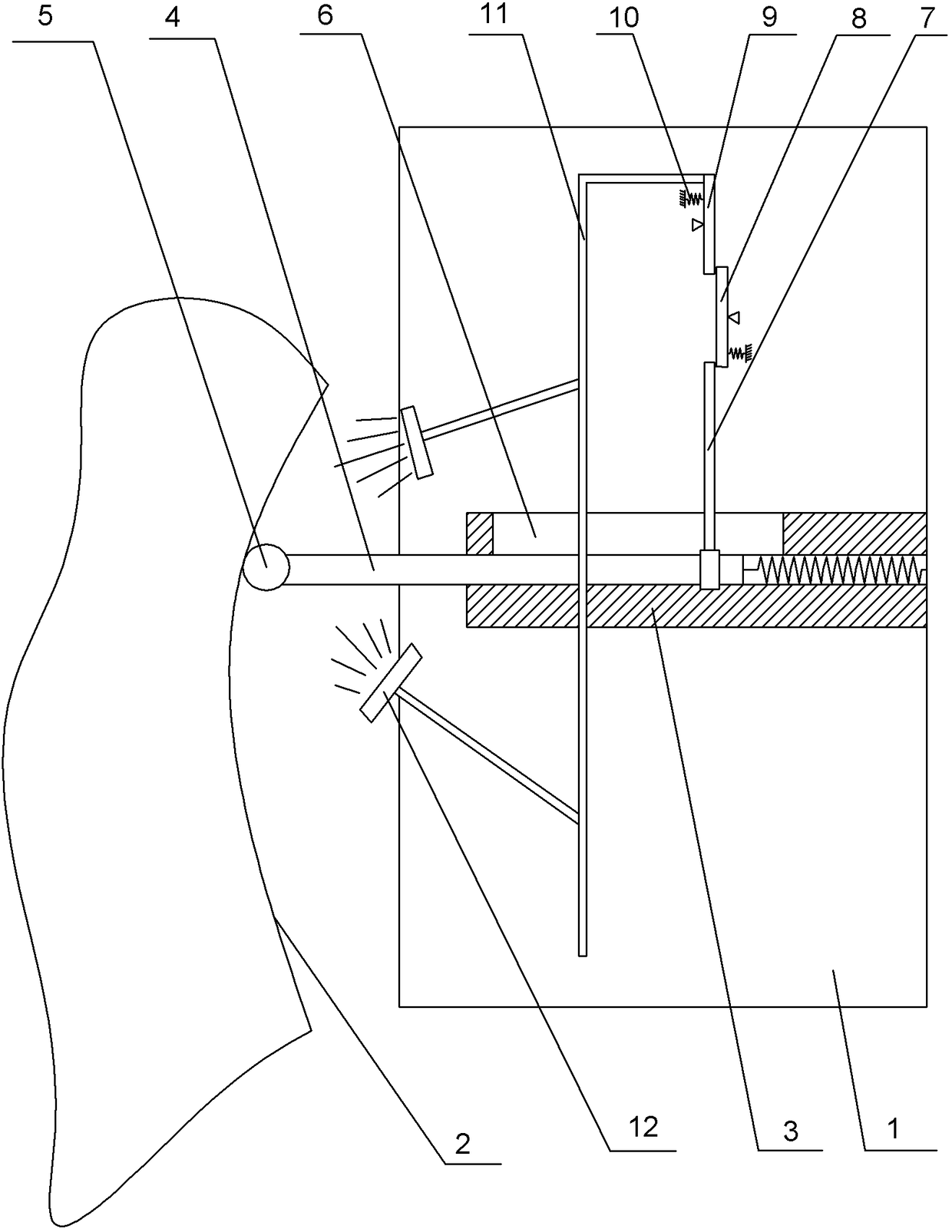

Embodiment 1

[0023] The manufacturing method of the guitar of the present embodiment comprises the following steps:

[0024] 1. Material selection: The panel material is spruce, white pine or red pine, the side plate material is walnut or mahogany, etc., the fingerboard material is Indonesian rosewood, the handle body material is mahogany or Okoume, and the materials are dried to The humidity is 5% to 7%.

[0025] 2. Making the handle: Saw the whole piece of handle material at a 7° angle, and then stick it together in reverse, so as to form a 14° oblique position. Brush the handle with glue and place it on the headstock and press it with an air cylinder. , until the glue dries, then drill the tune button holes on the headstock, and drill 6 holes at a time.

[0026] 3. To make the piano case, first make the panel: use the veneer splicing method to saw out a board in the shape of a guitar, use a bench drill to cut out the set sound hole size and the slot for the sound hole flower that needs...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the first lever 8 and the second lever 9 are unequal arm levers, the length ratio of the power arm of the first lever 8 to the resistance arm is 0.5, and the length ratio of the power arm of the second lever 9 to the resistance arm is 0.5. The arm length ratio is 2, or other values, as long as the length ratios of the power arm and the resistance arm of the two levers are reciprocal to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com