Hydraulic transmission stepless speed-changing system

A continuously variable speed, hydraulic transmission technology, applied in the field of variable speed systems, can solve the problems of high requirements for parts processing and lubrication, the system cannot absorb and damp vibration, and the equipment of the electric drive system is complicated, so as to ensure the transmission ratio and reduce oil leakage. phenomenon, the effect of preventing component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

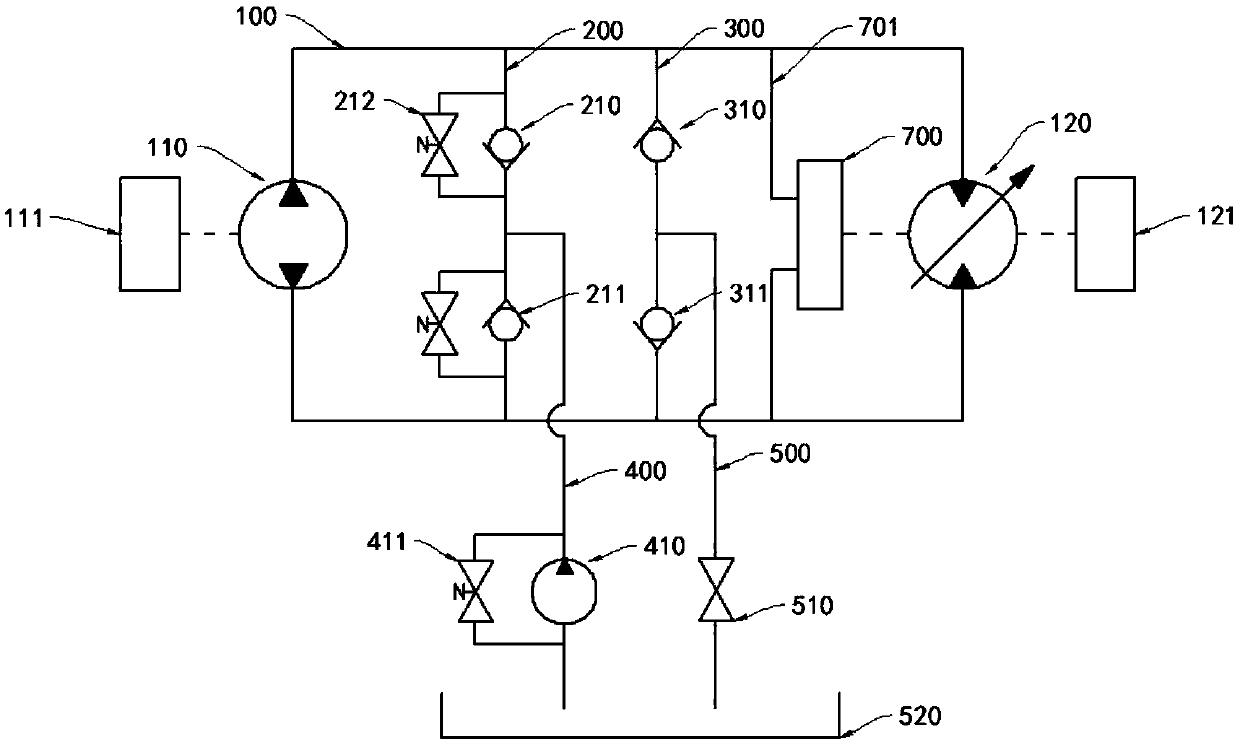

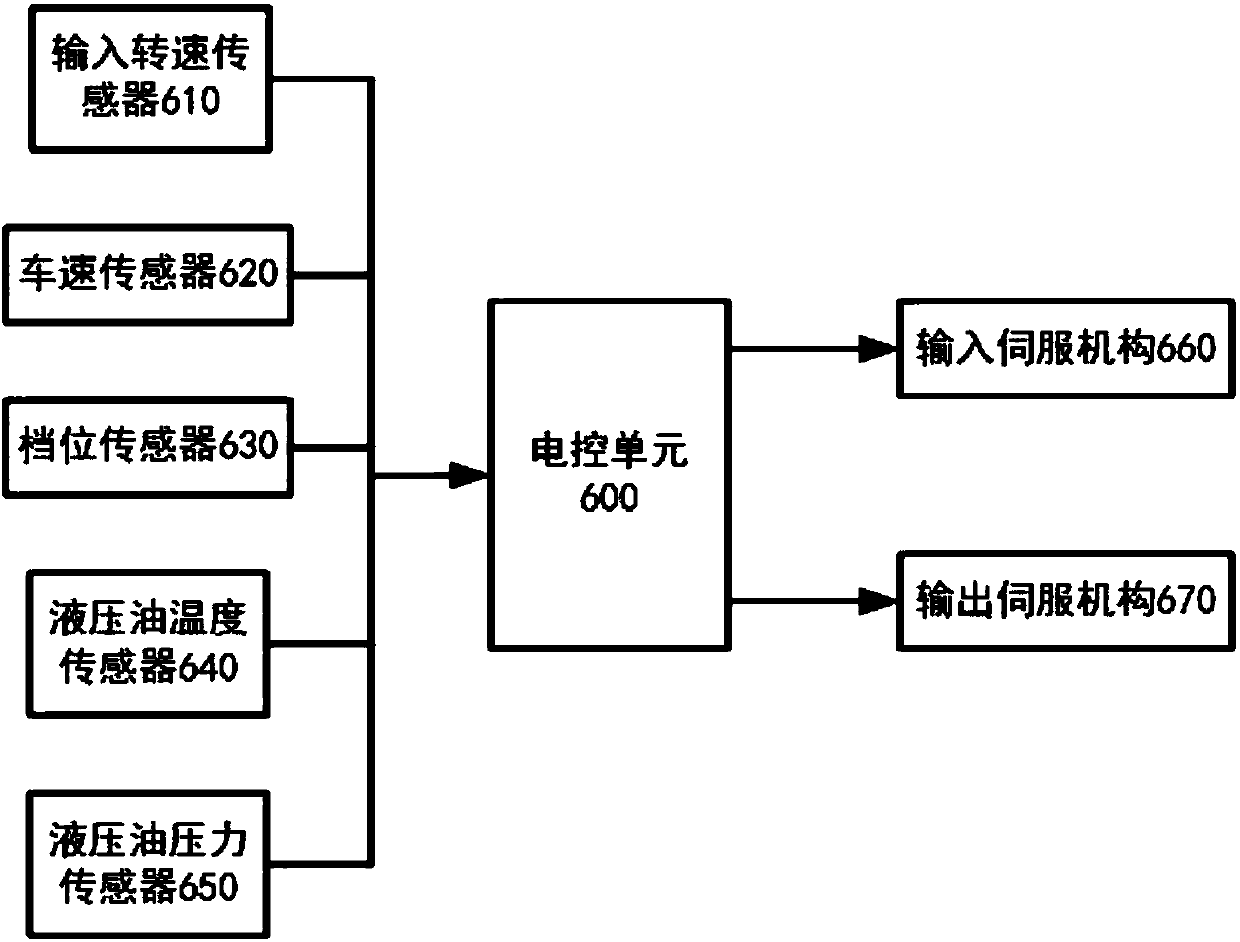

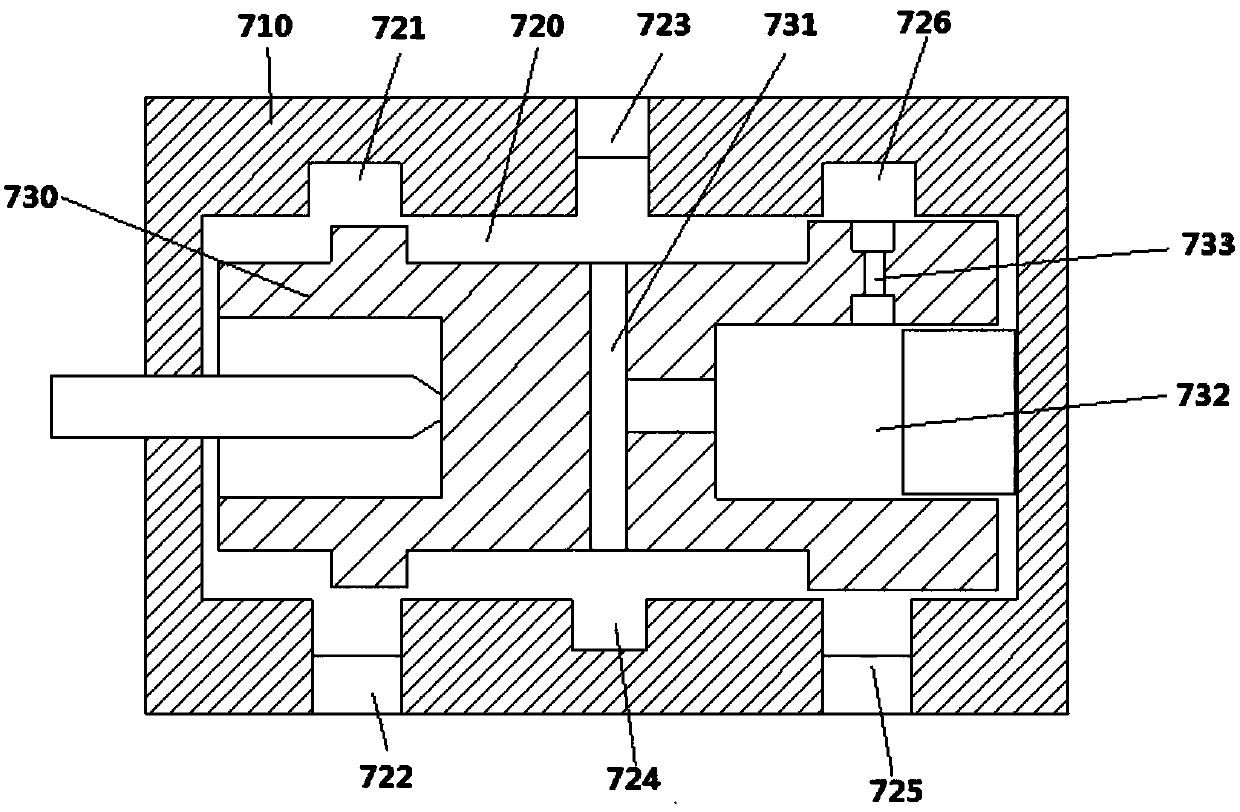

[0029] Embodiment: hydraulic transmission continuously variable transmission system, constitutes as figure 1 , figure 2 and image 3 As shown, it includes a main circuit 100 composed of a pump 110 and a motor 120. The main circuit 100 is provided with a first branch 200 and a second branch 300 in sequence; The first one-way valve 210 and the second one-way valve 211, the oil supply branch 400 is connected between the first one-way valve 210 and the second one-way valve 211, the oil supply branch 400 is connected with the oil tank 520, the oil supply The branch 400 is provided with a charge pump 410; the second branch 300 is provided with a third one-way valve 310 and a fourth one-way valve 311 oppositely arranged and the flow direction is outflow, and the third one-way valve 310 and the fourth one-way valve An oil outlet branch 500 is connected between the valves 311, the oil outlet branch 500 is connected to the oil tank 520, and a safety valve 510 is provided on the oil o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com