Patents

Literature

90results about How to "Flow balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

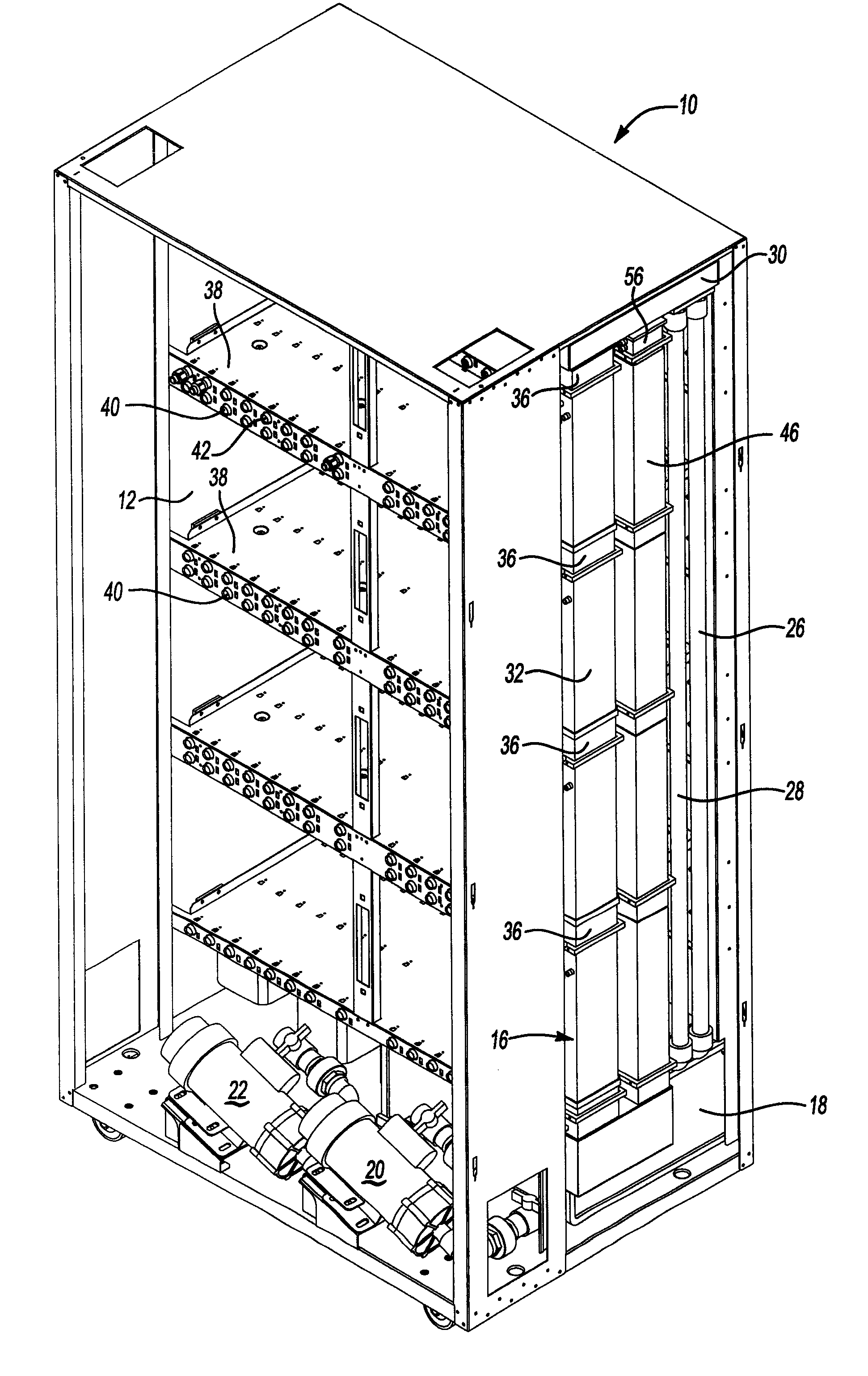

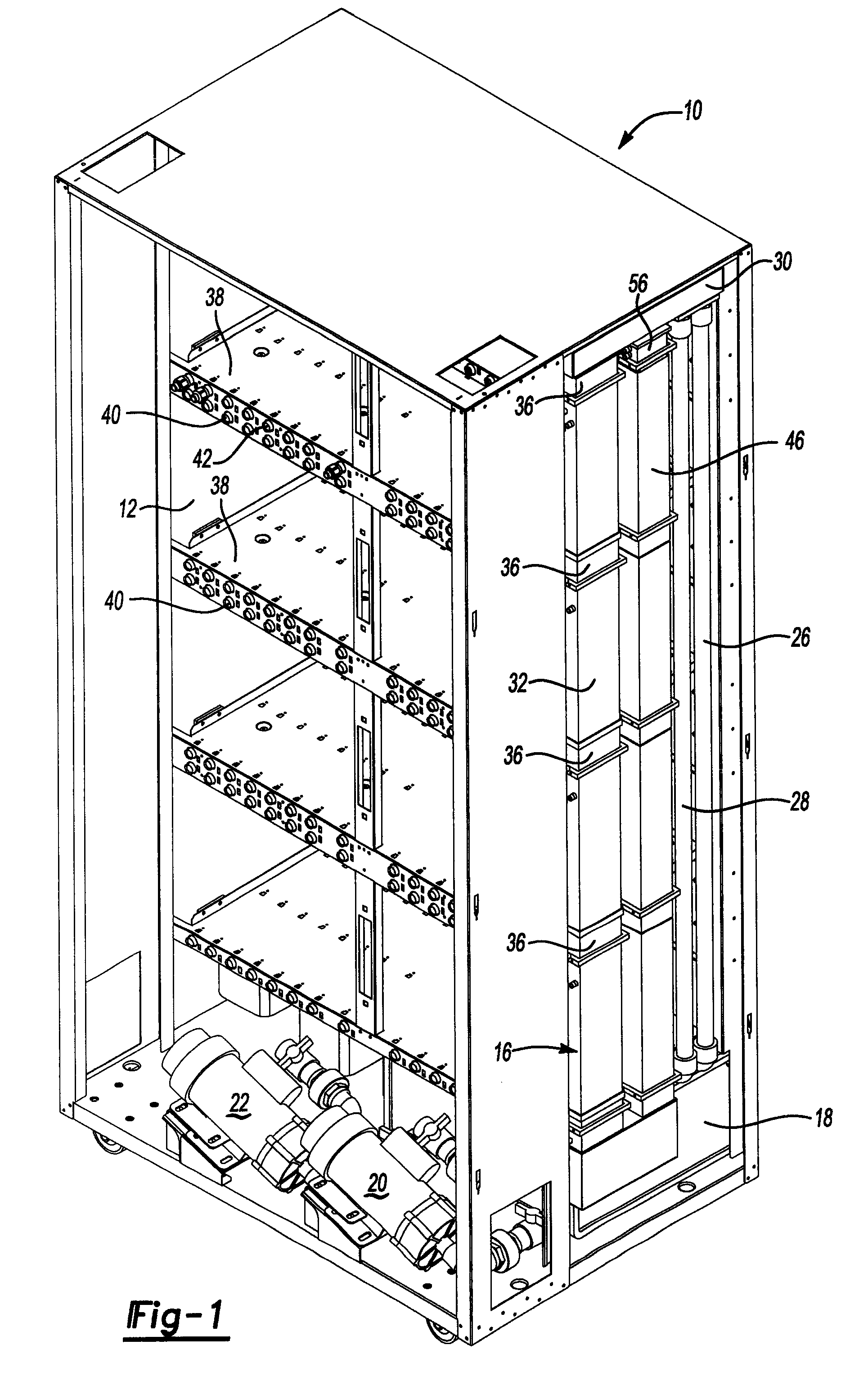

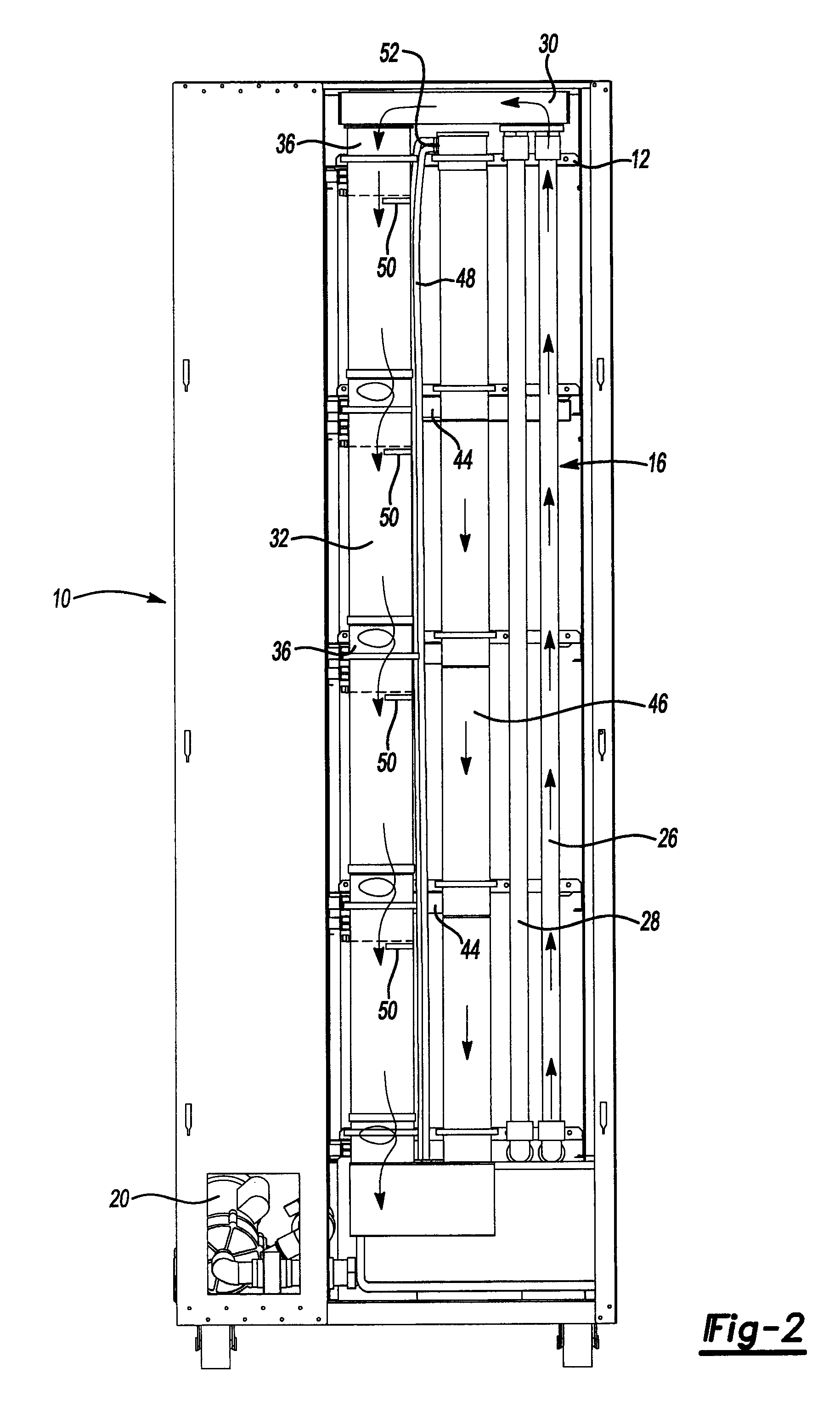

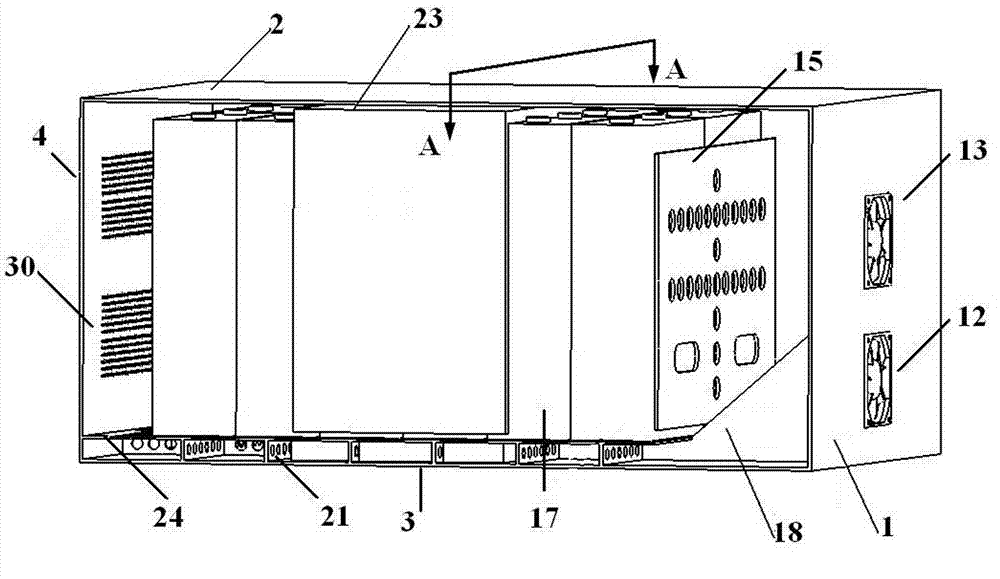

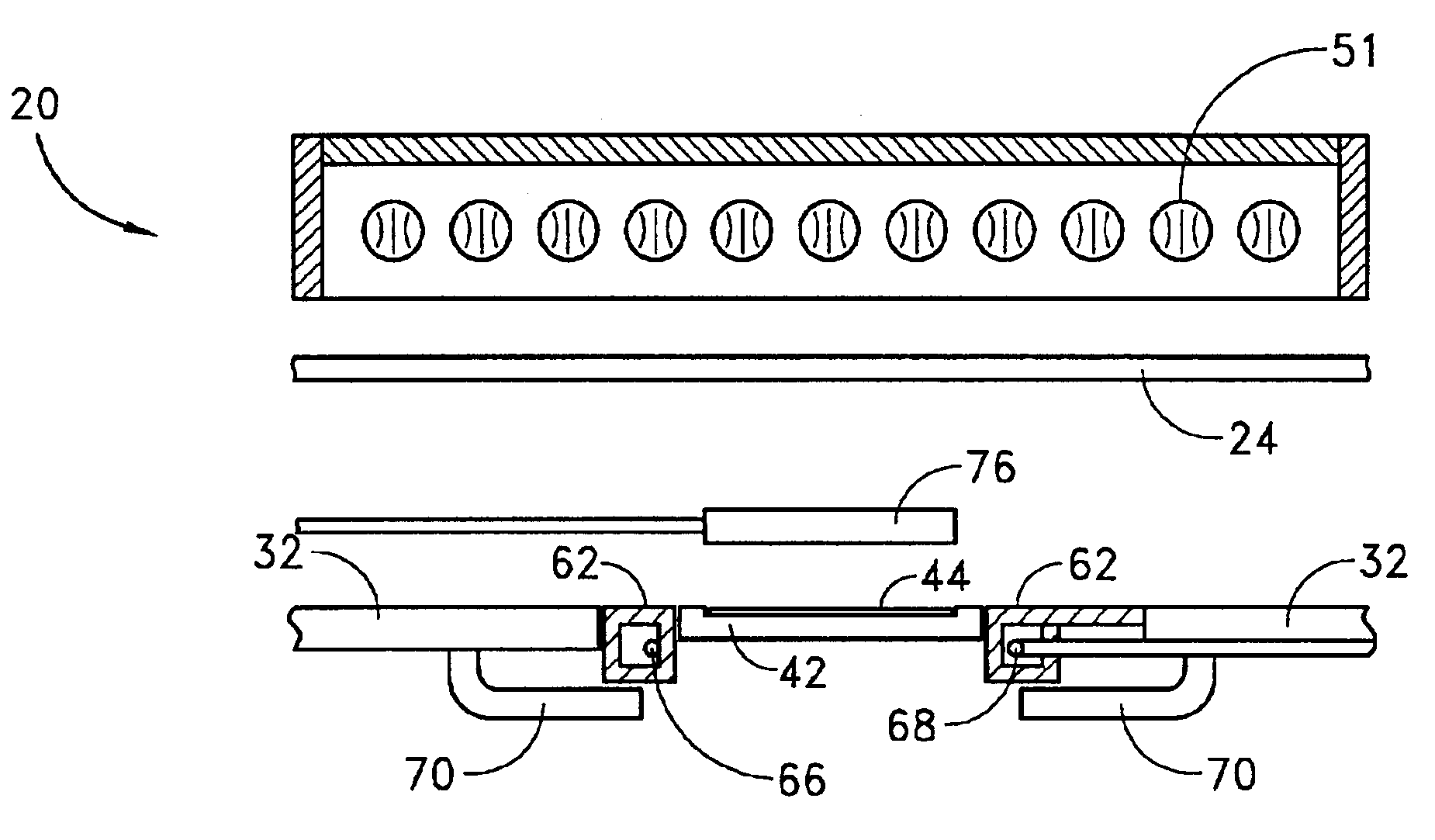

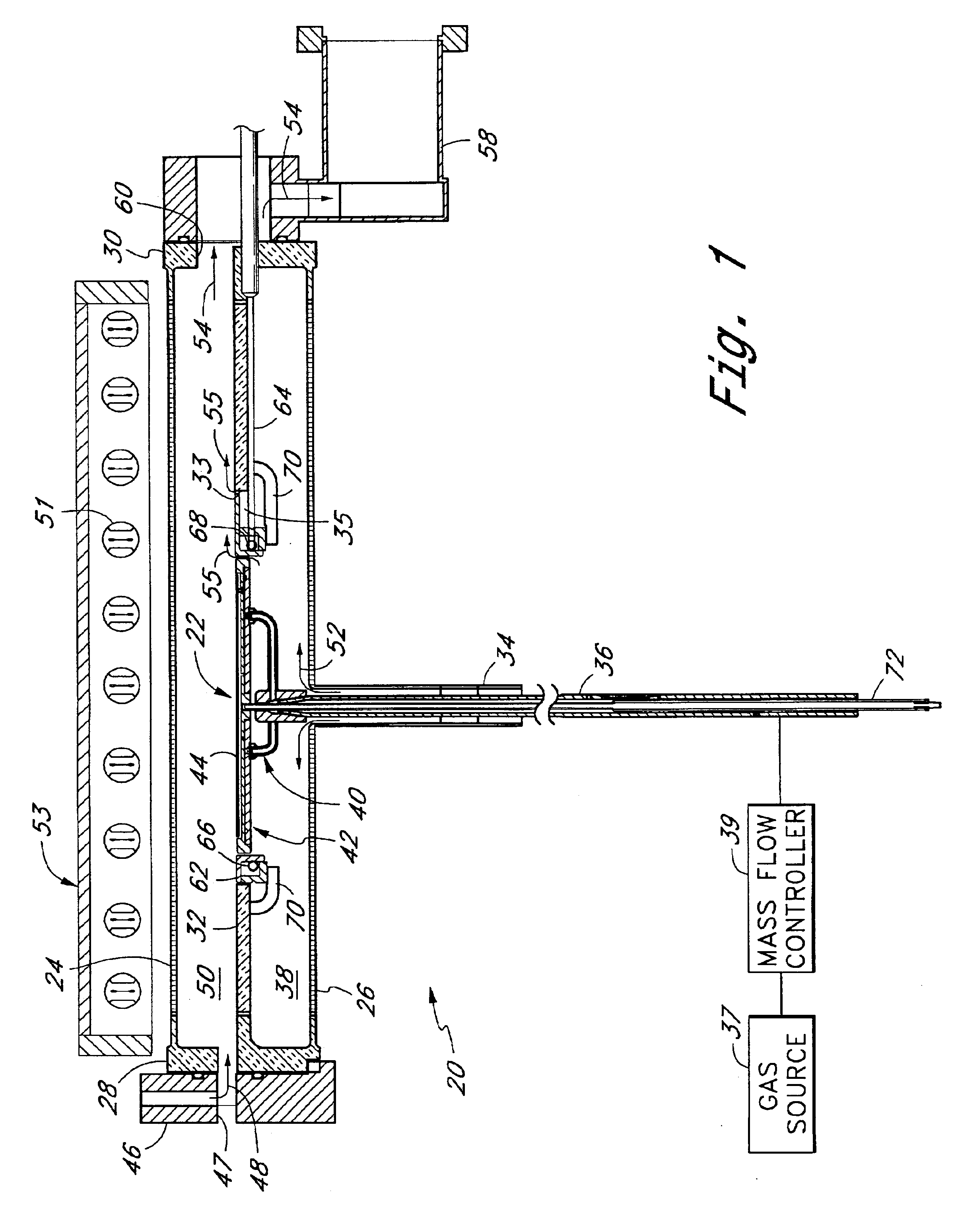

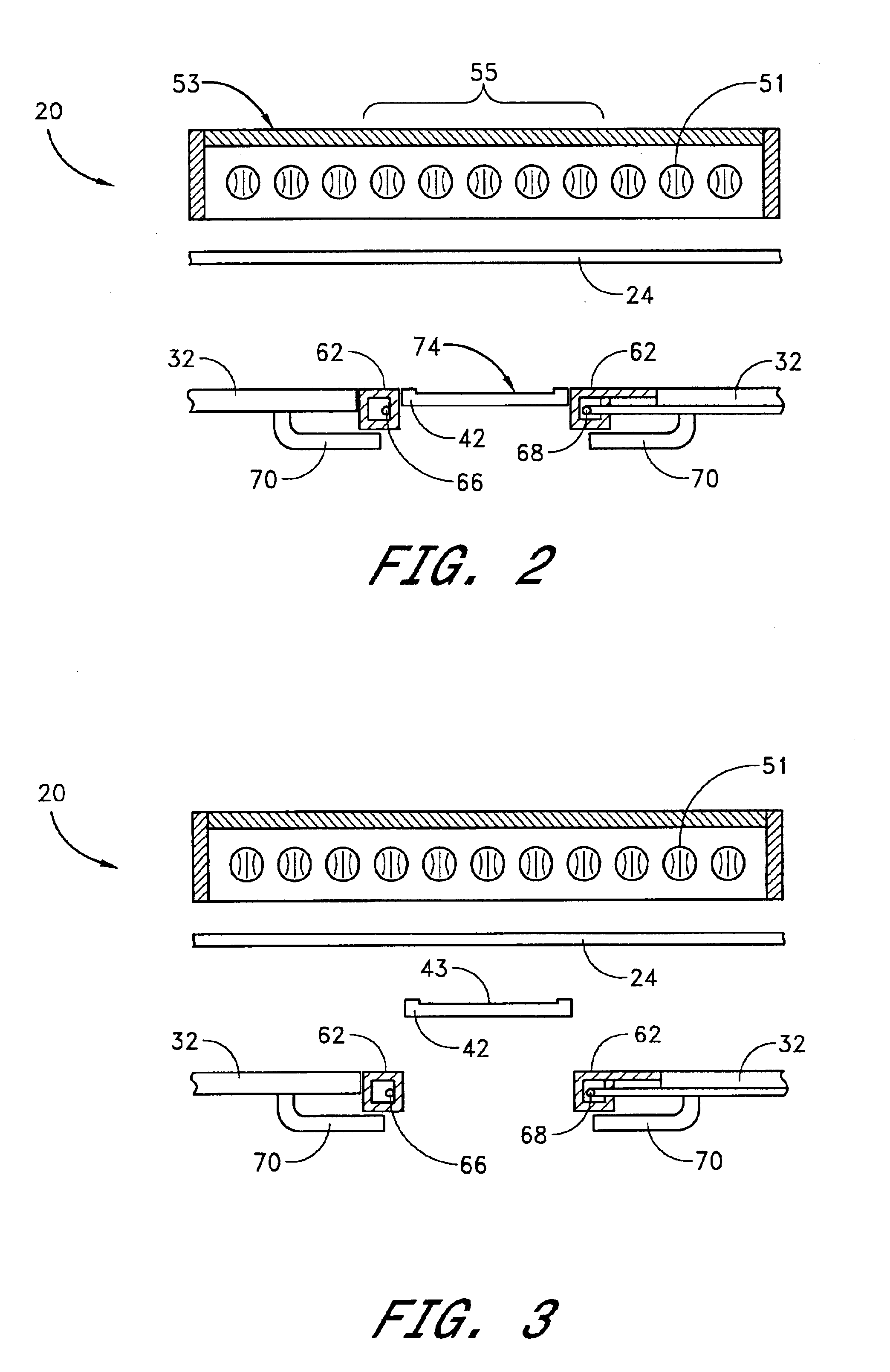

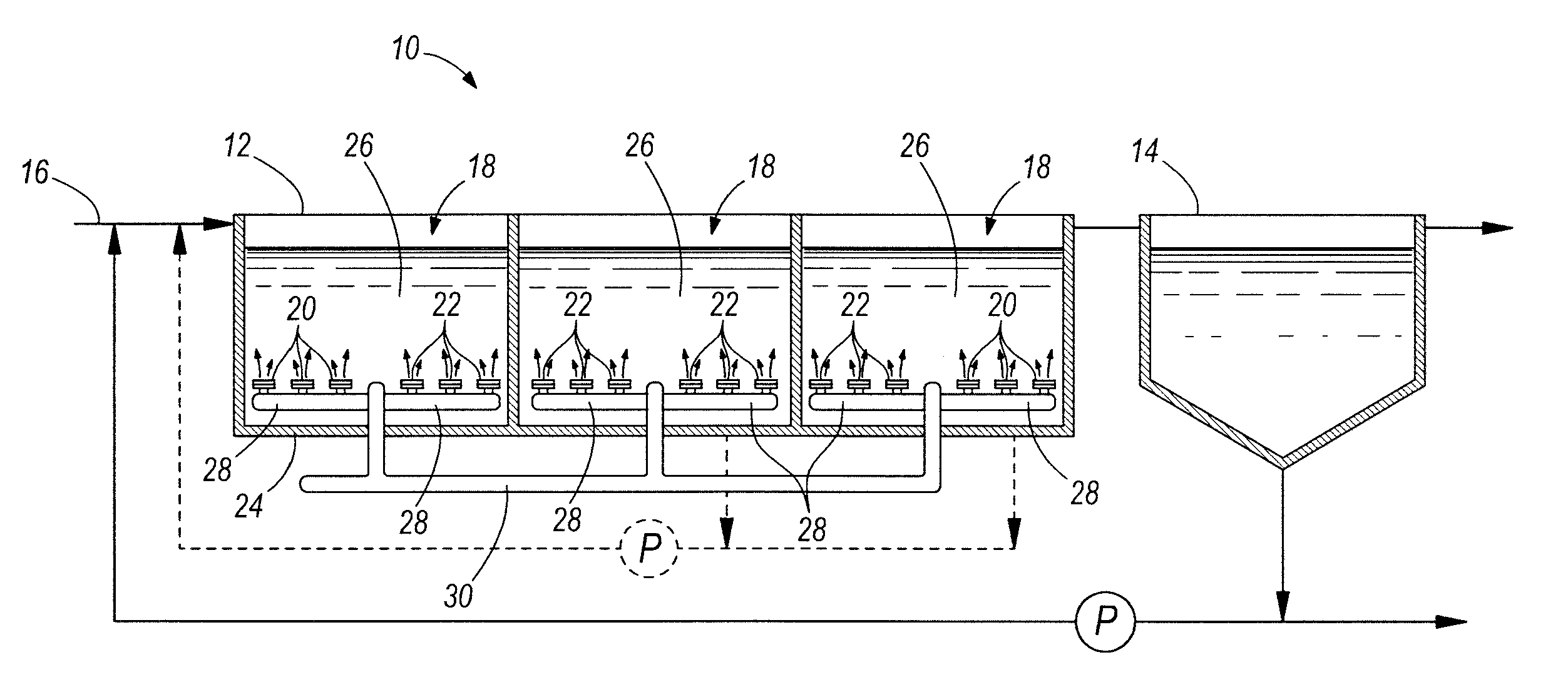

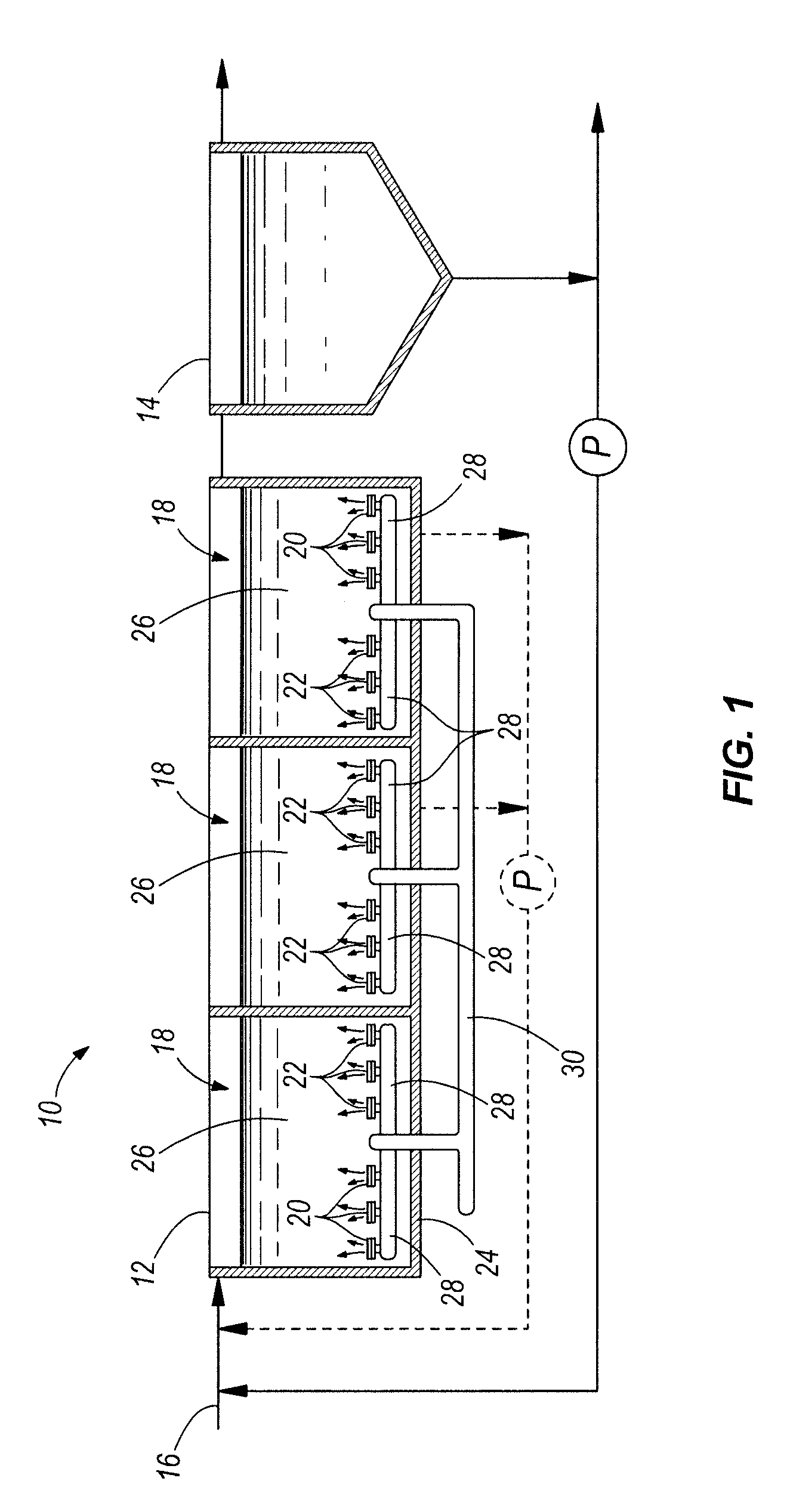

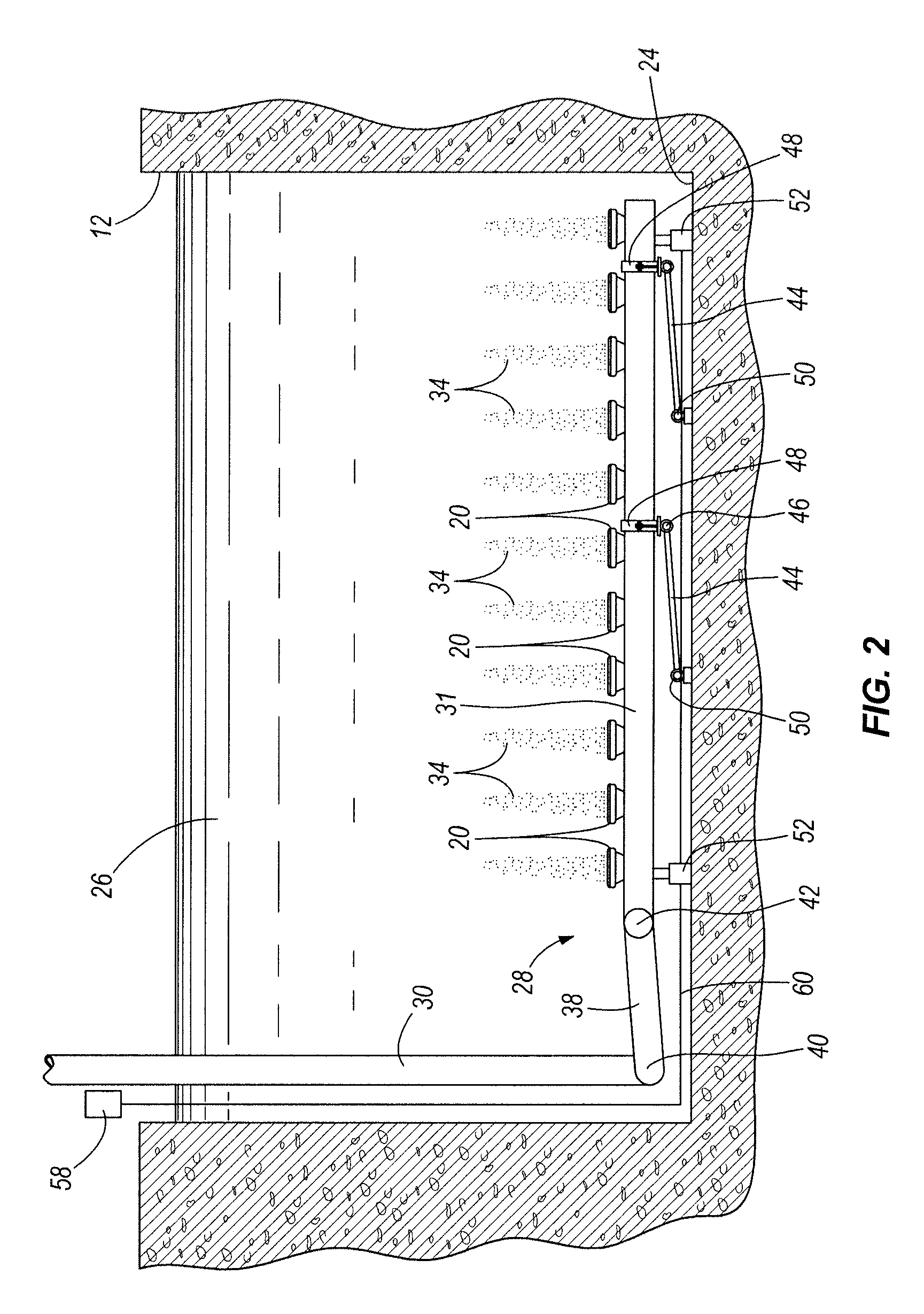

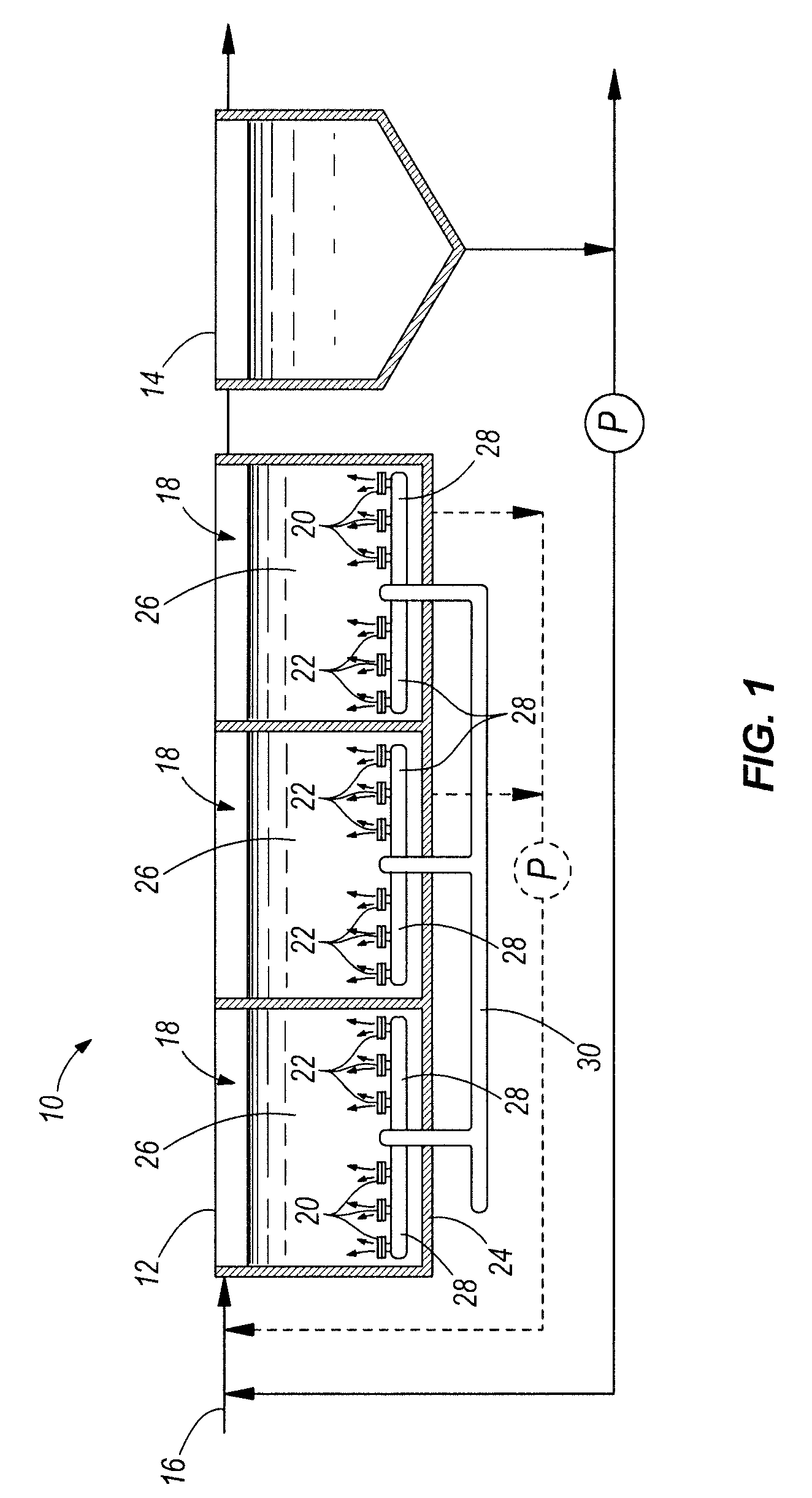

Method and apparatus for liquid cooling computer equipment

ActiveUS8035972B2Prevent leakageMore reliableDigital data processing detailsIndirect heat exchangersEngineeringAtmospheric pressure

A cooling system for cooling computer component with a liquid provided at atmospheric pressure, or low pressure, that flows through channel defined in the computer component. The liquid is pumped from a reservoir to a discharge port, or weir, that is located above the computer component. The liquid flows through an in-feed manifold to diverters that direct the liquid into in-feed tanks located above a row of the computer component. The liquid flows through the channels and flow control orifices to a drain that returns the liquid to the reservoir.

Owner:ORACLE INT CORP

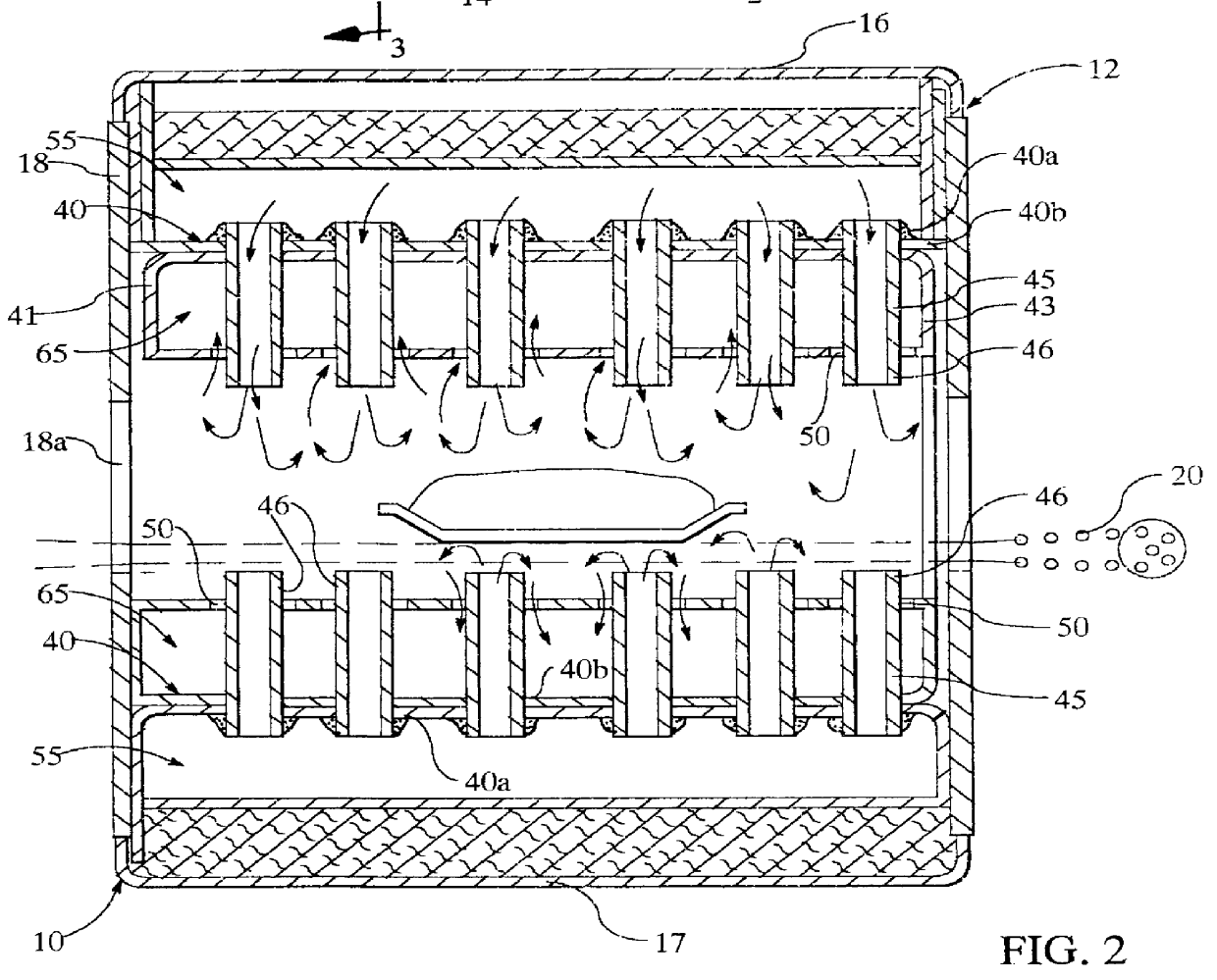

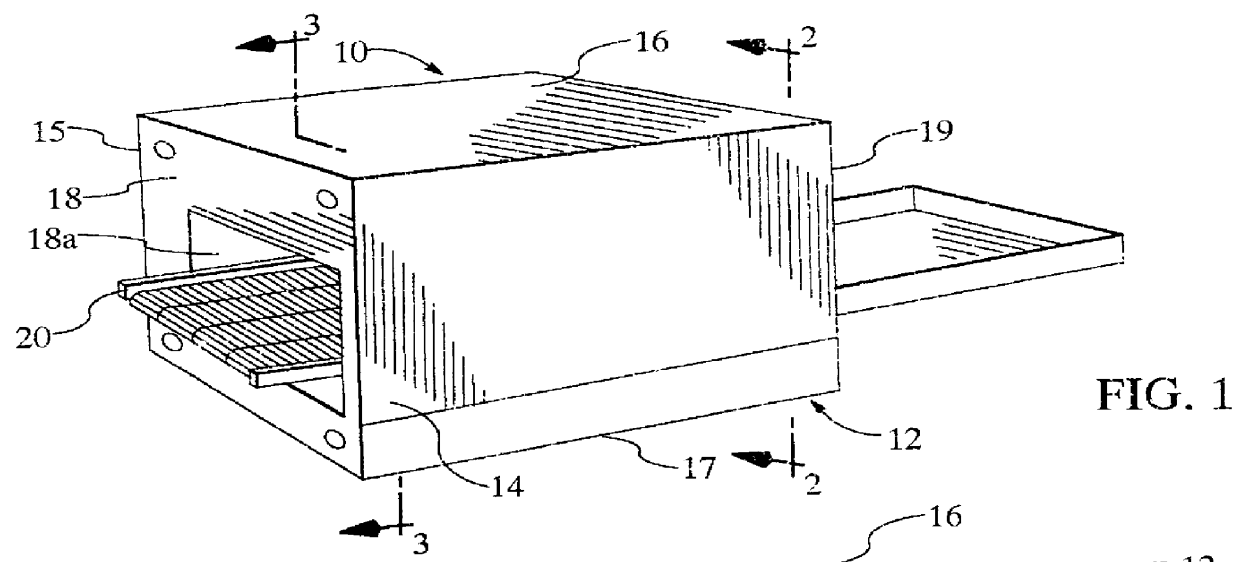

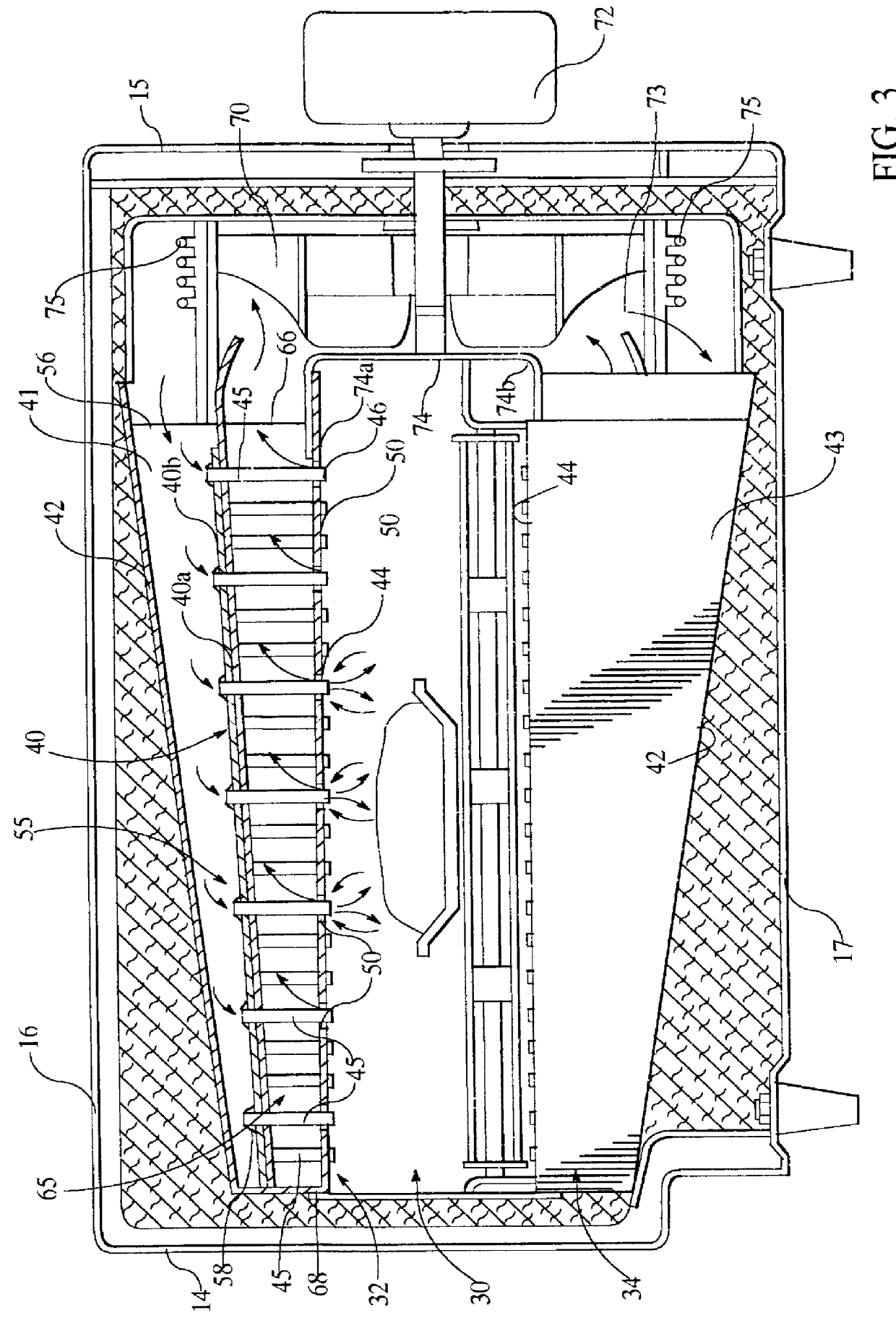

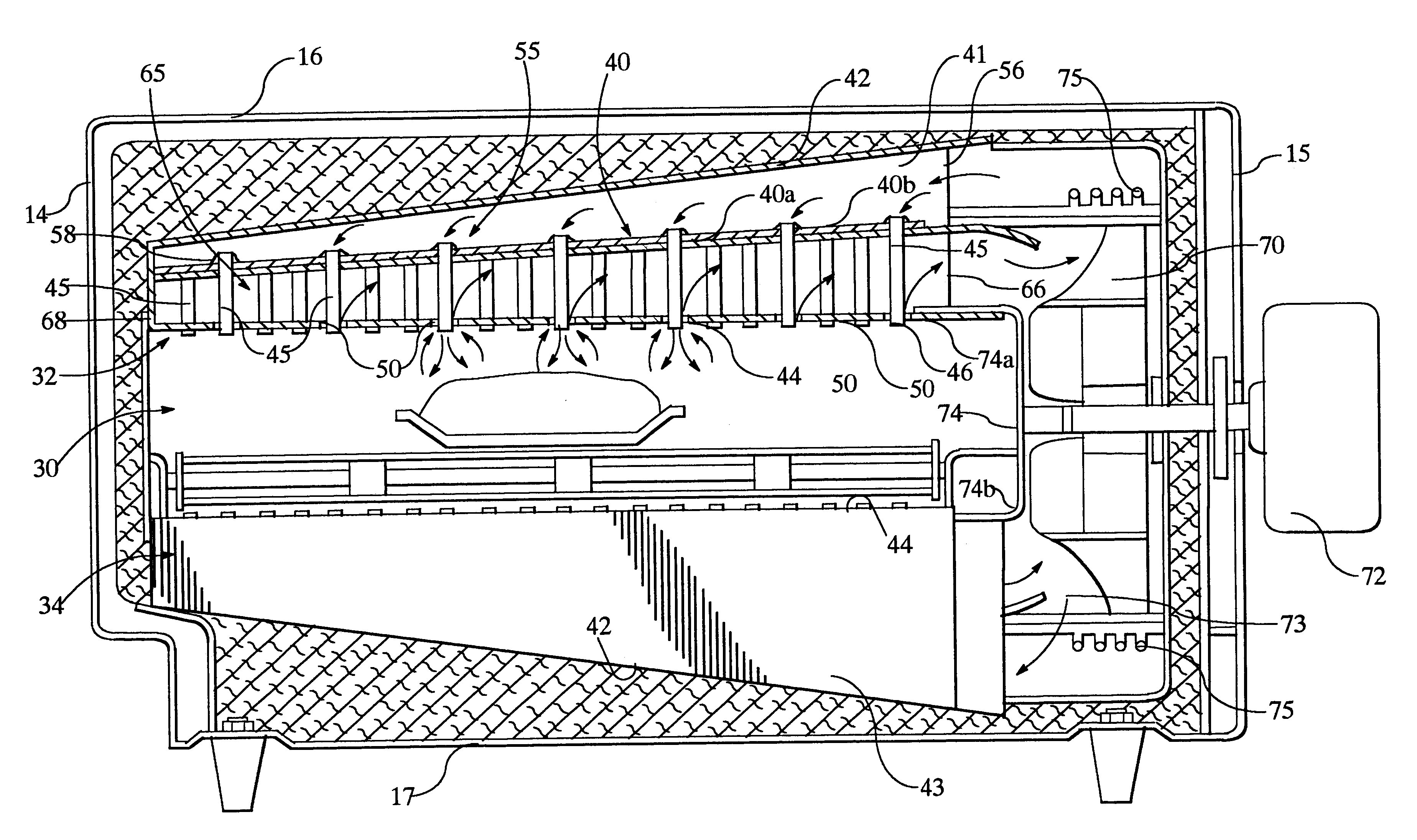

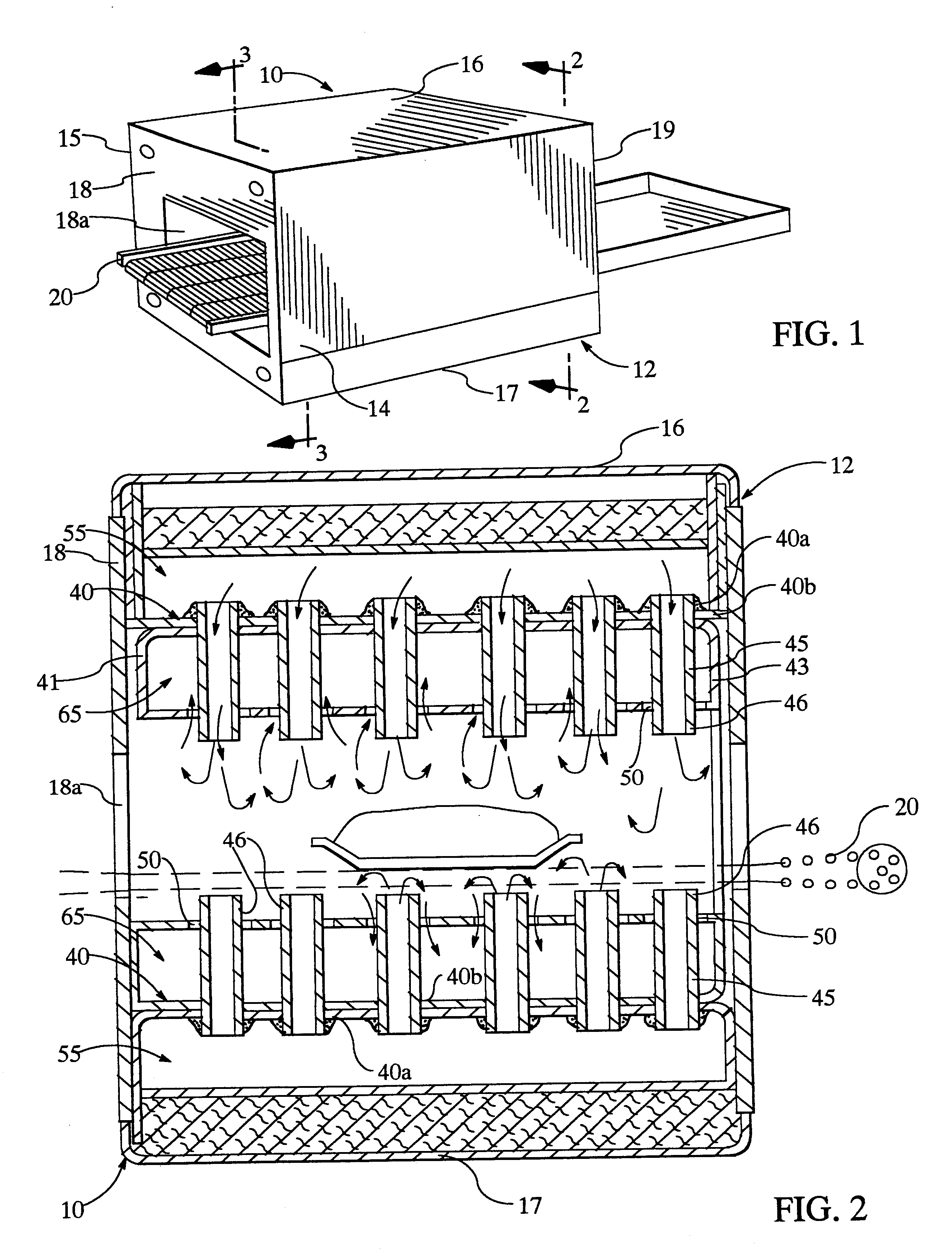

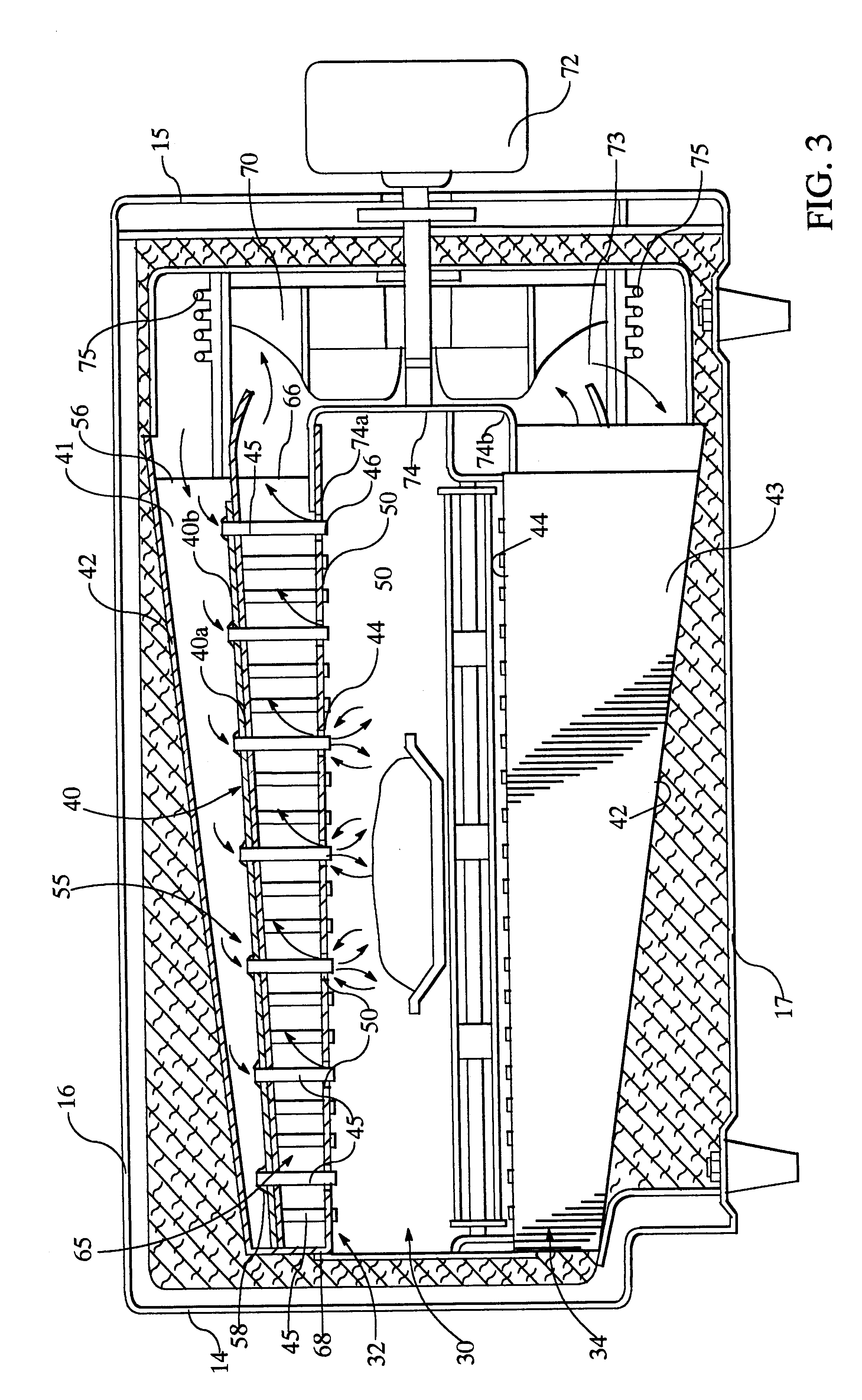

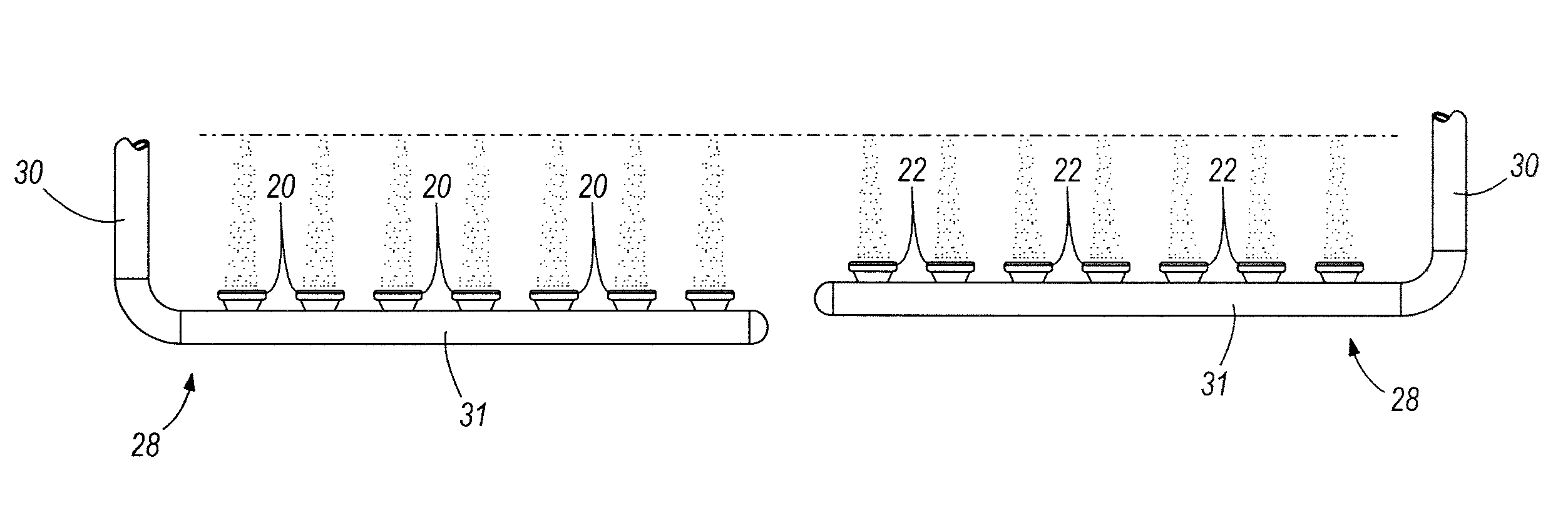

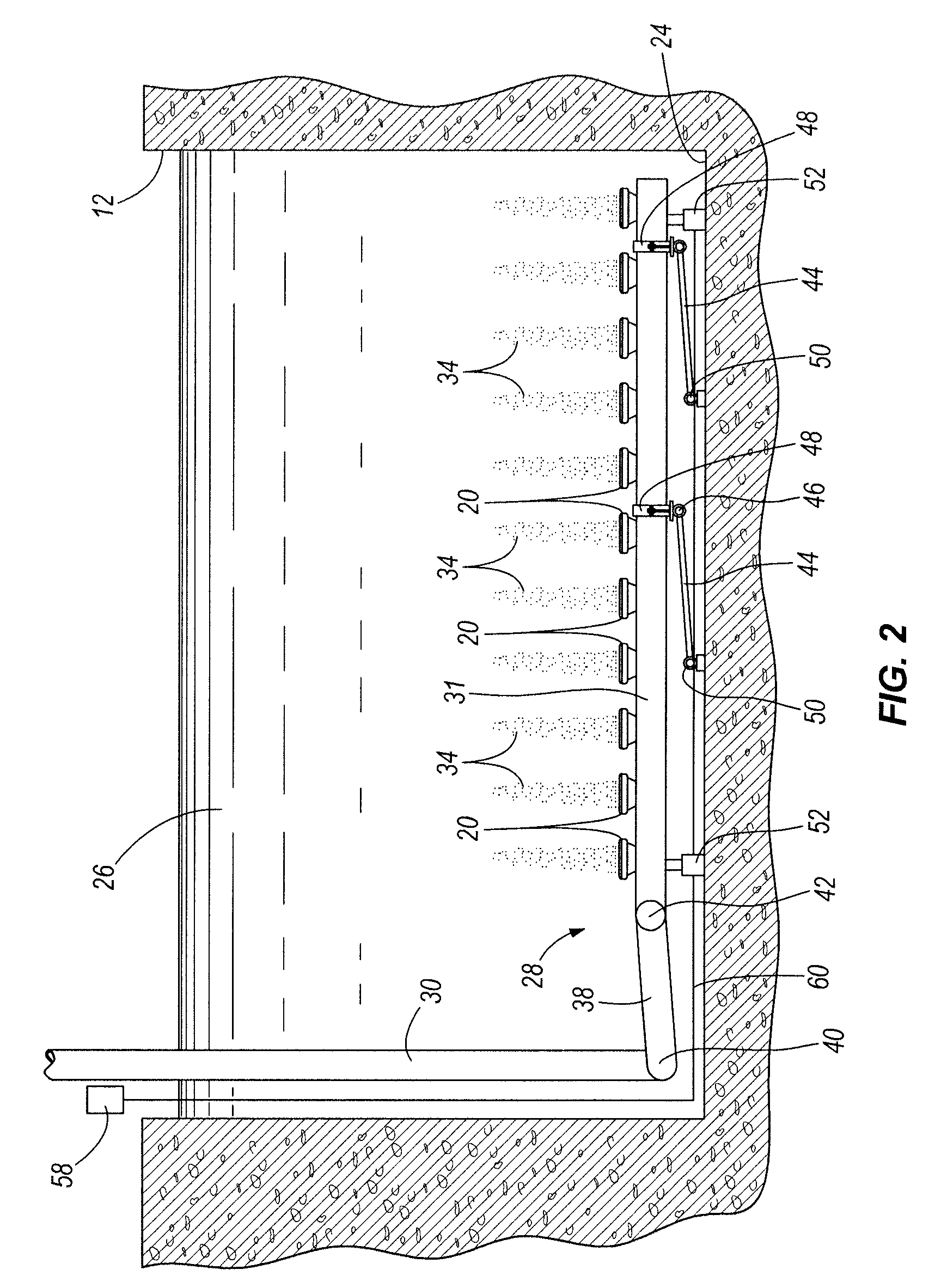

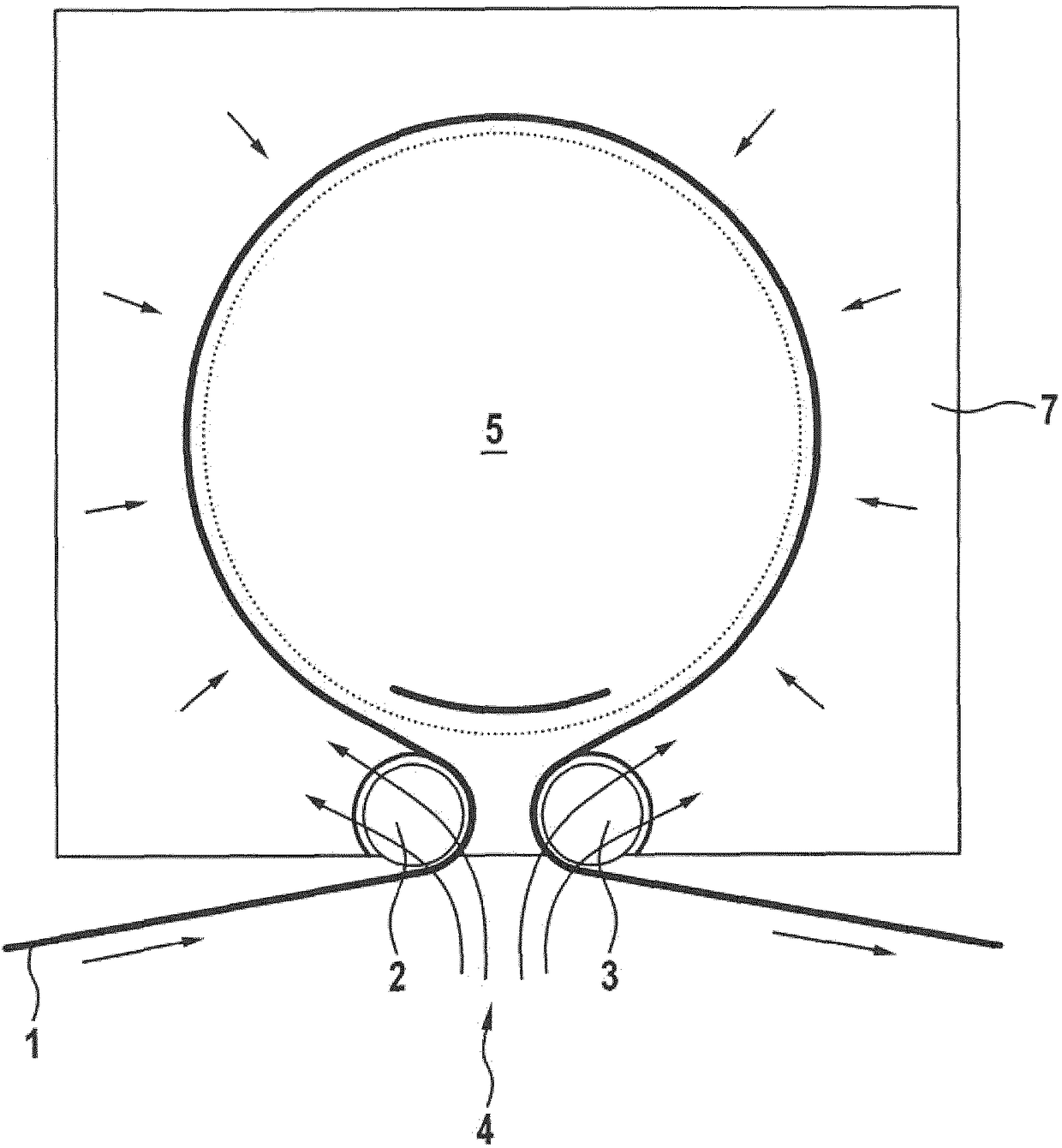

Concentric air delivery and return oven

InactiveUS6049066AFlow balanceDomestic stoves or rangesCooking fumes removalTemperature controlAir cycle

An impingement heat transfer device for transferring heat between a stream of temperature controlled air and a product wherein an air supply duct and an air return duct have a common wall. A tube has one end communicating with the inside of the air supply duct and another end extending through an opening in the air return duct. Air is circulated to reduce pressure in the air return duct and increase pressure in the air supply duct such that a stream of air flows through and out of the tube and spent air is drawn through the opening encircling the tube into the air return duct.

Owner:WILSON W ROBERT

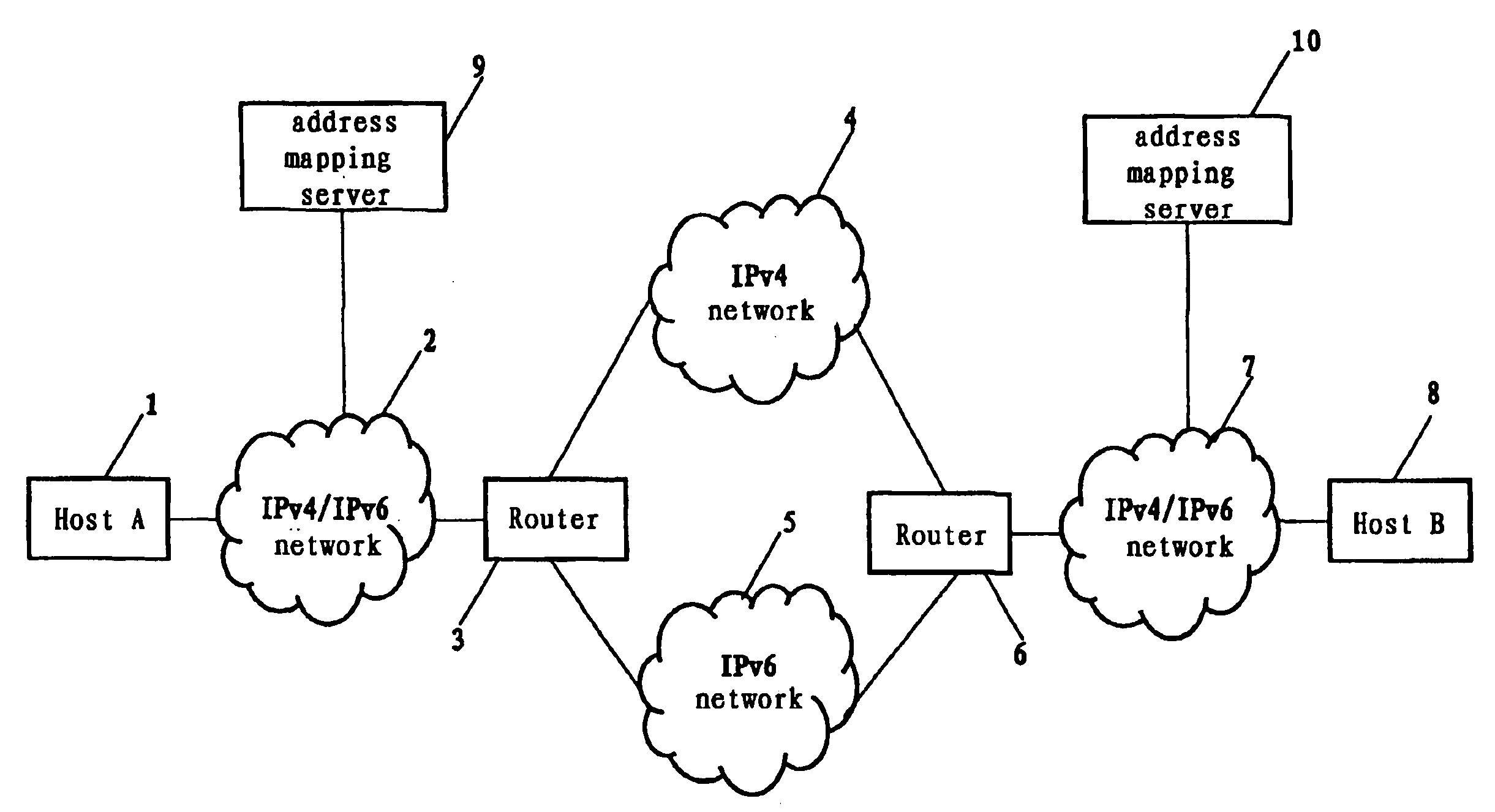

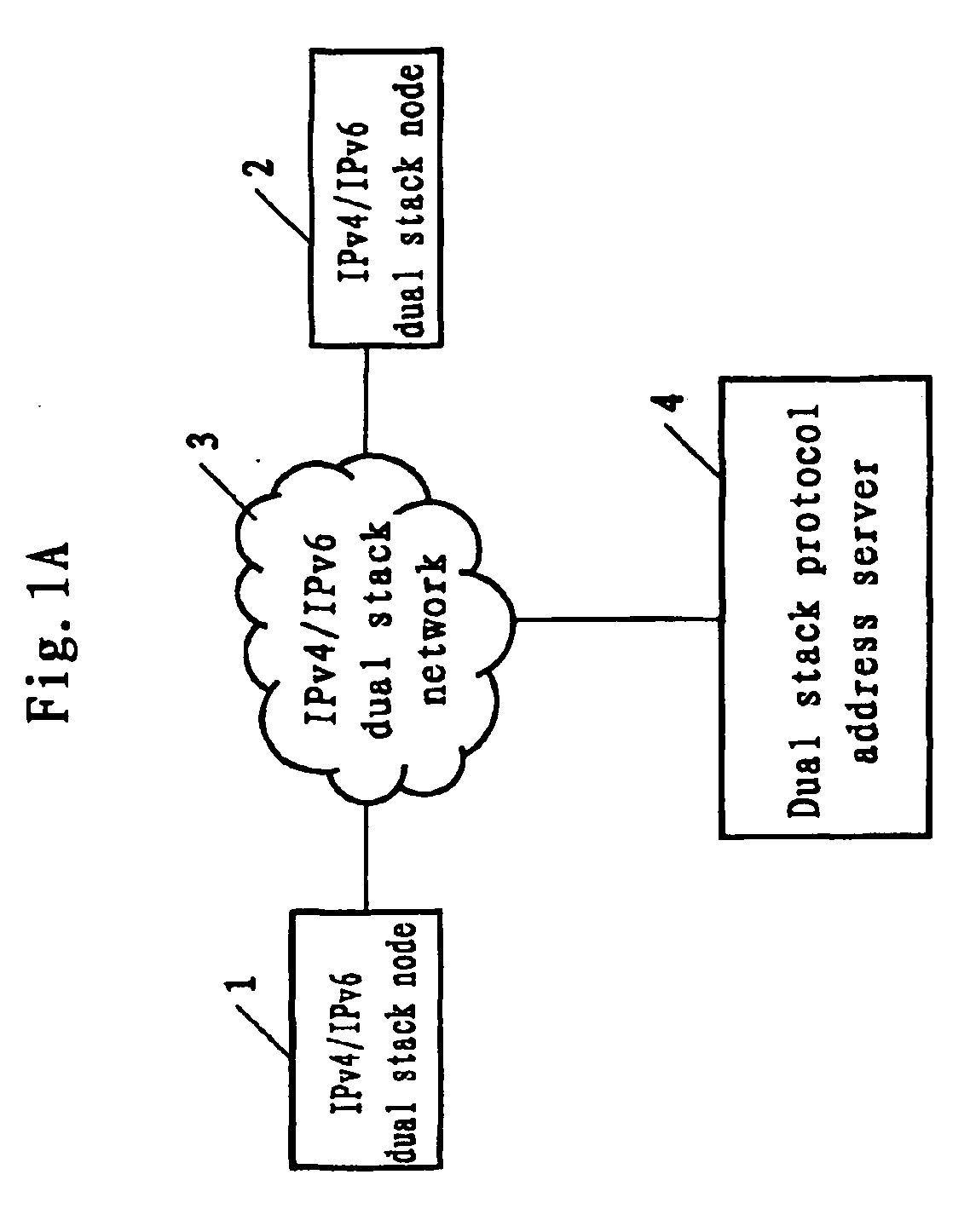

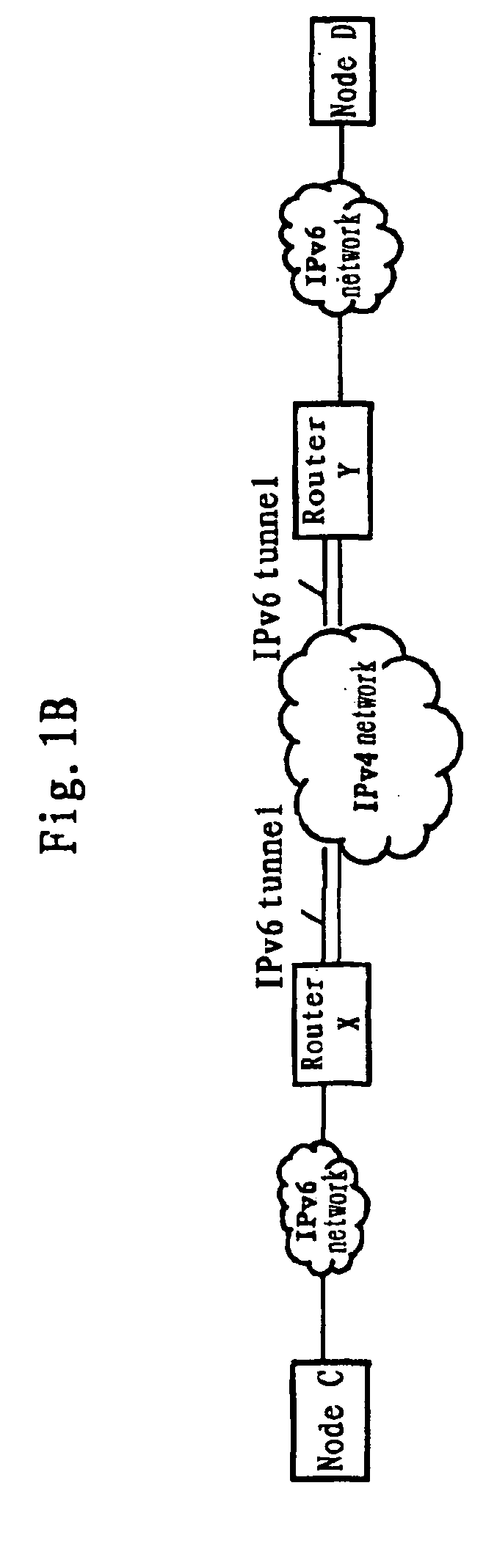

Network system, traffic balancing method, network monitoring device and host

ActiveUS20080273461A1Traffic controlControl balanceError preventionTransmission systemsTraffic capacityIp address

A traffic balancing system, traffic balancing device and traffic balancing method that converts IP packets by switching IP address of the destination host between the dual stack hosts communicating with each other, in order to control traffic balancing in the networks.

Owner:IBM CORP

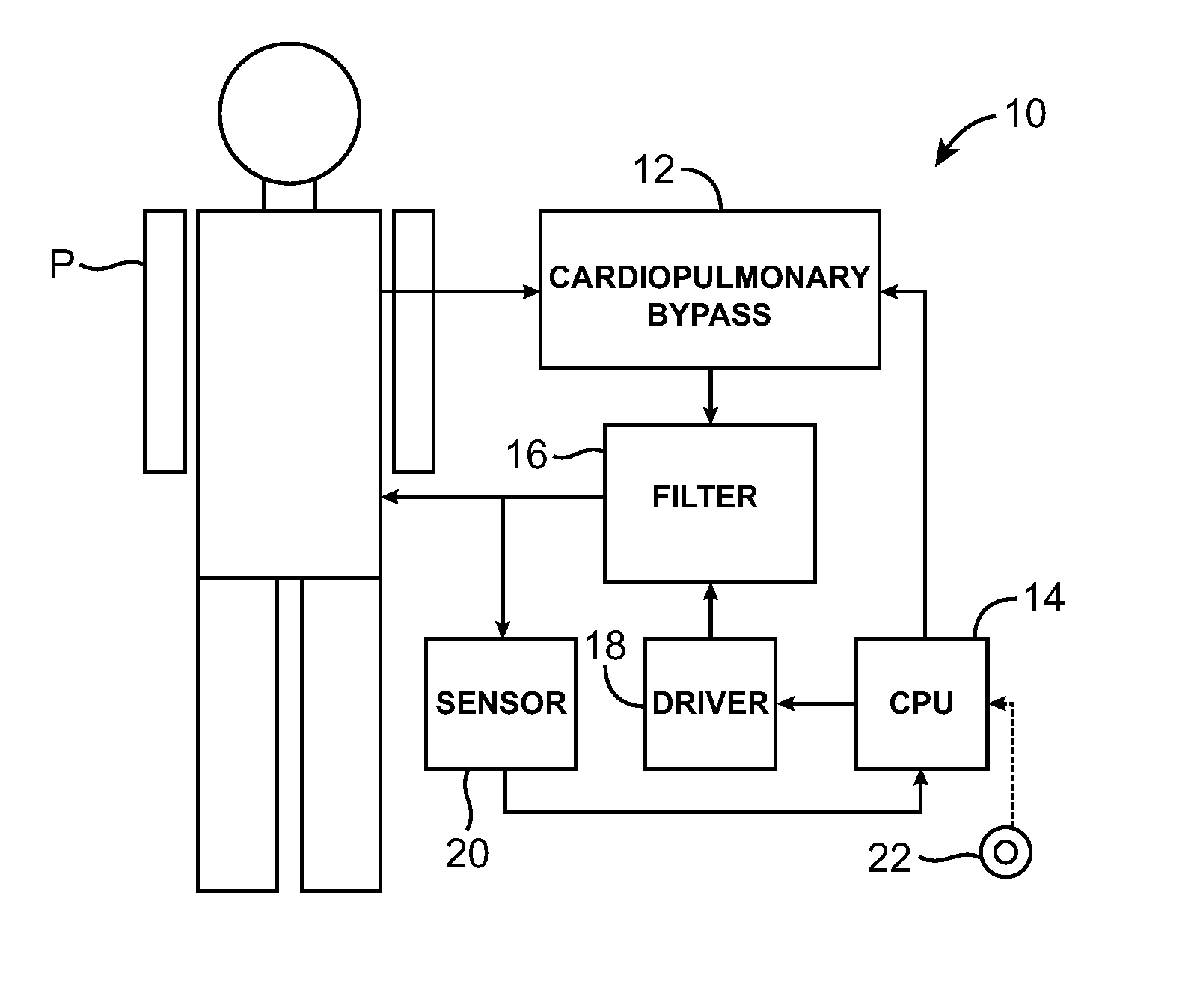

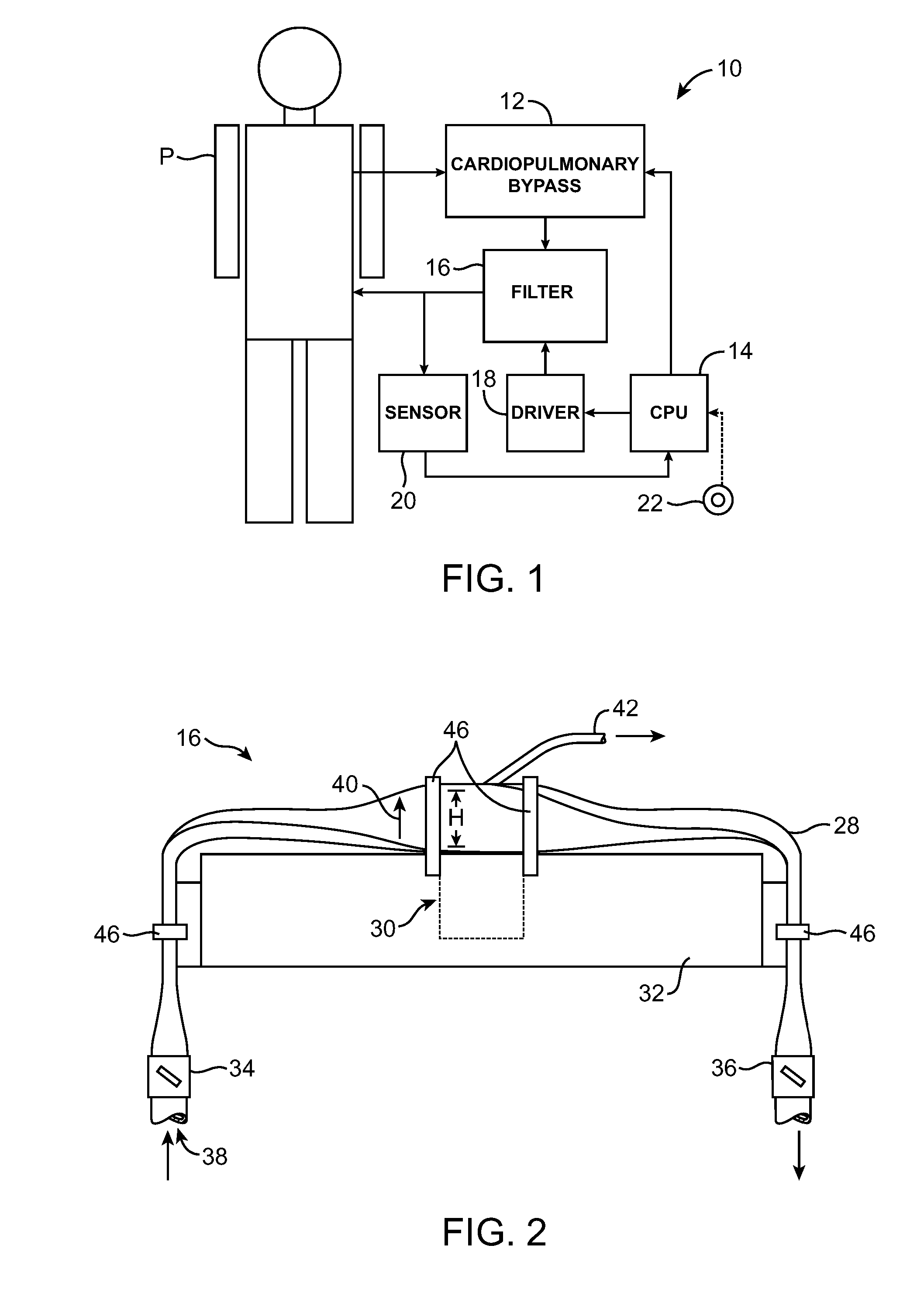

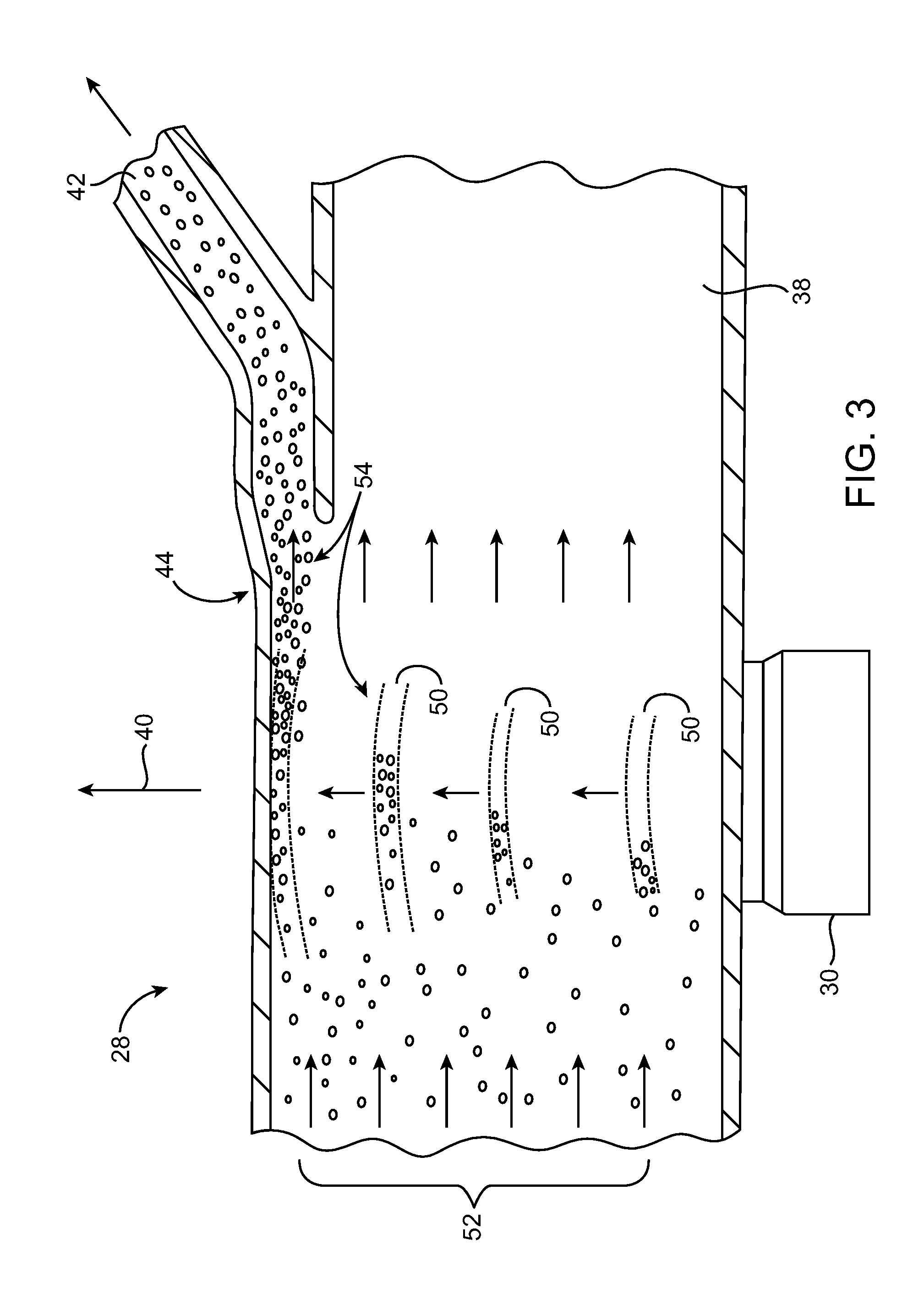

Ultrasonic Material Removal System for Cardiopulmonary Bypass and Other Applications

InactiveUS20070045188A1Easy to sterilizeFlow balanceSemi-permeable membranesLiquid degasificationExtracorporeal circulationMaterial removal

Devices, systems, and methods manipulate target materials within fluids, and may be useful for removing microbubbles and other materials from blood. Ultrasound or acoustic filtering waves may be directed across a flow of blood, and differences in density between the target microbubbles and the blood may enhance separation by driving the lighter matter upward for removal from the blood stream. A disposable acoustically transmissive conduit can replaceably engage an ultrasound transmitter to facilitate sterilization. Exemplary conduits have elongate lumen cross-sections and an axial path resembling a portion of a Mobius strip.

Owner:CEEBEN SYST

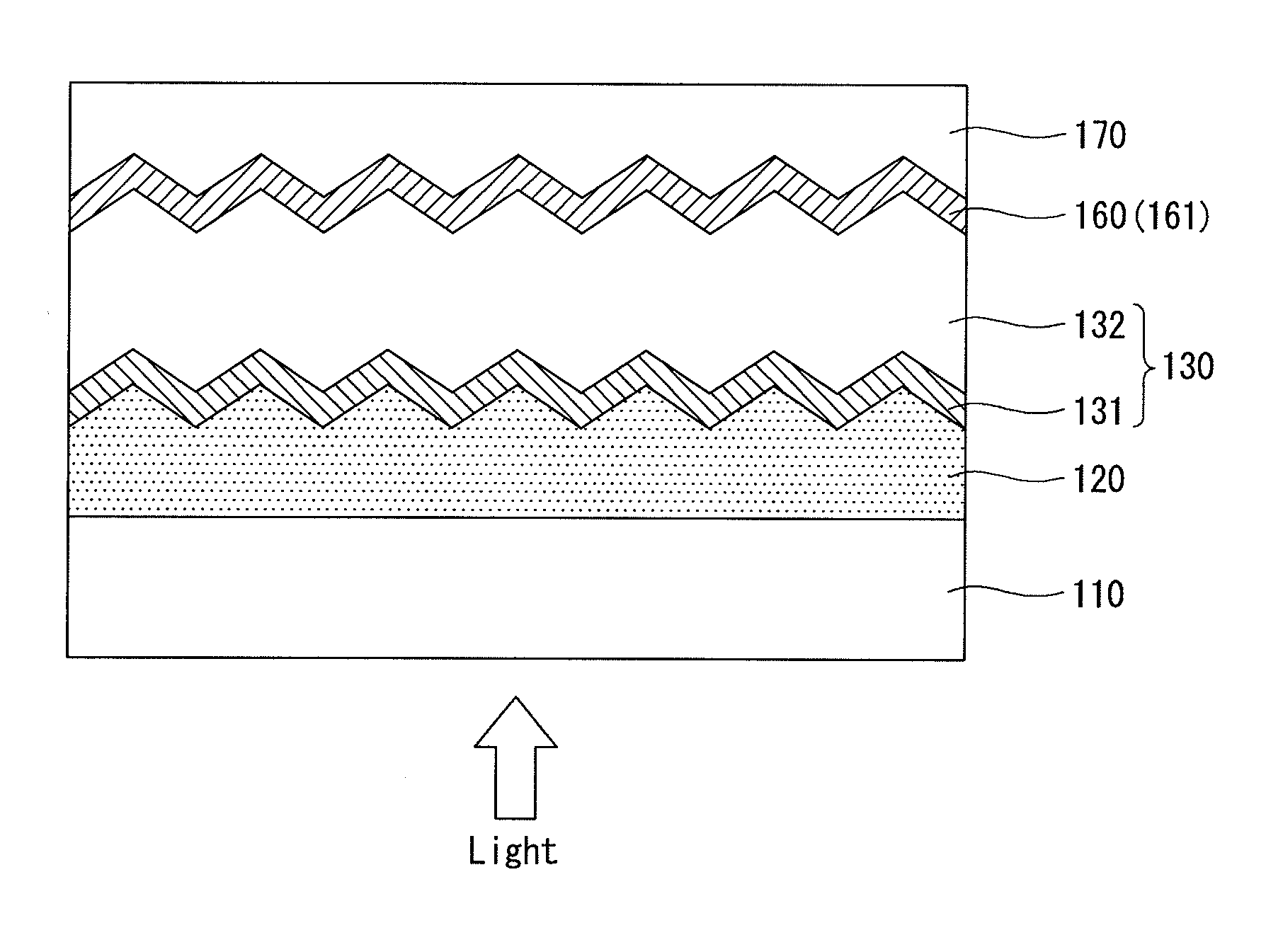

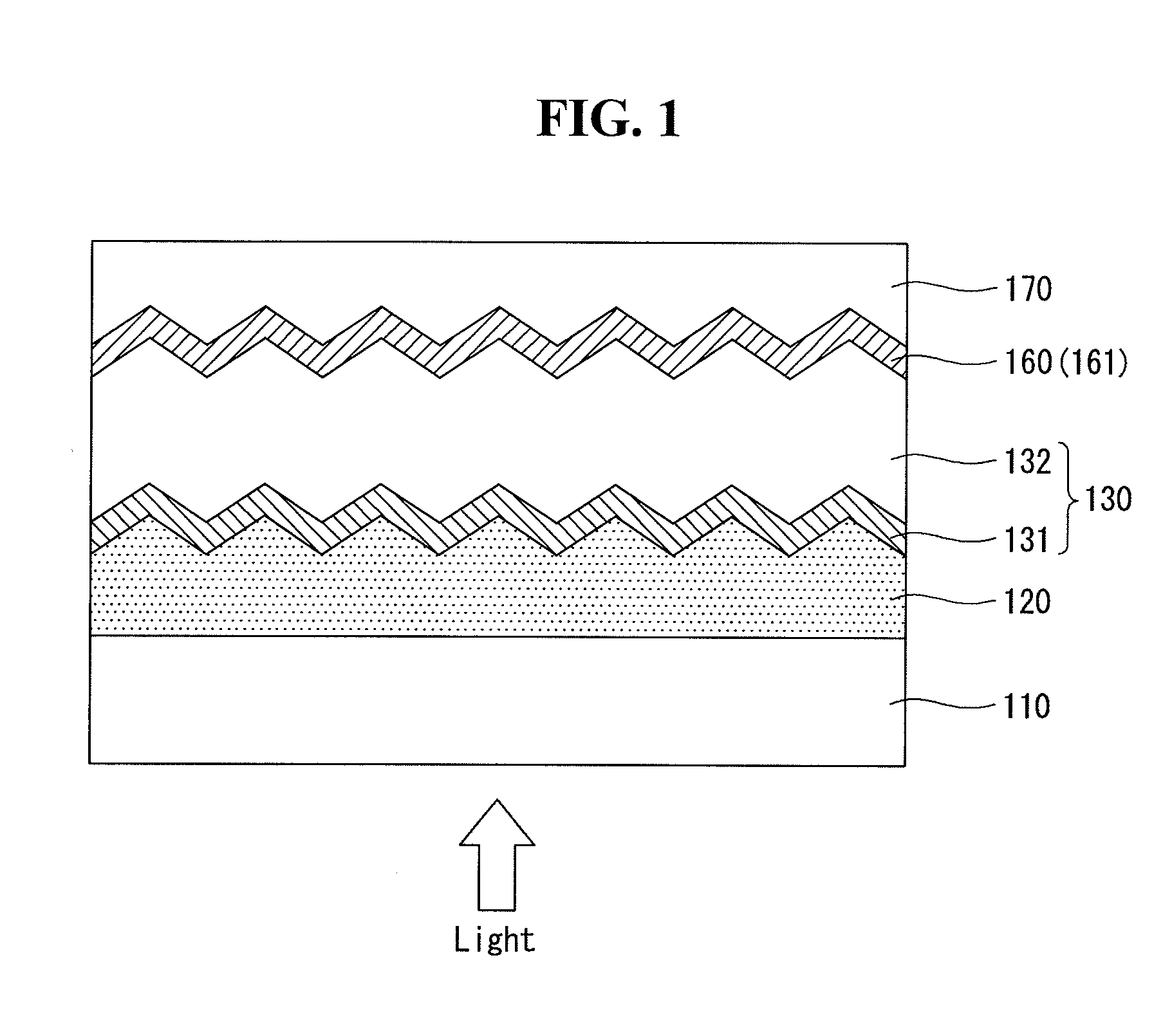

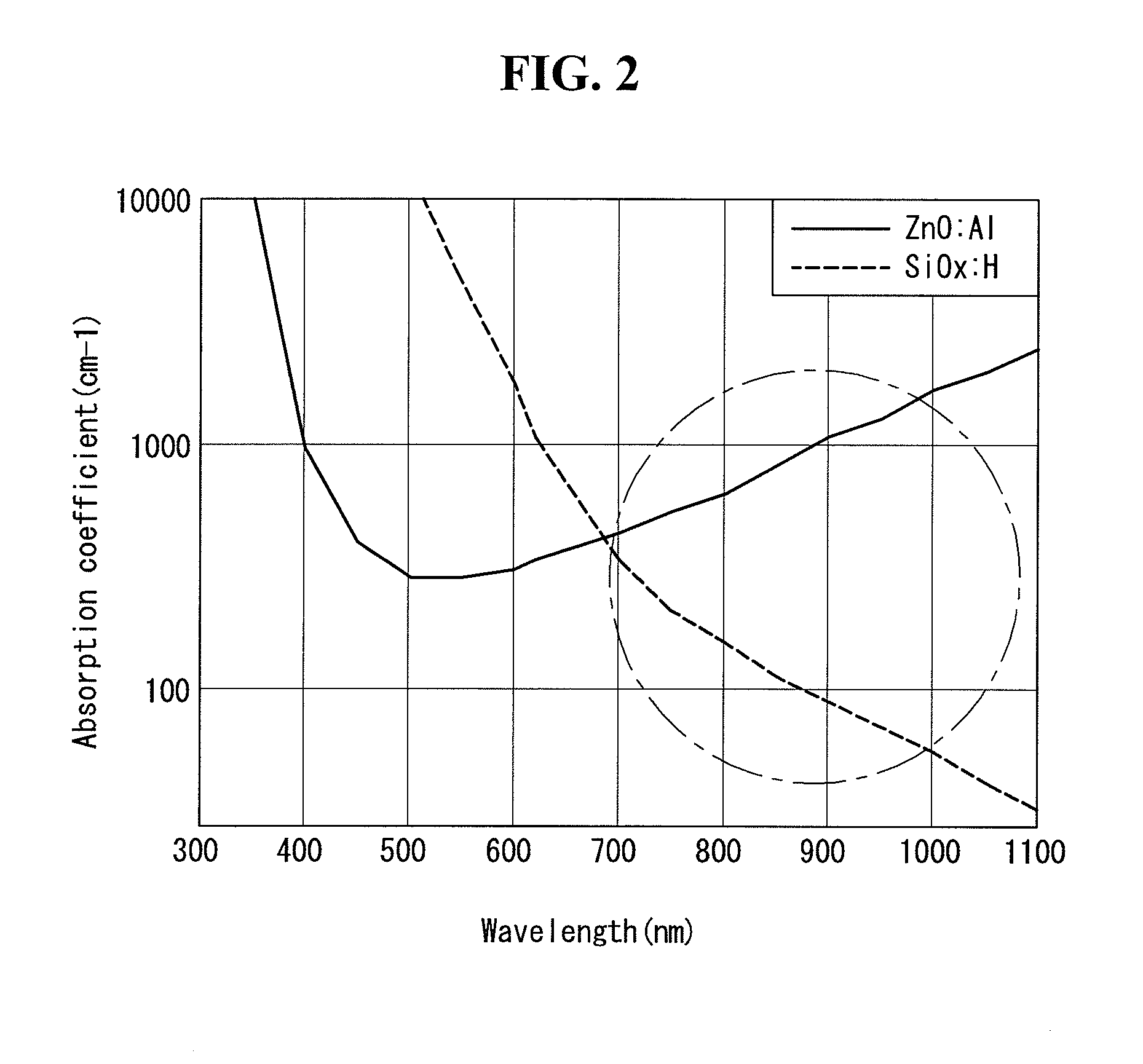

Thin film solar cell

InactiveUS20110180128A1Reduce currentEfficiently reflectedPhotovoltaic energy generationSemiconductor devicesPhotoelectric conversionReflective layer

A thin film solar cell is discussed. The thin film solar cell includes a substrate, a first photoelectric conversion unit positioned on the substrate, and a back reflection layer for reflecting back light transmitted by the first photoelectric conversion unit to the first photoelectric conversion unit. The first photoelectric conversion unit includes a first intrinsic layer for light absorption. The back reflection layer includes a first back reflection layer doped with n-type or p-type impurities, and the first back reflection layer directly contacts the first intrinsic layer of the first photoelectric conversion unit.

Owner:LG ELECTRONICS INC

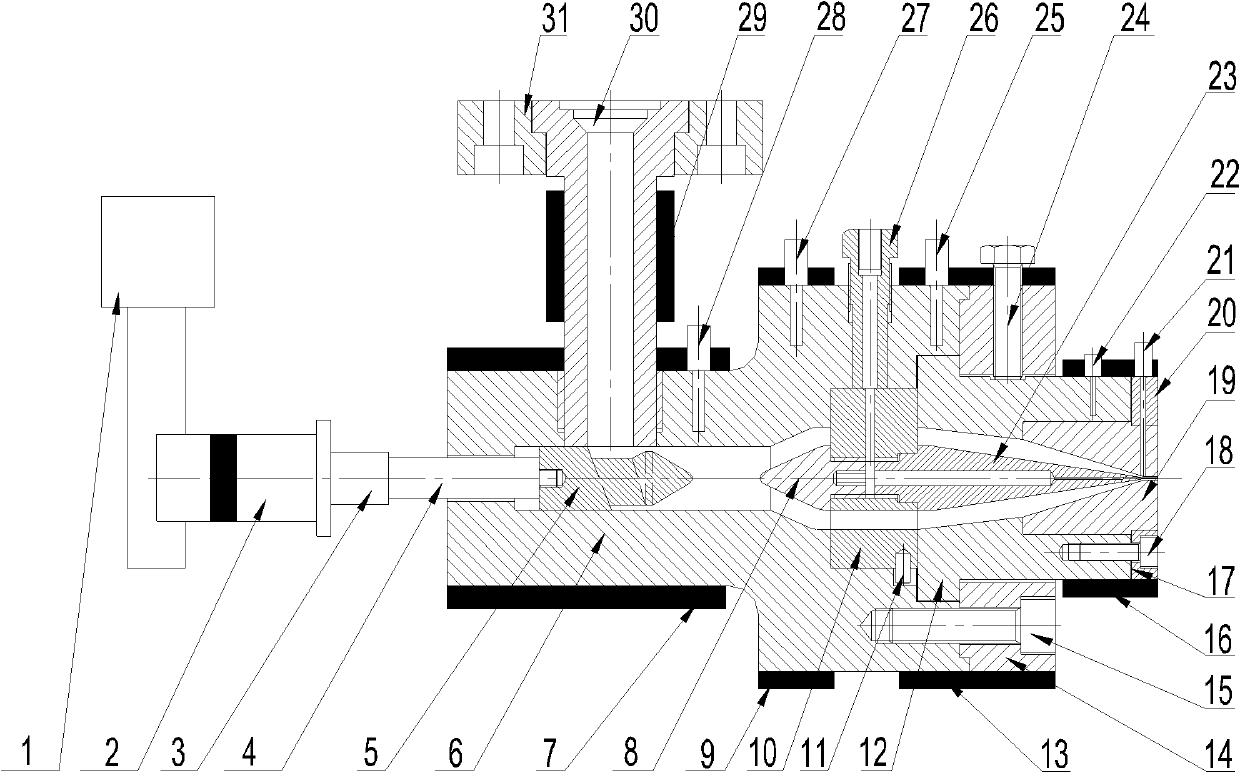

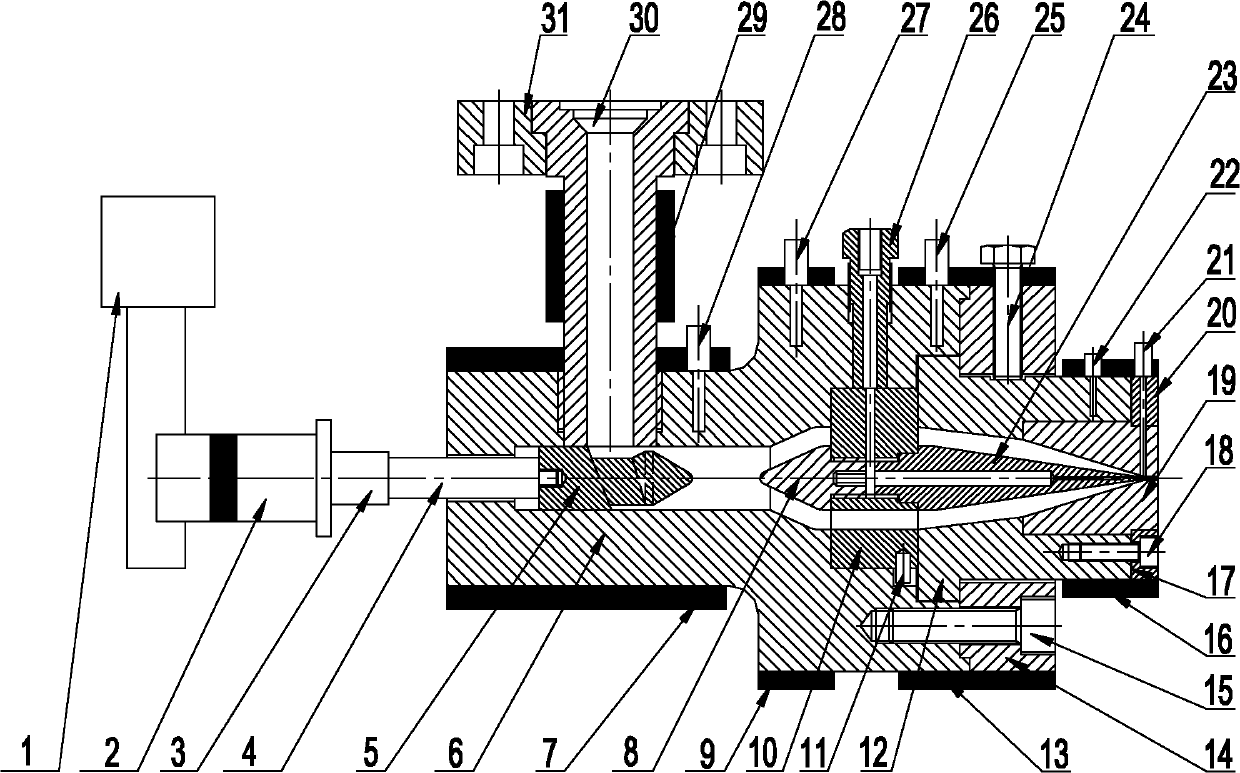

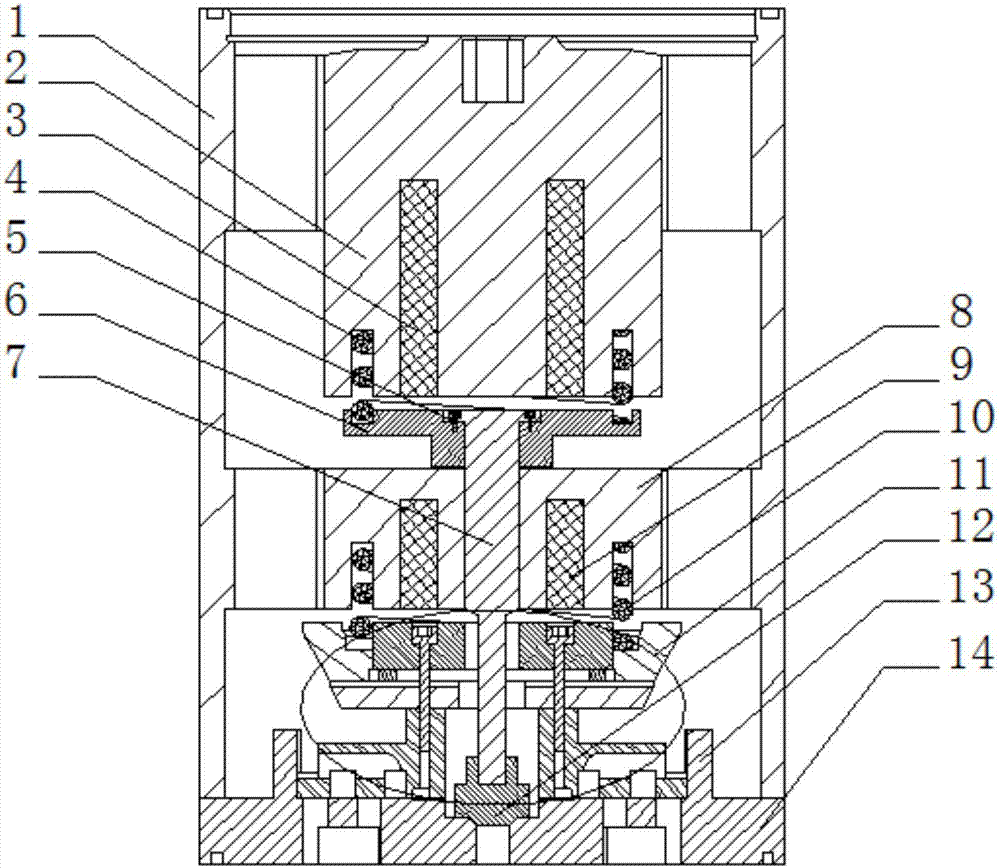

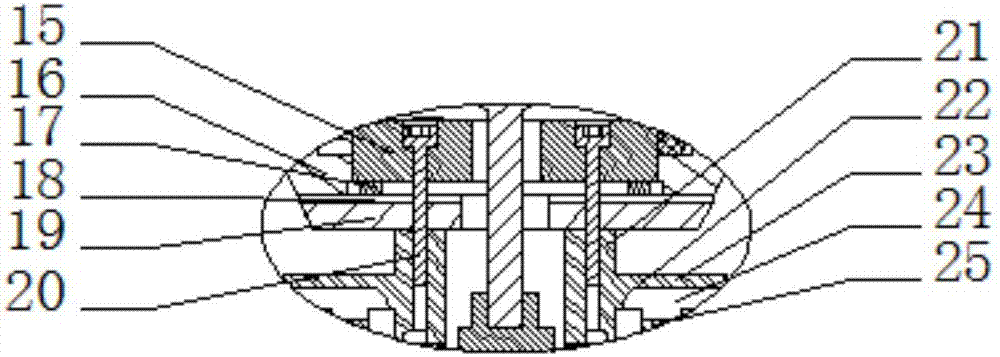

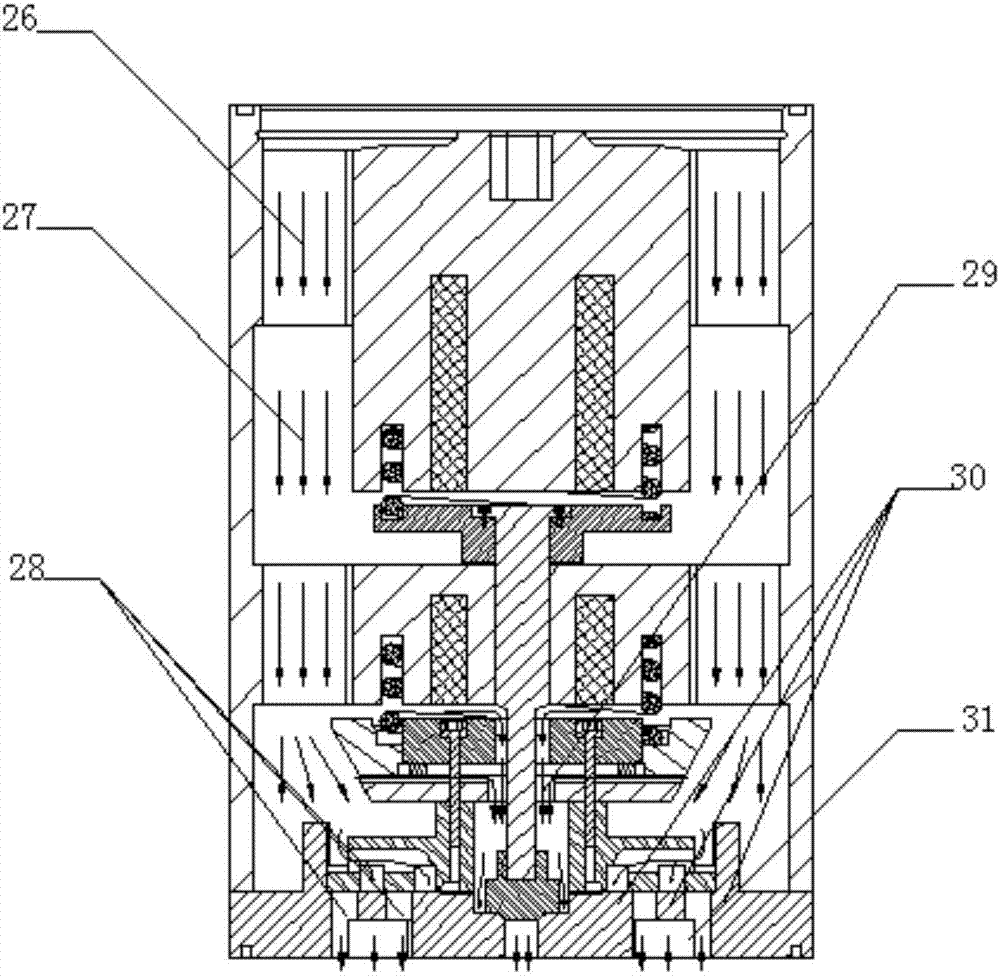

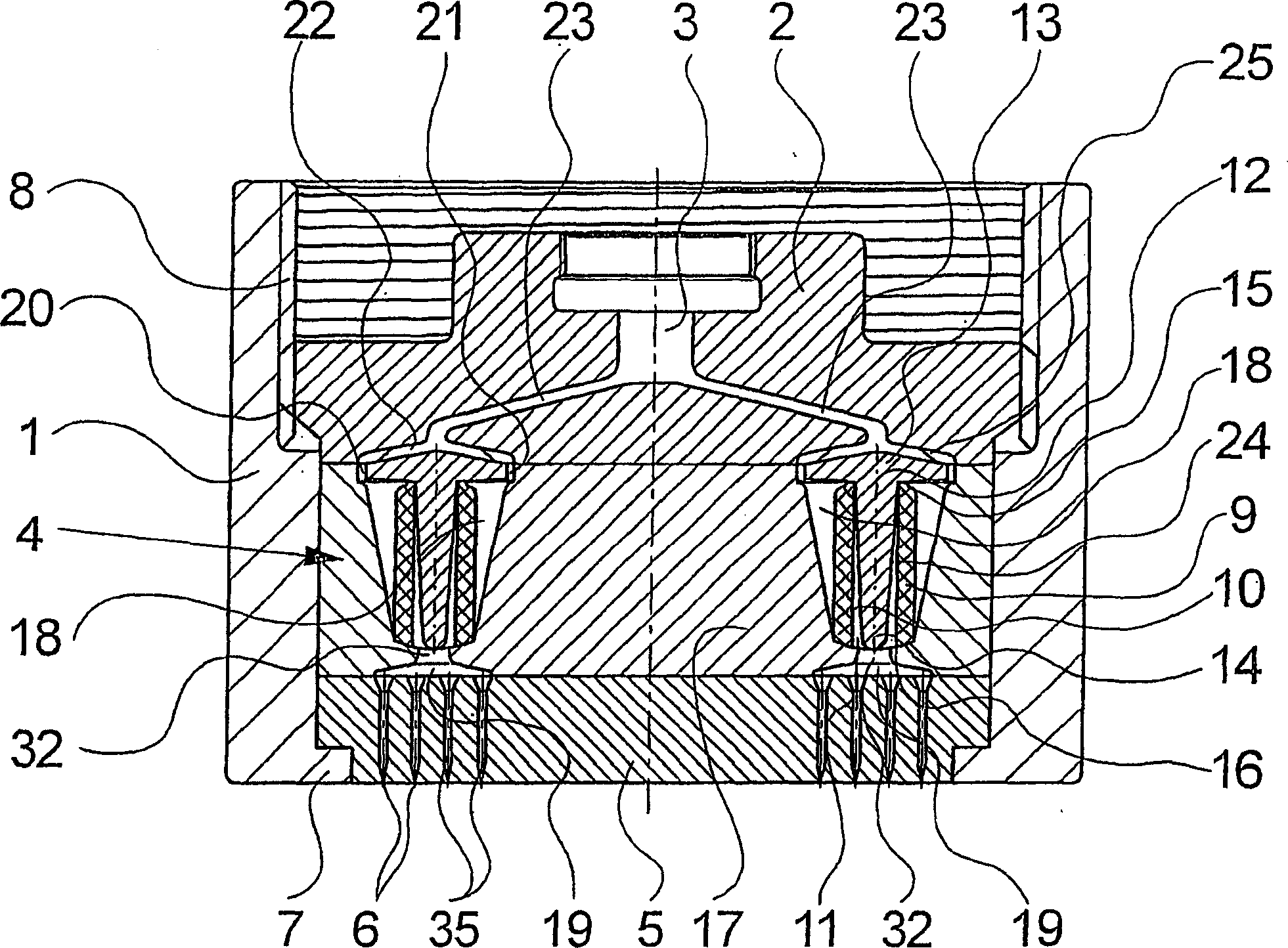

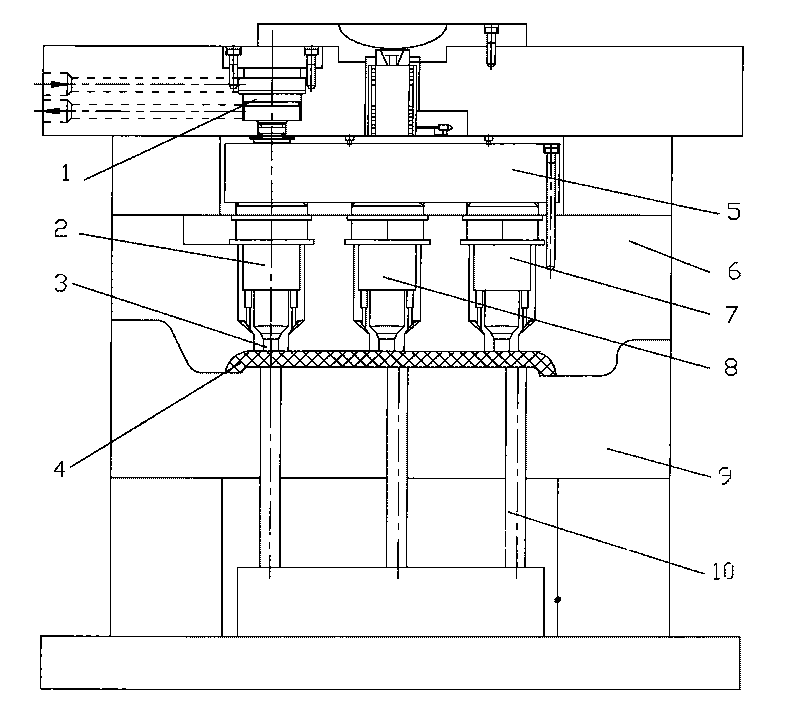

Ultrasonic vibration microtube extrusion mould

InactiveCN101947846AUniform distribution of melt flow fieldUniform distribution of flow fieldTubular articlesTransformerEngineering

The invention discloses an ultrasonic vibration microtube extrusion mould, belonging to the technical field of polymer extrusion moulding. The invention is characterized in that the mould comprises an ultrasonic-frequency power supply, an energy converter, a vibration rod, an amplitude transformer, a vibration head, a die head body, a spure sperader, a support plate, a positioning pin, a die supporting plate, a baffle plate, a fastening bolt, a washer, a die, a check ring, an integrated pressure / temperature sensor, a mandrel, an adjusting bolt, an air vent bolt, a heating ring, a temperature sensor, a connecting pipe and a flange plate. The mould adopts a feeding mode of which feeding direction is perpendicular to the extrusion direction; the vibration head adopts a spiral groove type structure and vibrates along the microtube extrusion direction; different spure speraders, mandrels and dies with different structural parameters can be changed according to demands; and the integrated pressure / temperature sensor is used to measure the changes of the pressure / temperature in the runner of the mould. By designing the ultrasonic vibration microtube extrusion mould capable of realizing vertical feeding, ultrasonic vibration is combined with the plastic microtube extrusion moulding, thus reducing flow resistance, increasing the production efficiency and obtaining the plastic microtube with high quality.

Owner:DALIAN UNIV OF TECH

Concentric air delivery and return oven

InactiveUS6259064B1Flow balanceDomestic stoves or rangesCooking fumes removalAir cycleTemperature control

An impingement heat transfer device for transferring heat between a stream of temperature controlled air and a product wherein an air supply duct and an air return duct have a common wall. A tube has one end communicating with the inside of the air supply duct and another end extending through an opening in the air return duct. Air is circulated to reduce pressure in the air return duct and increase pressure in the air supply duct such that a stream of air flows through and out of the tube and spent air is drawn through the opening encircling the tube into the air return duct.

Owner:WILSON W ROBERT

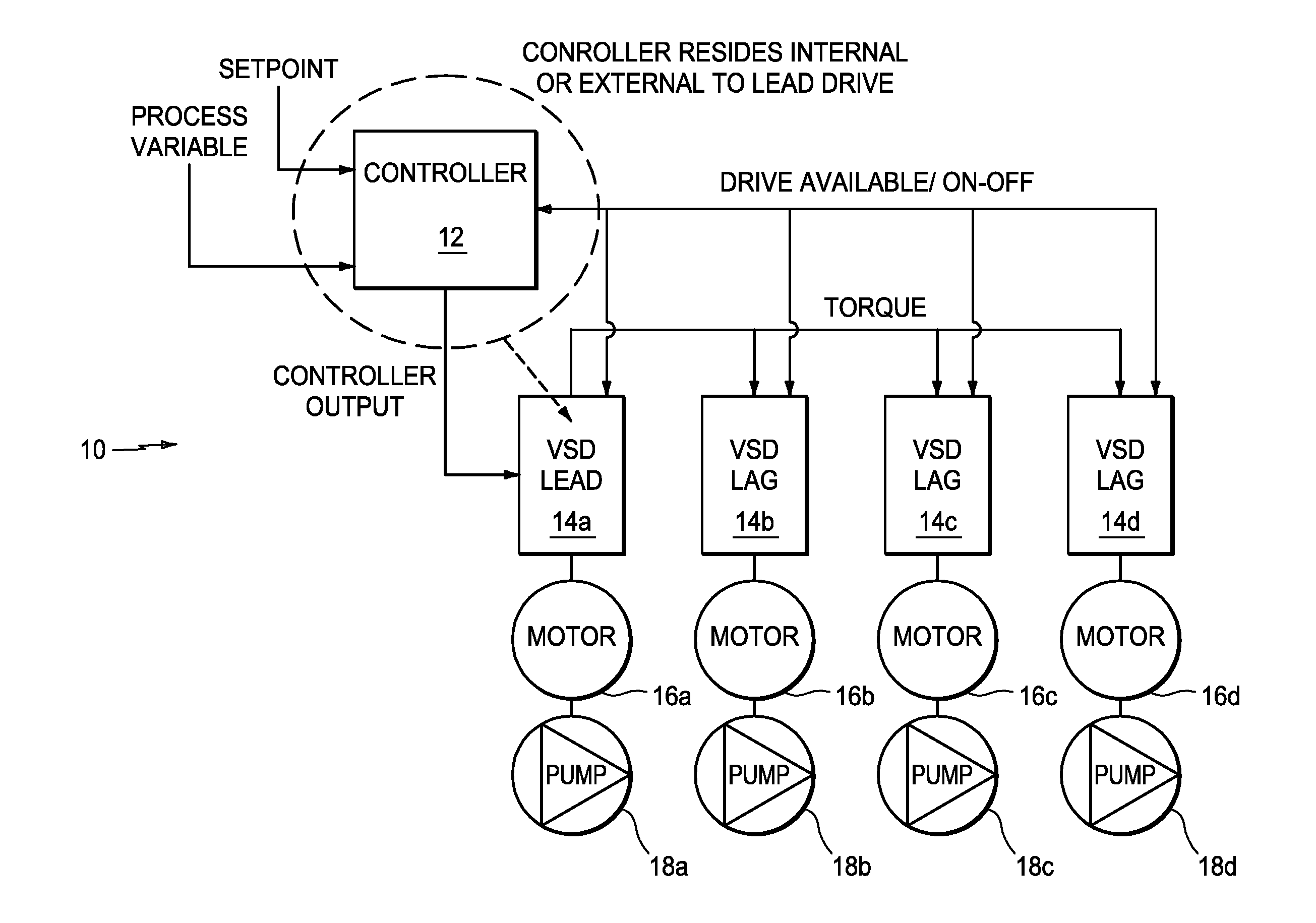

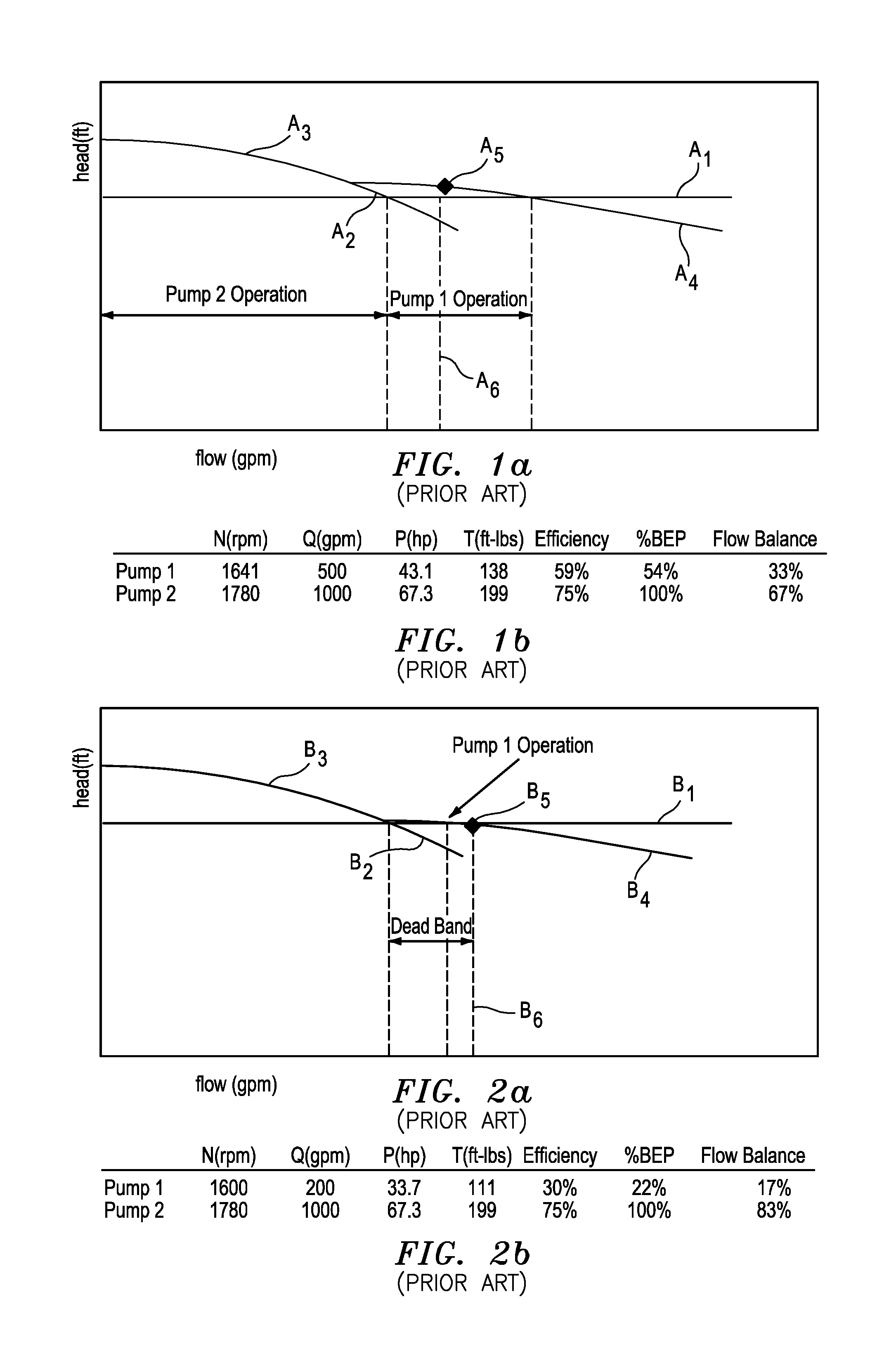

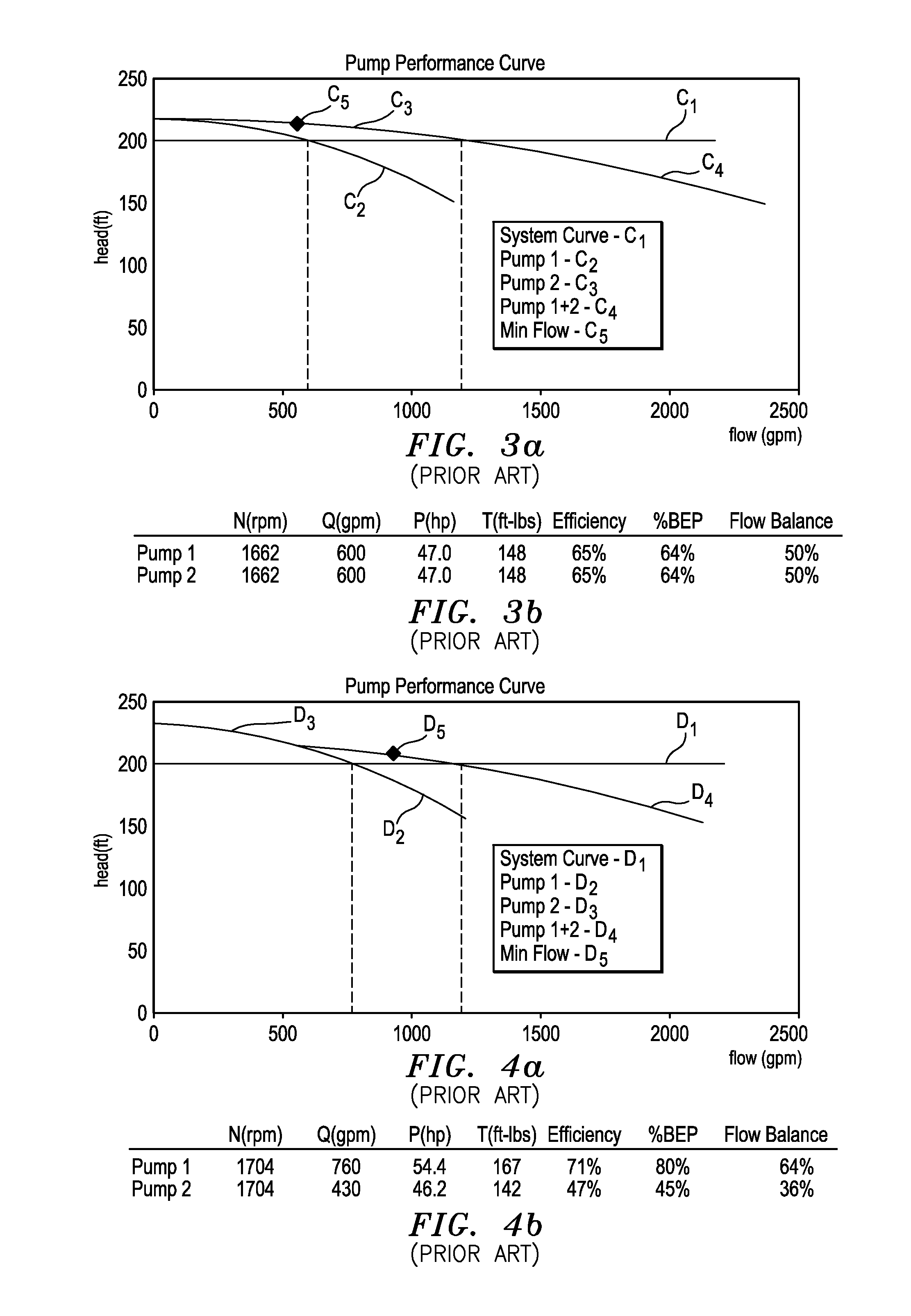

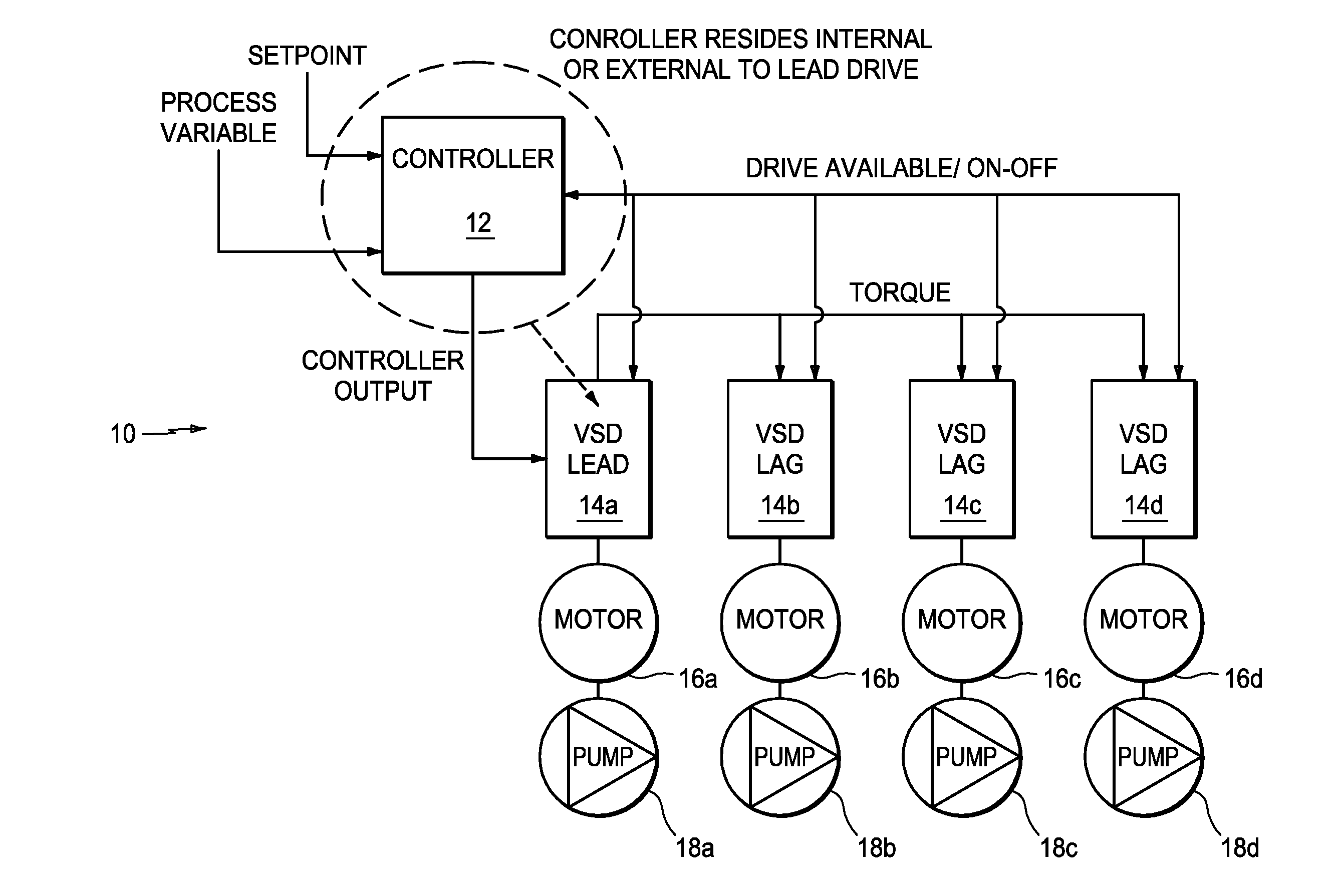

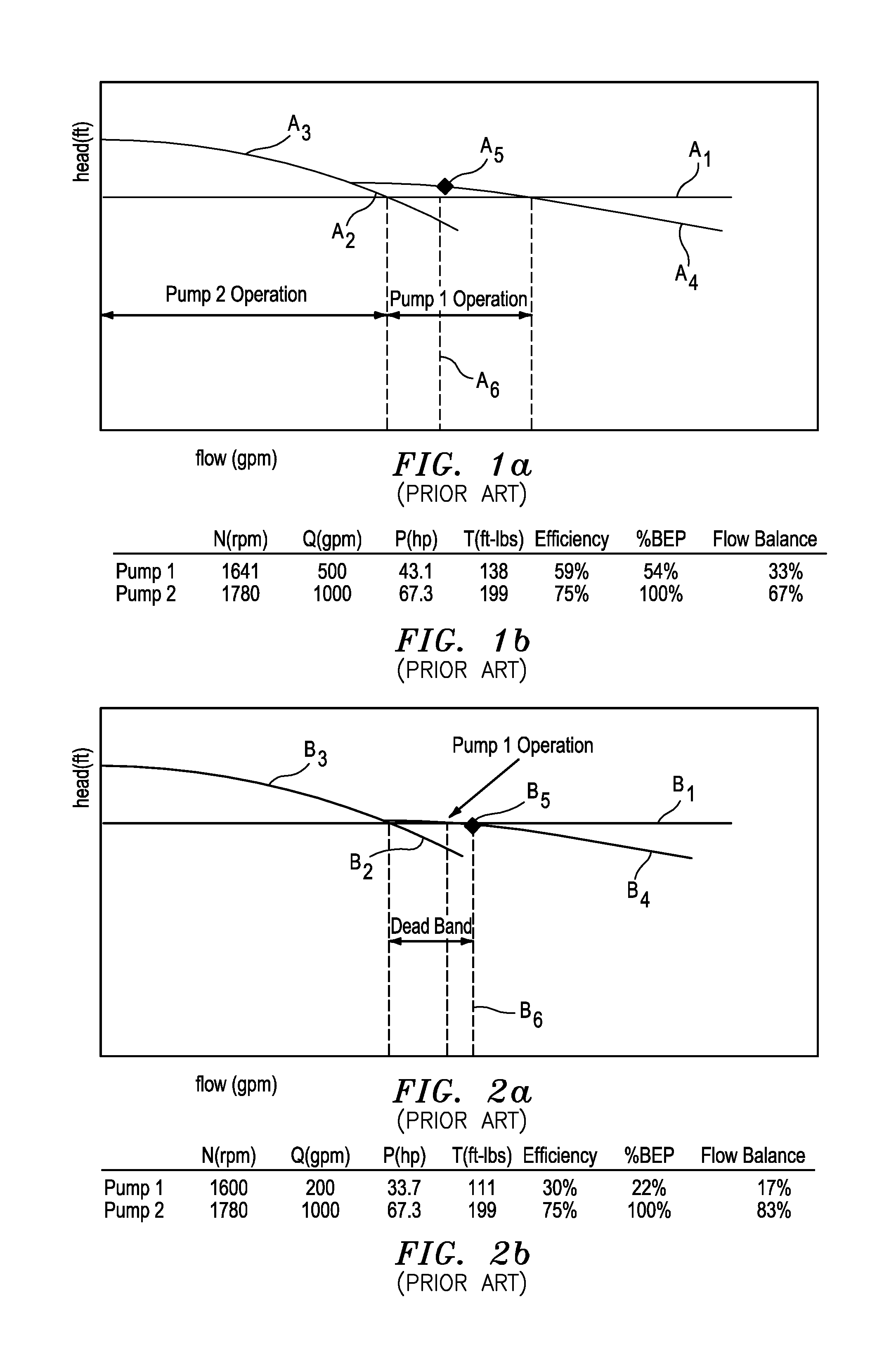

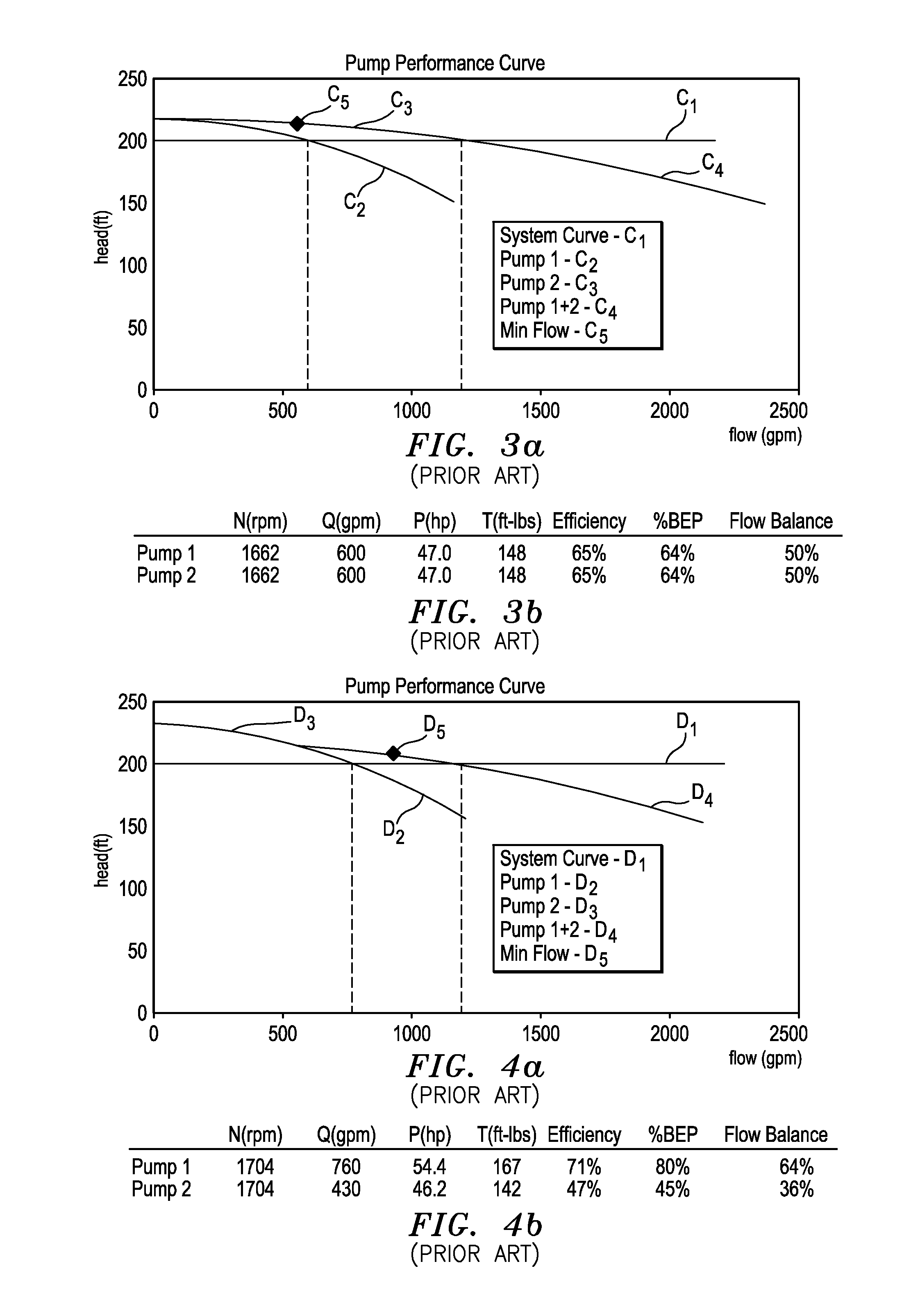

Synchronous torque balance in multiple pump systems

The present invention provides a new and unique method and apparatus for operating and running multiple pumps in a system together at a substantially synchronous torque to achieve a desired setpoint. Each of the multiple pumps may be operated with a variable speed drive. The present invention may also take the form of the system having the multiple pumps with a system controller for operating and running the multiple pumps, a pump for operating and running in such a system, a system control module for such a system controller, as well as a pump control module for running and operating such a pump.

Owner:ITT MFG ENTERPRISES LLC

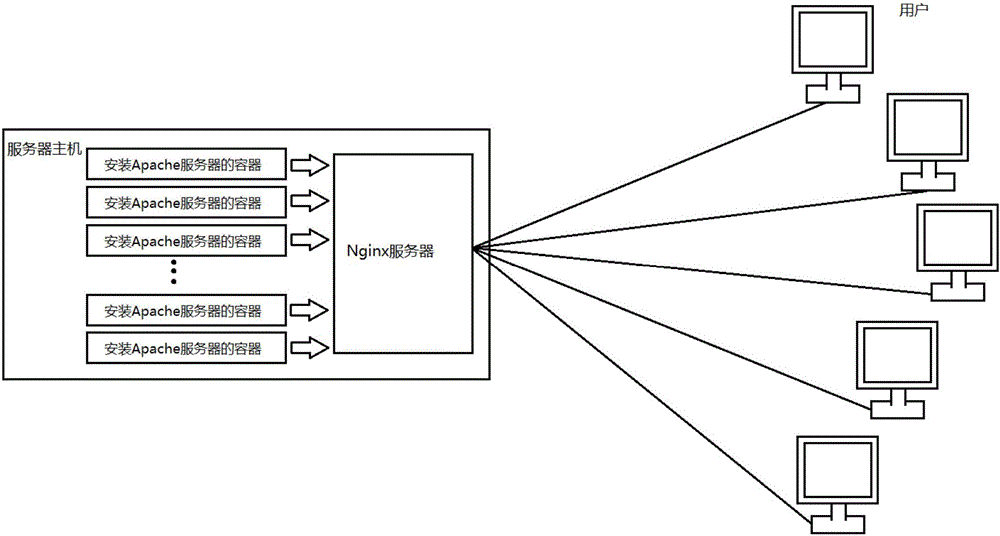

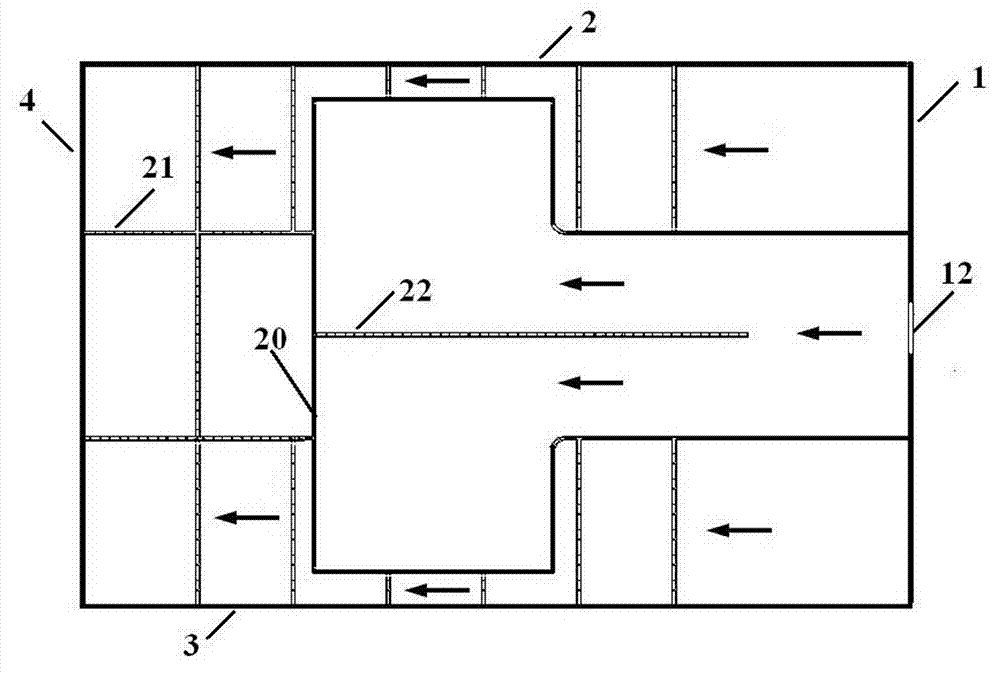

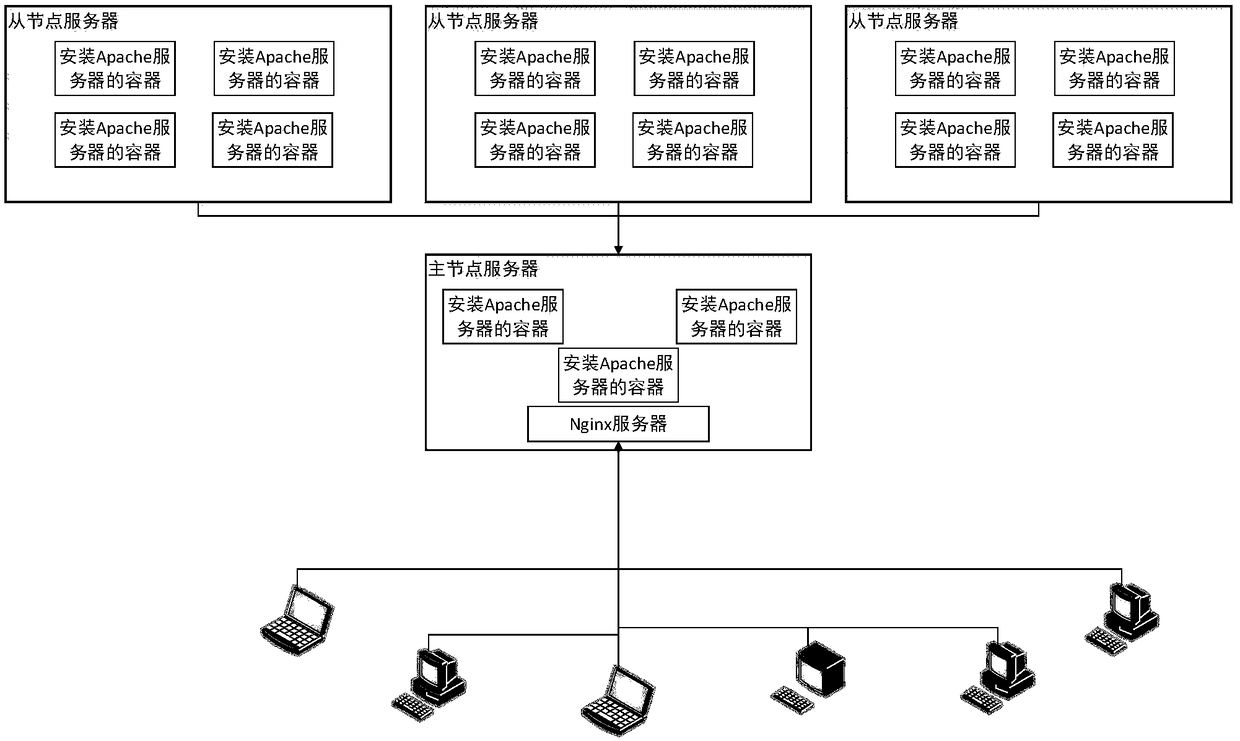

Docker container based network load balancing system and establishment method and operating method thereof

The invention relates to a Docker container based network load balancing system and an establishment method and an operating method thereof. According to the invention, a Docker container technology is adopted to act as a foundational technology of the system, and the complete network load balancing system is realized on a server host by using the characteristic that a Docker container saves hardware resources and can establish a lot of containers in the server host; and a Web server is added through container mirroring conveniently and quickly so as to perform shunting on the access amount or a data stream by using the characteristics that the Docker container can be established in a second level through mirroring and that the containers established through mirroring can be ensured to be identical. The Docker container based network load balancing system not only can save the implementation cost of the system, but also can efficiently solves a problem that the original system cannot bear because of increase in access amount or data stream.

Owner:SHANDONG UNIV

Synchronous torque balance in multiple pump systems

ActiveUS20090304521A1Flow balanceMechanical power/torque controlPump controlComputer moduleControl theory

The present invention provides a new and unique method and apparatus for operating and running multiple pumps in a system together at a substantially synchronous torque to achieve a desired setpoint. Each of the multiple pumps may be operated with a variable speed drive. The present invention may also take the form of the system having the multiple pumps with a system controller for operating and running the multiple pumps, a pump for operating and running in such a system, a system control module for such a system controller, as well as a pump control module for running and operating such a pump.

Owner:ITT MFG ENTERPRISES LLC

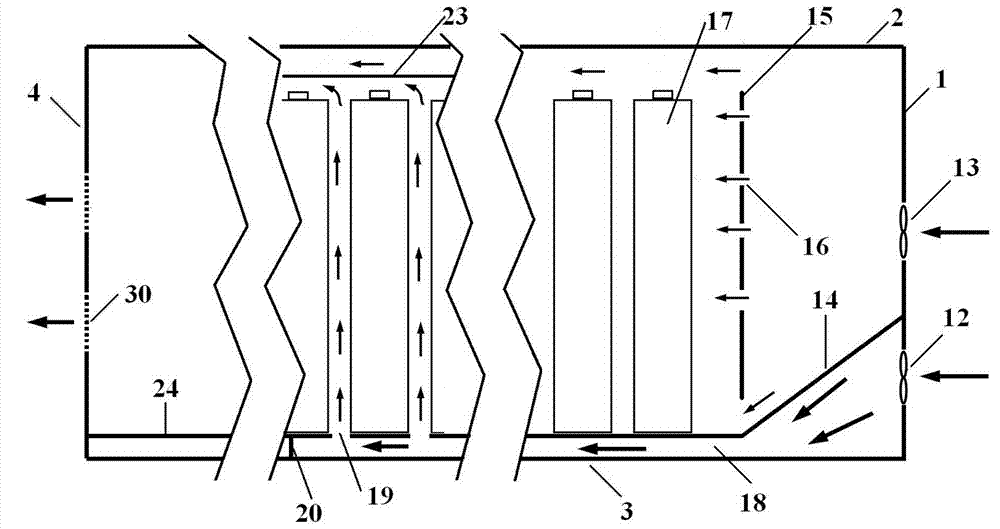

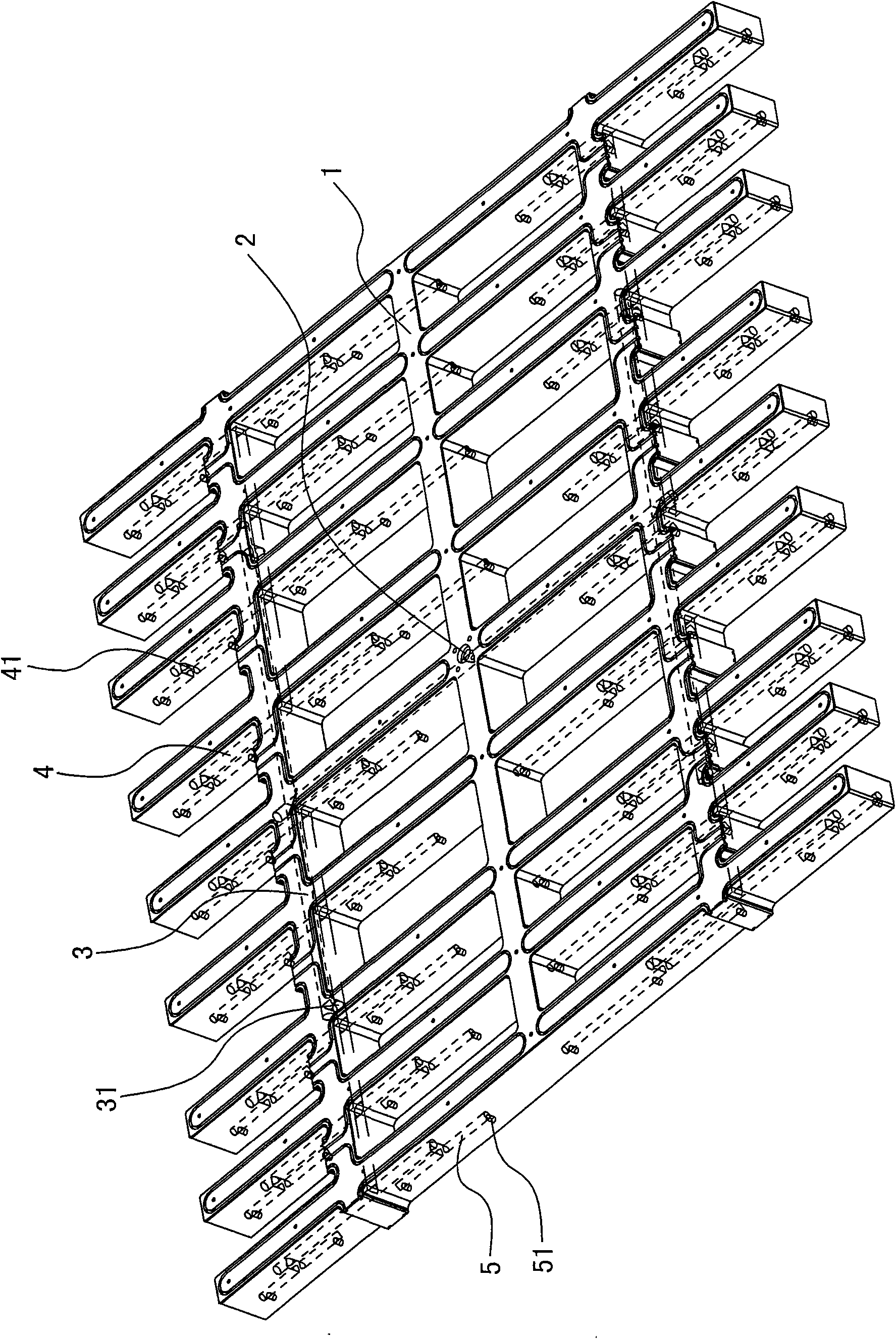

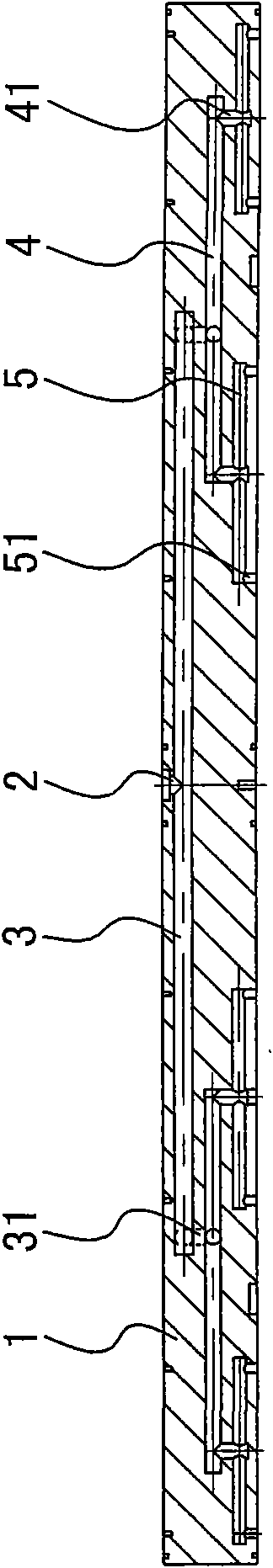

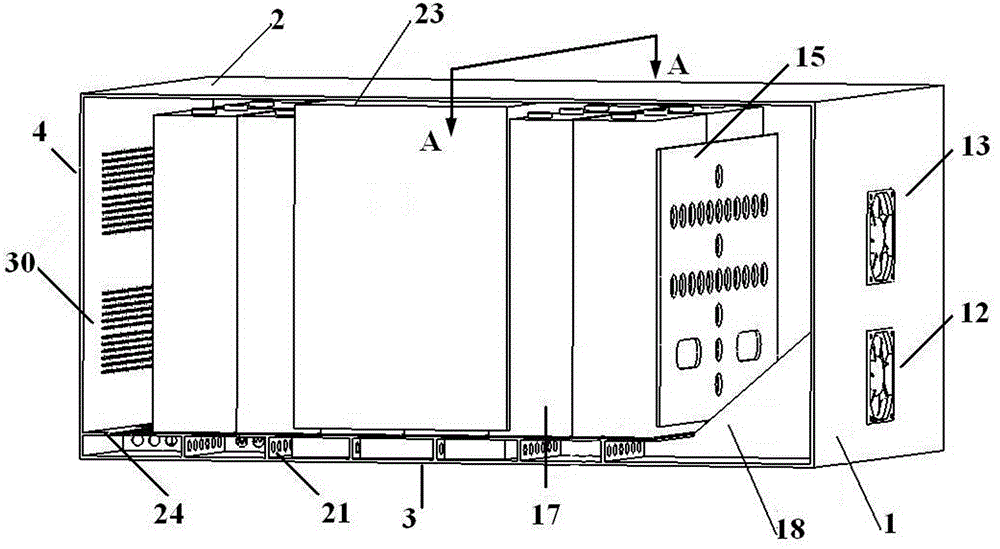

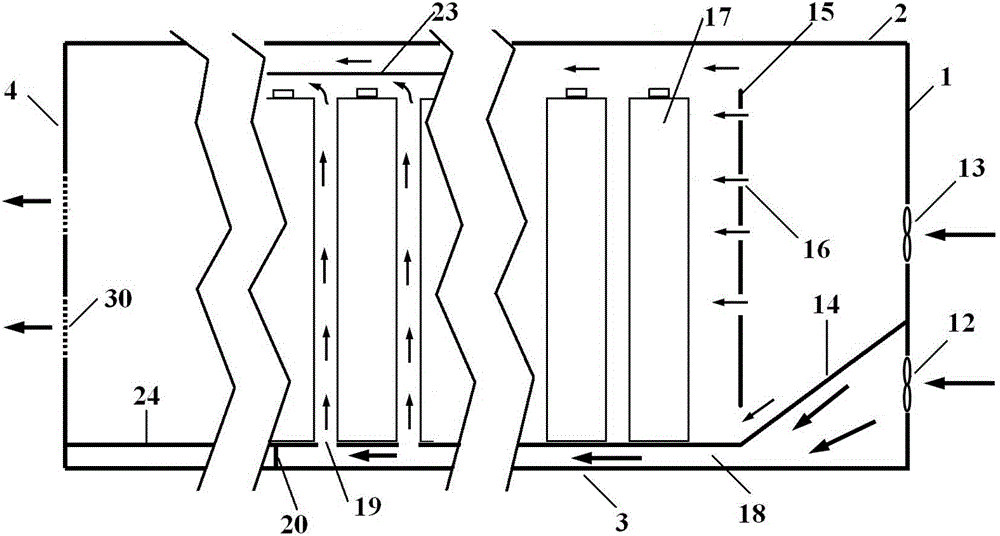

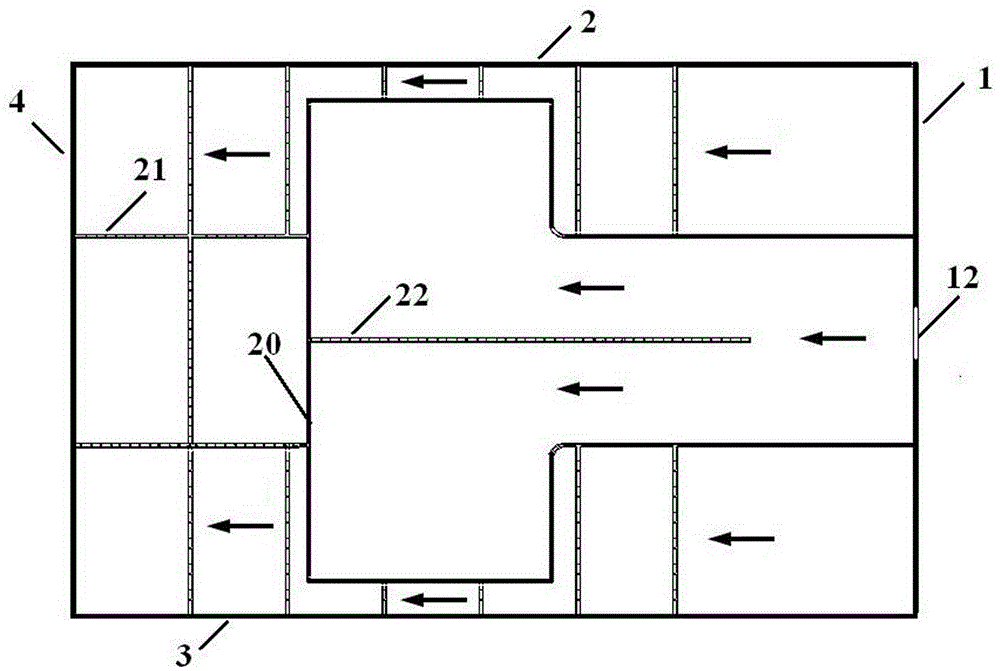

Lithium ion power battery box

ActiveCN103199203ACool evenlyObvious temperature differenceSecondary cellsCell component detailsLithiumPower battery

The invention relates to a lithium ion power battery box, which comprises a battery box body for alternately arranging batteries inside the body along a set arrangement direction, and a base air channel arranged in the battery box body, wherein the flow direction of the base air channel is consistent with the set arrangement direction; the battery box is also provided with a reinforced cooling air channel for delivering cooling air separated from the base air channel; the reinforced cooling air channel is provided with jet holes for directing the cooling air into a set cooling area in the battery box body; and the cooling area is a gap between front and back adjacent batteries along the battery arrangement direction in set positions or batteries in the set positions. By adopting the lithium ion power battery box, the problem in the prior art that cooling capacity distribution in various parts in the battery box body is non-uniform because the batteries are successively cooled along a single base air channel is solved; and the lithium ion power battery box of the invention can uniformly cool the batteries and improve the overall discharge performance and the service life of the batteries in the battery box.

Owner:CALB CO LTD

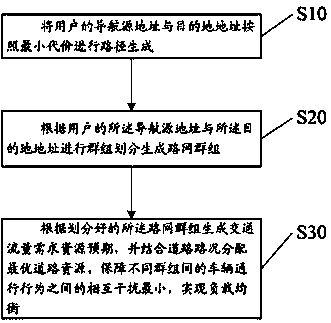

Route cluster planning method

InactiveCN103968854AOvercome unreasonable designImprove traffic capacityInstruments for road network navigationTraffic capacityPlanning approach

The invention discloses a route cluster planning method, which is applied to vehicle navigation. The method comprises the following steps: carrying out route generation on a navigation source address and a destination address of users at minimum cost; dividing groups according to the navigation source address and the destination address of the users to generate road net groups; and generating a traffic flow demand resource expectation according to the divided road net group and distributing the optimum road resource in combination with the road condition. The mutual interference between the vehicle passing behaviors in different groups is minimum, the load balance is realized, routes are reasonably planned, the traffic resources are fully utilized, the flow of load in an urban road net is effectively balanced, traffic jam of urban roads is alleviated and relieved, and the technical effect of traffic capacity of the urban road net is greatly improved.

Owner:四川汇源吉迅数码科技有限公司

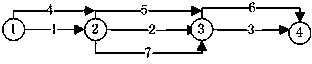

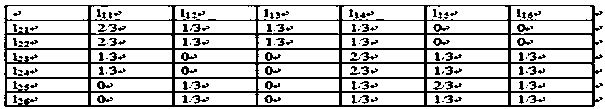

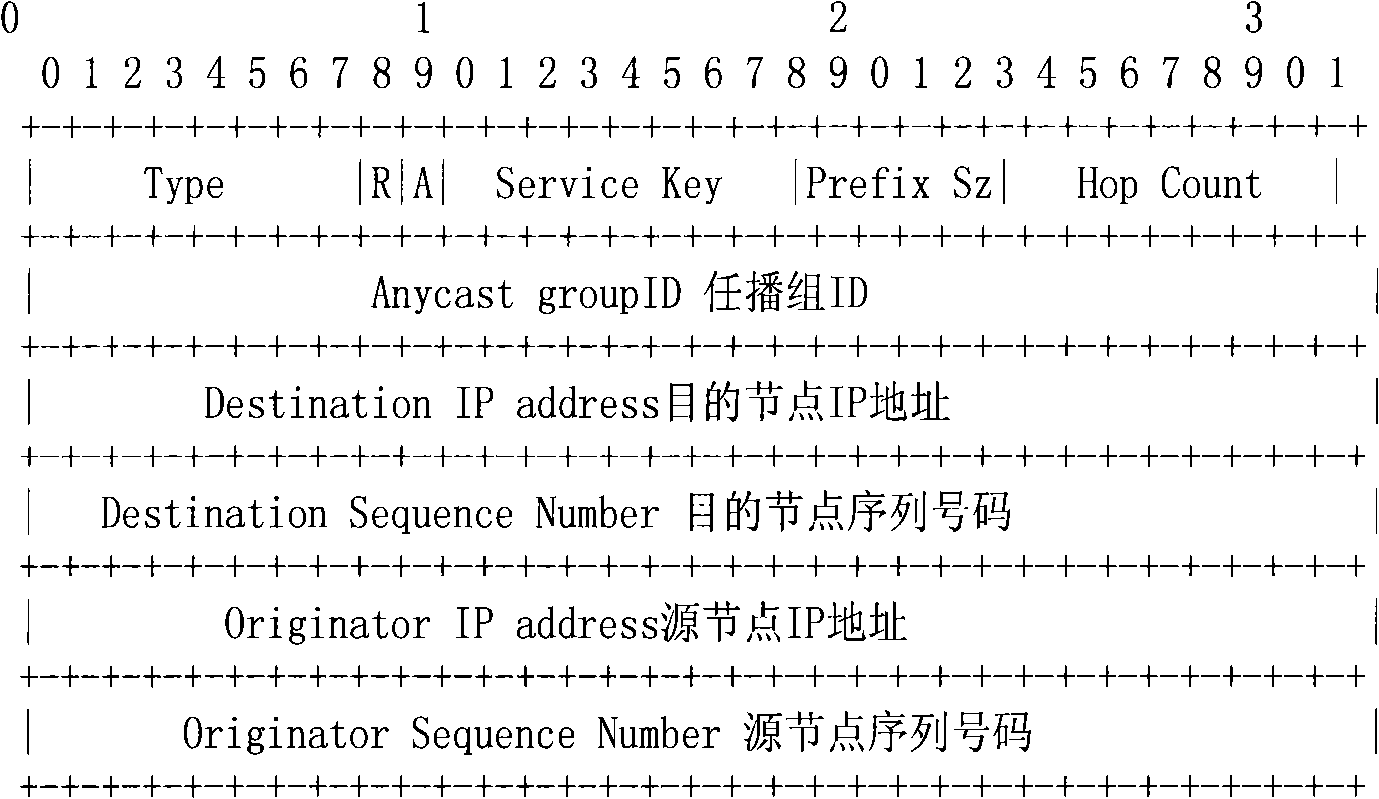

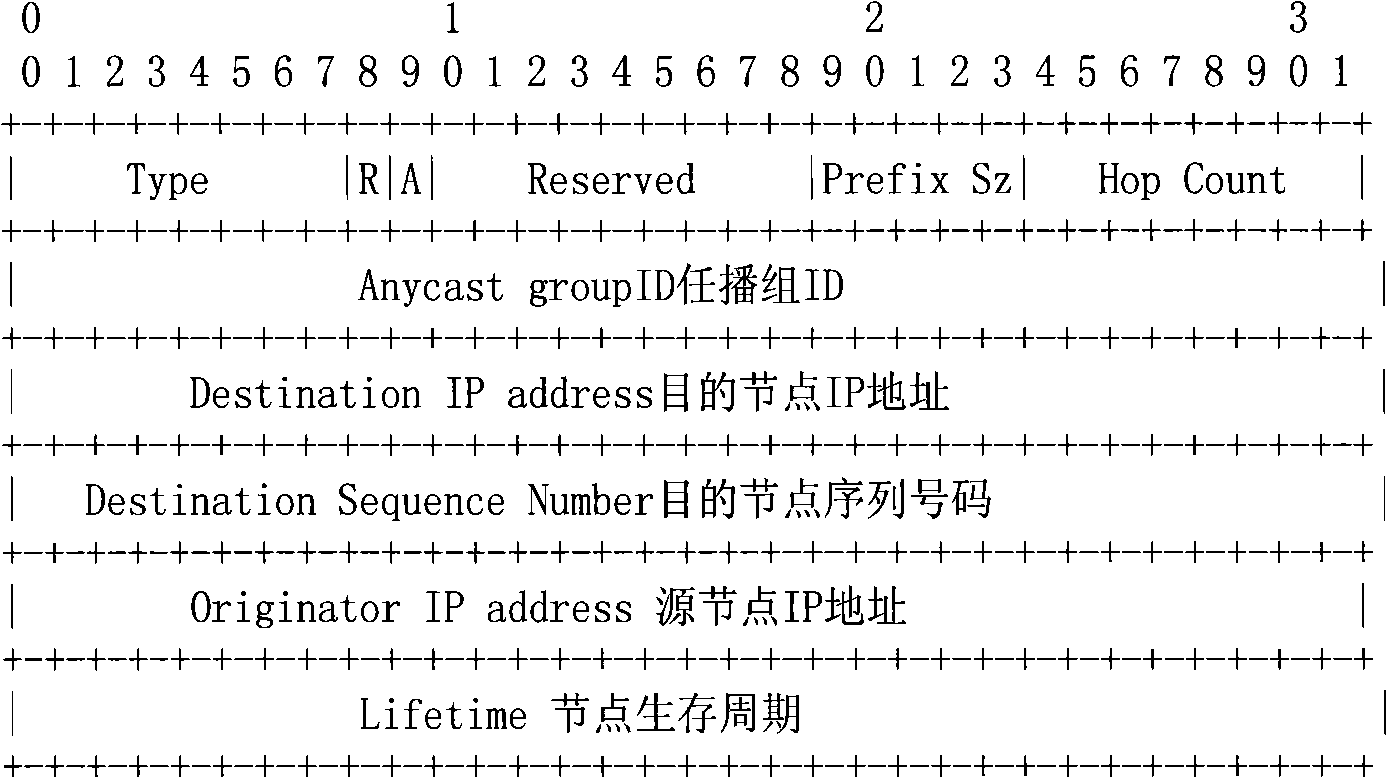

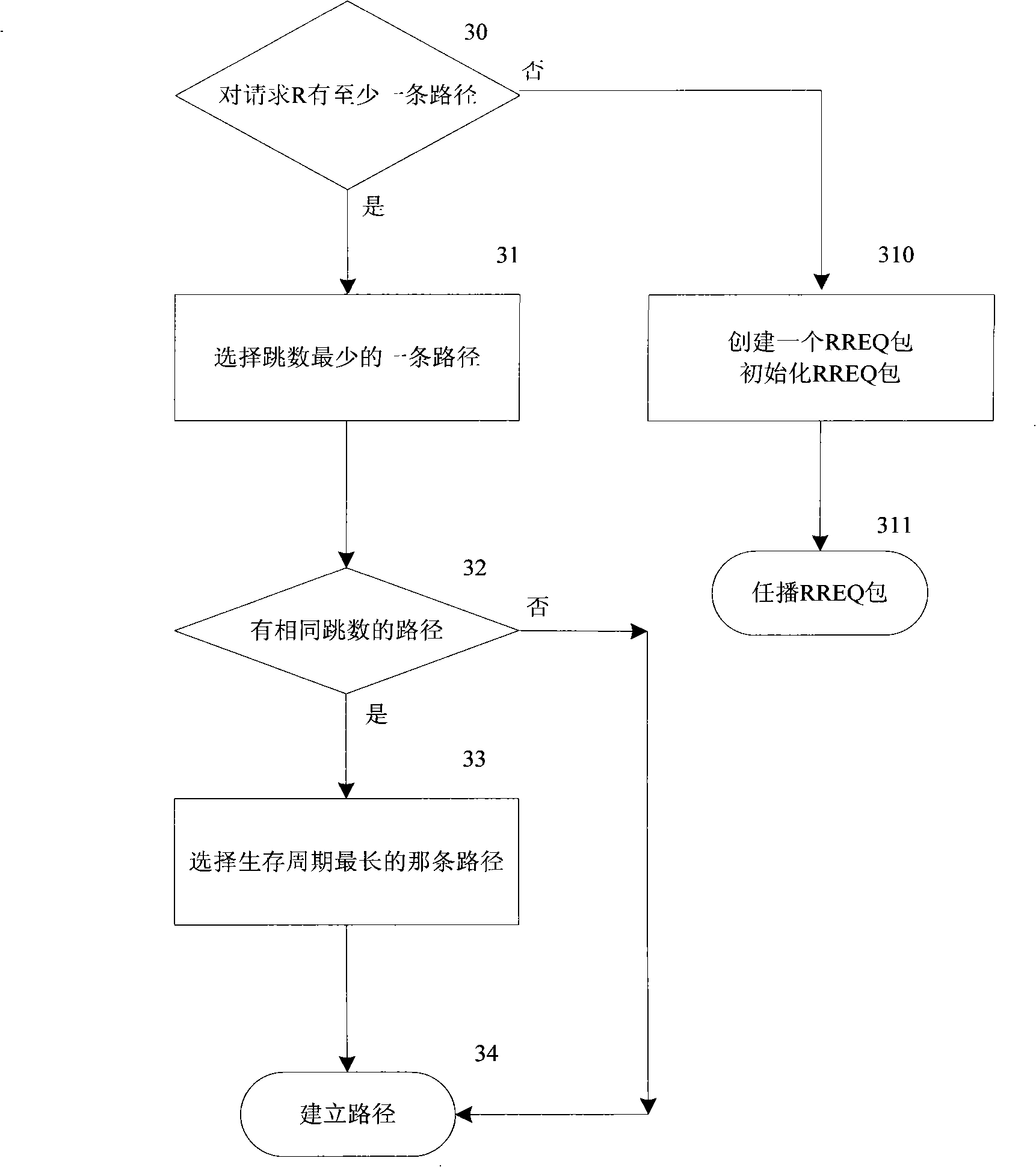

Routing method for mobile multi-hop grouping wireless network based on random broadcast mode

InactiveCN101409905AImprove query efficiencyBalance network trafficSpecial service provision for substationNetwork topologiesTelecommunicationsAnycast

The embodiment of the invention provides a mobile multi-hop packet wireless network routing method based on an anycast manner. The method comprises the following steps: a source node sends a routing request packet containing a service value and an anycast group address of the source node; a forwarding node which receives the routing request packet searches a destination node in the anycast group of the forwarding node, if the destination node is not found, an anycast group which is closest to the anycast group of the forwarding node is determined by a function algorithm according to the anycast group address information, and the routing request packet is sent to the closest anycast group so as to continue searching the destination node in the closest anycast group; the steps are repeated until the destination node is found; and communication connection between the source node and the destination node is established. The method achieves rapid search of the destination node and enhances the resource retrieval and inquiry efficiency.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Method of loading a wafer onto a wafer holder to reduce thermal shock

InactiveUS6861321B2Reduce the possibilityGreat gradientSemiconductor/solid-state device manufacturingCharge manipulationEngineeringThermal shock

One or more of three different measures are taken to preheat a wafer before it is loaded into direct contact with a wafer holder, in order to provide optimal throughput while reducing the risk of thermal shock to the wafer. The first measure is to move the wafer holder to a raised position prior to inserting the wafer into the reaction chamber and holding the wafer above the wafer holder. The second measure is to provide an increased flow rate of a heat-conductive gas (such as Hs purge gas) through the chamber prior to inserting the wafer therein. The third measure is to provide a power bias to radiative heat elements (e.g., heat lamps) above the reaction chamber.

Owner:ASM IP HLDG BV

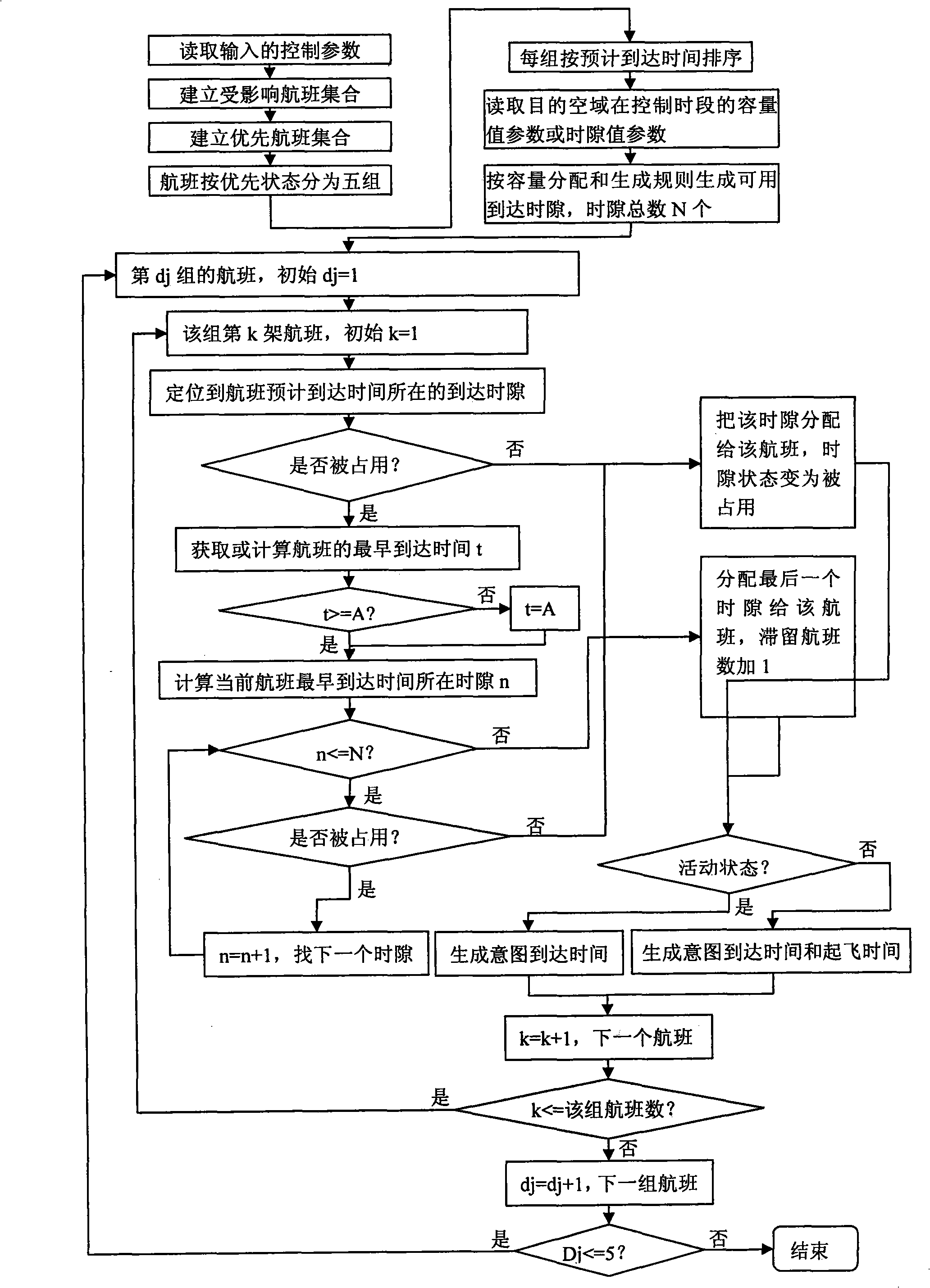

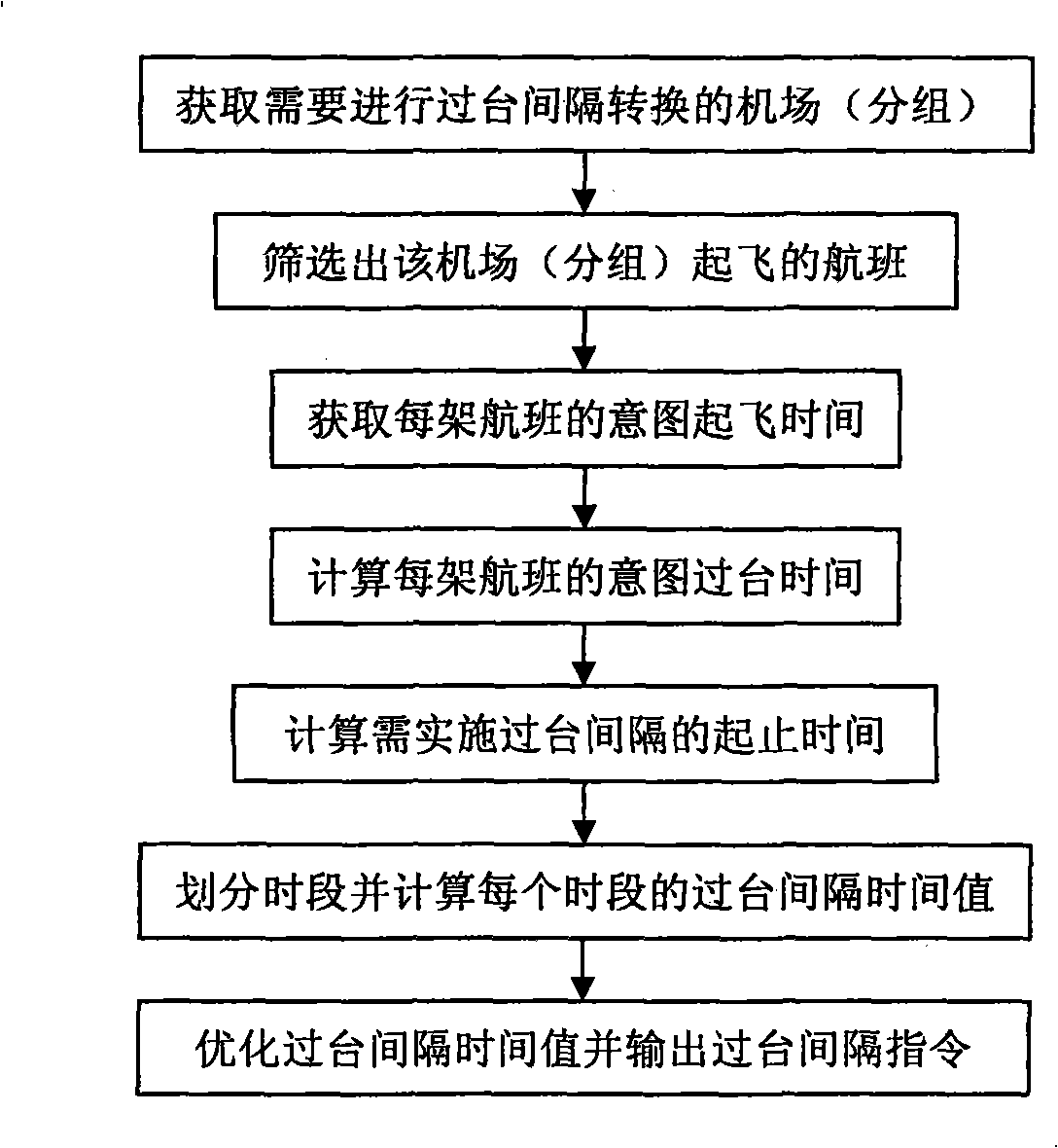

Method for implementing flight transmit interval

InactiveCN101527087AAchieve indirect controlFlow balanceAircraft traffic controlTraffic volumeOff time

The invention relates to a method for implementing flight transmit interval, which is realized through the assistance of a computer management system. The computer management system also comprises a flow management program generating / evaluating subsystem which is used as an operation platform for the method for implementing the flight transmit interval. The method has the advantages that flights needing ground delay are allocated with take-off intervals meeting integrally optimal, impartial and just principles through take-off time slot allocation algorithm based on statistics and prediction of flow and capacity, and corresponding transmit interval instructions are only generated for the flights taking off from the airports and entering the local area in order to balance the control of the flights inside and outside the area under the condition that the take-off airports are not in the control area, thus achieving interval control of take-off time of the flights taking off in external areas and finally achieving the aim of balancing the flow and the capacity of the crowded airports; and the method has innovation, practicability and higher promotional value.

Owner:CIVIL AVIATION UNIV OF CHINA

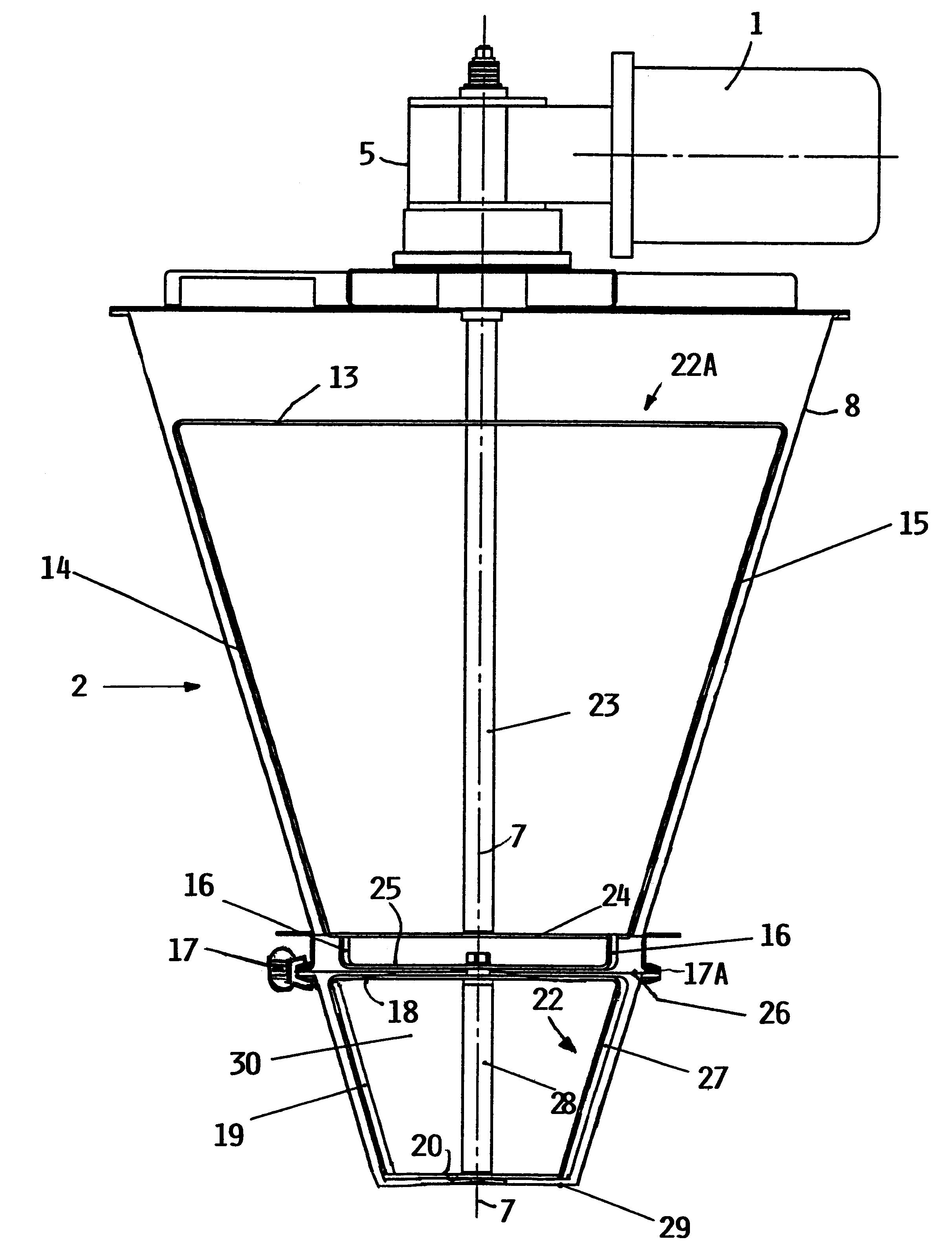

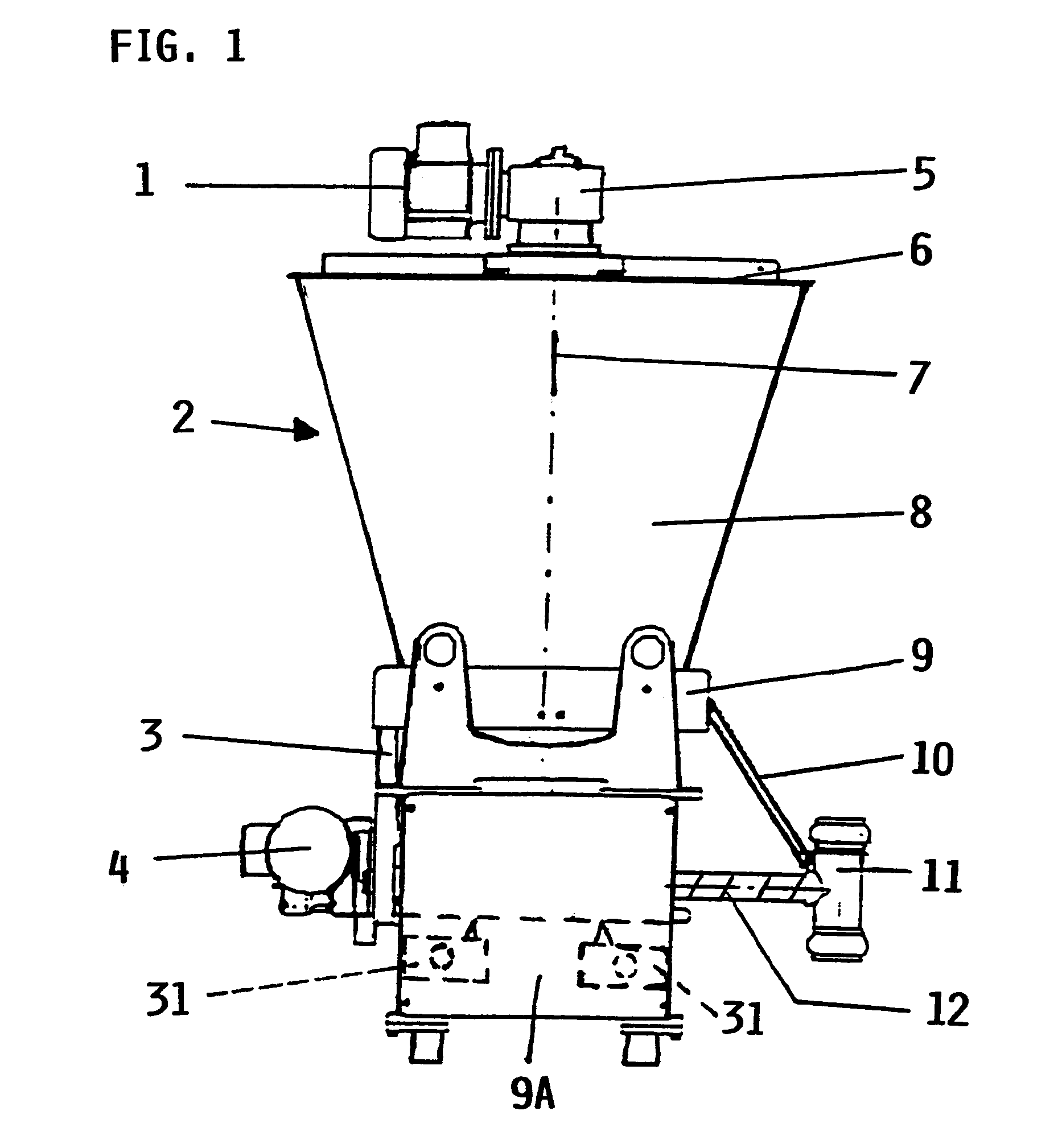

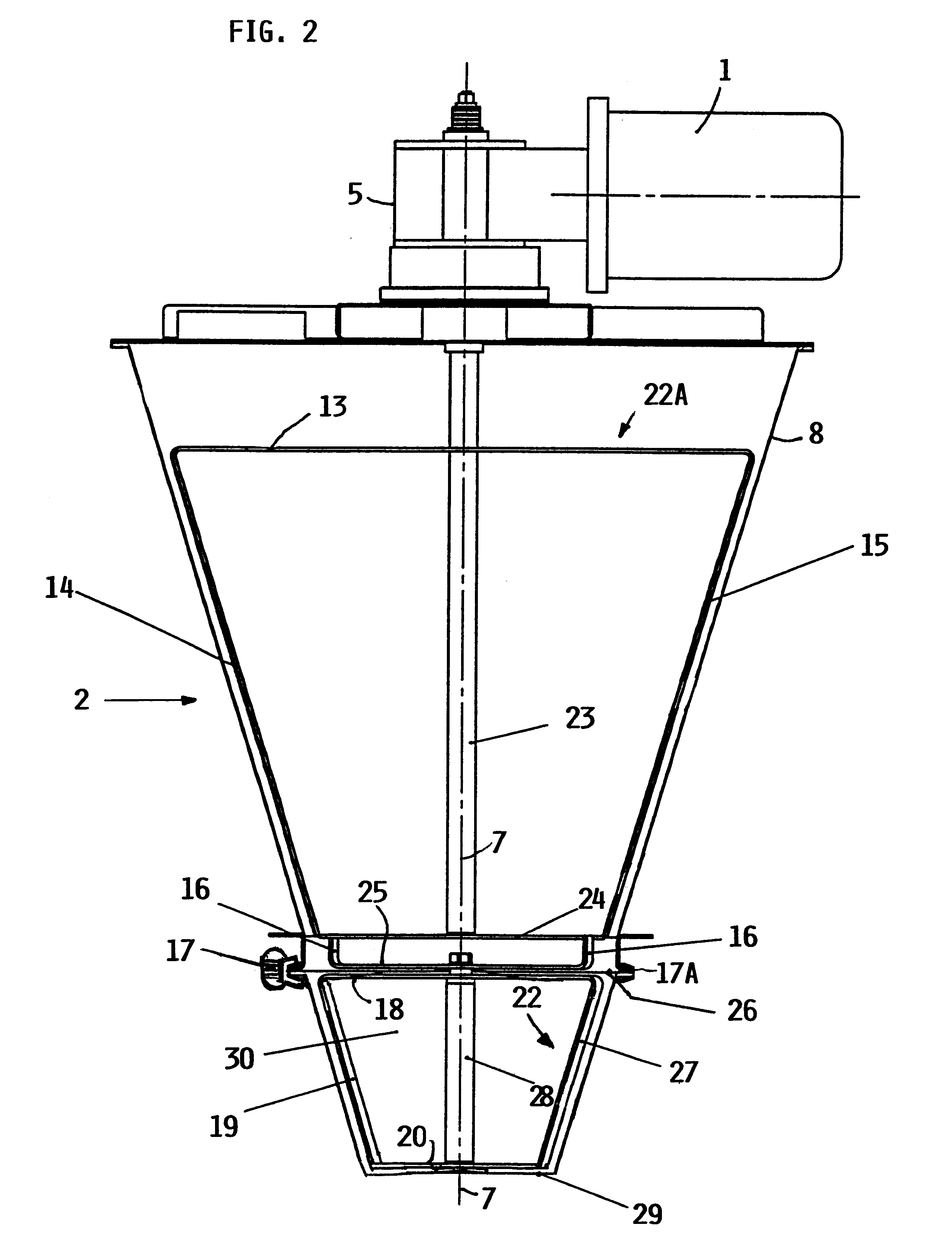

Dosing device for bulk materials

InactiveUS6688496B1Easy accessFlow balanceMovable measuring chambersClosure using stoppersCouplingEngineering

The invention relates to a dosing device containing a supply container (8), a dosing container (30) and a discharge device (12). A separate vertical stirring section (22, 22A) is provided in each container, namely the supply container (8) and the dosing container (30). The vertical stirring section 22A located in the supply container (8) is provided with a drive unit (1) which is also used to drive the lower stirrring section (22) of the dosing container (30). The dosing container (30) can be removed horizontally, sideways. The two stirring sections (22) and (22A) have coupling elements (16, 25) with which they are detachably or releasably interconnected. A coupling arm (25) is provided to this purpose with driving pins (16) which engage in the rotating area of the driven upper stirring section (22A) so that the two stirring sections can be coupled and one stirring section can drive the other stirring section.

Owner:SCHENCK PROCESS GMBH

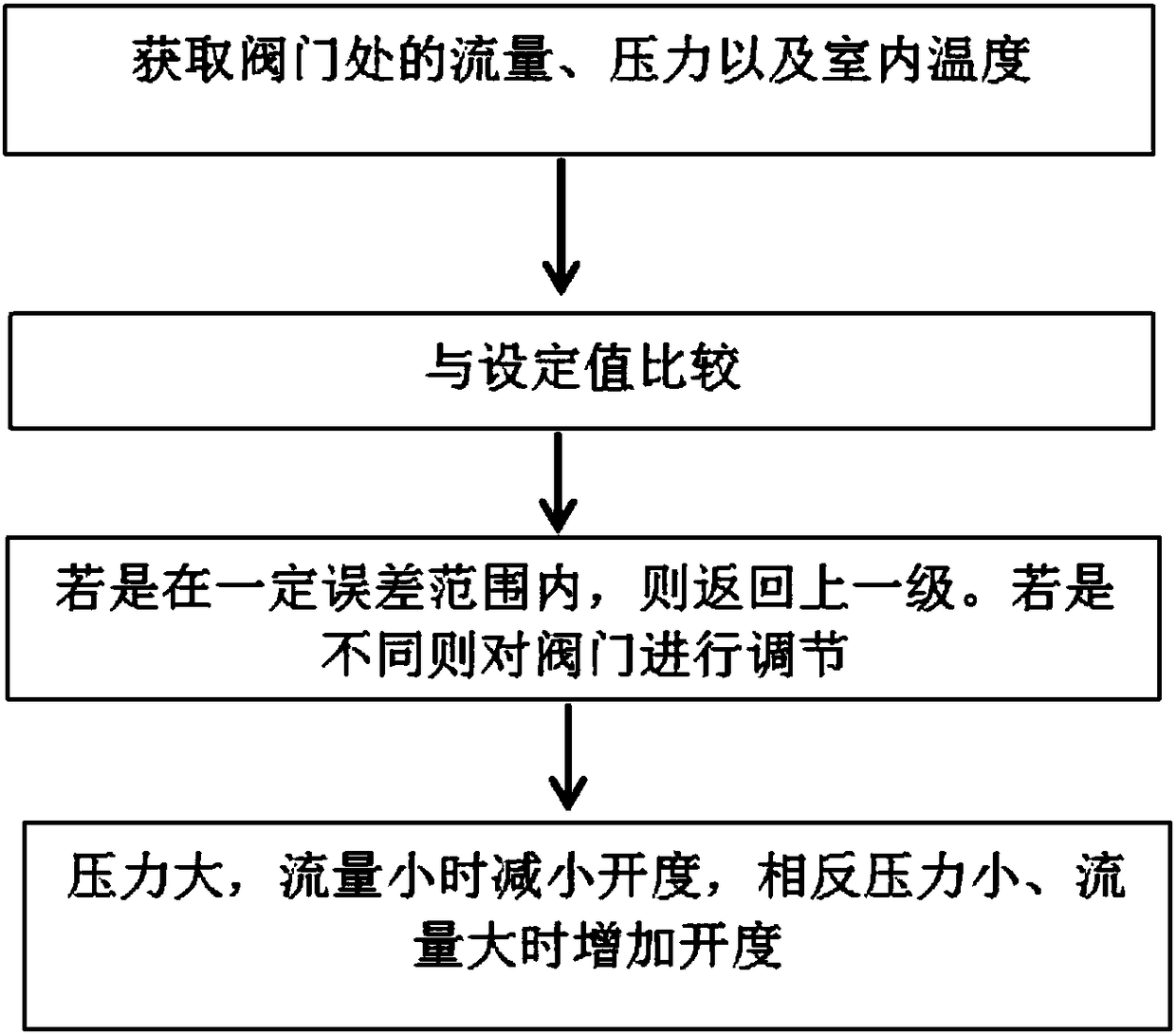

Heat-supply pipe network self-adaptive flow balancing method and device

InactiveCN108253521ARealize automatic adjustmentFlow balanceLighting and heating apparatusSpace heating and ventilation detailsOutdoor temperatureData processing

The invention discloses a heat-supply pipe network self-adaptive flow balancing method and a heat-supply pipe network self-adaptive flow balancing device. The method comprises the following steps: firstly, acquiring the flow and the pressure at a valve, an indoor temperature and an outdoor temperature; secondly, comparing measured data with set values; and thirdly, adjusting the opening degree ofthe valve according to whether the measured data exceed the range of the set values, and balancing the flow in a system by adjusting the opening degree of the valve, so that the purpose of balancing the flow is achieved. The device comprises flowmeters, pressure sensors and thermometers which are mounted beside the valve; the flowmeters, the pressure sensors and the thermometers are all connectedwith a data acquisition module; the data acquisition module communicates with a data processing module; the data processing module is also connected with an indoor thermometer and an outdoor thermometer; and the data processing module is connected with an executing mechanism which controls the opening degree of the valve. The heat-supply pipe network self-adaptive flow balancing method and the heat-supply pipe network self-adaptive flow balancing device can adjust automatically in real time to balance the flow in a pipe network; and the timeliness is good. The professional requirement on working personnel of a heating power company is reduced.

Owner:华能青岛热电有限公司 +1

Docker Swarm container cluster-based network load balancing system, building method and working method thereof

The invention relates to a Docker Swarm container cluster-based network load balancing system, a building method and a working method thereof. The network load balancing system comprises a reverse proxy server, a host, and multiple background Web servers, wherein the host comprises multiple server hosts, the reverse proxy server receives a connection request from Internet and forwards the connection request to the background Web server on an internal network, and the background Web server outputs a result and returns the output result to a client requesting connection on the Internet. In the system, multiple servers with Docker clients are connected to form a cluster by using a Docker Swarm container cluster; the whole cluster comprises a multi-state server, and has enough hardware resource and calculating capacity, thereby being capable of processing larger network load; and defects of insufficient hardware resource and limited calculating capability of a single server are overcome.

Owner:SHANDONG UNIV +1

Hybrid diffuser system headloss balancing

InactiveUS20070120276A1Balanced flowSmall differenceCarburetting airMixing methodsWastewaterEngineering

In a tank for treating wastewater and including a first plurality of air diffuser elements and a second plurality of air diffuser elements, means for adjusting the relative height of the first diffuser elements with respect to the height of the second diffuser elements in response to changing operating conditions in the tank and changes in the characteristics of the diffusers.

Owner:EVOQUA WATER TECH LLC

Coaxial dual-electromagnetic fuel gas injection valve with flowing sectional area adjustable

ActiveCN107091362AAvoid axial forceQuick responseOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringPressure balance

The invention aims at providing a coaxial dual-electromagnetic fuel gas injection valve with the flowing sectional area adjustable. The adjustable gas injection flow is achieved through a dual-valve-element dual-electromagnet control structure. The air inflowing and flow guiding process is achieved through a bypass structure and a flow guiding cavity structure; valve element control and gas way control are achieved through actuator control, and a gas injection function is achieved; through cooperation of an external guiding structure, an internal flow guiding cavity and a pressure balancing groove, the perpendicularity of a valve element is guaranteed, stable and reliable work of gas flow is achieved, and the high responding speed is achieved; through a mixed gas inflowing mode of combining direct gas inflowing of an axial main gas groove and gas inflowing of circumferential gas supplementing holes, high flow is achieved, the gas supplying efficiency of an engine is effectively improved, and meanwhile gas flow interference can be avoided, so that gas way stability is achieved; face sealing and high reliability of the fuel gas injection valve are achieved through multiple annular strip structures between the valve element and a valve base.

Owner:HARBIN ENG UNIV

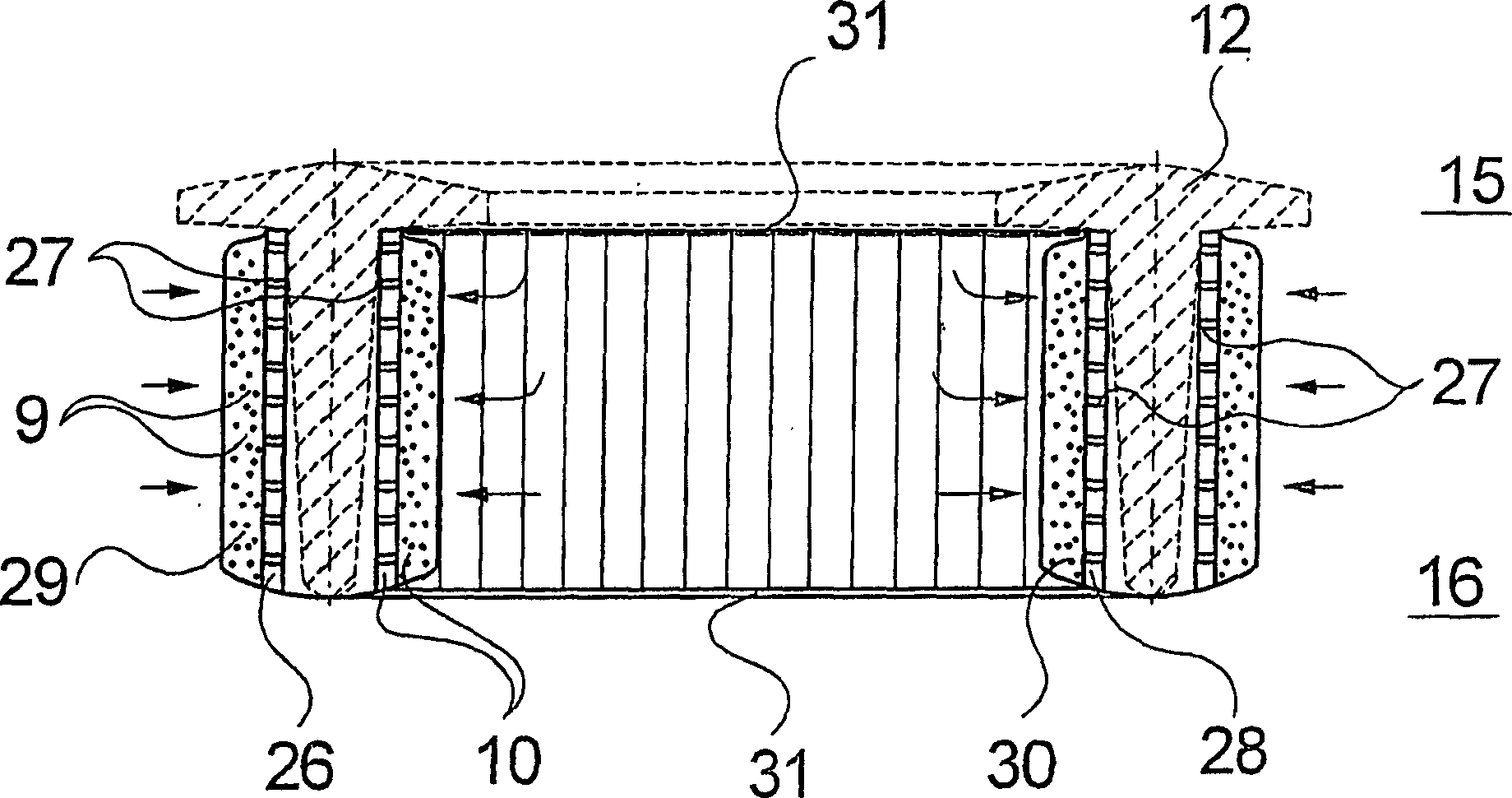

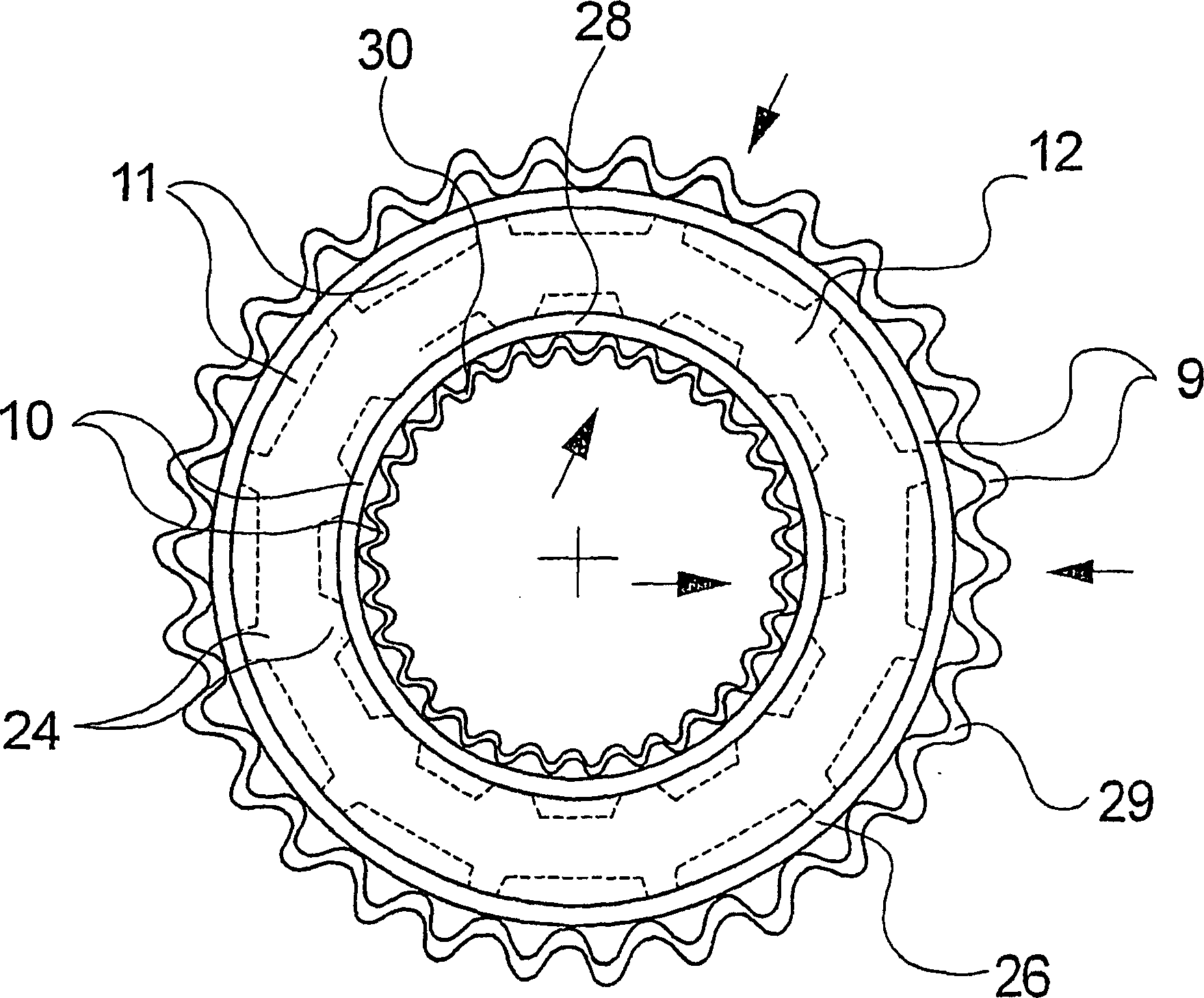

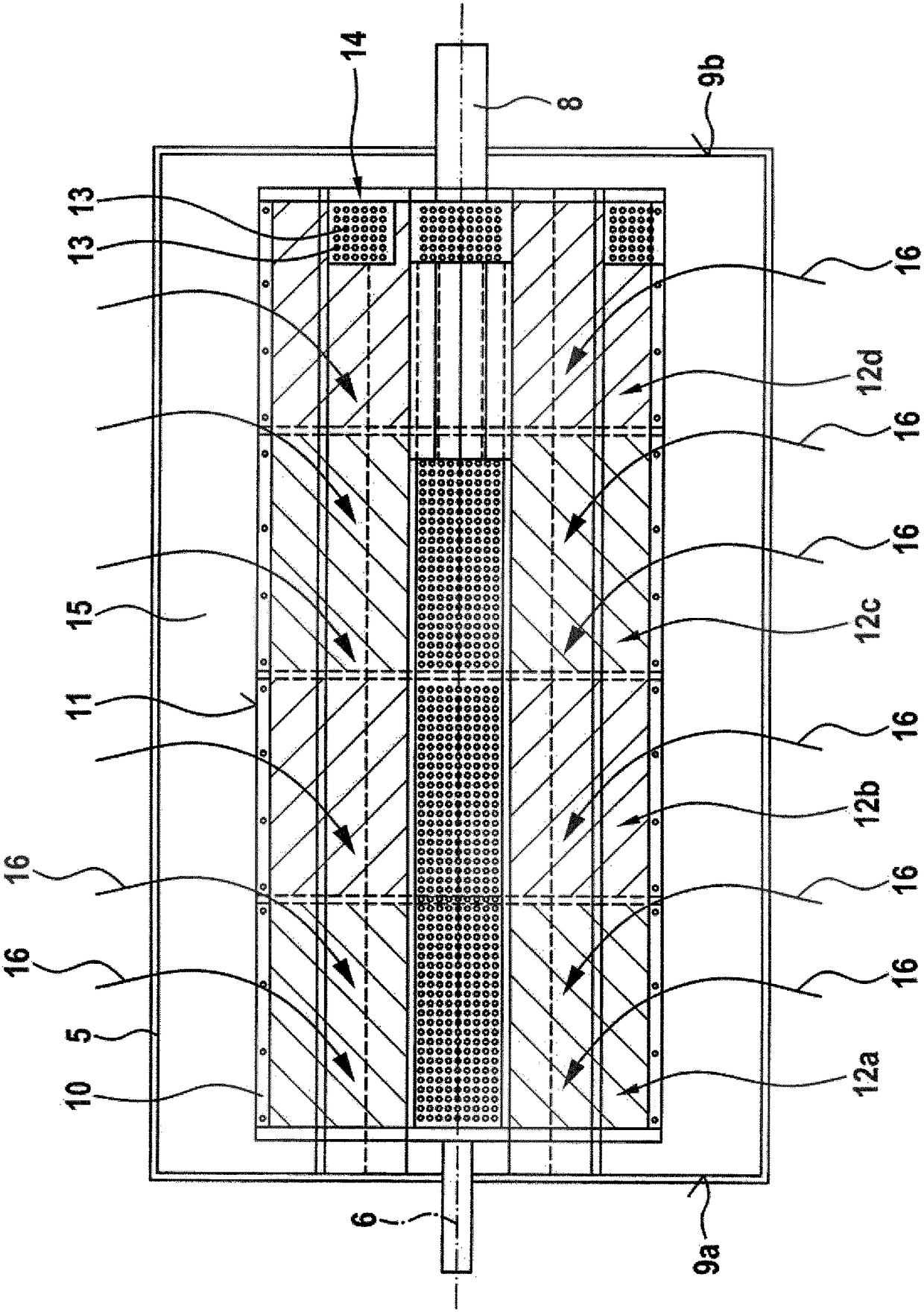

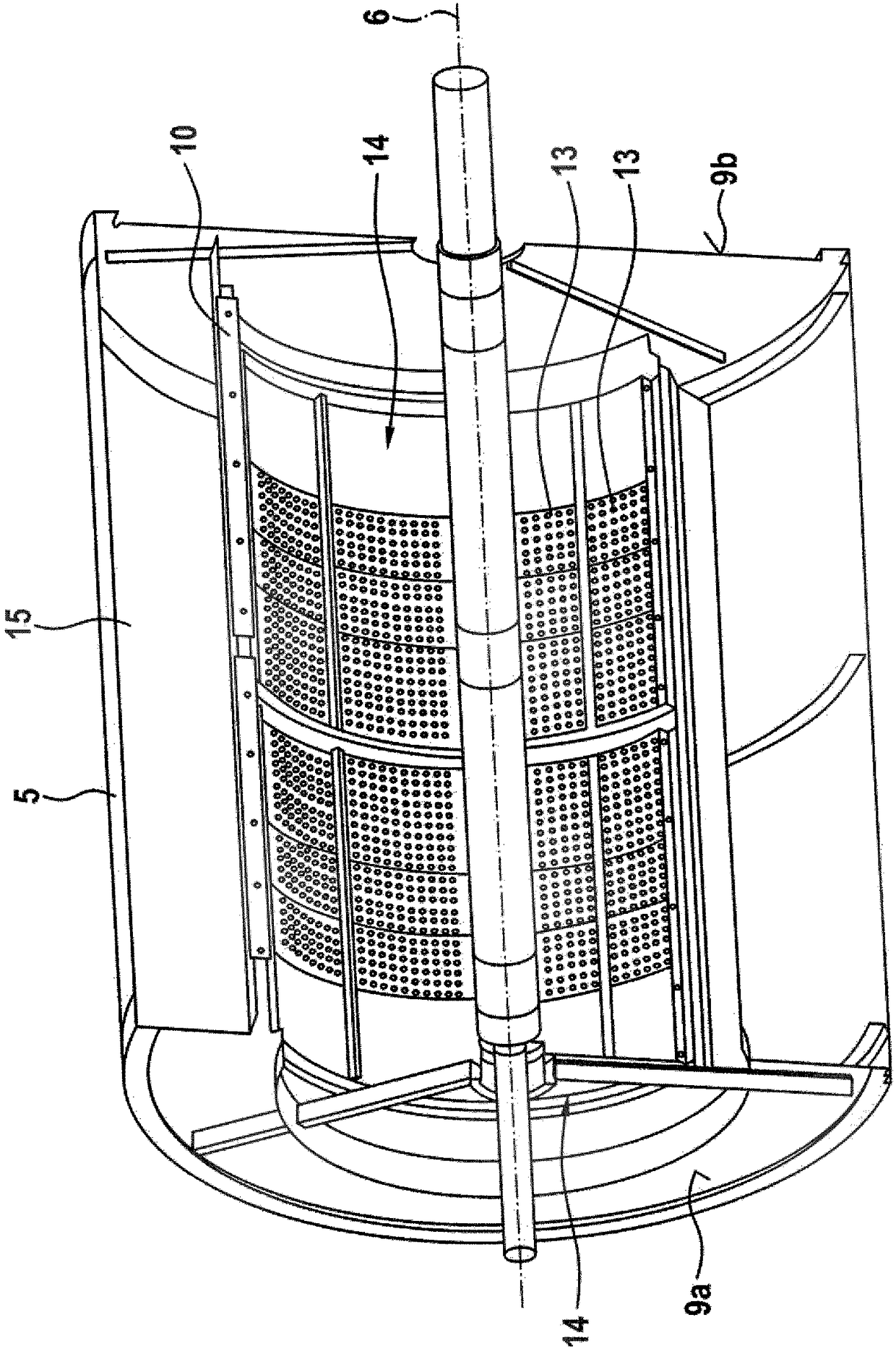

Spinning head and filter device for said type of spinning head

InactiveCN1863947AFlow balanceHomogeneous flowSpinning solution de-aeratingSpinnerette packsProduction rateBiomedical engineering

The invention relates to a spinning head which is used to melt spin a plurality of synthetic filaments, and to a filter device for said type of spinning head. A filter device is arranged between an inlet plate comprising a melt inlet and a die base comprising several die holes, said filter device comprising a cylindrically-shaped filter ring element which can be cross-flown from the outside to the inside. A separate second filter ring element is associated with the first filter ring element in order to form a sufficient filter surface with large melt through-put rates, said second ring element being arranged at a distance in relation to the outer lying first filter ring element. A first partial flow of the melt is guided through the first filter ring element from the outside to the inside and a second partial flow of the melt is guided through the second filter ring element from the inside to the outside in order to combine them together in a release chamber formed between the filter ring elements.

Owner:SAURER GMBH & CO KG

Hybrid diffuser system headloss balancing

Owner:EVOQUA WATER TECH LLC

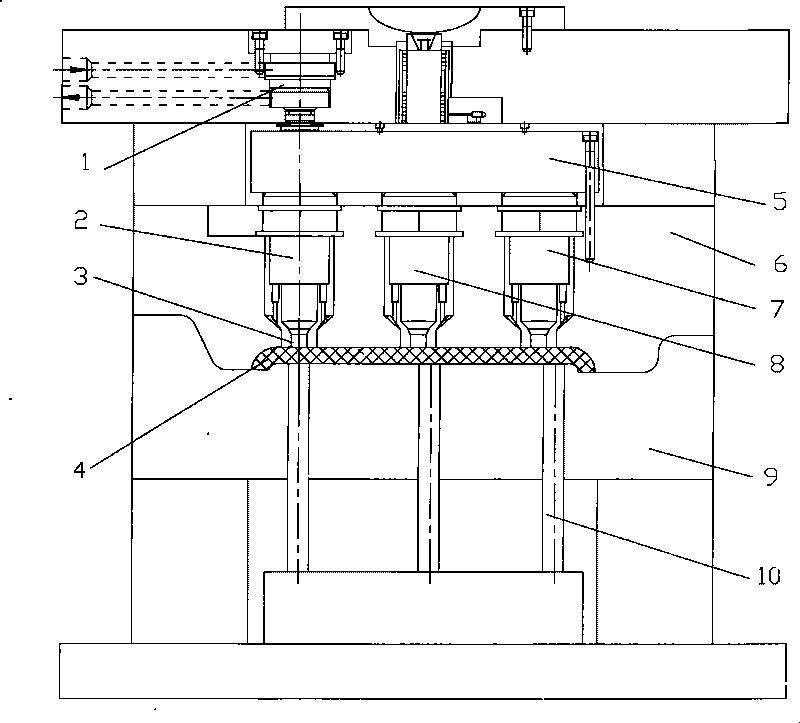

Needle-valve order hot runner injection molding device

The invention relates to a needle-valve order hot runner injection molding device, which is composed of a conventional injection molding die part and a needle-valve order hot runner pouring system part, wherein the conventional injection molding die part consists of a die carrier, a die plate, a cavity, an ejection mechanism, and the like; and the needle-valve order hot runner pouring system part consists of control cylinder, a hot runner plate, a needle valve, gates, a sensor, and the like. The needle-valve order hot runner injection molding device can effectively improve and eliminate welding marks and sink marks of injection molding products, effectively improve the internal stress of the injection molding products, and increase the performance quality of the injection molding products. The needle-valve order hot runner injection molding device is especially suitable for producing large injection molding products.

Owner:CHONGQING TECH & BUSINESS UNIV

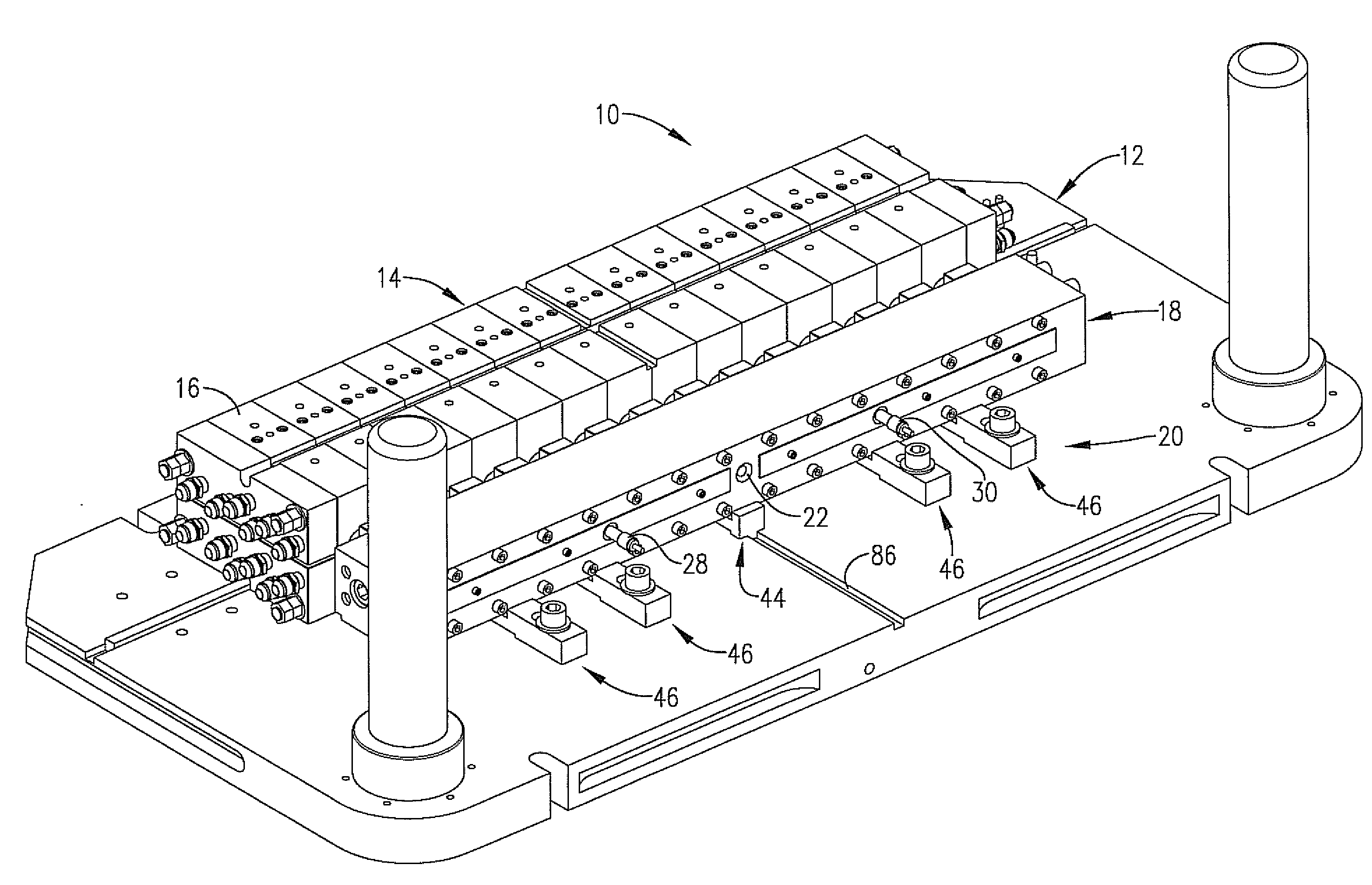

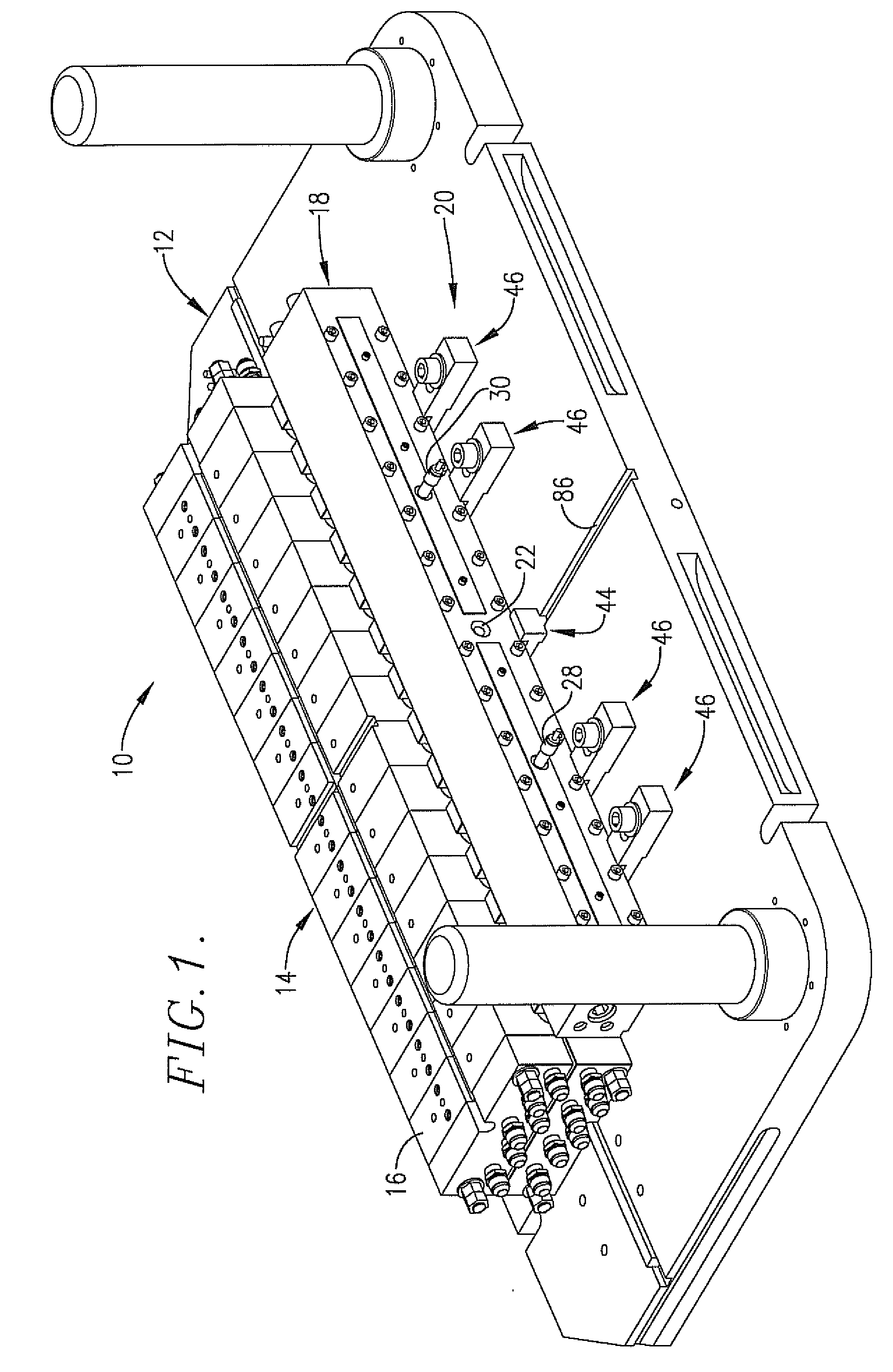

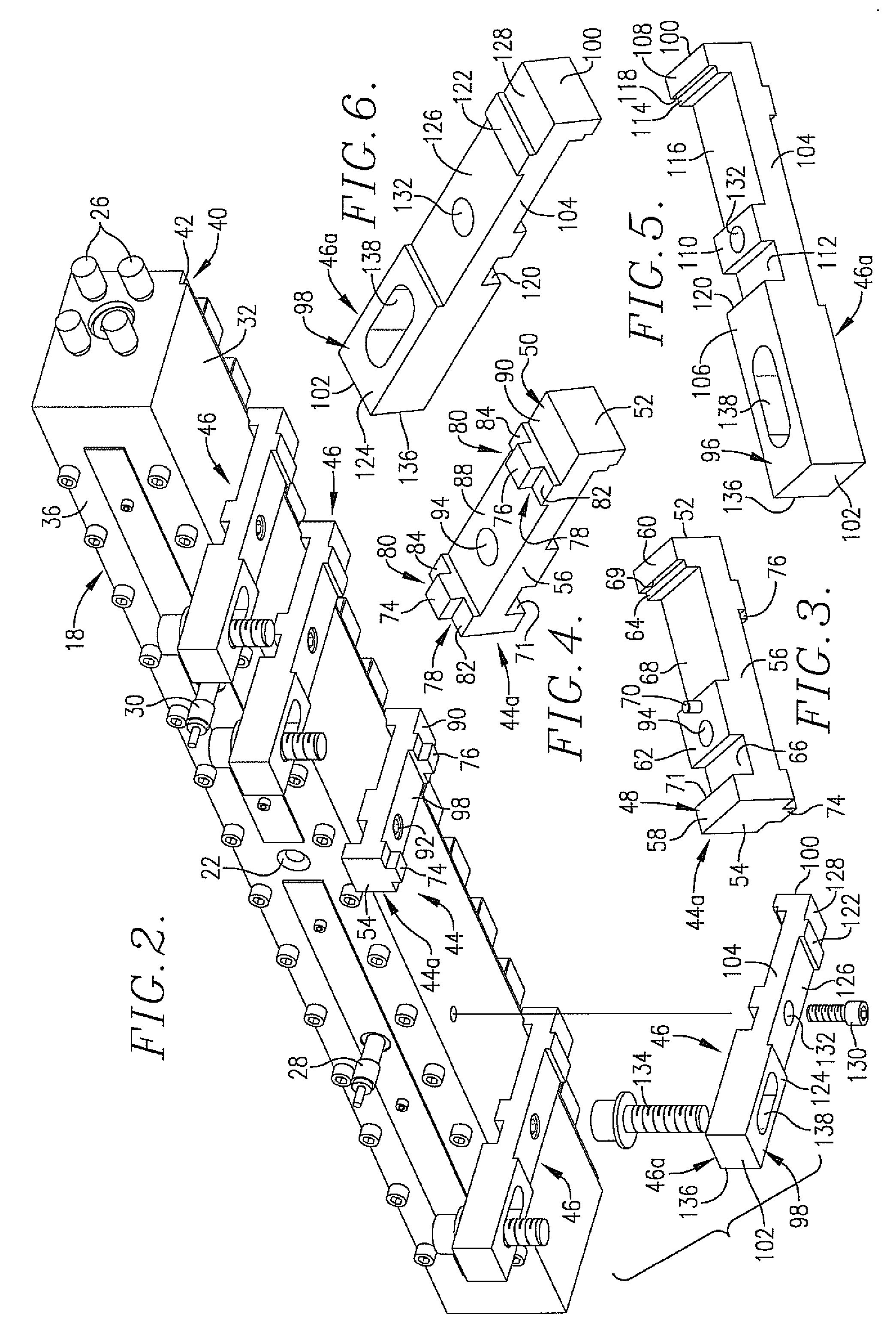

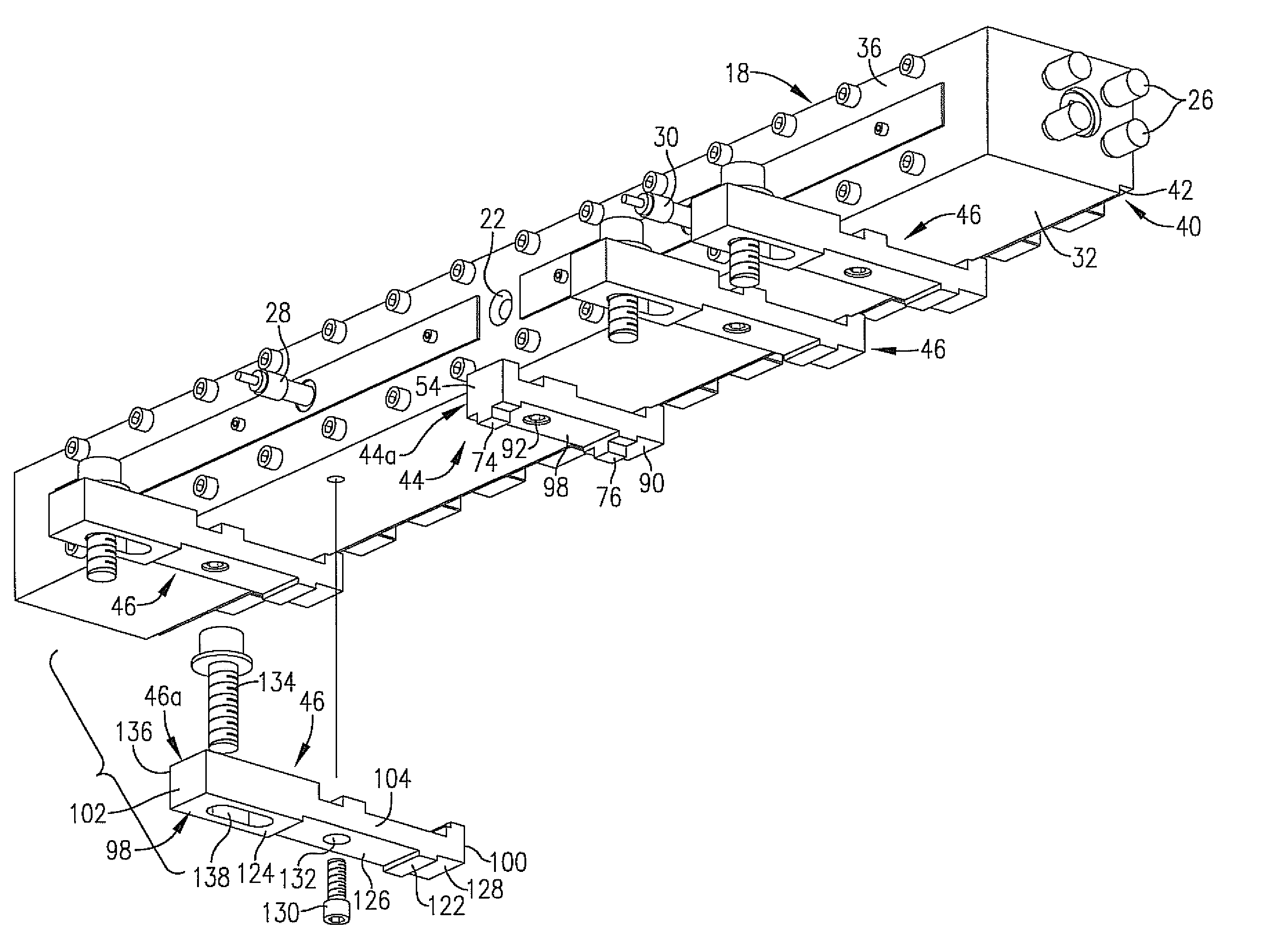

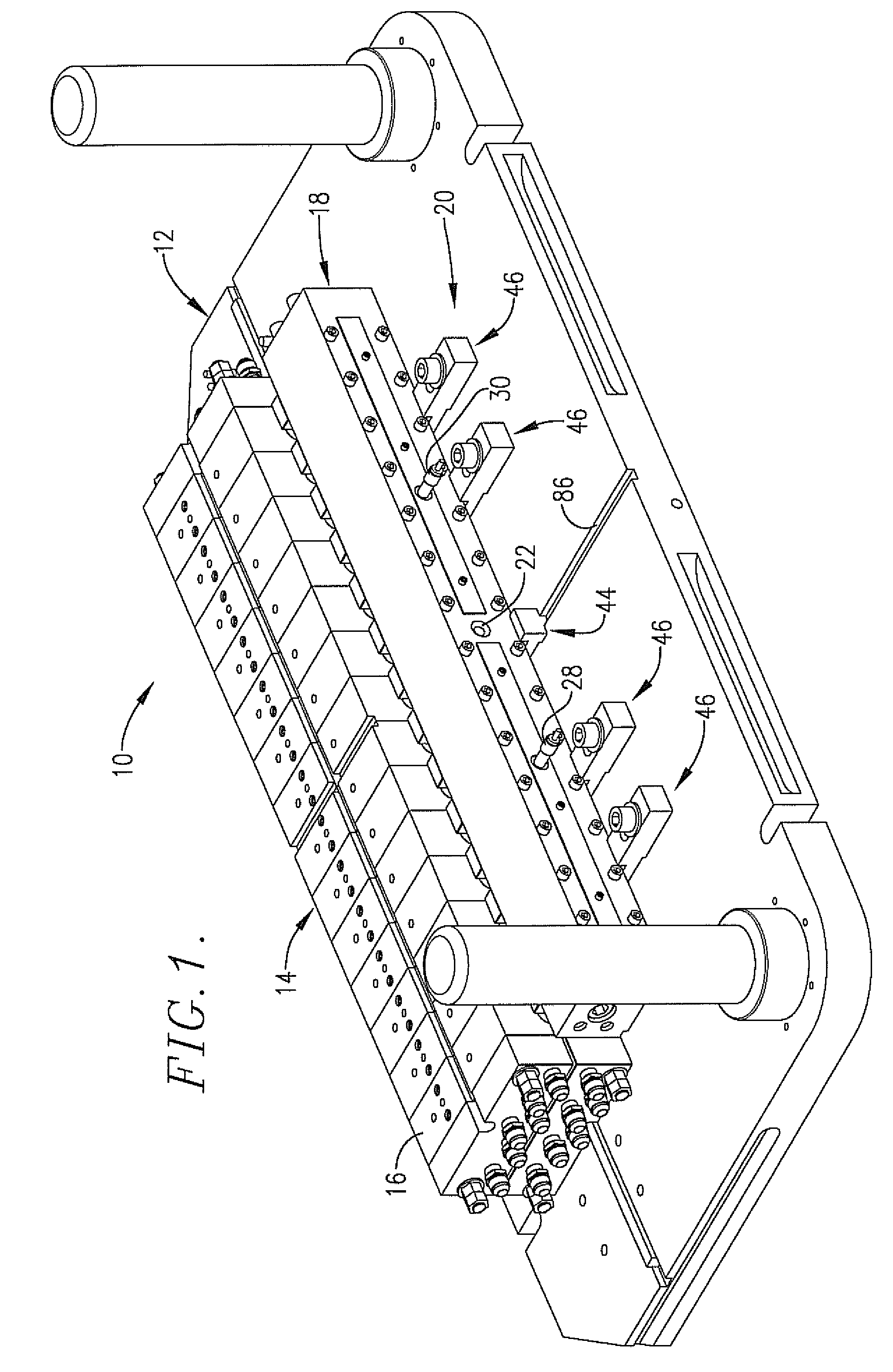

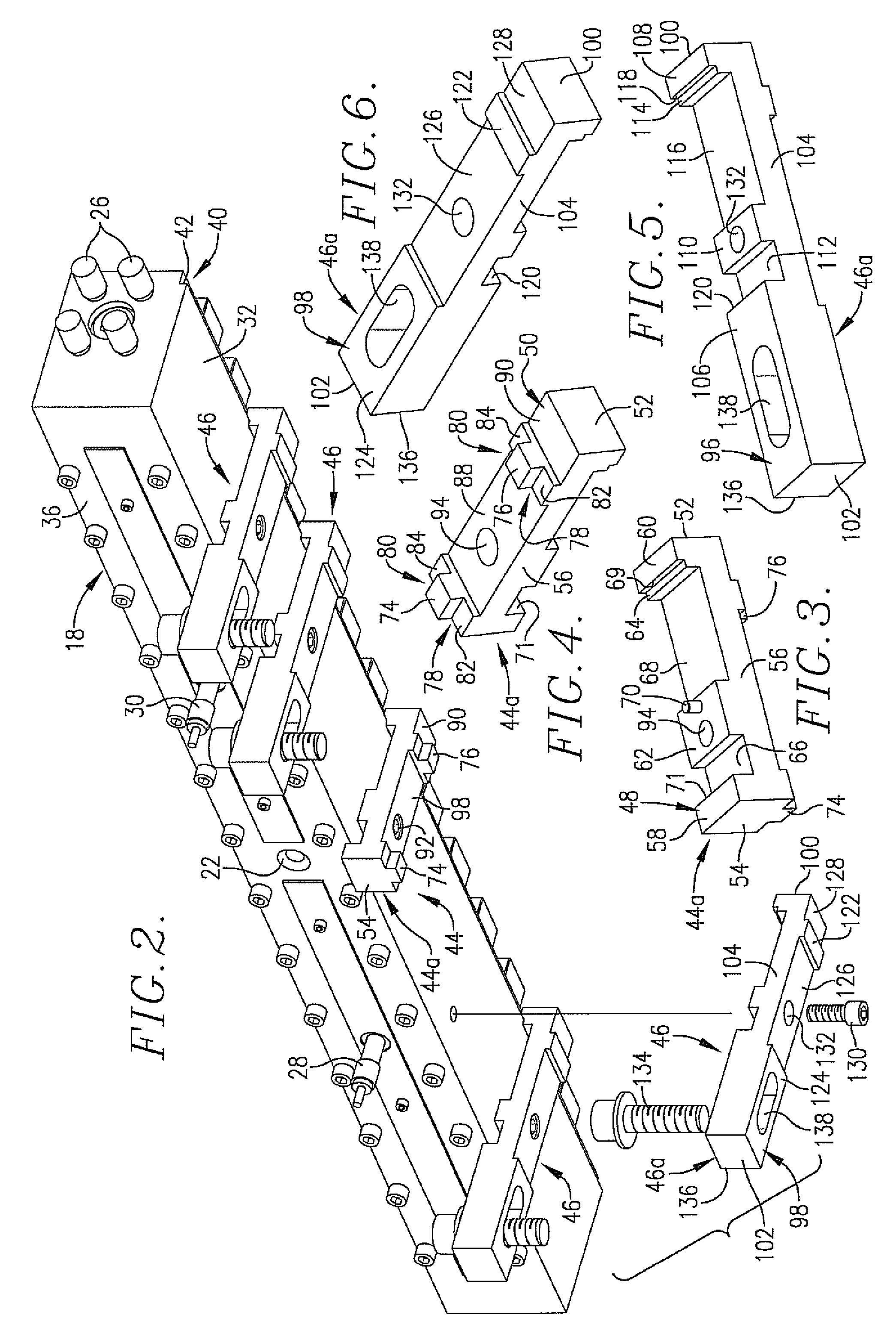

Universal Mounting Brackets for Attaching a Hot Injection Manifold to the Lower Die Set of an Injection Blow Molding Machine

InactiveUS20070218158A1Reduce heat lossFlow balanceCandle holdersLighting support devicesBlow moldingThermal contact

Tooling for the injection station of an injection blow molding machine includes a set of individual mounting bracket assemblies that attach an elongated manifold block to the lower die set of the machine. The relatively slender brackets are designed to have minimal thermal contact with the manifold block without sacrificing stability and structural integrity. Standard sizes of the brackets maybe manufactured in advance to accommodate manifold blocks of different lengths but standard widths.

Owner:R & D TOOL & ENG

Universal mounting brackets for attaching a hot injection manifold to the lower die set of an injection blow molding machine

InactiveUS7481644B2Flow balanceReduce heat lossCandle holdersLighting support devicesBlow moldingThermal contact

Tooling for the injection station of an injection blow molding machine includes a set of individual mounting bracket assemblies that attach an elongated manifold block to the lower die set of the machine. The relatively slender brackets are designed to have minimal thermal contact with the manifold block without sacrificing stability and structural integrity. Standard sizes of the brackets maybe manufactured in advance to accommodate manifold blocks of different lengths but standard widths.

Owner:R & D TOOL & ENG

Three-layer divided-flow hot runner rack

The invention relates to a three-layer divided-flow hot runner rack comprising a hot runner rack in which a main gate is arranged. The invention is characterized in that a layer of first runner, a layer of secondary runner and a layer of third runner are arranged in the hot runner rack, wherein the first runner is communicated with the main gate; first blanking holes are arranged in the first runner and are communicated with the secondary runner in which secondary blanking holes are arranged; the secondary blanking holes are twice or more than twice as many as the first blanking holes; the secondary blanking holes are communicated with the third runner; and discharge holes twice or more than twice as many as the secondary blanking holes are arranged in the third runner. The scheme uses the integration of the three layers of runners and the multi-layer hot runner, outlets in the hot runners progressively increase in a ladder form, and the discharge holes of the third runner are uniformly distributed on the lower surface of the hot runner rack, as well as flow is in balance, thereby causing the arrival time of each point position of a product gate to be consistent so as to cause products to reach smoothness, sufficient injection molding, high intensity and long service life.

Owner:浙江荣信模具塑料有限公司

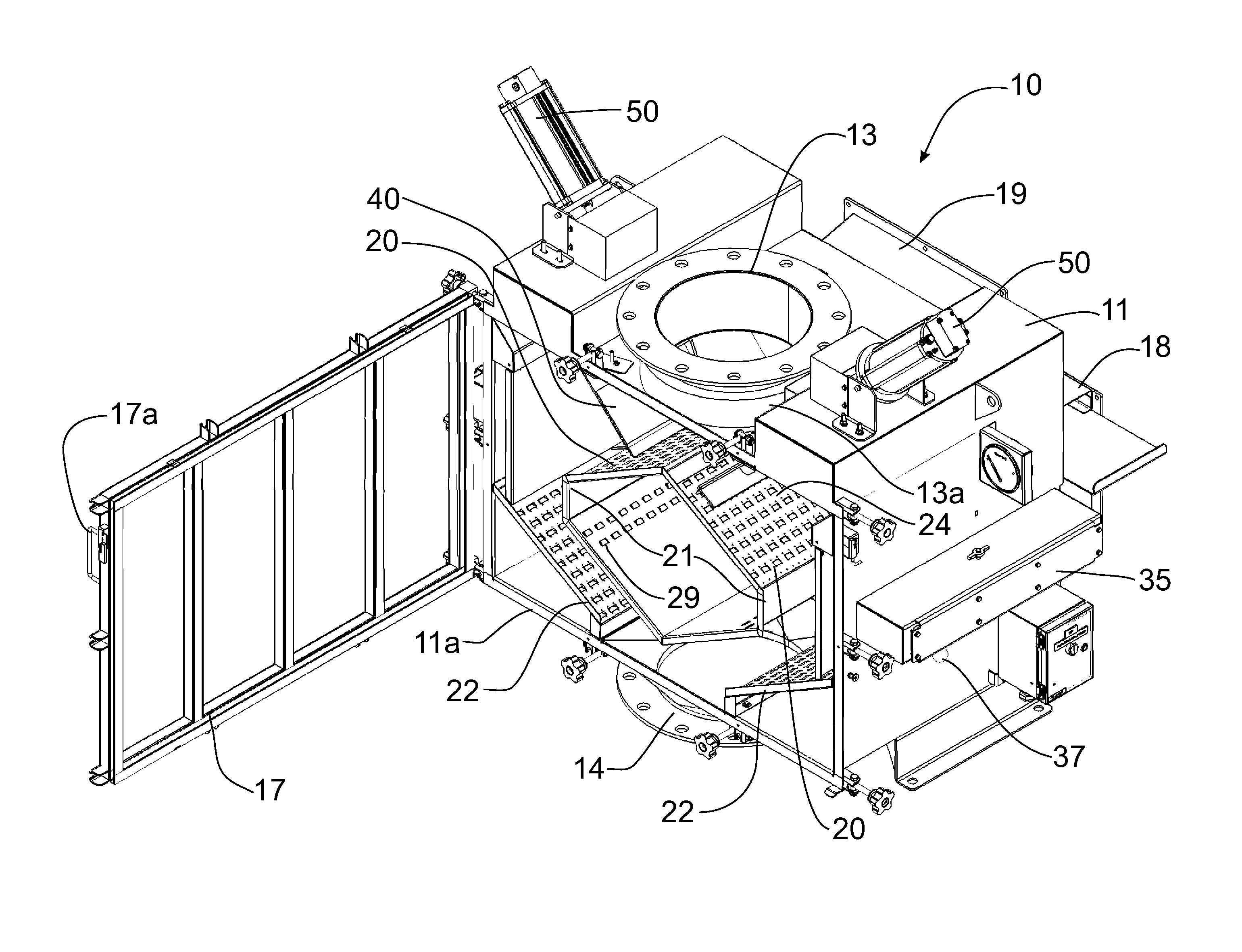

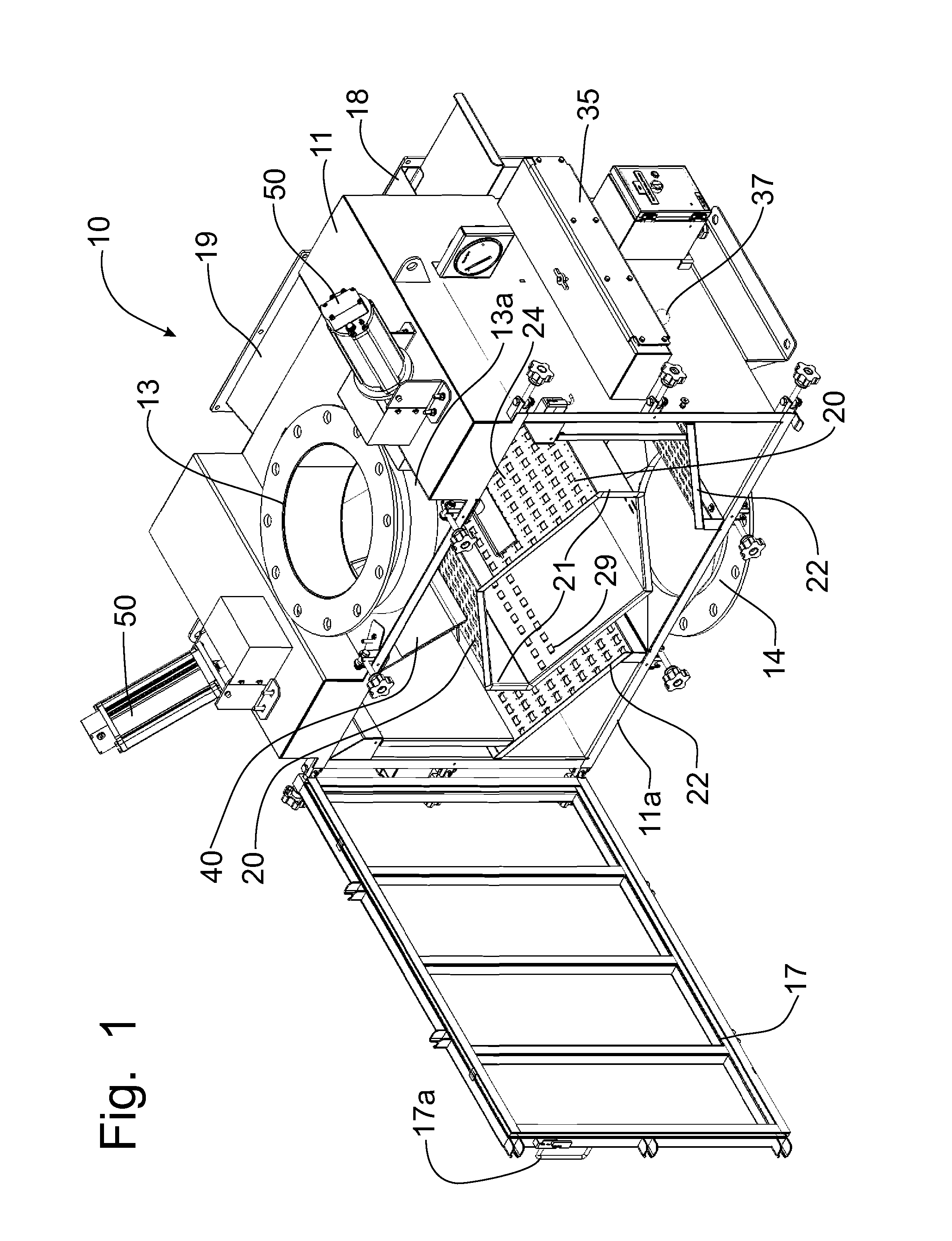

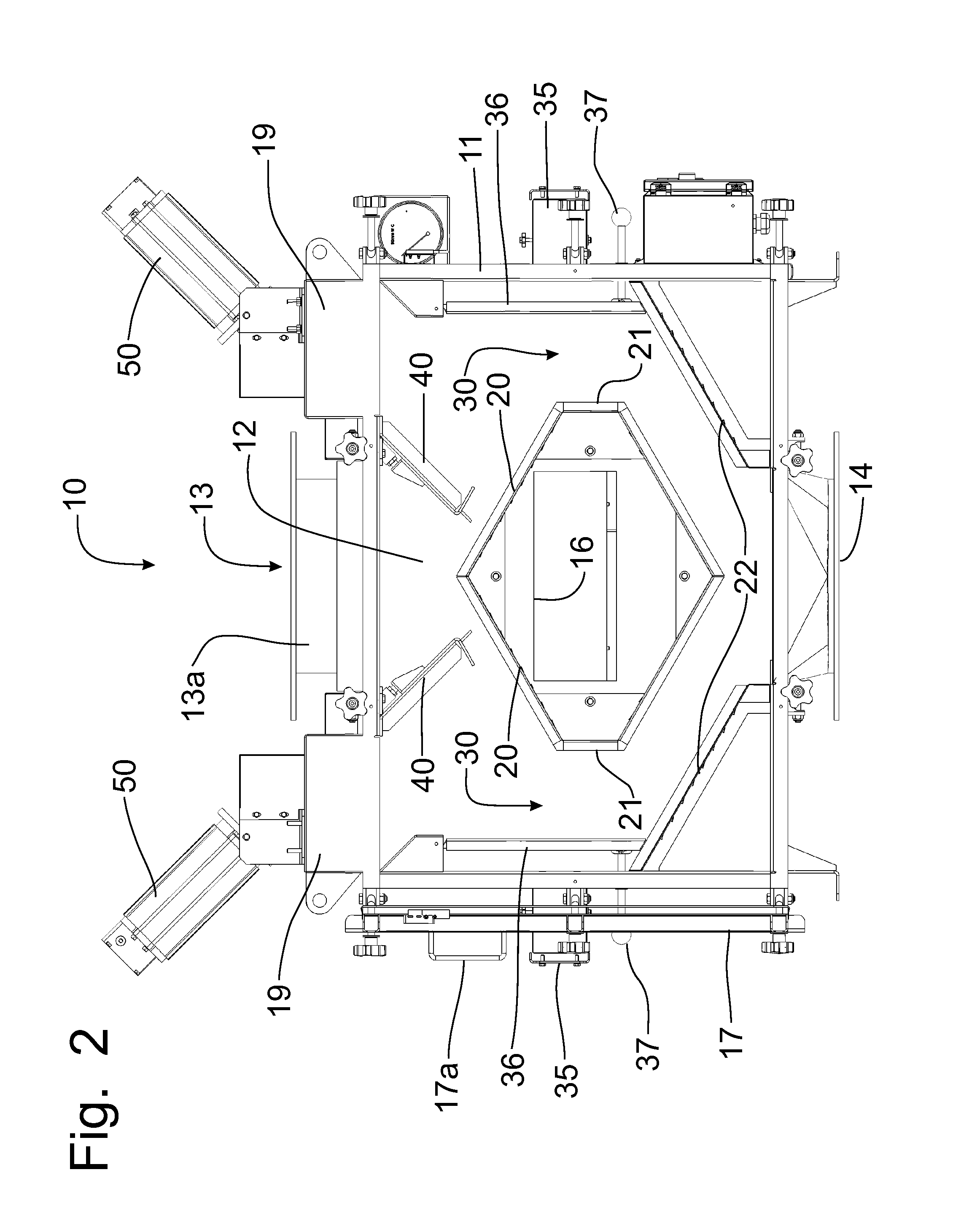

Dedusting Apparatus Having Actuator Controlled Inlet Deflectors to Provide Adjustable Product Flow Regulation

A dedusting apparatus is provided with movable inlet deflectors that are positionally controlled by actuators to vary the rate of flow of particulate material over the wash decks. The inlet deflectors are formed with a fixed member that extends between the front and rear walls of the dedusting apparatus and extends downwardly from the top wall to terminate in a spaced relationship to the surface of the wash decks. A movable member is operatively coupled to an actuator to overlie the fixed member and be movable to be adjacent the surface of the wash deck to terminate flow of material past the deflectors. Particulate material can accumulate above the wash decks and between the deflectors to fill the volume to the inlet opening to permit a full loading of flow over the full width of the wash decks when the deflectors are raised by the actuators.

Owner:PELLETRON CORP

Device and method for thermally treating textile material web

PendingCN108139149AFlow Inhomogeneity Compensation and CorrectionRegulate permeabilityDrying solid materials with heatDrying gas arrangementsHeat treatedElectrical and Electronics engineering

The invention relates to a device and a method for thermally treating a textile material web, having at least one through-air drum with a perforated lateral surface and with a casing which is at leastpartly looped by a material web, wherein a heated gas flows through the material web and the casing of the through-air drum. The invention is characterized in that an air conducting cylinder (10) with a plurality of openings (13) is arranged within the through-air drum (5), and the heated gas is drawn off via the interior of the air conducting cylinder, the air or gas permeability of the air conducting cylinder (10) being adjustable.

Owner:TRUETZSCHLER GRP SE

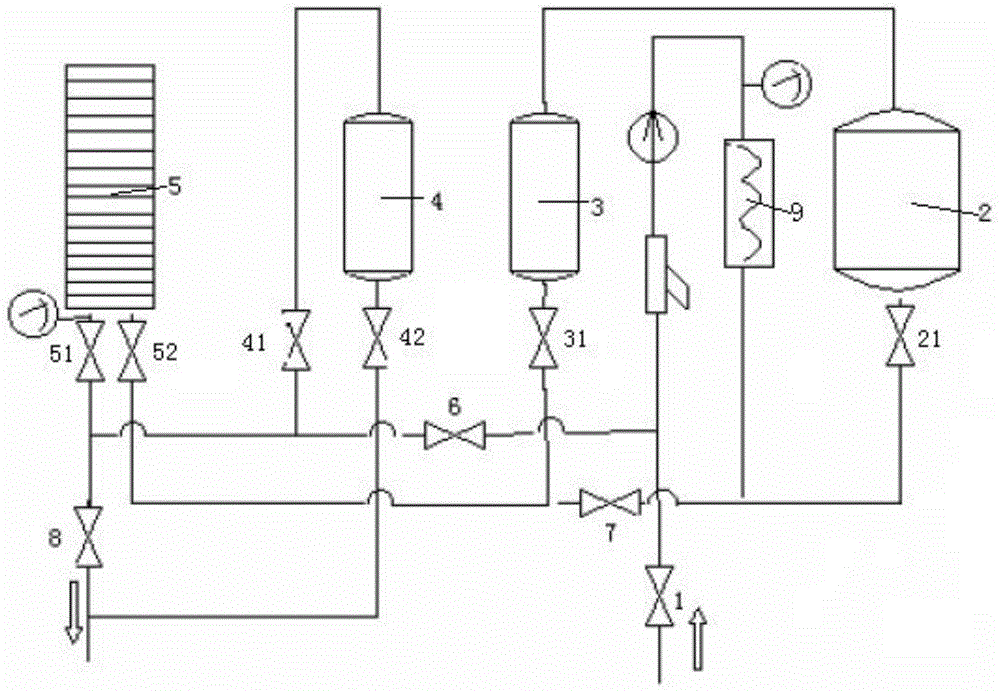

Oil processor for transformer

InactiveCN104575965AImprove adsorption efficiencyFlow balanceTransformers/inductances coolingFiltration circuitsTransformerInlet valve

The invention discloses an oil processor for a transformer. The oil processor comprises an oil inlet valve, an adsorption tank group, a first buffering tank, a second buffering tank, a slab oil filter and an oil outlet valve, wherein the outlet of the oil inlet valve is connected with the inlet of the adsorption tank group, the outlet of the adsorption tank group is connected with the inlet of the first buffering tank, and the outlet of the first buffering tank is connected with the inlet of the slab oil filter; the outlet of the slab oil filter is respectively connected with the inlet of the oil outlet valve and the inlet of the second buffering tank group, the outlet of the second suffering tank group is connected with the outlet of the oil outlet valve, and two ends of an inner circulating valve are correspondingly connected with the outlet of the first buffering tank and the outlet of the oil inlet valve; two ends of an oil pumping valve are correspondingly connected with the inlet of the slab oil filter and the inlet of the adsorption tank group. The oil processor has the beneficial effects that the deteriorated oil can be retextured conveniently, rapidly, safely and efficiently on the scene, vast resources are saved, the production cost of an enterprise is lowered, and the environmental pollution is reduced.

Owner:STATE GRID CORP OF CHINA +3

Lithium ion power battery box

ActiveCN103199203BCool evenlyObvious temperature differenceSecondary cellsCell component detailsLithiumPower battery

The invention relates to a lithium ion power battery box, which comprises a battery box body for alternately arranging batteries inside the body along a set arrangement direction, and a base air channel arranged in the battery box body, wherein the flow direction of the base air channel is consistent with the set arrangement direction; the battery box is also provided with a reinforced cooling air channel for delivering cooling air separated from the base air channel; the reinforced cooling air channel is provided with jet holes for directing the cooling air into a set cooling area in the battery box body; and the cooling area is a gap between front and back adjacent batteries along the battery arrangement direction in set positions or batteries in the set positions. By adopting the lithium ion power battery box, the problem in the prior art that cooling capacity distribution in various parts in the battery box body is non-uniform because the batteries are successively cooled along a single base air channel is solved; and the lithium ion power battery box of the invention can uniformly cool the batteries and improve the overall discharge performance and the service life of the batteries in the battery box.

Owner:CALB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com