Patents

Literature

53results about How to "Processing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

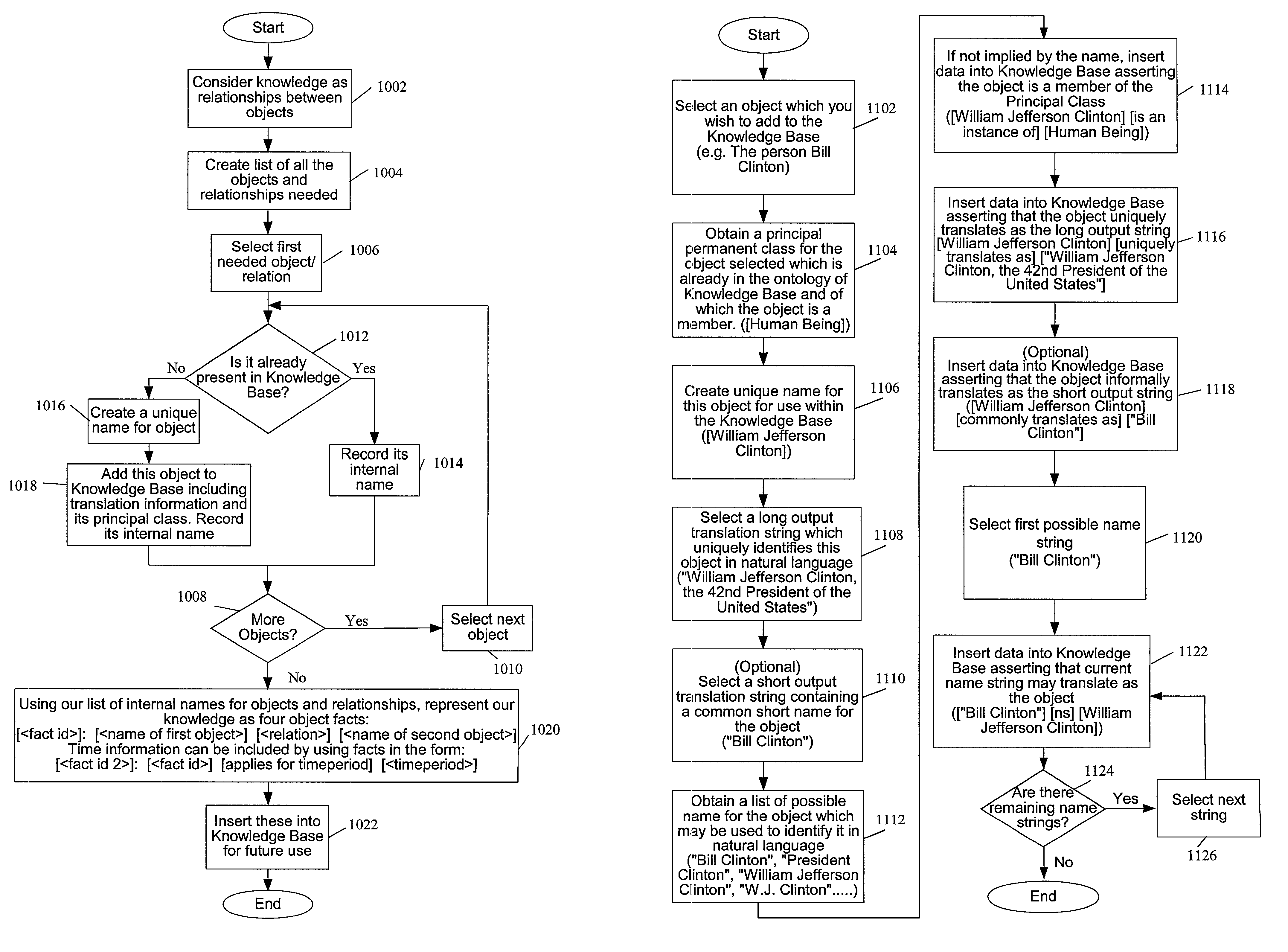

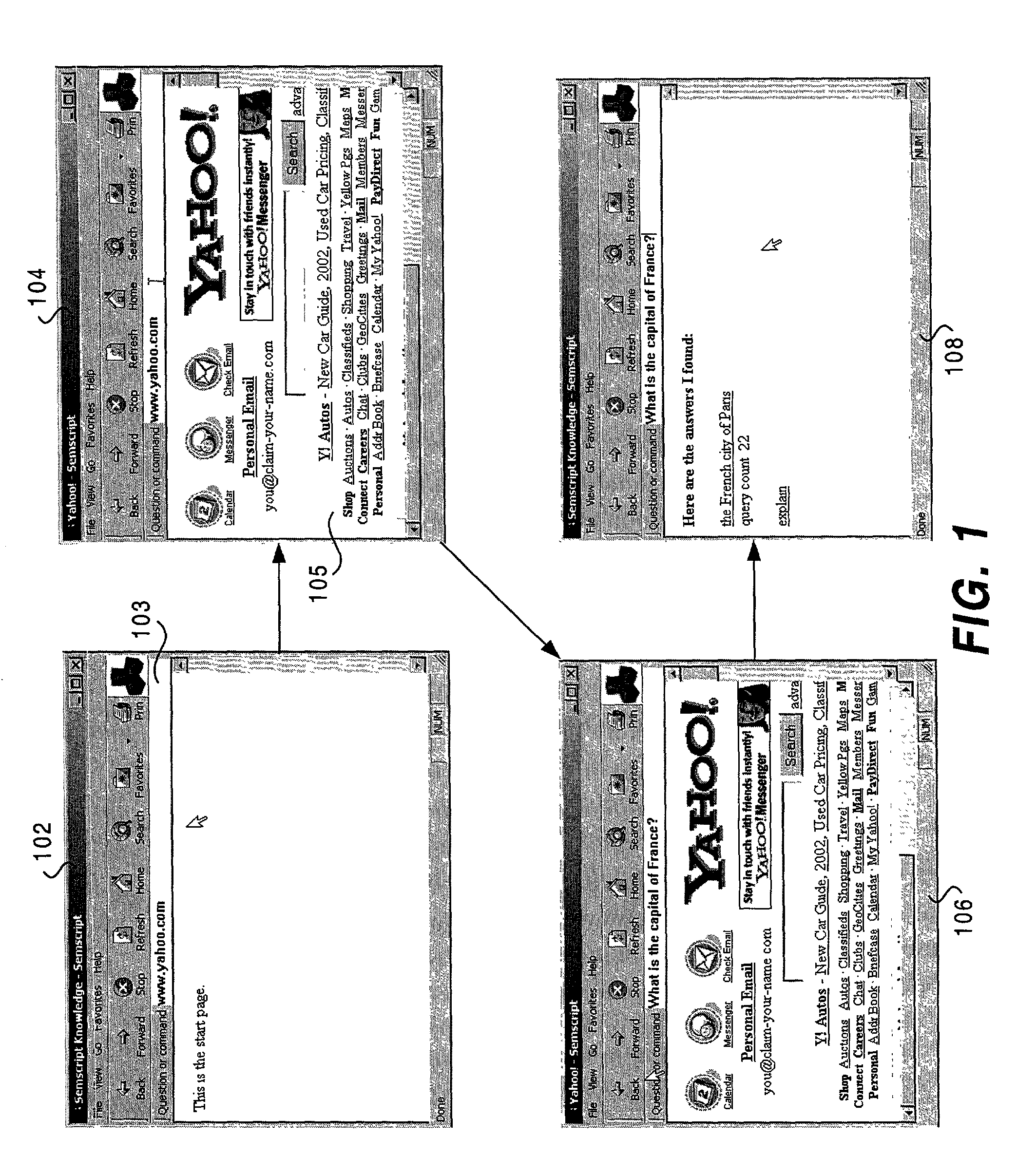

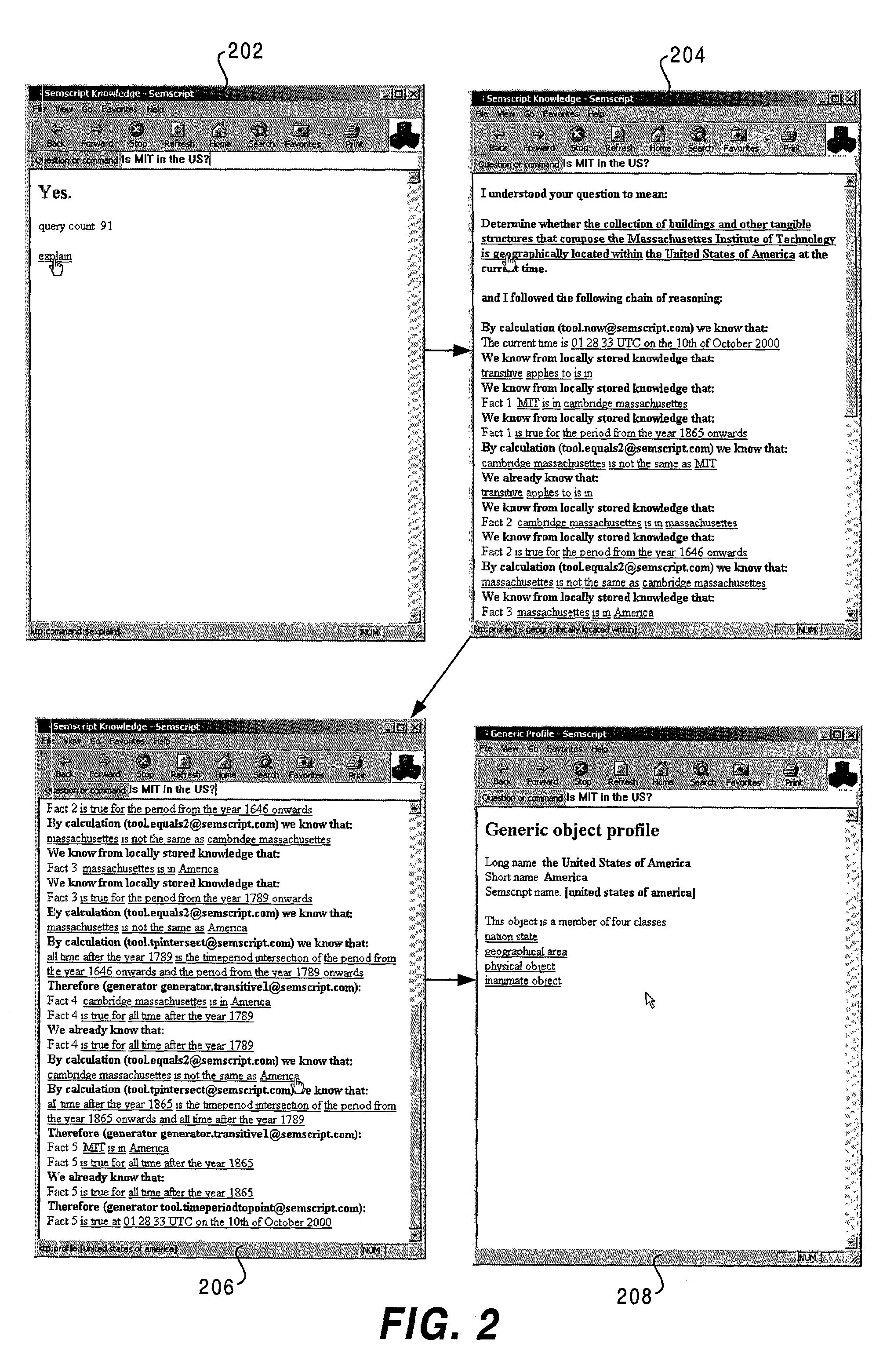

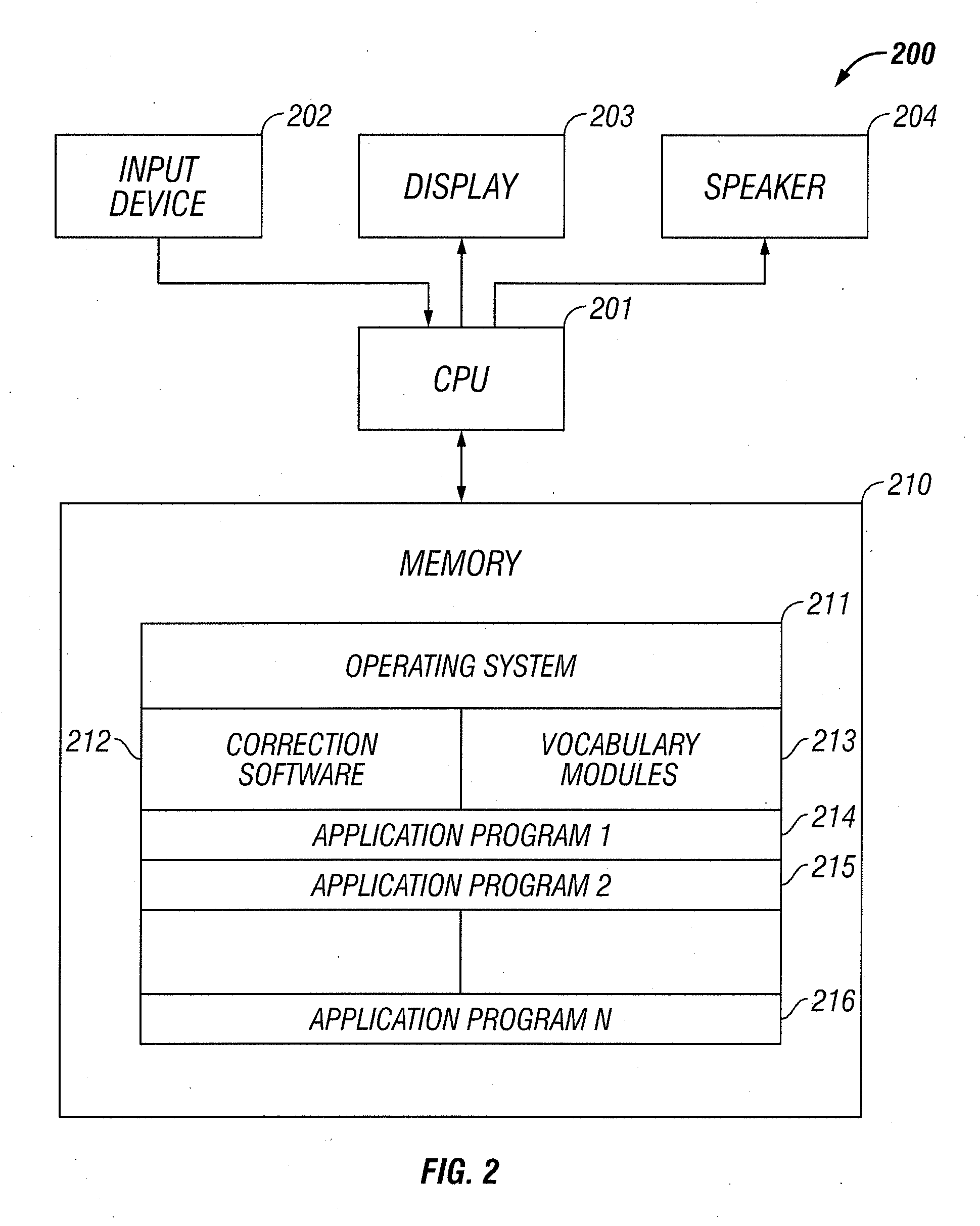

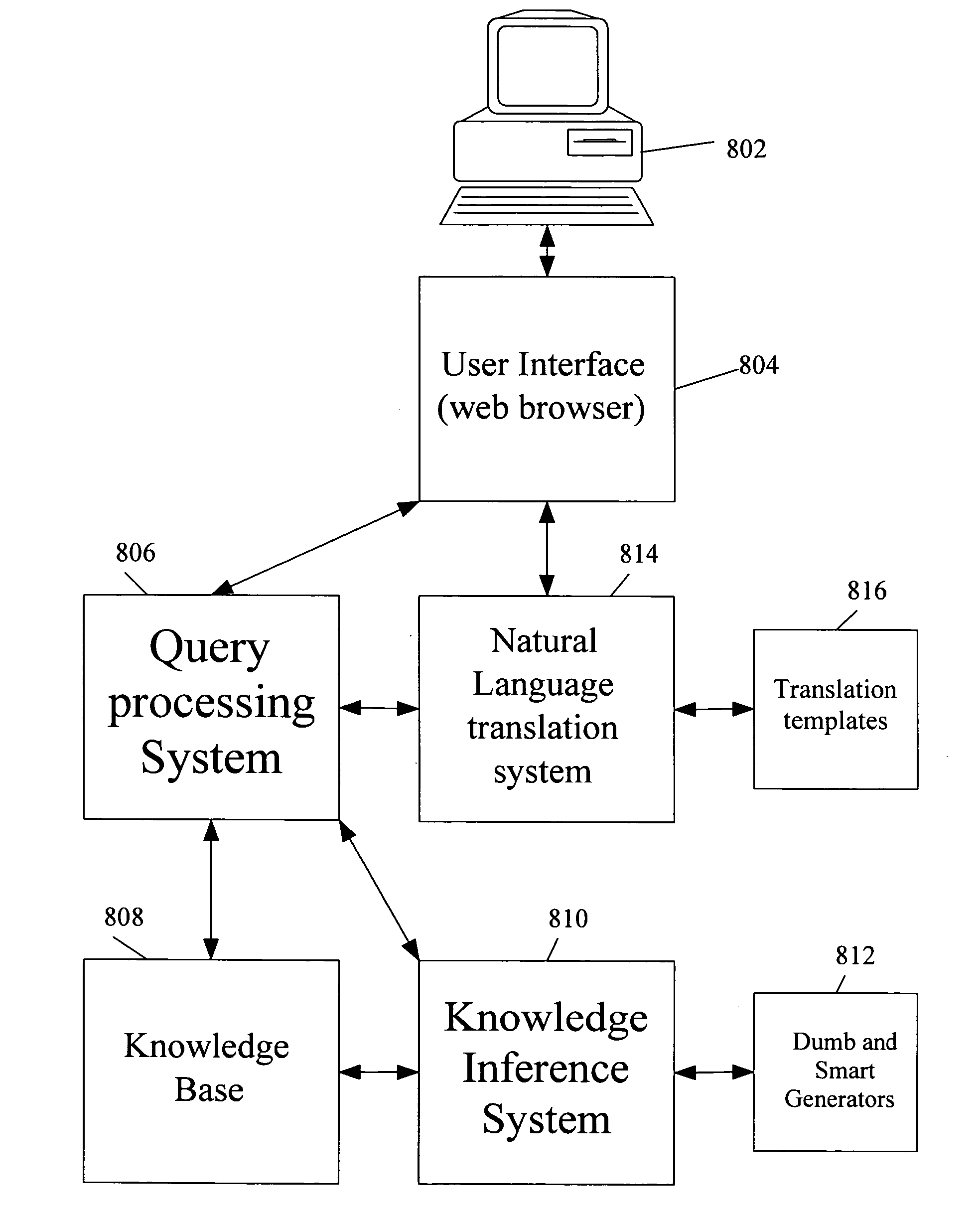

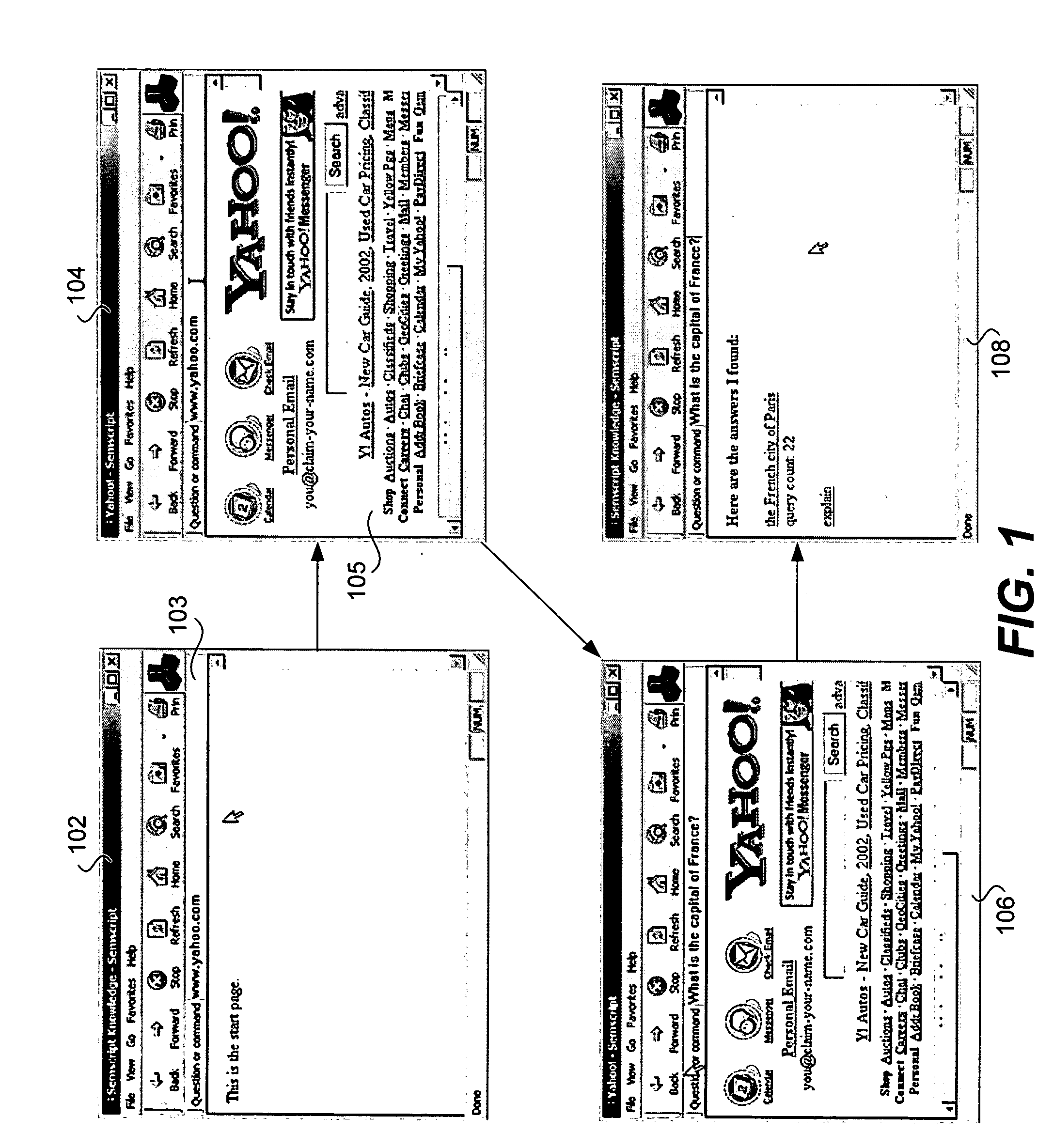

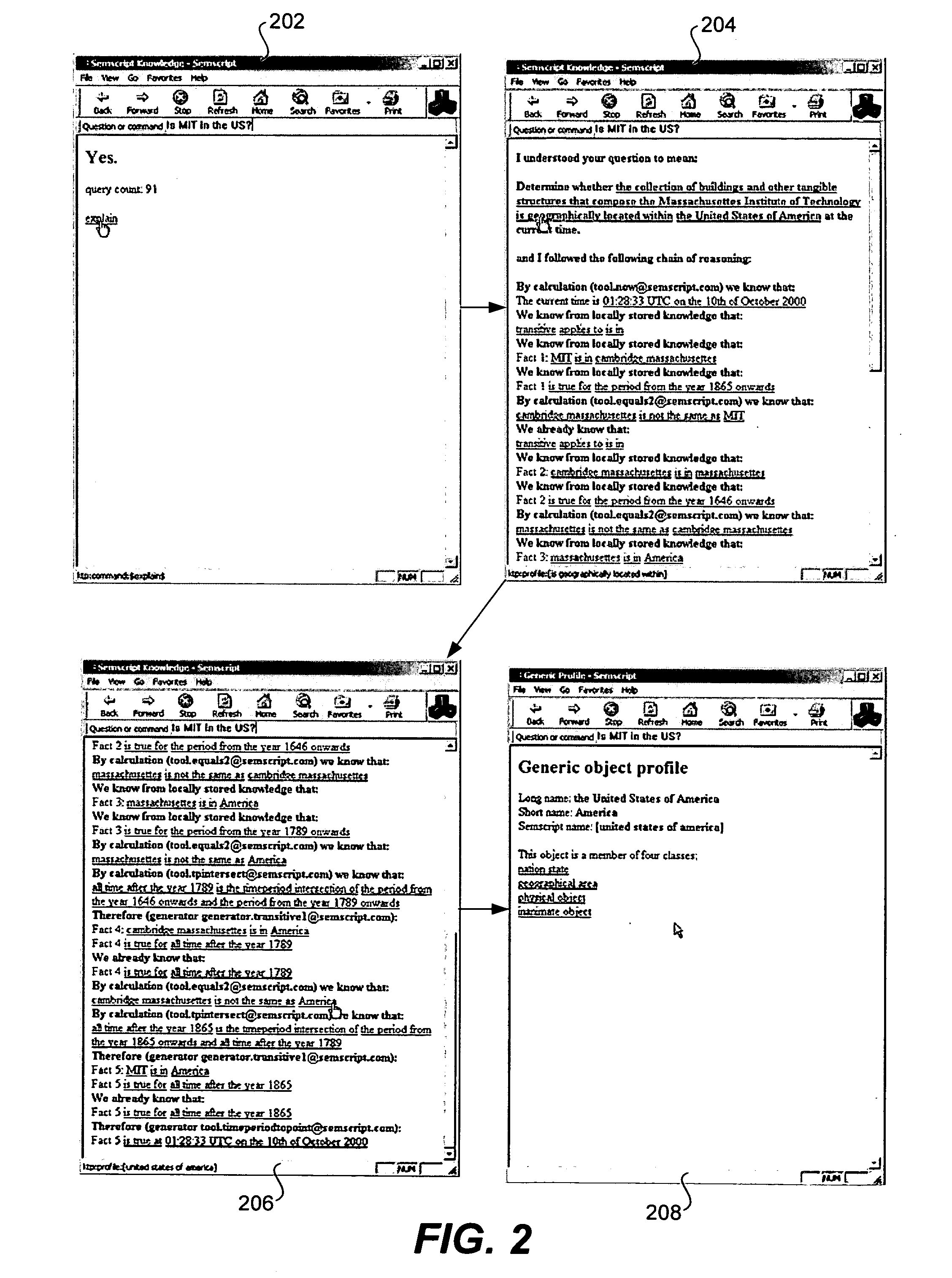

Knowledge storage and retrieval system and method

InactiveUS7013308B1Smooth interfaceSimple processDigital data information retrievalData processing applicationsProgramming languageWeb browser

A system and method for representing, storing and retrieving real-world knowledge on a computer or network of computers is disclosed. Knowledge is broken down into permanent atomic “facts” which can be stored in a standard relational database and processed very efficiently. It also provides for the efficient querying of a knowledge base, efficient inference of new knowledge and translation into and out of natural language. Queries can also be processed with full natural language explanations of where the answers came from. The method can also be used in a distributed fashion enabling the system to be a large network of computers and the technology can be integrated into a web browser adding to the browser's functionality.

Owner:AMAZON TECH INC

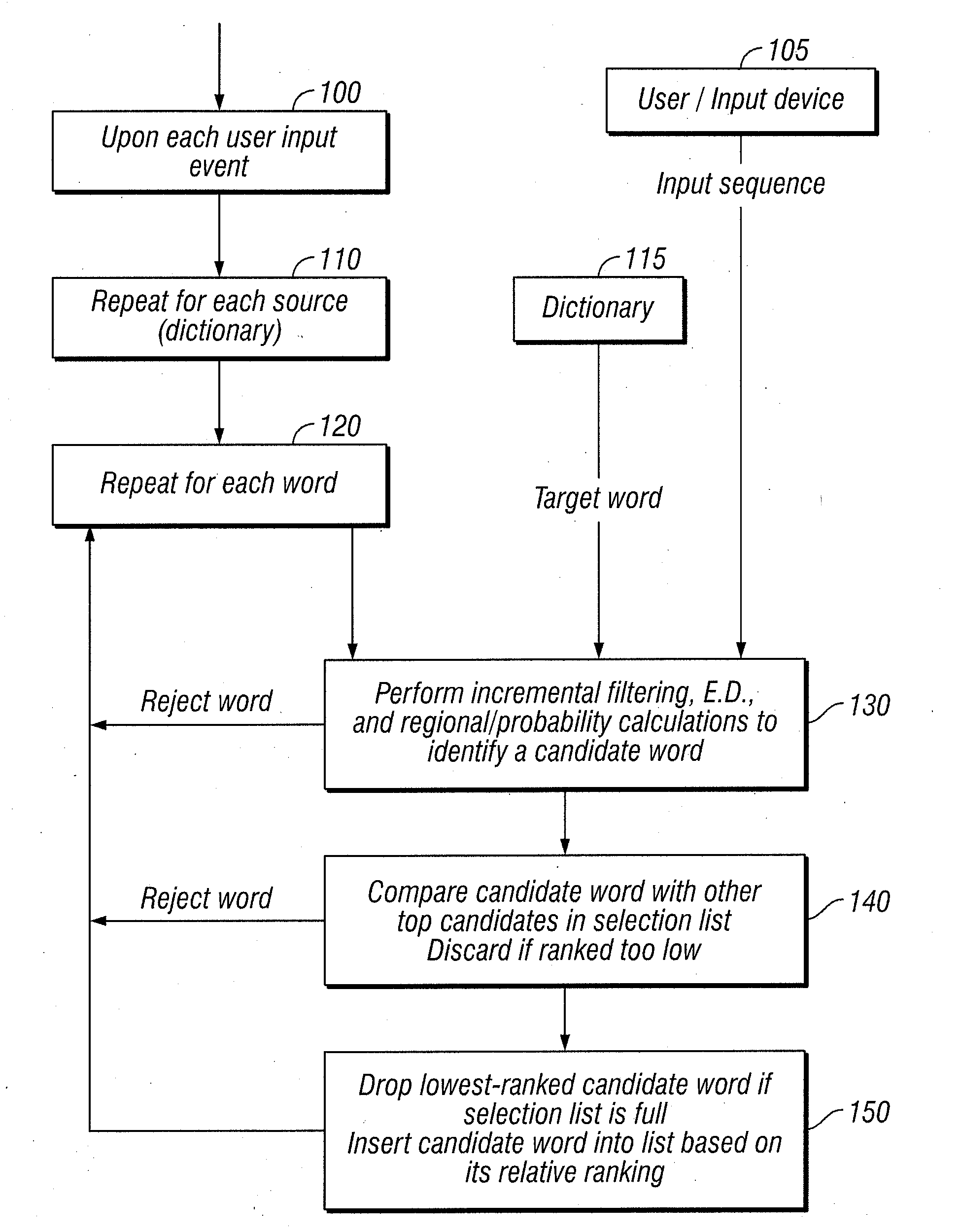

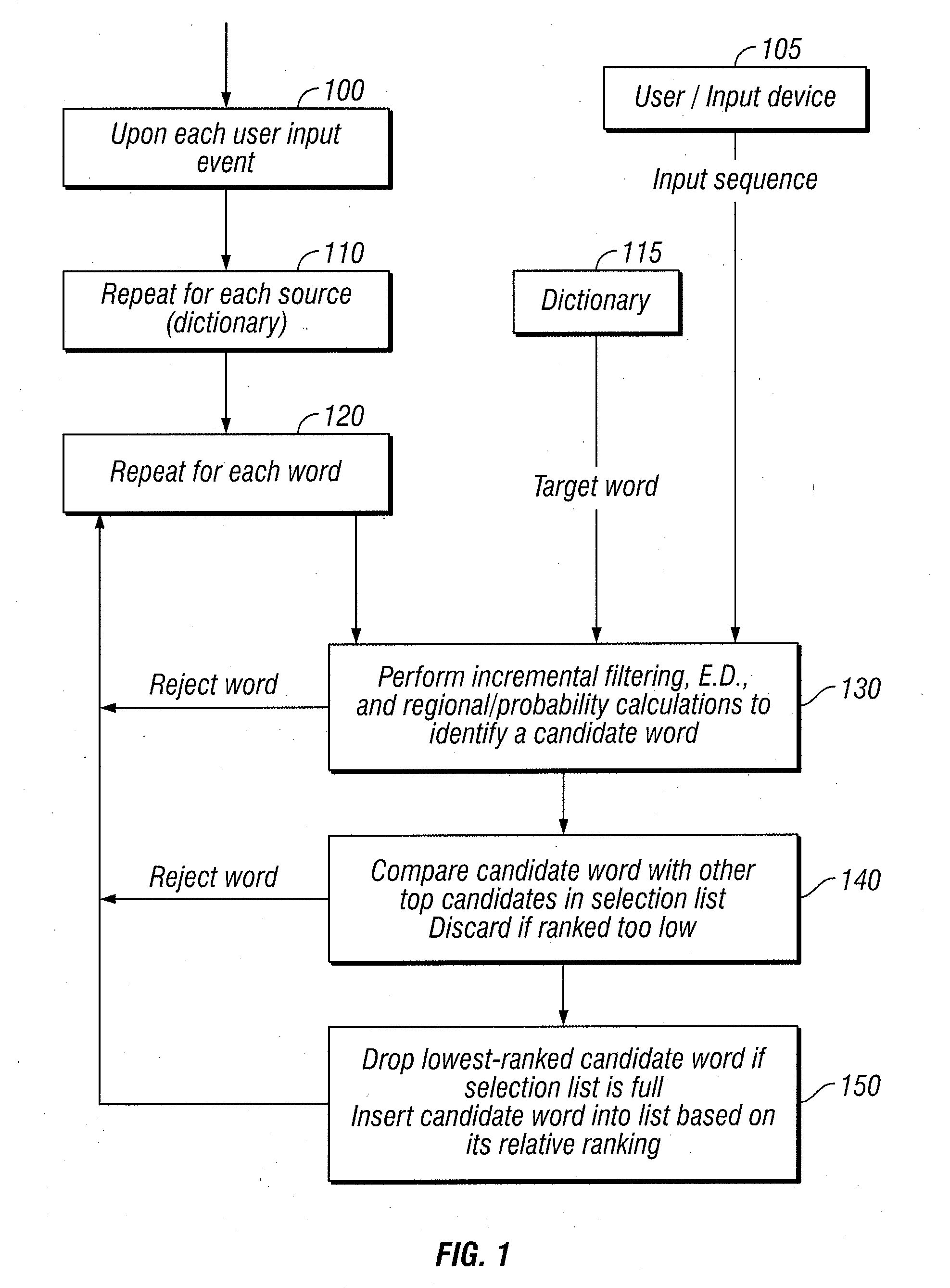

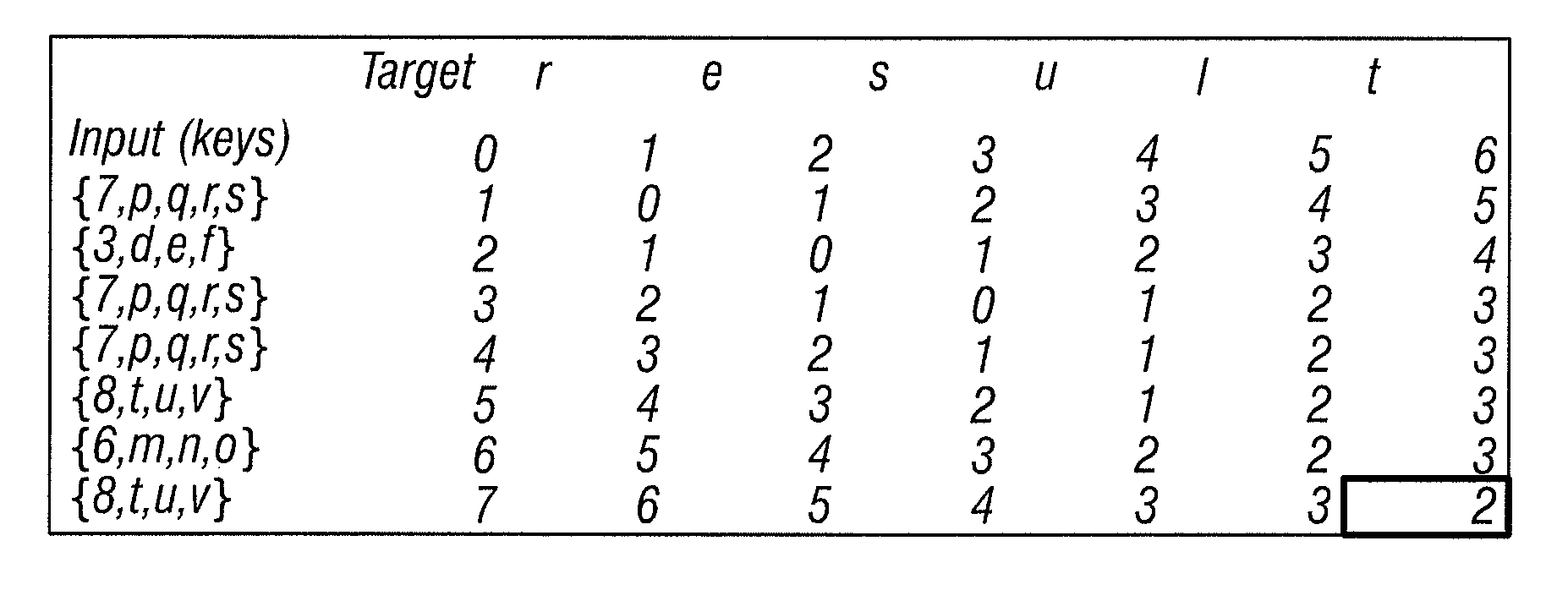

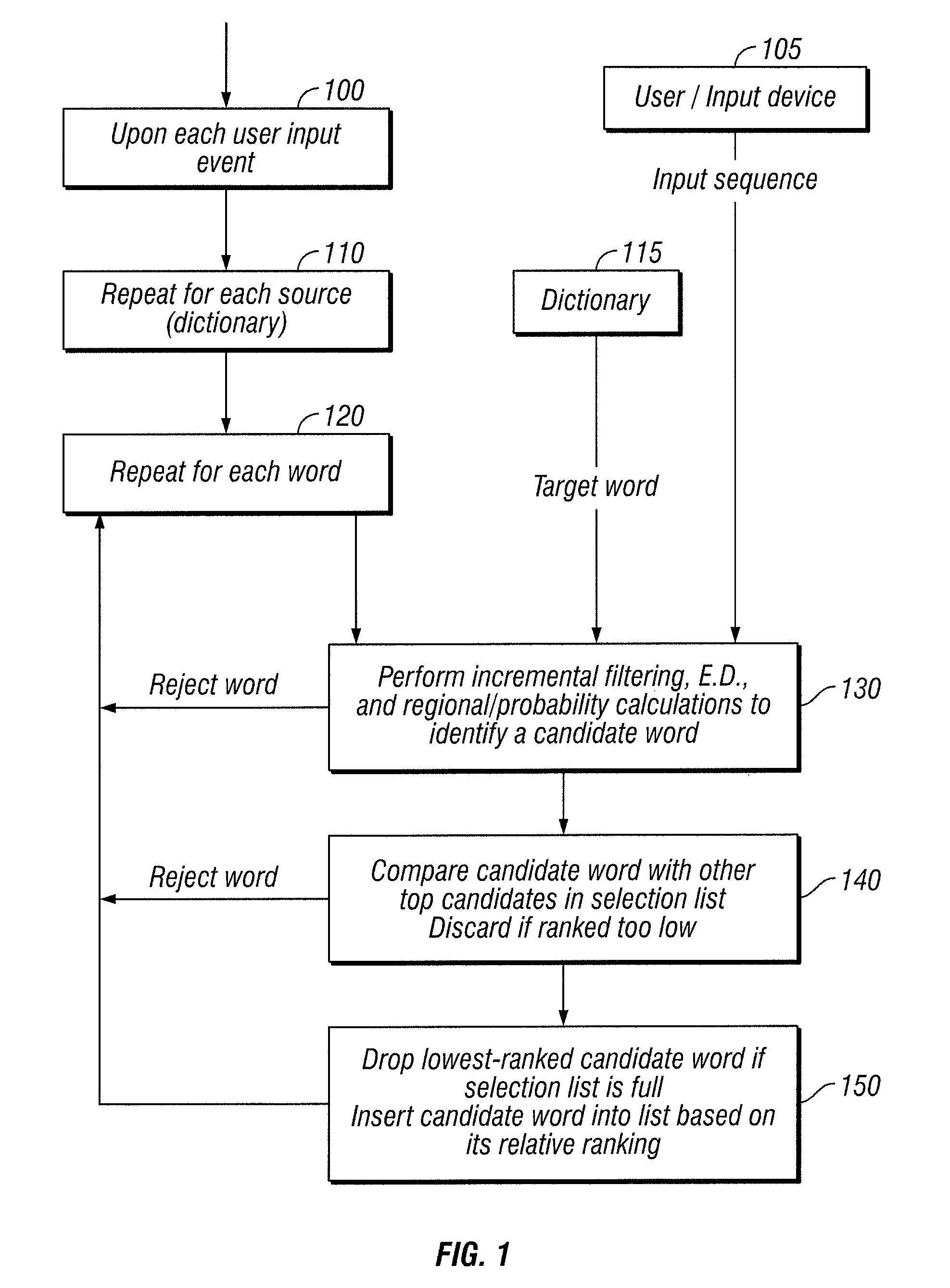

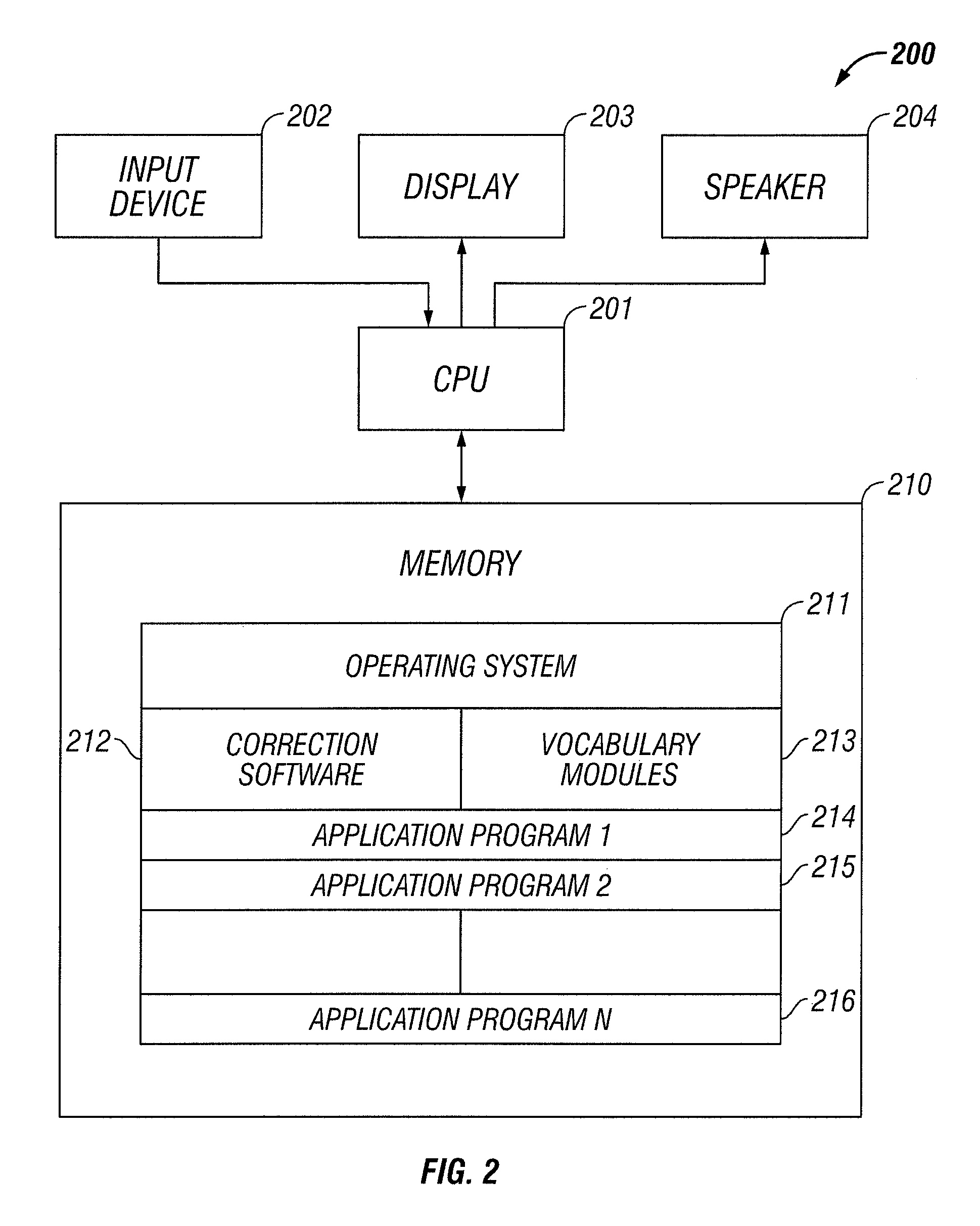

Spell-check for a keyboard system with automatic correction

InactiveUS20080189605A1Text entryType accurateNatural language data processingSpecial data processing applicationsCorrection algorithmAutocorrection

An adaptation of standard edit distance spell-check algorithms leverages probability-based regional auto-correction algorithms and data structures for ambiguous keypads and other predictive text input systems to provide enhanced typing correction and spell-check features. Strategies for optimization and for ordering results of different types are also provided.

Owner:TEGIC COMM

Knowledge storage and retrieval system and method

ActiveUS20070043708A1Simple processProcessing timeData processing applicationsNatural language data processingProgramming languageWeb browser

A system and method for representing, storing and retrieving real-world knowledge on a computer or network of computers is disclosed. Knowledge is broken down into permanent atomic “facts” which can be stored in a standard relational database and processed very efficiently. It also provides for the efficient querying of a knowledge base, efficient inference of new knowledge and translation into and out of natural language. Queries can also be processed with full natural language explanations of where the answers came from. The method can also be used in a distributed fashion enabling the system to be a large network of computers and the technology can be integrated into a web browser adding to the browser's functionality.

Owner:AMAZON TECH INC

Spell-check for a keyboard system with automatic correction

InactiveUS8201087B2Text entryType accurateNatural language data processingSpecial data processing applicationsCorrection algorithmAutocorrection

An adaptation of standard edit distance spell-check algorithms leverages probability-based regional auto-correction algorithms and data structures for ambiguous keypads and other predictive text input systems to provide enhanced typing correction and spell-check features. Strategies for optimization and for ordering results of different types are also provided.

Owner:TEGIC COMM

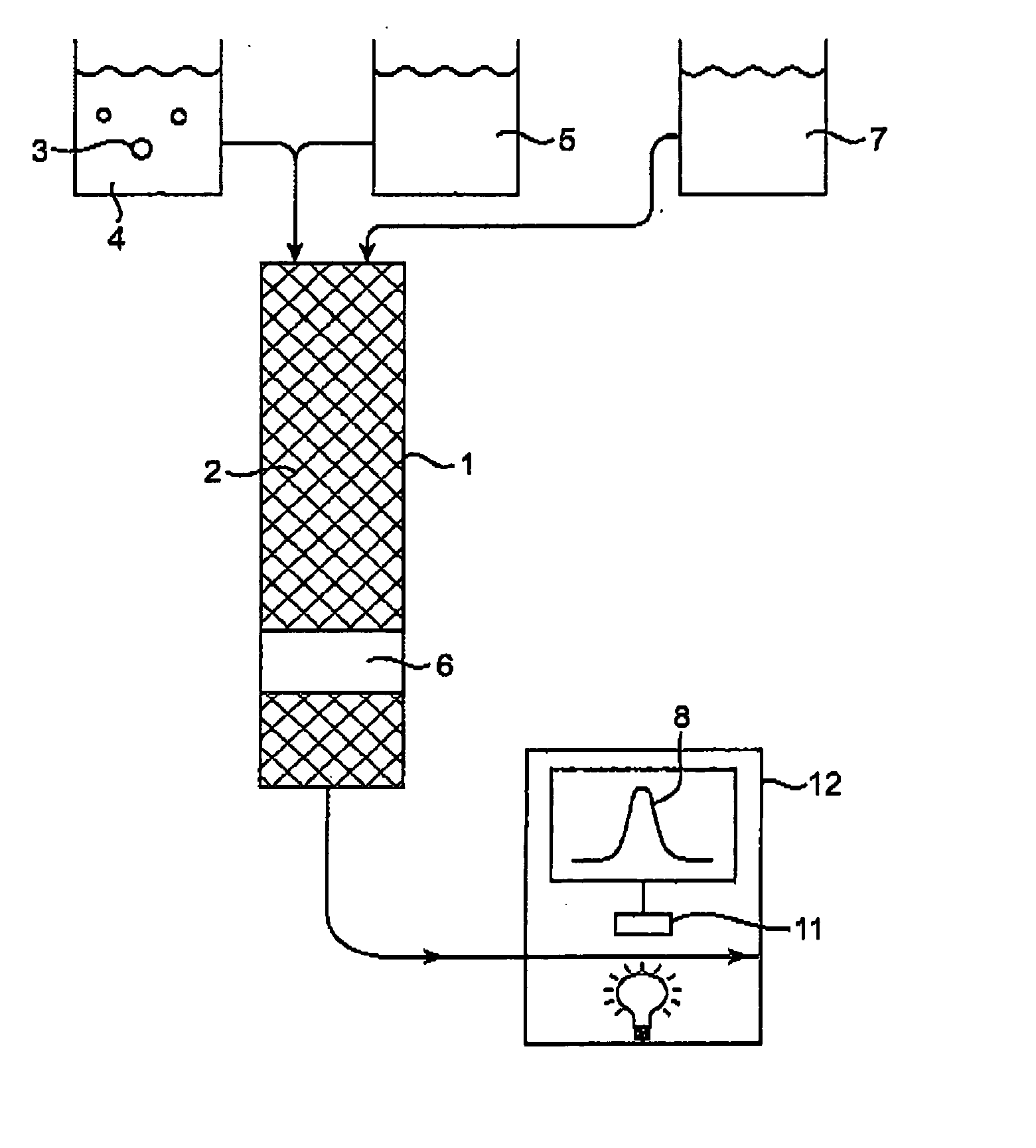

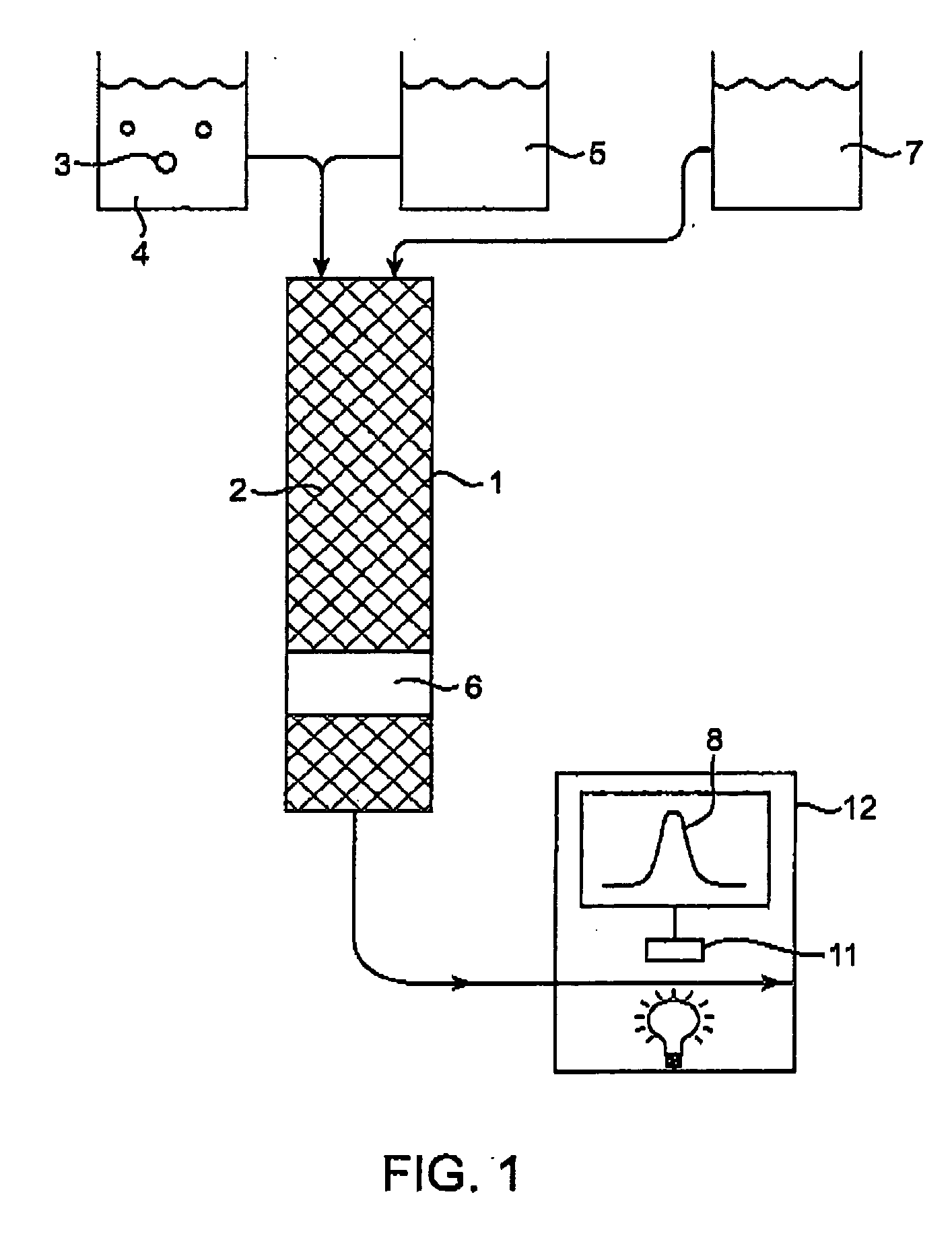

Devices and methods for microfluidic chromatography

InactiveUS20070138076A1Easy to separateSmall dead volumeIon-exchange process apparatusComponent separationSmall sampleCoupling

Embodiments of the invention provide devices, methods and systems for performing microfluidic chromatography. Particular embodiments provide microfluidic chromatography column devices which can perform chemical separation using small sample volumes and low pressure differentials across the column. One embodiment provides a microfluidic chromatography column device comprising a first, second and third capillary tube. A chromatographic packing is disposed in the second tube with a first and second support layer disposed on opposite ends of the second tube. The support layers are disposed in a substantially flat orientation within the tube. An external coupling joins the tubes such that the tubes are fluidically sealed. The device is configured to have a fluidic resistance such that a pressure differential across the column of less than about 10 psi produces a flow rate through the device of at least about 0.5 ml / min for a liquid solution.

Owner:FLUIDIGM CORP

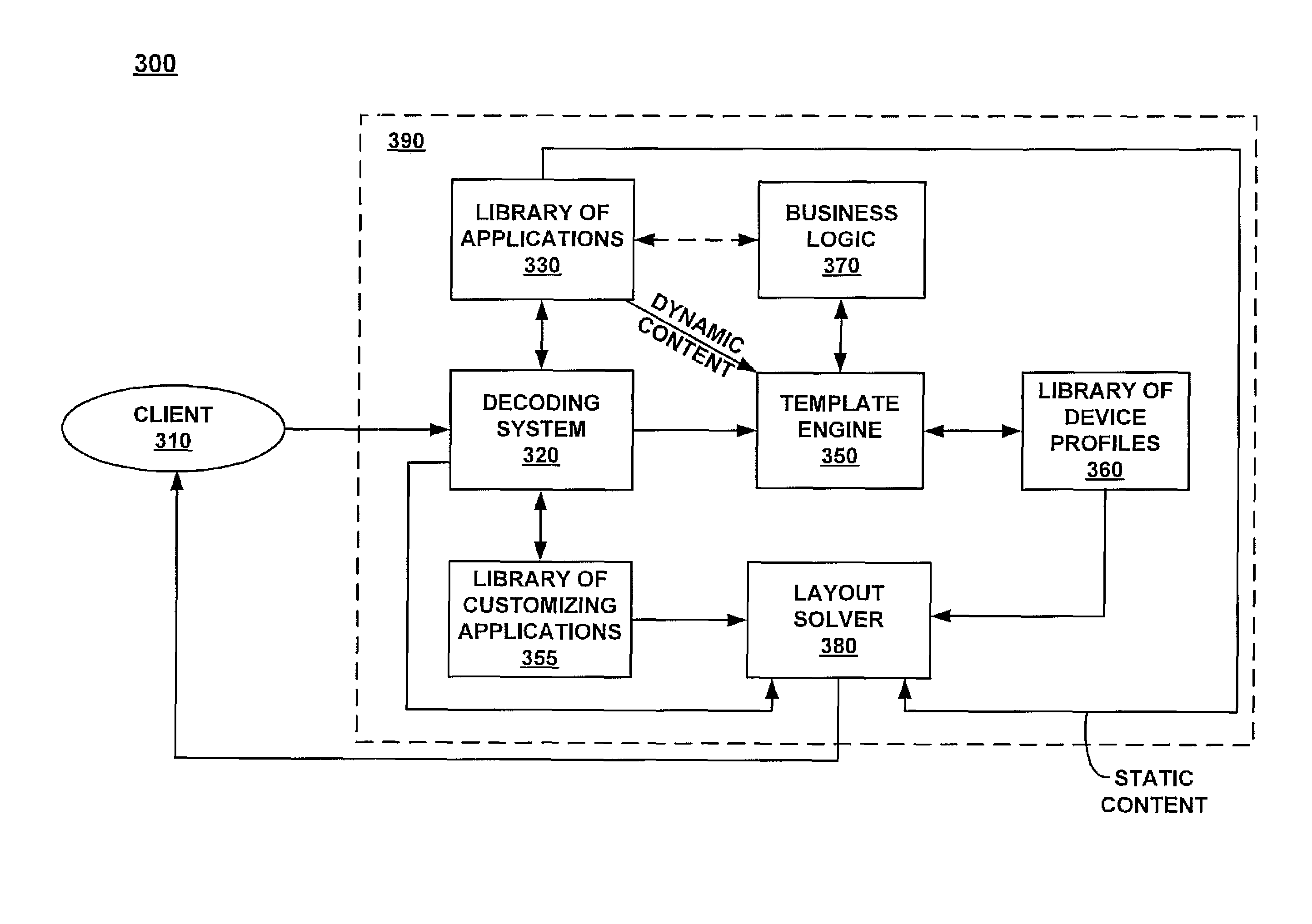

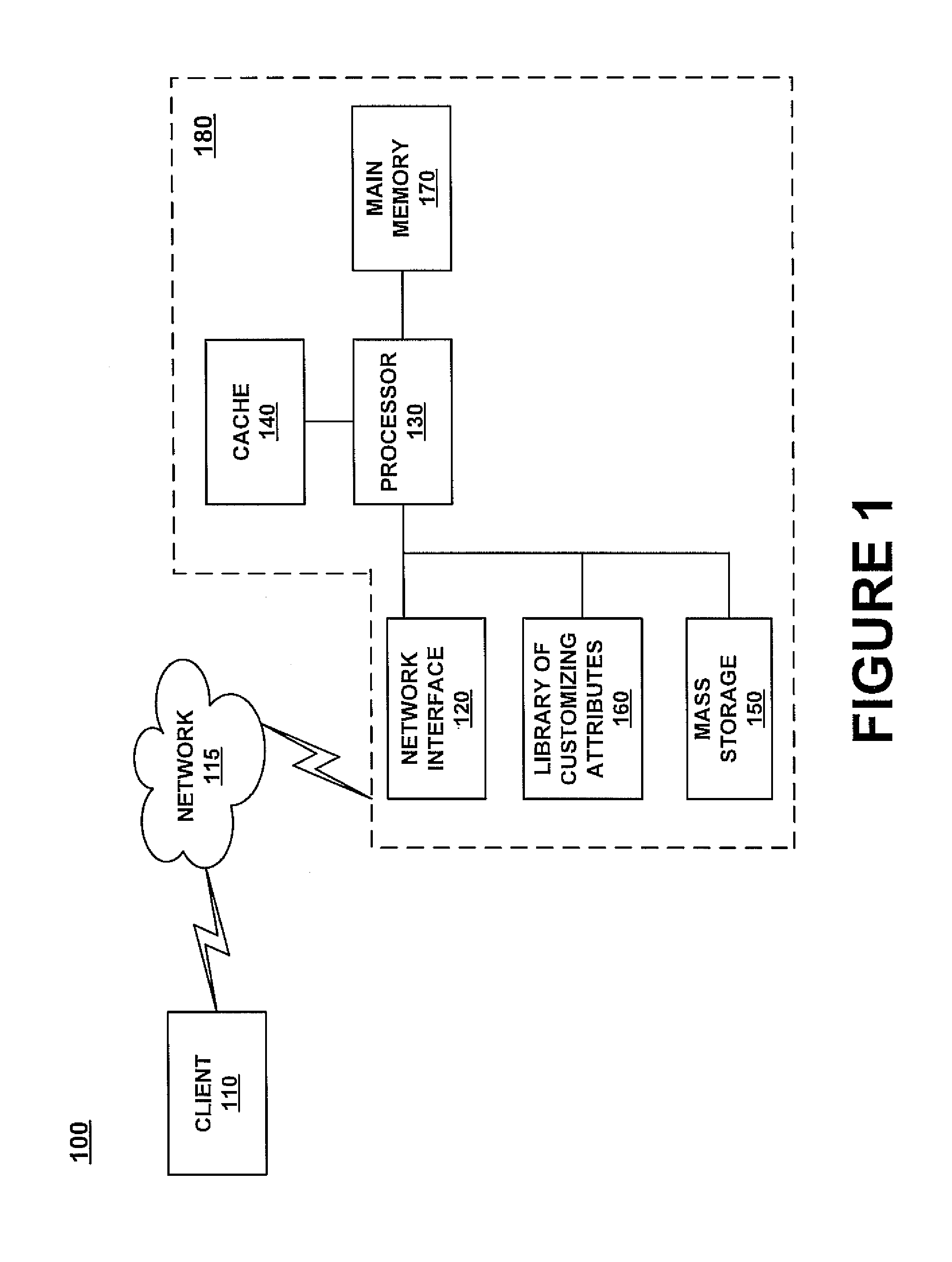

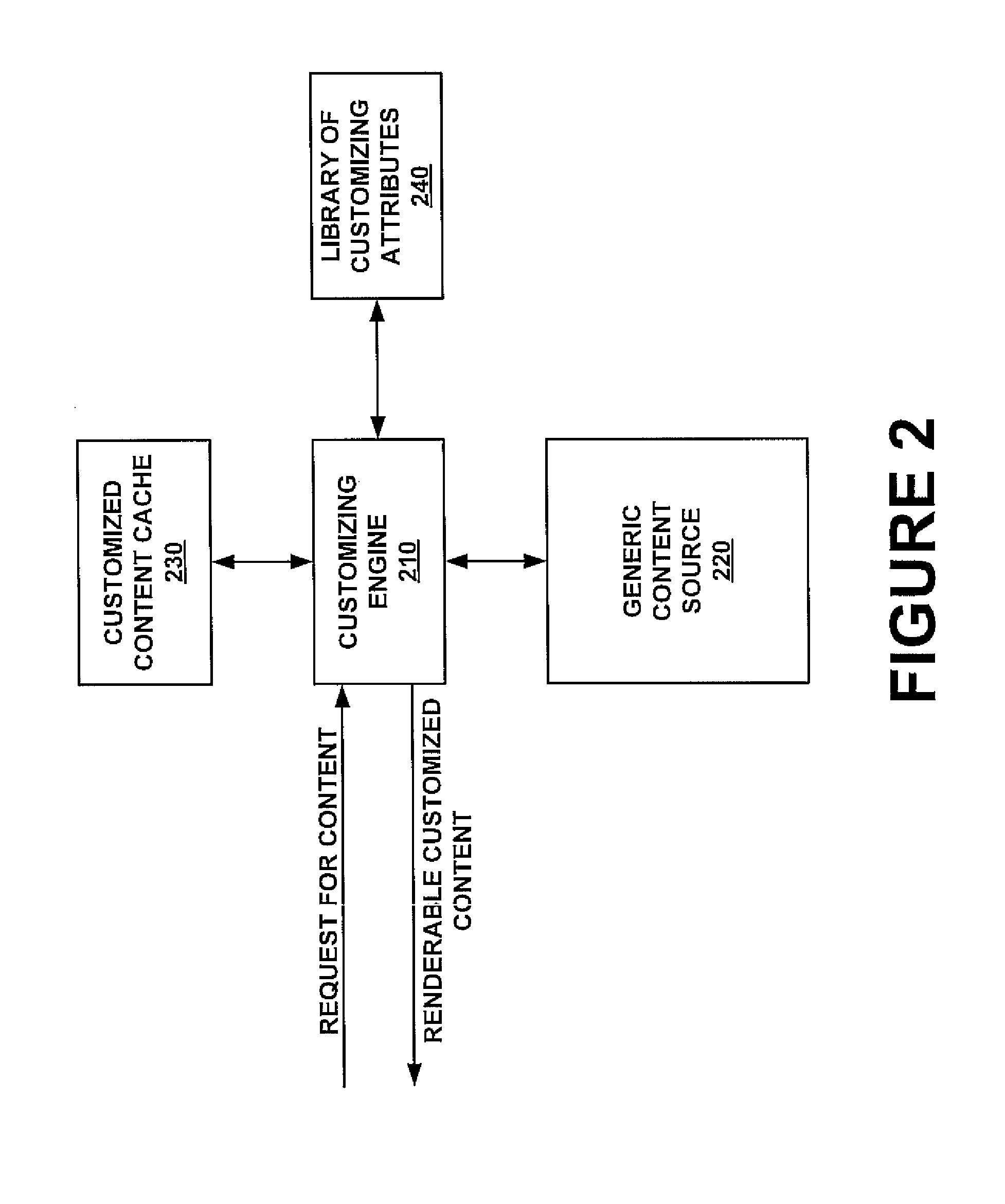

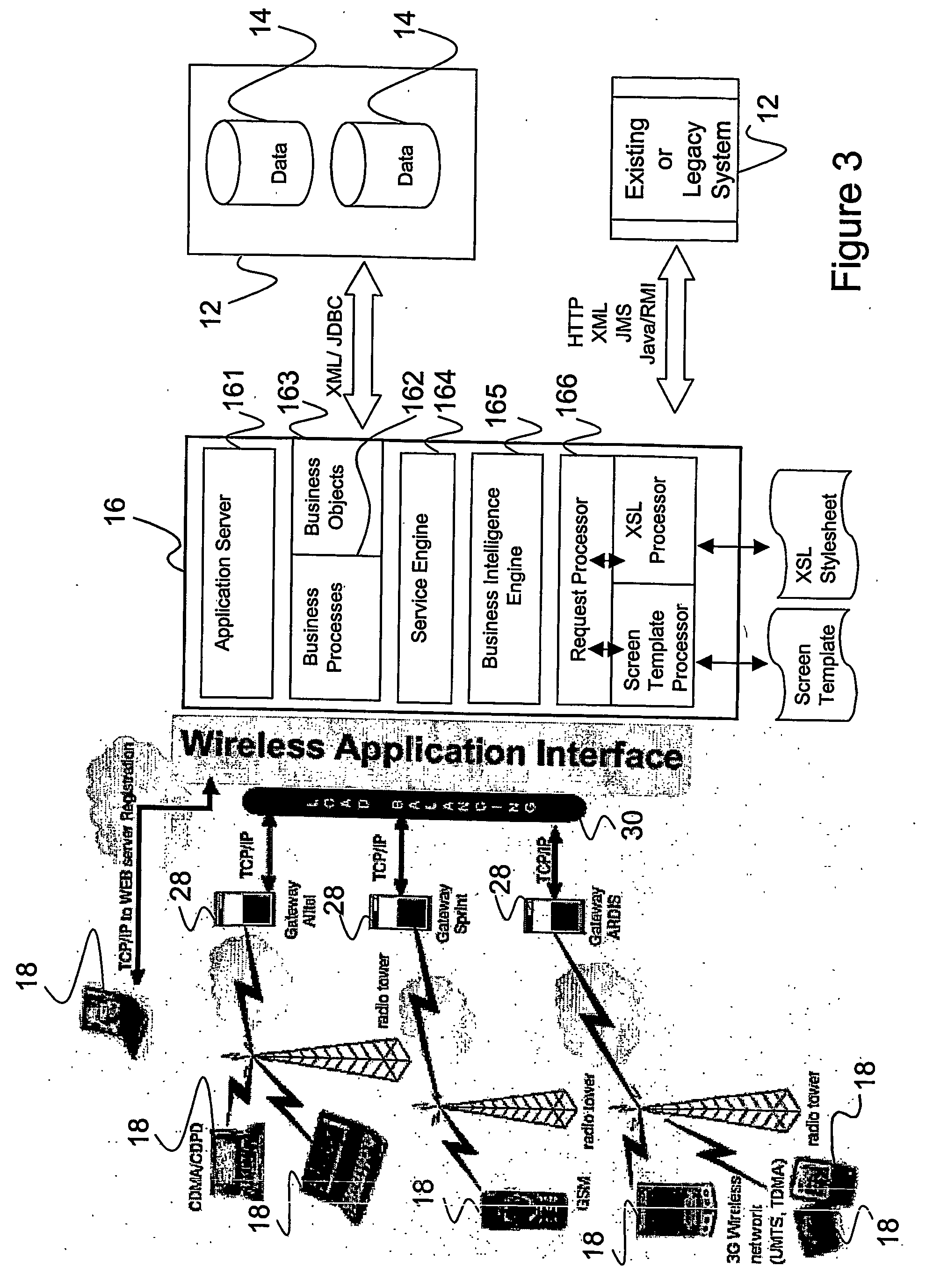

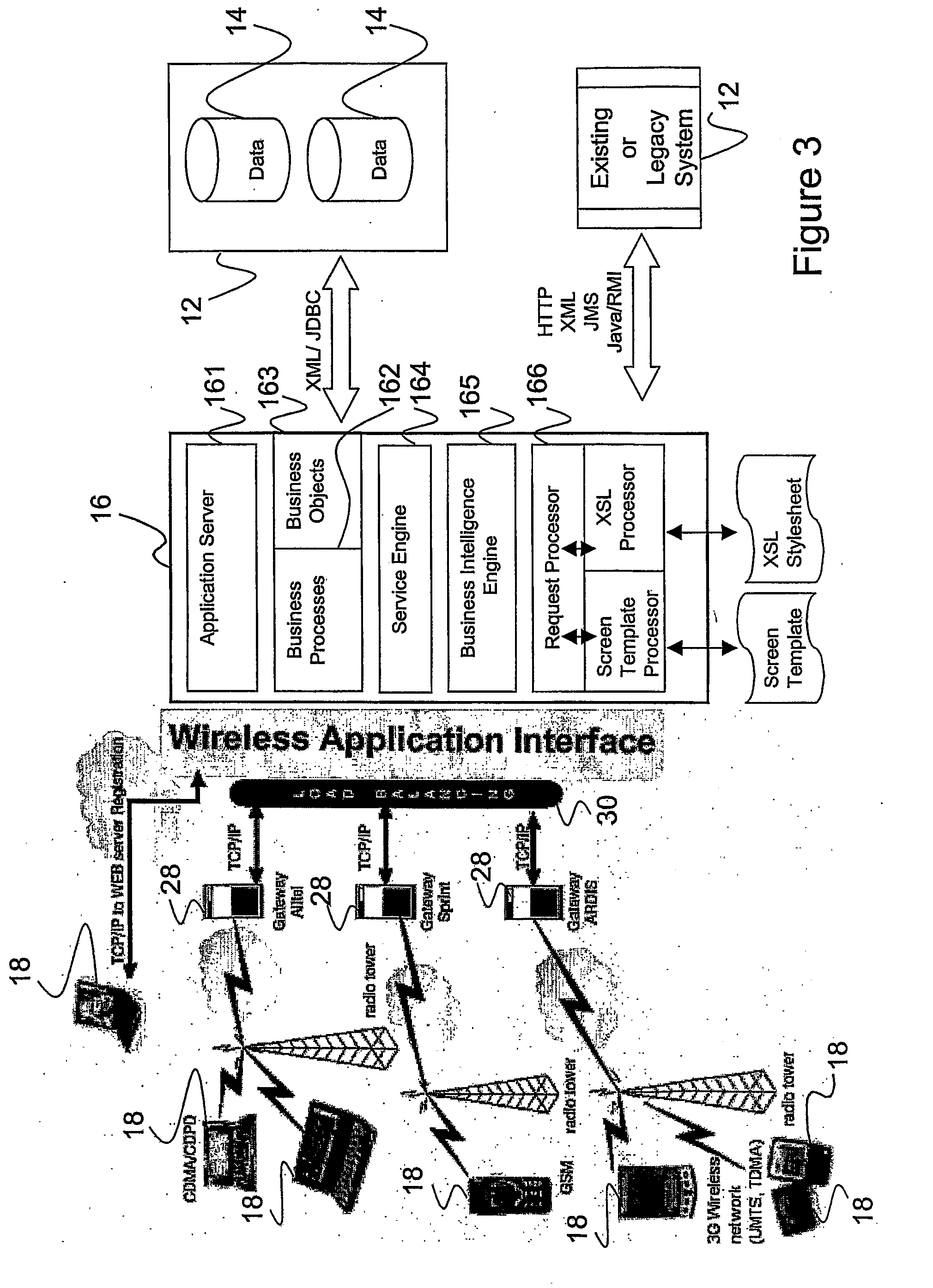

Method and system for customizing content on a server for rendering on a wireless device

ActiveUS9015692B1Cost reductionImprove user 's experienceWeb data retrievalText database queryingApplication softwareTime zone

A server implemented method for processing data for rendering on a wireless device. A request to execute a generic application may be received. The server identifies a custom configuration for the generic application based on the wireless device access attributes, e.g., time zone, location, date, time zone, season, user's habit, user's interaction, user's interest, etc., wherein the custom configuration is operable to tailor the appearance of the generic application. The server configures the generic application based on the identified custom configuration to generate a customized application. The customized application may be executed on the server to generate a renderable customized application that is operable for rendering by the wireless device. The renderable customized application may be provided for transmission to the wireless device. The renderable customized application may be transmitted to the wireless device for rendering.

Owner:PHUNWARE

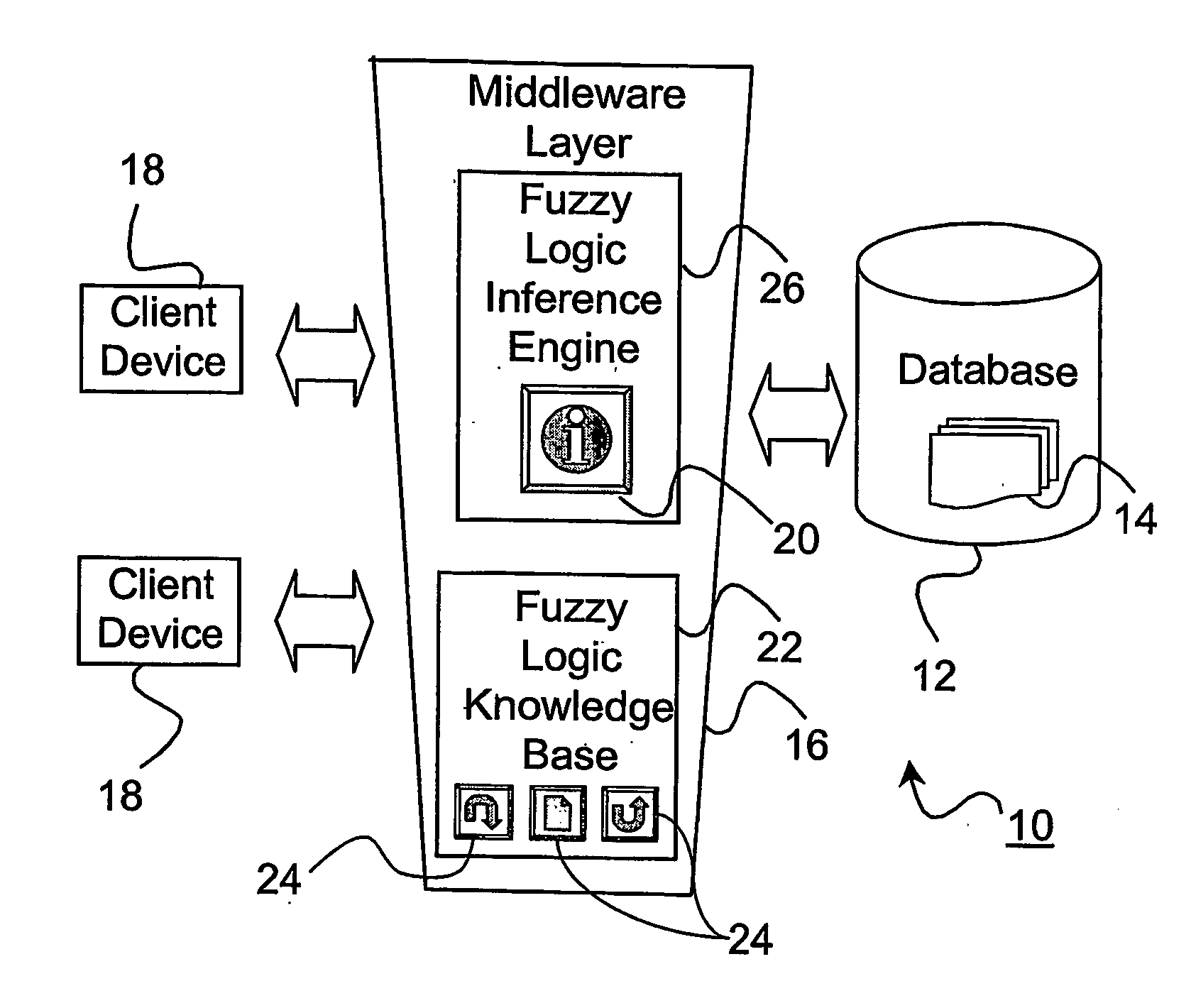

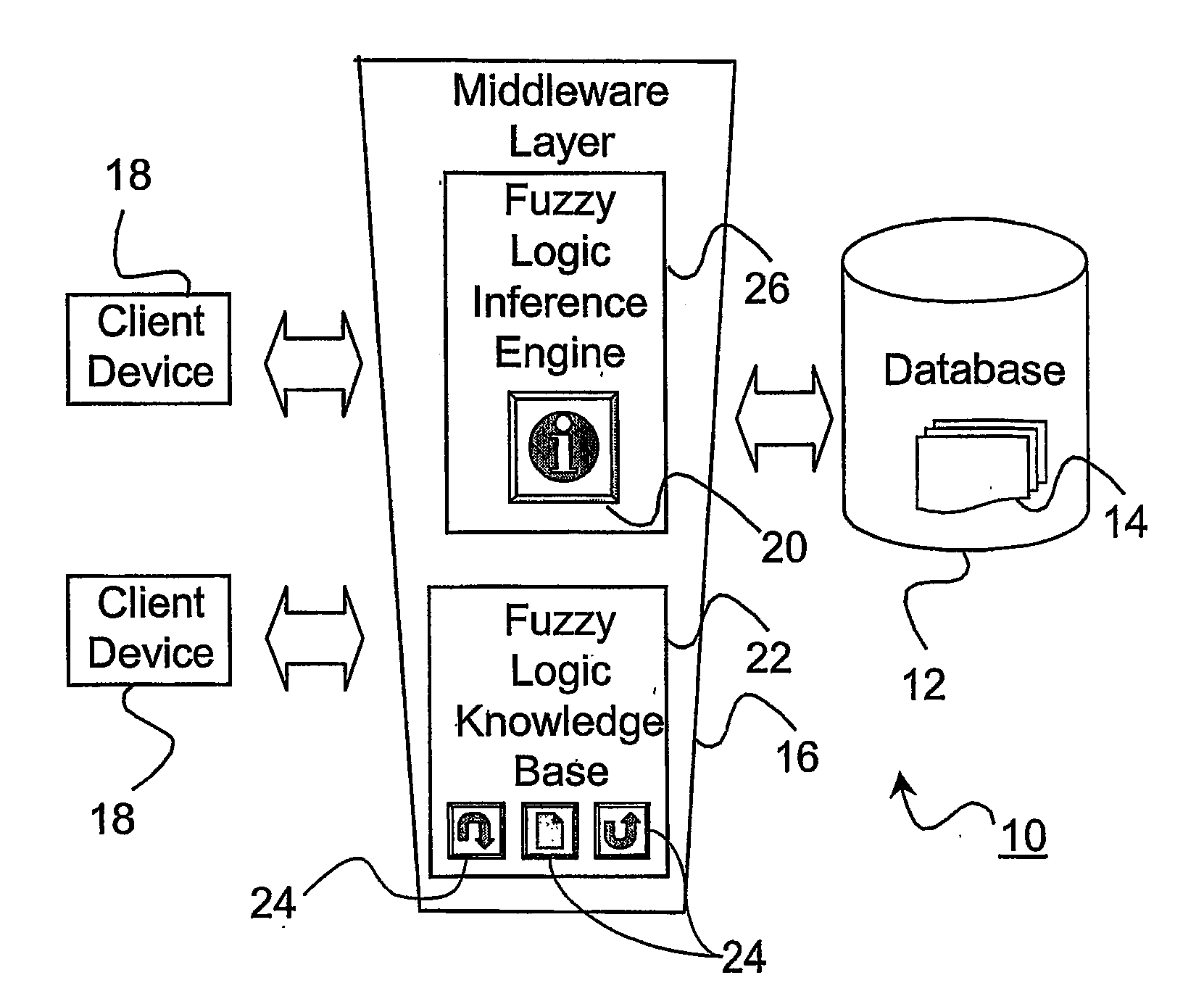

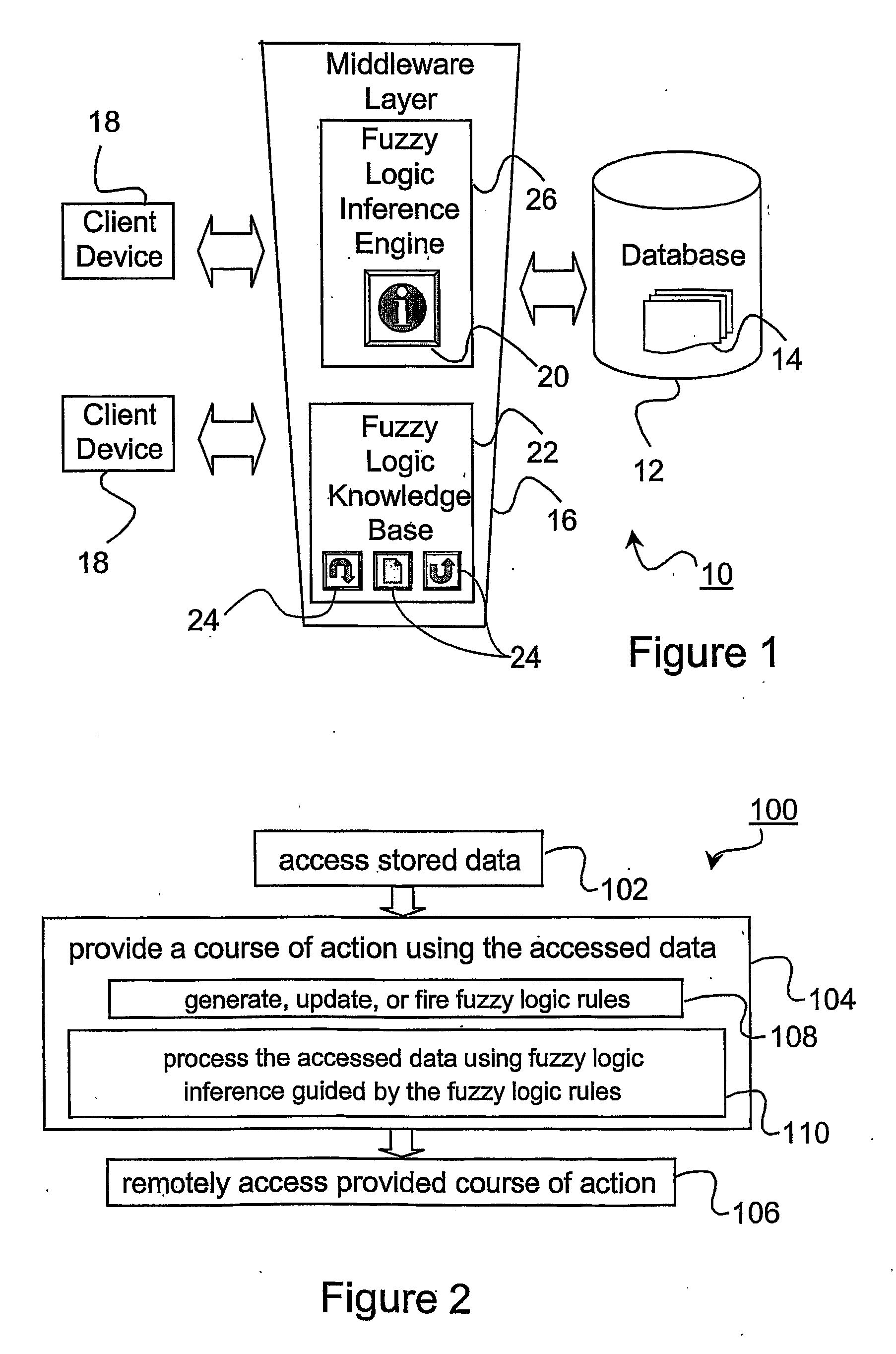

Intelligent Data Management System and Method

InactiveUS20080005054A1Without any changeCost efficientData processing applicationsMedical automated diagnosisFuzzy logic inferenceData management

An intelligent data management system and method are disclosed. The system includes a database of stored data, a middleware layer having access to the stored data, and at least one client device for remotely accessing a provided course of action. The middleware layer includes a fuzzy logic knowledge base for generating, updating, or firing fuzzy logic rules and a fuzzy logic inference engine for processing the stored data guided by the fuzzy logic rules to provide the course of action.

Owner:ALPHAGLOBAL IT

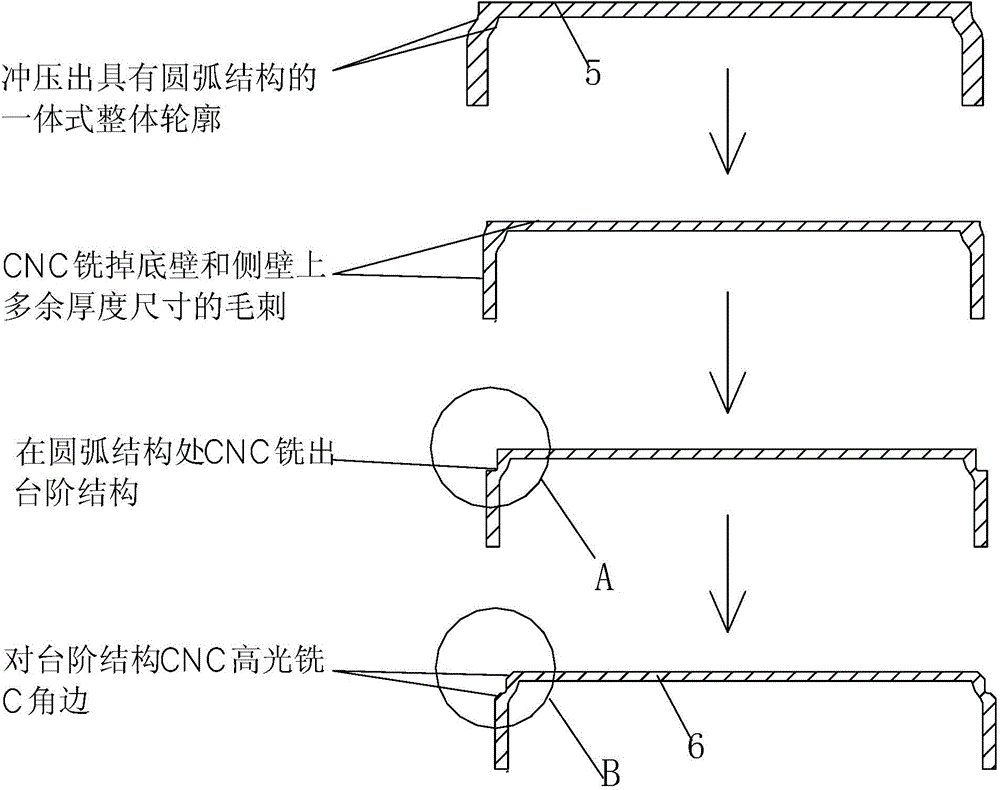

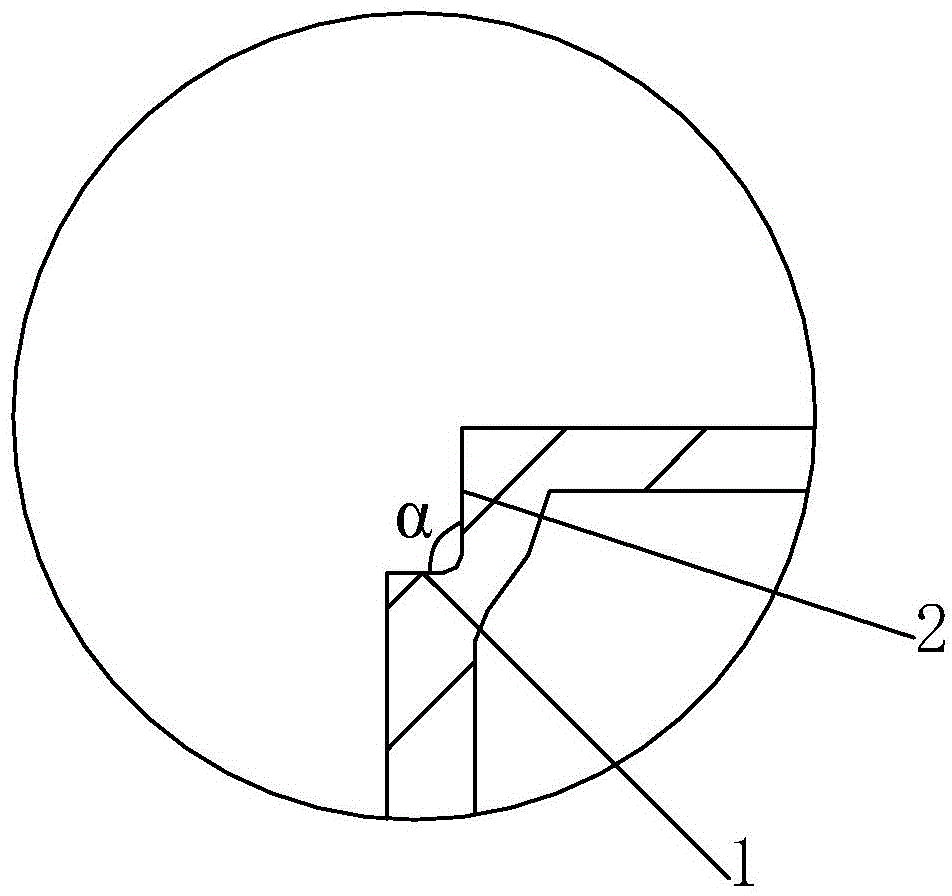

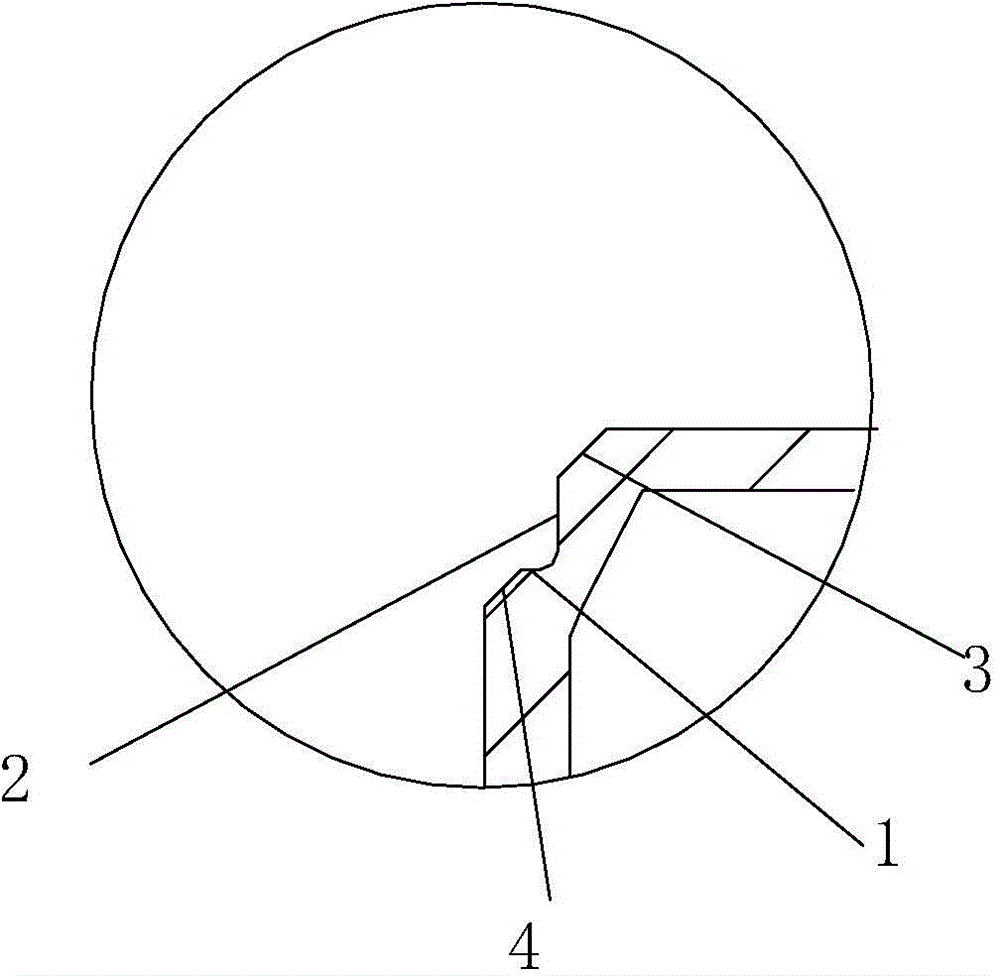

Method for forming metal mobile phone shells

ActiveCN104476136AProcessing time is shortSolve processabilitySubstation equipmentNumerical controlWork in process

The invention discloses a method for forming metal mobile phone shells, and relates to the technical field of mobile phones. The method for forming the metal mobile phone shells includes stamping and bending metal plates to obtain integral outlines of the integrated mobile phone shells so as to obtain initial blank products; carrying out CNC (computer numerical control) machining on the initial blank products to obtain semi-finished products of the metal mobile phone shells; carrying out post-processing on the semi-finished products of the metal mobile phone shells to obtain the metal mobile phone shells. Arc structures are arranged between the side walls and the bottom walls of the integral outlines of the integrated mobile phone shells. CNC machining procedures include (1), milling off burrs on redundant thickness-size sides of the bottom walls and the side walls of the initial blank products under the CNC; (2), inwardly milling the outer walls of arc corners between the side walls and the bottom walls of the initial blank products under the CNC to obtain step structures and respectively forming C-angle edges at the step structures; (3), finely milling the C-angle edges of the step structures under the CNC. The C-angle edges are close to the bottom walls and the side walls of the initial blank products. The method has the advantages that a stamping forming procedure and a CNC machining procedure are combined with each other, so that the metal mobile phone shells can be formed, and the method is stable in process, high in machining precision and production efficiency, short in machining elapsed time and low in production cost.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

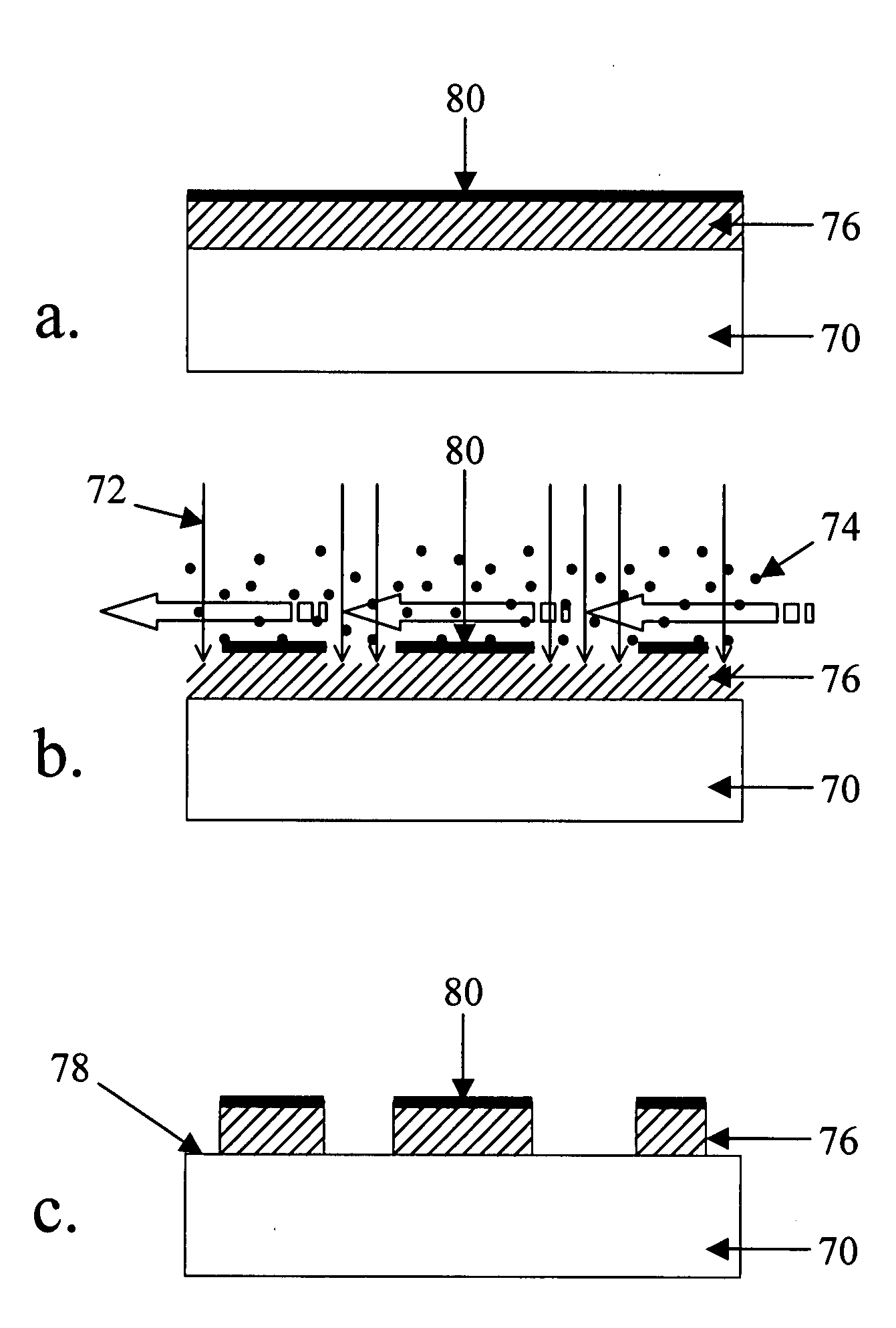

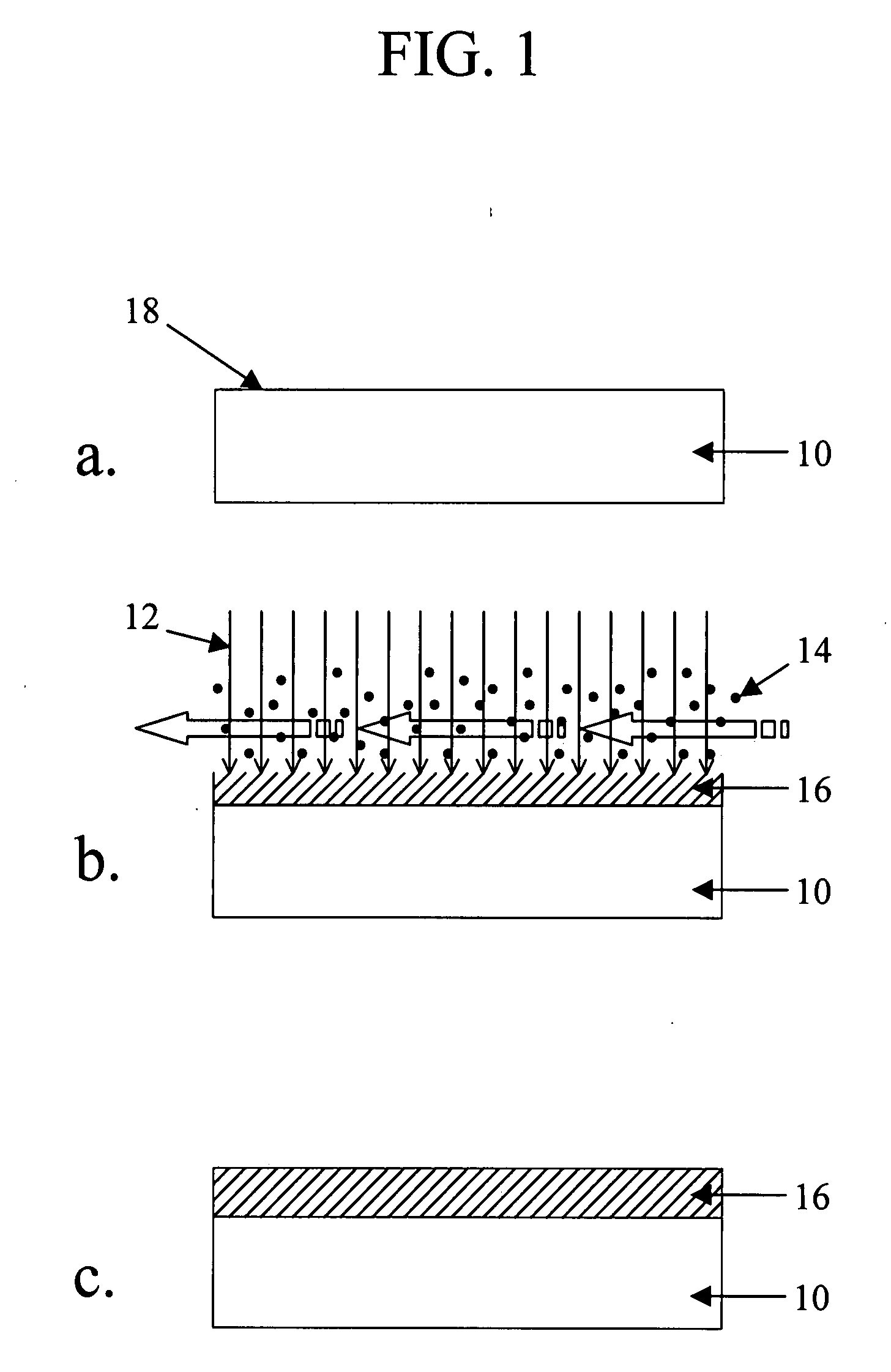

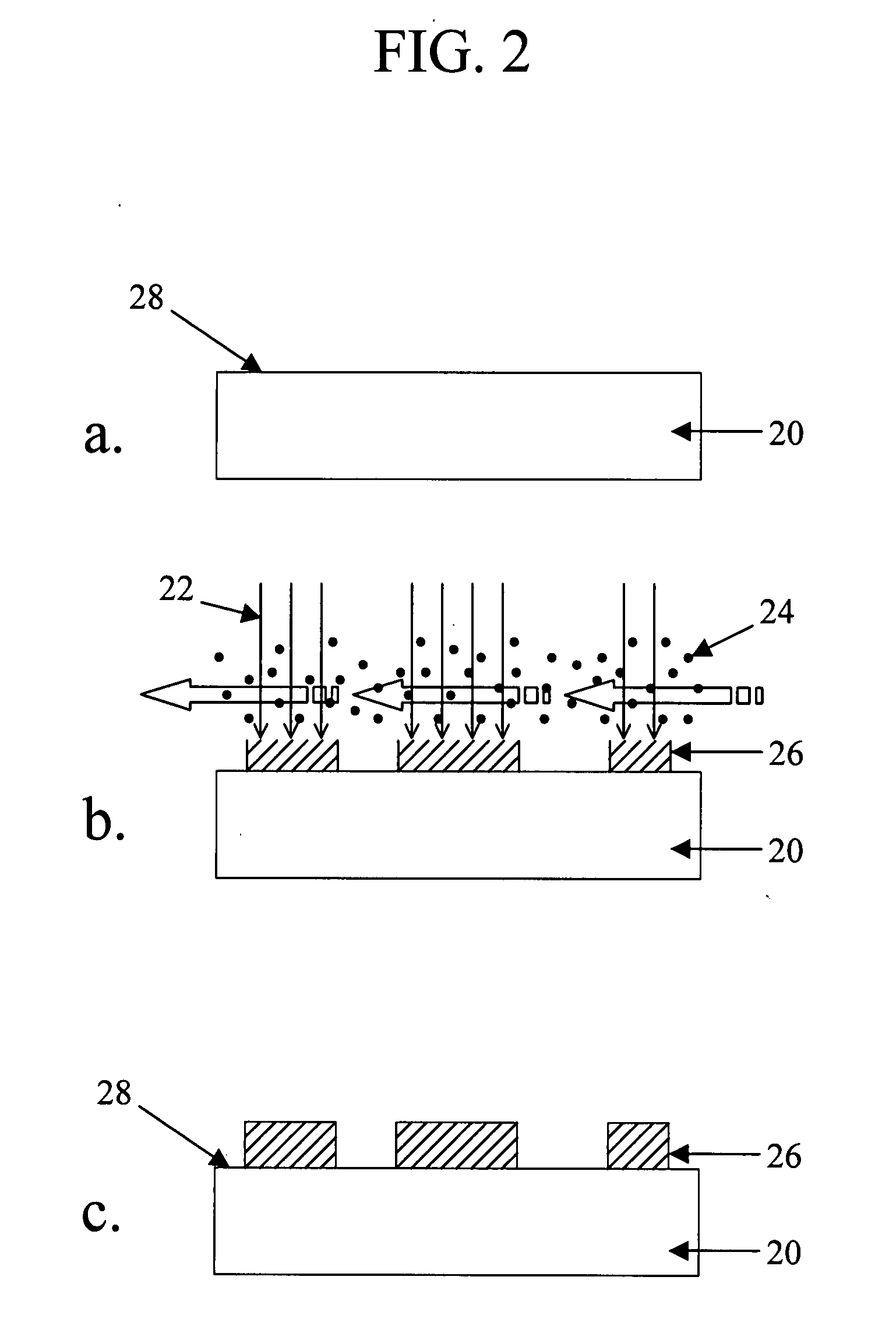

Method and apparatus for laser oxidation and reduction

InactiveUS20080299780A1Significant handlingSignificant process timeSemiconductor/solid-state device manufacturingCorrosive chemicalProduct gas

A method and apparatus using electromagnetic radiation and gas to create oxidation and reduction reactions on a device, such as a semiconductor wafer surface. In one embodiment, a scanned laser and gas may be employed in a number of oxidation and / or reduction reactions in a single system without using multiple pieces of equipment, corrosive chemicals and gases, high temperature and pressure chamber environments, waste treatment processes, and / or extra process steps typically required in existing processes.

Owner:UVTECH SYST

Microwave and far infrared heating under reduced pressure

Microwave and far infrared heating under reduced pressure is carried out on objects to be dried, concentrated, defrosted, roasted or sterilized by placing the objects in plate-shaped or tray-shaped object-holding jigs arranged on a shelf-type jig which is held motionless in a pressure reducing chamber during heating, wherein the provision of reflector plates, reflective frames, specific object-holding jigs and cutting methods are employed to achieve uniform heating.

Owner:YAGI SHUNICHI

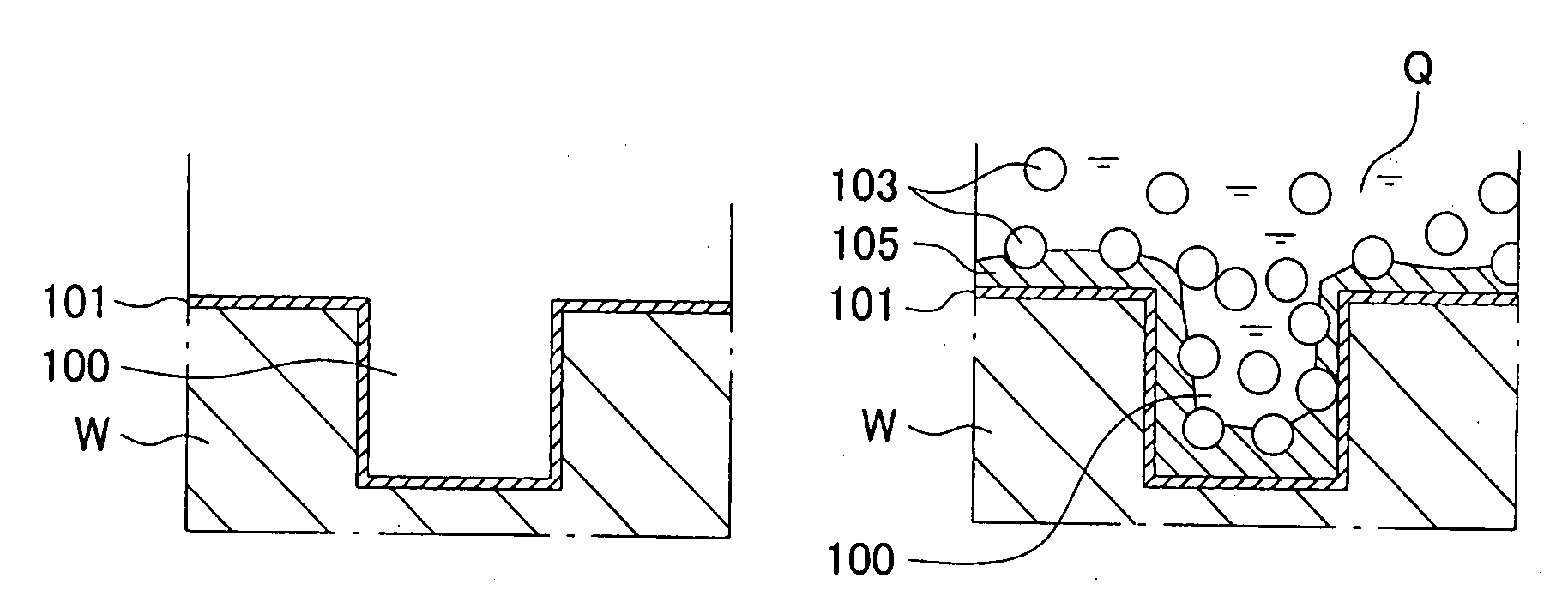

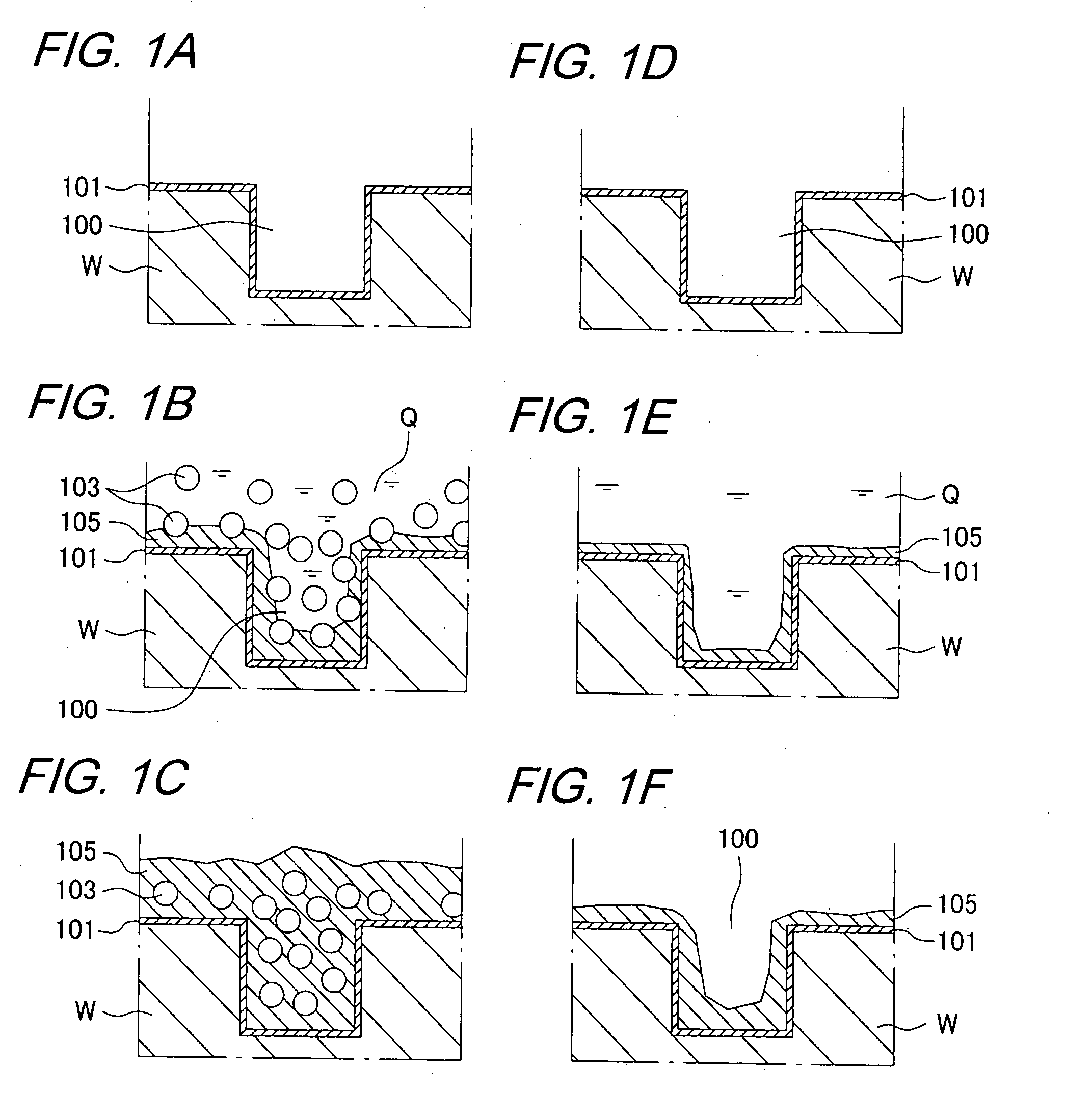

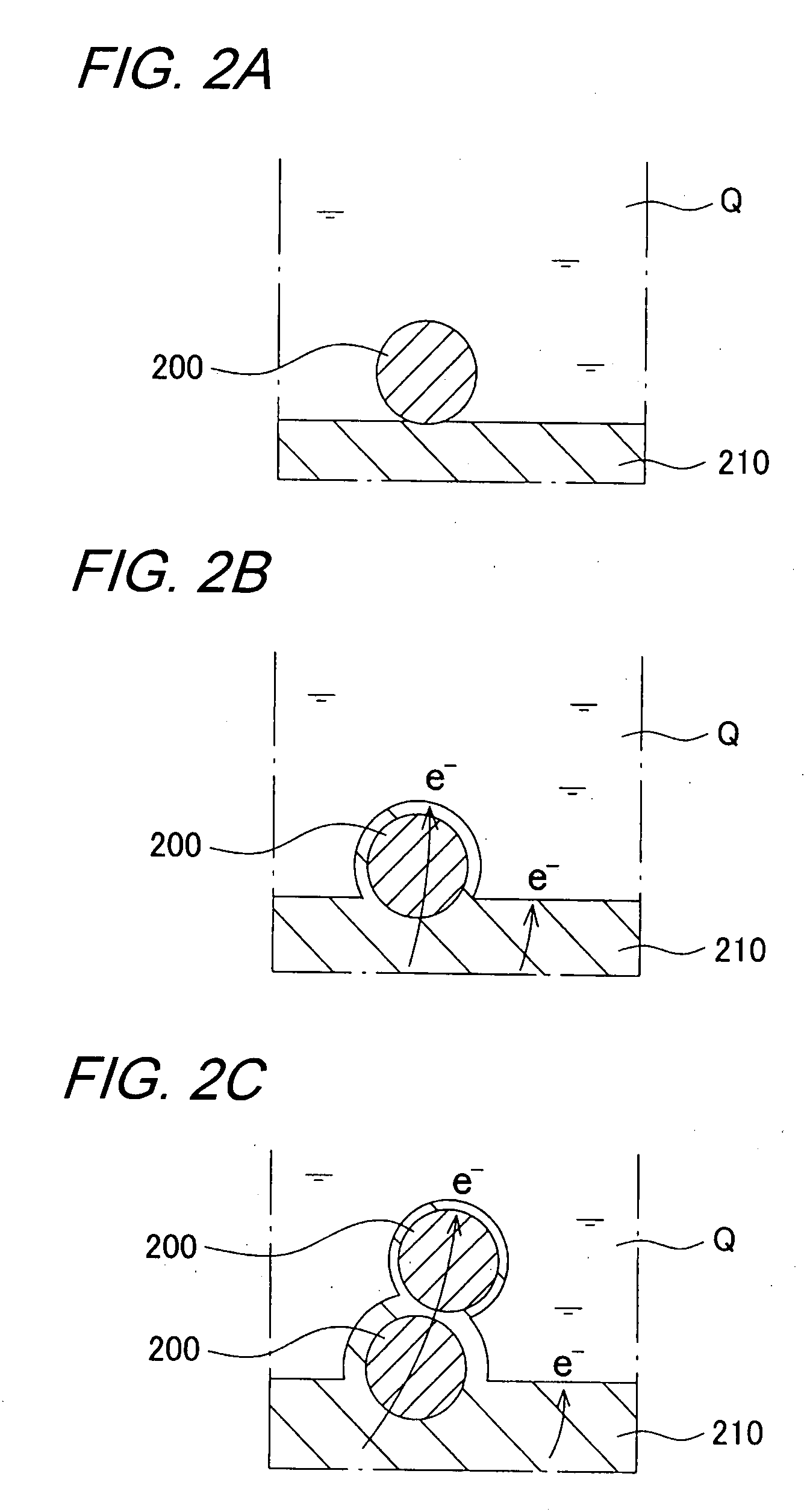

Substrate processing method and apparatus

InactiveUS20070251088A1Improve reliabilityProcessing timePrinted circuit assemblingElectrolysis componentsSolid particleConductive materials

A substrate processing method is useful for filling a hole formed in a substrate with conductive material. The substrate processing method includes forming a non-through hole in a substrate, and filling the non-through hole with conductive material by plating. The plating is performed using a plating solution containing solid particles.

Owner:EBARA CORP

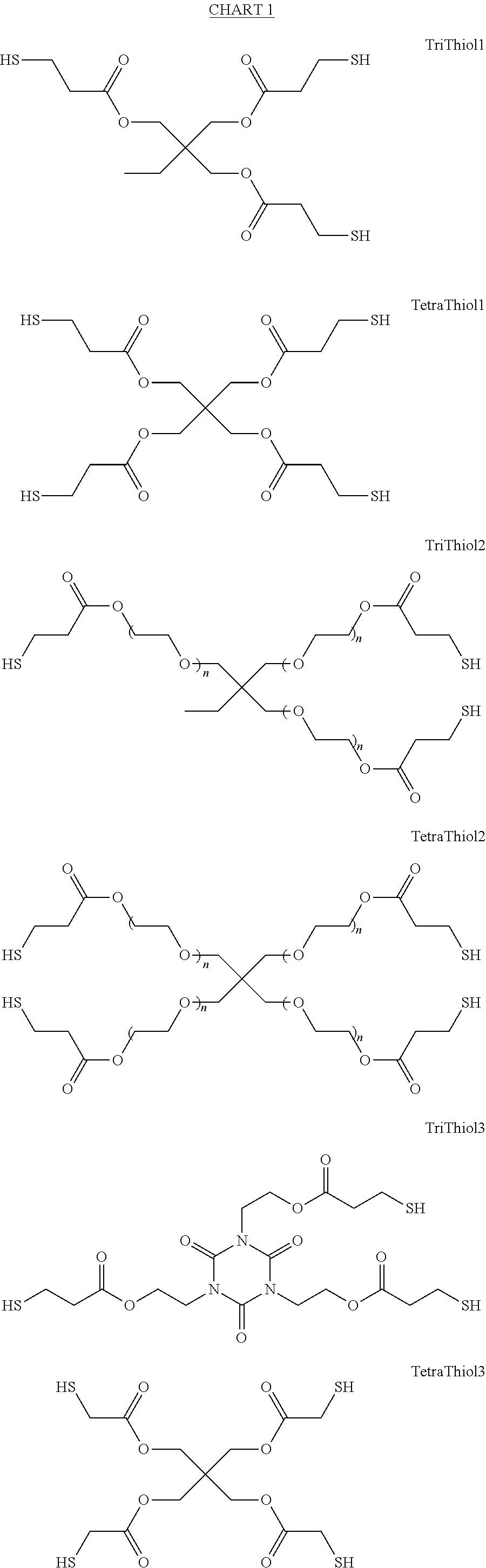

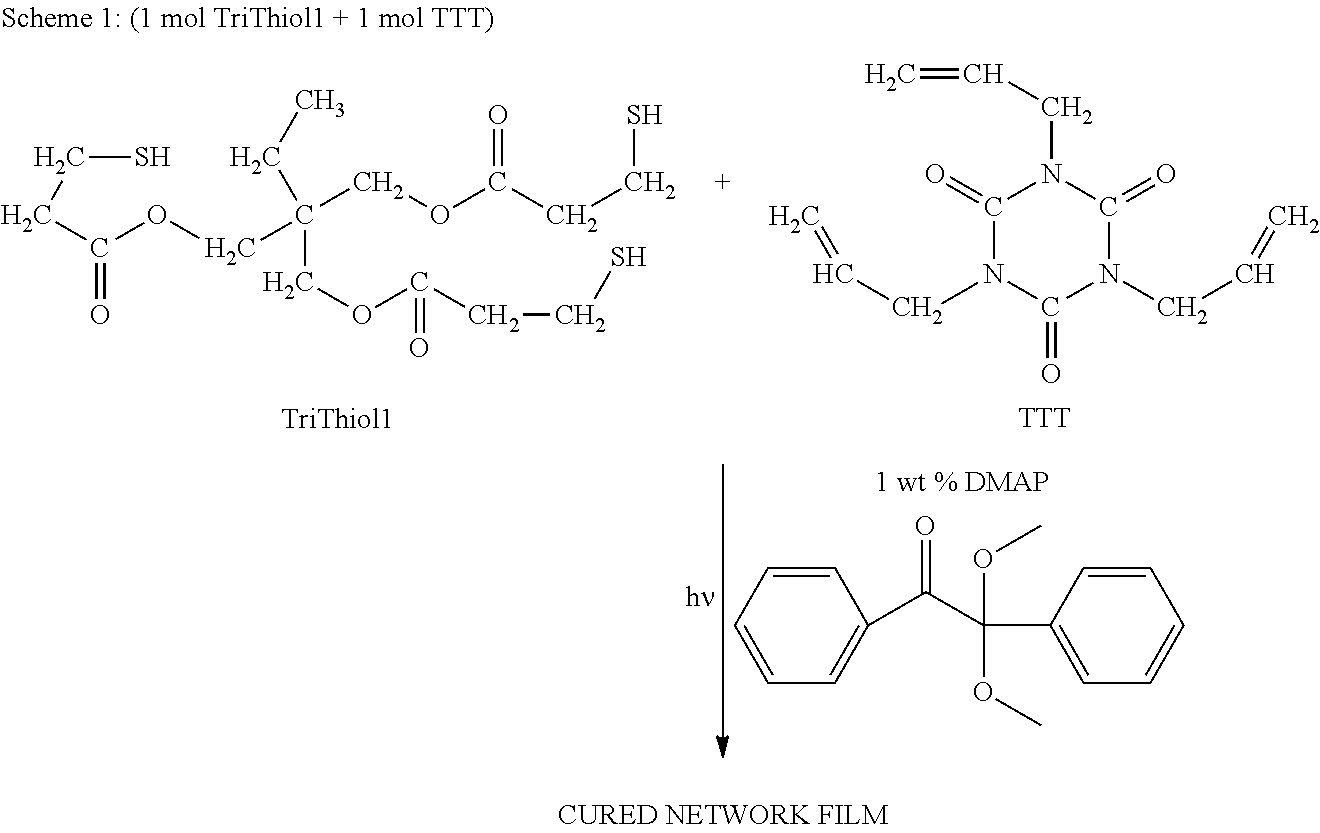

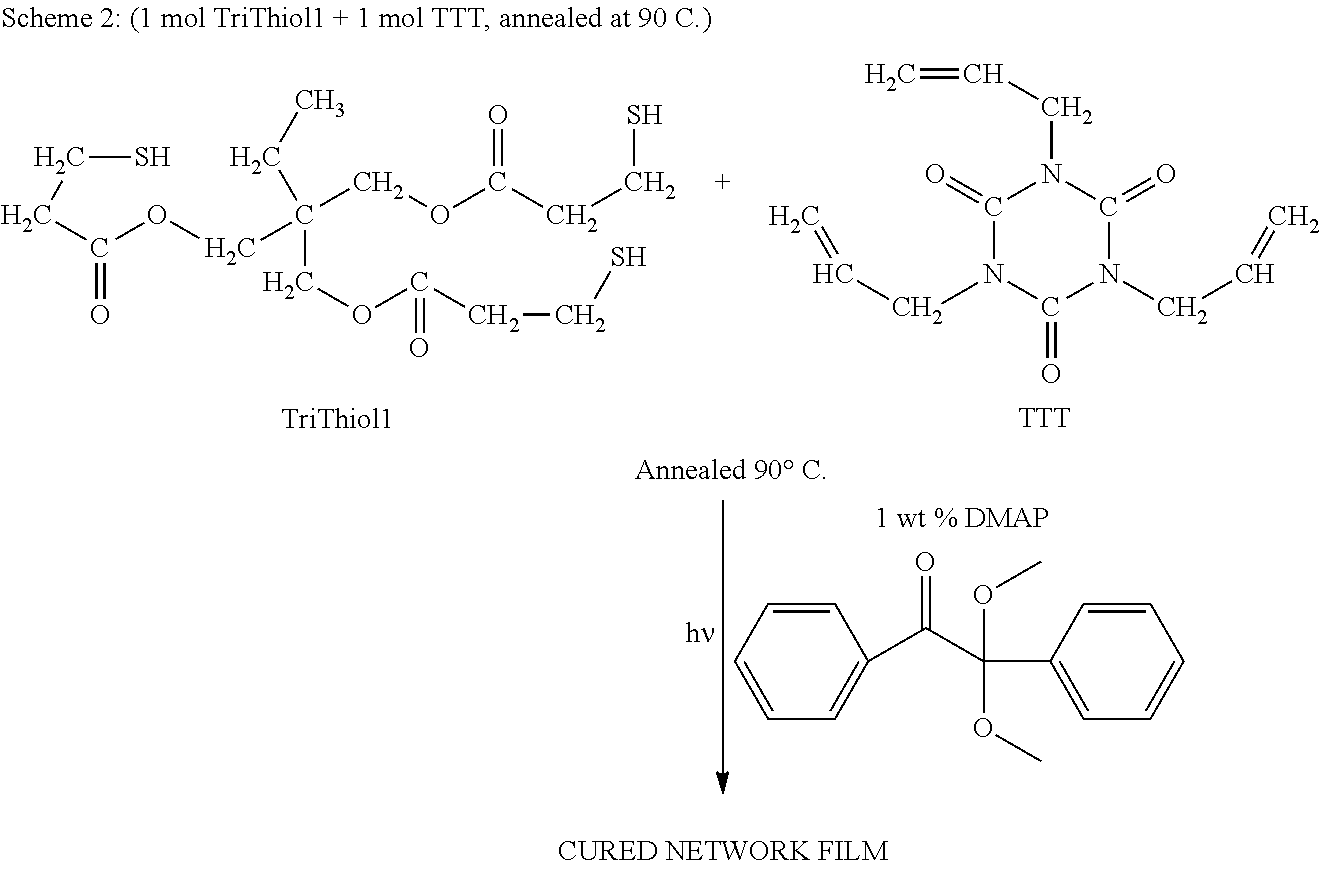

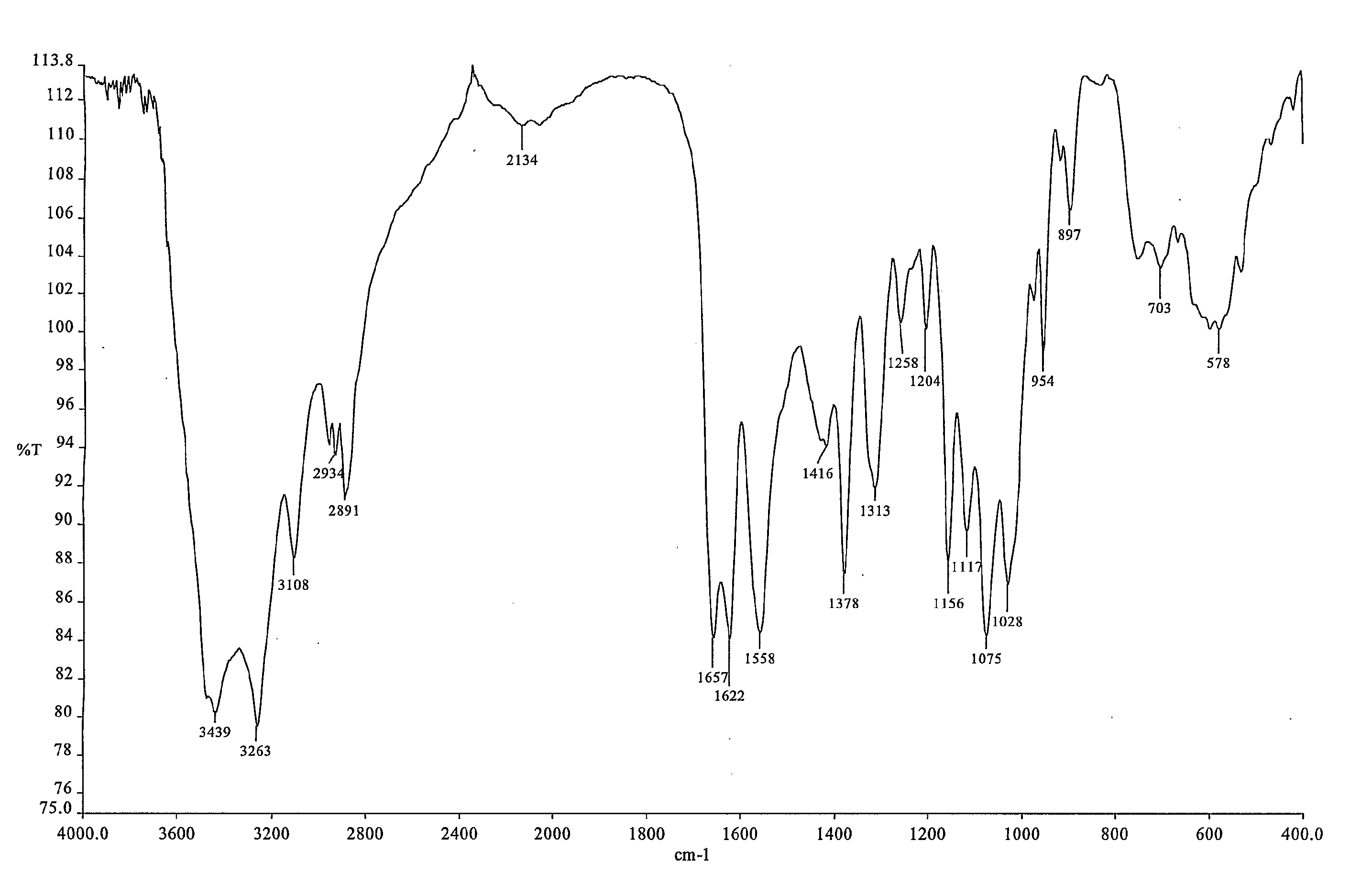

Photocuable thiol-ene low gas permeability membranes

InactiveUS8440736B2Improve gas barriersEfficient use ofOrganic chemistryOrganic compound preparationThiolPolymer substrate

The present invention provides modified multifunctional thiol-ene monomers wherein one or more thiols are reacted with a Michael addition reactive double bond compound. The present invention further discloses photocurable thiol-ene formulations comprising thiol-ene monomers including the modified multifunctional thiols. The present invention further discloses photocurable thiol-ene formulations comprising thiol-ene monomers and Michael addition reactive double bond molecules and a Michael catalyst. The formulations of the present invention can be photocured to make films or coatings. In a further disclosure, the formulations, including those comprised of unmodified multifunctional thiols and multifunctional enes, are photocured to form films applied to non-flexible or flexible polymer or non-polymer substrates suitable for food packaging, electronic products, optical products and other applications and free-standing films. The present invention further discloses photocurable thiol-ene formulations comprising thiol-ene monomers and Michael addition reactive double bond molecules and a Michael catalyst. These formulations are disclosed to form free-standing films and coatings on substrates when applied to flexible substrates. Such materials are suitable for use in the packaging of food products and other products which are to be maintained in a hermetically sealed relationship to the atmosphere.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

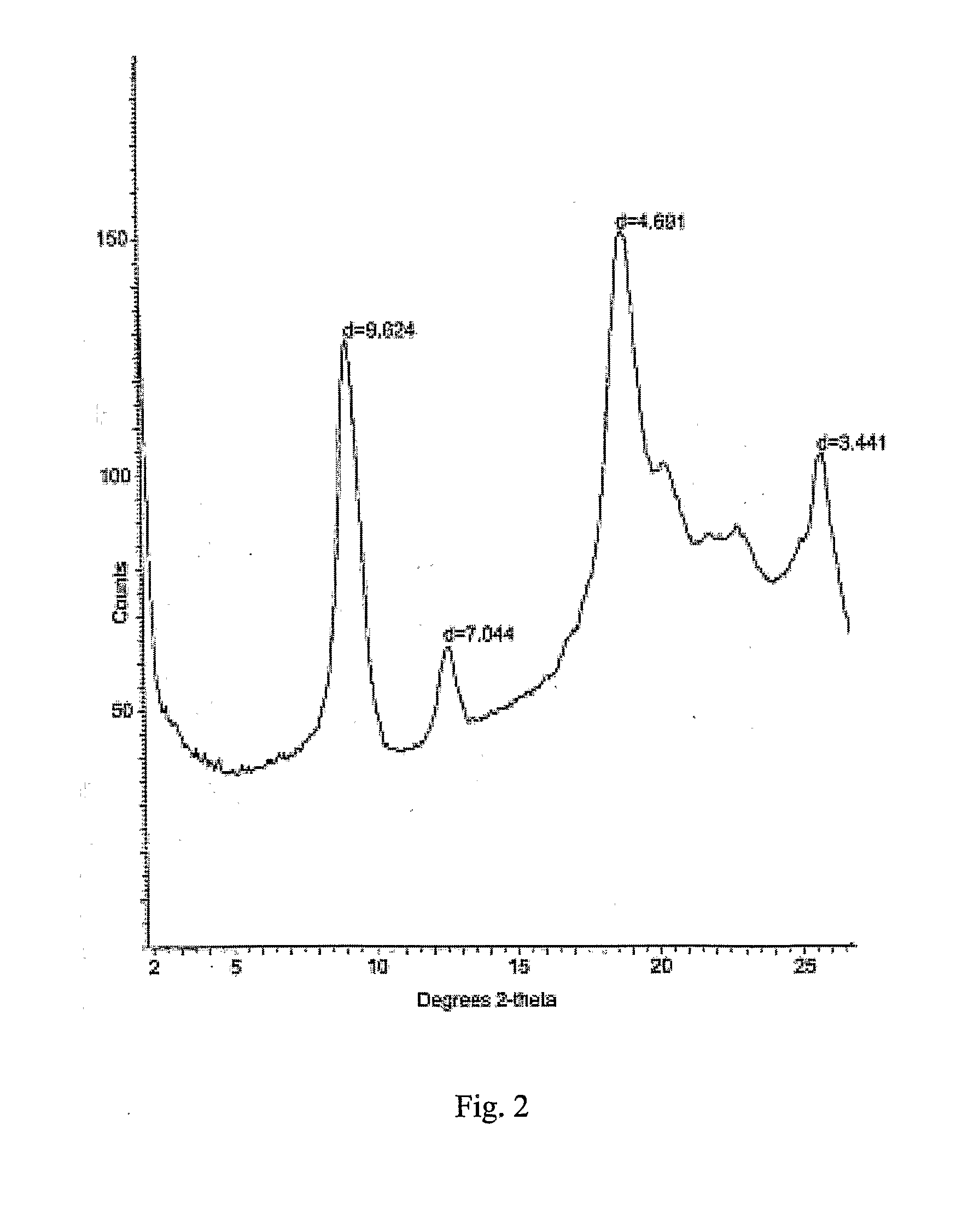

Spray-dried chitin nanofibrils, method for production and uses thereof

ActiveUS20090203642A1Faster and less-expensiveProcessing timeBiocideCosmetic preparationsFiberChitin formation

The invention relates to a novel method for production of nanofibrillar chitin, sustainable from an industrial manufacturing standpoint and suitable for producing chitin nanofibrils having improved properties and free from less crystalline components. The invention also relates to novel chitin nanofibrils obtained with said method and characterized by an increased dispersibility in aqueous media. The invention further relates to uses of nanofibrils in pastes and aqueous gels useful for topical on-skin application, to the manufacturing of materials of biomedical interest, as well as to the deposition of chitin nanofibrils on coating surfaces or the incorporation of the same inside of items like, e.g., fibers and fabrics of any Origin, natural as well as synthetic or mixed ones.

Owner:MAVI SUD

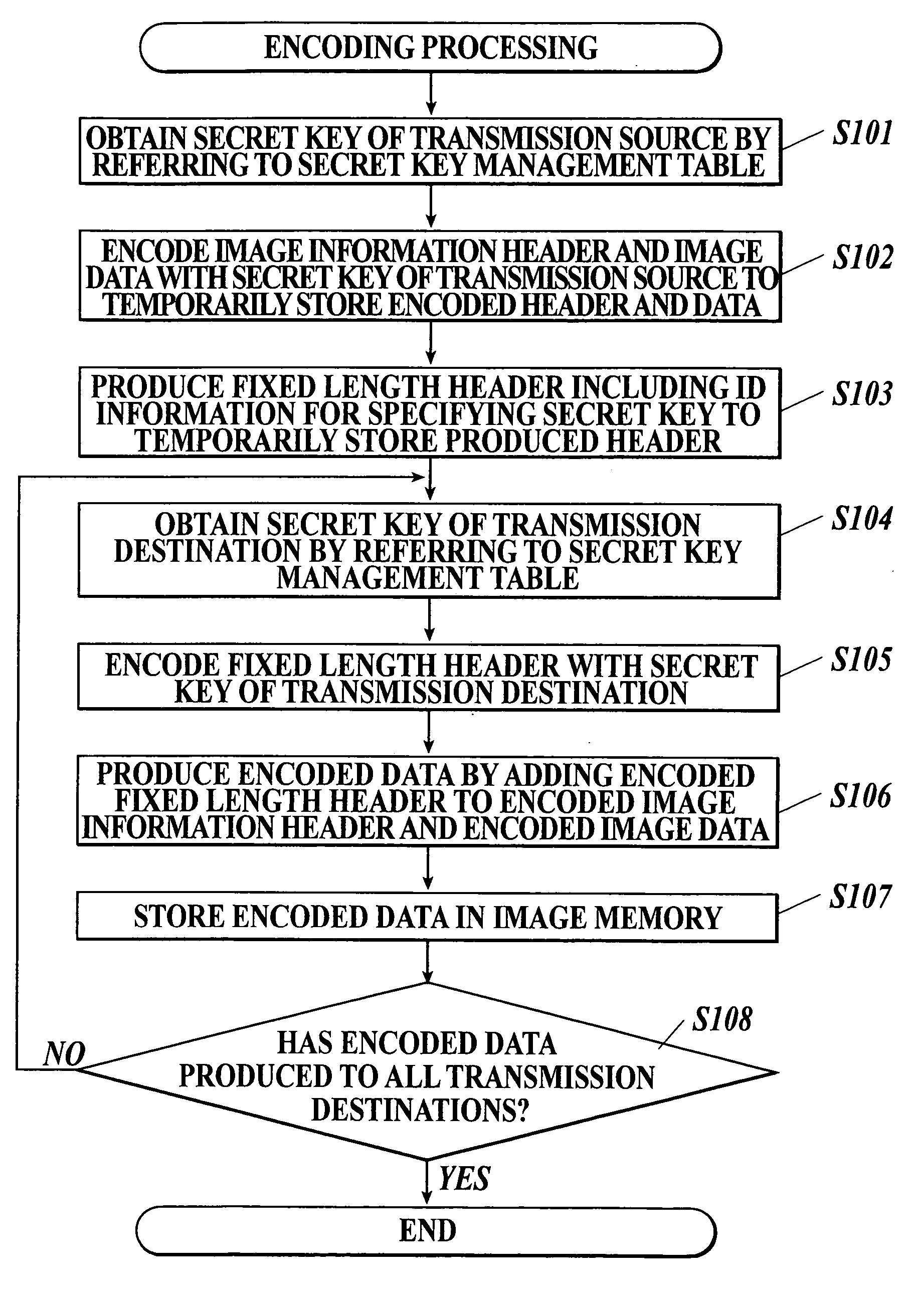

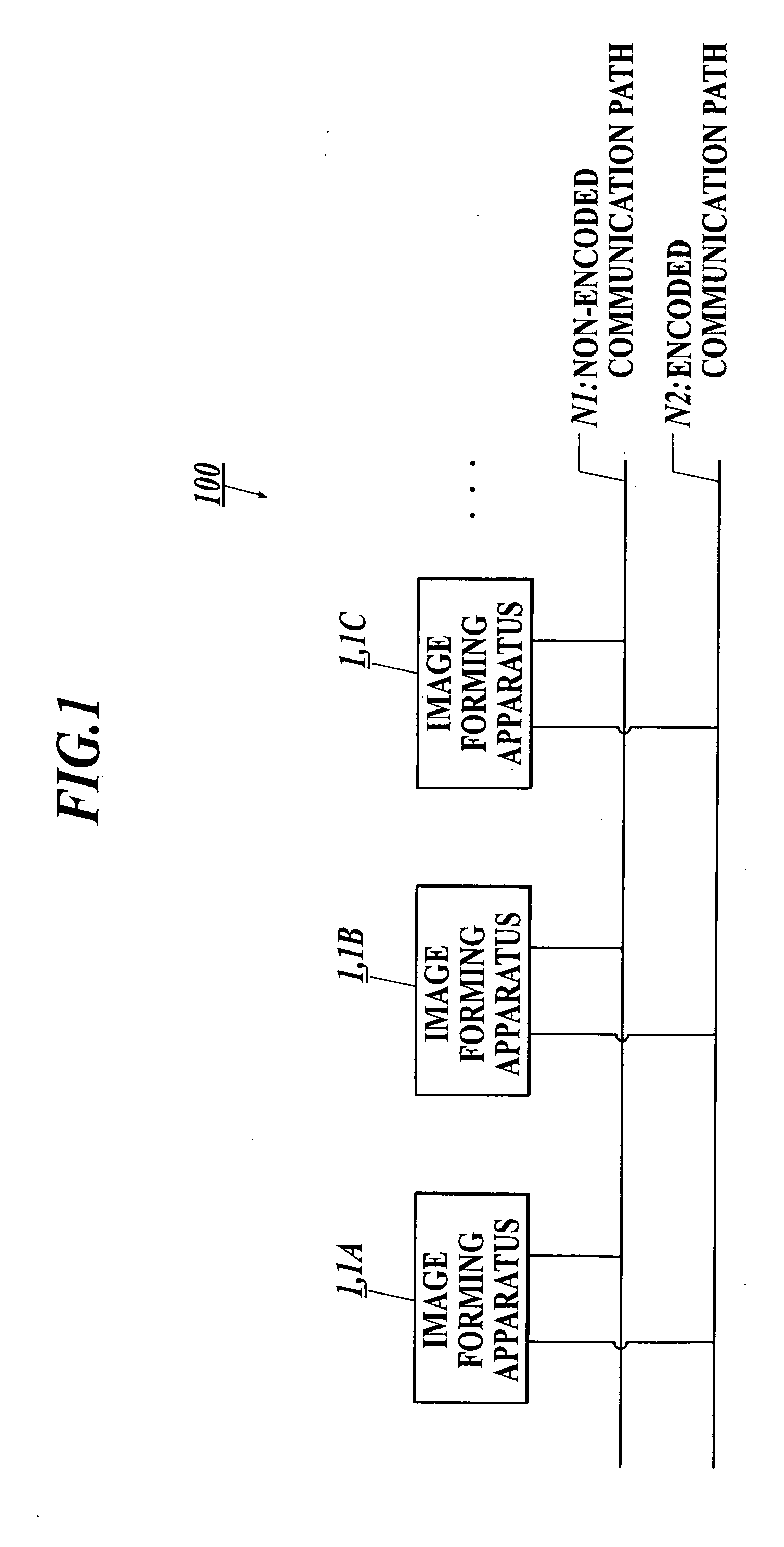

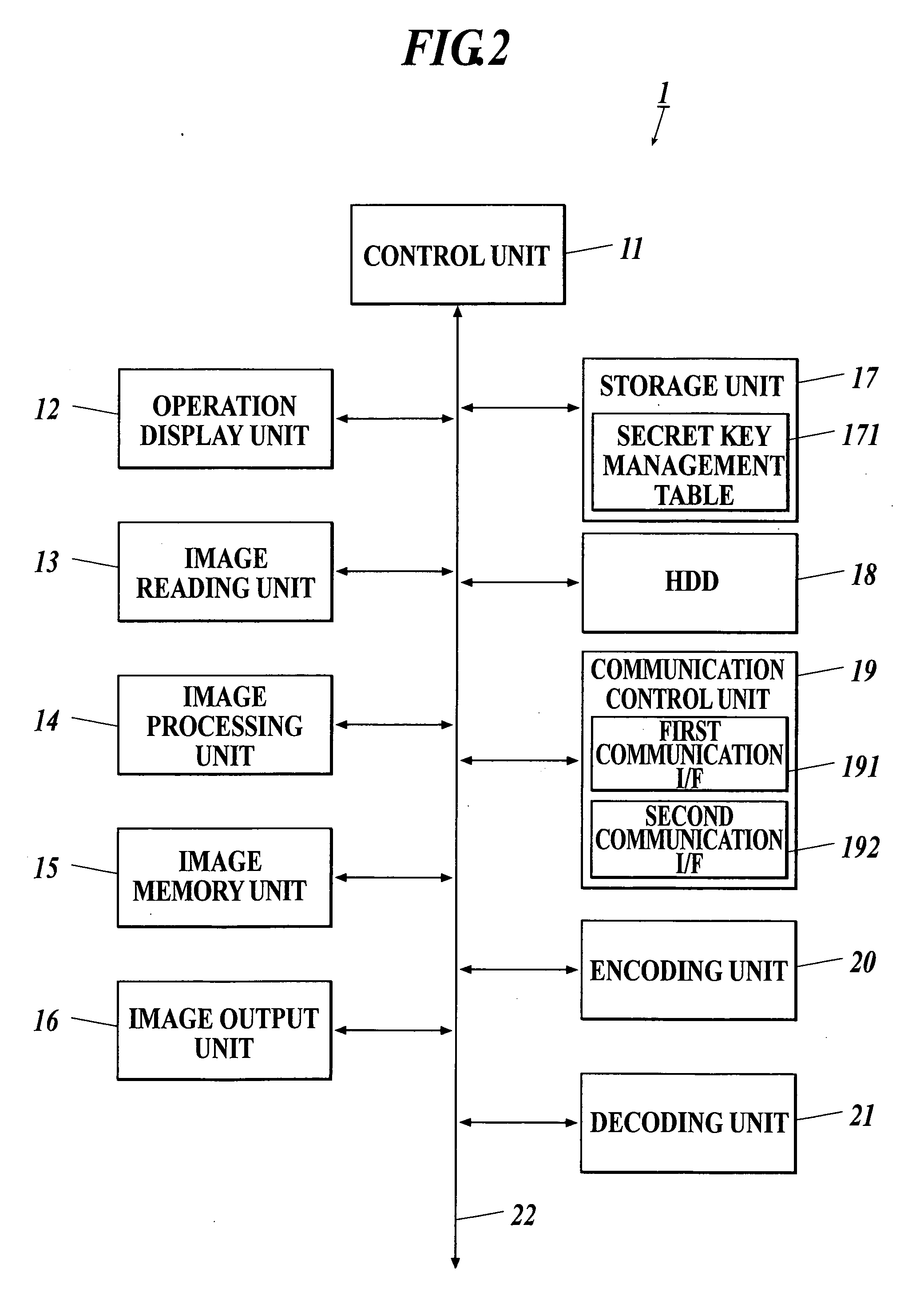

Data transmitting and receiving system, data processing apparatus and encoding communication method

InactiveUS20070019810A1Processing timeMultiple keys/algorithms usageComputer security arrangementsComputer hardwareData transmission

A data processing apparatus, comprising: an encoding unit to encode data to be transmitted, produce header information including identification information for specifying a key enabling decoding the encoded data, encode the produced header information by using a key of a transmission destination, and add the encoded header information to the data to be transmitted to produce header-added encoded data; and a transmission unit to transmit the header-added encoded data encoded by the encoding unit to a data processing apparatus of a transmission destination through a communication network.

Owner:KONICA MINOLTA BUSINESS TECH INC

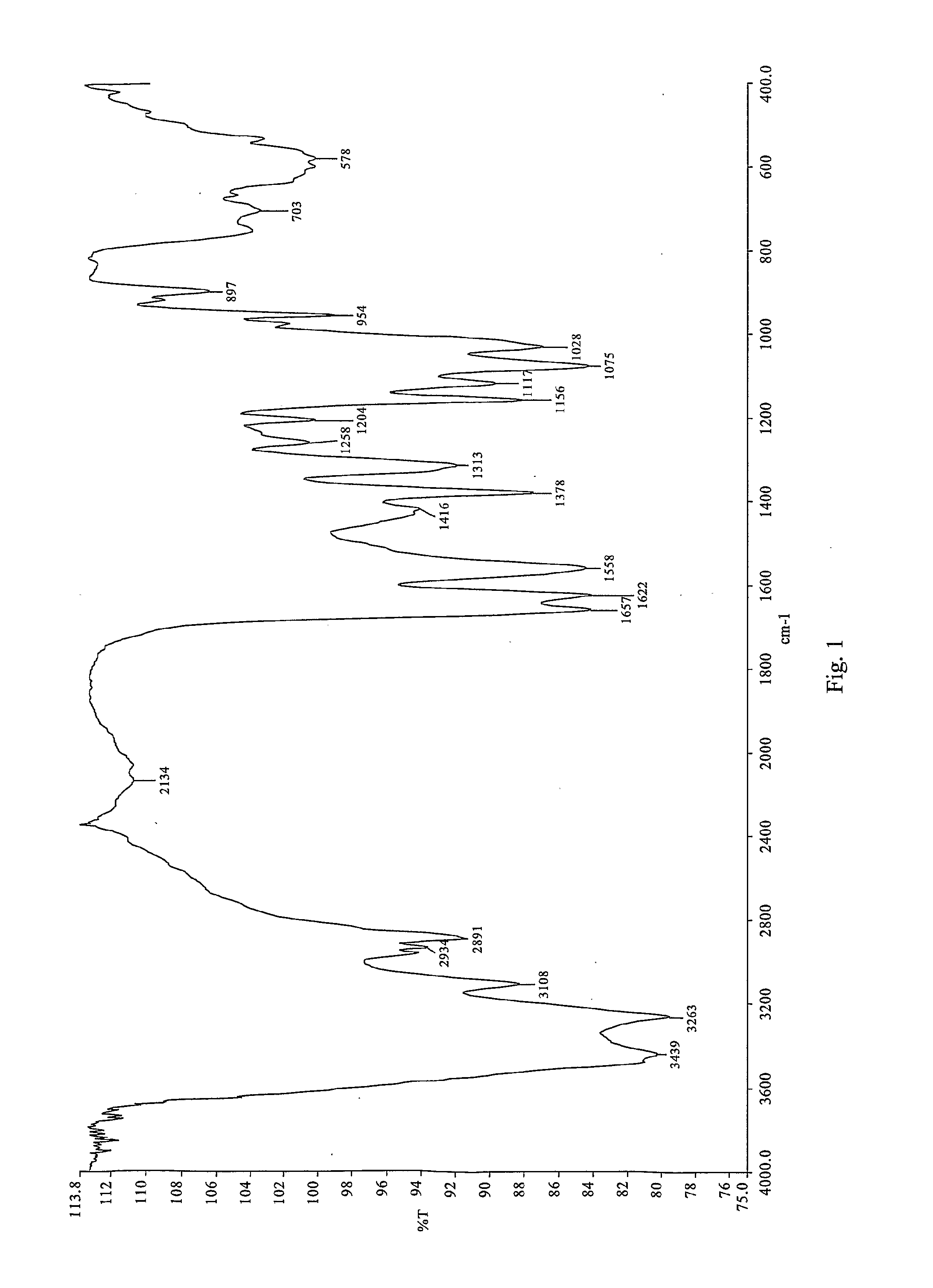

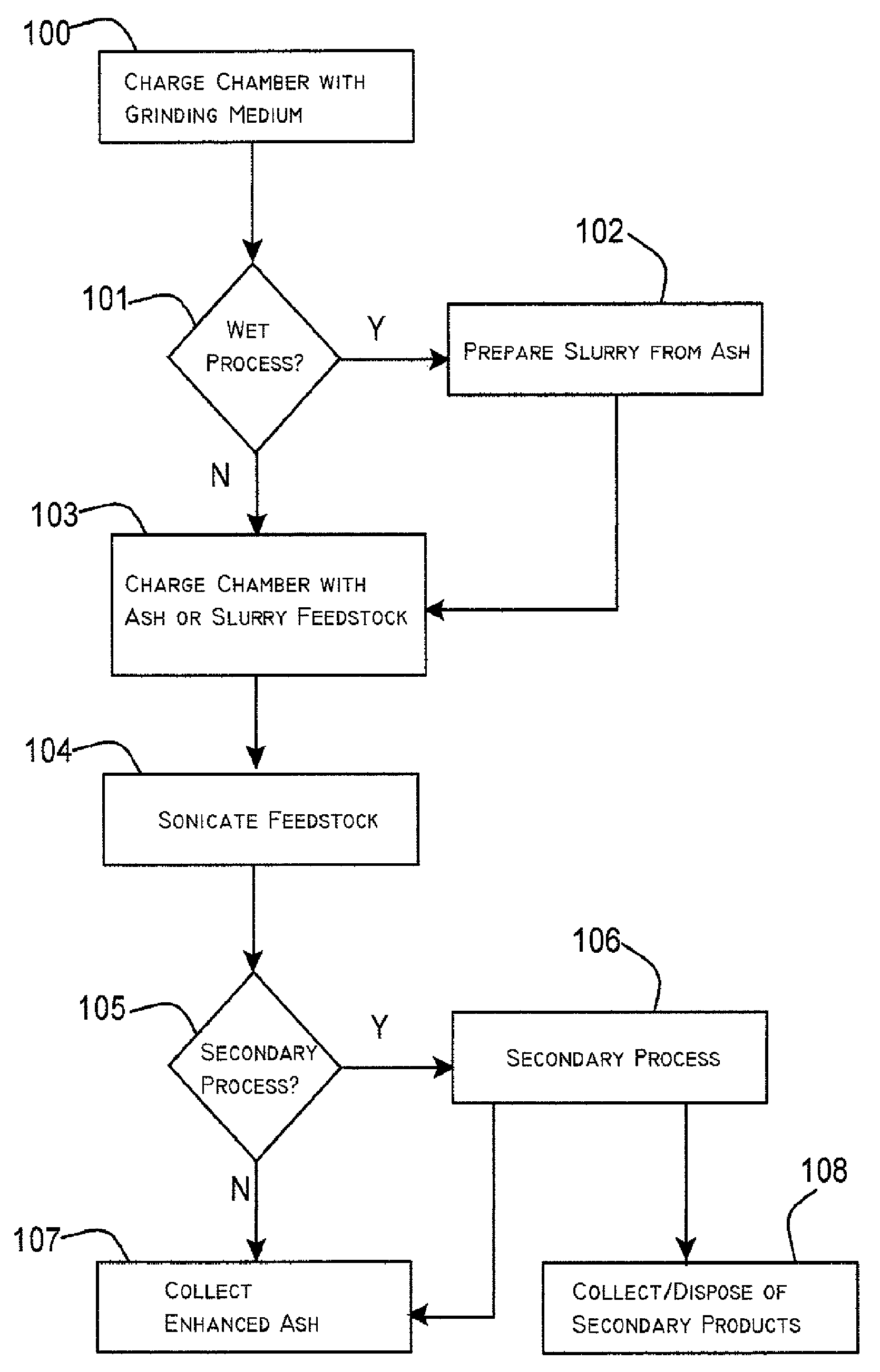

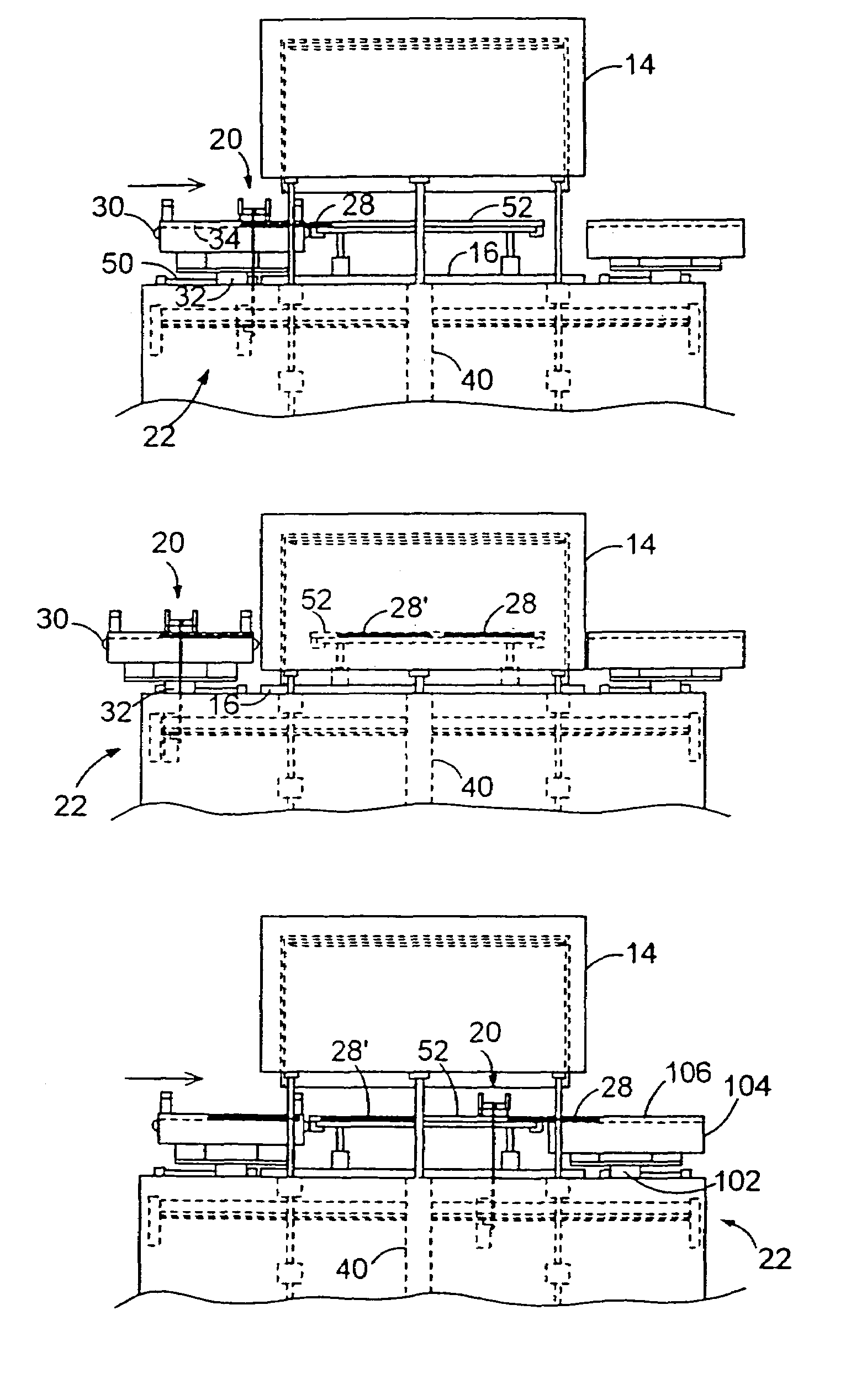

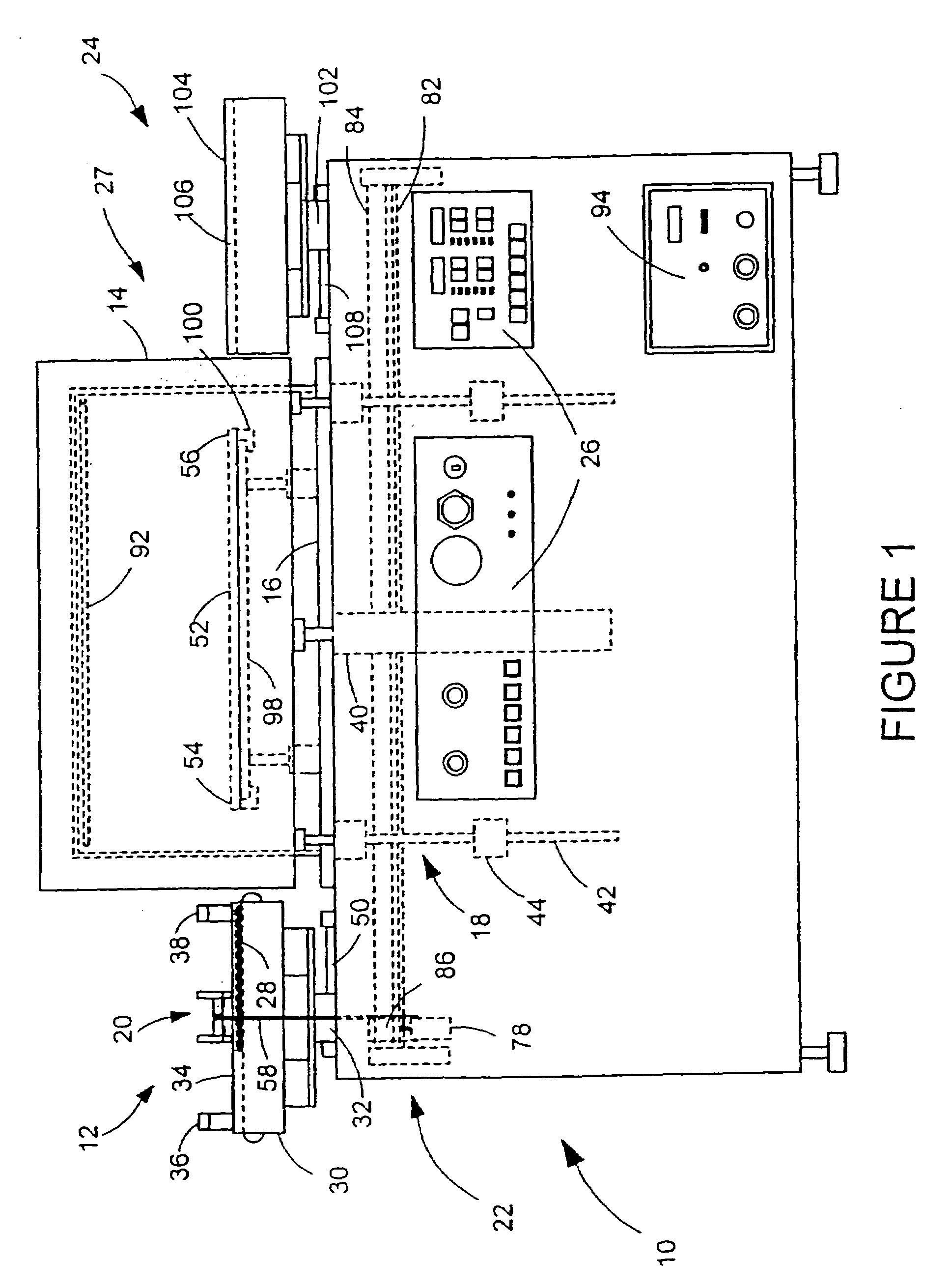

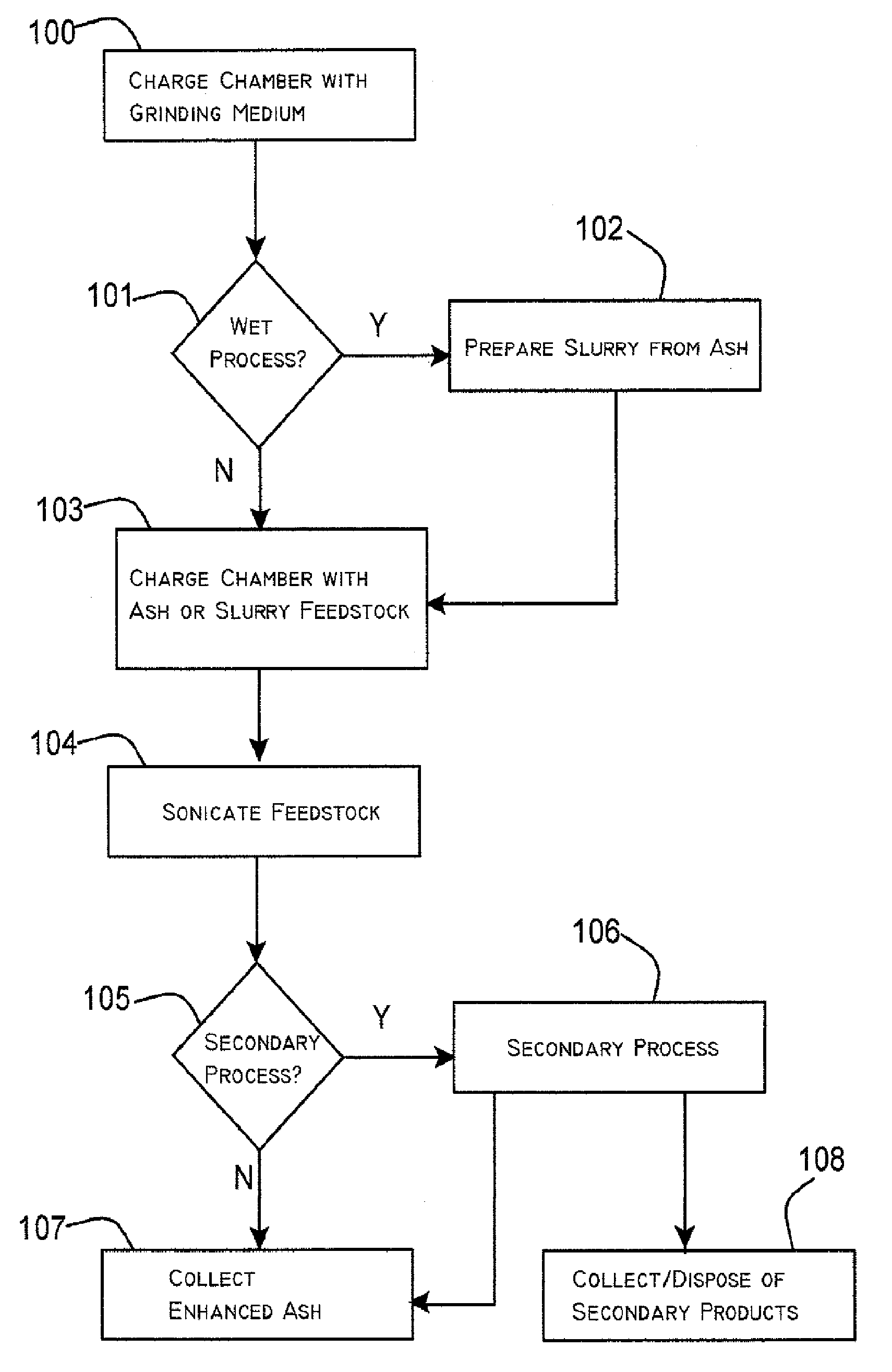

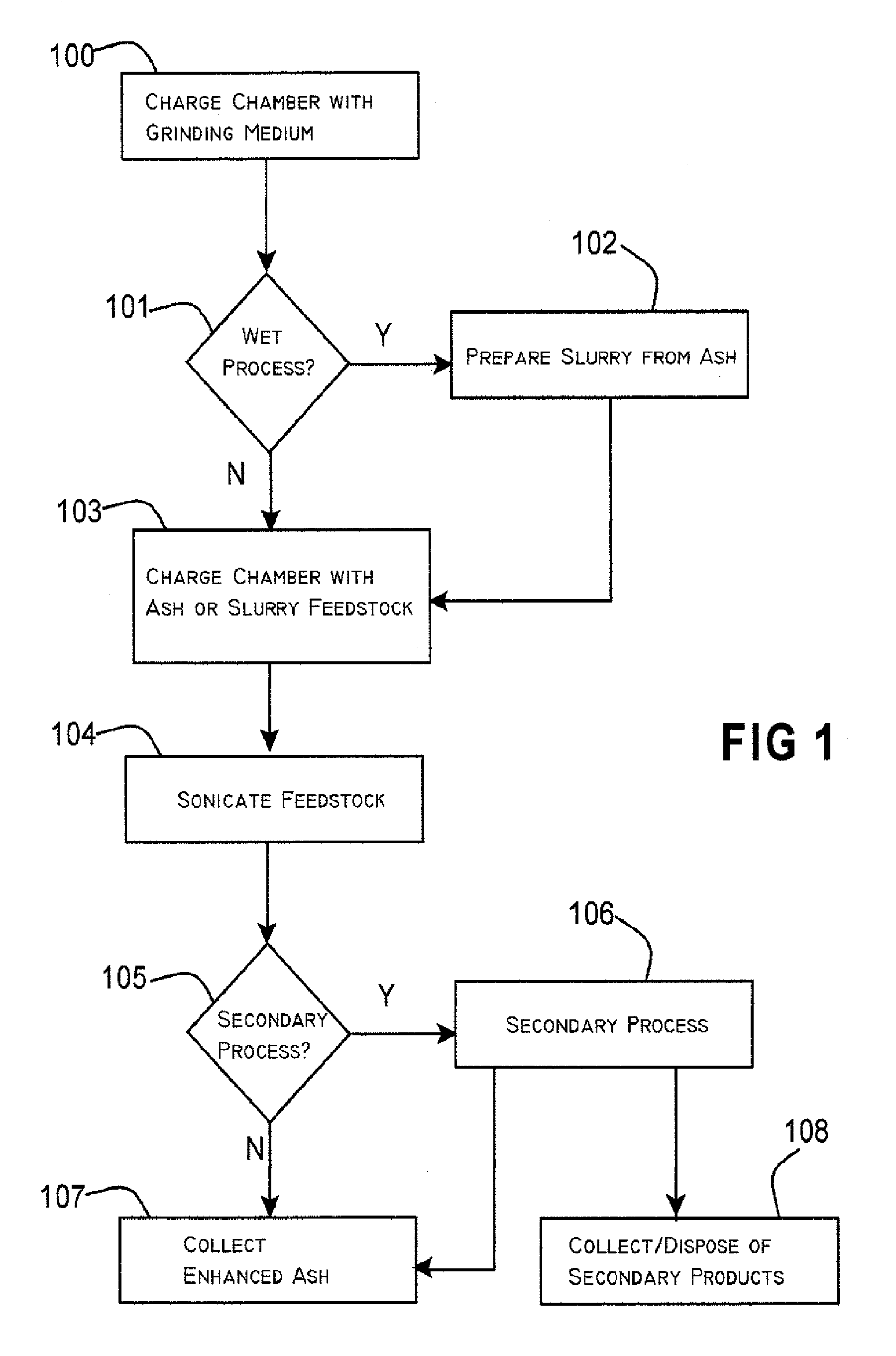

Upgraded combustion ash and its method of production

ActiveUS8876027B2Enhance numerous qualityIncrease surface areaSolid waste managementCement productionCombustionMethods of production

Described and claimed herein is a method of producing enhanced combustion ash for use in pozzolanic applications or cement clinker manufacture. The method employs a primary process in which wet or dry feedstock is pulverized with sonication using one or more grinding media having a maximum component size of about 2 mm. Alternatively, the media may have a true grinding medium volume to chamber volume ratio of at least 0.29. Also disclosed an claimed is an enhanced combustion ash produced by the method, whereby the enhanced combustion ash has one or more qualities that make it particularly suitable in pozzolanic applications or cement clinker manufacture.

Owner:PROVECTUS ENGINEERED MATERIELS

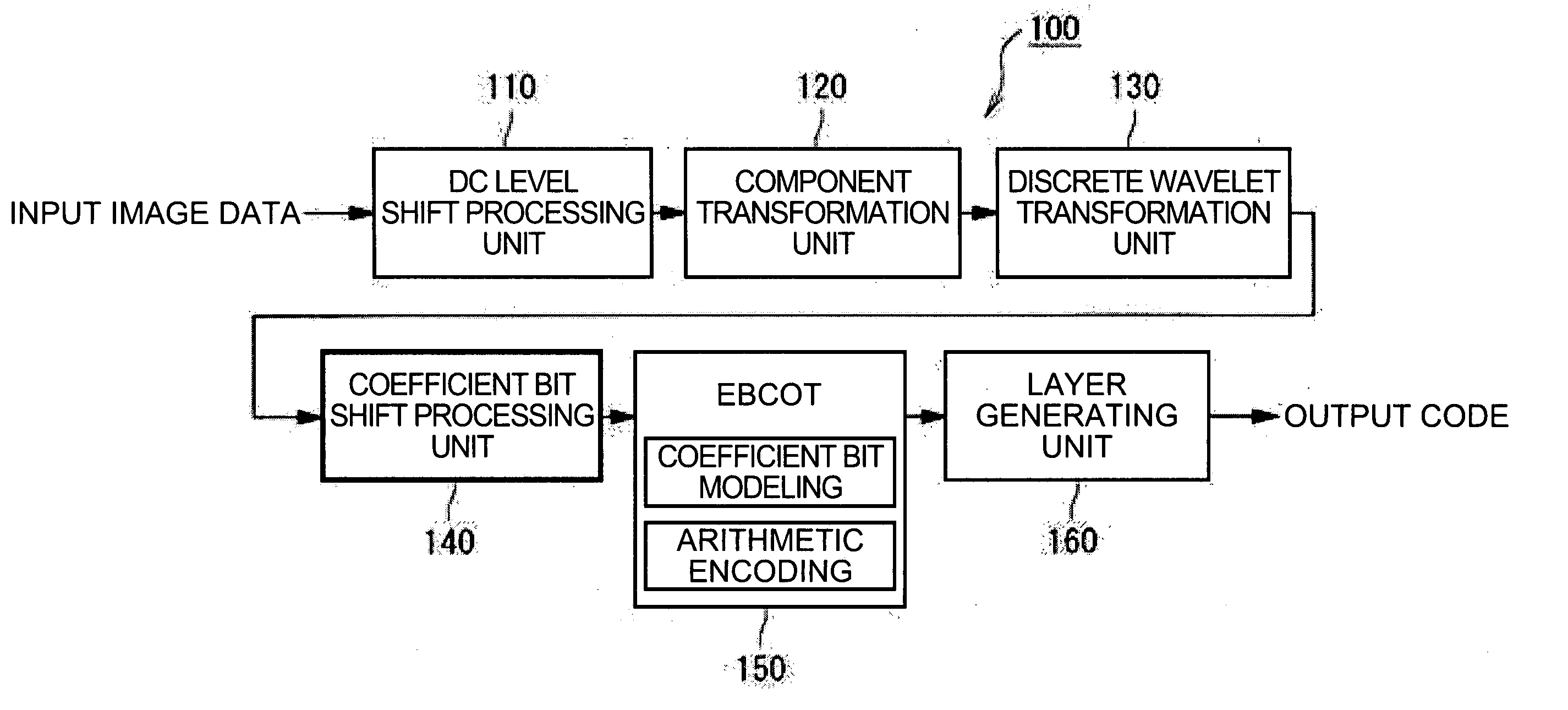

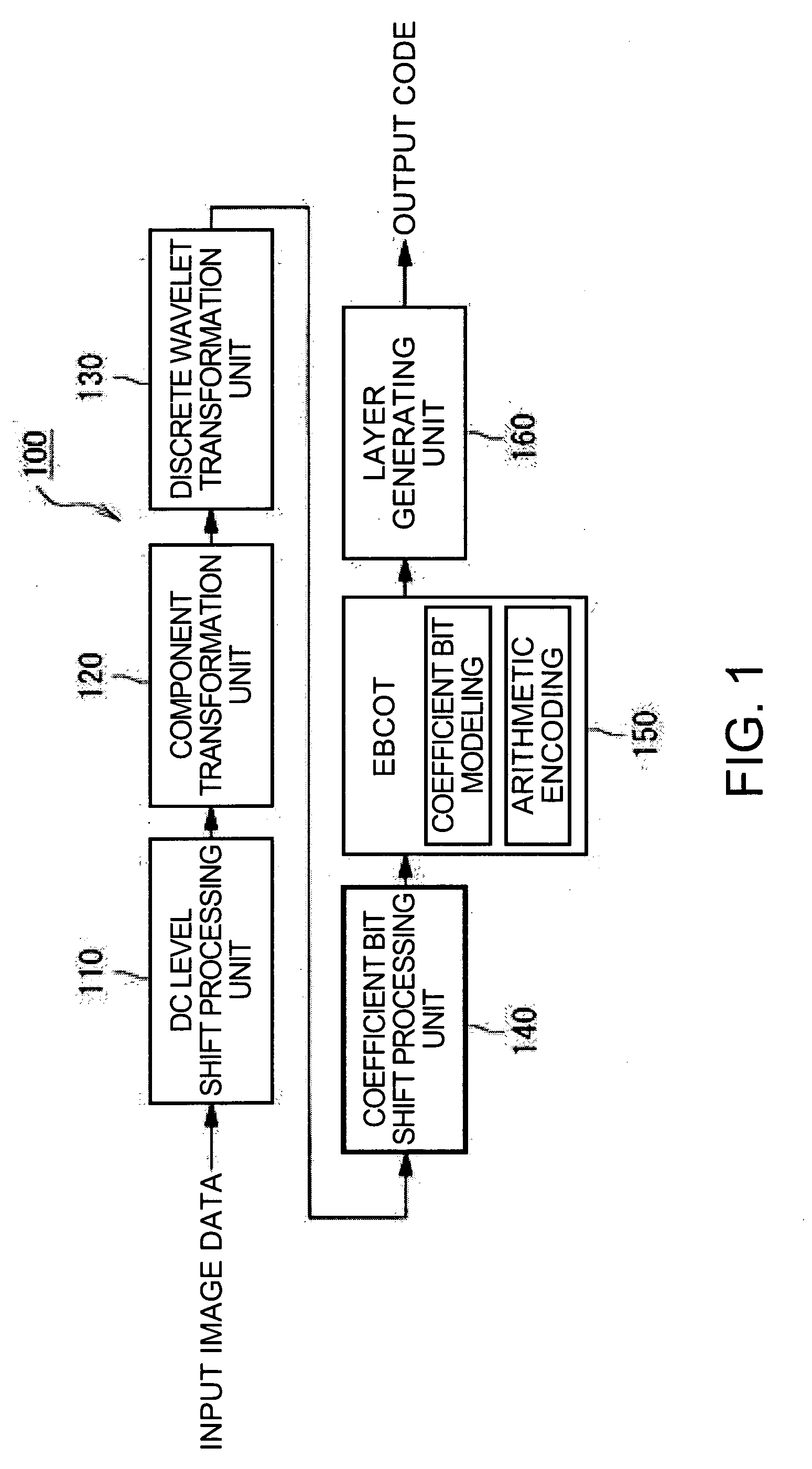

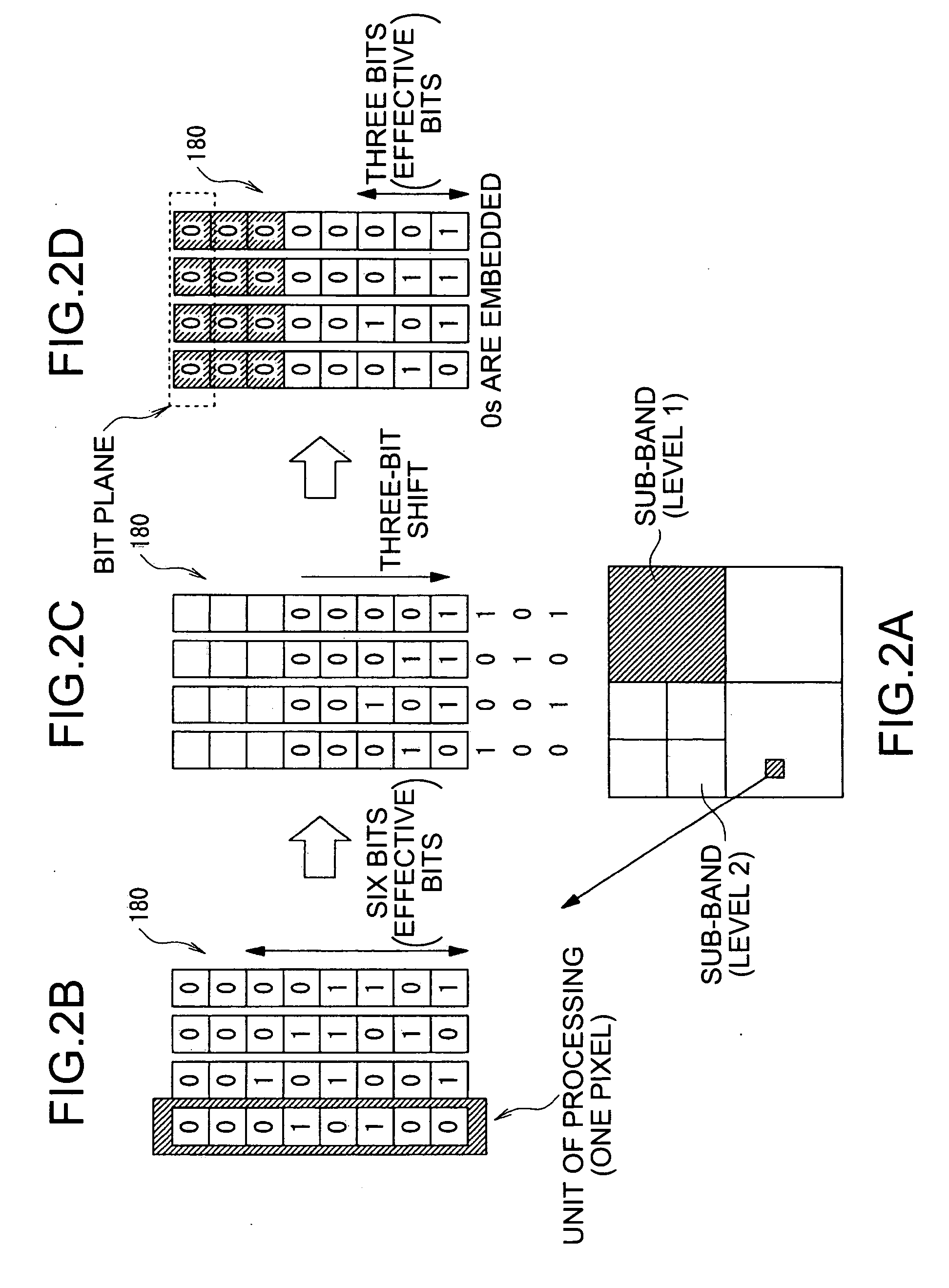

Digital image encoding device, digital image encoding program, digital image encoding method, digital image decoding device, digital image decoding program, and digital image decoding

InactiveUS20060034525A1Reduce processing timeReduce data volumeCode conversionCharacter and pattern recognitionDigital image dataDiscrete wavelet transform

A digital image encoding device, which encodes digital image data using a discrete wavelet transform, includes a coefficient bit shift processing unit that performs bit shift processing on a wavelet coefficient after the discrete wavelet transform. The coefficient bit shift processing shifts the wavelet coefficient to a lower bit side by a predetermined number of bits to truncate a lower bit, and reduces the number of effective bits to create a new wavelet coefficient.

Owner:SEIKO EPSON CORP

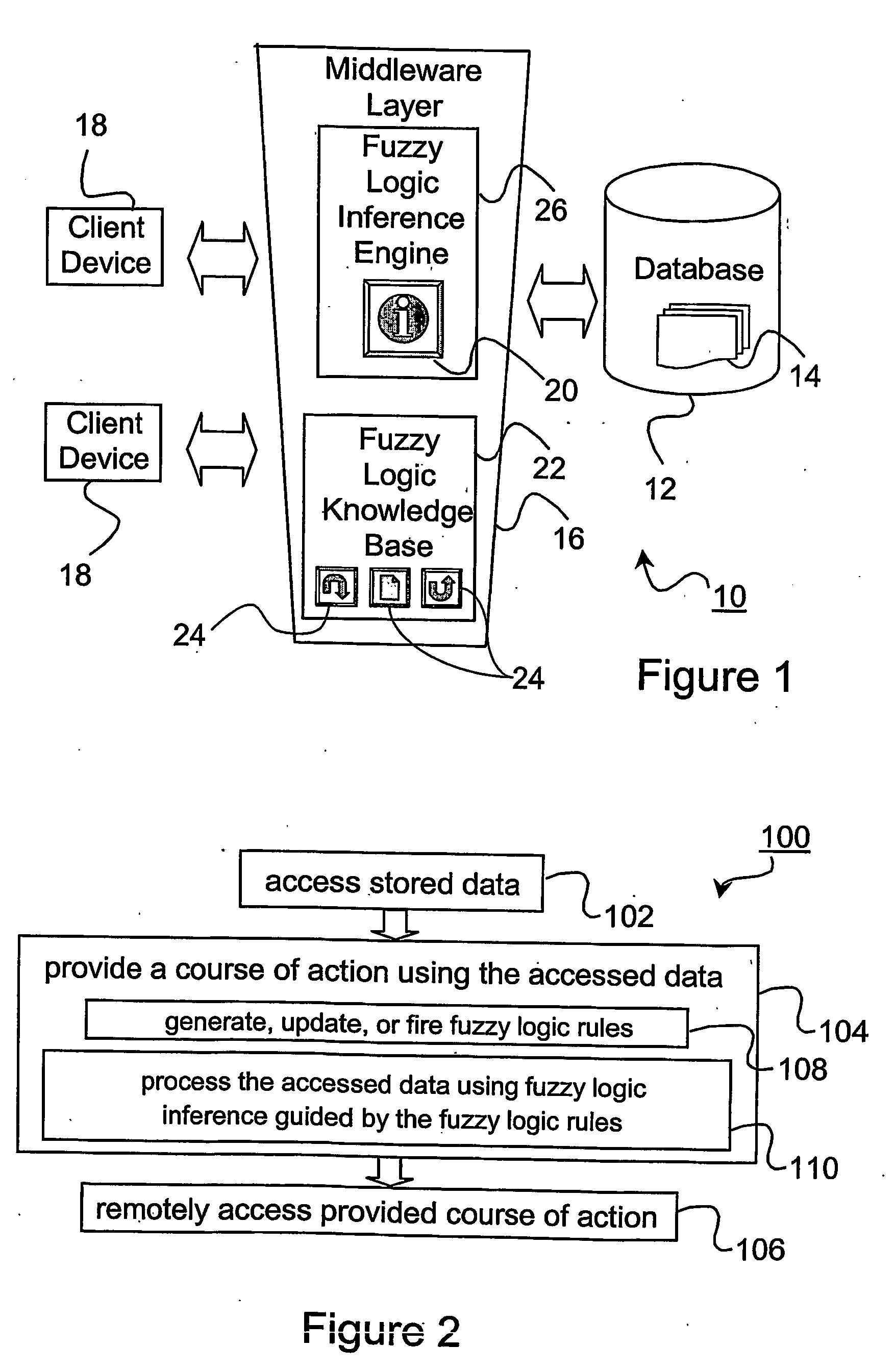

Intelligent data management system and method

ActiveUS20090070149A1Accurate diagnosisAccurate treatmentData processing applicationsMedical automated diagnosisFuzzy logic inferenceCourse of action

Owner:ALPHAGLOBAL IT

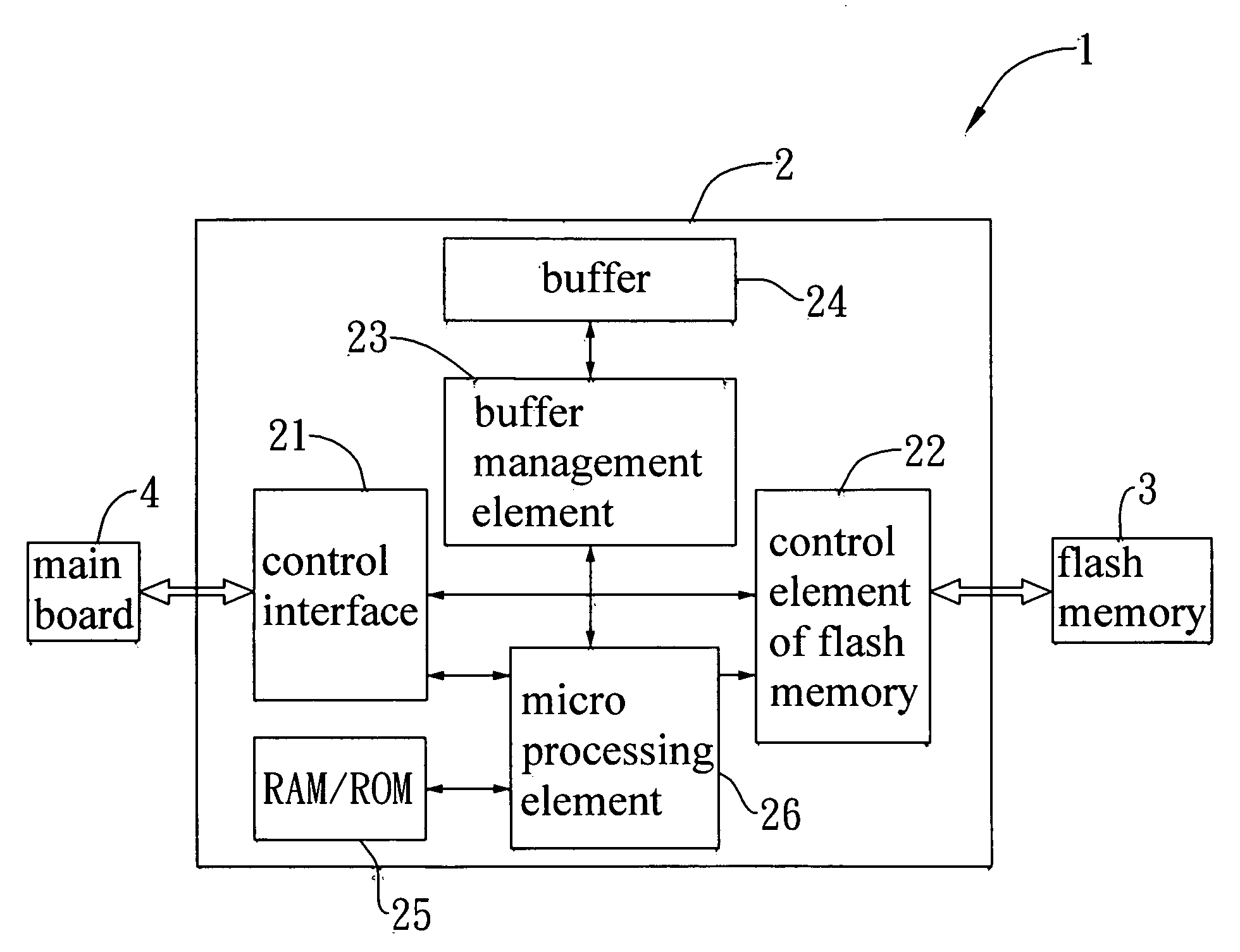

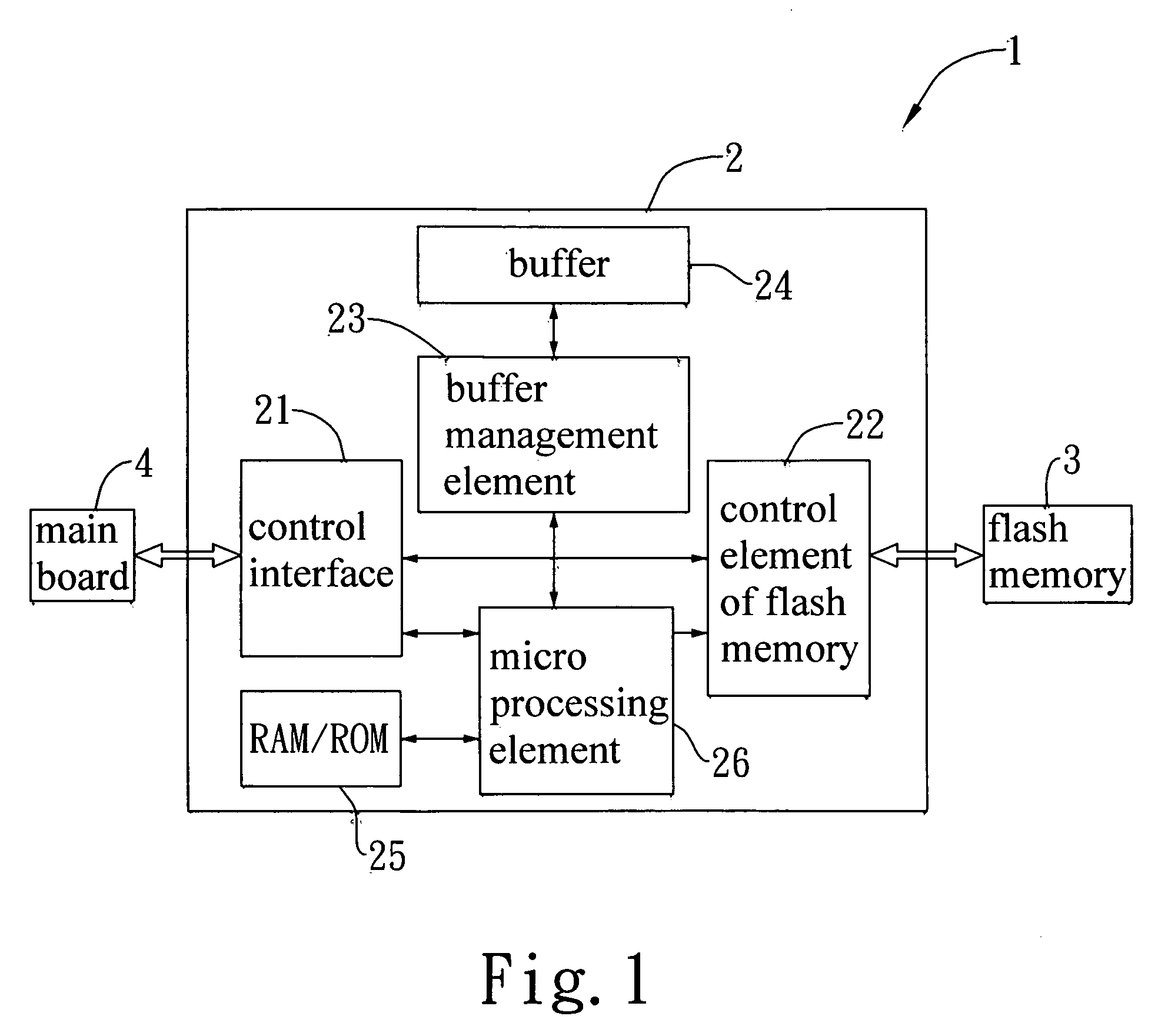

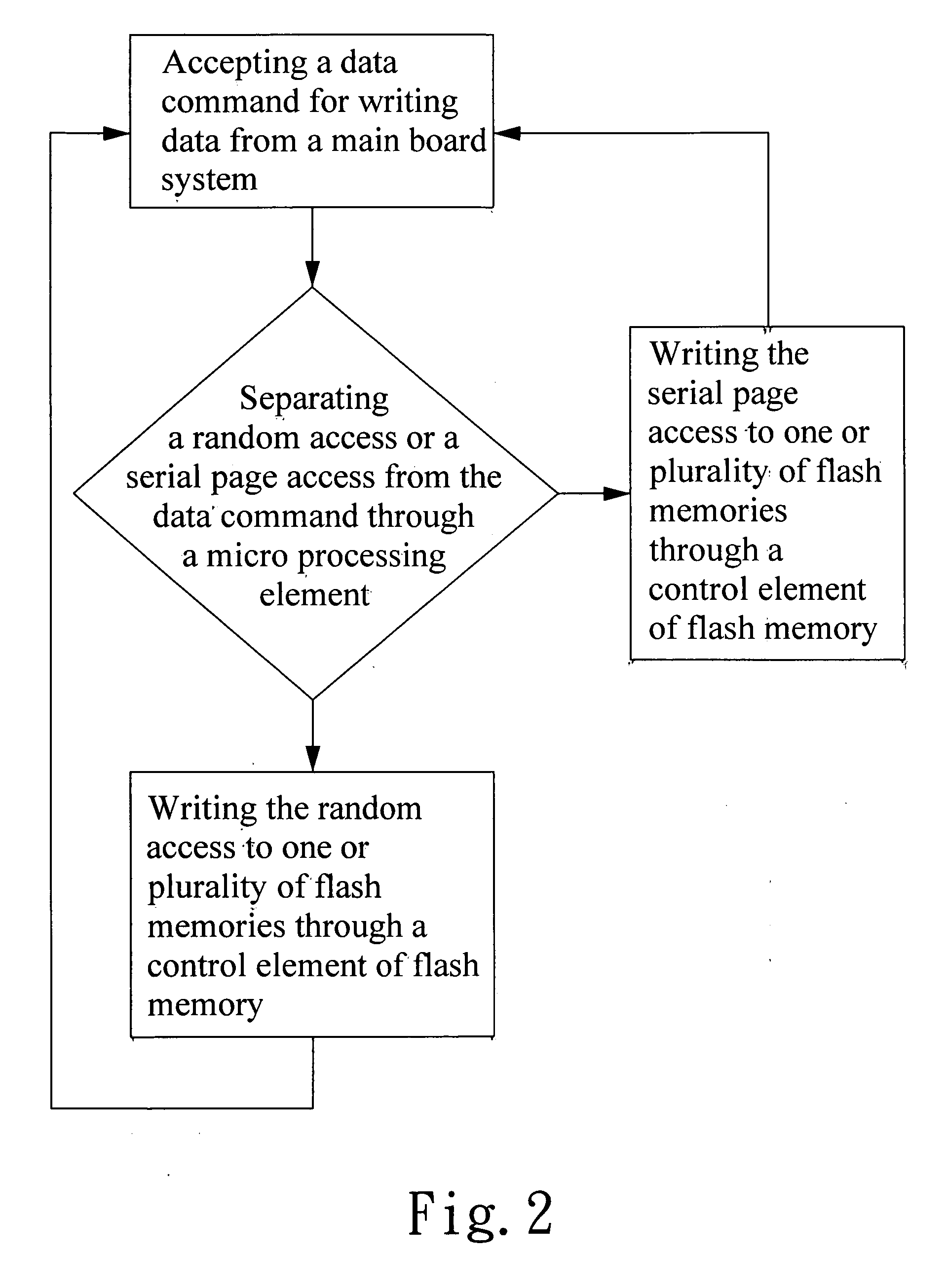

Flash memory device for storing data and method thereof

A flash memory device which comprises a controller and one or plurality of flash memories for storing data and method thereof are disclosed. The controller comprises a control interface to accept data access which is from a main board and is managed by a control element of flash memory and a buffer management element. Through a micro-processing element in the controller, the data access from main board is checked for a random access or a serial page access. The random access and serial page access are written to different blocks by different processes in one or plurality of flash memories. The lifetime and processing speed of flash memories are improved for reduced erasure times during writing data.

Owner:ITE TECH INC

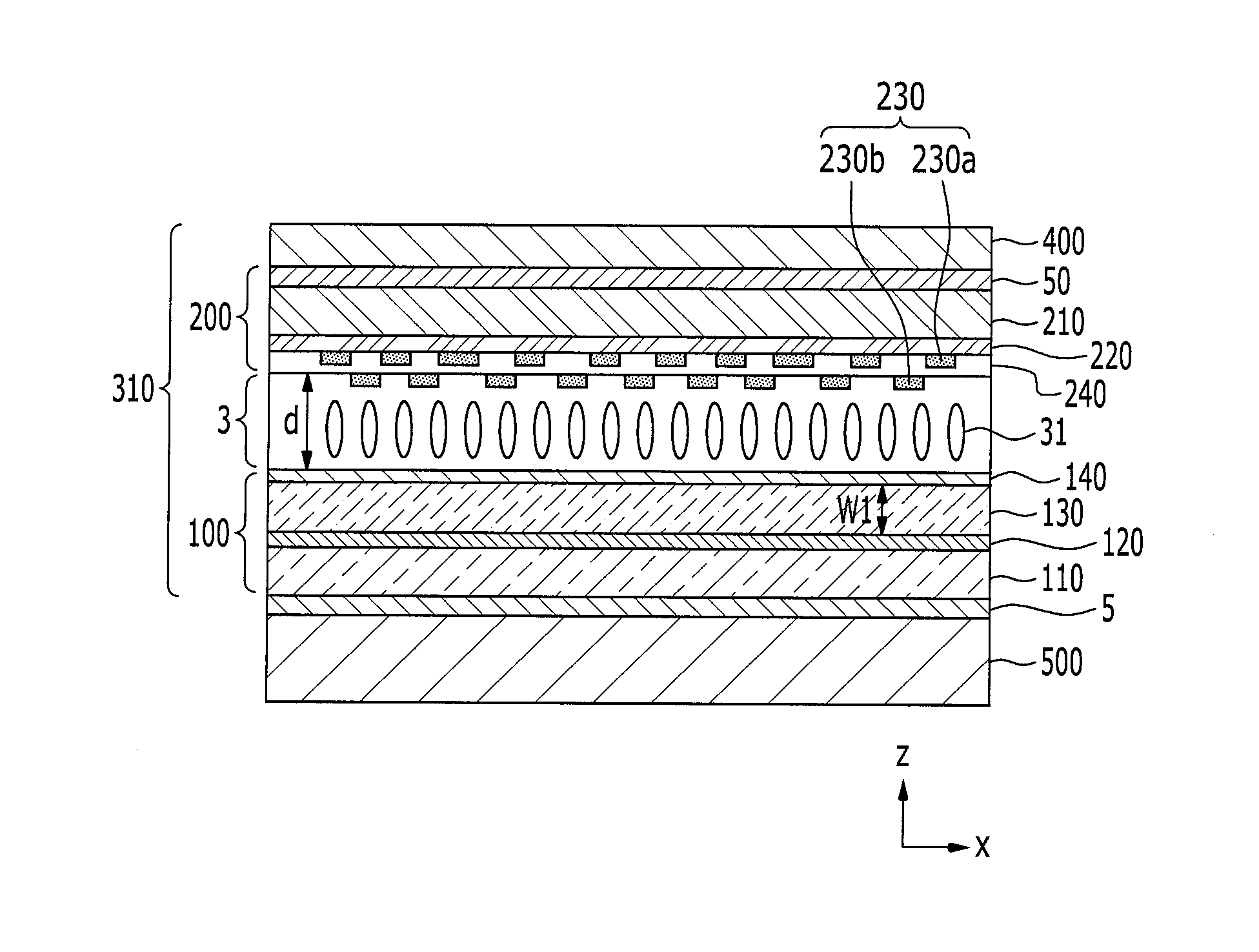

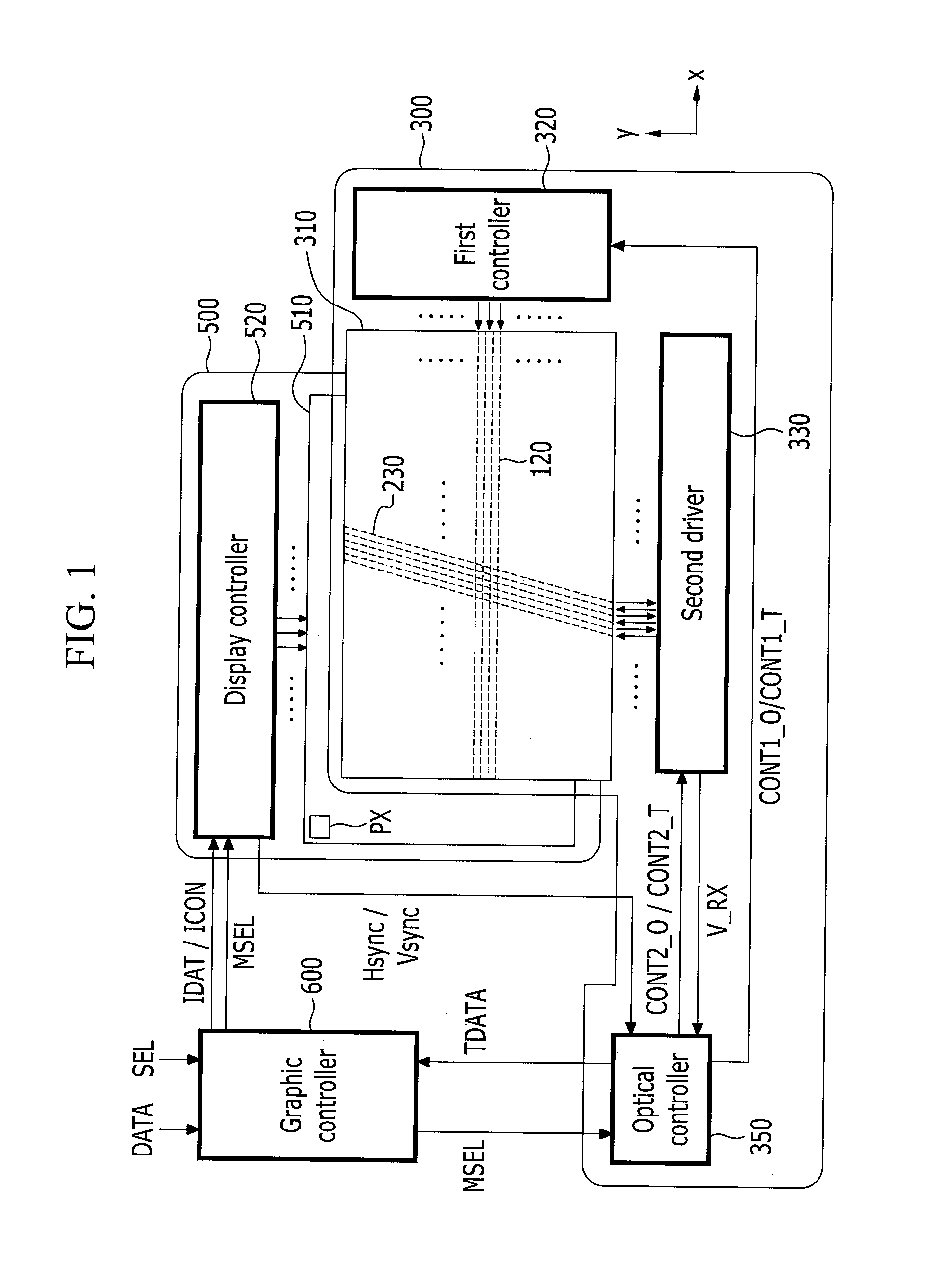

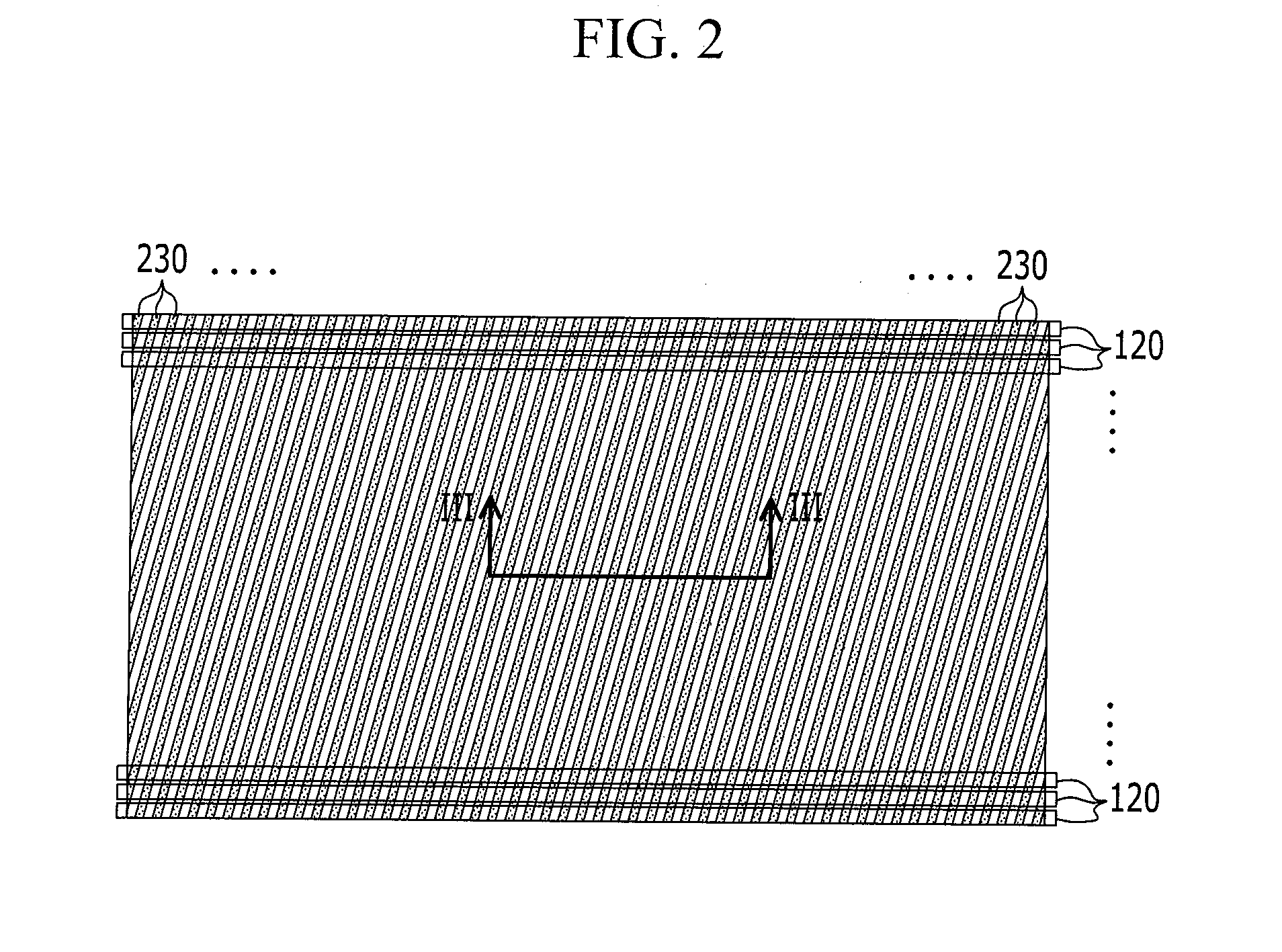

Touch sensing optical system and display device including the same

ActiveUS20160077368A1Processing timeReduce processing costsSteroscopic systemsNon-linear opticsElectric fieldCapacitance

An optical system includes: a first panel including a plurality of first electrodes extending in a first direction; a second panel facing the first panel and including a plurality of second electrodes extending in a second direction crossing the first direction; an optical conversion layer between the first panel and the second panel; and a first insulating layer between the first electrodes and the second electrodes, the first insulating layer including an organic material, wherein, in a touch mode, one or more of the first electrodes and one or more of the second electrodes crossing each other form a touch sensing capacitor, and wherein, in a multi-view mode, the first electrodes and the second electrodes apply an electric field to the optical conversion layer, the electric field depending on a voltage difference between the first electrode and the second electrode, to generate different phase differences.

Owner:SAMSUNG DISPLAY CO LTD

Microalgae biodiesel production method

InactiveCN106221888AWidely distributedIncrease biomassFatty acid esterificationBiofuelsBiodieselVegetable oil

The invention discloses a microalgae biodiesel production method. The production method comprises the following steps of inoculating nannochloropsis oculata to a culture medium, irradiating through a red-blue dual-color LED light supplementing lamp for 8 to 14 hours per day, cultivating for 6 to 8 days at a temperature of 24 to 26 DEG C, and collecting nannochloropsis oculata cells; performing a wall breaking process on the collected nannochloropsis oculata cells through ultrasonic wave, then extracting through an organic solvent to obtain microalgae grease, and then adding the microalgae grease, methyl alcohol and a zeolite molecular sieve catalyst into to a reactor according to a mass ratio of 1 : (5 to 7) : (0.01 to 0.03) to perform esterification reaction, so as to obtain an esterification product; then separating and purifying the esterification product to obtain the biodiesel. According to the production method, the nannochloropsis oculata which is short in production period, wide in distribution, strong in photosynthesis and high in grease content is utilized as a raw material, so that the problem of vegetable oil and fat raw materials in biodiesel development is solved. The production method also has the advantages of being simple in preparation technology, high in catalytic efficiency, high in grease extraction rate, high in product yield, and the like, and also lays a good foundation for industrialization and scale of the biodiesel.

Owner:南宁华侨投资区政孙贸易有限公司

Radiation curable ink

ActiveUS20190315978A1Improve reliabilityProcessing timeDuplicating/marking methodsInksMethacrylateRoom temperature

The present invention relates to a radiation curable ink, wherein the polar portion of the surface tension is equal to or greater than 10%, of the total surface tension, and the total surface tension is between 25 and 31 mN / m, the vapor pressure of the total formulation is equal to or less than 25 mPa at room temperature and the ink includes up to 30% by weight, based on the total ink composition, of unsaturated, hydroxy-functional vinylic and / or methacrylic acid esters.

Owner:TIGERWERK LACK & FARBENFAB

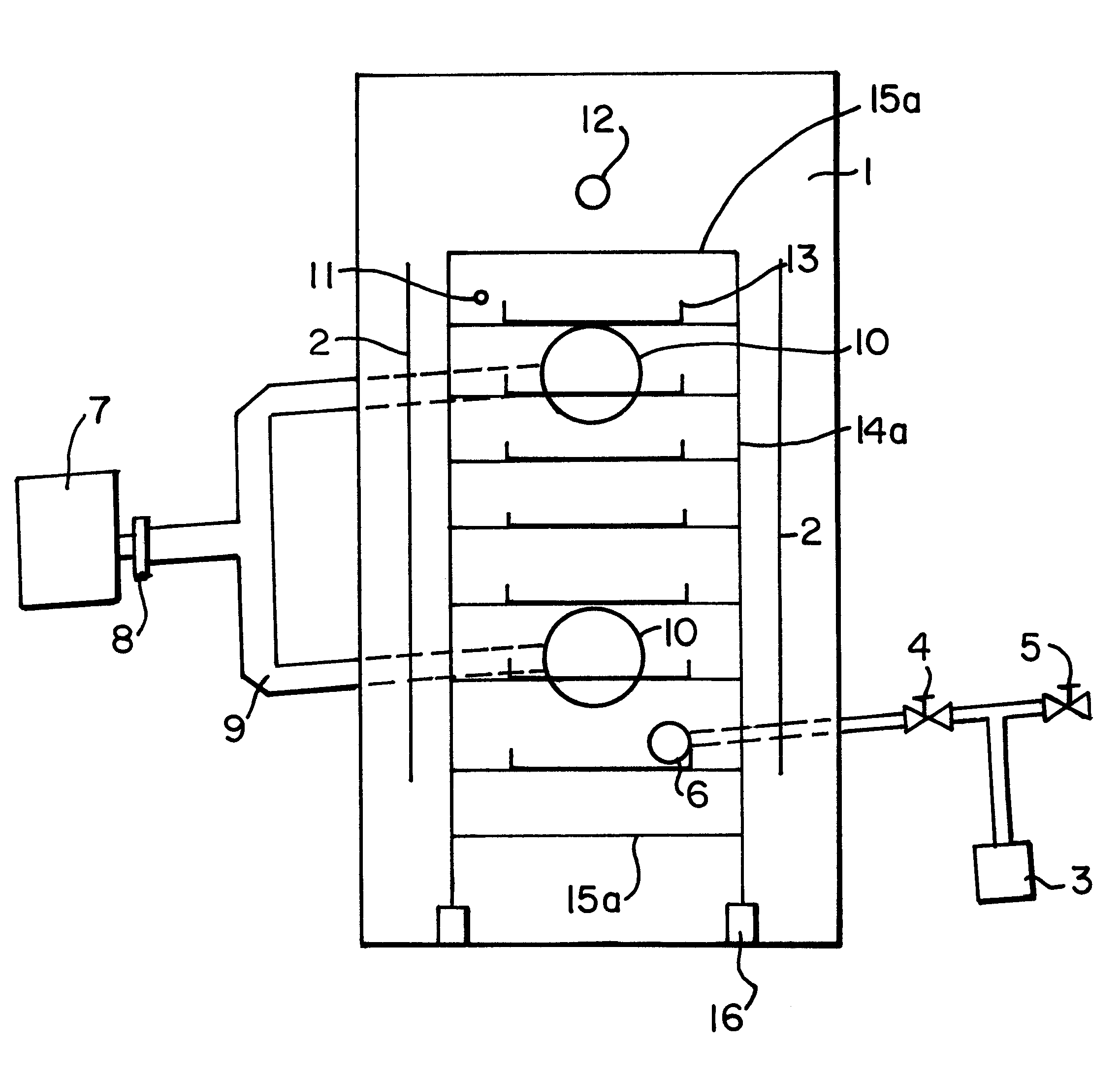

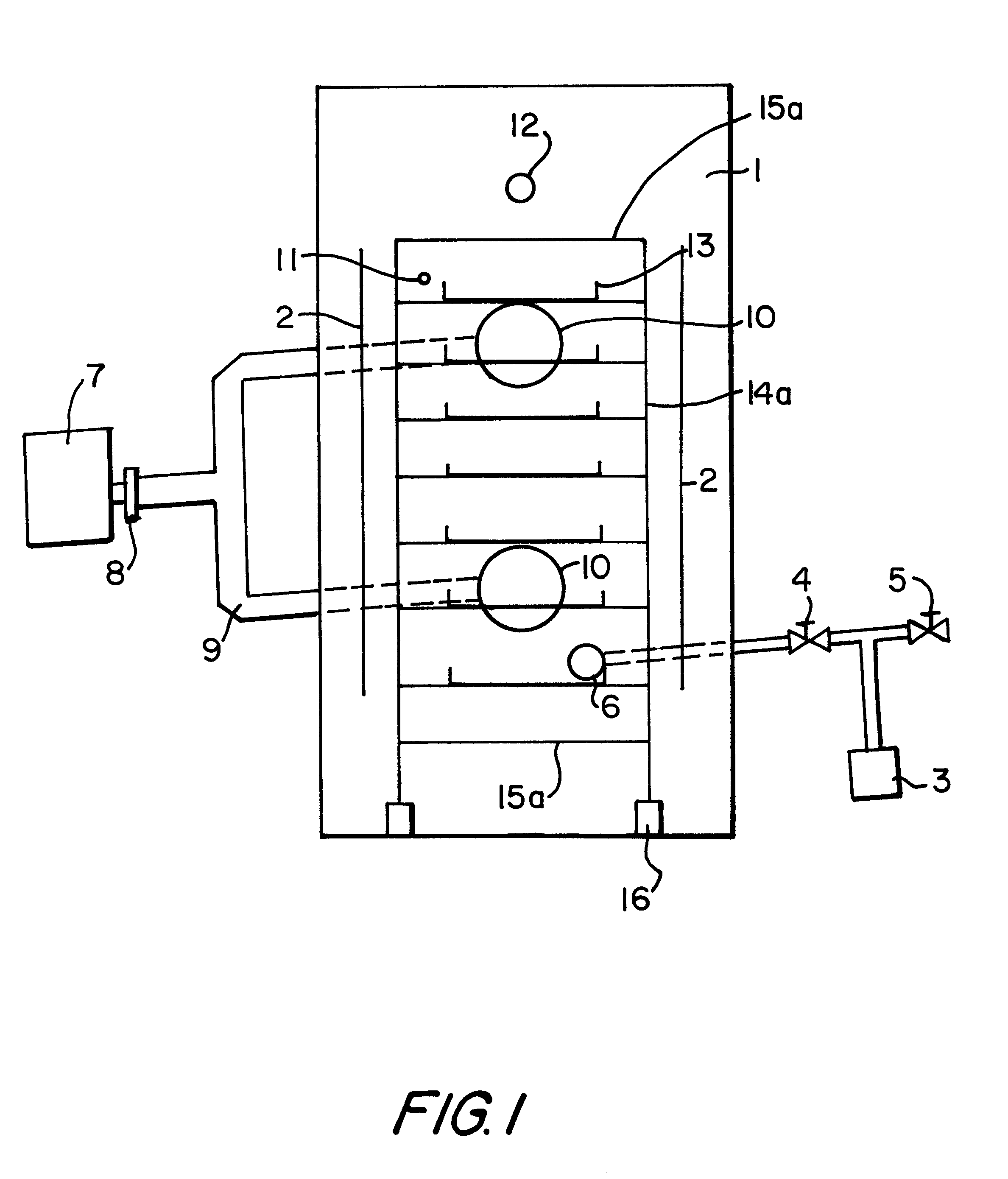

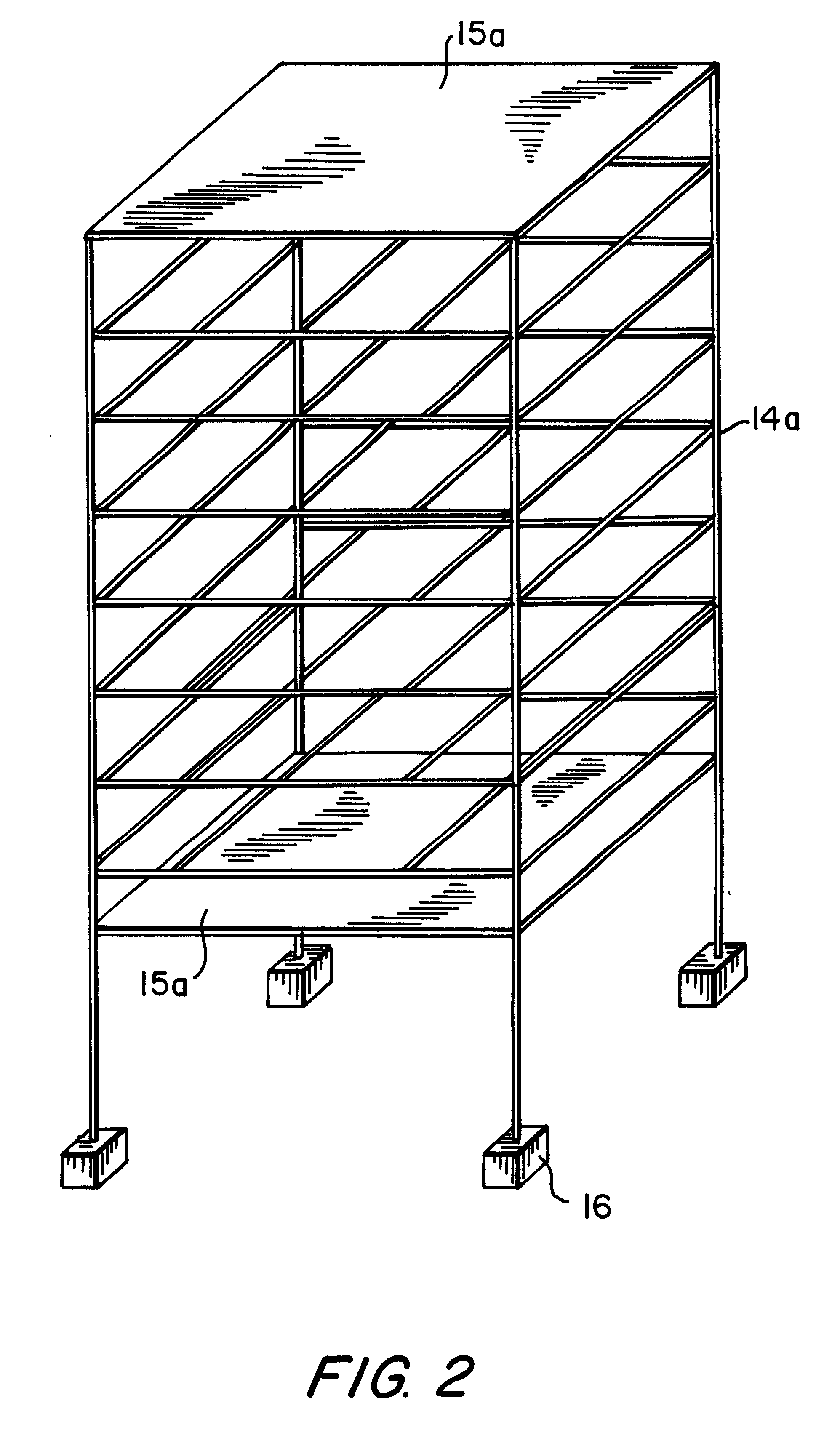

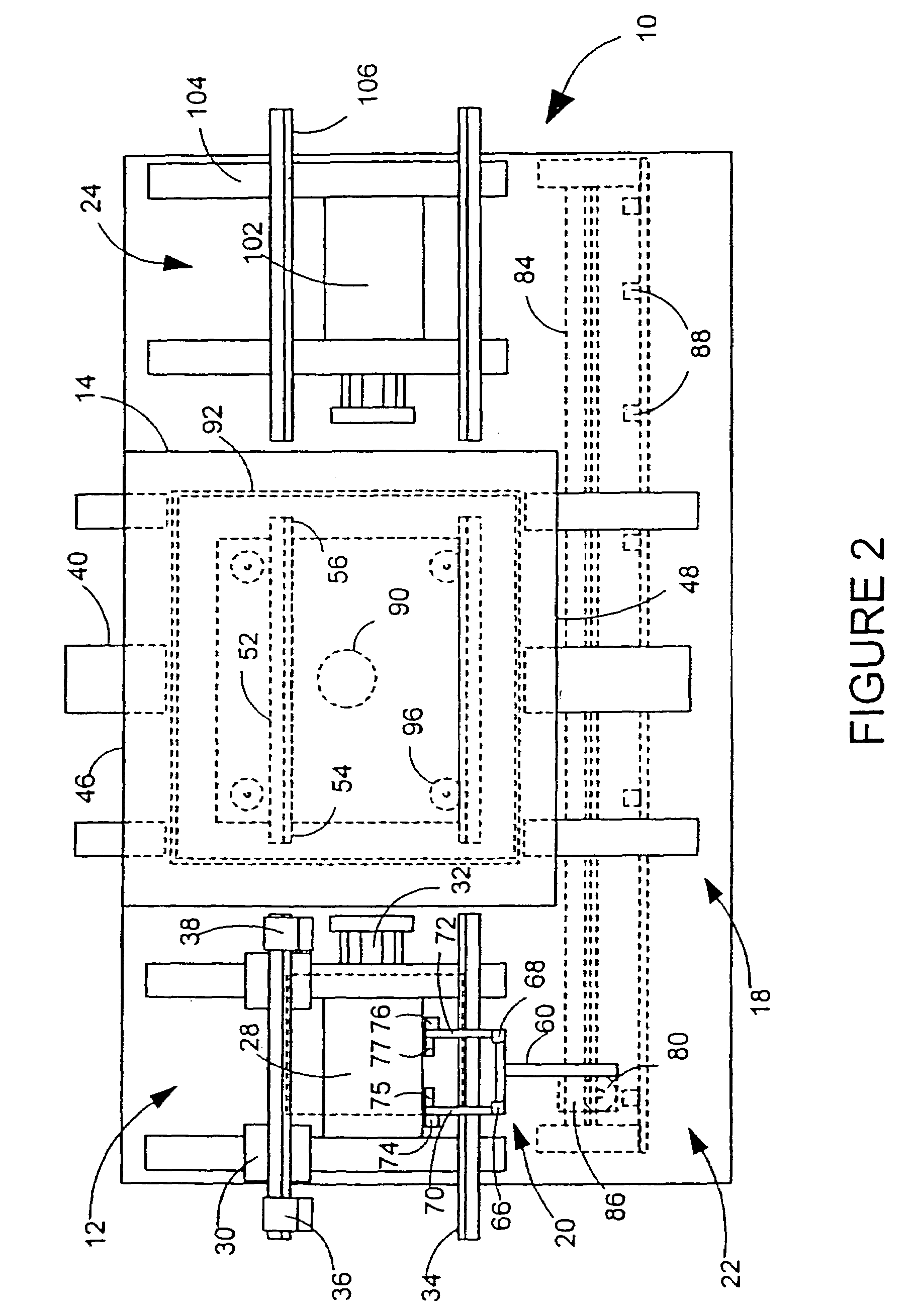

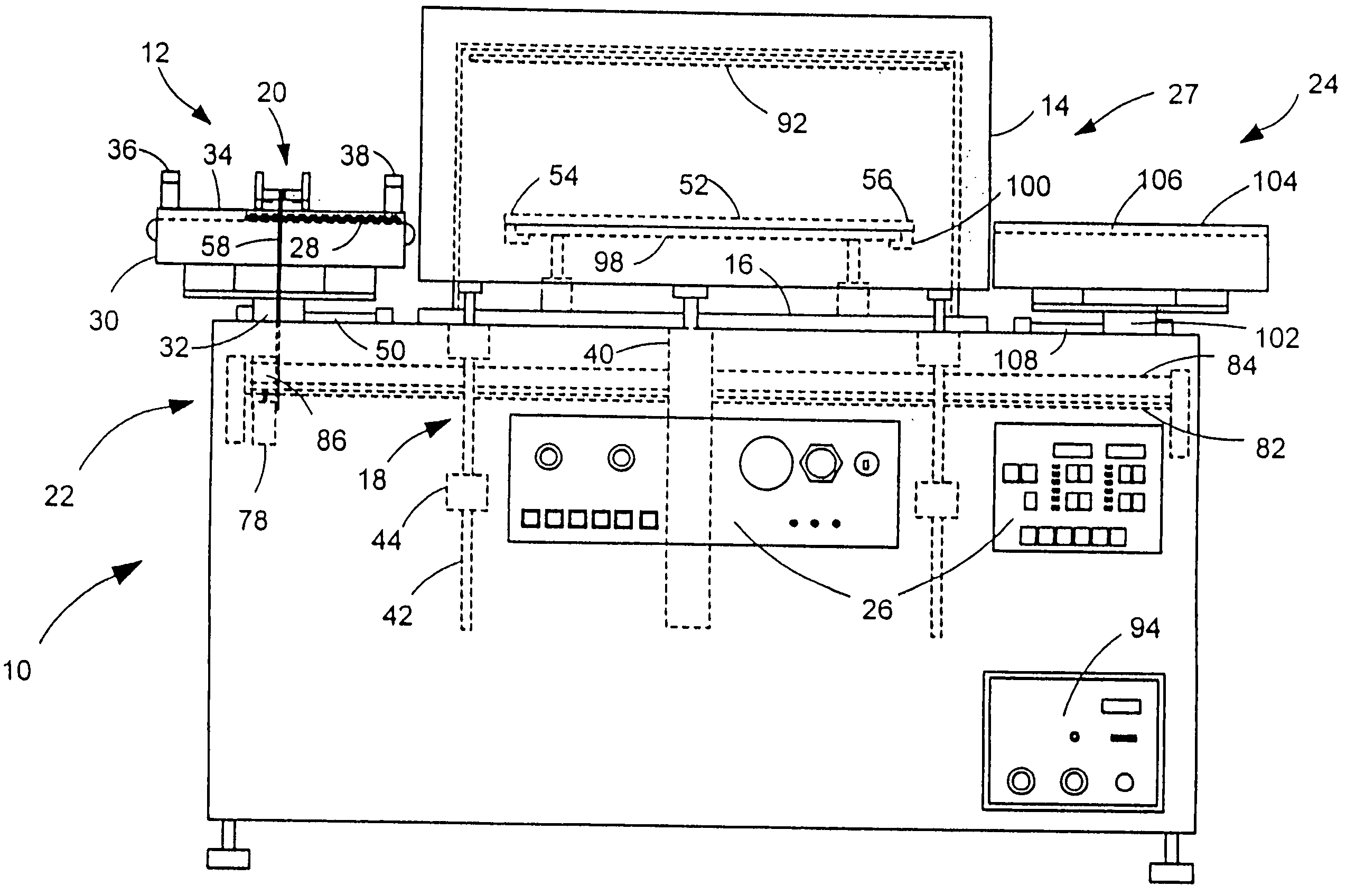

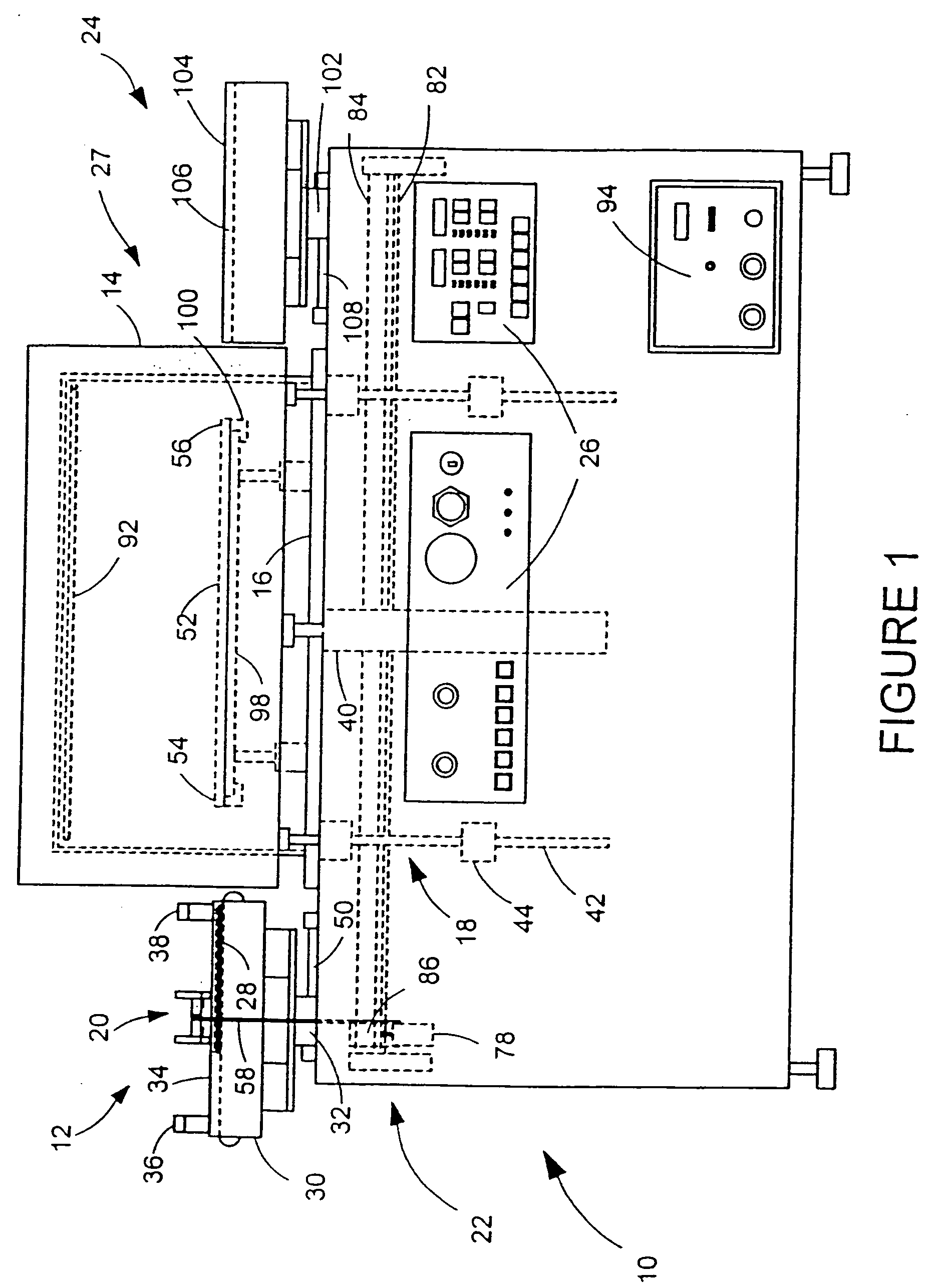

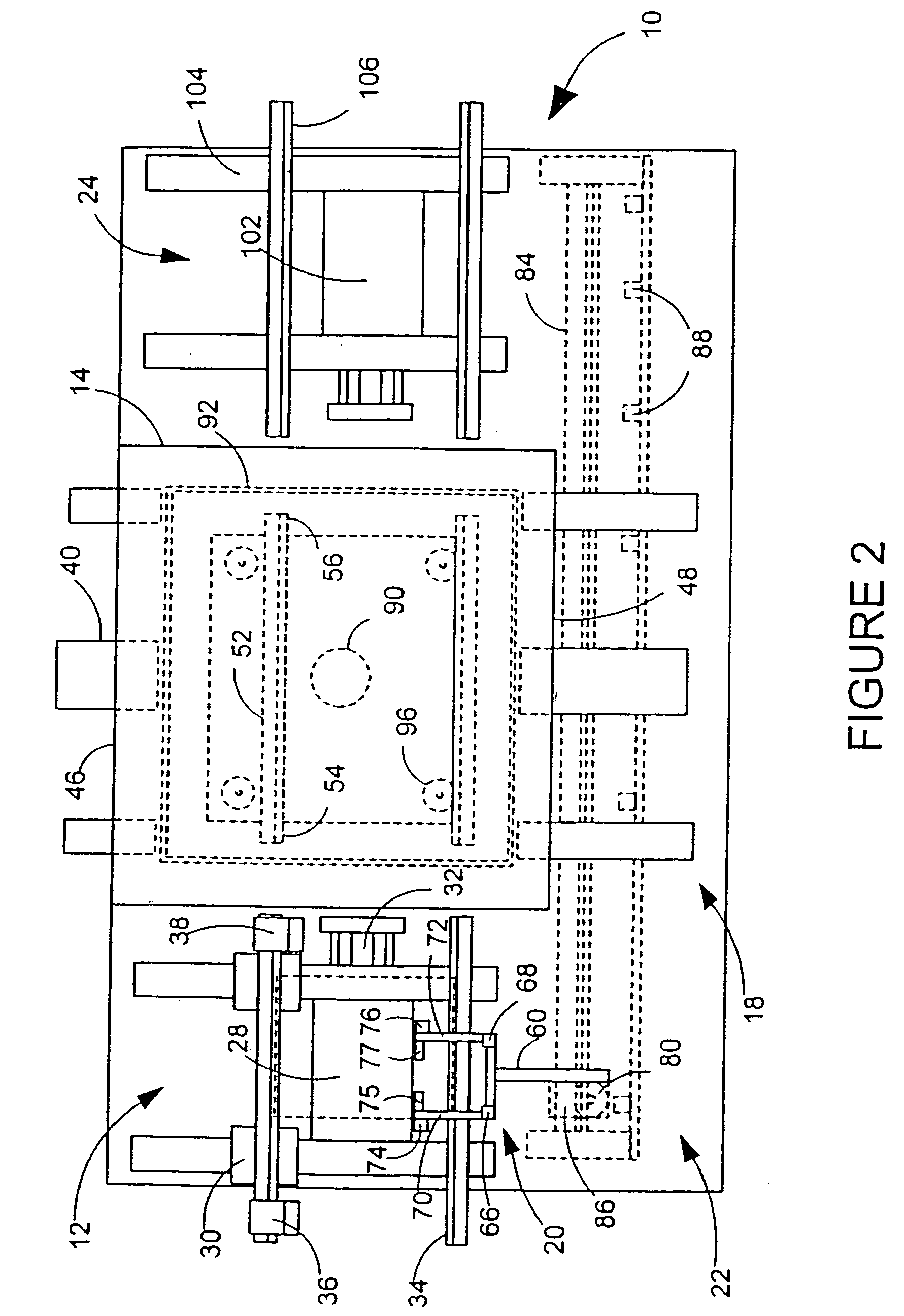

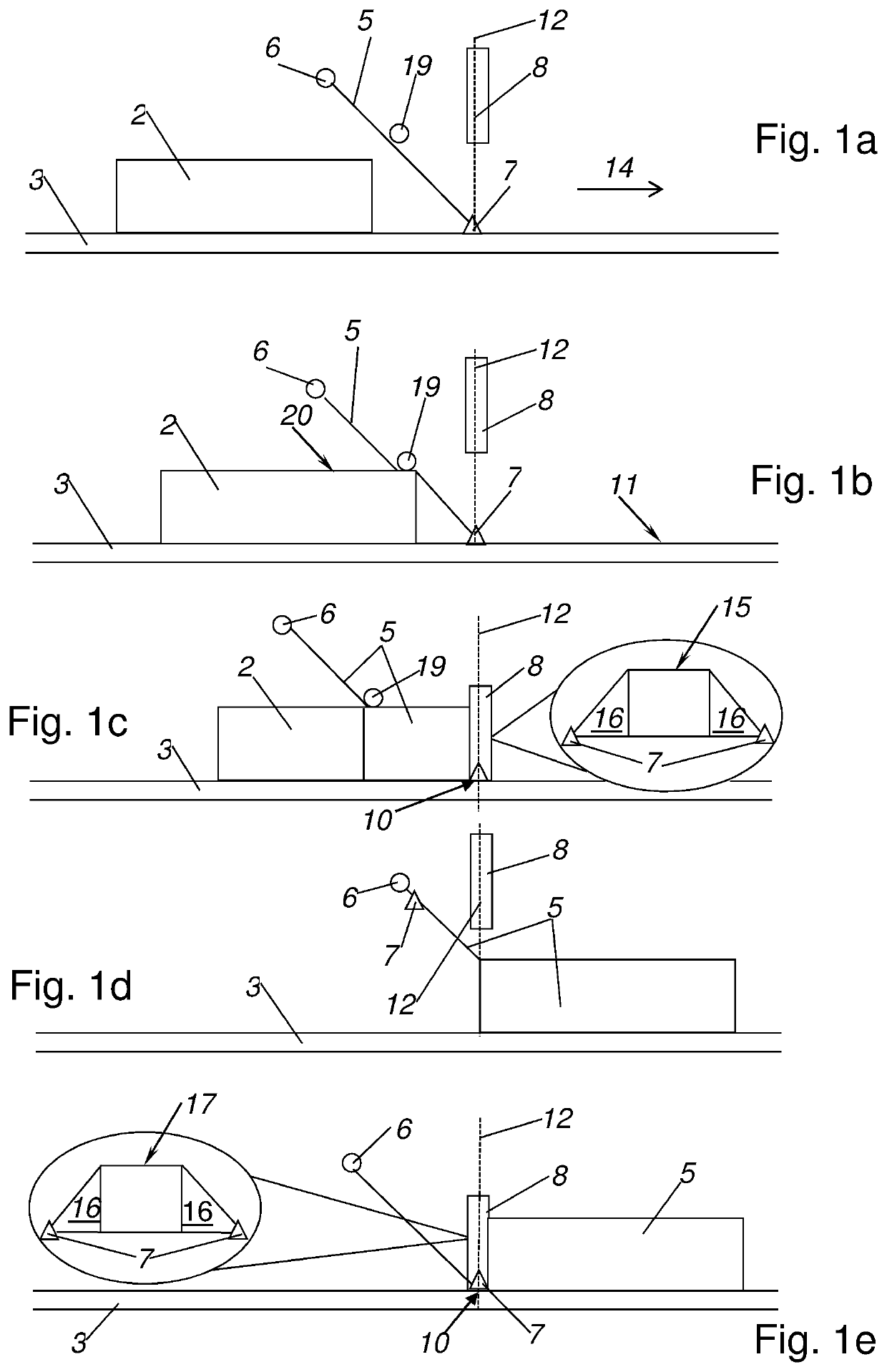

High throughput plasma treatment system

InactiveUS7201823B2Processing timeImprove throughputElectric discharge tubesSolid-state devicesAfter treatmentEngineering

A method for the plasma treatment of parts. The method includes sending loading signals from an electronic control to a transfer mechanism and loading the parts from a position outside of the treatment chamber to a plurality of treatment positions within the treatment chamber based on the loading signals. A plasma is generated within the treatment chamber to treat the parts. After treatment, unloading signals are sent from the electronic control to the transfer mechanism and the parts are unloaded from the treatment chamber based on the unloading signals. Each of the parts may be guided to a corresponding one of the treatment positions during loading.

Owner:NORDSON CORP

Upgraded combustion ash and its method of production

ActiveUS20110120348A1Enhance numerous qualityDecreased ash particle sizeSolid waste managementCement productionCombustionMethods of production

Described and claimed herein is a method of producing enhanced combustion ash for use in pozzolanic applications or cement clinker manufacture. The method employs a primary process in which wet or dry feedstock is pulverized with sonication using one or more grinding media having a maximum component size of about 2 mm. Alternatively, the media may have a true grinding medium volume to chamber volume ratio of at least 0.29. Also disclosed an claimed is an enhanced combustion ash produced by the method, whereby the enhanced combustion ash has one or more qualities that make it particularly suitable in pozzolanic applications or cement clinker manufacture.

Owner:PROVECTUS ENGINEERED MATERIELS

High throughput plasma treatment system

InactiveUS20050039853A1Extended processing timeImprove throughputElectric discharge tubesSolid-state devicesAfter treatmentEngineering

A method for the plasma treatment of parts. The method includes sending loading signals from an electronic control to a transfer mechanism and loading the parts from a position outside of the treatment chamber to a plurality of treatment positions within the treatment chamber based on the loading signals. A plasma is generated within the treatment chamber to treat the parts. After treatment, unloading signals are sent from the electronic control to the transfer mechanism and the parts are unloaded from the treatment chamber based on the unloading signals. Each of the parts may be guided to a corresponding one of the treatment positions during loading.

Owner:NORDSON CORP

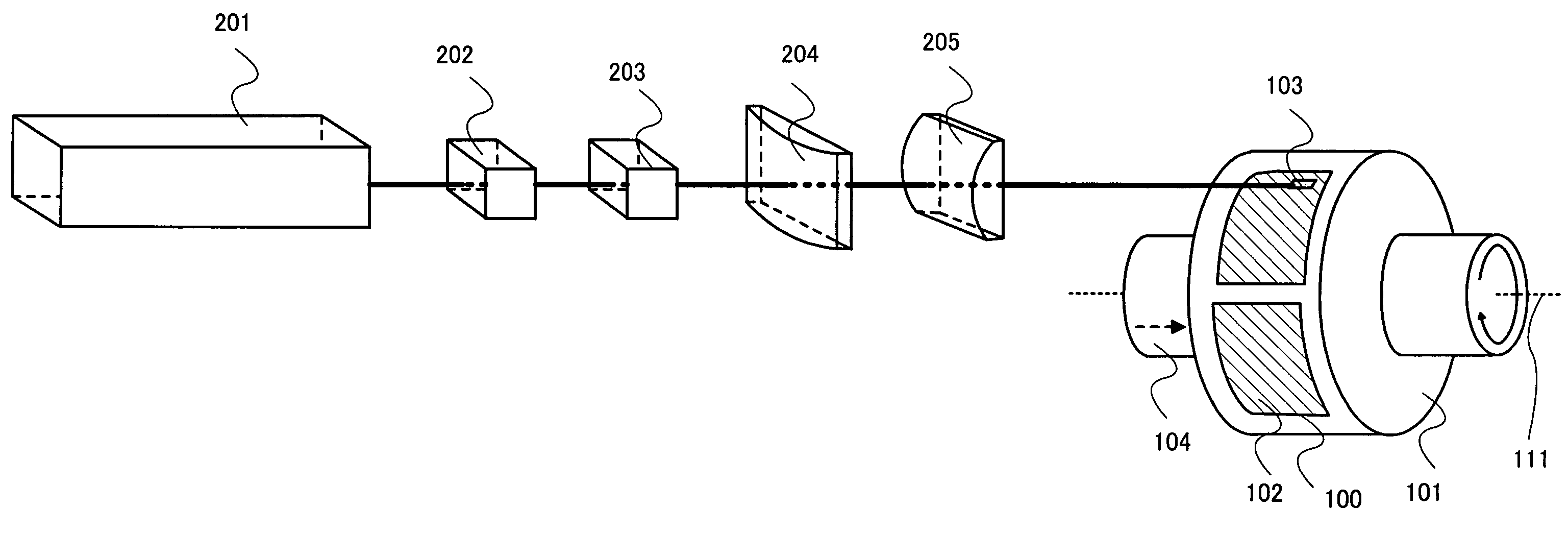

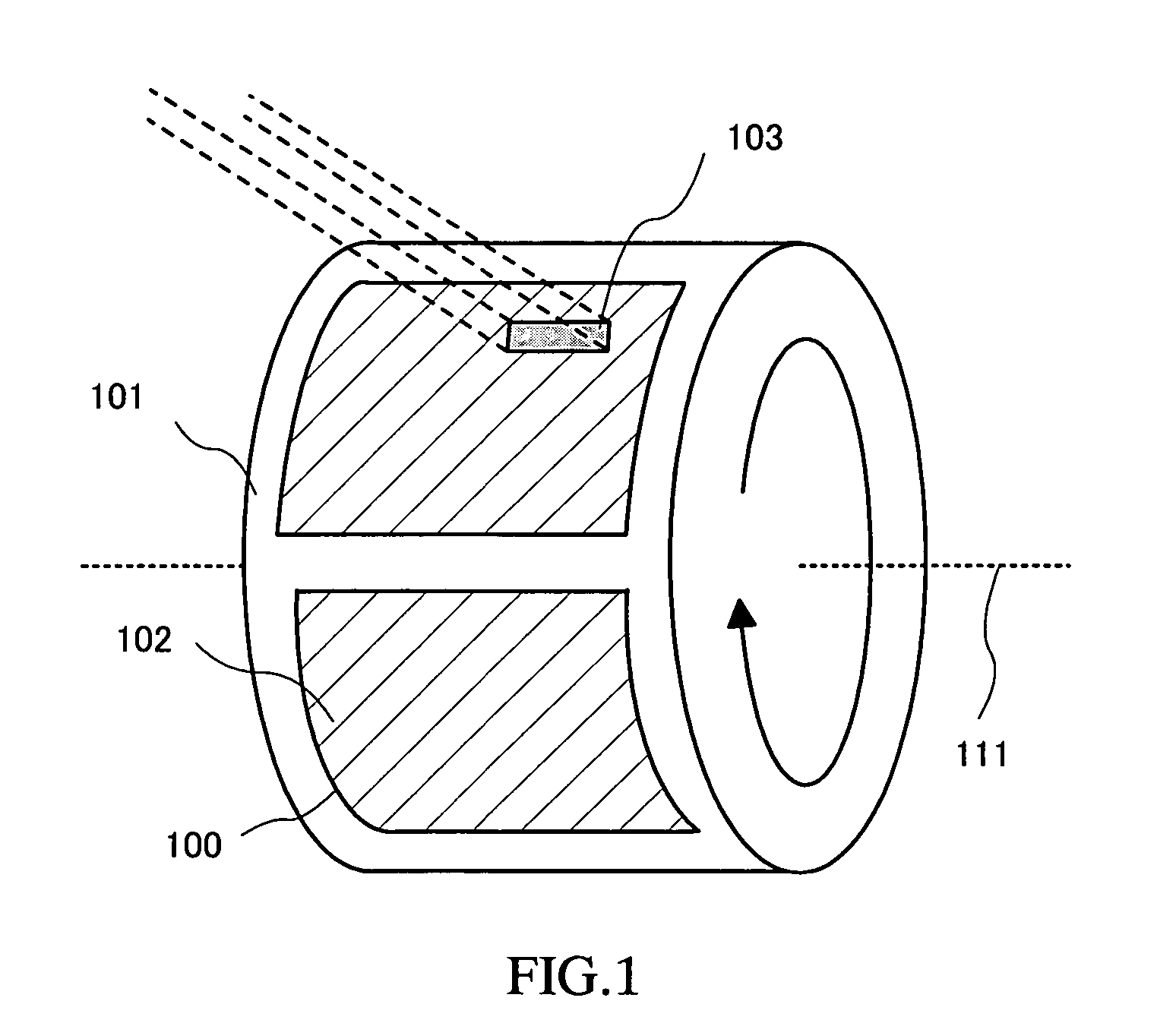

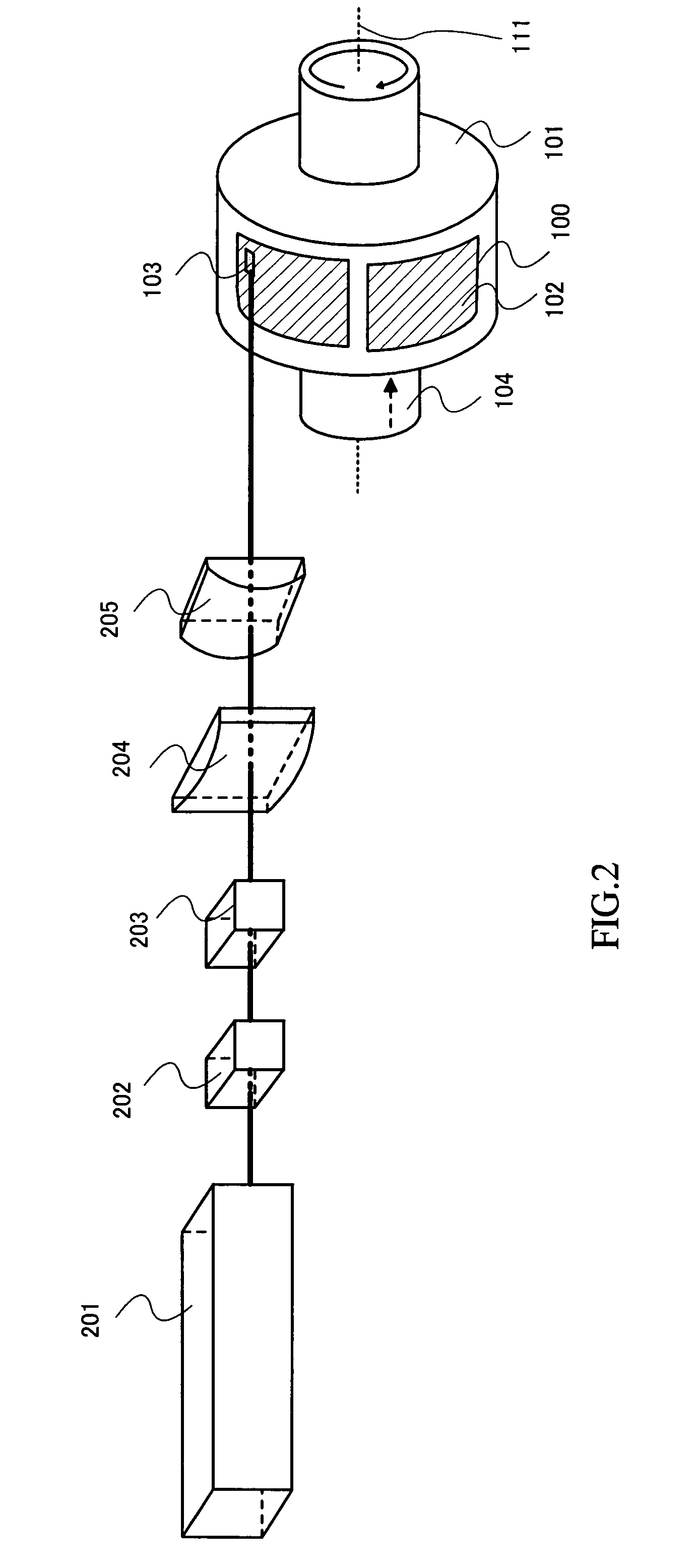

Laser process apparatus, laser irradiation method, and method for manufacturing semiconductor device

InactiveUS7390704B2Suppress generationReduce generationSolid-state devicesSemiconductor/solid-state device manufacturingRotational axisIrradiation

To mass-produce semiconductor devices with high reliability in short time by suppressing the generation of vibration at the laser irradiation and moving a laser beam having homogeneous energy profile in one direction.A substrate is sucked onto a surface of a cylindrical rotator along the curvature of the rotator, the rotator is rotated, and a semiconductor film formed over the substrate is irradiated with a laser at one time. Moreover, a moving mechanism is provided in a rotational axis direction of the rotator, and an irradiation position is displaced at each rotation of the rotator. Alternatively, the irradiation position can be moved in the rotational axis direction while rotating the rotator.

Owner:SEMICON ENERGY LAB CO LTD

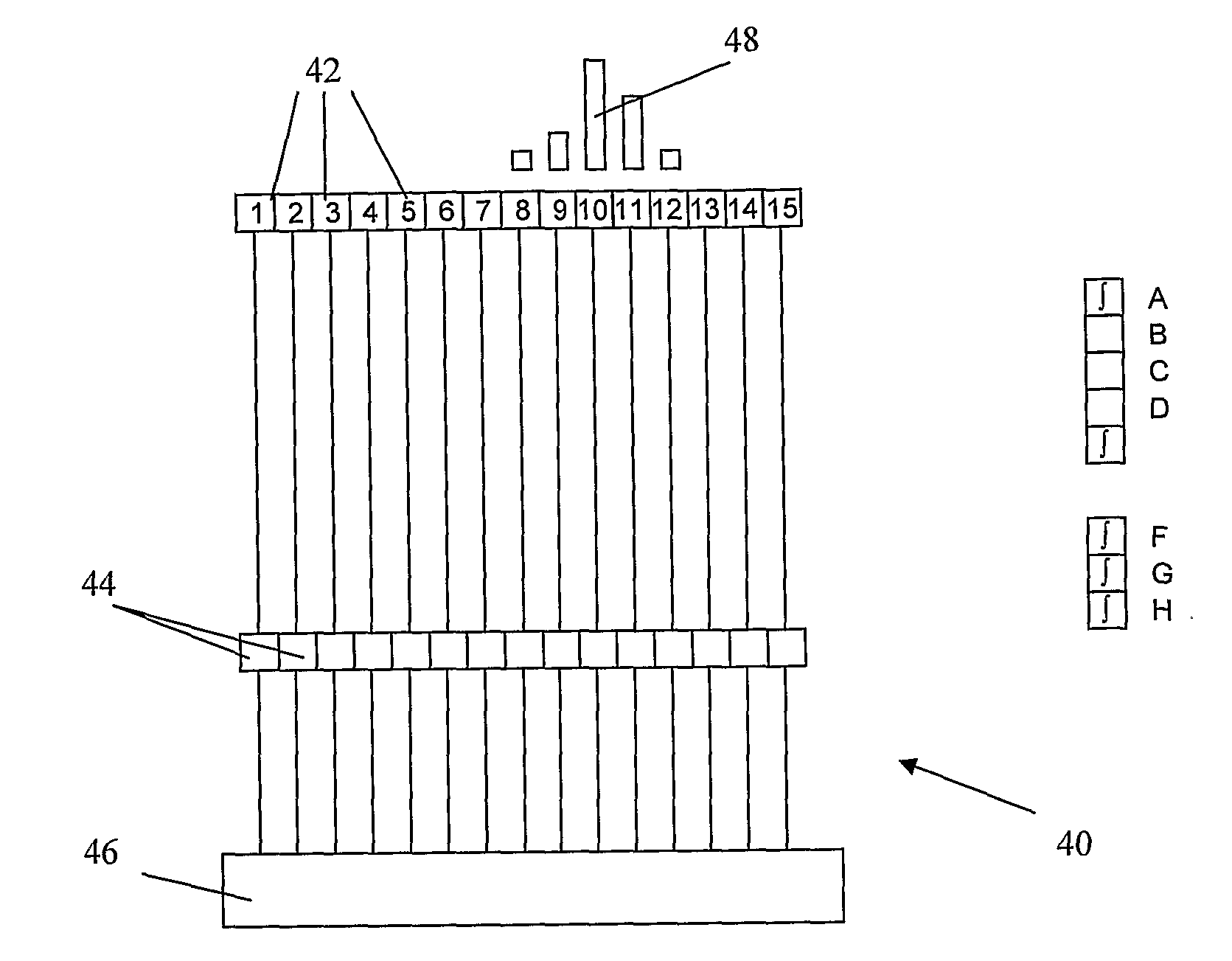

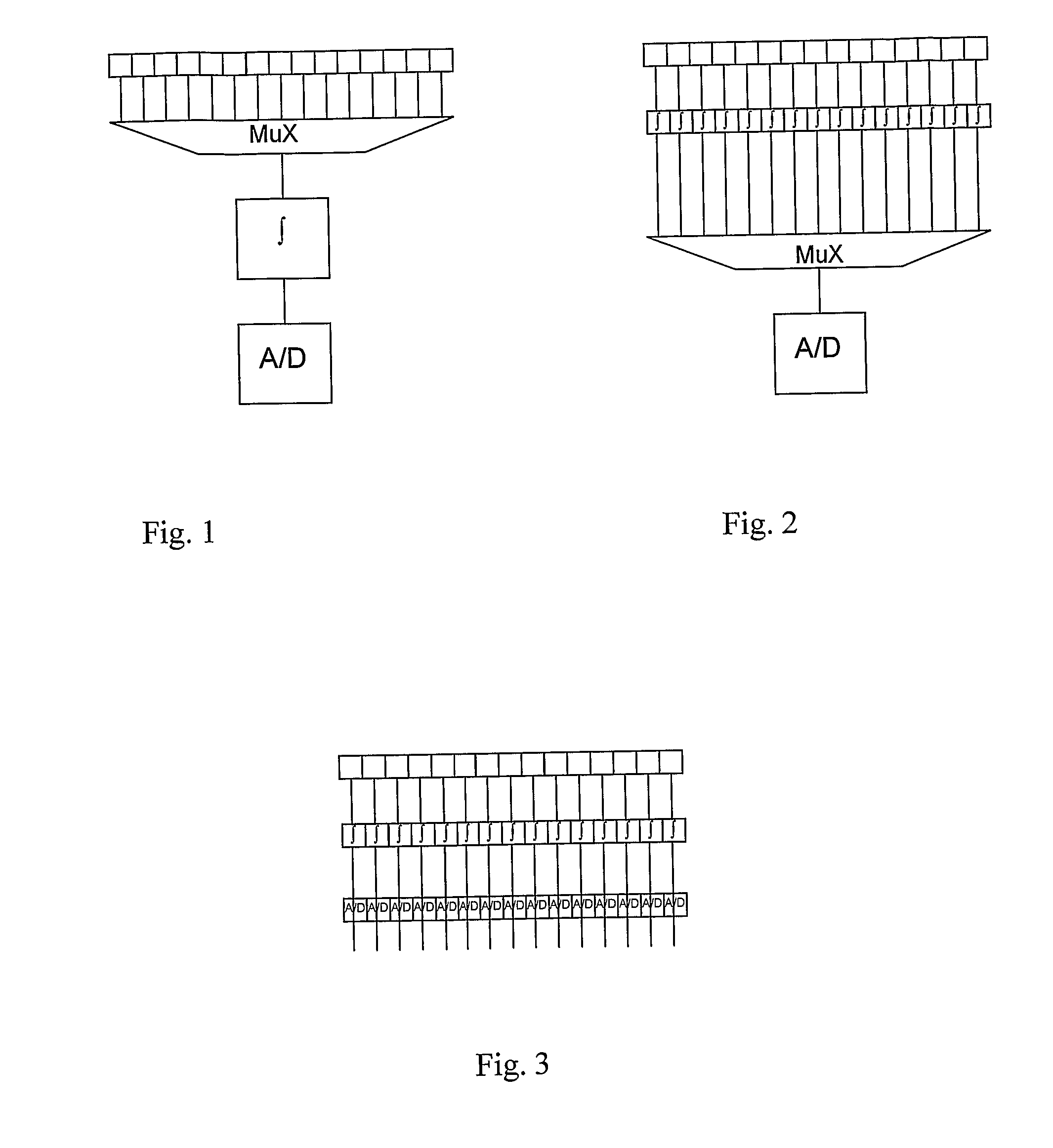

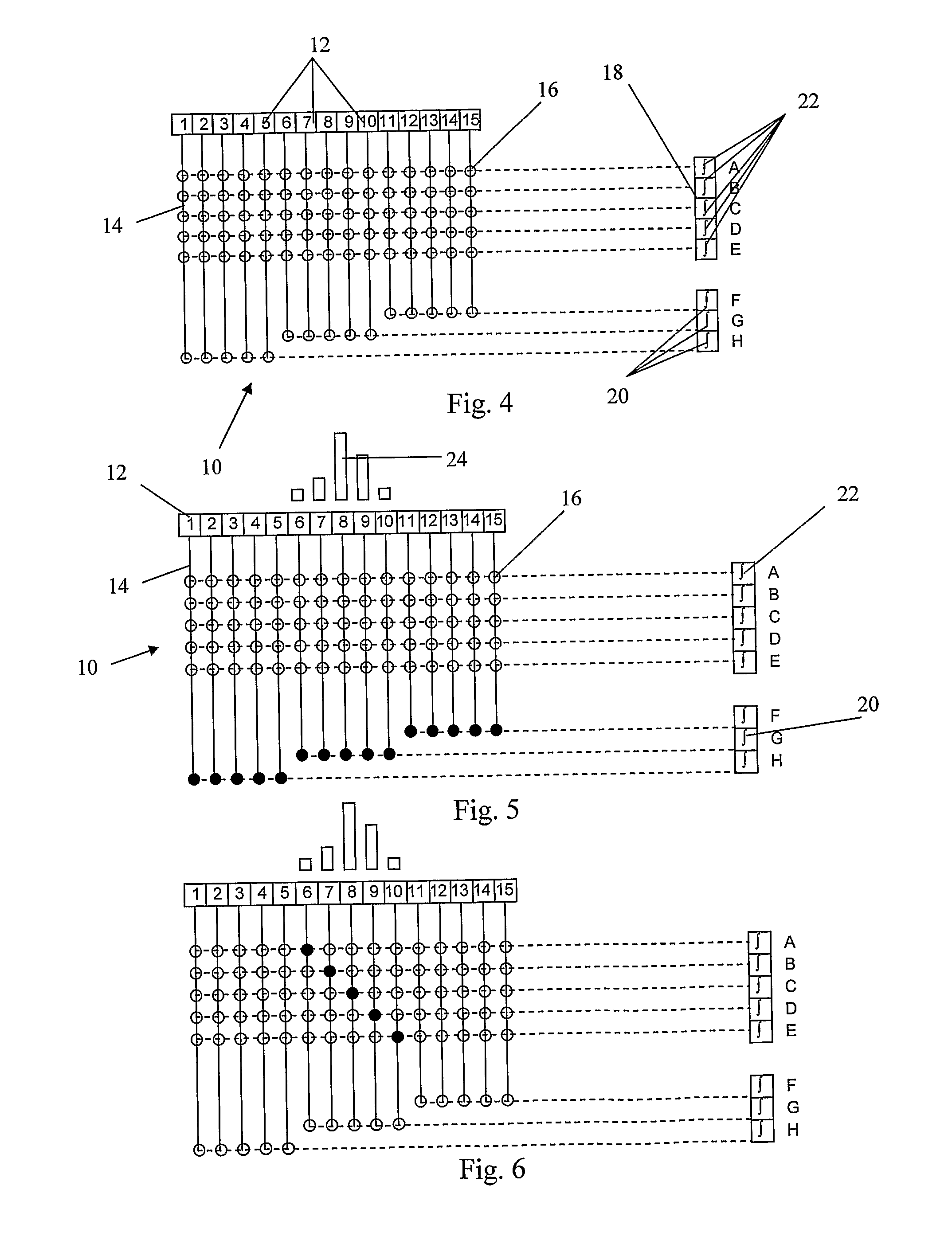

Apparatus and method for operating a spectrometer

InactiveUS20110261358A1Accurate identificationReduce the number of pixelsOptical measurementsRadiation pyrometryGratingFiber Bragg grating

A method of operating a spectrometer to determine the wavelength of an optical signal, in particular for determining the resonant wavelength of an optical fibre Bragg grating. The spectrometer comprises an array of photosensitive pixels each of which generates an output signal in response to the intensity of light incident on the pixel, and a refractive element arranged to direct light to a particular position in the array depending on the wavelength of the light. The method involves selecting a first group of pixels in the array by reference to an expected wavelength distribution of the optical signal and monitoring the output signals from the first group of pixels. On the basis of the output signals from the first group of pixels a second group of pixels is selected and the wavelength of the optical signal is determined from the output signals of the second group of pixels. The method has the advantage that the wavelength of the optical signal can be determined without scanning every pixel in the array individually.

Owner:MOOG INSENSYS

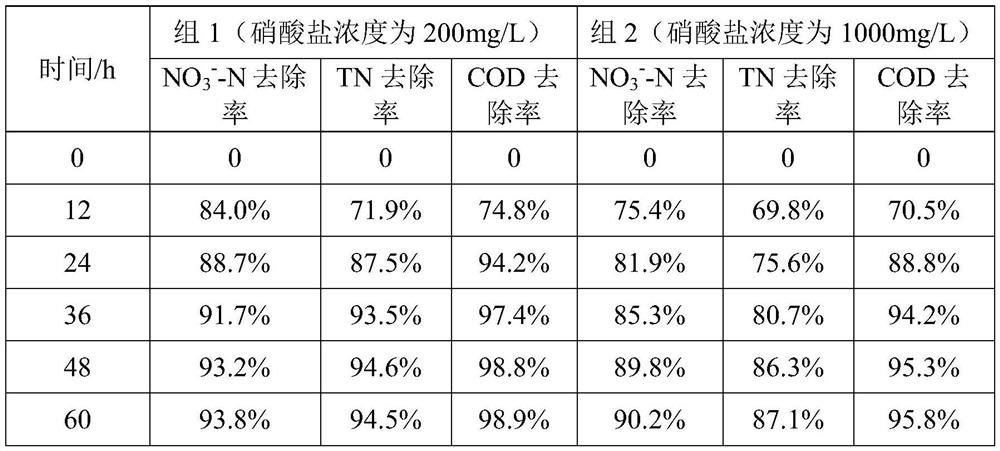

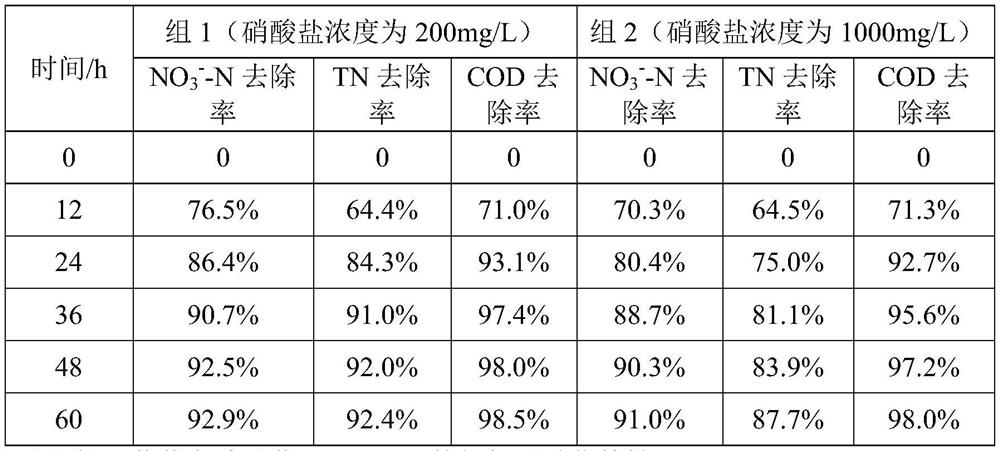

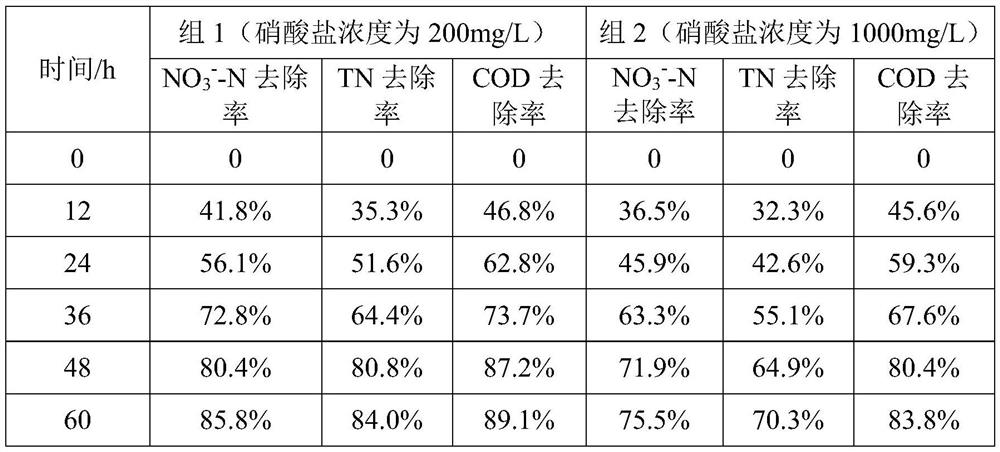

Nitrogen-containing wastewater treatment method

PendingCN112850911AThe total nitrogen content decreasedWill not cause accumulationTreatment with aerobic and anaerobic processesTotal nitrogenIndustrial wastewater treatment

The invention relates to the technical field of wastewater treatment, and provides a nitrogen-containing wastewater treatment method. Nitrogen-containing wastewater is treated through the combination of aerobic denitrification Rheinheimera sp. and nano Fe3O4, the method is not only suitable for aerobic denitrification treatment of high-concentration wastewater, but also obviously improves the nitrate treatment efficiency. Compared with the treatment of wastewater with single Rheinheimera sp., the treatment method disclosed by the invention is more suitable for treating high-concentration nitrogen-containing wastewater, the treatment time is short, the denitrification efficiency is high, most nitrate in the nitrogen-containing wastewater is converted into gaseous nitrogen to be separated from the wastewater after the denitrification of Rheinheimera sp., the total nitrogen content in the wastewater is obviously reduced, and secondary pollutants such as ammonia nitrogen and nitrite nitrogen accumulated in water are not caused. The treatment method has a good application prospect in large-scale industrial wastewater treatment.

Owner:JINAN UNIVERSITY

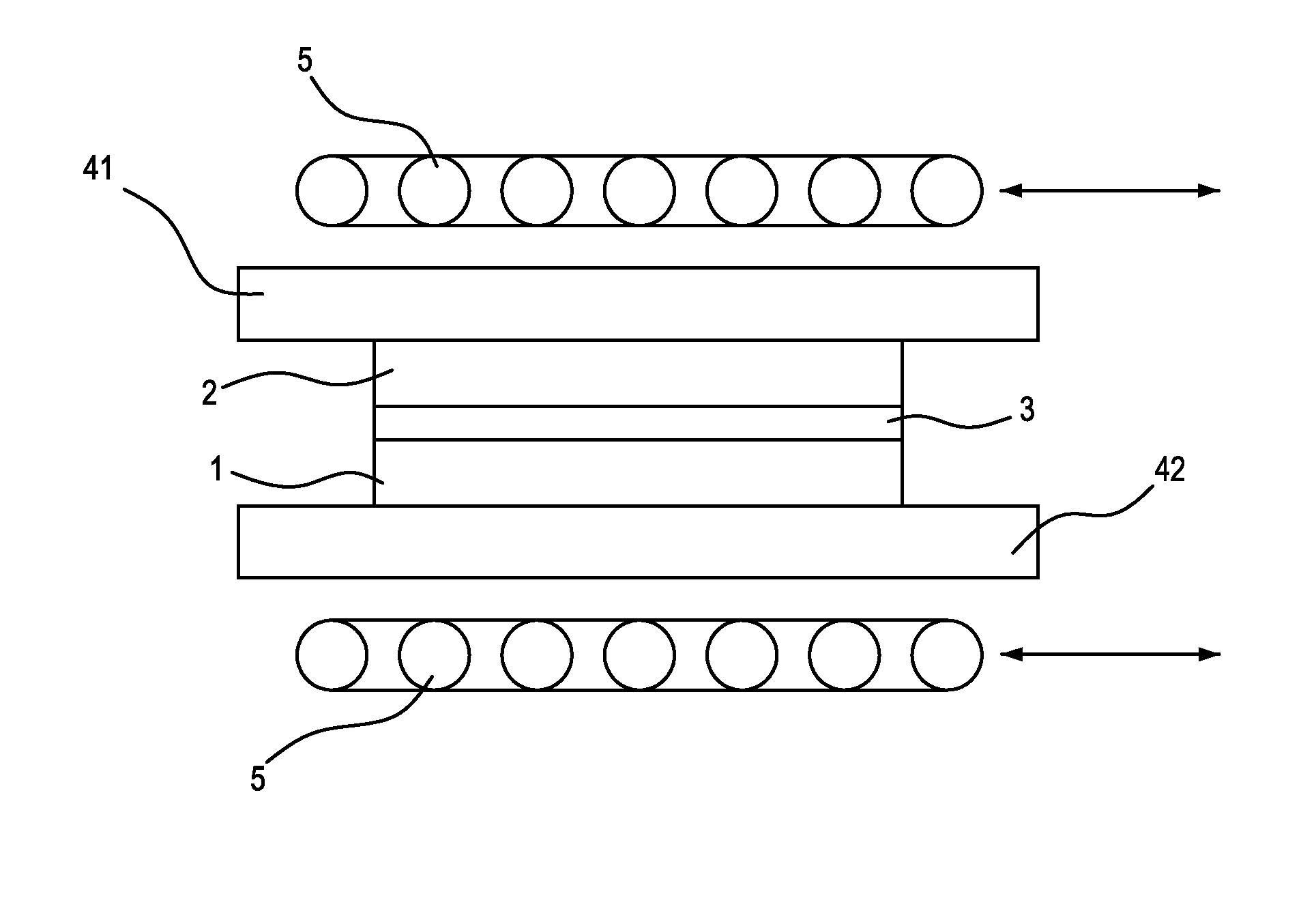

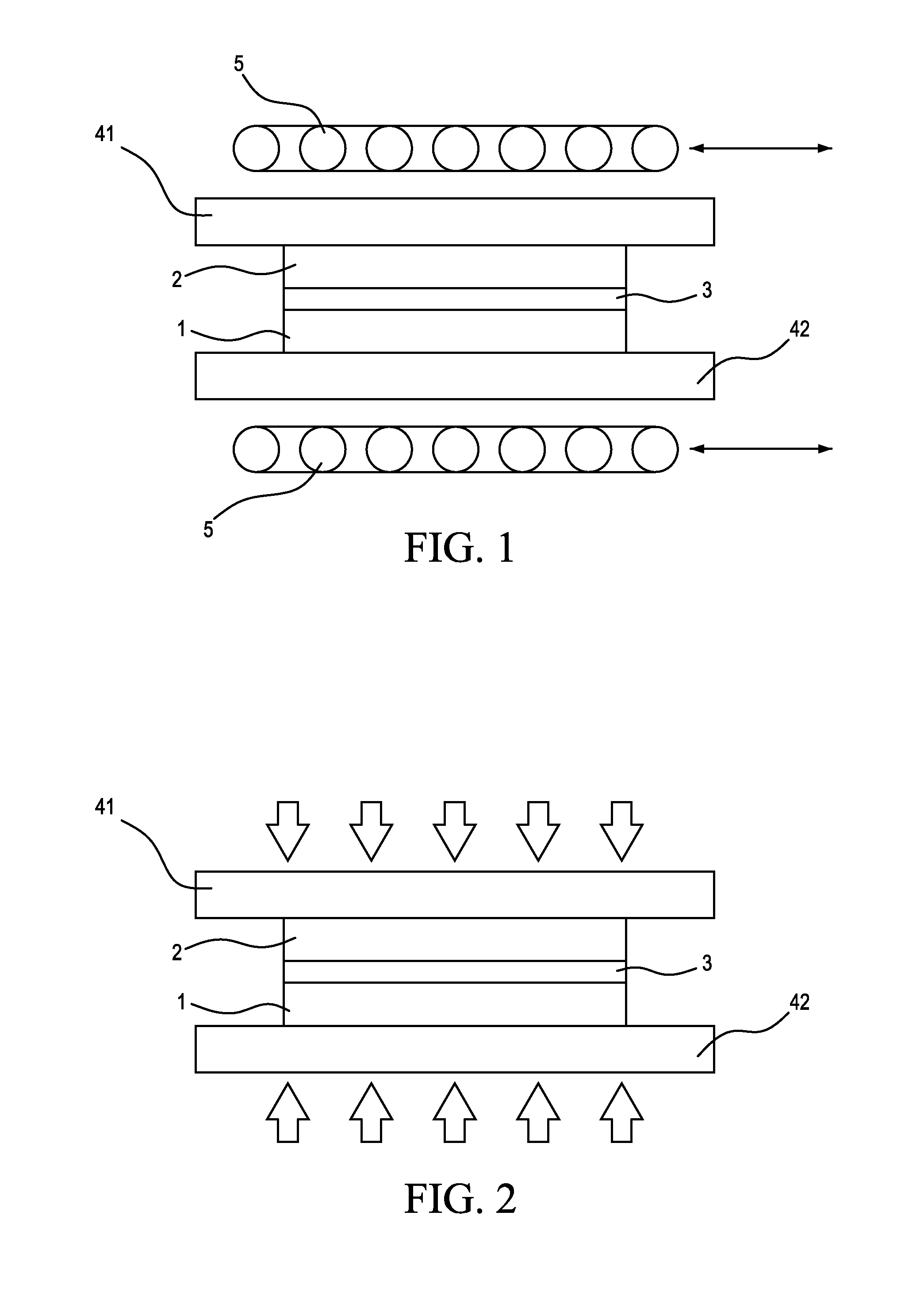

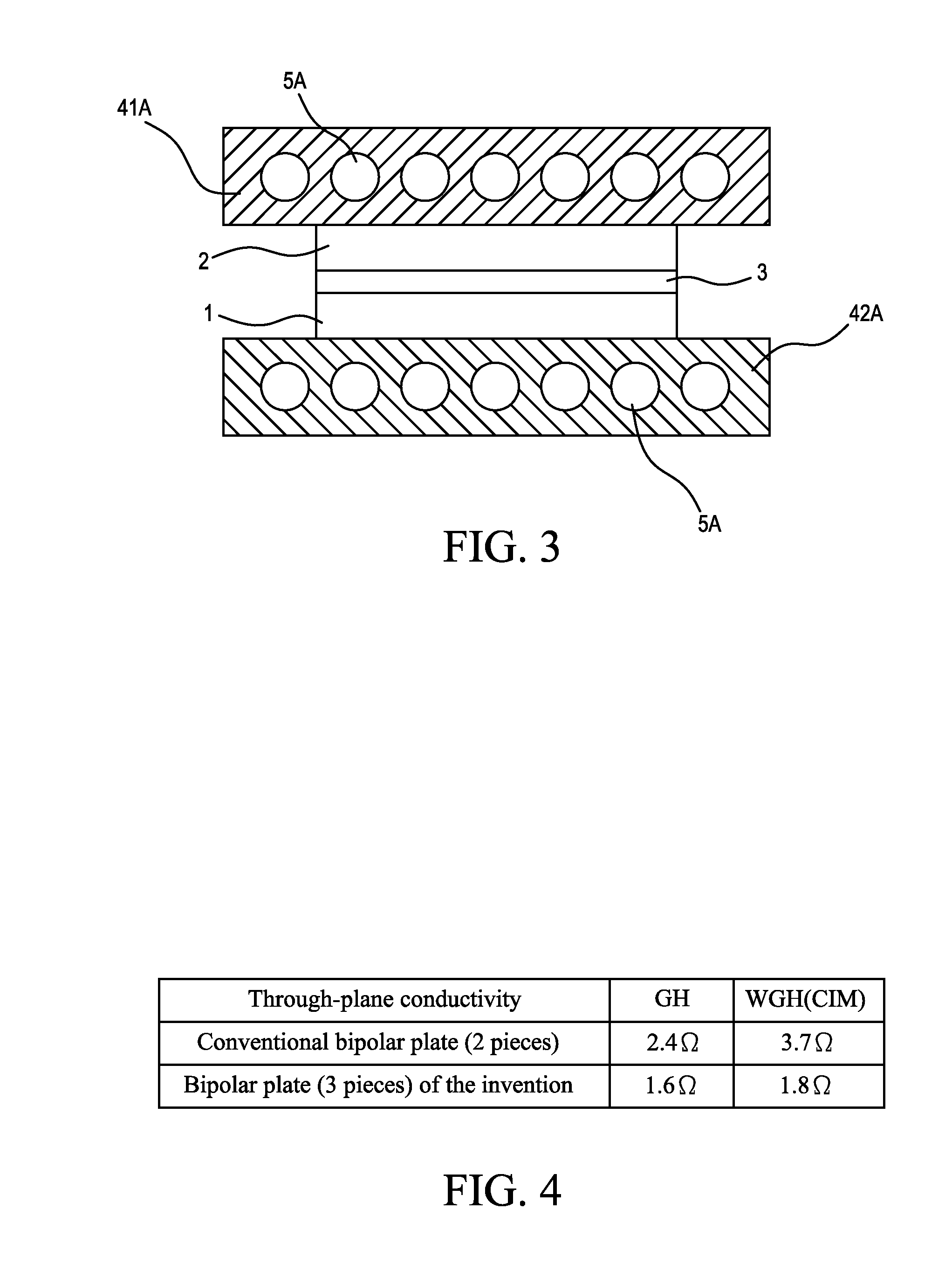

Fabrication method for enhancing the electrical conductivity of bipolar plates

InactiveUS20120021340A1Enhanced electrical conductivityGood heating efficiencyLamination ancillary operationsLayered product treatmentLayered structureElectrical and Electronics engineering

A fabrication method for enhancing the electrical conductivity of bipolar plates, adapted for laminating a three-layered structure that is constructed by sandwiching a bonding layer made of a conductive material between two bipolar plates made of a thermoplastic polymer composite, is disclosed, which comprises the steps of: using an induction coil to heat up the bonding layer; and exerting a pressure upon the two bipolar plates for laminating the bonding layer to the two bipolar plates. With the aforesaid method, not only the through-plane conductivity with regard to the two bipolar plates can be enhanced, but also the processing time is greatly reduced.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

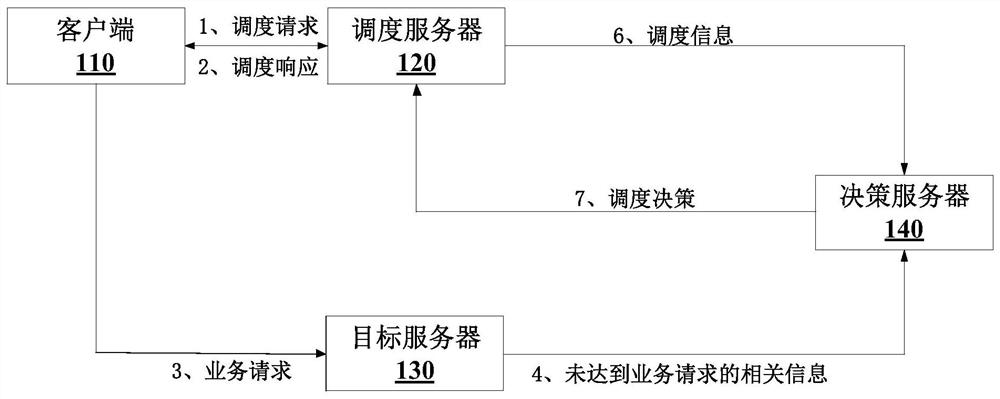

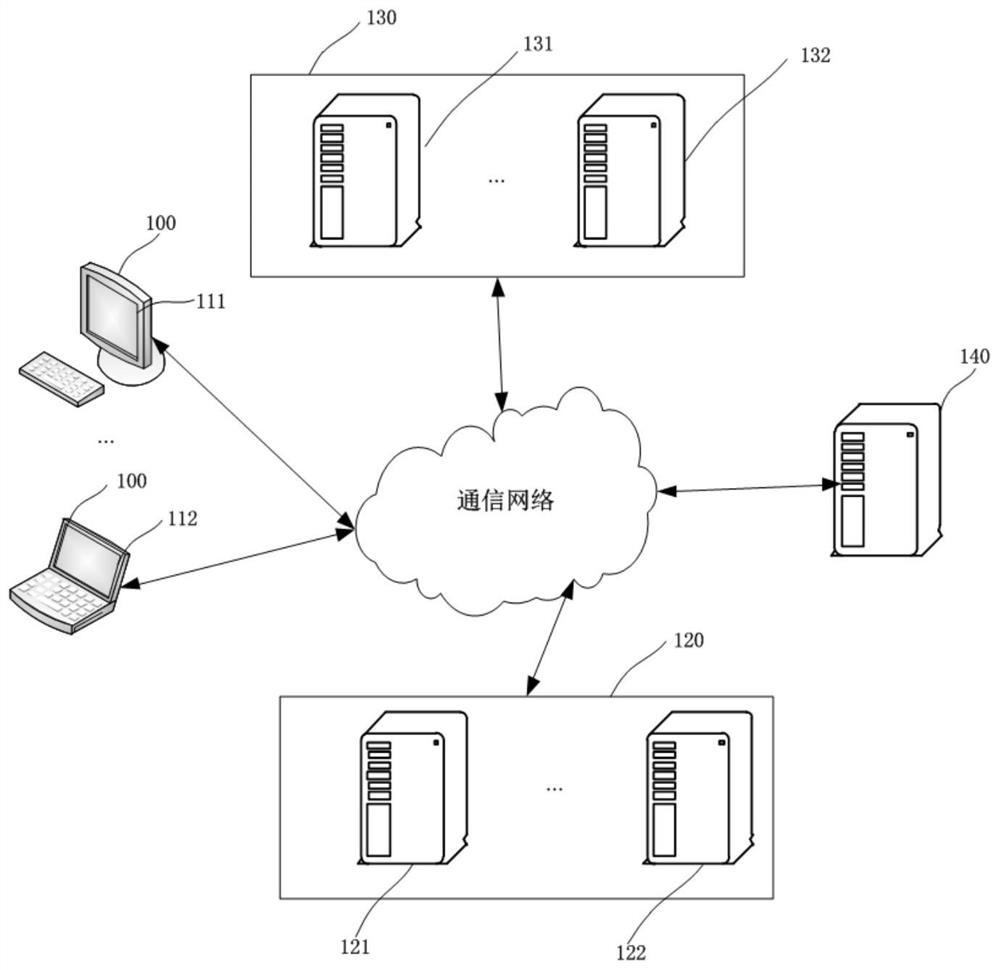

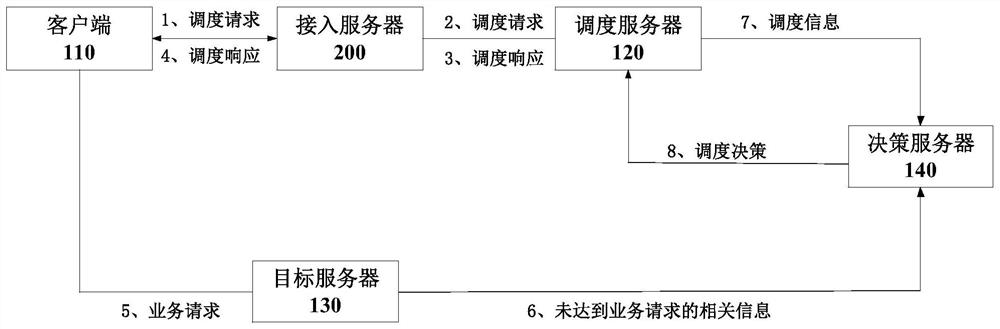

Service request detection method and device, and medium

ActiveCN112054923AReduce storage overheadReduce search overheadBus networksContent distributionReal-time computing

The invention relates to the technical field of cloud, in particular to a service request detection method and device, and a medium, the method can be applied to a content distribution network, and the method comprises the following steps: obtaining scheduling order indication information of each first service request from scheduling parameters carried in each first service request; wherein the scheduling parameter of each first service request is obtained by the client from the scheduling response of the scheduling server, and the scheduling sequence indication information is used for indicating the sequence of the scheduling server for scheduling the target server corresponding to the service request; obtaining scheduling order indication information of the second service request according to the obtained scheduling order indication information; and transmitting the scheduling order indication information of the second service request, according to the method, the target server is used for detecting and reporting the related information of the service requests which do not reach the target server, so that the storage occupation, the search overhead and the like in the service request detection process are reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

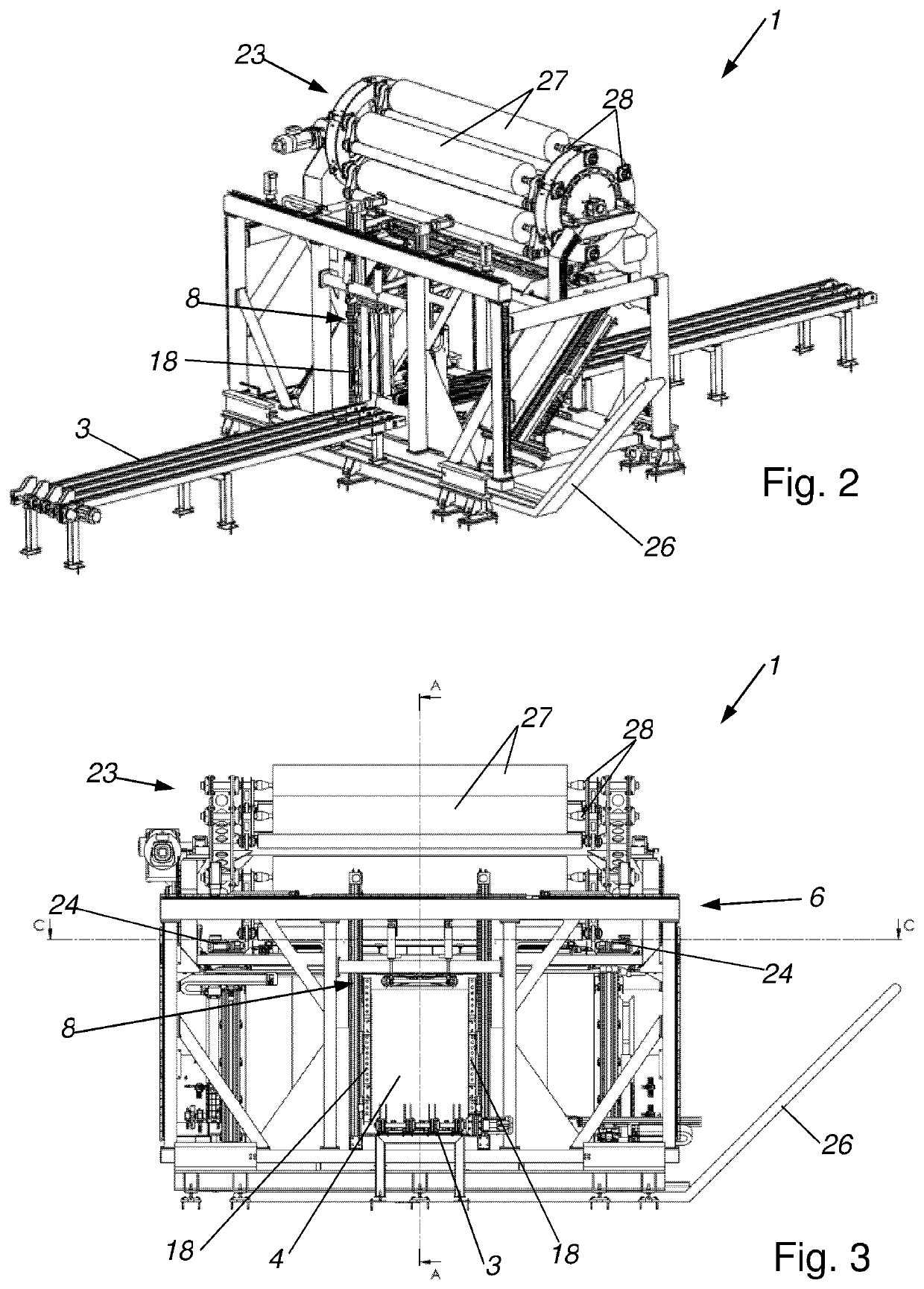

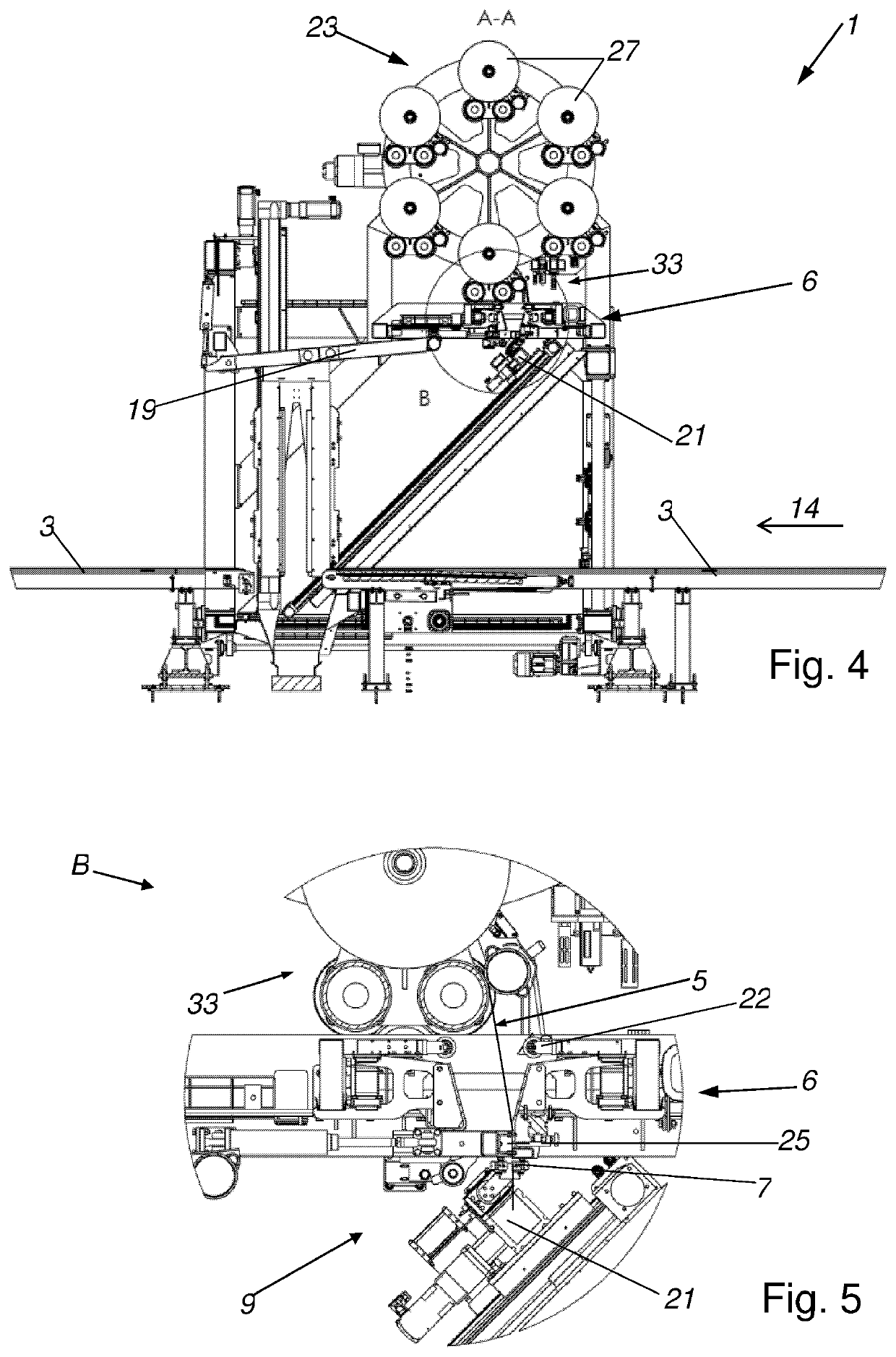

Film-wrapping apparatus and method

ActiveUS11034471B1Simple and space-saving and fully automatic film-wrappingAvoid disadvantagesWrapping material feeding apparatusWrapper folding/bending apparatusFilm materialPhysics

A film-wrapping apparatus for the automatic film-wrapping of articles is provided that includes a conveying device for conveying an article through a film-wrapping channel of the film-wrapping apparatus. The film-wrapping apparatus has a film-supply device arranged above the film-wrapping channel. The film-wrapping apparatus also includes at least two movably arranged grippers and a sealing device. The at least two grippers are predefinably movably arranged between a supply position and a sealing position. The grippers, in the supply position, grip two opposite corners of the film material supplied by the film-supply device and pull the film material from the supply position into the sealing position and hold the material. In the sealing position, the grippers are arranged in a sealing plane and substantially level with an upper side of the conveying device. The sealing device seals the two side edges of the article that are arranged in the sealing plane.

Owner:SPRINGER MASCHFAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com