Microwave and far infrared heating under reduced pressure

a technology of far infrared radiation and microwave heating, which is applied in microwave heating, electrical equipment, electric/magnetic/electromagnetic heating, etc., can solve the problems of difficult control of this type of heater, high production efficiency cannot be achieved, and the heaters of the prior art have a rotatable jig for rotating objects to be heated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

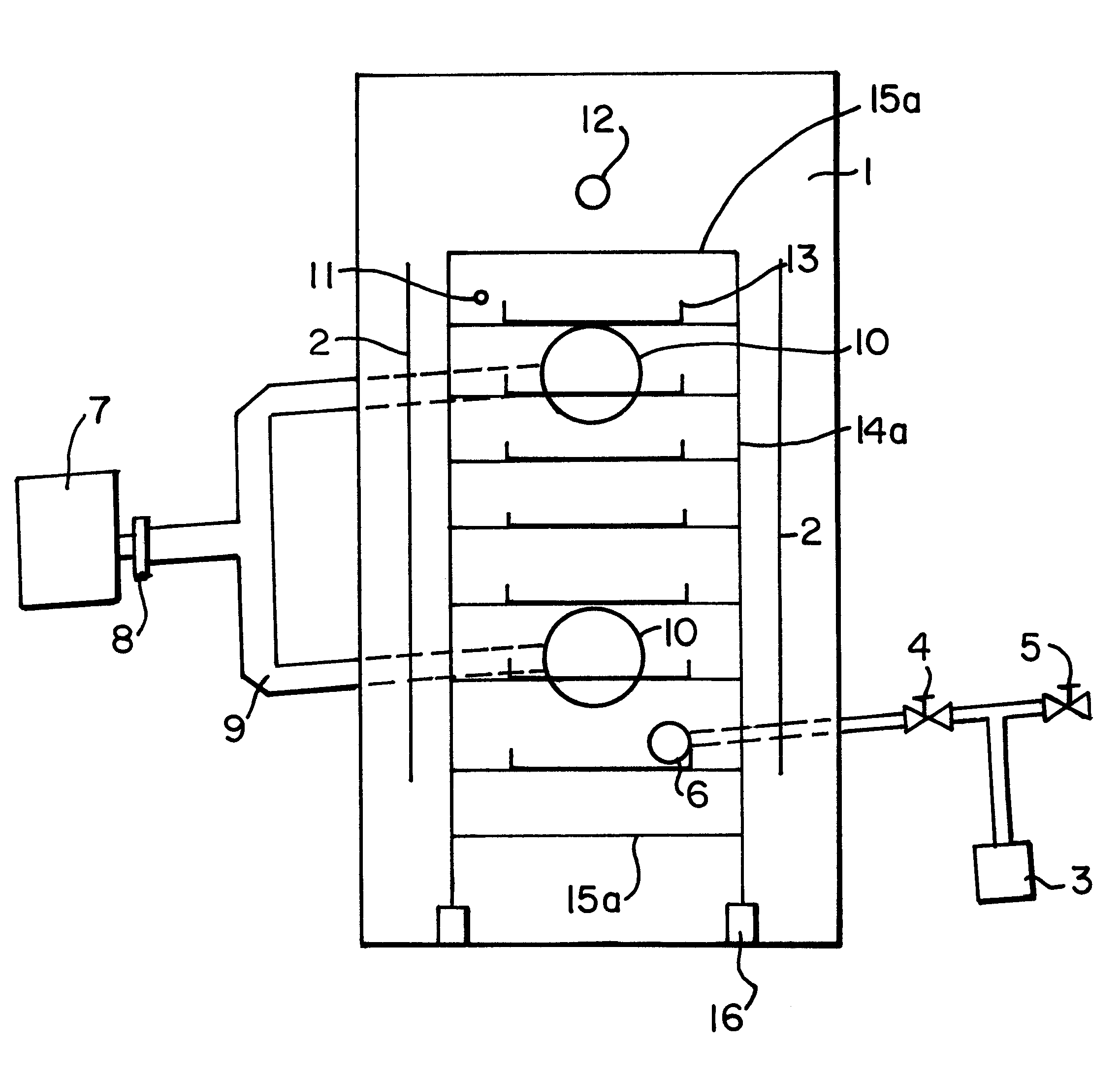

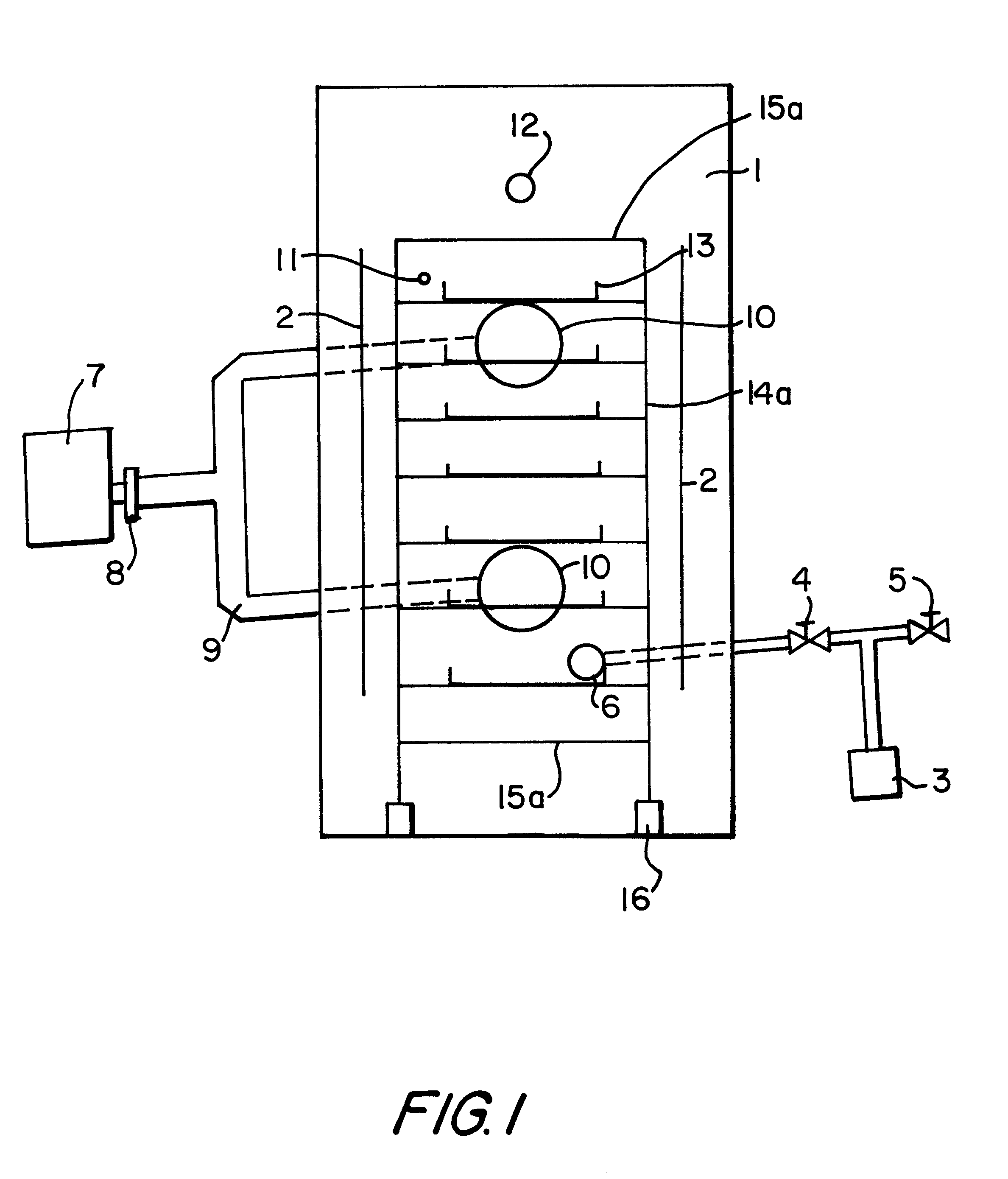

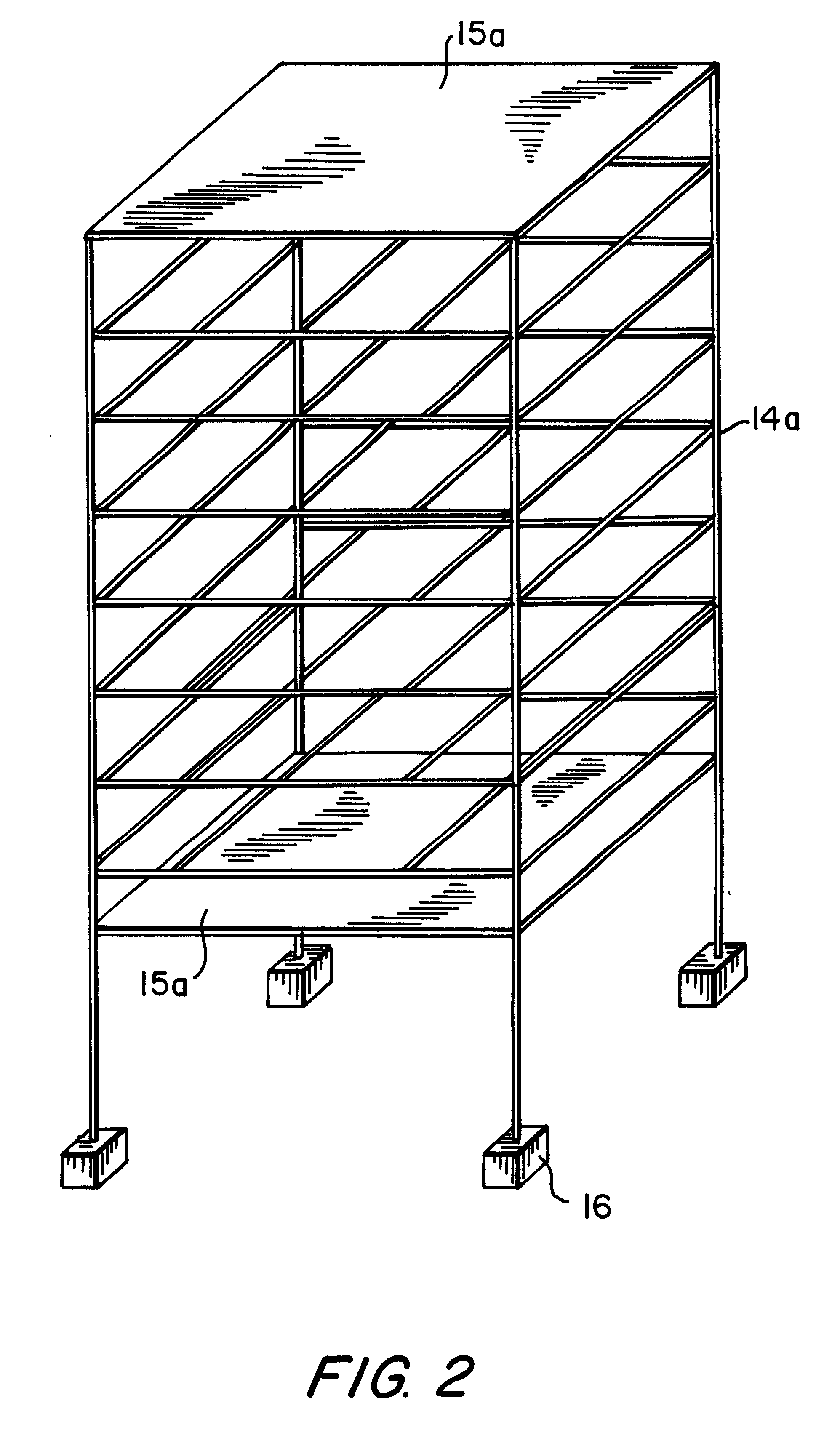

Method used

Image

Examples

example embodiment 2

Next, using the structure described in Example Embodiment 1 a test of the effectiveness of a structure built in accordance with the embodiment described in claim 8 was carried out by drying 7 kg of seasoning paste. First, using a flat bottom tray, the paste was filled to a horizontal level, and then drying was carried out. When the tray was being removed, it was discovered that the center portion was not completely dried, so a drying process was carried out again. After the second drying, the center portion was completely dried, but a portion of the surrounding area was burnt. Next, a dome-shaped center bulging portion; convex portion 18 formed in the tray bottom having a diameter of 80 mm and a height of 7 mm was formed in the center of a tray or plate 13 to create a structure and then after this tray was filled with 7 kg of seasoning paste to a horizontal level, a drying process was carried out. In this case, a complete uniform drying of the paste was confirmed. In this connection...

example embodiment 3

Next, a test of the effectiveness of a structure where the object holding jigs are open shaped and are made of heat resistant and microwavable material was carried out by concentrating 7 kg of strawberries. First, the strawberries were loaded onto aluminum plates, and then drying was begun with a goal of removing 60% of the water content. However, because microwave radiation can not penetrate through the bottom surface of the aluminum plates, only 35% of the water content was removed within a prescribed drying time. Next, 7 kg of strawberries were loaded onto plates made of polysulfone, and after drying was carried out for the prescribed drying time, it was confirmed that roughly 60% of the water content had been removed. Further, when these dried strawberries were ground up, an extremely delicious paste was created.

example embodiment 4

Next, a concentration process for concentrating 7 kg of strawberries was carried out again for the case of a plate where the object-holding jigs are made from paper and the portions that come into contact with the objects are coated with a microwave permeable resin or covered with paper coated with a microwave permeable resin. Namely, after a 1 mm-thick cardboard plate was prepared and covered with a sheet of silicon-treated paper, the strawberries were loaded and drying was begun. After drying had been carried out over the prescribed drying time, measurements were taken, and the results showed that 55% of the water content had been removed. Further, even though a small quantity of the strawberries had rolled away, the provision of the sheet made it possible to smoothly pick up all the concentrated strawberries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com