Device and method for thermally treating textile material web

A technology of fabric belts and equipment, applied in lighting and heating equipment, drying solid materials, heating to dry solid materials, etc., can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

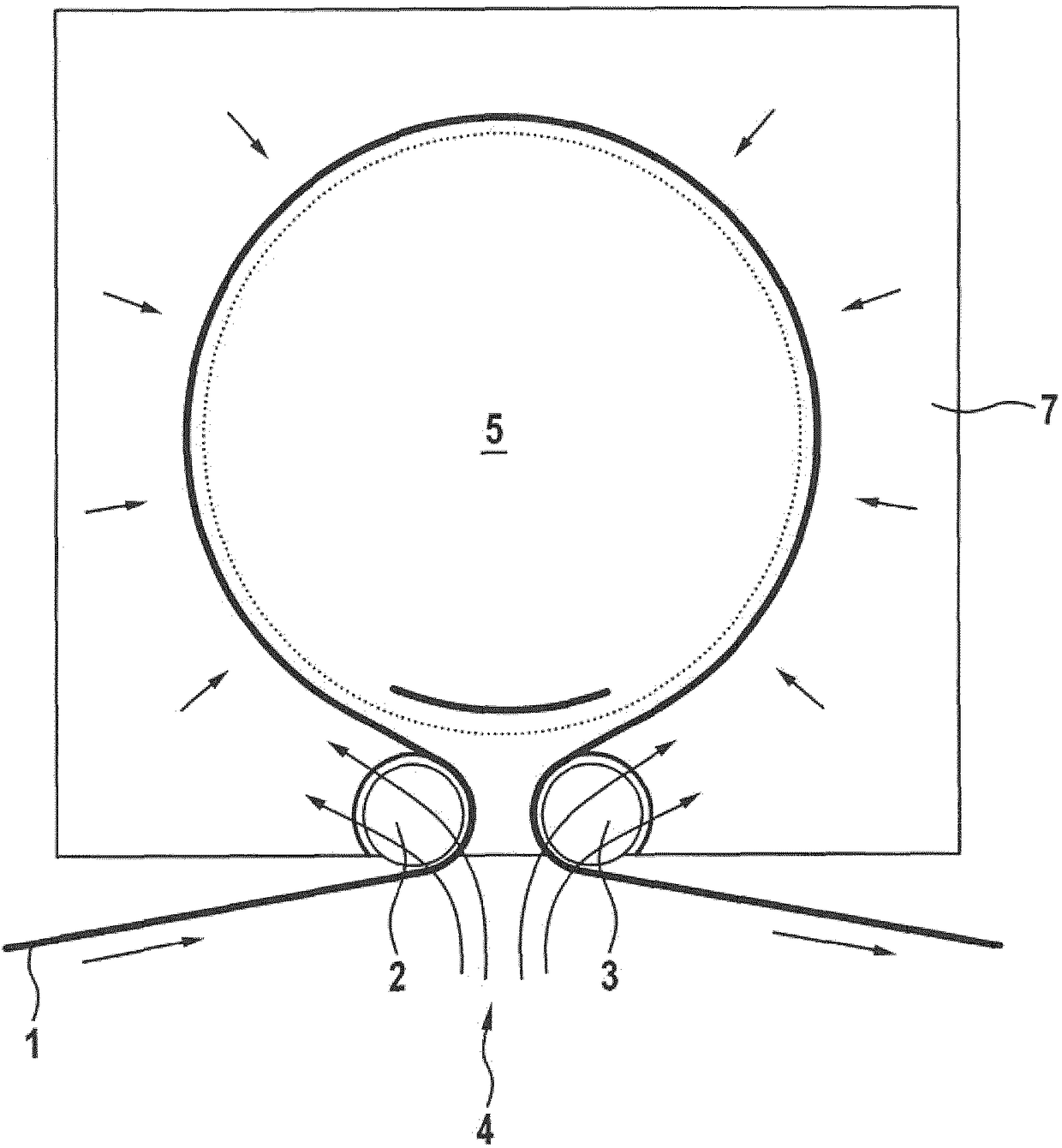

[0021] figure 1 Shown is a dryer operating with hot air with an omega (Ω) construction according to the prior art. The textile web 1 to be dried enters the dryer in the entry area 4 via a deflection drum 2 , winds around a gas-permeable flow-through drum 5 in a clockwise direction and exits the dryer again via a further deflection drum 3 . The circulation drum 5 and the two deflection drums 2 , 3 are arranged in a housing 7 into which hot air is introduced by means not shown. The hot air flows through the fabric web 1 , thereby drying it and is sucked in by a fan, not shown, via suction elements arranged on one or more end faces of the through-flow drum 5 . for example in figure 2 Suction piece 8 in. In this case, the throughflow drum 5 is placed under negative pressure, whereby different flow conditions occur in the dryer.

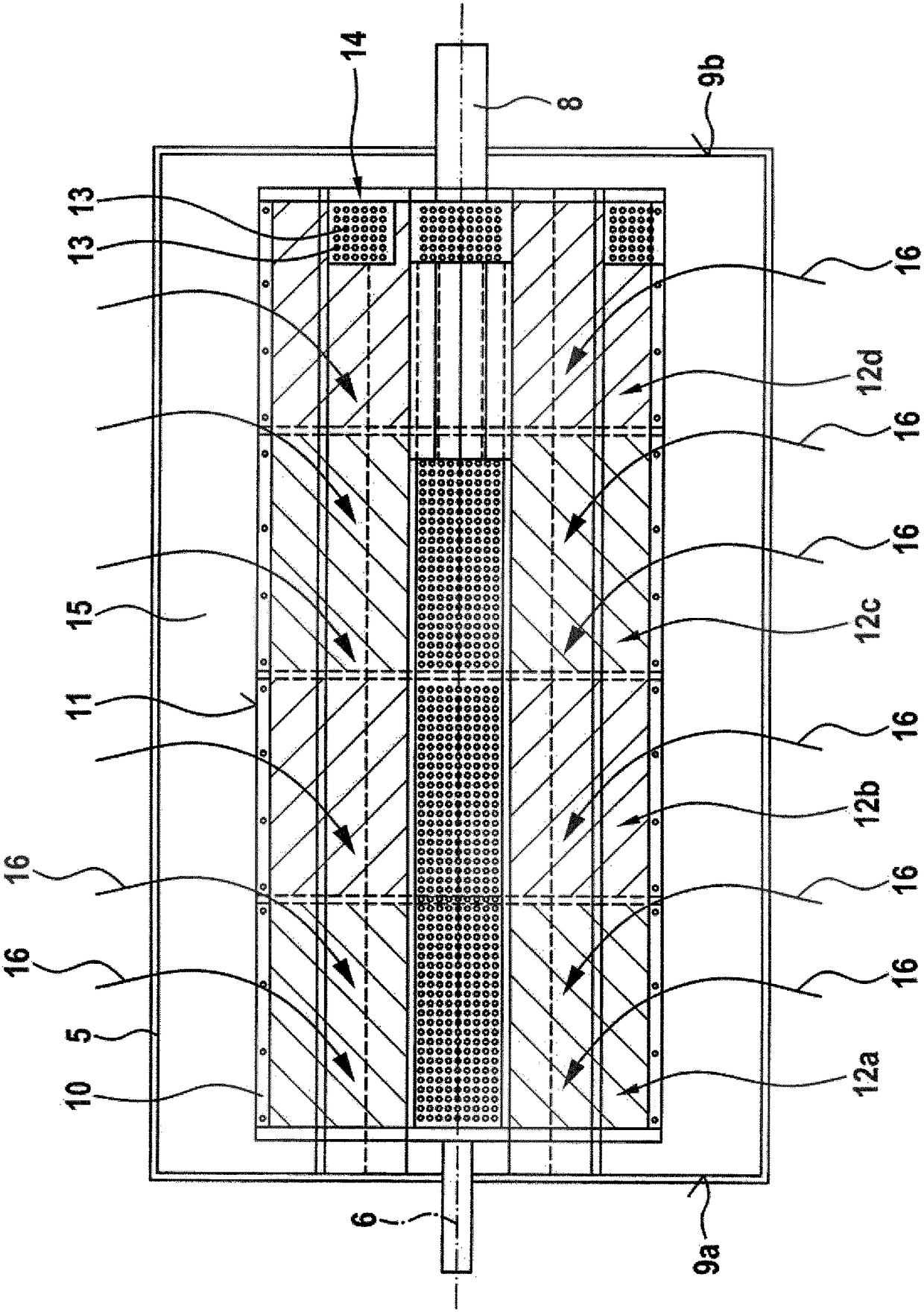

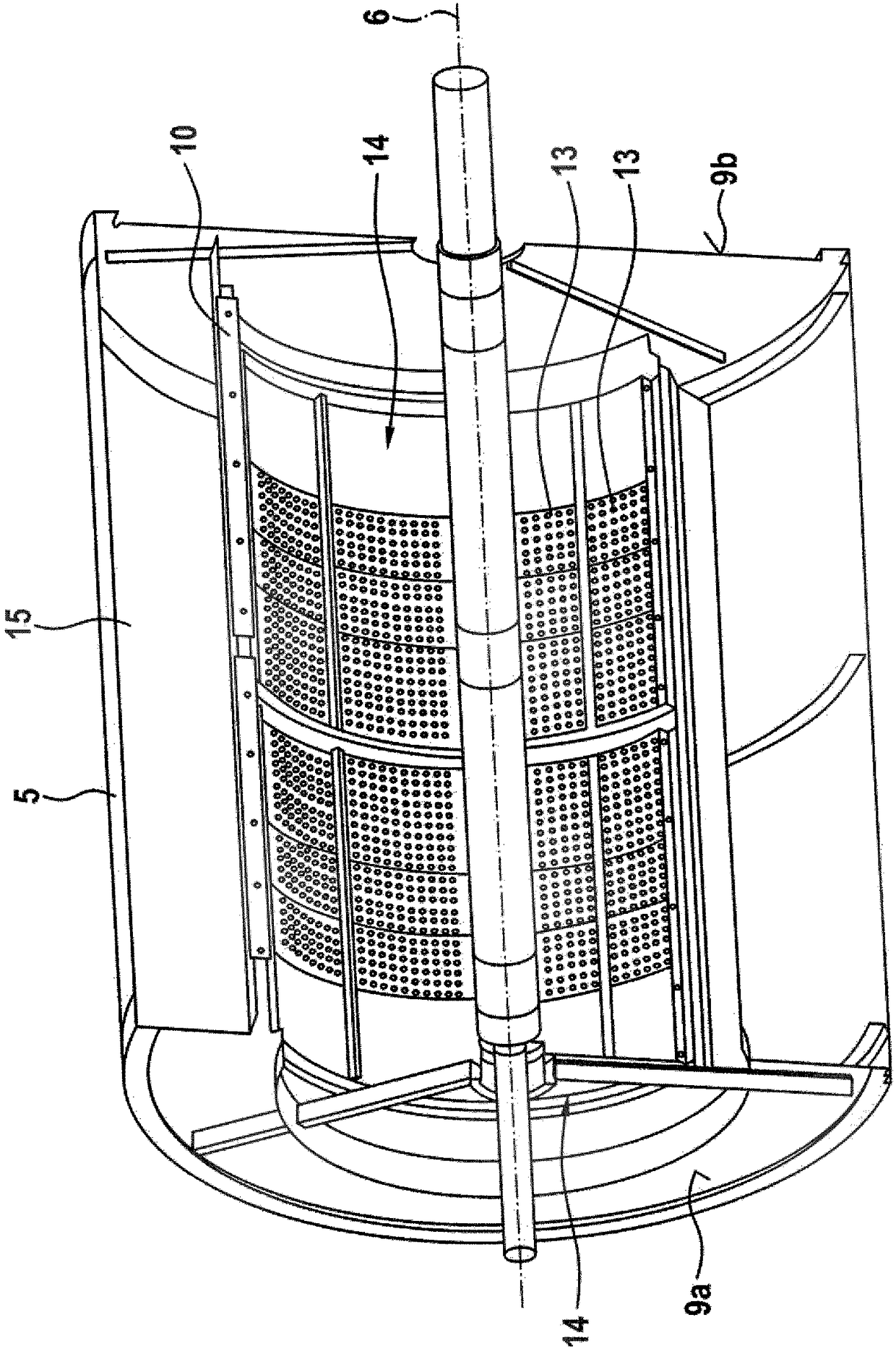

[0022] according to figure 2 , according to the invention, an at least partially air-permeable air guide cylinder 10 is arranged concentrically wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com