Process for accelerating ageing of yellow rice wine by gamma rays

A gamma ray and rice wine technology, applied in the technological field of gamma ray aging rice wine, can solve the problems of unstable peracetic acid, colloid damage, material failure, etc. The effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

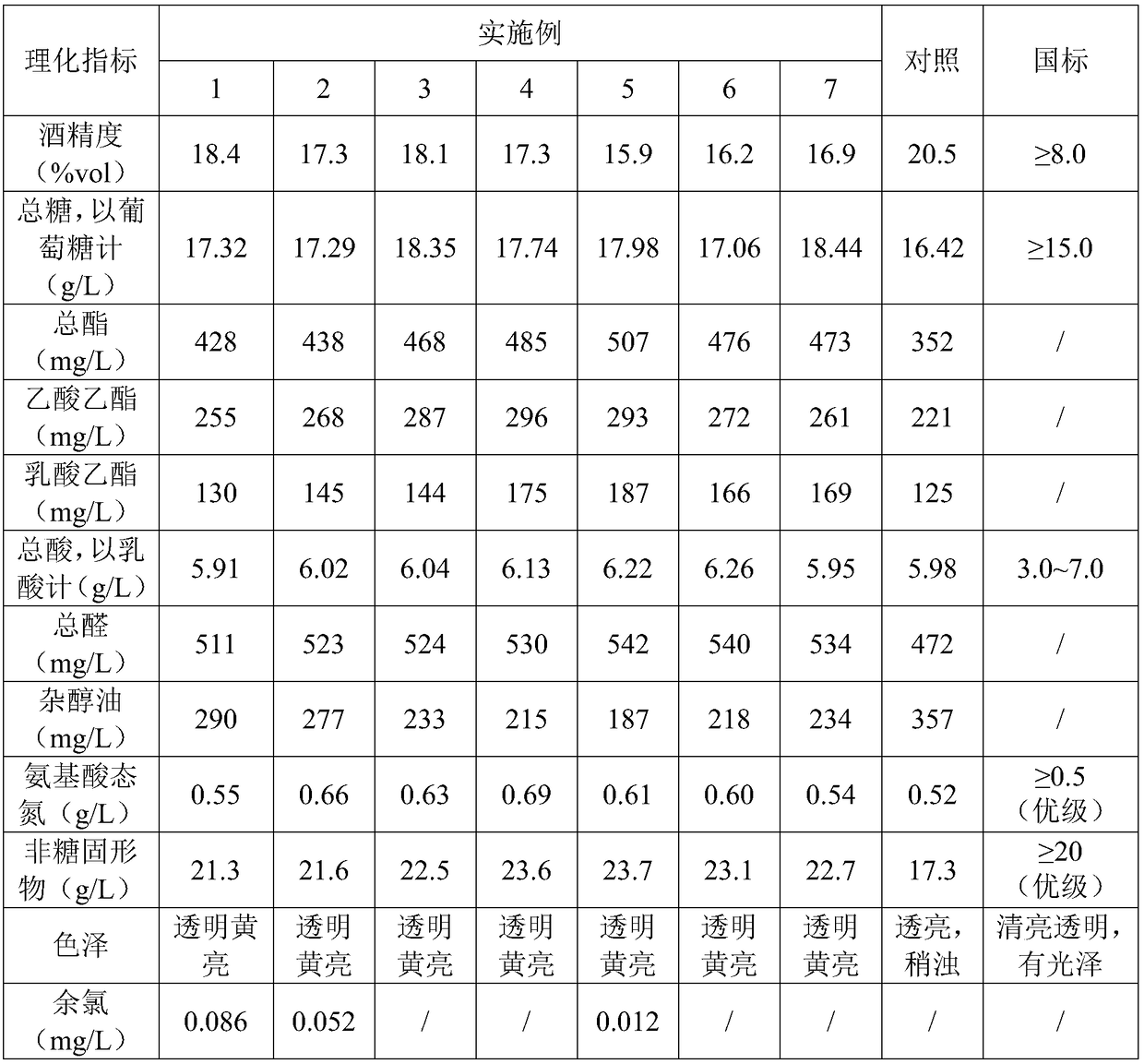

Examples

preparation example Construction

[0044] The preparation method of described catalyst is:

[0045] S1, soak the ceramic carrier with hydrochloric acid solution, then wash with deionized water until neutral and dry;

[0046] S2. Grinding the non-metallic oxide through a 200-mesh sieve to obtain the undersieve, adding water, and mixing to obtain mud;

[0047] S3, mixing the mud material with the ceramic carrier, pressing and forming, drying, and then cooling naturally;

[0048] S4. High-temperature calcination, the temperature of the high-temperature calcination is 450-500° C., the firing time is 12-24 hours, and it is cooled for later use. The internal organic matter of non-metal oxides is removed by high-temperature calcination. In addition, calcination is also conducive to the growth of non-metal oxide grains and improves the adhesion effect.

Embodiment 1

[0050] A kind of technology of gamma ray aging rice wine, the process steps are as follows: the new wine is sent into an aging device, calcium hypochlorite is used as an oxidant, calcium hypochlorite solution is added to the rice wine to be treated, and in every liter of rice wine to be processed, The corresponding mass fraction of available chlorine is 100mg / L, which is used under normal temperature and pressure conditions 60 Co-γ-ray irradiation, the irradiation dose is 3kGy, once every 6h for 18 times, redox reaction is carried out, and the treated rice wine is sealed and stored at room temperature for 2 months.

Embodiment 2

[0052] A kind of technology of gamma ray aging rice wine, the process steps are as follows: the new wine is sent into an aging device, calcium hypochlorite is used as an oxidant, calcium hypochlorite solution is added to the rice wine to be treated, and in every liter of rice wine to be processed, The corresponding mass fraction of available chlorine is 80mg / L, and it can be used under normal temperature and pressure conditions. 60 Co-γ-ray irradiation, the irradiation dose is 1kGy, irradiated once every 6h, lasts 24 times, redox reaction is carried out, and the rice wine after treatment is sealed and stored at room temperature for 2 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com