Tractor capable of realizing hi-crop working

A tractor and high ground clearance technology, applied in the field of tractors, can solve the problems of inability to carry out weeding and cultivating management operations between rows, low utilization rate of tractors, and inability to complete common tractor ploughing, ploughing, and sowing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

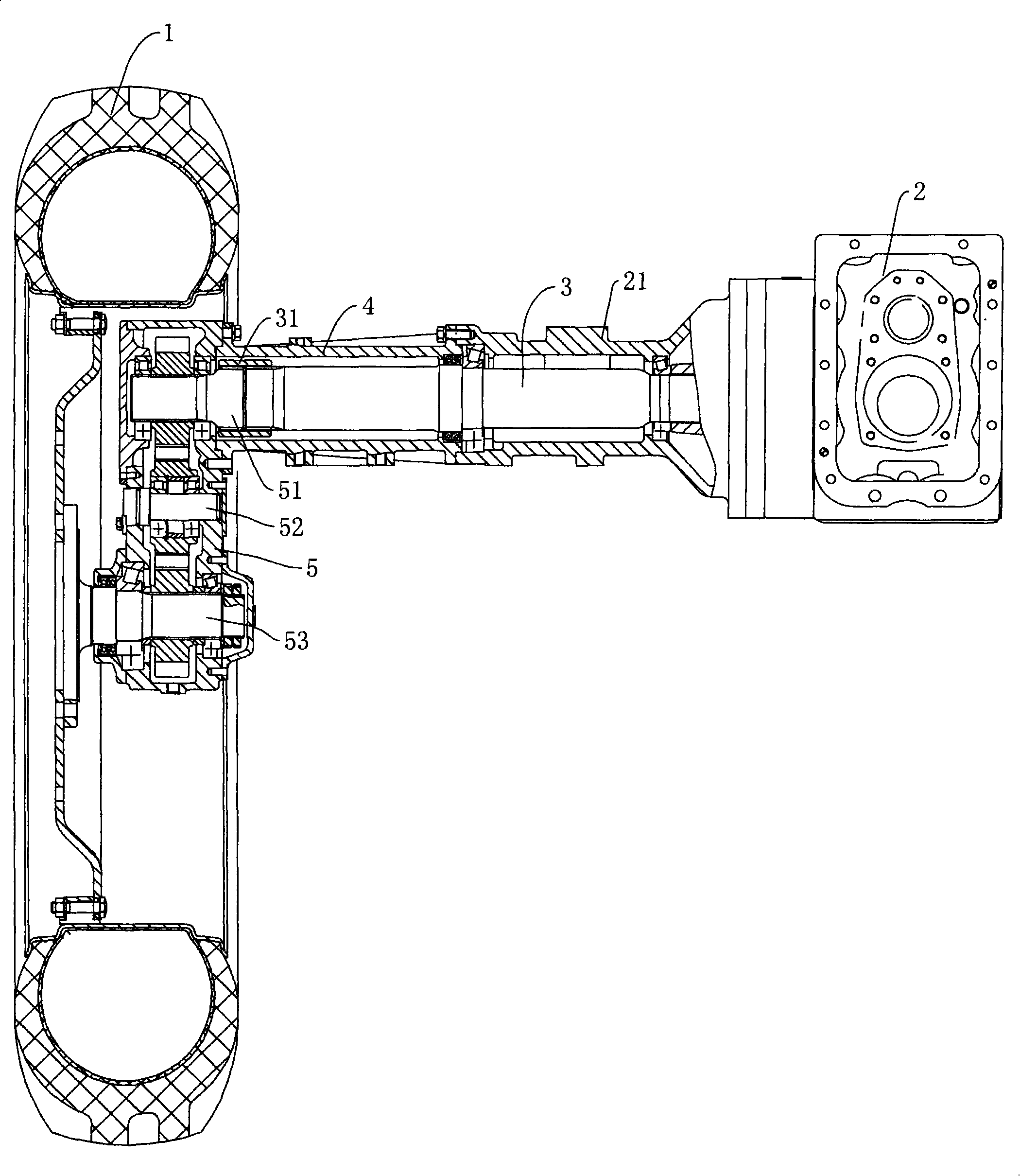

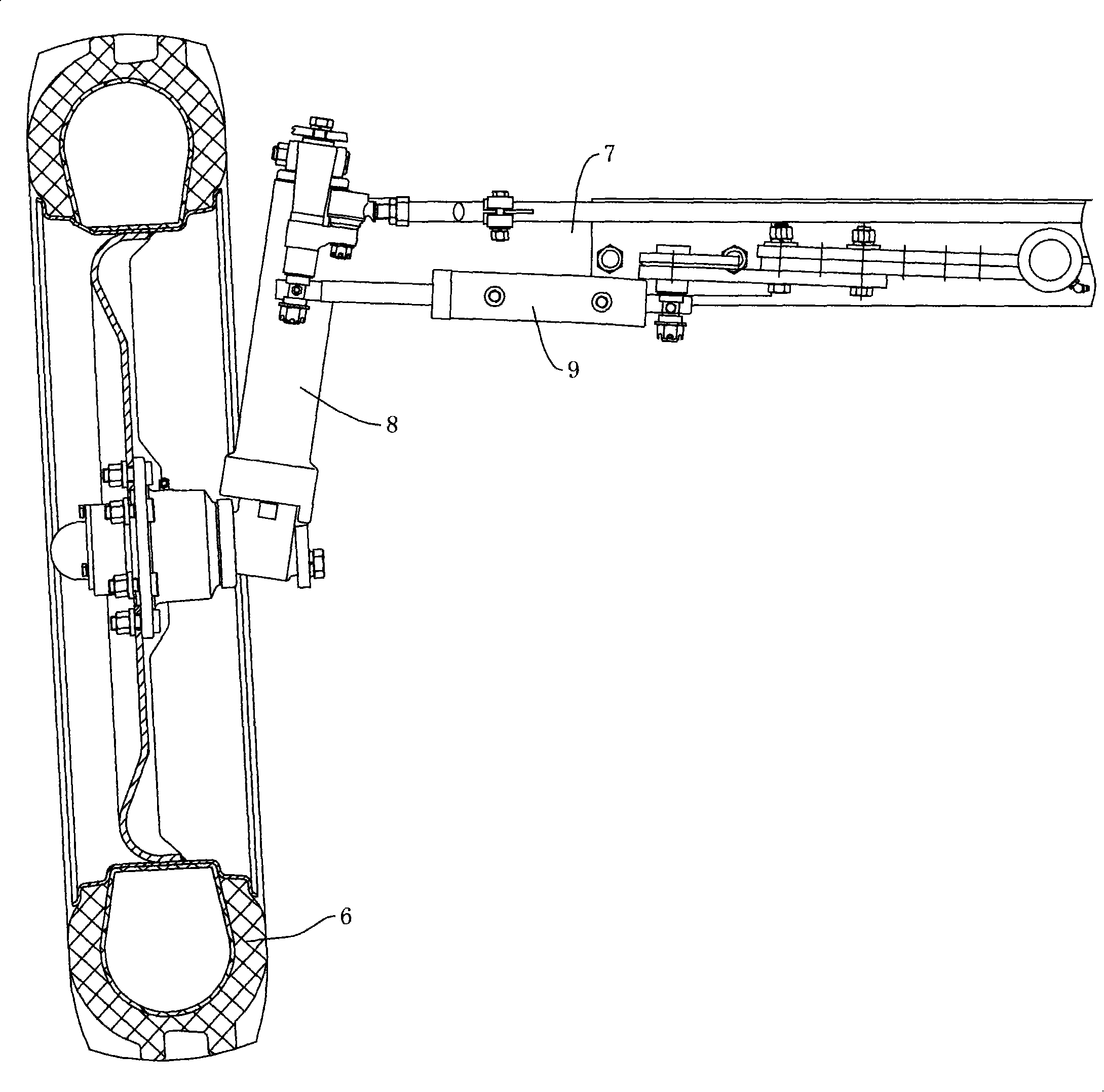

[0012] Such as figure 1 ,Such as figure 2 As shown, a tractor capable of cultivating in high ground clearance includes two rear wheels 1 and two front wheels 6 mounted on the body through the rear drive axle and the front axle respectively, and the rear drive axle includes two left and right rear axles fixedly arranged Shaft tube 21, passing through the two rear axle shaft tubes 21 are respectively provided with left and right drive shafts 3, and the two drive shafts 3 are respectively connected to the output ends on both sides of the rear axle transmission box 2 and driven by the power device to drive the left and right rear wheels 1 Thereby driving the tractor to advance; and the front axle then comprises the sleeve pipe 7, oil cylinder assembly 9 etc. that two ends are detachably connected with auxiliary sleeve pipe 8 respectively, and two auxiliary sleeve pipes 8 are connected respectively and support left and right two front wheels 6, like this, can Through the replacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com