A follow-up inkjet equipment

A follow-up, coding technology, applied in printing, typewriters, etc., can solve problems such as waste of manual labor, misalignment of information printing positions, etc., and achieve the effects of reducing noise, avoiding motion interference, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

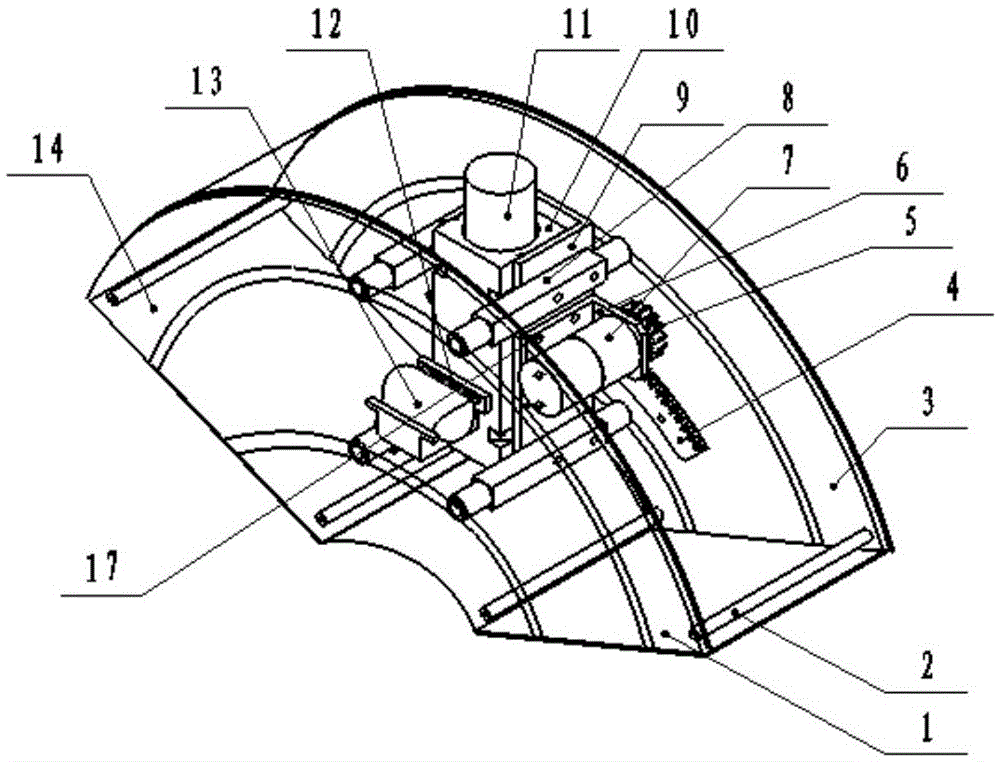

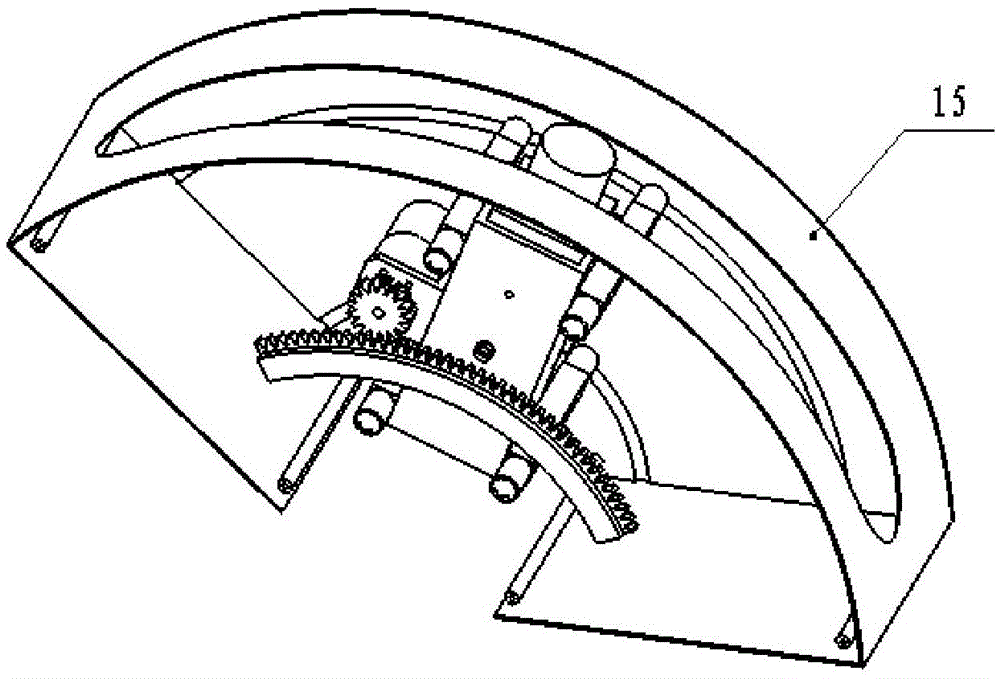

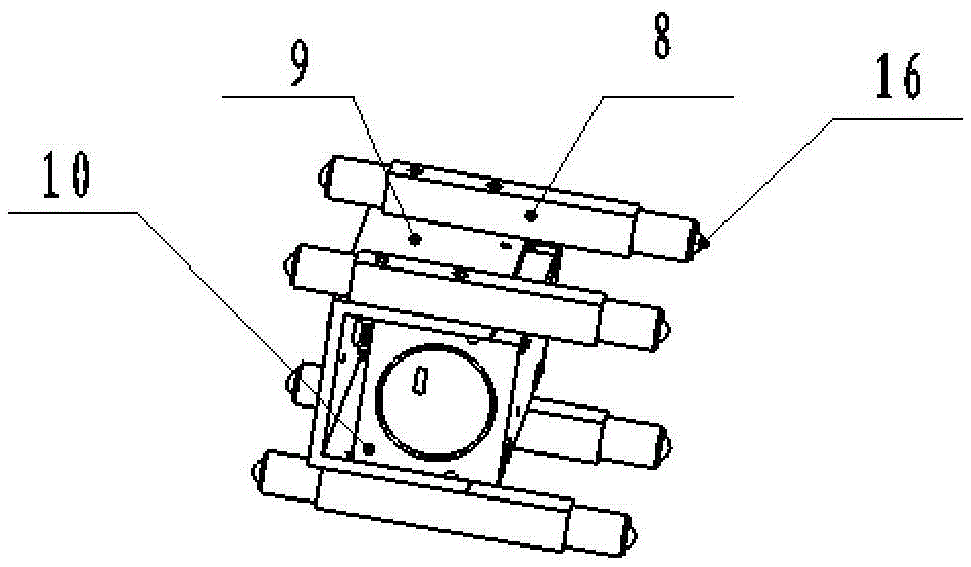

[0016] A follow-up type coding equipment is composed of a rib 1, a support column 2, a rear arc surface 3, a tooth arc 4, a gear 5, a motor mounting plate 6, a DC deceleration motor 7, a roller support column 8, and a coding assembly Set 9, code spraying set 10, spraying terminal 11, CCD bracket 12, CCD13, front arc surface 14, upper cover plate 15 and roller 16, characterized in that: each side of the equipment has a rib 1, two blocks The side surfaces of the limit 1 are respectively equipped with a back arc 3 and a front arc 14, four support columns 2 are installed between the front arc 14 and the back arc 3, and upper arcs 14 and the back arc 3 are equipped with upper The cover plate 15, the tooth arc 4 is installed on the inner side of the rear arc surface 3, and the inner sides of the rear arc surface 3 and the front arc surface 14 are provided with arc-shaped roller grooves 302, and four rollers with rollers 16 are installed. The support column 8 is installed on the codi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com