Pad printing device

A technology of pad printing and equipment, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of rubber head deformation, printing quality, adverse effects, etc., and achieve the effect of improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

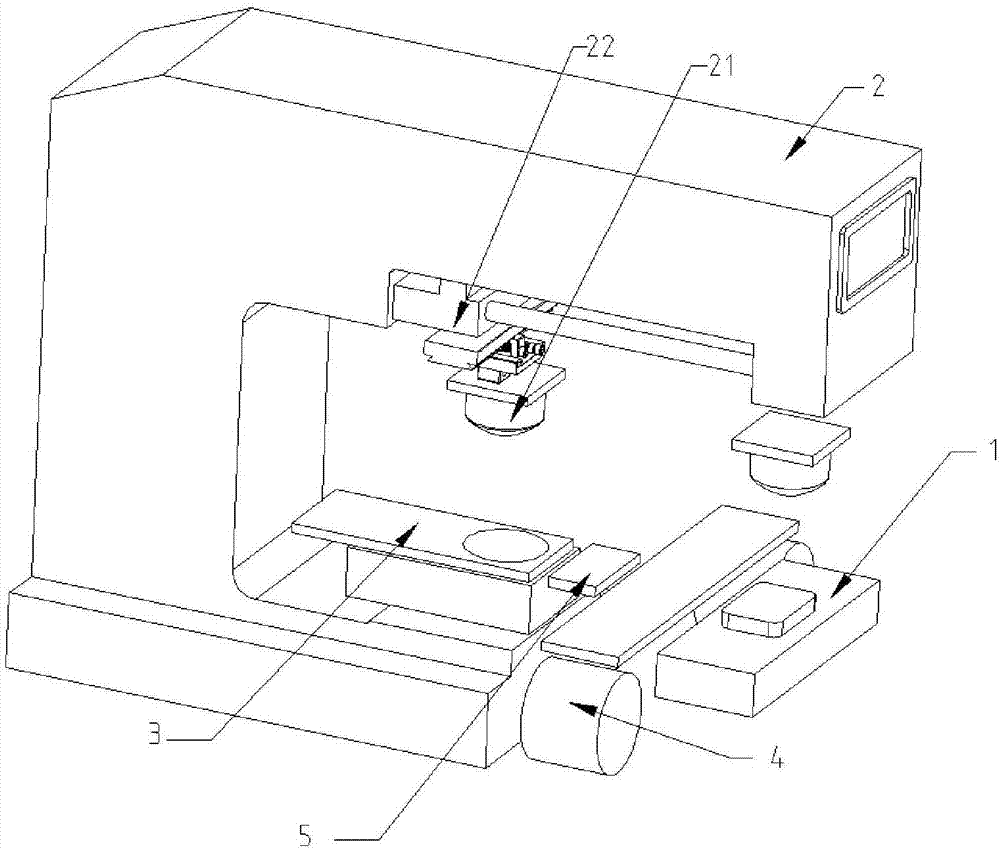

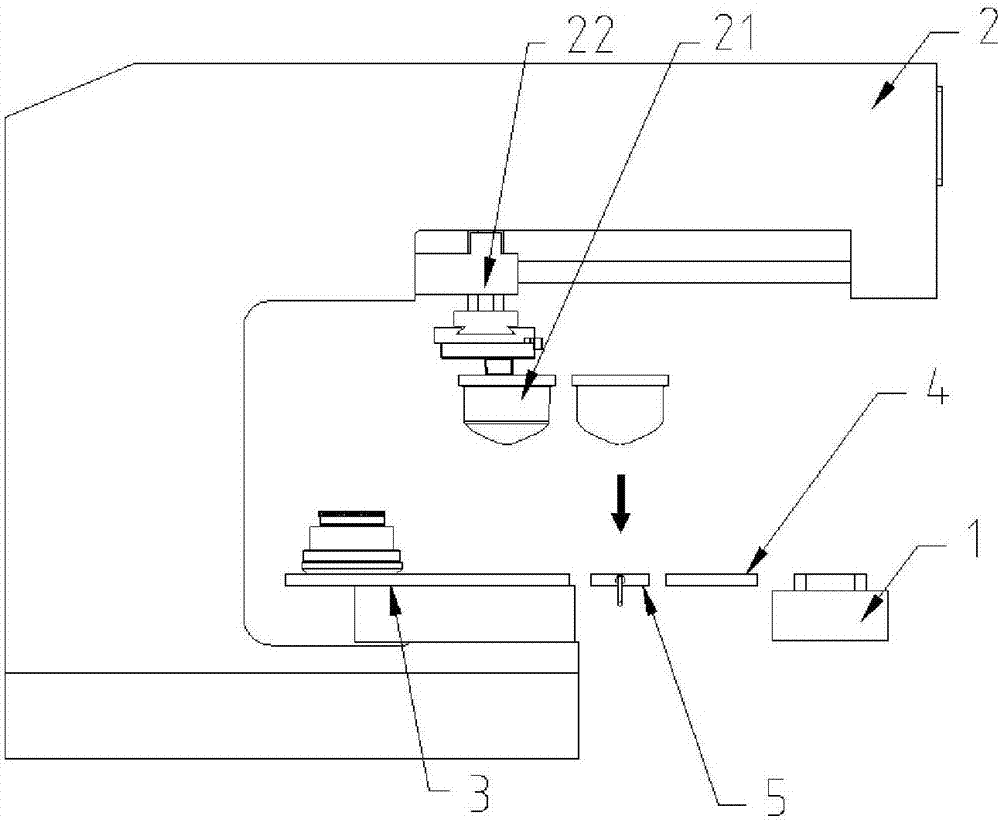

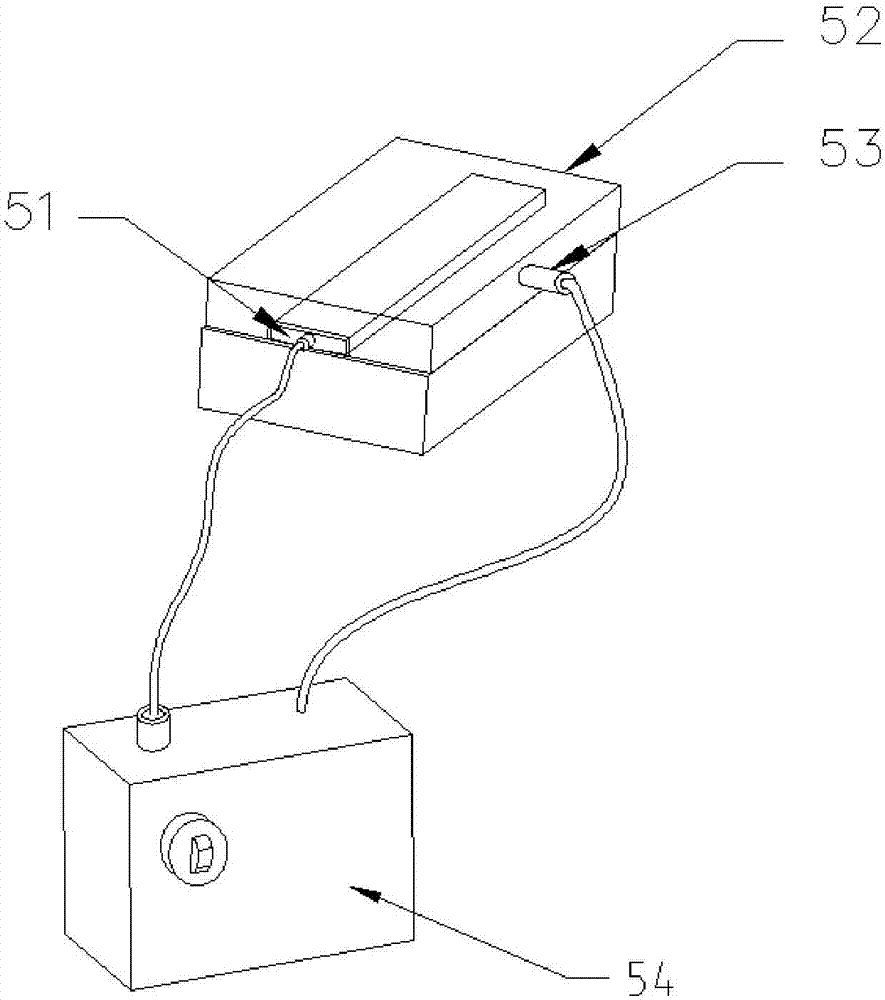

[0025] like figure 1 , 2 As shown, the pad printing equipment of this embodiment includes a pad printing machine head 2 for placing an object to be printed on a workbench 1, a rubber head 21, an ink supply device 3 for providing ink patterns, and a rubber head for cleaning. The cleaning device 4 of 21 further includes a heating device 5 for heating the rubber head 21 before the rubber head 21 dips the ink pattern on the ink supply device 3 . The pad printing equipment of this embodiment is a "bull head type" pad printing equipment, and the pad printing machine head 2 is provided with a push pad 21 on the heating device 5, the ink supply device 3, the workbench 1 and the cleaning device. 4, a shifting mechanism 22 that circulates between 4, the shifting mechanism 22 includes a polished rod horizontally arranged below the pad printing head 2, and a slide seat that is arranged on the polished rod and is driven by an air cylinder (hydraulic cylinder) or a motor to move along the ...

Embodiment 2

[0028] like Figure 5 , 6 As shown, the pad printing equipment of this embodiment includes an ink supply device 3 for providing ink patterns, a cleaning device 4 for cleaning the rubber head 21, and an adjustment platform 6 for placing objects to be printed, and also includes at least A mobile printing device of a glue head 21 and a heating device 5 for heating the glue head 21 before the glue head 21 dips the ink pattern on the ink supply device 3 . By setting the heating device 5, the heating device 5 is used to heat the rubber head 21 before the rubber head 21 dips the ink pattern on the ink supply device 3, thereby realizing the control of the volatilization speed of the ink solvent on the rubber head 21, thereby improving print quality. After the rubber head 21 is heated by the heating device 5 before dipping the ink pattern, the temperature of the surface layer of the rubber head 21 rises, which can ensure that a thicker ink pattern is dipped from the ink supply device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com