Monocrystal culture device and monocrystal culture method

A culture device and culture method technology, applied in the direction of single crystal growth, chemical instruments and methods, crystal growth, etc., can solve the problems of uncontrollable solvent diffusion rate, limit the quality of single crystal growth, etc., and achieve reduction of influence, volatility, solubility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

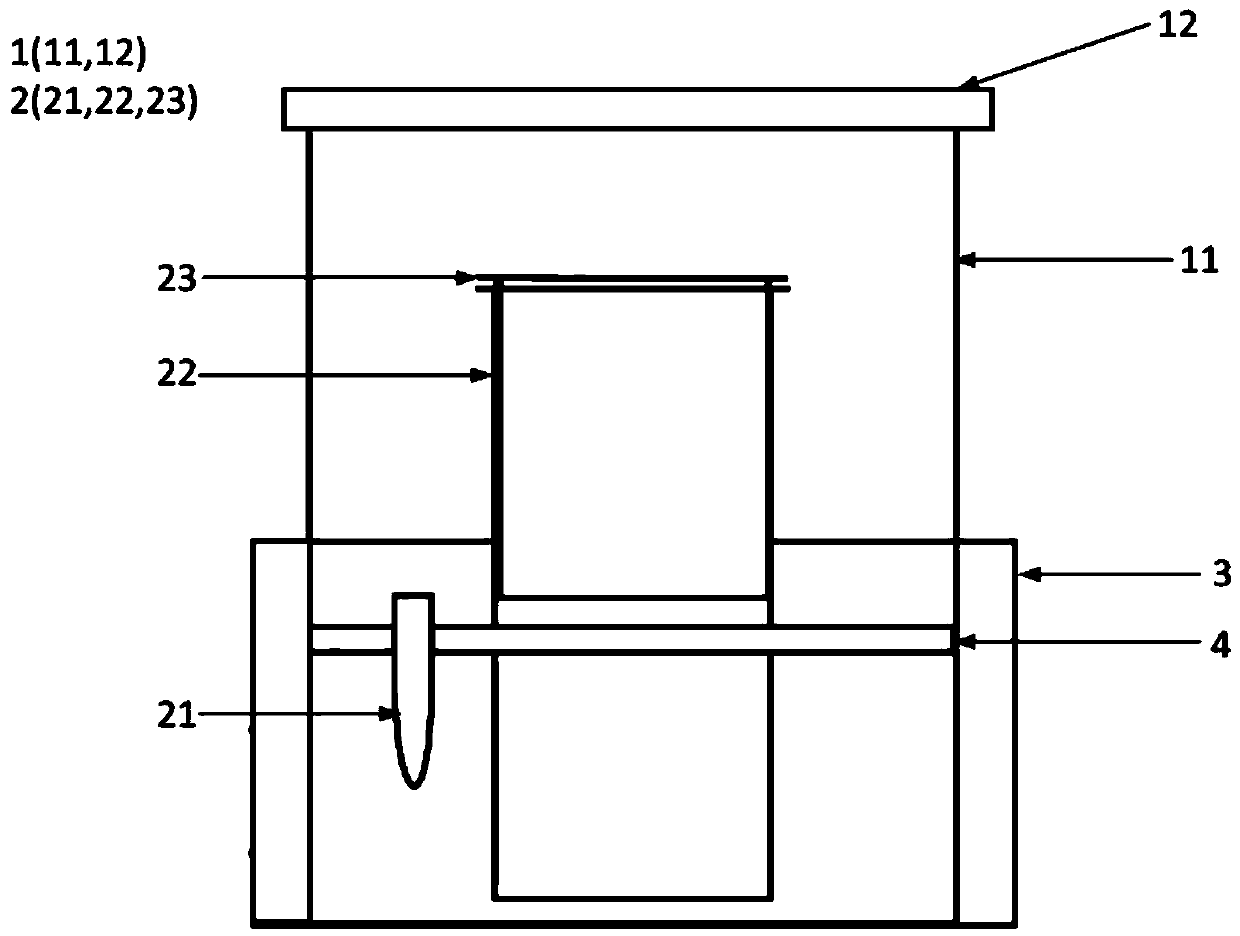

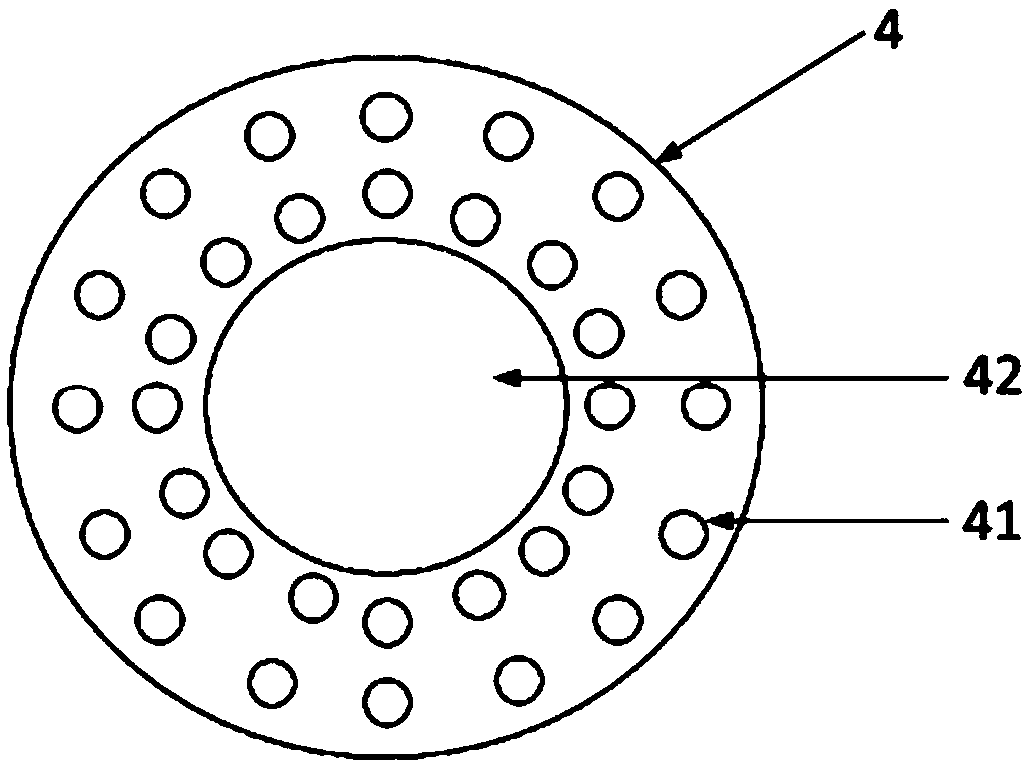

[0068] This embodiment provides a single crystal cultivation device, including a housing unit 1 , a cultivation unit 2 , a temperature control unit 3 and a support unit 4 . Wherein, the accommodation unit 1 has an accommodation cavity, the culture unit 2 and the support unit 4 are disposed in the accommodation cavity, and the temperature control unit 3 is disposed outside the accommodation unit 1 .

[0069] Such as figure 1 As shown, the housing unit 1 includes a culture container 11 and a seal 12 . Wherein, the culture container 11 has an accommodating inner cavity and a third opening that communicates the accommodating inner cavity with the outside world. For example, the culturing container 11 is a cylindrical container, and an accommodating inner cavity is formed inside the cylindrical container, and the top of the cylindrical container Form the 3rd opening; Sealing member 12 is suitable for being installed in the 3rd opening and makes accommodating cavity form sealing ca...

Embodiment 2

[0081] This embodiment provides a method for growing a single crystal. For example, the target material for growing a single crystal is NPAFN, a red-light host material, and the chemical structure of NPAFN is as follows:

[0082]

[0083] Utilize any one single crystal cultivation device provided in embodiment 1 to cultivate, and the cultivation method comprises the following steps:

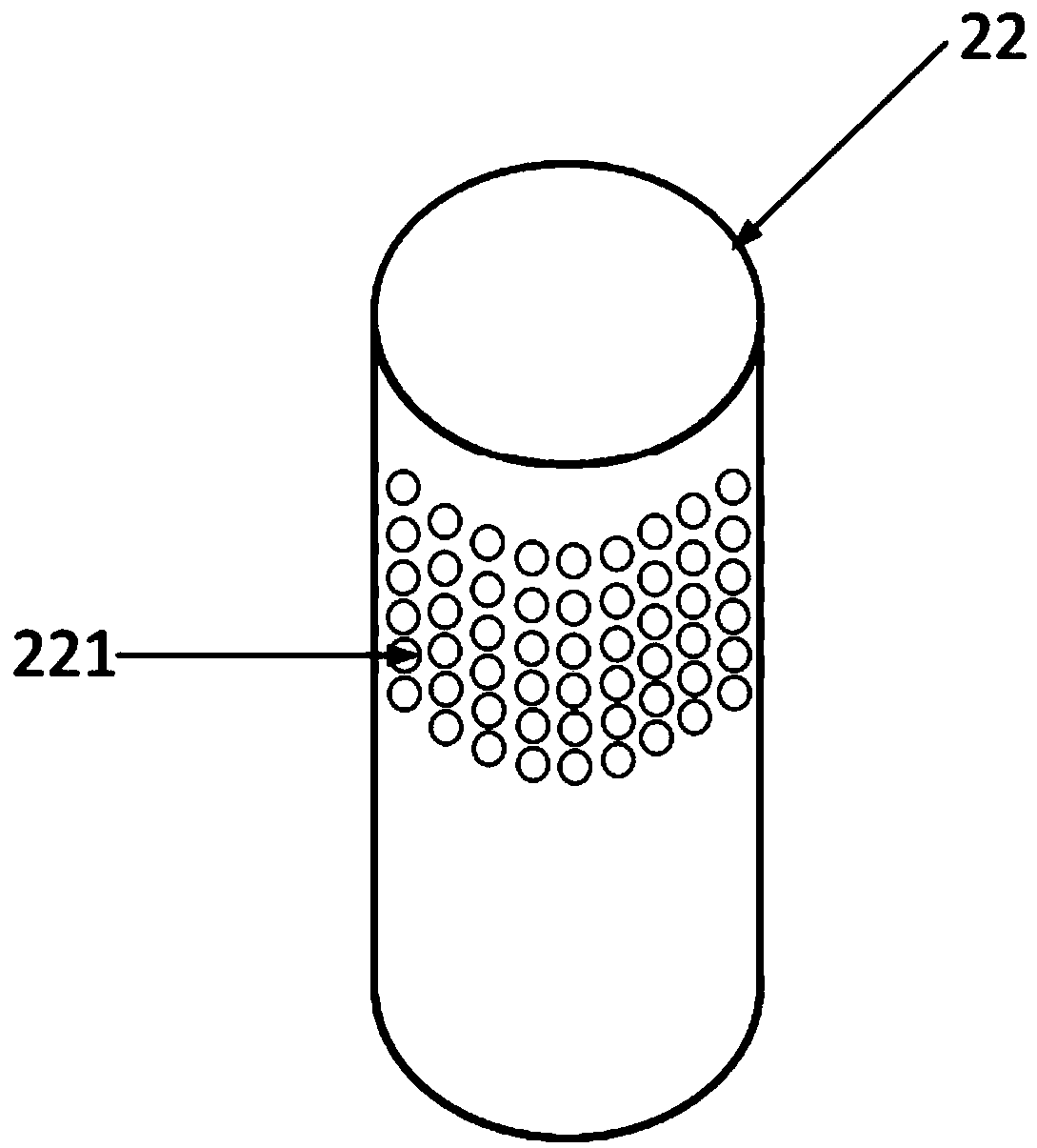

[0084] S1, adding a second solvent (for example: n-hexane) to the second bottle body 22, the liquid level of the second solvent is lower than the height of the first region;

[0085] S2, install the second cover body 23 on the second opening of the second bottle body 22, the extension part 232 of the second cover body 22 blocks part of the through holes on the first area, and the remaining part of the through holes are opened, record The opening ratio of the through hole;

[0086] S3, take about 5 mg of the target material into the test tube with a clean spatula, add about 3 ml of the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com