IR baking type light guiding and brightening optical emulsion and preparation method thereof

An emulsion and optical technology, which is applied in the field of light-guiding optical emulsion and its preparation, can solve the problems affecting the display effect of the LCD screen, affecting the health of printing workers, and the limited hardness of the ink, so as to achieve the effect of anti-scratch, improve the display effect, The effect of increasing the withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

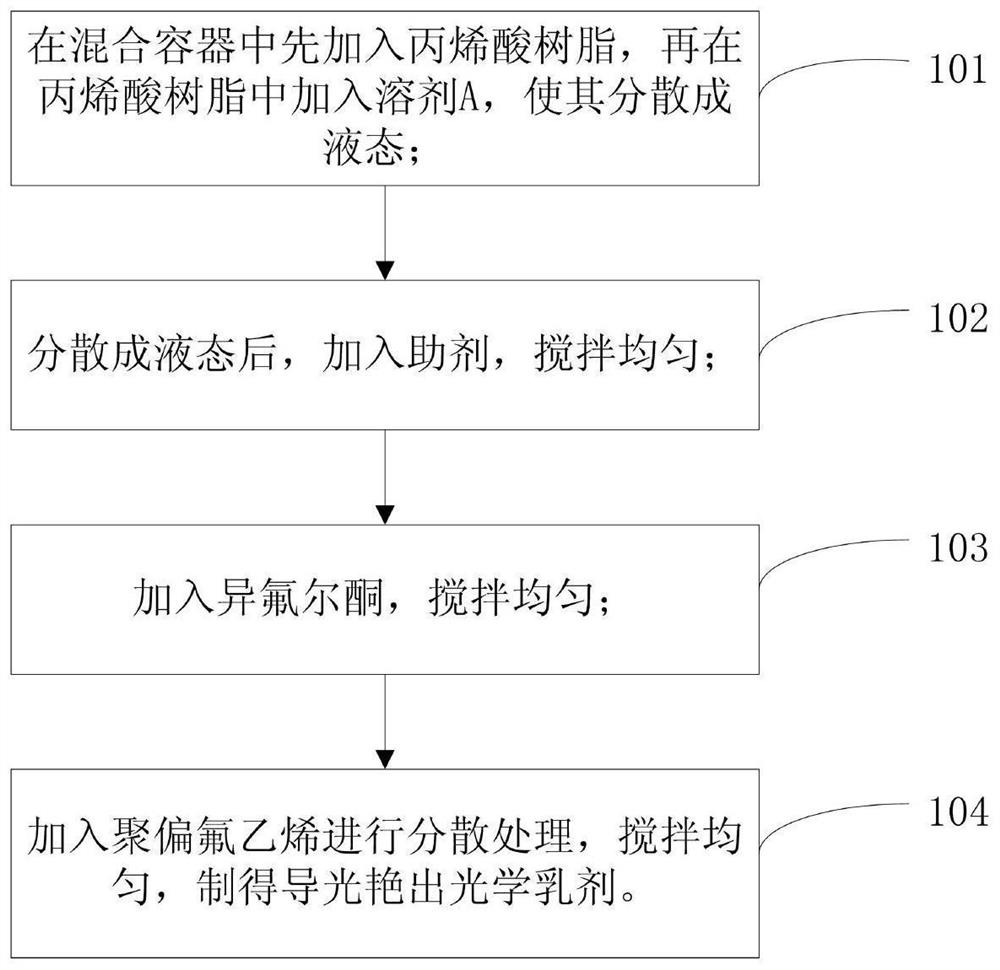

Method used

Image

Examples

Embodiment 1

[0038]An IR baking-type light-guiding and brightening optical emulsion, comprising the following components and parts by weight: 140-260 parts of acrylic resin, 400-760 parts of solvent A, 10-30 parts of isophorone, 10-30 parts of additives, 10-25 parts of polyvinylidene fluoride.

[0039] Further, the solvent A includes the following components and parts by weight: 30-60 parts of ethylene glycol butyl ether, 90-150 parts of propylene glycol ethyl ether, 90-180 parts of ethylene glycol diacetate, 150-240 parts of carbitol Parts, 30-80 parts of dibasic acid ester, 10-50 parts of diethylene glycol butyl ether acetate. Through the ratio of ethylene glycol butyl ether and propylene glycol ether, it is beneficial to increase the dissolution and dispersion speed of the resin; by adding isophorone and its ratio, the acrylic resin is fully dissolved; through ethylene glycol diacetate, carbitol , divalent ester and diethylene glycol butyl ether acetate ratio, effectively control the e...

Embodiment 2

[0051] An IR baking-type light-guiding and brightening optical emulsion, comprising the following components and parts by weight: 70-130 parts of methacrylic resin, 70-130 parts of n-butyl methacrylate, 30-130 parts of ethylene glycol butyl ether 60 parts, 90-150 parts of propylene glycol ethyl ether, 90-180 parts of ethylene glycol diacetate, 150-240 parts of carbitol, 30-80 parts of divalent ester, 10-50 parts of diethylene glycol butyl ether acetate 10-30 parts of isophorone, 2-7 parts of polyether-modified polydimethylsiloxane solution, 3-8 parts of foam-breaking polymer and polysiloxane mixed solution, structured acrylate copolymer 2-6 parts of solution, 3-9 parts of copolymer solution of filler affinity groups, and 10-25 parts of polyvinylidene fluoride.

[0052] Further, the hardness of the n-butyl methacrylate is 2-3H, and the hardness of the methacrylic resin is F.

[0053] The preparation method of the light-guiding brightening optical emulsion of above-mentioned IR...

Embodiment 3

[0061] An IR baking-type light-guiding and brightening optical emulsion, comprising the following components and parts by weight: 70 parts of methacrylic resin, 70 parts of n-butyl methacrylate, 30 parts of ethylene glycol butyl ether, 90 parts of propylene glycol ethyl ether Parts, 90 parts of ethylene glycol diacetate, 150 parts of carbitol, 30 parts of divalent ester, 10 parts of diethylene glycol butyl ether acetate, 10 parts of isophorone, polyether modified polydimethyl 2 parts of base siloxane solution, 3 parts of foam breaking polymer and polysiloxane mixed solution, 2 parts of structured acrylate copolymer solution, 3 parts of filler affinity group copolymer solution, 10 parts of polyvinylidene fluoride .

[0062] Further, the hardness of the n-butyl methacrylate is 2H, and the hardness of the methacrylic resin is F.

[0063] The preparation method of the light-guiding brightening optical emulsion of above-mentioned IR baking type, comprises the following steps:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com