Electrostatic spinning device of continuous nanometer fiber net and method for preparing nanometer fiber net

A nanofiber web and electrospinning technology is applied in the fields of preparing nanofiber webs, electrospinning devices for continuous nanofiber webs, and spinning devices. The effect of weakening mutual interference and reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

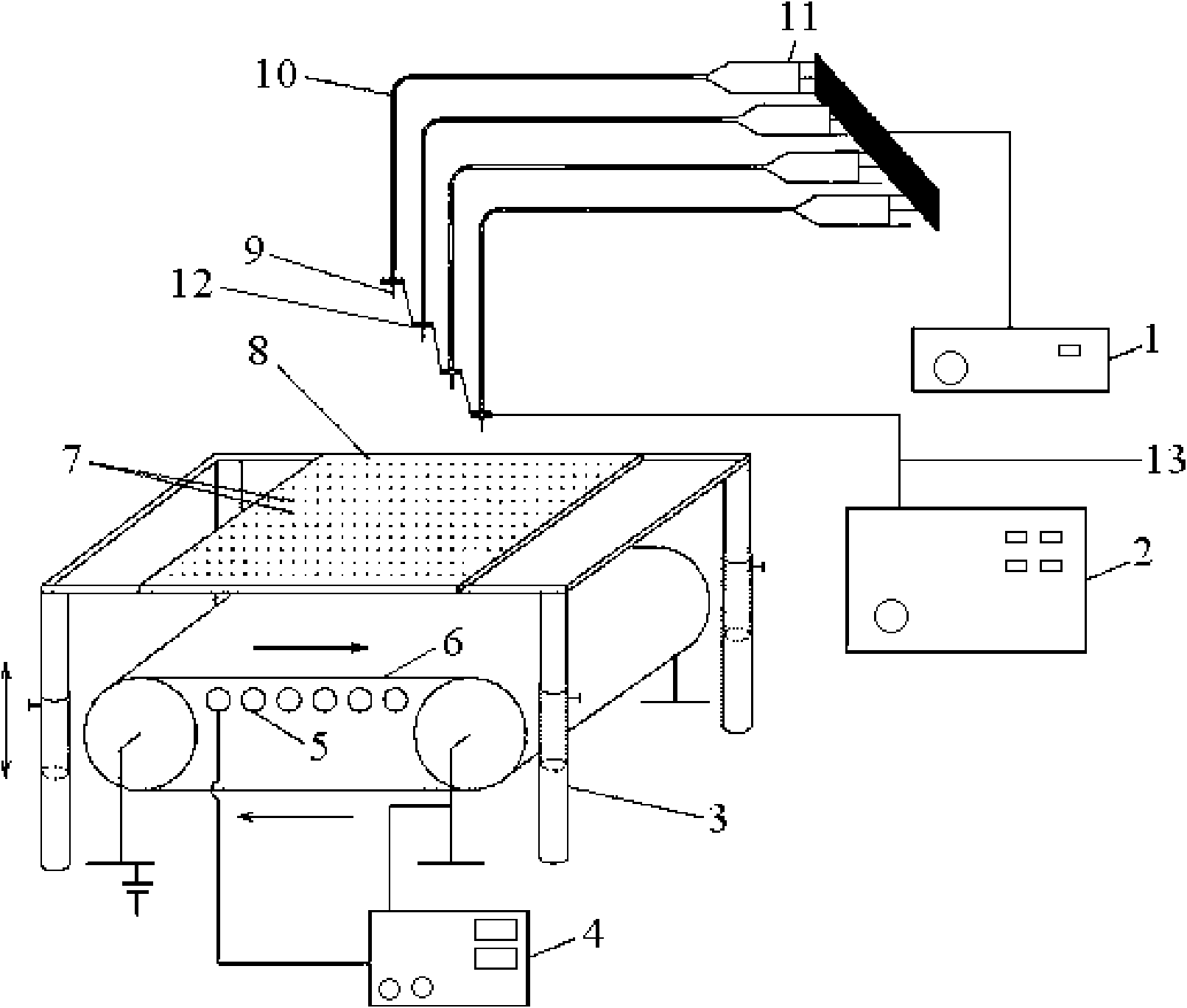

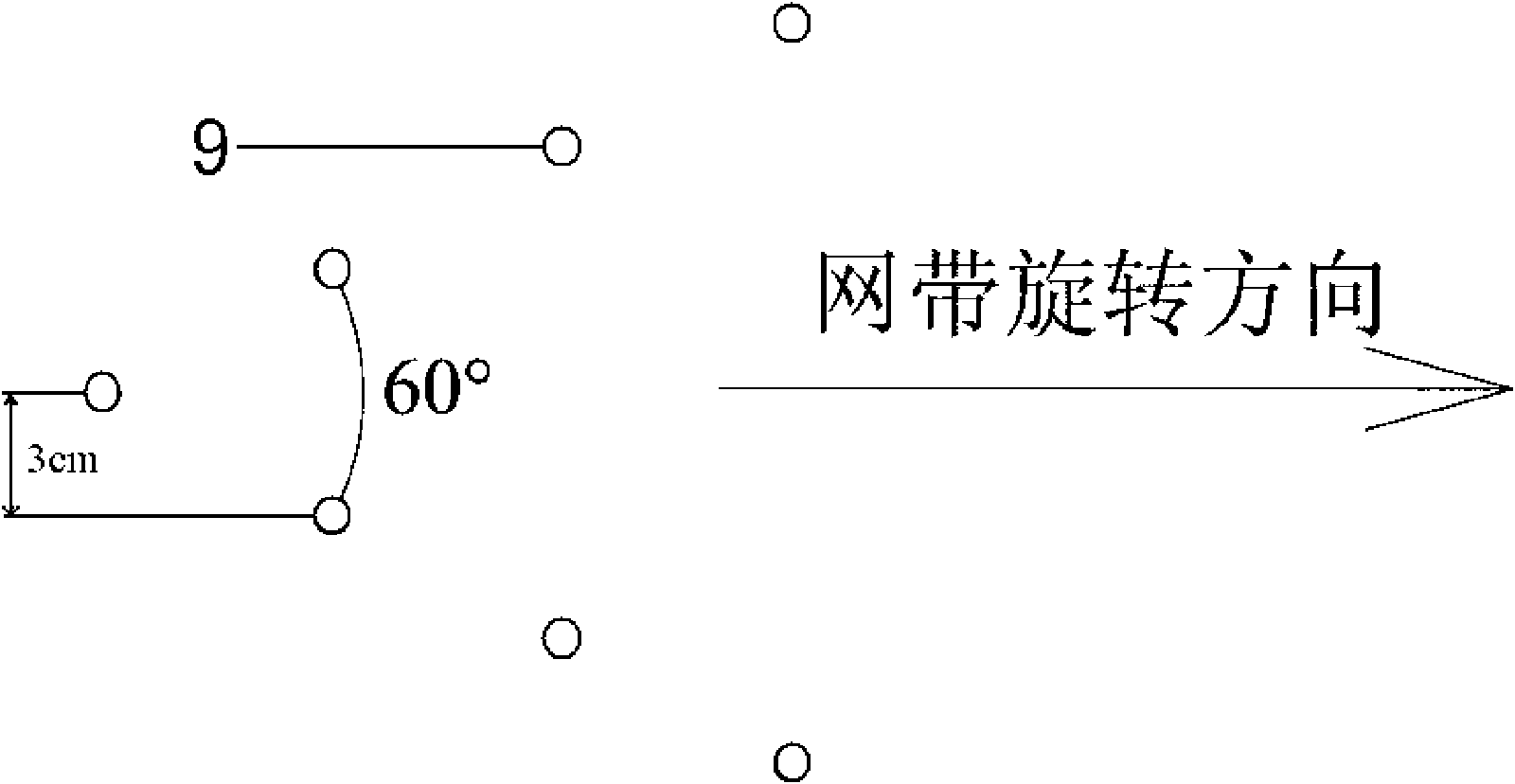

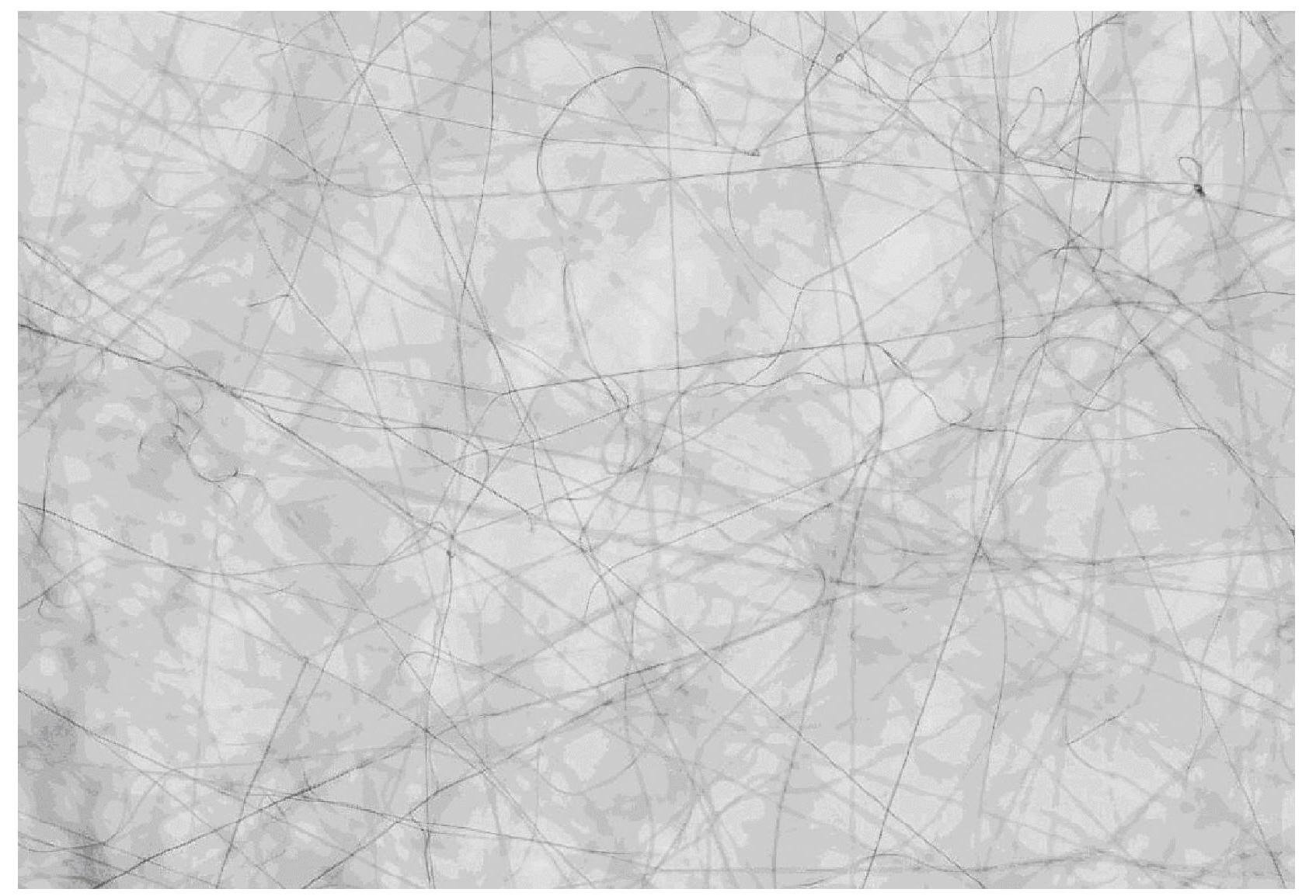

[0038] Polyacrylonitrile (PAN) (Mw=70,000 g / mol) was dissolved in N,N-dimethylformamide (DMF) to prepare a spinning solution with a concentration of 13 wt%. Under the environment of room temperature and relative humidity being 60%, this spinning solution is injected in the syringe 11, and there are 7 syringes 11 in total, which are respectively connected by 7 metal needles 9 on the PTFE catheter 10 and the rubber plate 8, as figure 2 As shown, the metal needles 9 are arranged in a cone shape along the rotation direction of the endless mesh belt 6, the cone angle is 60°, and the distance between adjacent metal needles 9 is 6cm. Start the driving motor and the heating pipe 5 to allow the endless mesh belt 6 to rotate at a speed of 12m / min, and keep the temperature of the endless mesh belt 6 at 30°C. Turn on the DC high-voltage generator 2, control the voltage to 20kV, adjust the receiving distance between the metal needle 9 and the endless mesh belt 6 to 120mm, and the electros...

Embodiment 2

[0040] Polyacrylonitrile (PAN) (Mw=70,000 g / mol) was dissolved in N,N-dimethylformamide (DMF) to prepare a spinning solution with a concentration of 13 wt%. At room temperature and a relative humidity of 40%, the spinning solution is injected into the syringe 11. There are 11 syringes 11 in total, which are respectively connected by 11 metal needles 9 on the PTFE catheter 10 and the rubber plate 8. The metal needles 9 presents a conical arrangement along the rotation direction of the endless mesh belt 6, the cone angle is 60°, and the distance between adjacent metal needles 9 is 4cm. Start the driving motor and the heating pipe 5 to allow the endless mesh belt 6 to rotate at a speed of 6 m / min, and keep the temperature of the endless mesh belt 6 at 200° C. Turn on the DC high-voltage generator 2, control the voltage to 15kV, adjust the receiving distance between the metal needle 9 and the endless mesh belt 6 to 50mm, and the electrospinning jet will deposit on the surface of t...

Embodiment 3

[0042] Polyacrylonitrile (PAN) (Mw=70,000 g / mol) was dissolved in N,N-dimethylformamide (DMF) to prepare a spinning solution with a concentration of 13 wt%. At room temperature and a relative humidity of 70%, the spinning solution is injected into the syringe 11. There are 3 syringes 11, which are respectively connected by 3 metal needles 9 on the PTFE catheter 10 and the rubber plate 8. The metal needles 9 are arranged in a cone shape along the rotation direction of the endless mesh belt 6, the cone angle is 60°, and the distance between adjacent needles is 12cm. Start the driving motor and the heating pipe 5 to allow the endless mesh belt 6 to rotate at a speed of 60 m / min, and keep the temperature of the endless mesh belt 6 at 300° C. Turn on the DC high-voltage generator 2, control the voltage to 50kV, adjust the receiving distance between the metal needle 9 and the endless mesh belt 6 to 300mm, and the electrospinning jet will deposit on the surface of the endless mesh be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com