Automatic weaving and twisting machine

A twisting machine and automatic technology, which is applied in the direction of braided fabrics, textiles and papermaking, can solve problems such as difficult knotting, achieve the effect of solving difficult knotting, realizing continuous work, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

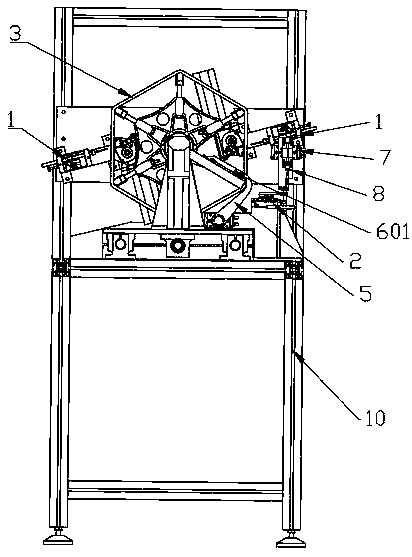

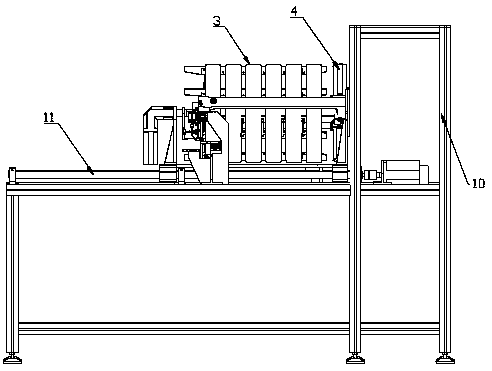

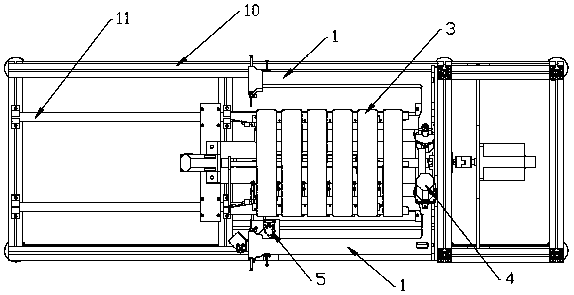

[0071] An automatic braiding machine, including a winding mechanism 1 for winding wires into bundles, an automatic knotter 2 for knotting winding thread ends 14, inner layer thread ends 12 and outer layer thread ends 13, a wire frame 3 and a power system 4, The power system 4 drives the wire frame 3 to move axially and rotate around the axis under the winding mechanism 1; the winding mechanism 1 winds the wire harness in lanes; after winding, the winding thread 14, the inner thread 12 and the outer Layer thread end 13 is knotted through automatic knotter 2.

[0072] Further, the winding mechanism 1 of the present invention includes a needle bar 101 that reciprocates in the vertical direction, and the needle bar 101 is provided with a needle 102 with an upper thread for winding; The rotating hook 103 that rotates in a circle in the direction; the wire frame 3 is arranged between the needle bar 101 and the rotating hook 103 and presents a progressive movement.

[0073] Further,...

Embodiment 2

[0101] The wire harness is placed on the wire frame 3, and the wire frame 3 is fixed on the present invention by the wire frame fixer. The needle bar 101 passes through the wire harness on the wire frame 3, moves to the lowest position and rises to form a wire loop I, and the wire loop I is immediately hooked by the rotating hook 103 that rotates counterclockwise 102; the needle bar 101 rises and exits the wire harness, and the rotating hook 103 pulls Lengthen and expand the thread loop I, the thread loop I slides to the middle, and the thread frame 3 advances; the needle bar 101 passes through the wire harness for the second time, and at this time the rotating hook 103 turns 180°; the needle bar 101 rises from the lowest position again and starts to form a thread Ring II, when the rotating hook 103 turns over 360°, hook into the wire ring II for the second time and stretch and expand the wire ring II, so that the wire ring II penetrates the wire ring I; the wire ring I slips o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com