Patents

Literature

164results about How to "Guaranteed resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

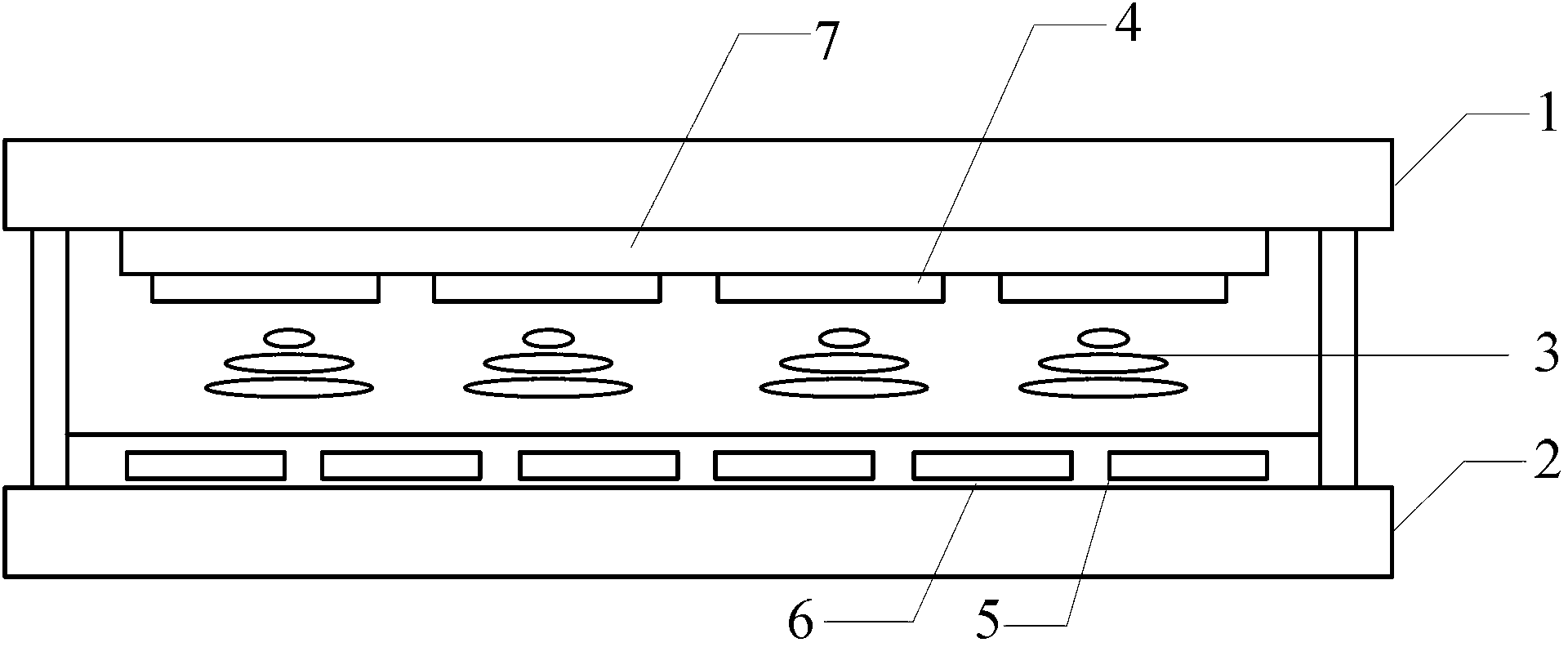

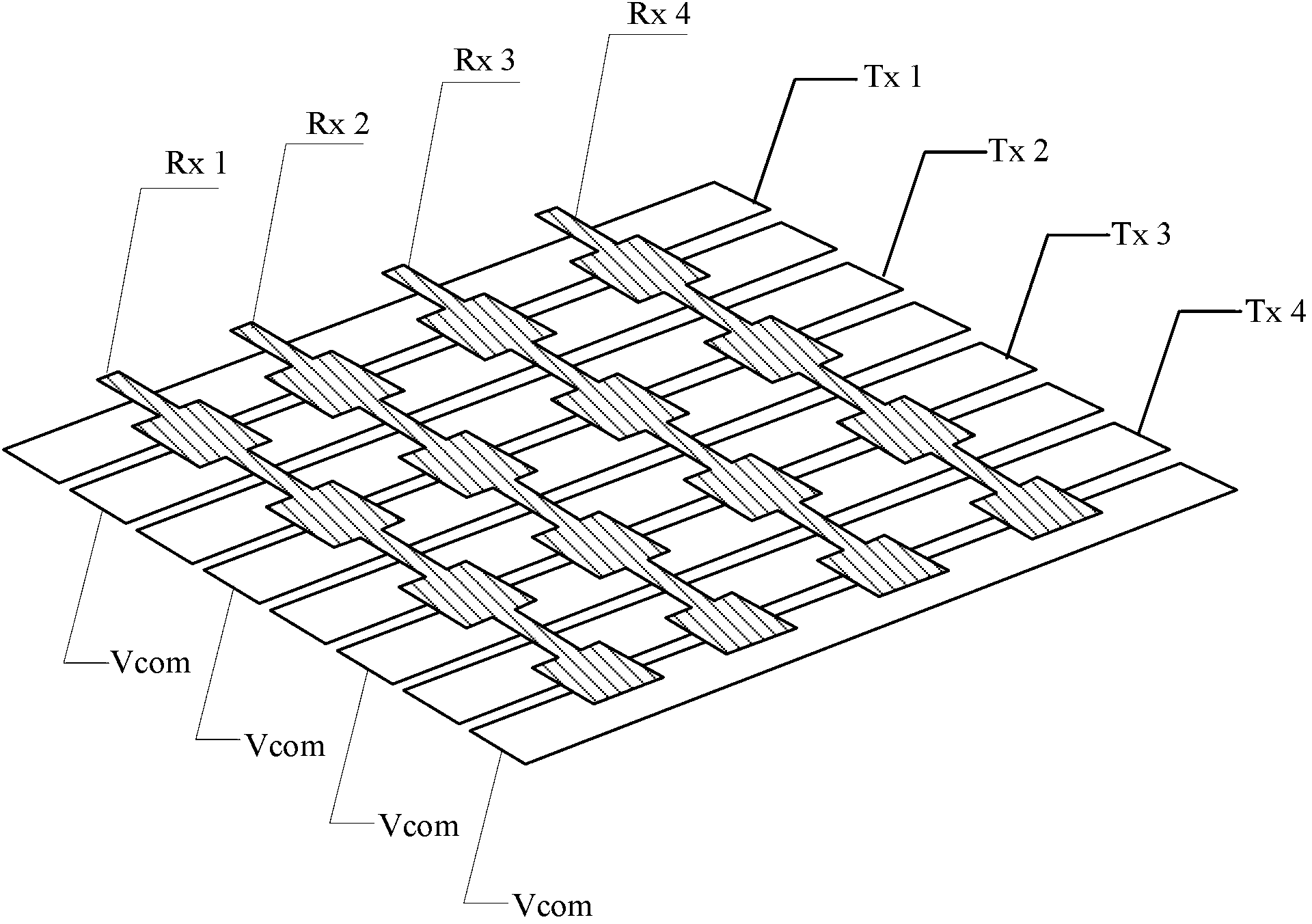

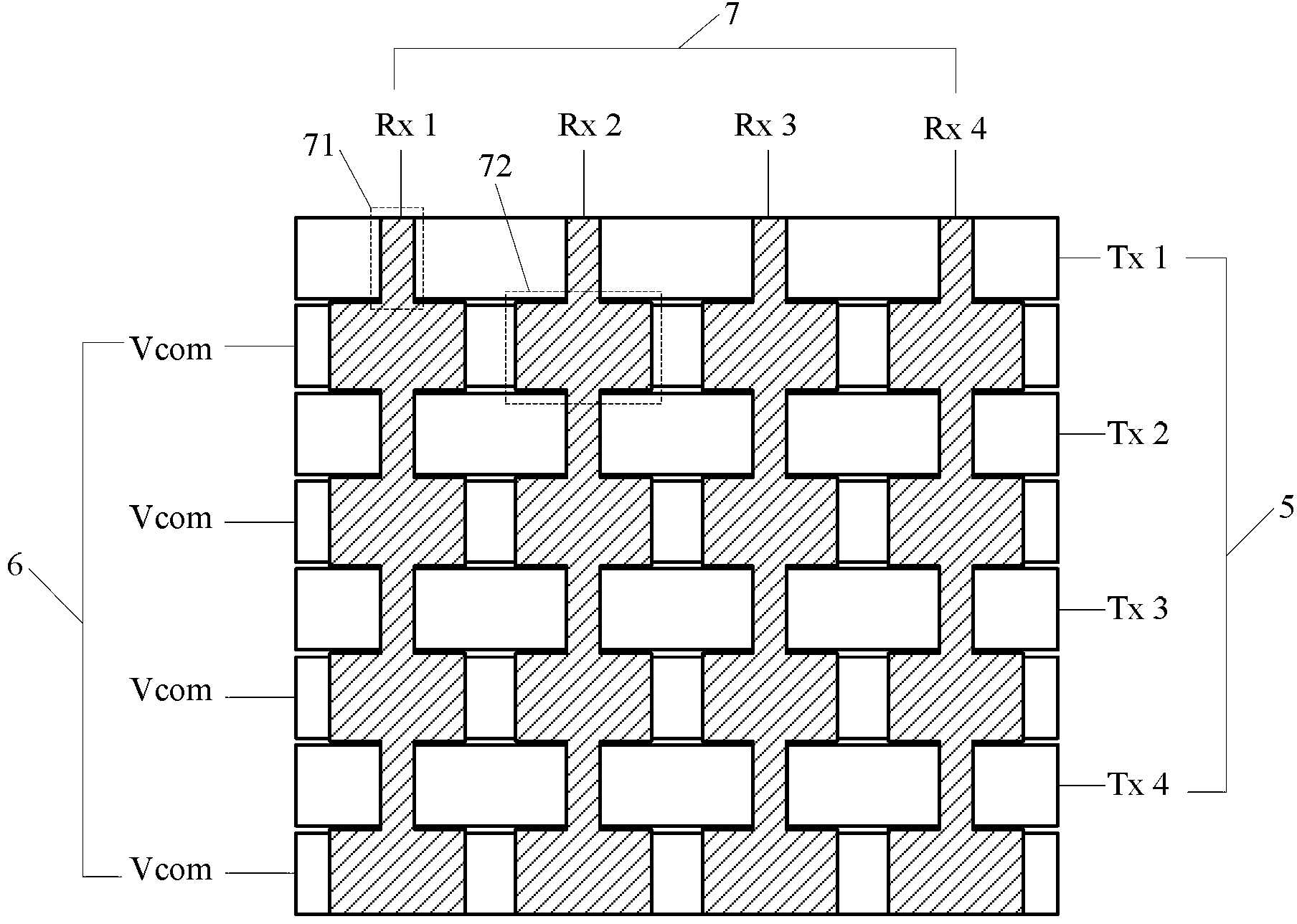

Capacitance embedded touch screen, driving method and display device thereof

ActiveCN102914920ALower resistanceGuaranteed resistanceStatic indicating devicesNon-linear opticsCapacitanceTouch Senses

The invention discloses a capacitance embedded touch screen, a driving method of the capacitance embedded touch screen and a display device of the capacitance embedded touch screen. A touch sensing electrode is arranged on a color film substrate, a wholly connected common electrode layer in the TFT (thin film transistor) array substrate is divided into a touch driving electrode and a common electrode, the touch driving electrode adopts a time-sharing driving mode to achieve the display and touch functions, the time-sharing driving mode helps to reduce the mutual interference between display and touch and increase the picture quality and the touch accuracy; an overlapping area of the touch sensing electrode and the touch driving electrode indents to from an indentation part to reduce the facing area between the touch sensing electrode and the touch driving electrode, so as to reduce the sensing capacitance formed at the overlapping area; in order to solve the problem of the increase of resistance of the touch sensing electrode because of the reduction of the area of the indentation part, the area at the overlapping area between the touch sensing electrode and the common electrode is expanded outwards to form an expansion part to reduce the resistance of the touch sensing electrode, thereby enabling the resistance of the entire touch sensing electrode to meet the requirement of the touch screen.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

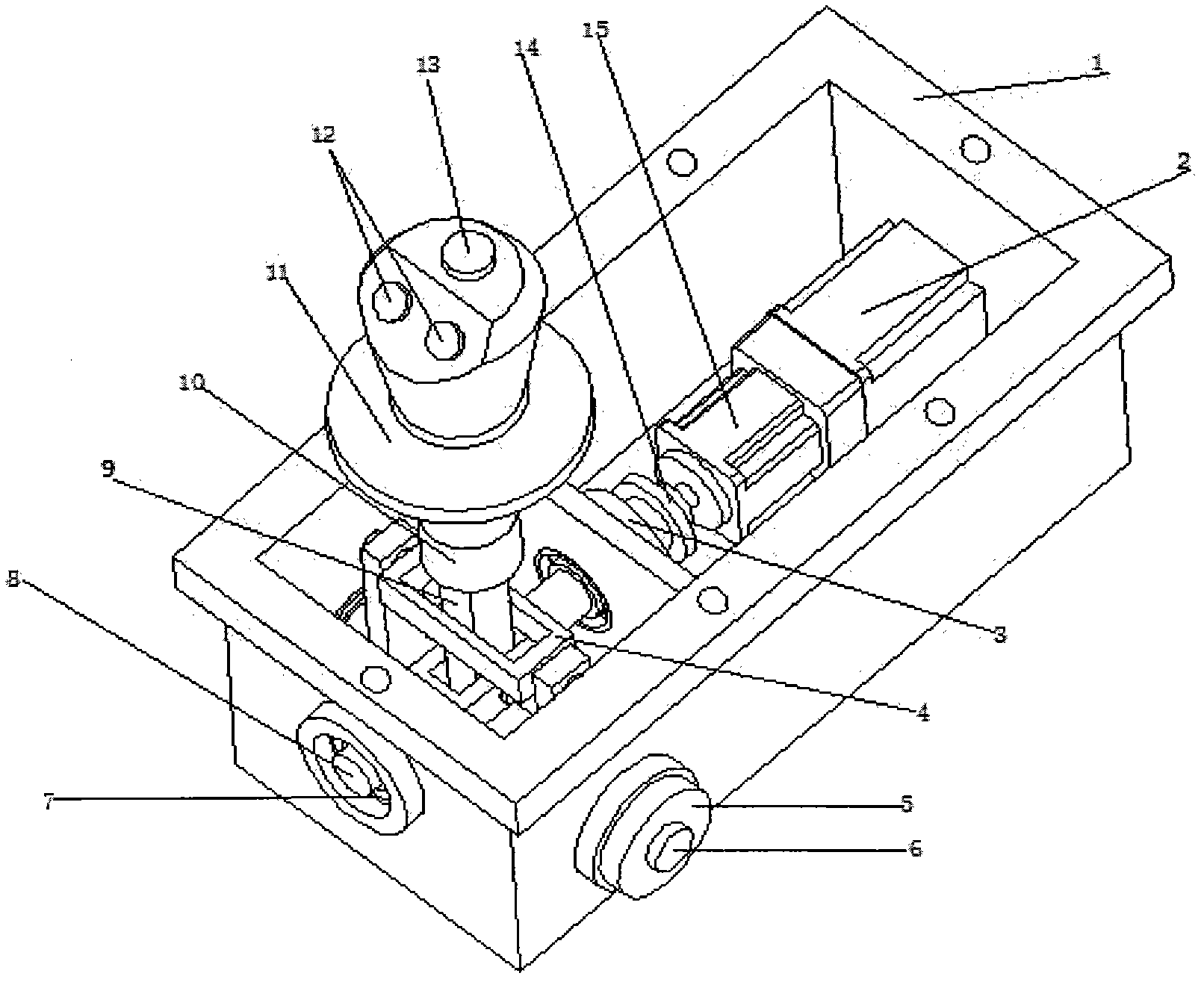

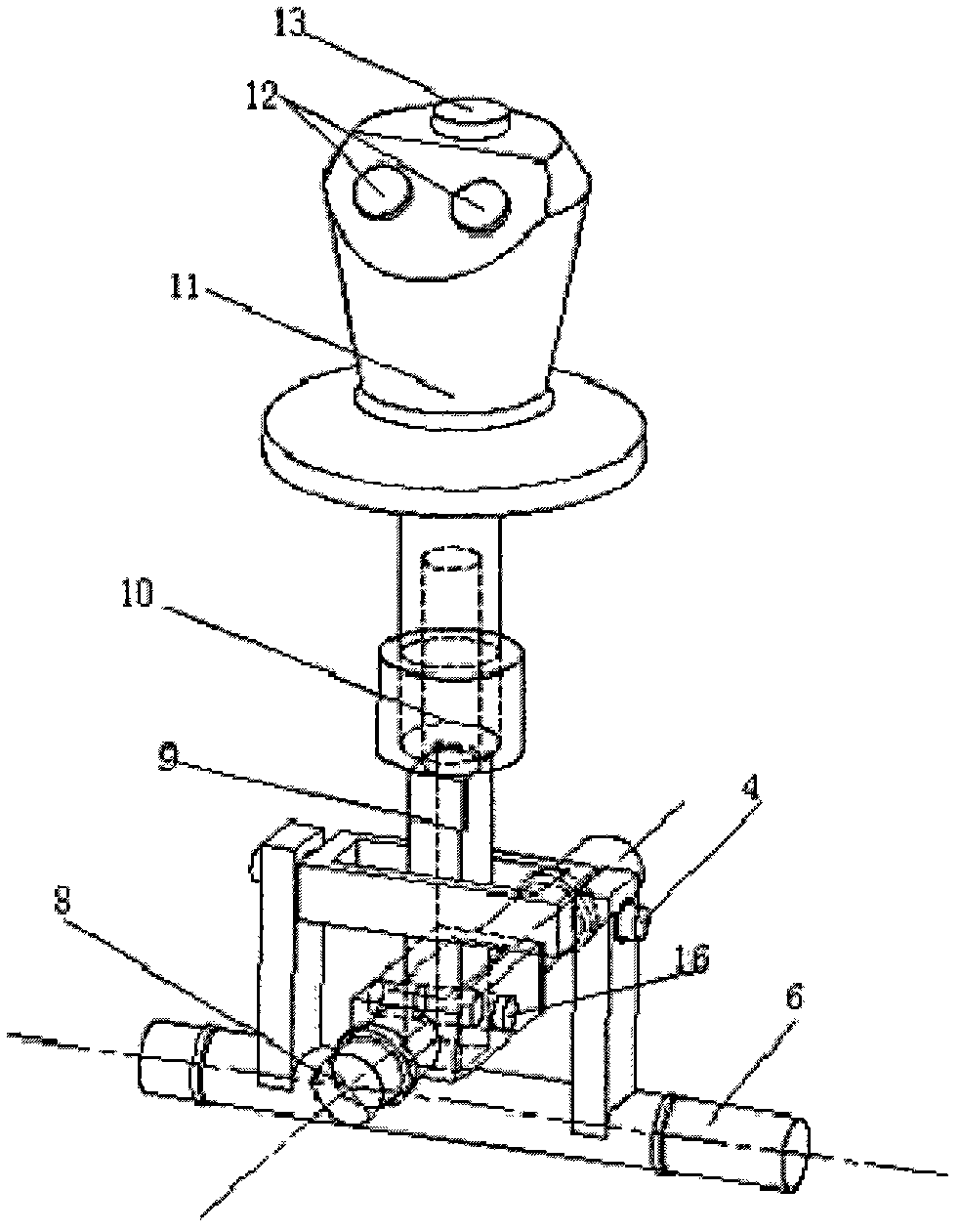

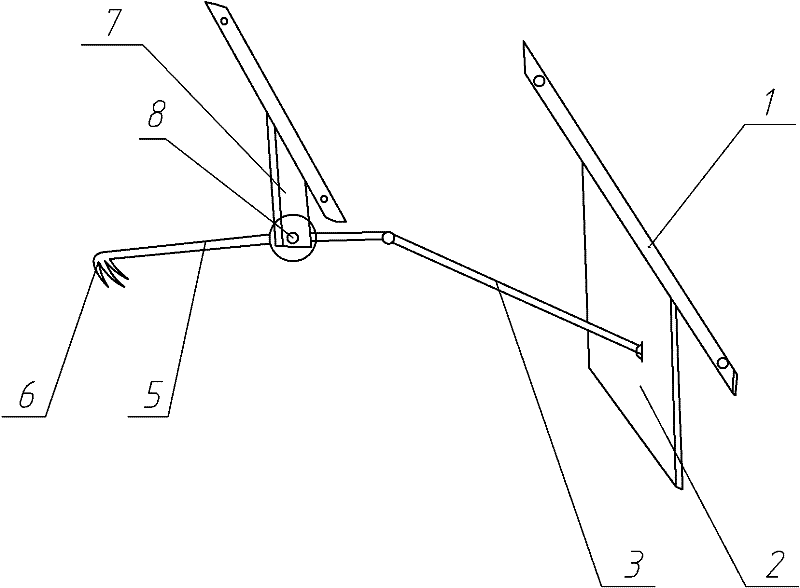

Automobile-line-control-system-based control lever device integrating steering, braking and speed change

InactiveCN102530050AGuaranteed auto-correction functionGuaranteed resistanceHand leversHand actuated initiationsTransverse axisCar driving

The invention relates to an automobile-line-control-system-based control lever device integrating steering, braking and speed change. The steering, speed change and braking of an automobile can be controlled simultaneously by a control lever. The conventional complex control mechanism on the automobile can be replaced by the control lever device, a comfortable driving space is provided for drivers, and the automobile is easy to drive and control. According to the control lever device, a cross shaft 6 and a longitudinal shaft 8 which are orthogonalized are arranged in a box body 1; two straight plates are arranged on the cross shaft 6; small cross grooves 4 are formed in small holes of the straight plates; a torsional spring 18 and an angular transducer 5 are arranged at the outer end of the cross shaft 6; a rectangular through groove is formed on the longitudinal shaft 8; and an angular transducer 3, a coupler 14, a speed reducer 15 and a road feel motor 2 are arranged at the outer end of the longitudinal shaft; a control lever sliding sleeve 11 can slide along a control lever 9 in a vertical direction and is locked by a locking nut 10; a button is arranged on the top of the control lever sliding sleeve 11, and two buttons are arranged on the lateral surface of the control lever sliding sleeve 11; and the control lever 9 and the control lever sliding sleeve 11 have a hollow structure.

Owner:JILIN UNIV

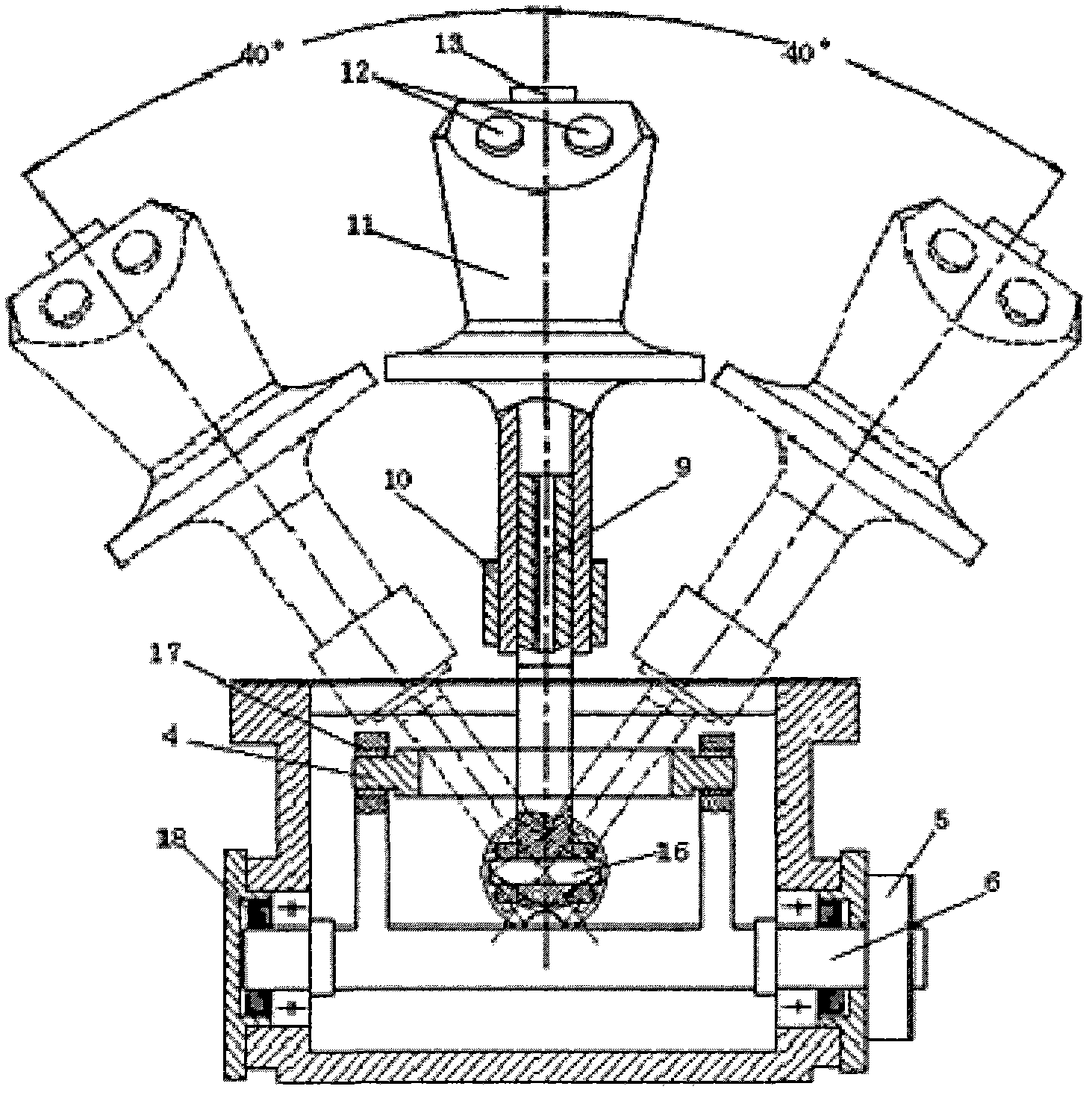

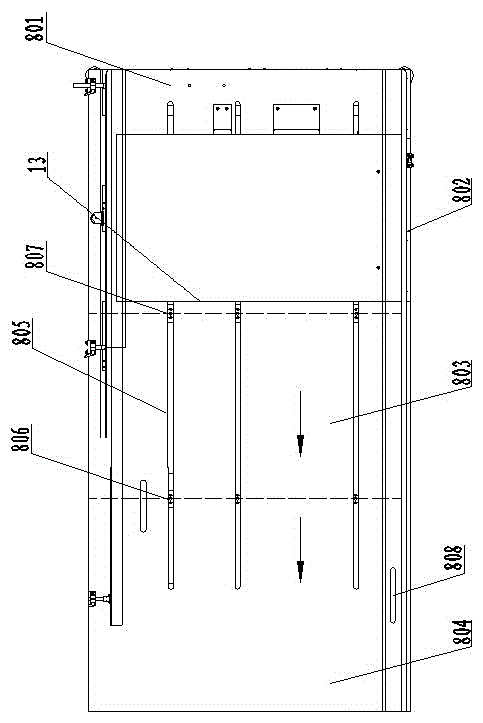

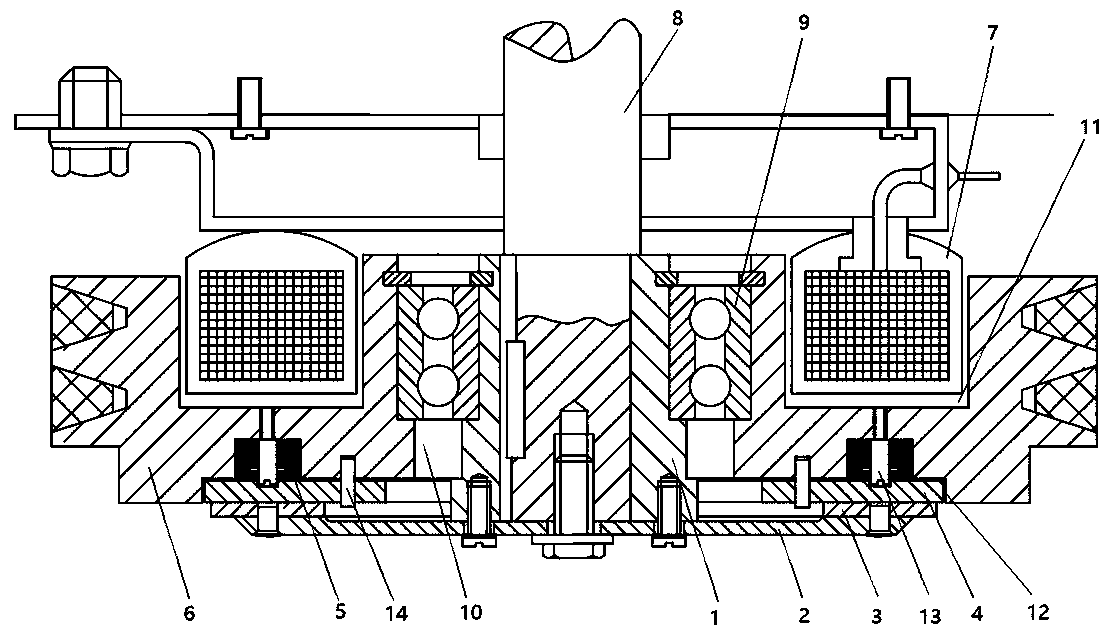

Liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions

ActiveCN108330233AEnsure structural stabilityGuaranteed operational safetyExhaust gas handlingRecycling and recovery technologiesMetallurgyIron industry

The invention discloses a liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions. The system comprises a molten slag buffer-storage and flow control unit, a granulation unit, a mobile bed unit and an afterheat utilization unit; the molten slag buffer-storage and flow control unit is arranged at the upper part ofthe granulation unit and is used for buffer-storage of the liquid molten slag and controlling the flow rate and speed of the liquid molten slag falling to the granulation unit; the granulation unit is used for granulating the falling liquid molten slag; the mobile bed unit is arranged at the lower part of the granulation unit and is used for cooling and temporarily storing the granulated molten slag; hot air inside the granulation unit and the mobile bed unit communicates with the afterheat utilization unit; and the afterheat utilization unit comprises a hot air flue, a primary dust collector, an afterheat boiler, a secondary dust collector, an exhaust fan and a chimney which are arranged in sequence. The system disclosed by the invention does not use water resources, is free of environmental pollution, can effectively recycle high-quality afterheat resources contained in the high-temperature liquid molten slag, and can meet the urgent requirements of energy conservation and emissionreduction of the present steel and iron industry.

Owner:XI AN JIAOTONG UNIV

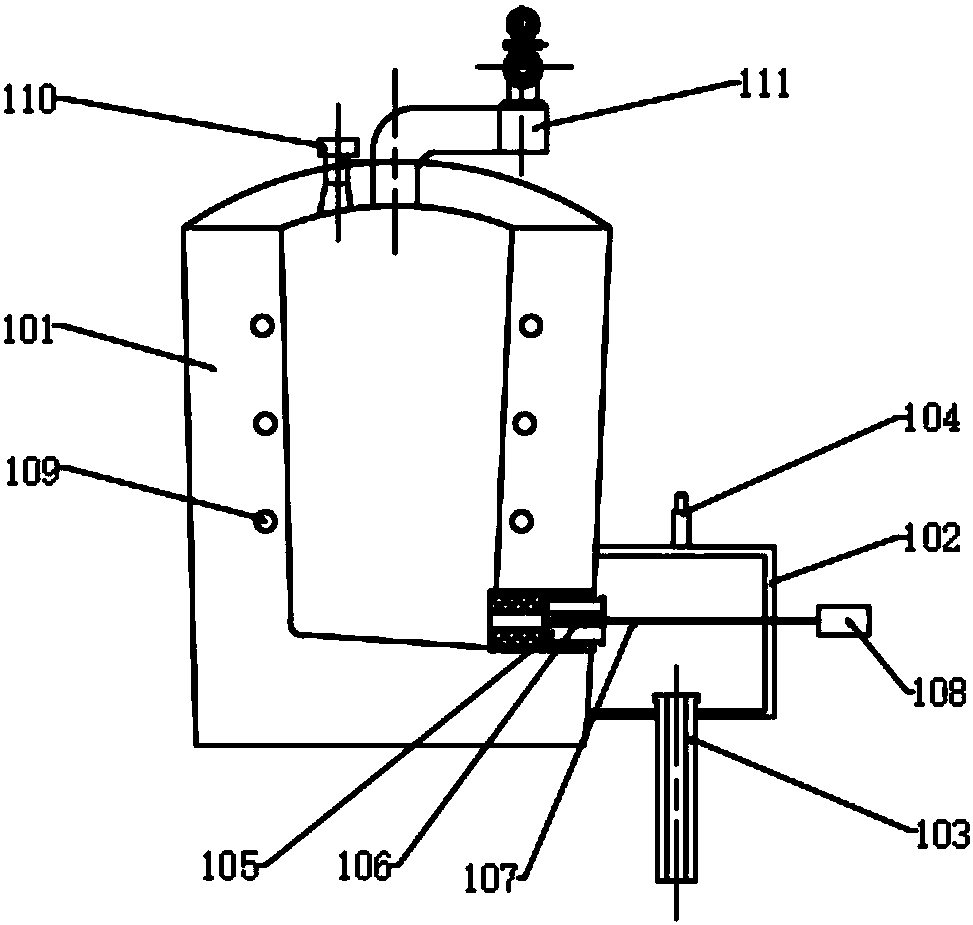

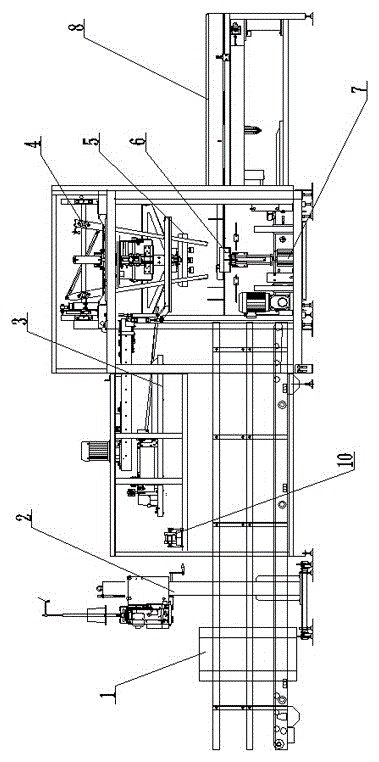

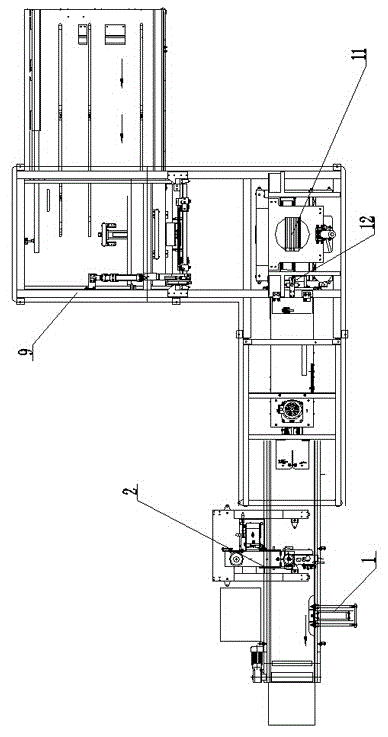

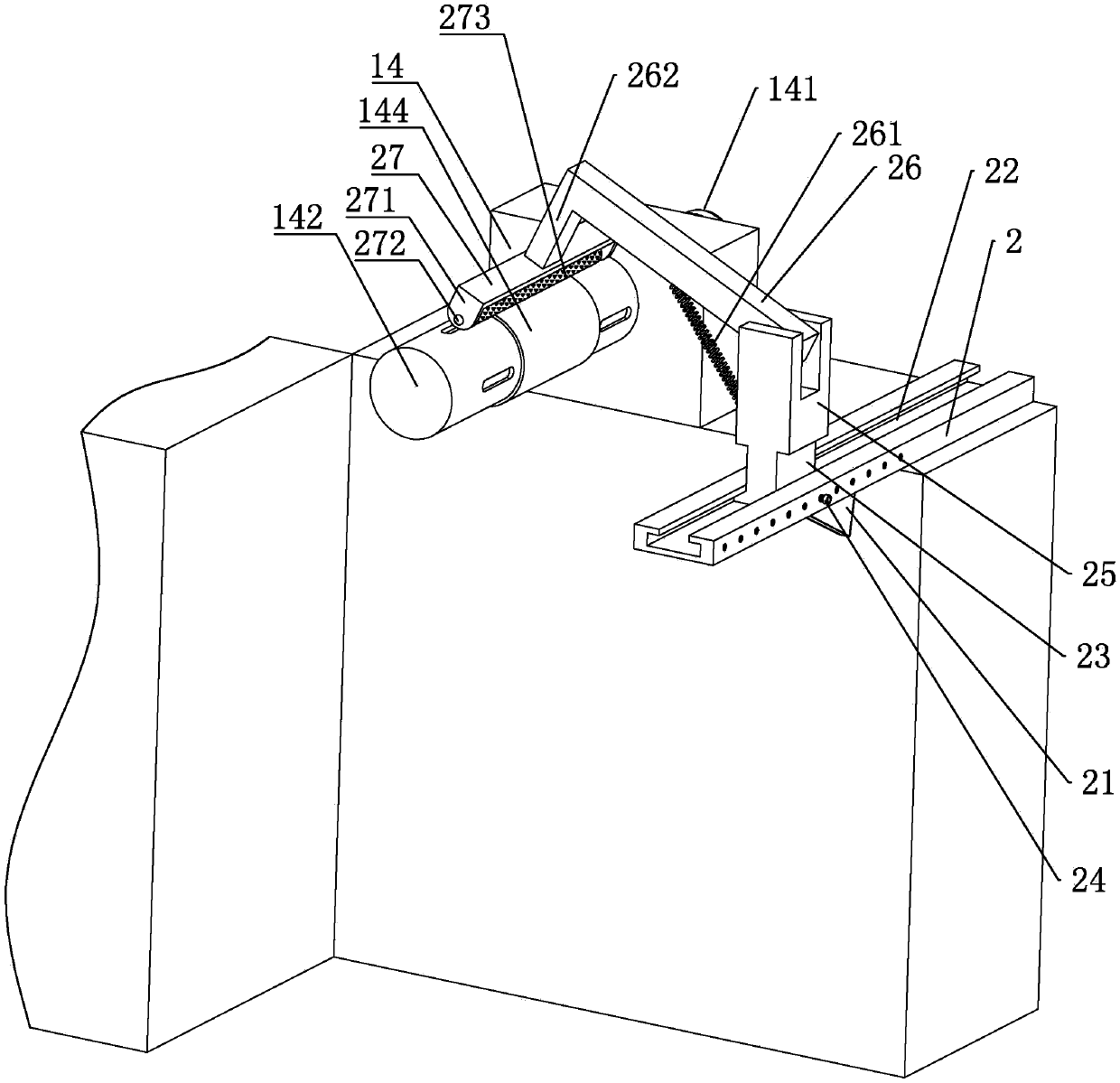

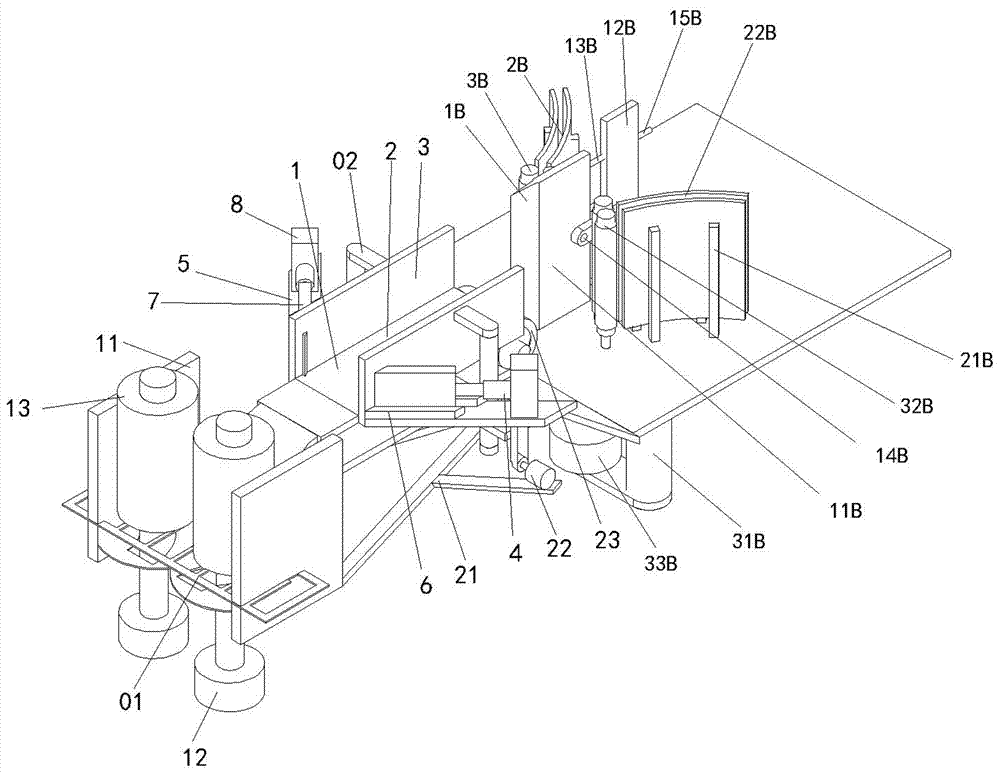

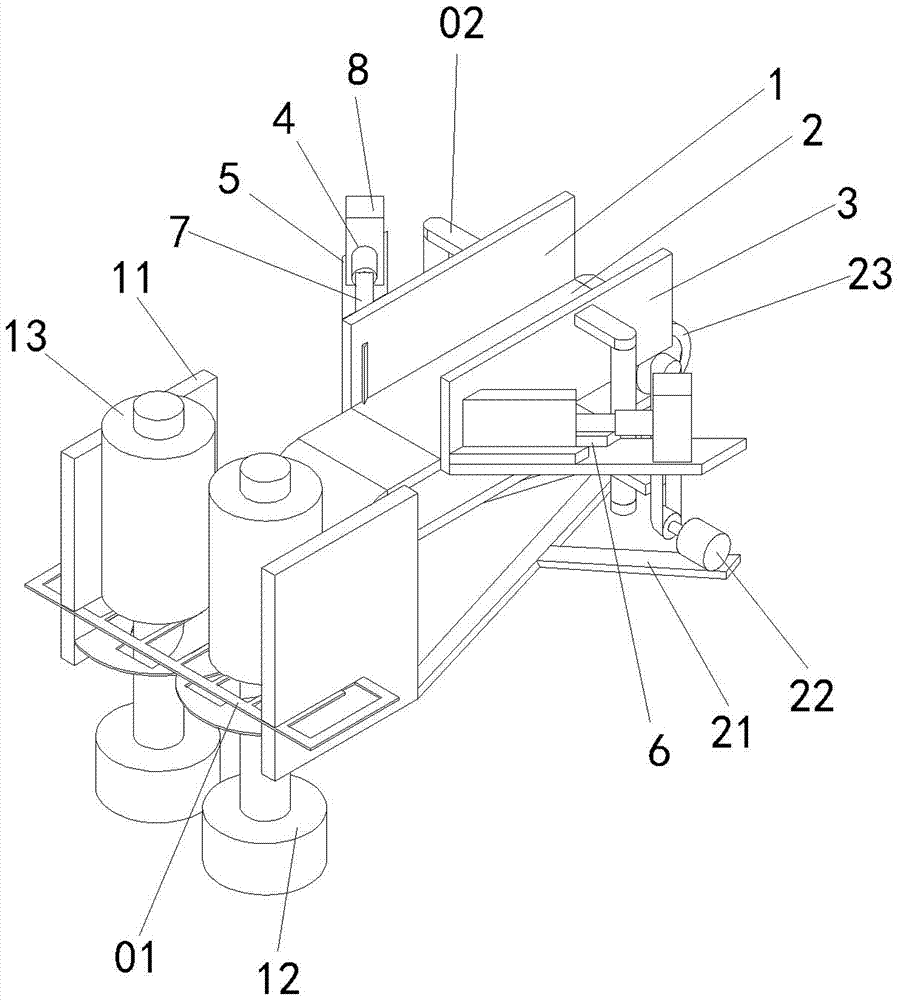

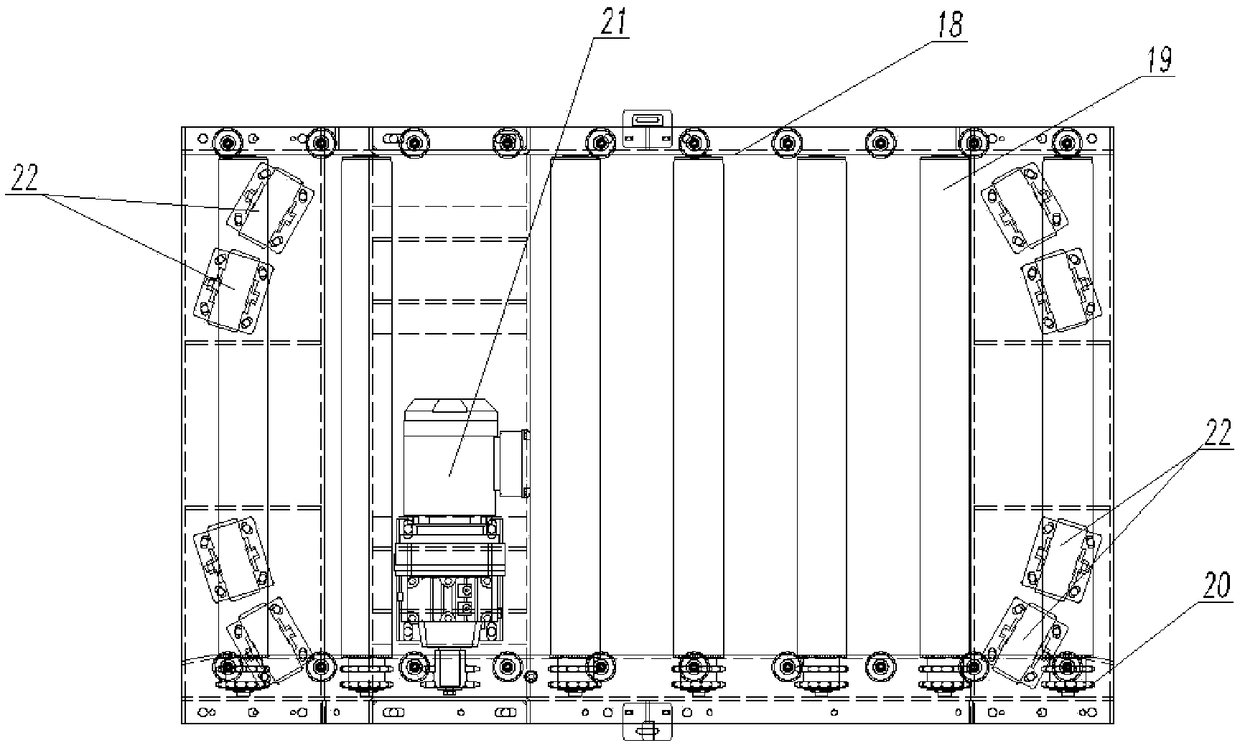

Full-automatic bagging system

ActiveCN105109753AReduce labor intensitySimple structural designWrapper twisting/gatheringProcess engineeringMechanical engineering

The invention belongs to the technical field of packing equipment, and particularly discloses a full-automatic bagging system. The full-automatic bagging system comprises a bag supply system, a bag suction system, a filling system, an automatic labeling system and a conveying system, which are connected in sequence, wherein the bag supply system comprises a bag supply platform and a packing bag stripping device which is arranged on the bag supply platform; the bag suction system comprises a packing bag suction device and a faulted bag elimination device; the filling system comprises a bag opening device, a filling device and a packing bag shaping device; the automatic labeling system comprises a label suction mechanism and a label supply mechanism; and the conveying system comprises an automatic packing bag leading-in device, a load balance compensation conveyor and an automatic bag sewing and pushing device. The full-automatic bagging system is reasonable in structure, high in degree of automation, and high in production efficiency.

Owner:河南济开电器有限公司

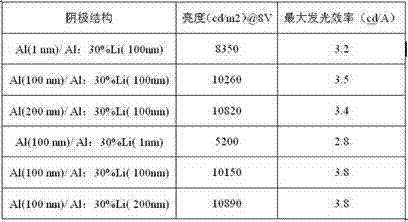

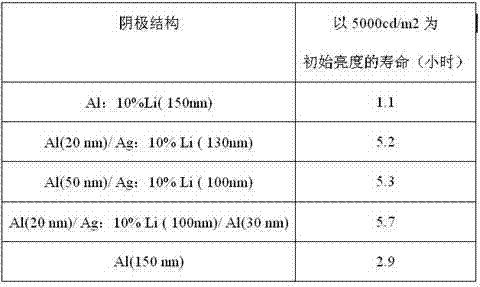

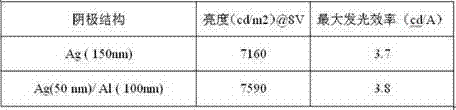

Organic electroluminescent device having multilayer cathode

InactiveCN102394275AEnhanced electron injection capabilityReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsOrganic electroluminescence

The invention relates to an organic luminescent device, especially to an organic luminescent device that enables luminous efficiency of the device to be improved and service life of the device to be prolonged by improving a cathode layer. More particularly, the invention relates to an organic electroluminescent device having a multilayer cathode. The device comprises: a glass substrate; an anode layer, which is on the glass substrate; an organic material layer, which is formed on the anode layer; an electron injecting layer, which is formed on the organic material layer; and a cathode layer, which is formed on the electron injecting layer. Besides, the cathode layer at least includes a first metal layer and a second metal layer or an alloy layer; and the second metal layer or the alloy layer at least contains a low-work function metal. According to the invention, an electron injection capability of the device can be effectively enhanced by improving a cathode, so that luminous efficiency of the device can be substantially improved. And moreover, the service life of the device will not be obviously reduced because an active metal component is used in the multilayer cathode.

Owner:涂洪明

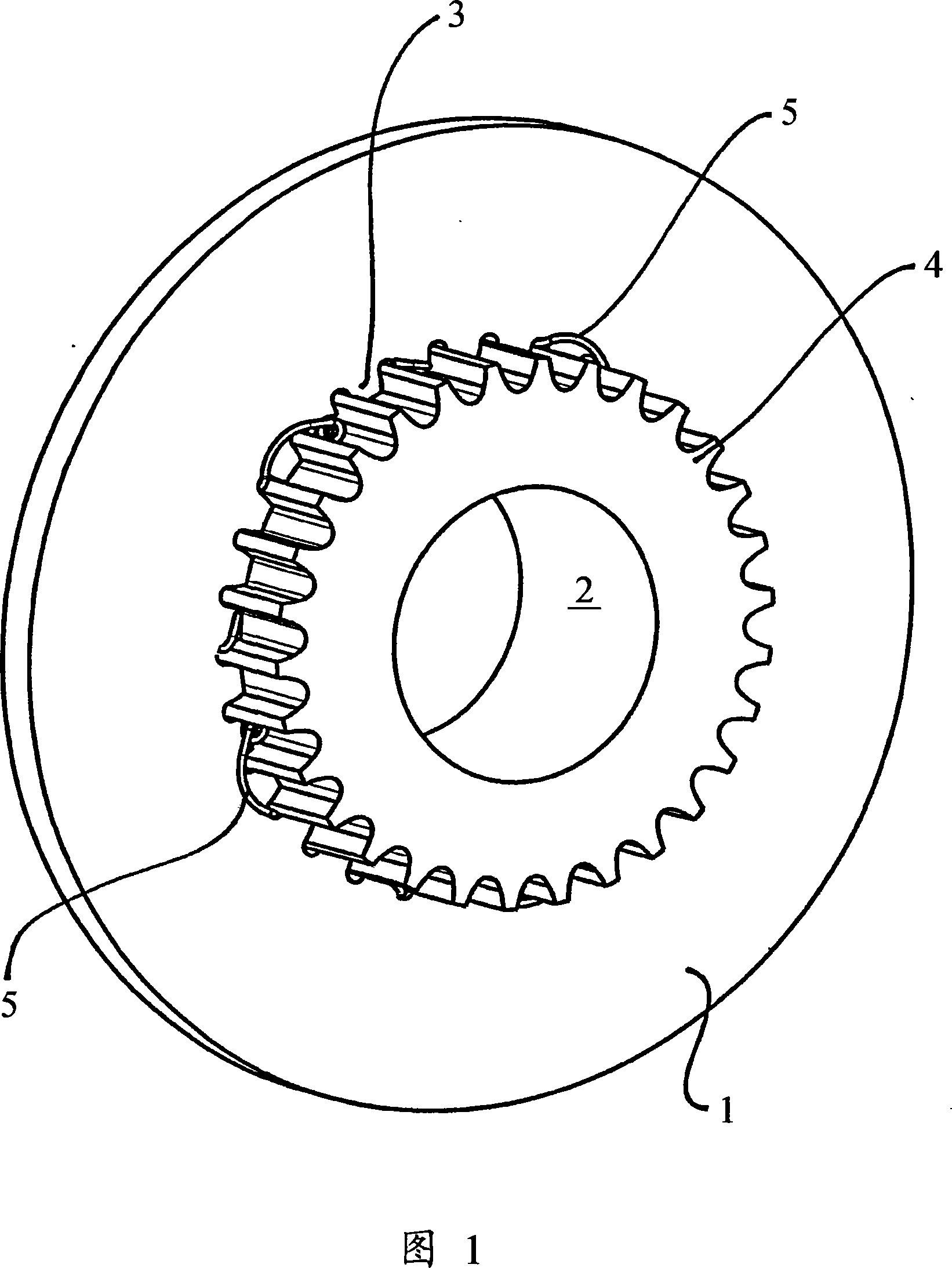

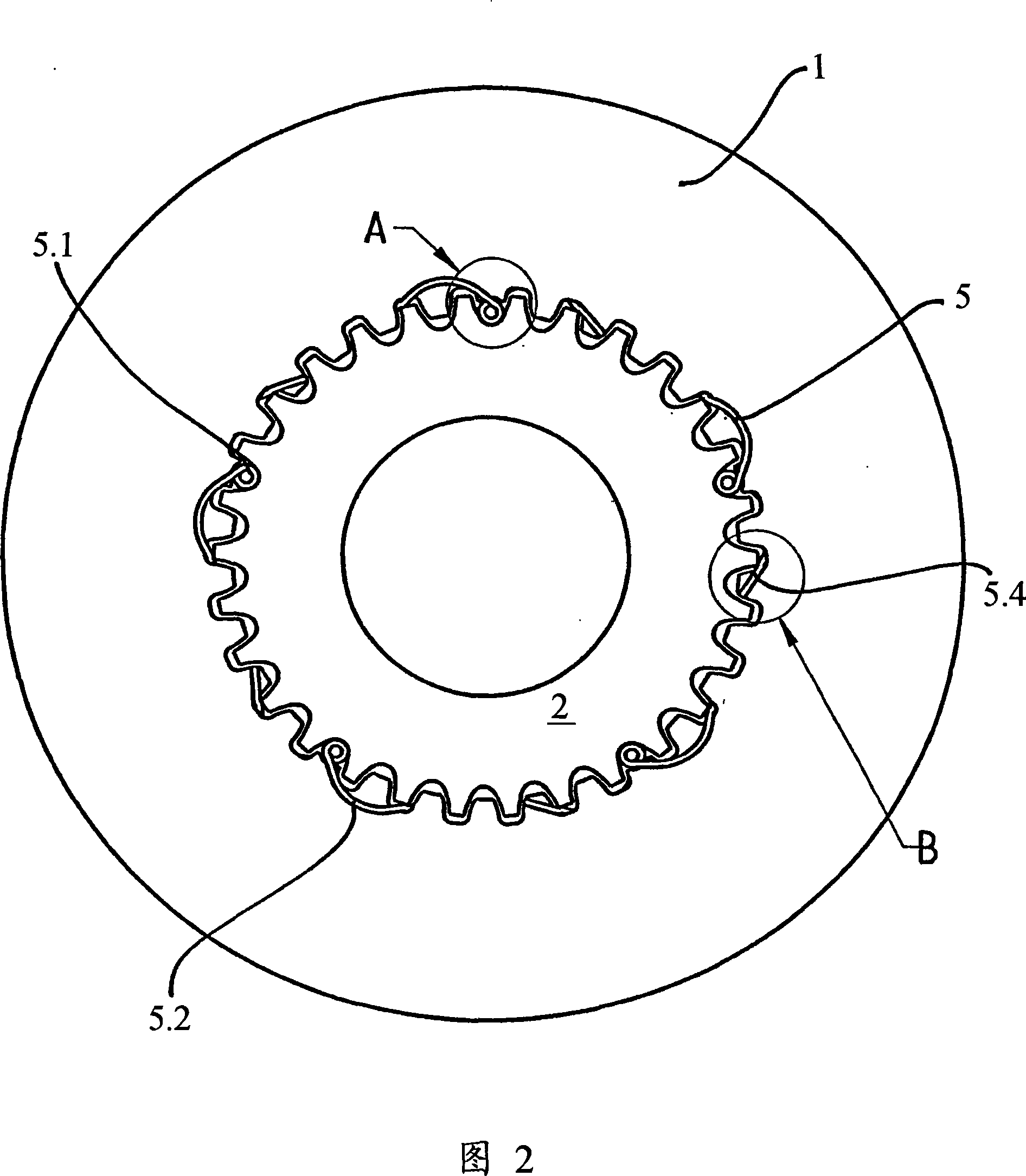

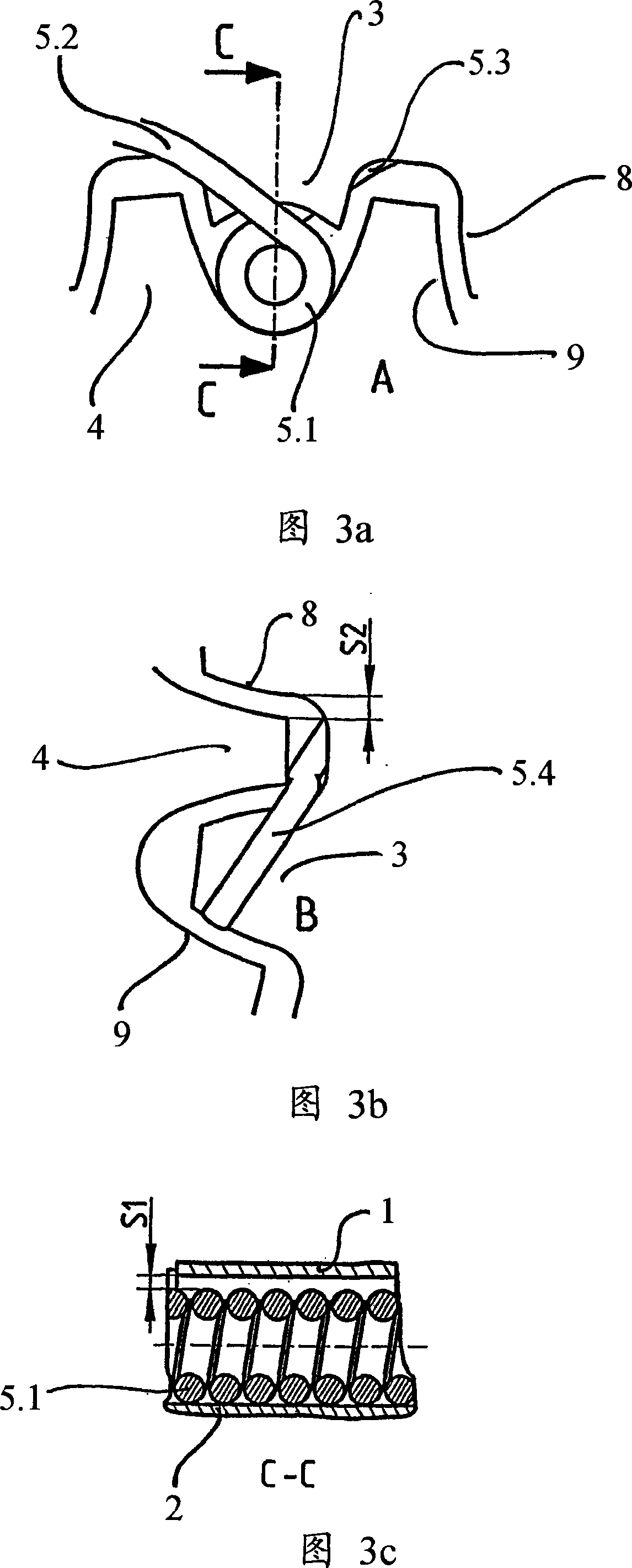

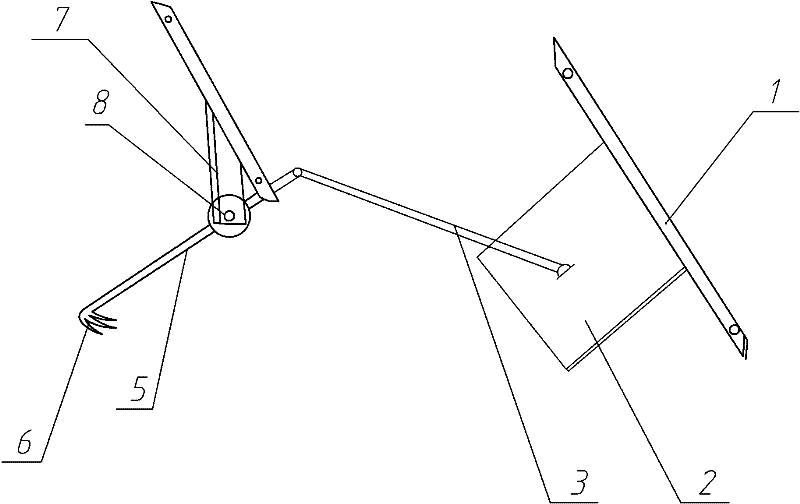

Disc brake and spacer element

The invention refers to a disc brake having a caliper encircling one or more brake discs, of which at least one brake disc is received slideably on a hub by means of intermeshing splines of both the brake disc and the hub, wherein spacer elements are placed between the brake disc and the hub which are arranged and configured so that contact between the flanks of the splines of the brake disc and the flanks of the splines of the hub is prevented exclusively for any radial movement of the brake disc relative to the hub.

Owner:HALDEX BRAKE PROD AB

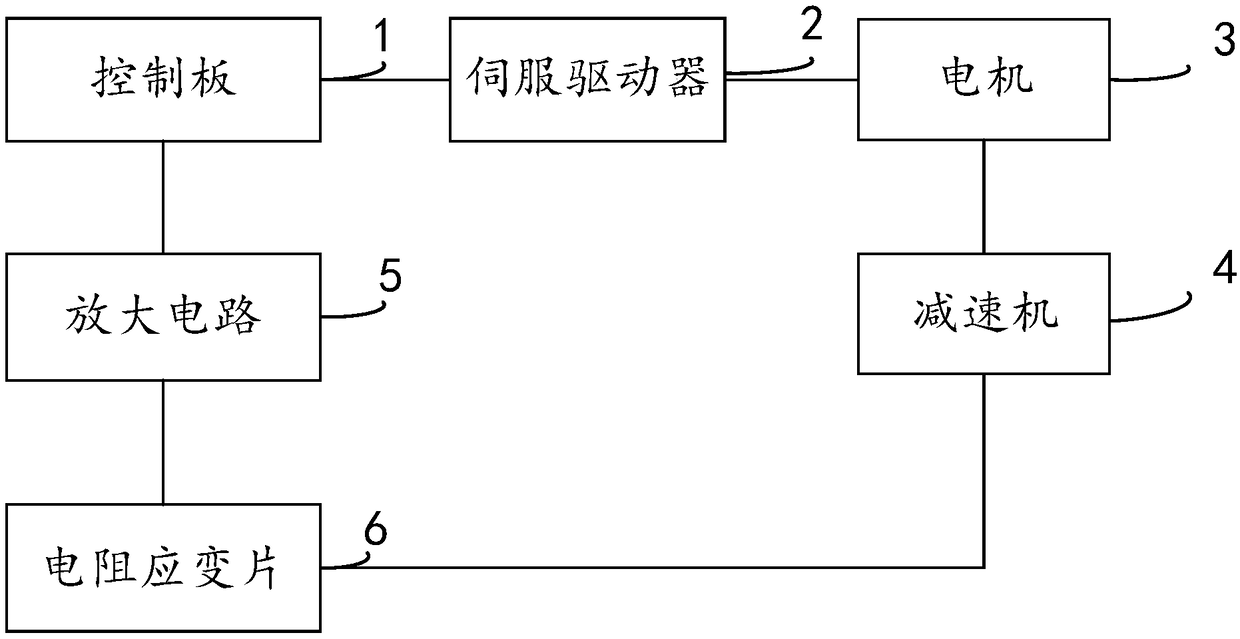

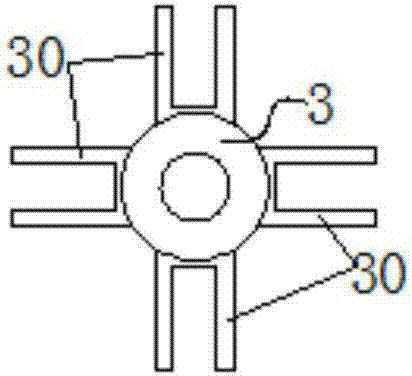

Isokinetic muscle force exercise system and control method thereof

PendingCN108553834AGuaranteed resistanceGuaranteed muscle strengthGymnastic exercisingMuscle forceReducer

The invention discloses an isokinetic muscle force exercise system and a control method thereof, and relates to the technical field of fitness equipment. The isokinetic muscle force exercise system ischaracterized in that a control board controls a servo driver to drive a motor and drive a reducer to rotate clockwise or counterclockwise; a resistance strain gauge is fixed to a revolving shaft ofthe reducer, and is used for converting the force of limbs on the revolving shaft into a voltage analog quantity through an amplifying circuit and transmitting the voltage analog quantity to the control board. The control method of the isokinetic muscle force exercise system comprises the following steps: when limb force is detected within the range of limb movement, the motor is controlled to accelerate to a required exercise speed according to a set exercise way; in a process of driving the revolving shaft to perform isokinetic exercise by the limbs, the motor provides equal reverse acting force for the limbs, so that the resistance load of limb movement is equal to the muscle force, thereby fulfilling the aim of isokinetic exercise and improving the exercise effect.

Owner:GUANGZHOU YIKANG MEDICAL EQUIP INDAL

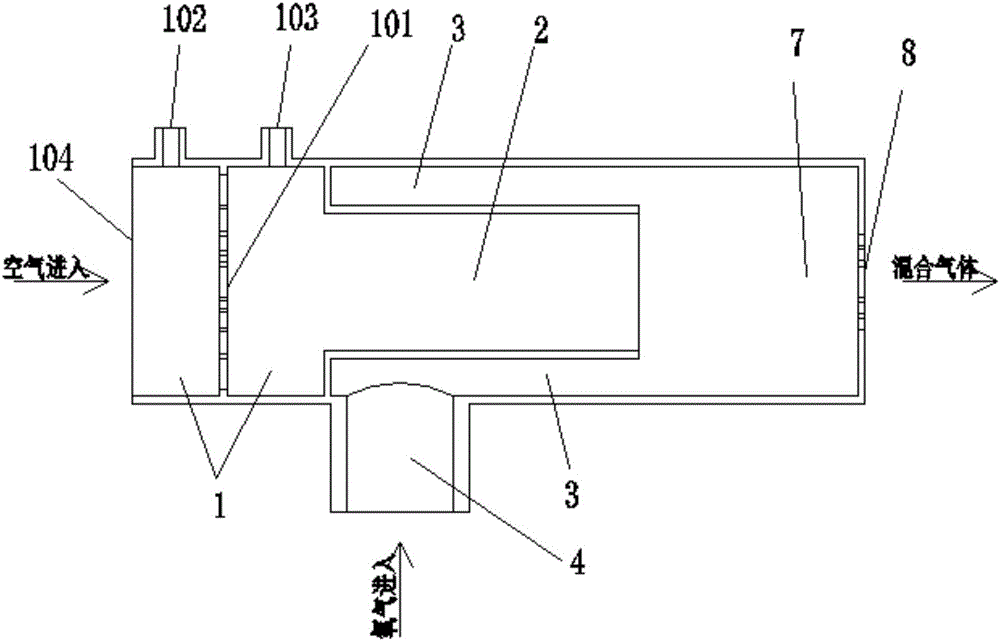

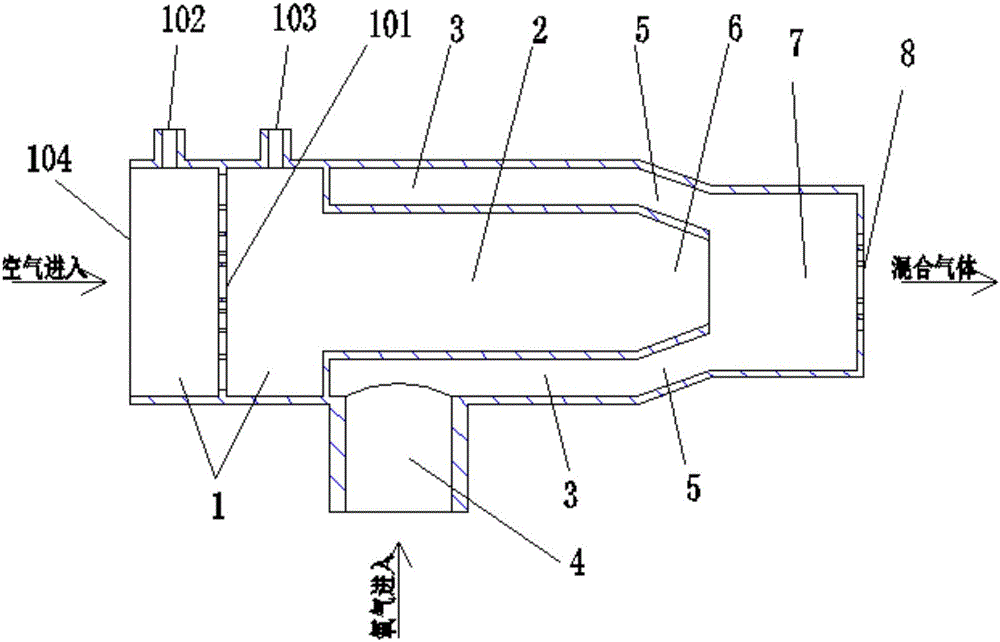

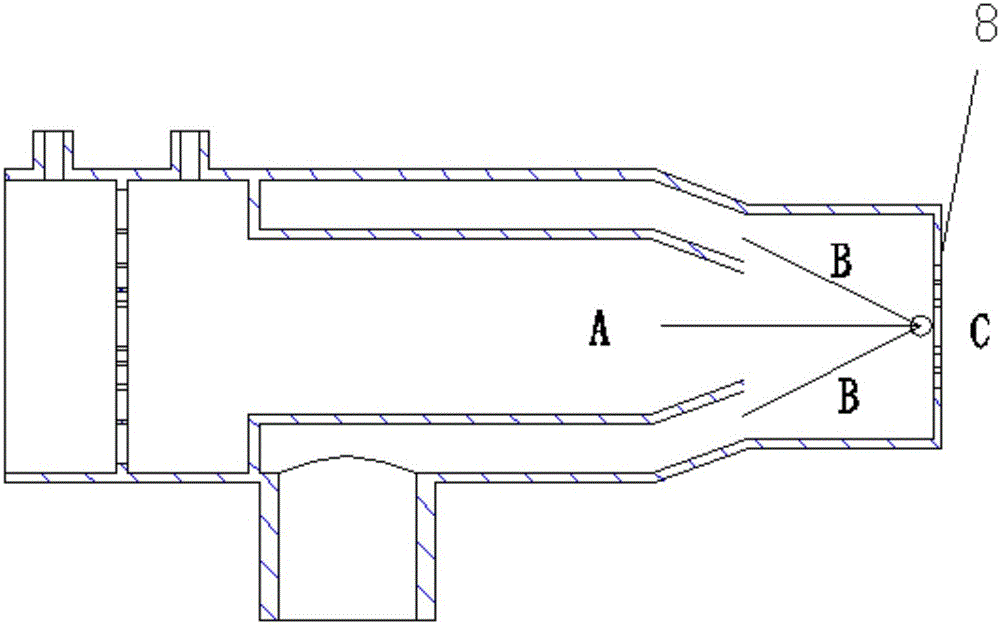

Air-oxygen mixing structure for breathing machine and breathing machine

The invention provides an air-oxygen mixing structure for a breathing machine and the breathing machine. The air-oxygen mixing structure comprises an air flow detecting cavity, an oxygen guide cavity, an air guide cavity and a mixing cavity. The inlet end of the air flow detecting cavity is an air inlet, and the outlet end of the air flow detecting cavity is communicated with the inlet end of the air guide cavity. A pressure-drop holed wall is arranged in the air flow detecting cavity, and a flow detecting port I and a flow detecting port II are respectively arranged on the front side and the rear side of the pressure-drop holed wall. The air guide cavity is a circular-ring-shaped cavity arranged on the periphery of the air guide cavity, and an oxygen inlet is formed in the outer wall of the oxygen guide cavity. The inlet end of an oxygen mixing guide cavity and the inlet end of an air mixing guide cavity are respectively communicated with the oxygen guide cavity and the air guide cavity, and the outlet ends of the two cavities are both communicated to the mixing cavity. The outlet end of the mixing cavity is provided with a mixing holed wall. The air-oxygen mixing structure is used for the breathing machine and has the advantages of being simple in structure, capable of preventing turbulent flows from influencing flow detection and making gases be mixed fully.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

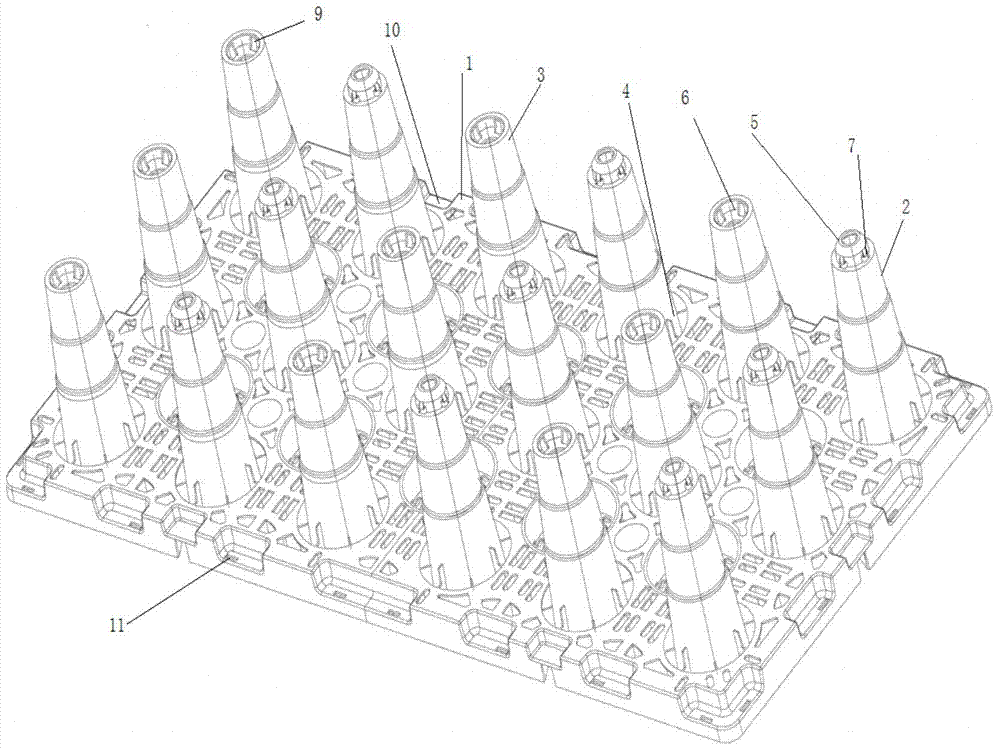

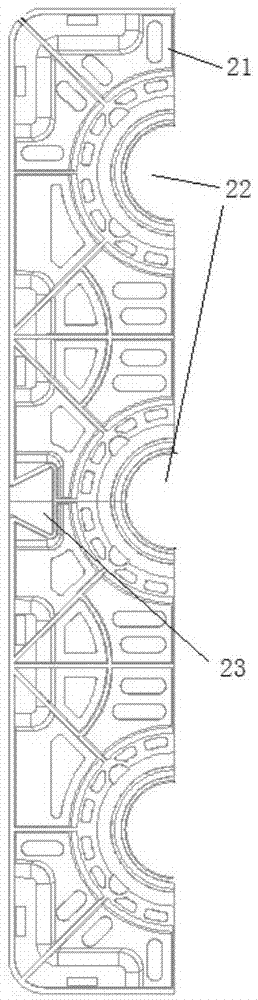

Plastic assembling module for rainwater collection and storage

InactiveCN104746631AReduce construction costsSmooth water flowSewerage structuresGeneral water supply conservationRainwater harvestingEngineering

Owner:江阴市星宇塑胶有限公司

Safety device for automobile

InactiveCN102358269AIncrease resistanceProtection securityBraking element arrangementsEngineeringAutomobile safety

The invention discloses a safety device for an automobile. The device comprises a driving part and a braking part, and is characterized in that: the driving part comprises a fixed part, a hanging plate and a connecting rod which are fixedly connected with an automobile chassis; one end of the hanging plate is hinged with the fixed plate; one end of the connecting rod is hinged with the hanging plate; the braking part comprises a mounting bracket, a brake ratchet and a cross rod which are fixedly connected with the automobile chassis; the brake ratchet is fixedly connected with one end of the cross rod, and the head part of the brake ratchet is downward; the middle part of the cross rod is connected with the mounting bracket by a fixed shaft; the other end of the cross rod is hinged with the other end of the connecting rod; the cross rod can oscillate about the fixed shaft under the drive of the connecting rod; and the fixed shaft is parallel to a hinge shaft between the hanging plate and the fixed part and a hinge shaft between the connecting rod and the cross rod respectively. The device can effectively reduce damages caused by accidents.

Owner:陈世法

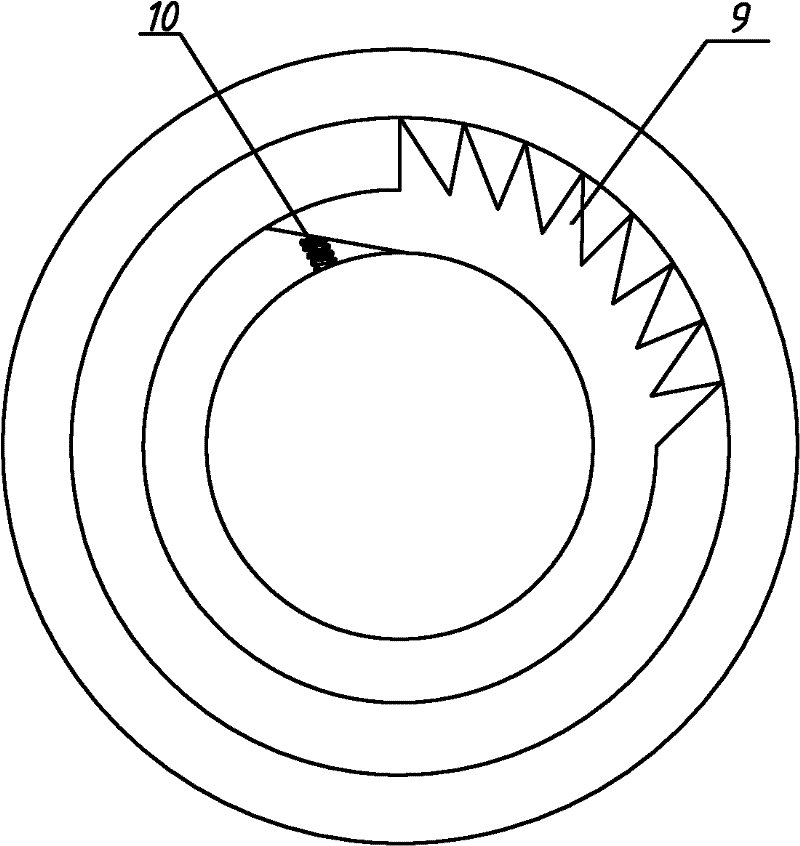

Novel seismic-isolation composite foundation and construction method thereof

ActiveCN110512637AGuaranteed resistanceIncrease resistanceProtective foundationSoil horizonWhole systems

The invention provides a novel seismic-isolation composite foundation and a construction method thereof. The novel seismic-isolation composite foundation comprises an upper structure, a raft board, afiber solidified soil layer, a double-layer wrapping type geotechnical composite broken stone layer, a solidified soil layer and piles sequentially from top to bottom, a segment is reserved at the topof each pile for being buried into the solidified soil layer, the reserving height accounts for 30-60% of the height of the solidified soil layer, the raft board is placed at the center of the grouped piles and buried into the fiber solidified soil layer, and fiber solidified soil is laid at the top of the raft board. The bearing capacity of the novel seismic-isolation composite foundation can beimproved, uneven settlement of a whole system is relieved, horizontal displacement is effectively prevented and controlled, piercing damage of the pile tops is prevented, seismic energy is absorbed and dissipated, and a novel and efficient anti-seismic and high-strength seismic-isolation composite foundation is constituted.

Owner:SOUTHEAST UNIV

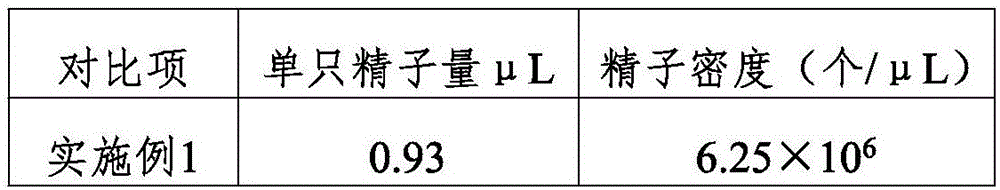

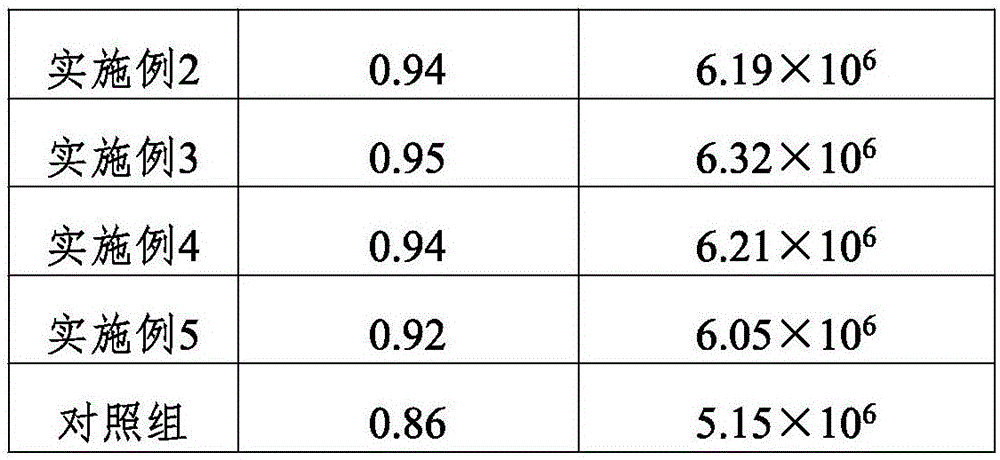

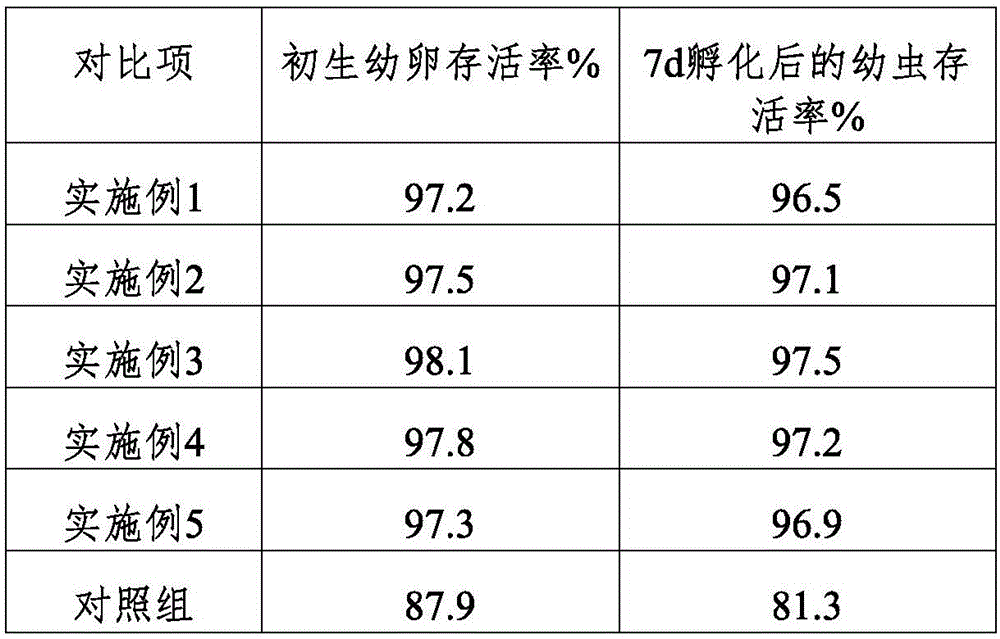

Wasp breeding method

The invention relates to the technical field of breeding, in particular to a wasp breeding method. The wasp breeding method comprises the following steps: (1) cultivating a queen bee; (2) feeding male bees; (3) breeding; (4) overwintering. According to the wasp breeding method, female bees are bred, feed is changed before mating, food materials and traditional Chinese medicines capable of promoting secretion of female hormone are added, the trace elements in the feed are supplemented, sufficient nutrition preparation is provided for mating, the resistance of the queen bee is effectively guaranteed, the survival rate of newly born bee eggs is effectively increased and reaches 98.1 percent, and the survival rate of young eggs after 7 days reaches 97.5 percent; feed is changed for the male bees before mating, the secretion of male hormone is effectively promoted, the sperm number of the male bees is increased, the sperm quality of the male bees is improved, the insemination rate is effectively increased during mating, guarantee is provided for increasing the survival rate of the young eggs, and the sperm number of single male bee reaches 0.95 [mu]L.

Owner:黔西南州天麒绿色产业开发有限公司

Biological organic acid composite additive for Litopenaeus vannamei and preparation method thereof

ActiveCN103704505AImprove the environmentIncrease food intakeAnimal feeding stuffDiseaseCalcium formate

The invention discloses a biological organic acid composite additive for Litopenaeus vannamei and a preparation method thereof. The composite additive is prepared from the following raw materials in parts by weight: 15-20 parts of lactic acid C3H6O3, 12-18 parts of fumaric acid C4H4O4, 10-16 parts of malic acid C4H6O5, 8-14 parts of calcium formate C2H2O4Ca, 16-20 parts of hawthorn powder, 12-16 parts of dark plum, 7-12 parts of schisandra chinensis and 0-4 parts of bentonite. The preparation method is as follows: weighing the components at a weight ratio; crushing the components, and uniformly mixing the components in a mixer, wherein the adding sequence is as follows: the bentonite, the hawthorn powder, the dark plum and the schisandra chinensis are firstly added, and the other components are added. The acidifier adopted by the biological organic acid composite additive disclosed by the invention can be used for effectively perfecting the environmental pH value in the digestive tract of Litopenaeus vannamei for a long time, cooperatively sterilizing and inhibit bacteria, promoting ingestion and digestion functions, effectively protecting the digestive tract health of the Litopenaeus vannamei and improving the breeding survival rate of the Litopenaeus vannamei. The biological organic acid composite additive disclosed by the invention has an obvious prevention and treatment effect on bacterial digestive system diseases in the existing Litopenaeus vannamei breeding.

Owner:ZHEJIANG YUEHAI FEED

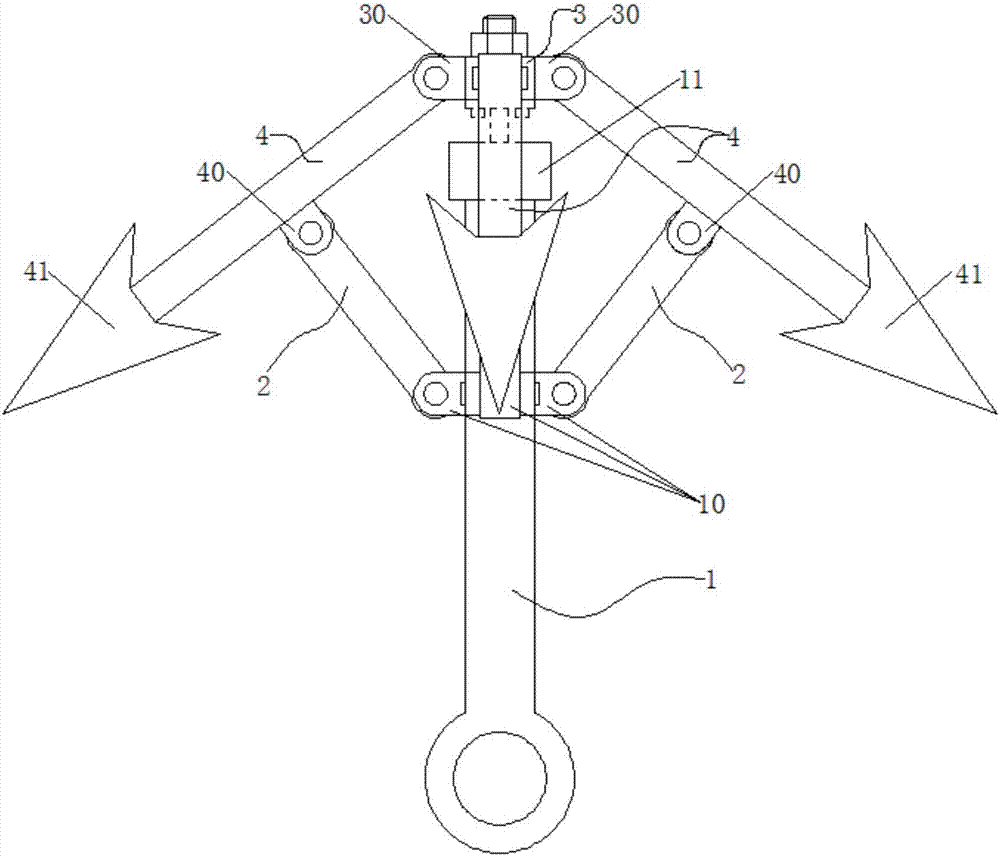

Boat anchor

The invention discloses a boat anchor comprising an anchoring rod, a supporting rod, a connecting disc and a hanging rod. A first hinging seat is arranged on the anchoring rod, an electric pushing rodis arranged at the front end of the anchoring rod, and the front end of the electric pushing rod is connected with the middle of the connecting disc. A second hinging seat is arranged on the connecting disc, a third hinging seat is arranged in the middle position of the hanging rod, one end of the supporting rod is hinged to the first hinging seat, and the other end of the supporting rod is hinged to the third hinging seat. The hanging rod is hinged to the second hinging seat. Adjustment of the opening angle of an anchor tip hook is achieved, and thus the anchor tip hook can adapt to different riverbed or seabed environments.

Owner:马鞍山海明船舶配件有限公司

Diesel engine drag reduction starting device

ActiveCN108999736AEnsure startReduce resistanceMachines/enginesEngine startersPower flowElectromagnetic clutch

The invention discloses a diesel engine drag reduction starting device. The diesel engine drag reduction starting device comprises an electromagnetic clutch device and a control device, wherein the electromagnetic clutch device is connected between the free end of a crankshaft of a diesel engine and an accessory belt wheel and is used for controlling the transmission and disconnection of force between the crankshaft and the accessory belt wheel, the control device is used for controlling the electromagnetic clutch device, and the control device controls the electromagnetic clutch device to act, so that no force is transmitted between the crankshaft and the accessory belt wheel, and the non-starting stage of the diesel engine is controlled by the control device to reset the electromagneticclutch device to enable the transmission force between the crankshaft and the accessory belt wheel. According to the device, the resistance of partial accessories during starting of the diesel enginecan be reduced, the action of the electromagnetic clutch device is stable, the vibration influence is small, the large current of a storage battery can be prevented from being discharged, and the service life of the storage battery is prolonged.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

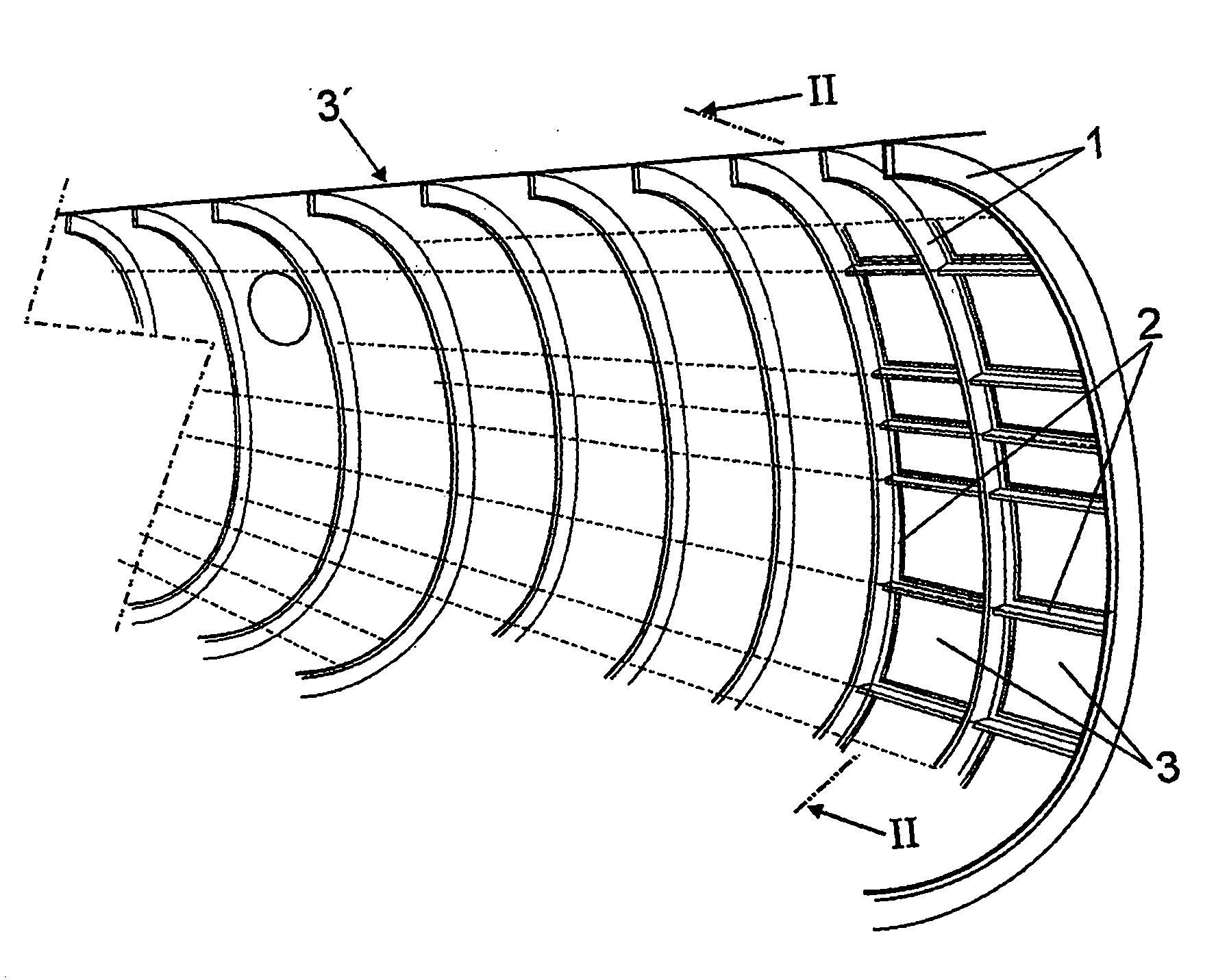

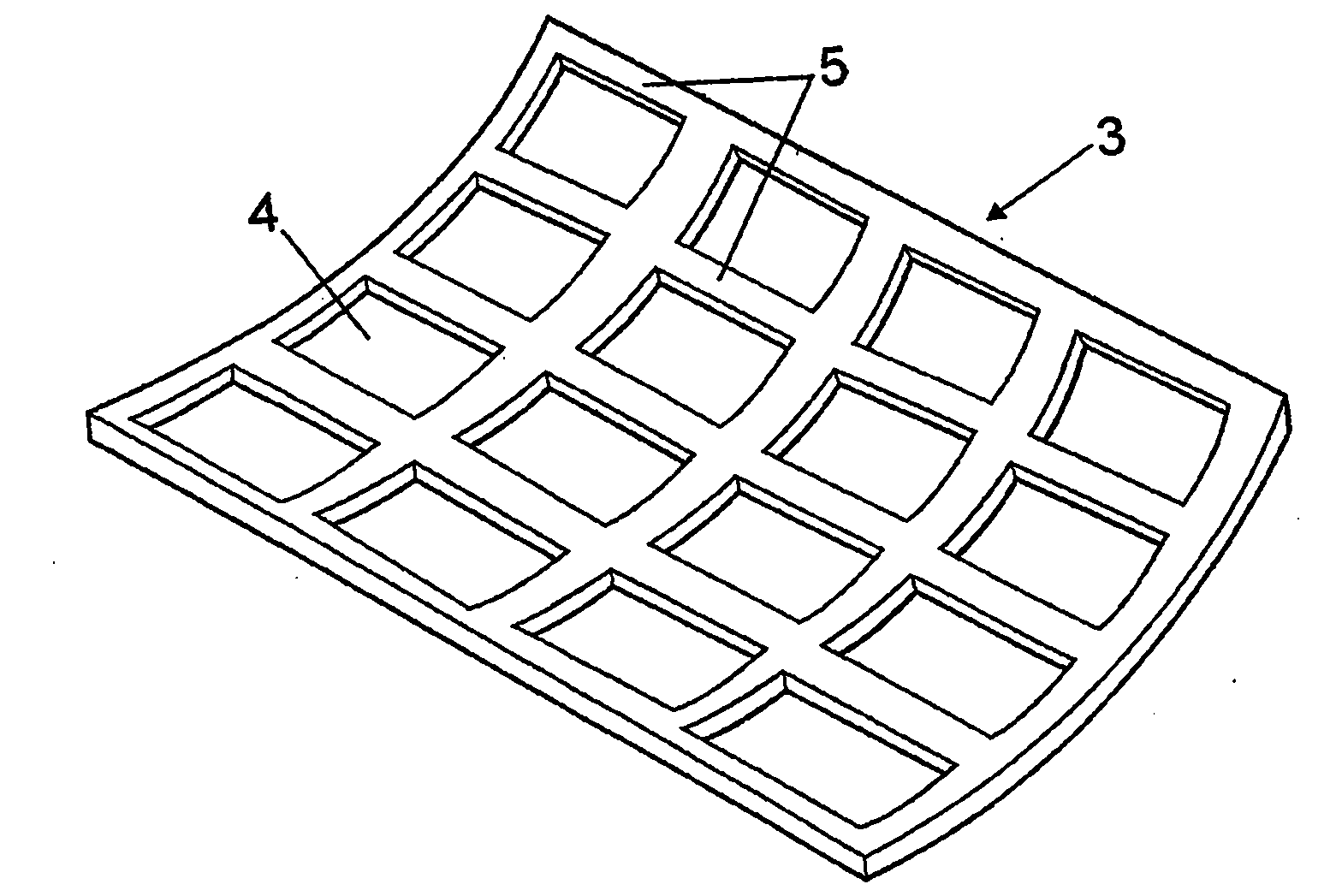

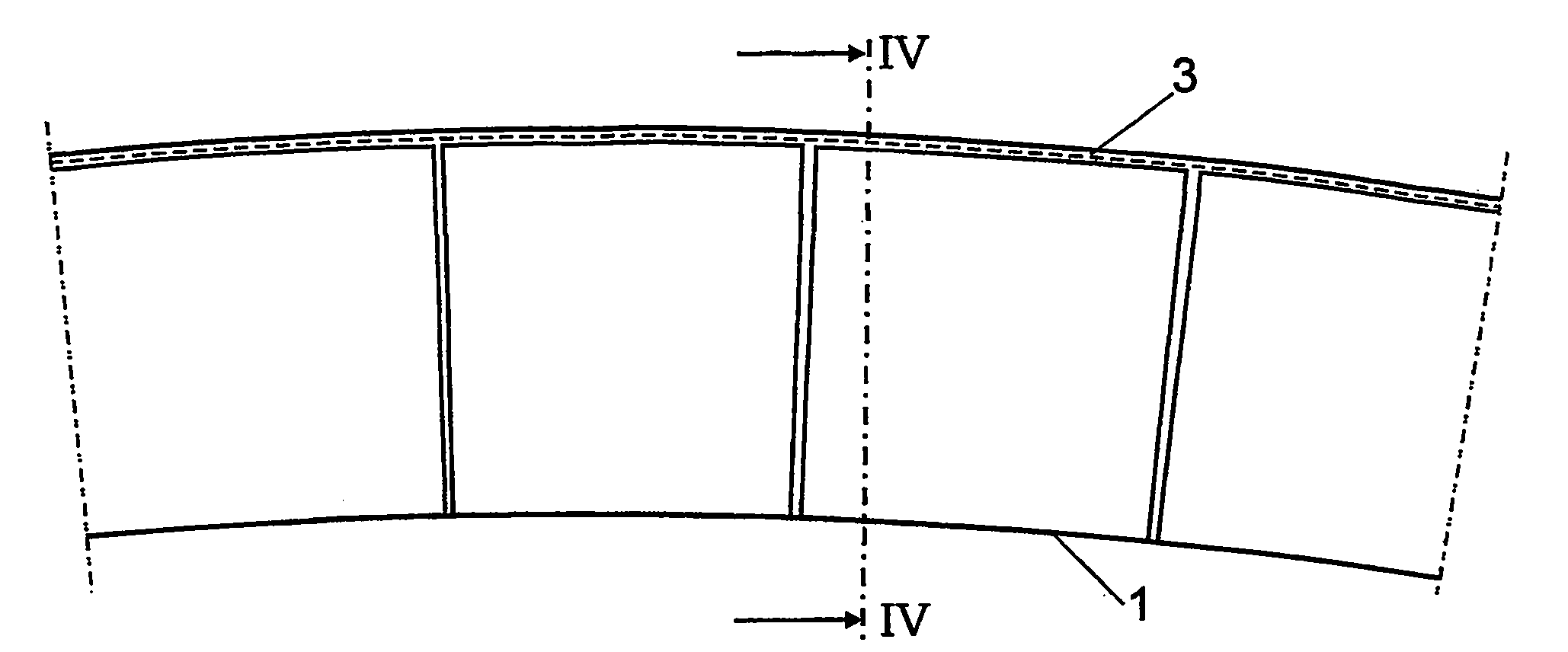

Coupling system intended for use between cladding and structural elements supporting same

ActiveCN102046465AEasy to cleanAvoid the risk of pressure leaksWingsFuselage bulkheadsCoupling systemEngineering

The invention relates to a coupling system for use between cladding and structural elements supporting same, said cladding comprising thin sheets (3) of alloys or composite materials. The facing surfaces of the sheets (3) and the structural elements (1 and 2) bear means for coupling said sheets and structural elements, which means are formed by male (6) and female (7) tongue-and-groove configurations provided along the length of at least part of the contact areas between the sheets and the structural elements.

Owner:FORPLAN METALES

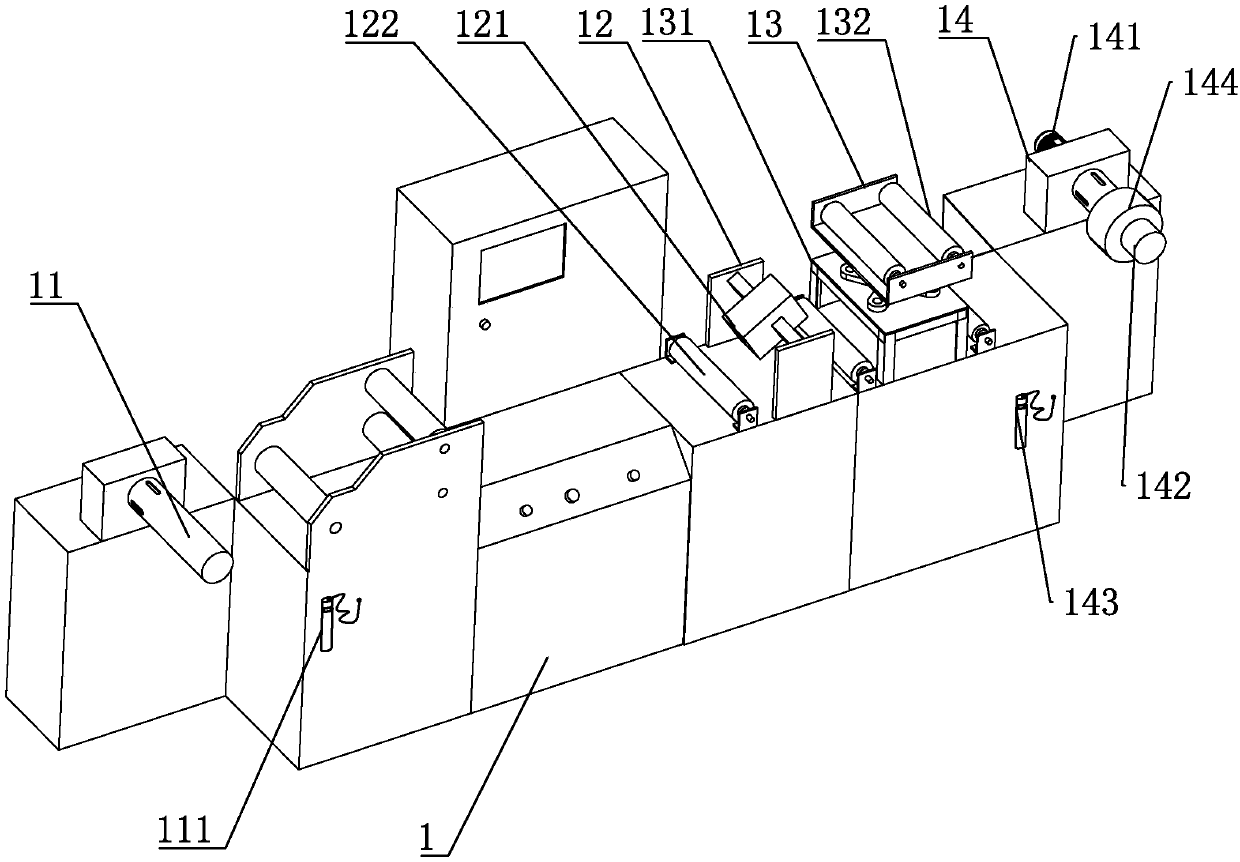

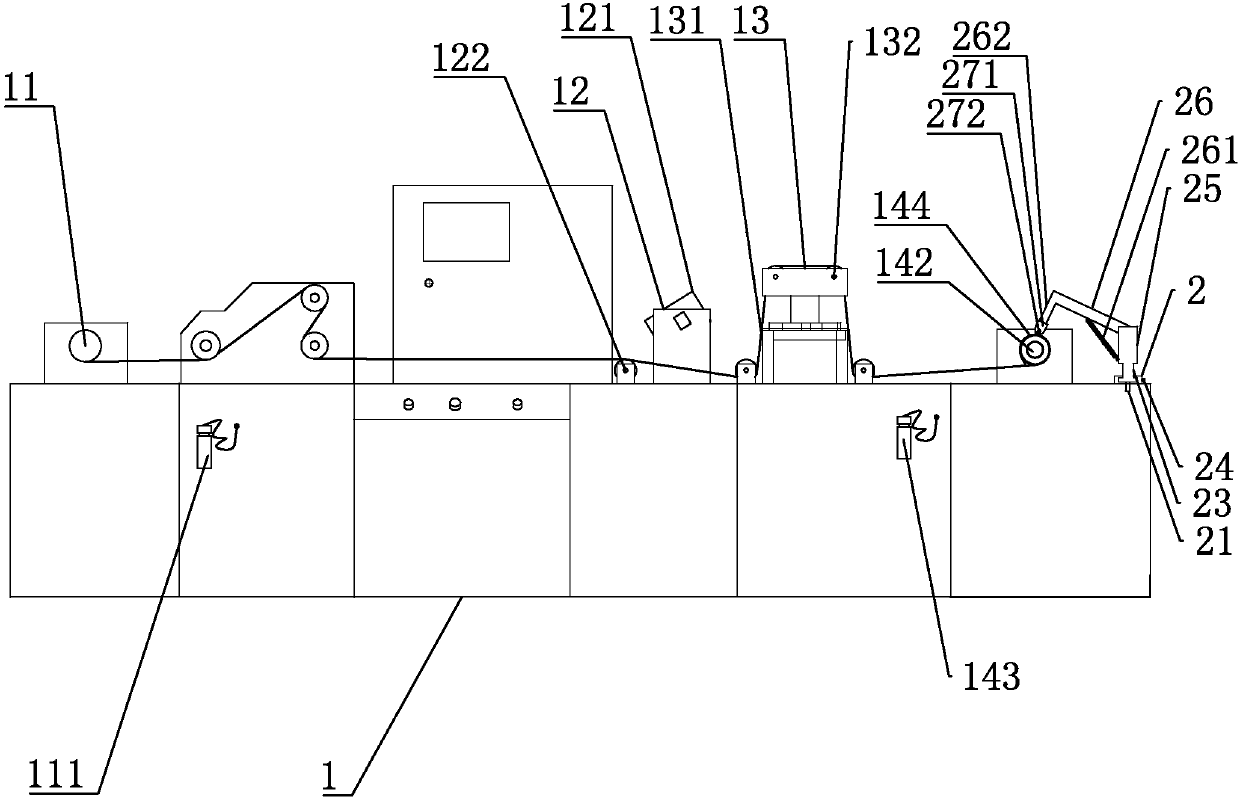

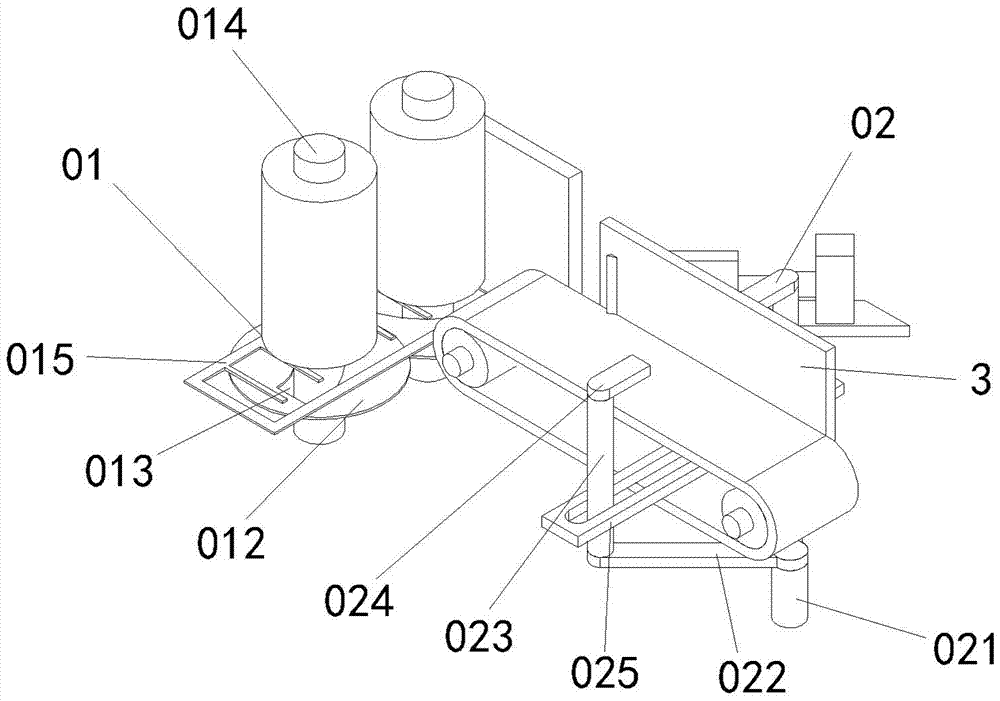

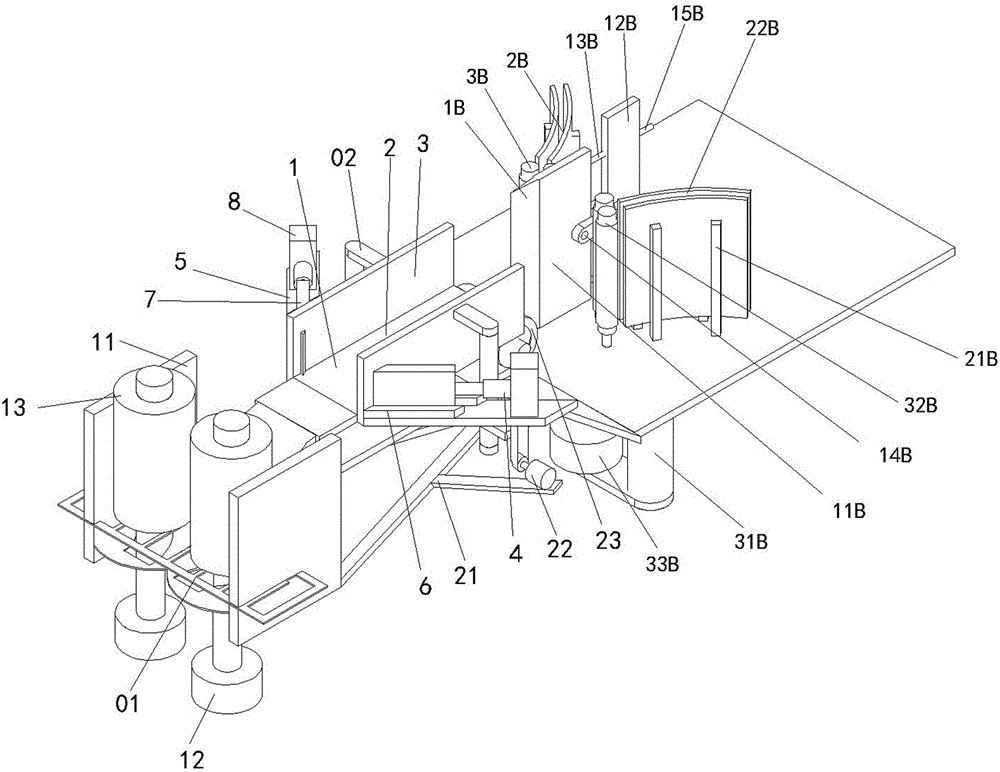

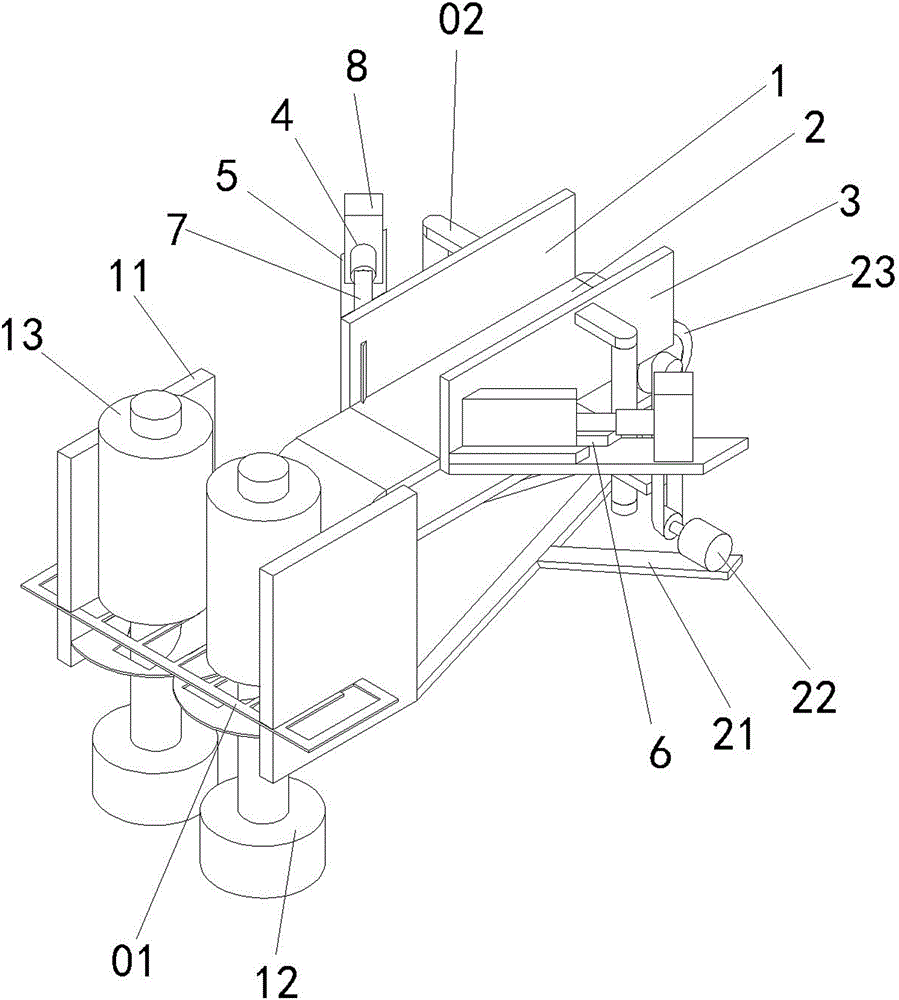

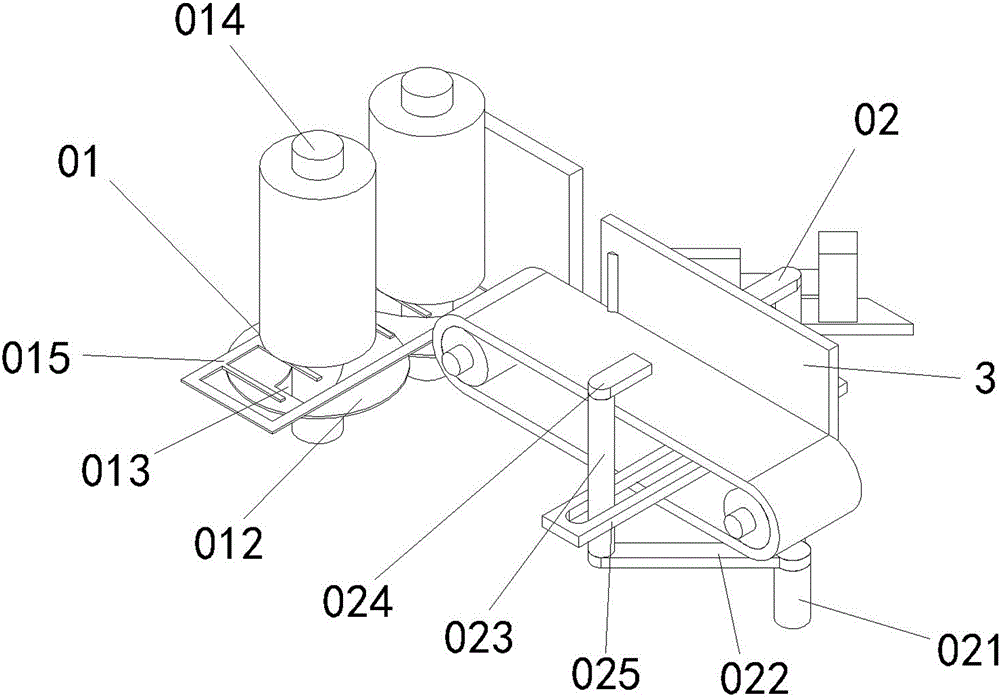

Printed product inspection machine

PendingCN107758398AHas a stretching effectSave spaceArticle deliveryWebs handlingProduct inspectionElectric machinery

The invention discloses a packaging bag inspection machine, belongs to the field of inspection machines, and aims to provide a printed product inspection machine. According to the printed product inspection machine, products can be rapidly fixed to paper tubes of a wind-up roller, so that the working efficiency is improved. The technical scheme of the packaging bag inspection machine is characterized by comprising a machine tool, a feeding roller, a detection mechanism, a tensioning mechanism and a wind-up mechanism, wherein the feeding roller, the detection mechanism, the tensioning mechanismand the wind-up mechanism are sequentially arranged on the machine tool; the wind-up mechanism comprises the wind-up roller which is driven by a motor and is used for being sleeved with the paper tubes; a supporting plate is arranged on the machine tool, and a supporting plate is arranged on the position, facing the wind-up roller and located on one side of the motor, of the machine tool; a supporting rod is vertically arranged on the supporting plate; a cantilever is hinged to the upper portion, facing the wind-up roller, of the supporting rod; a tension spring is fixedly connected to the sides, facing to the wind-up roller, of the cantilever and the supporting rod; a bending part is arranged at the end, far away from the supporting rod and facing the wind-up roller, of the cantilever; atransverse beam parallel to the wind-up roller is arranged under the bending part; and a pressing piece is rotationally connected under the transverse beam.

Owner:江苏飞视文化发展有限公司

Bulbil propagation technology for aconitum vilmorimianum Kom.

InactiveCN105660115AControl usePull out in timeAgriculture tools and machinesSeed and root treatmentContinuous croppingAxillary bud

Provided is a bulbil propagation technology for aconitum vilmorimianum Kom.. The bulbil propagation technology comprises the steps of 1, collecting, wherein mature axillary bud fruits are collected in batches from the middle of August to early November of the current year; 2, storing; 3, sterilizing; 4, grading, wherein the sterilized axillary bud fruits are graded according to the large, medium and small size shapes; 5, sowing; 6, field management; 7, pest control and prevention; 8, harvesting. Due to the fact that the axillary bud fruits are spherical nutrient bodies growing on plant vines, when the axillary bud fruits are used for propagation, a series of problems that lateral root tubers are difficult to store after being propagated and prone to be infected with diseases in the storage process, and continuous cropping is prone to cause damage can be effectively avoided.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

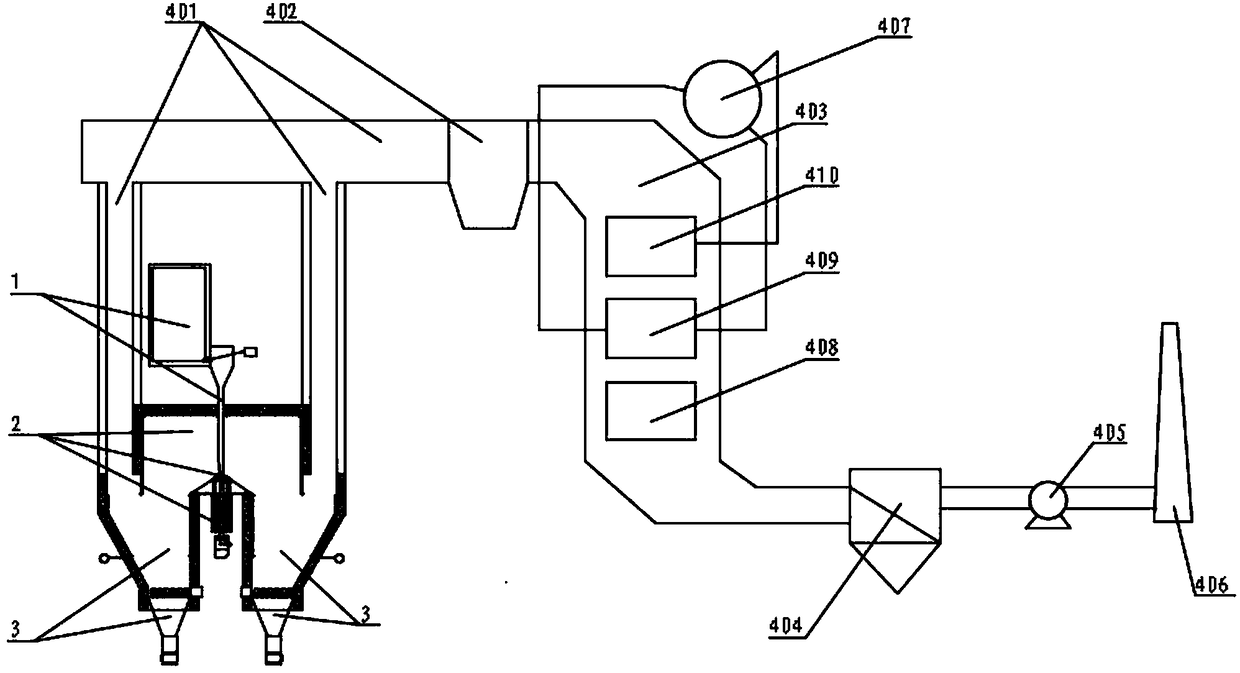

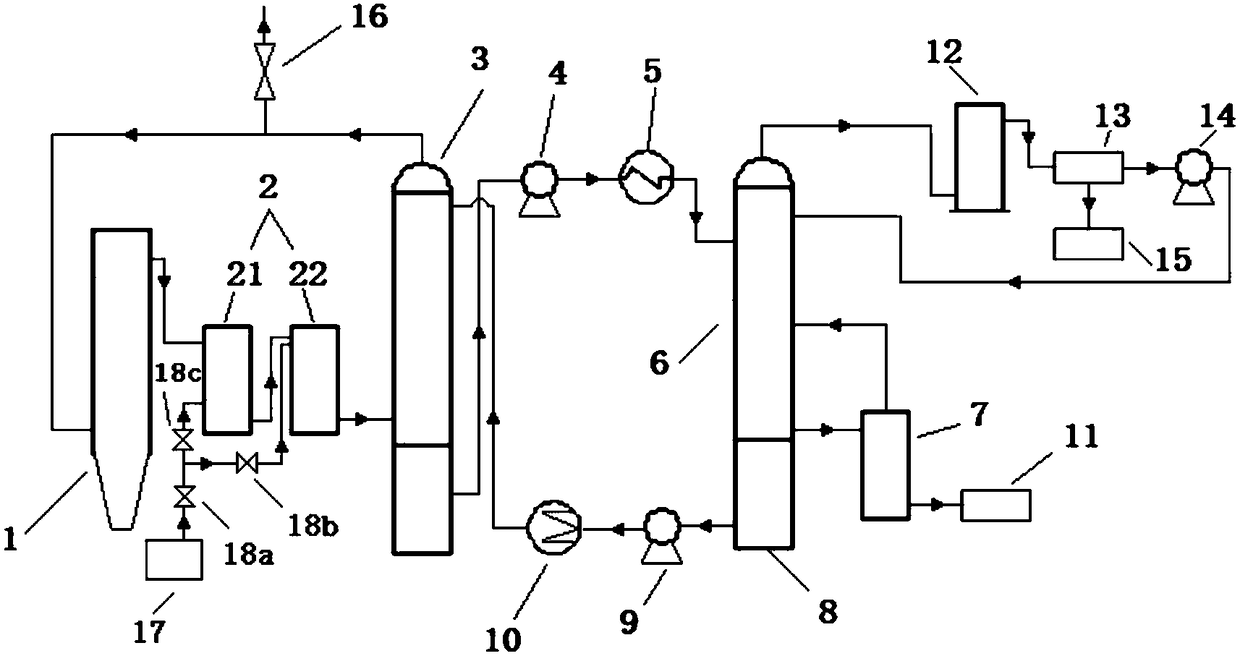

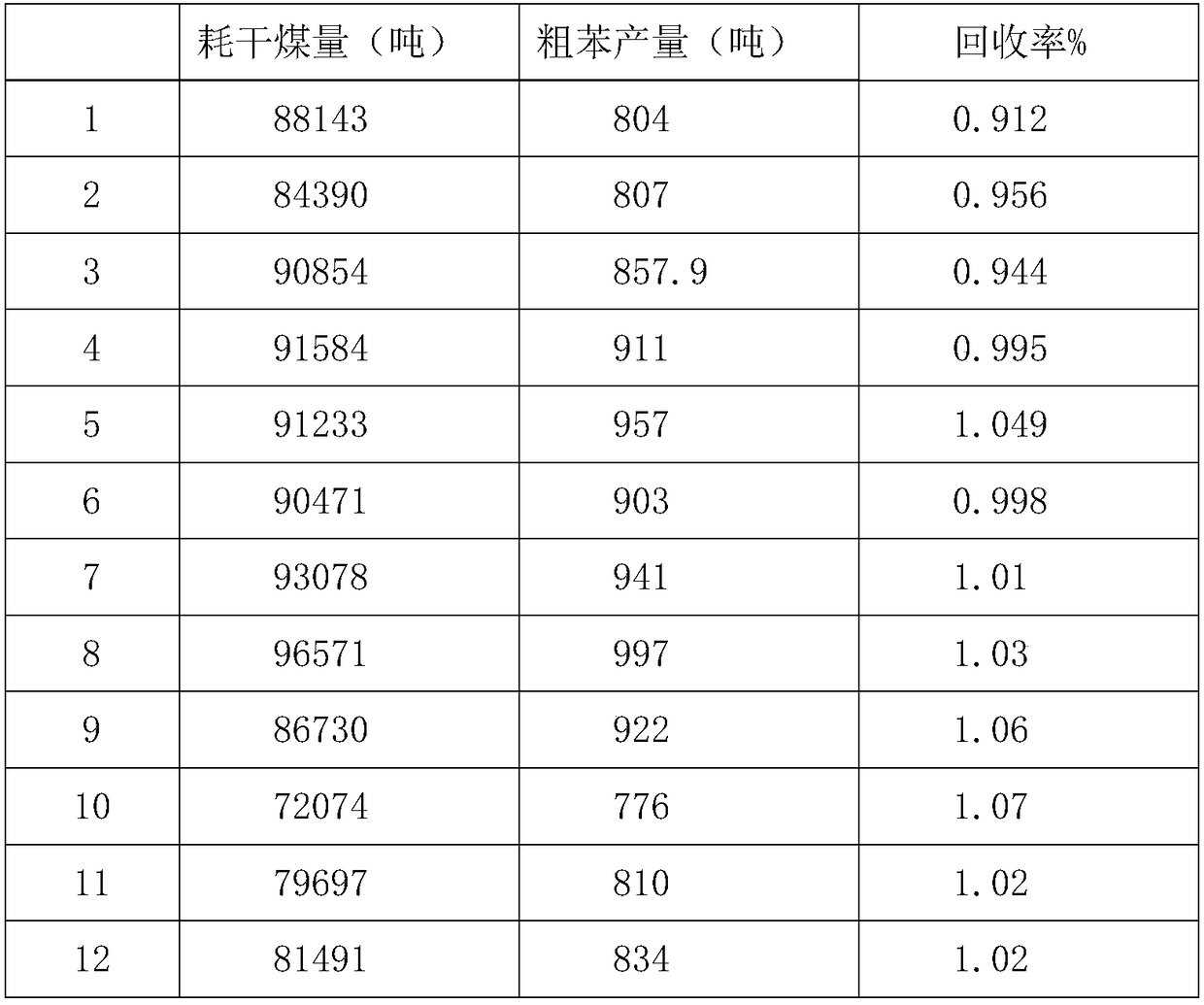

Coke oven gas treatment system and crude benzol recovery method

ActiveCN108441268AHigh recovery rateStable pressureChemical industryGas purification by liquid washingRecovery methodSlag

The invention relates to a coke oven gas treatment system. The treatment system comprises a former process unit (2), a benzol scrubber (3), a rich oil pump (3), a heat exchange and heating system (5),a debenzolization tower (6), a regenerator (7), a lean oil storage tank (8), a lean oil pump (9), a cooler (10), a slag storage tank (11), an oil-water separator (12), a reflux tank (13), a reflux pump (14), a crude benzol measuring tank (15) and an automatic clean gas exhaust system (16), wherein the former process unit (2) comprises a primary cooler (21) and a final cooler (22). By means of theprimary cooler and the final cooler with online cleaning capacity as well as the automatic clean gas exhaust system, crude benzol recovery rate is increased.

Owner:李劲松

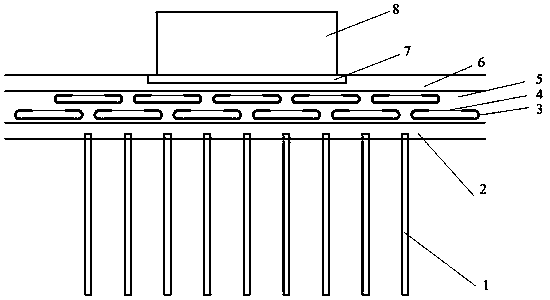

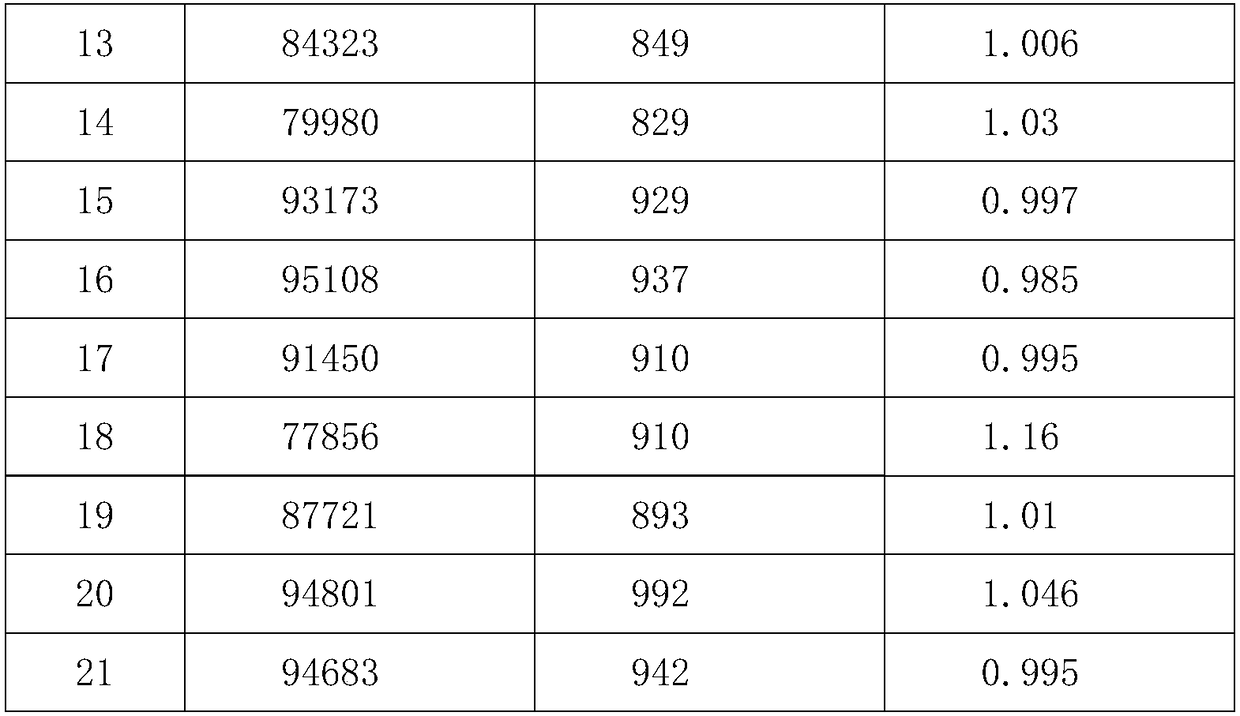

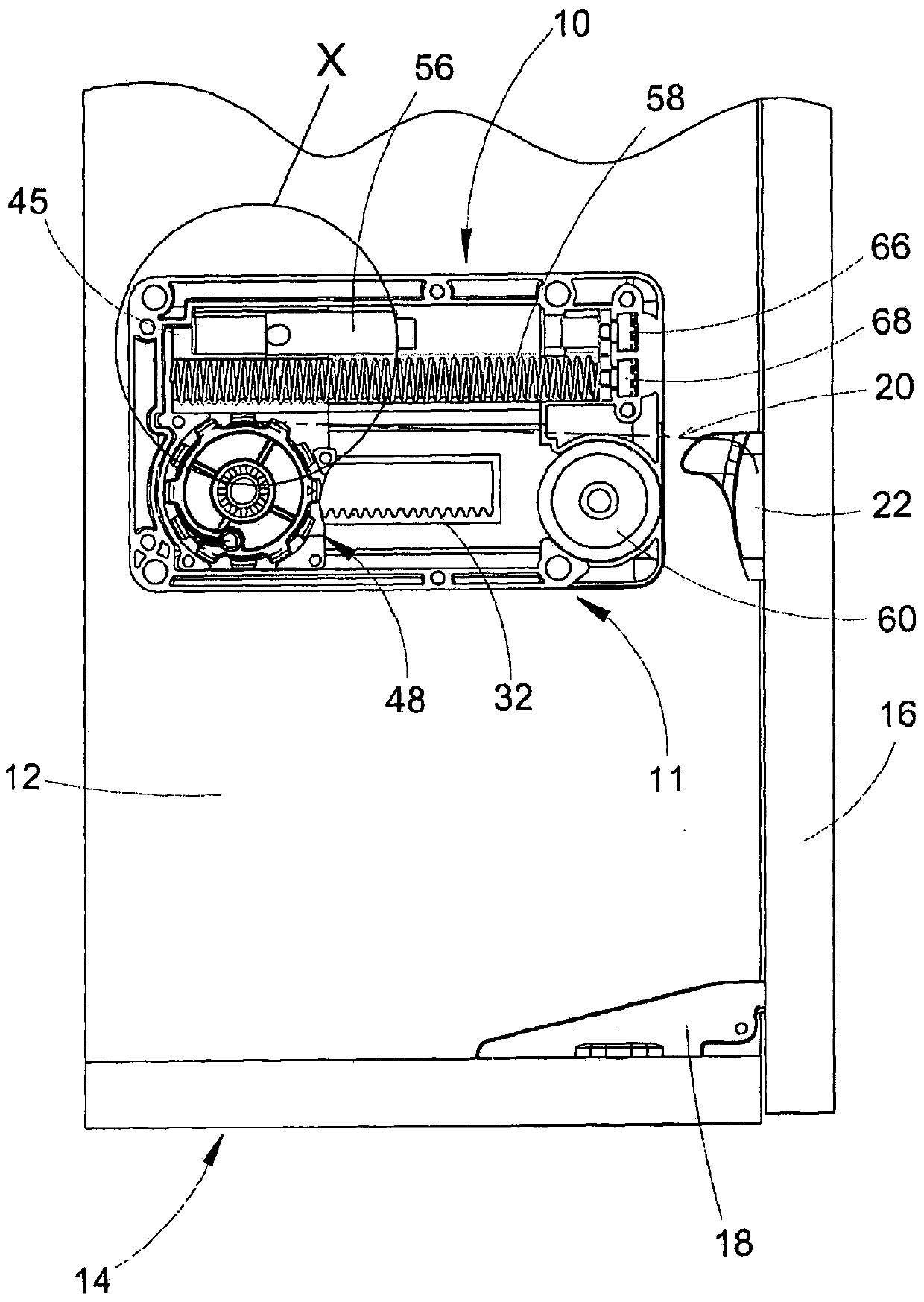

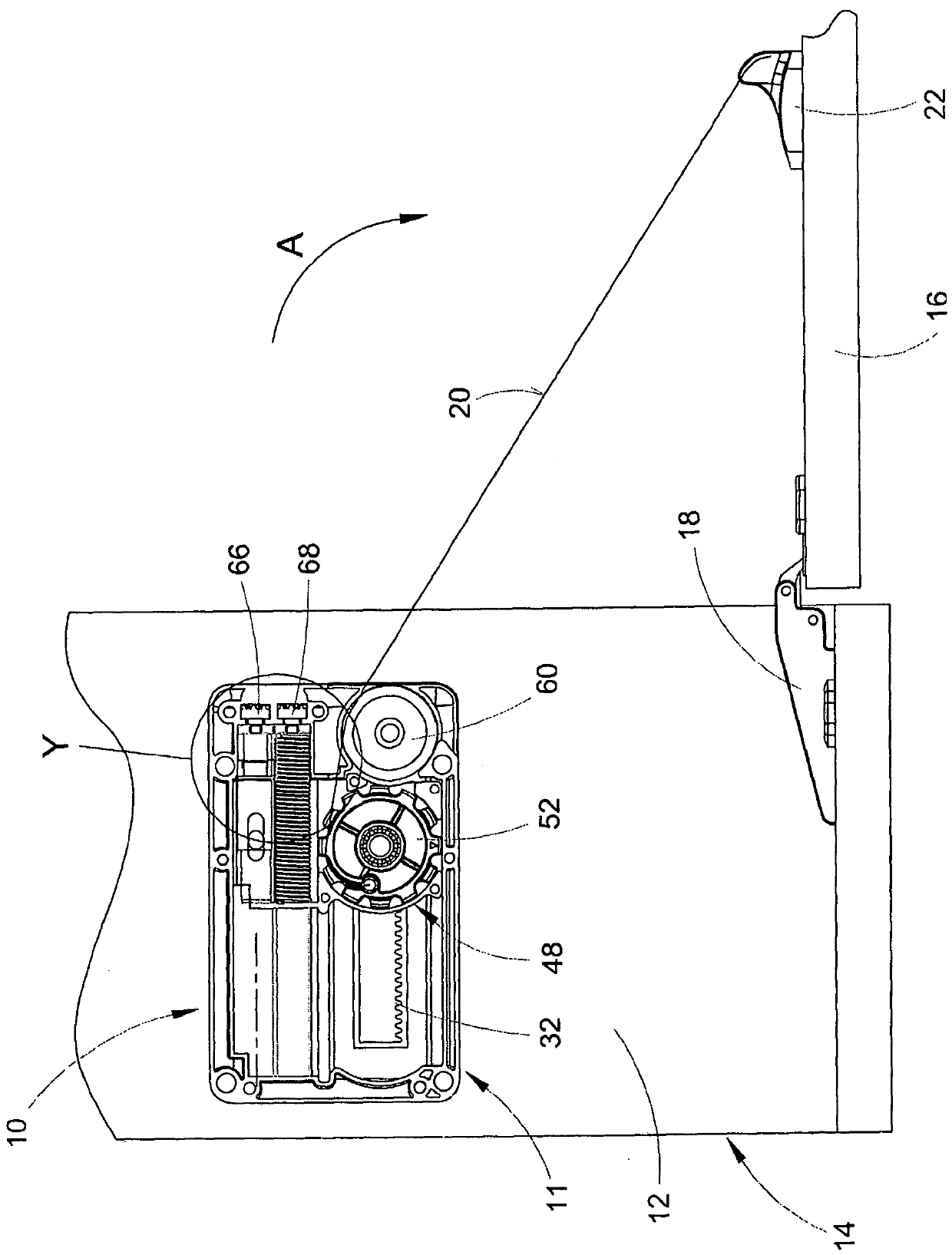

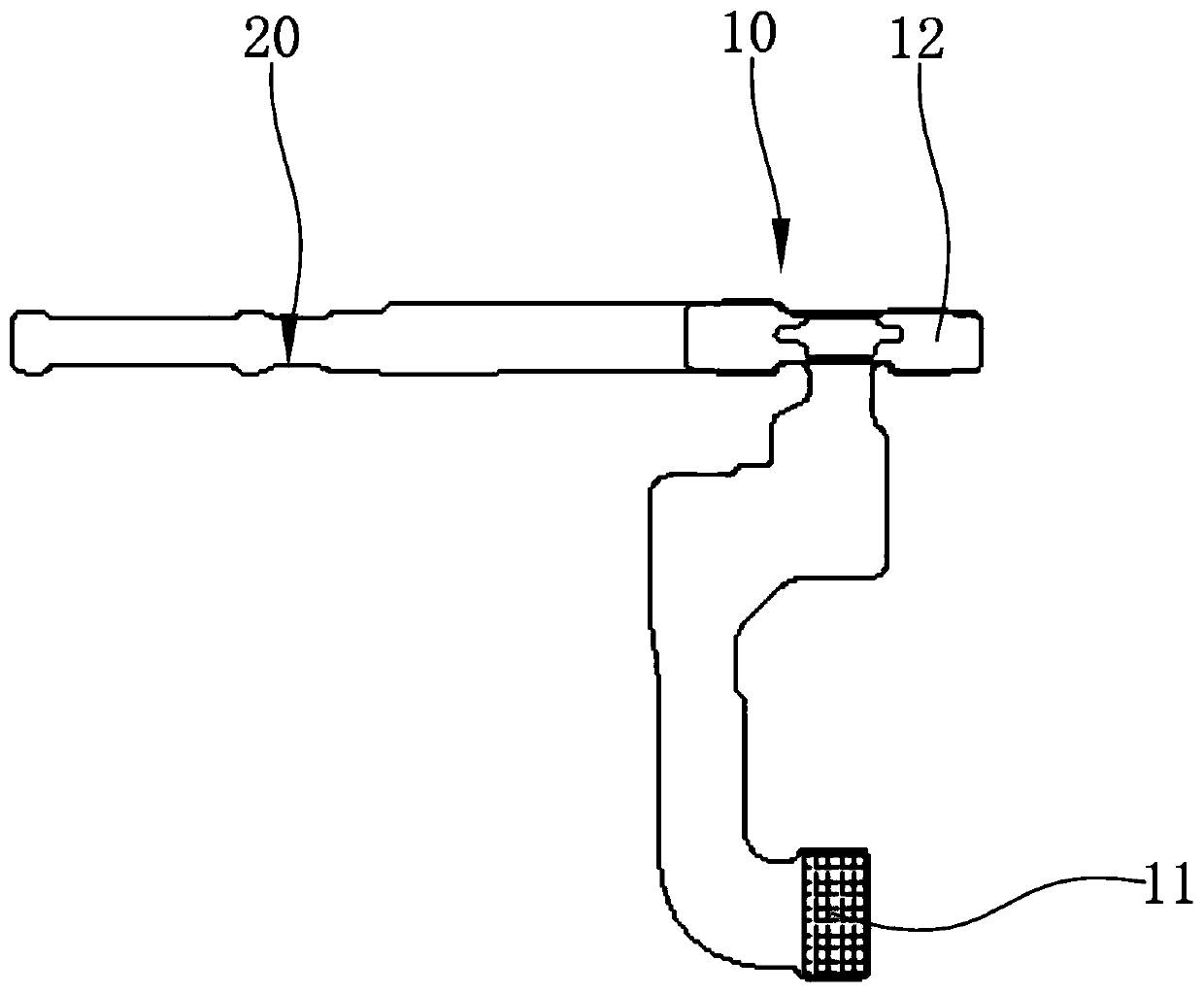

Improved guide device for the opening and the support of doors of furniture

ActiveCN105518239AReduce depthEasy to produceBuilding braking devicesMan-operated mechanismMechanical engineeringEngineering

An improved guide device (10) for the opening and the support of furniture doors suitable for guiding and supporting the movement thereof both during opening and closing phases, comprising a container body (11) of substantially rectangular shape attached on the inner face of a lateral shoulder (12) of a frame of an item of furniture (14) provided with a door (16) fall-front openable via at least one hinge (18) attached to the frame of the furniture (14) and operatively connected to the container body (11) by means of a cable (20) attached to said door (16) via a fastening element (22) constrained to an inner face of the same door (16), said device which likewise comprises a body-slide (48) sliding inside said container body (11) and integrating means roto-translating with respect to a cogged profile or rack (32) of the container body (11) for a movement of said body-slide (48) and an unwinding / winding of said cable (20) in contrast to or assisted by a return spring and / or by damping means.

Owner:EFFEGI BREVETTI

A piece opening device for vertical transmission of green and yellow sides of bamboo slices

InactiveCN105082279BGuaranteed resistanceSmooth goingCane mechanical workingWood working apparatusEdge surfaceTransmission channel

The invention relates to a piece-opening device for vertical transmission of green and yellow sides of bamboo chips, which belongs to the technical field of bamboo chip processing, and includes a channel body for vertically placing the green and yellow sides of bamboo chips, and the channel body includes a transmission bottom surface and a transmission bottom surface. The transmission ribs arranged on both sides of the transmission bottom surface, the outer surface preliminary treatment device is arranged on the transmission ribs, and the bamboo sheet transmission line behind the channel body is equipped with a vertical sheet opening cutter. Behind the cutting tool, there is a splitting transmission track symmetrical to both sides with the splitting tool as a symmetry axis, and a dynamic stabilizing structure is arranged between the splitting tool and the splitting transmission track. Using the above scheme to set the roadside vertically to realize the splitting of multiple bamboo slices, and also realize the rapid cutting of the bamboo slices through the thinner cutting knife, and also set up a more convenient and efficient bamboo slice Front transfer channel with brushed finish.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

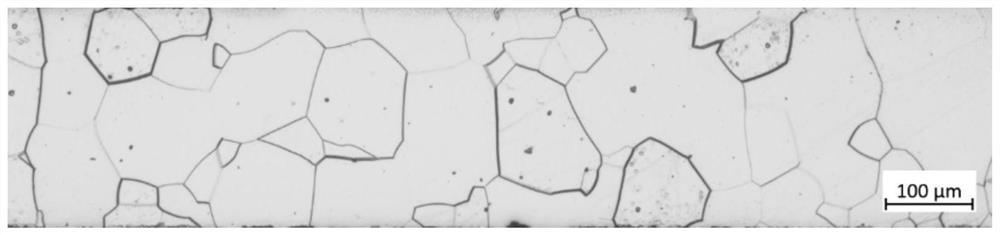

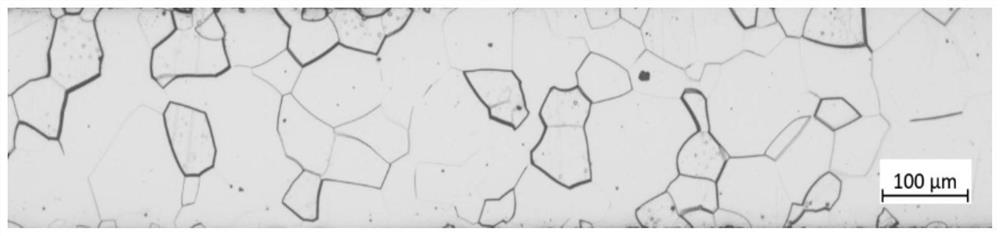

Non-oriented electrical steel for hub motor of portable electric bicycle and manufacturing method of non-oriented electrical steel

ActiveCN113215473ALow iron loss performanceImprove motor efficiencyFurnace typesHeat treatment furnacesElectrical steelElectric machine

The invention discloses non-oriented electrical steel for a hub motor of a portable electric bicycle and a manufacturing method of the non-oriented electrical steel, and belongs to the field of non-oriented steel. In order to solve the problems of high processing difficulty and low efficiency of existing non-oriented steel for a small motor, the invention provides the non-oriented electrical steel for the hub motor of the portable electric bicycle. The non-oriented electrical steel for the hub motor of the portable electric bicycle is prepared from the following components in percentage by weight: 1.50-3.00% of Si, 0.50% to 2.00% of Als;, 0.20% to 1.00% of Mn, 0.01% to 0.20% of P, less than or equal to 0.005% of C, less than or equal to 0.03% of S, less than or equal to 0.03% of N, less than or equal to 0.005% of Ti, and the balance of iron and inevitable impurities, wherein the weight percentage of C, S, N and Ti meets the following formula: C% + S% + N% + Ti% is less than or equal to 0.01%. According to non-oriented electrical steel for the hub motor of the portable electric bicycle, the ductility of silicon steel is improved by reasonably controlling the element content, and machining is convenient. According to the manufacturing method of the non-oriented electrical steel, eddy current and magnetic hysteresis loss in a wound iron core is reduced, meanwhile, surface oxidation and surface nitride precipitation of a steel coil can be avoided, and the iron core loss is reduced; compared with existing non-oriented silicon steel with the same iron loss level, the elongation is higher, the subsequent cold machining performance is more excellent, and the machining is convenient while the excellent performance is ensured.

Owner:MAANSHAN IRON & STEEL CO LTD

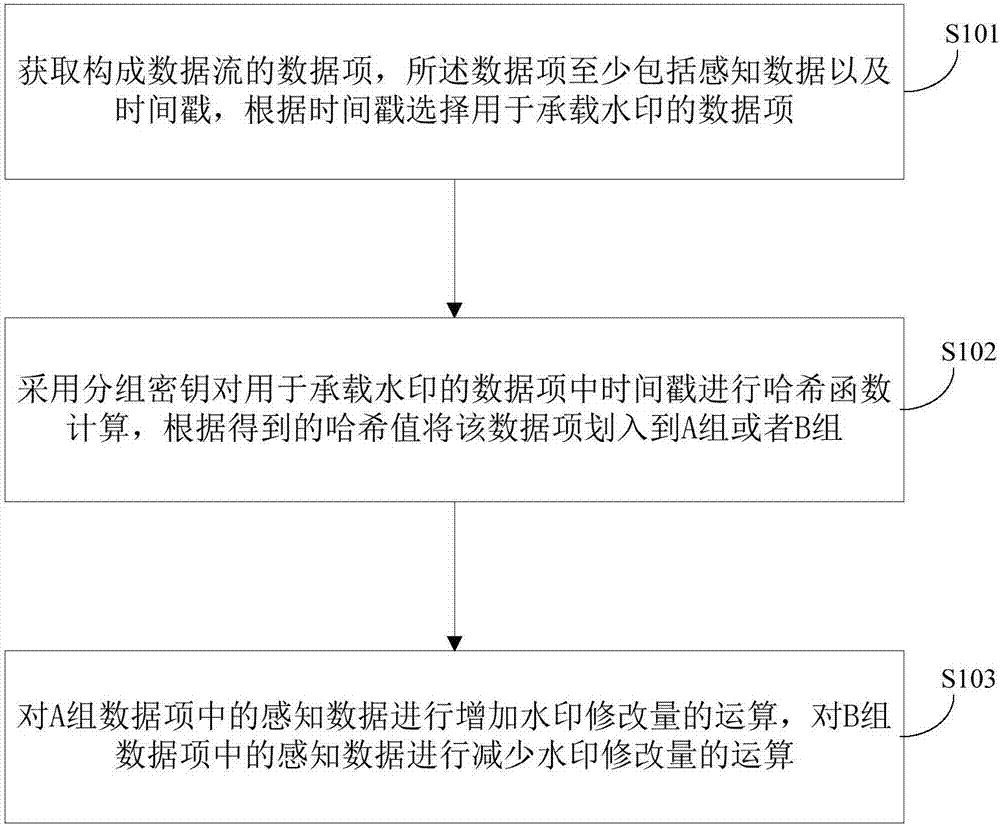

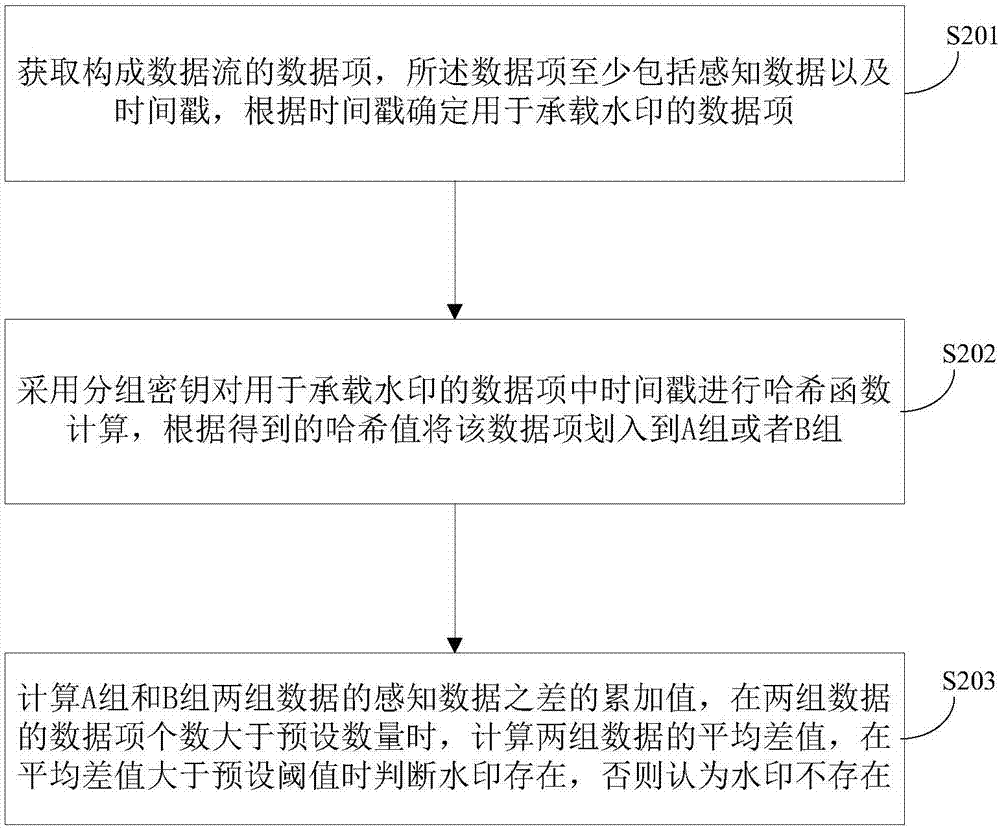

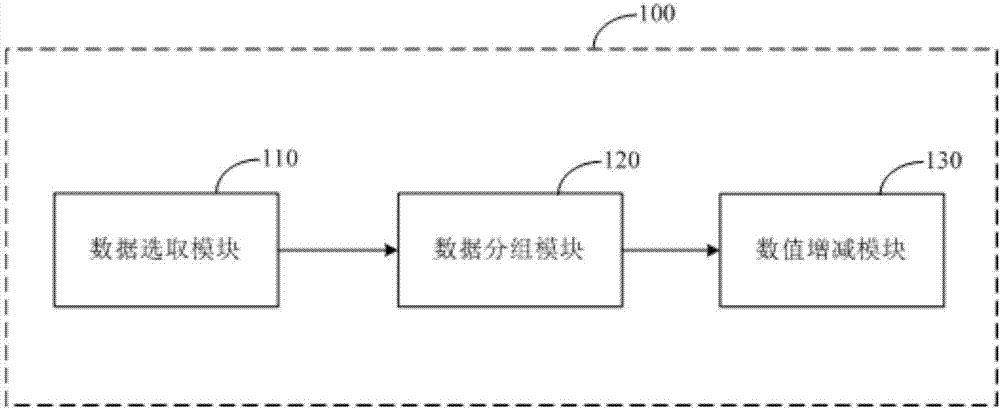

Robust watermark detection method and device for data flows

InactiveCN107369125AEnsure successful detectionPlay the role of copyright protectionImage watermarkingHash functionData stream

The invention relates to a robust watermark detection method and device for data flows. The watermark detection method comprises the following steps of: obtaining data items which form a data flow, wherein the data items at least comprise perception data and time stamps; determining data items for watermark bearing according to the time stamps and a probability p; carrying out hash function calculation on the time stamps in the data items for watermark bearing by adoption of a grouping secret key, and dividing the data items into a group A and a group B according to the obtained hash value; and calculating an accumulated value of differences of perception data of the two groups of data of the group A and group B, when the number of data items of the two groups of data is greater than a preset number, calculating an average difference value between the two groups of data, when the average difference value is greater than a preset threshold value, judging that a watermark exists, and otherwise, judging that the watermark does not exist. According to the method, the data items for watermark bearing is determined according to the time stamp and the data items are grouped, so that the successful detection of the watermark is ensured and the attack resisting ability is ensured at the same time.

Owner:CHONGQING UNIV OF EDUCATION

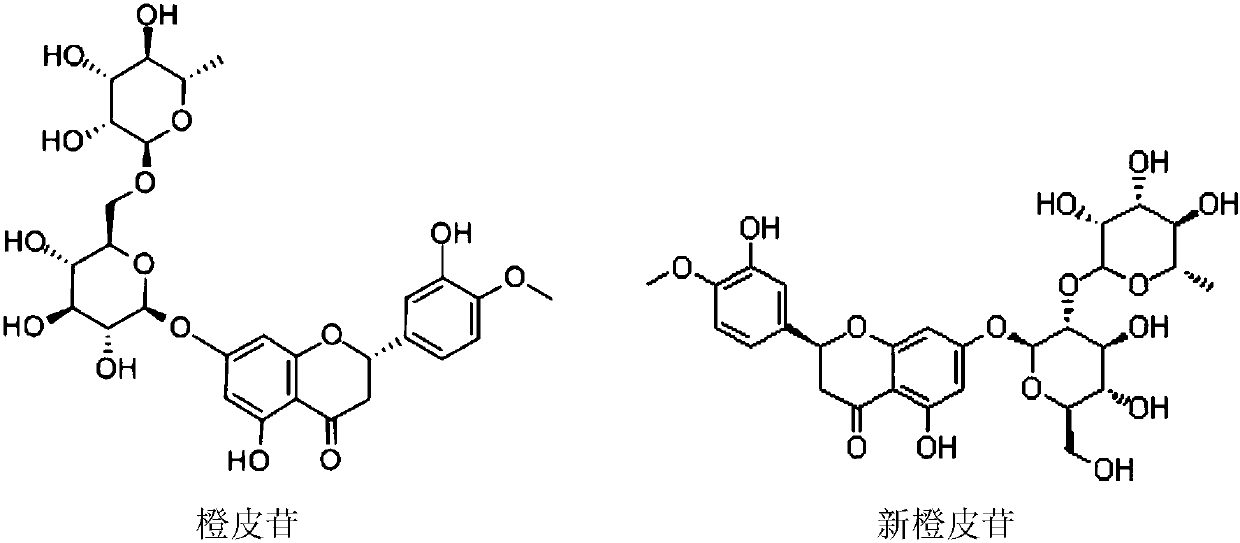

Method for processing fructus aurantii medicinal slices

ActiveCN107595983AReduce myocardial oxygen consumptionConstrict blood vesselsPlant ingredientsMedicineCurative effect

The invention provides a method for processing fructus aurantii medicinal slices. The method comprises the following steps: washing fructus aurantii, adding into a herbal medicine infiltrating machine, vacuumizing, and controlling a series of parameters such as infiltrating temperature and time, slice thickness, drying temperature and time and the like, thereby realizing preparation of the fructusaurantii medicinal slices. The content of active ingredients of the fructus aurantii medicinal slices, such as hesperidin, neohesperidin, naringin, narirutin and the like is high, and the curative effect of the drug is effectively ensured. The preparation method disclosed by the invention is simple and suitable for industrialized production.

Owner:TIANSHENG PHARMA GROUP

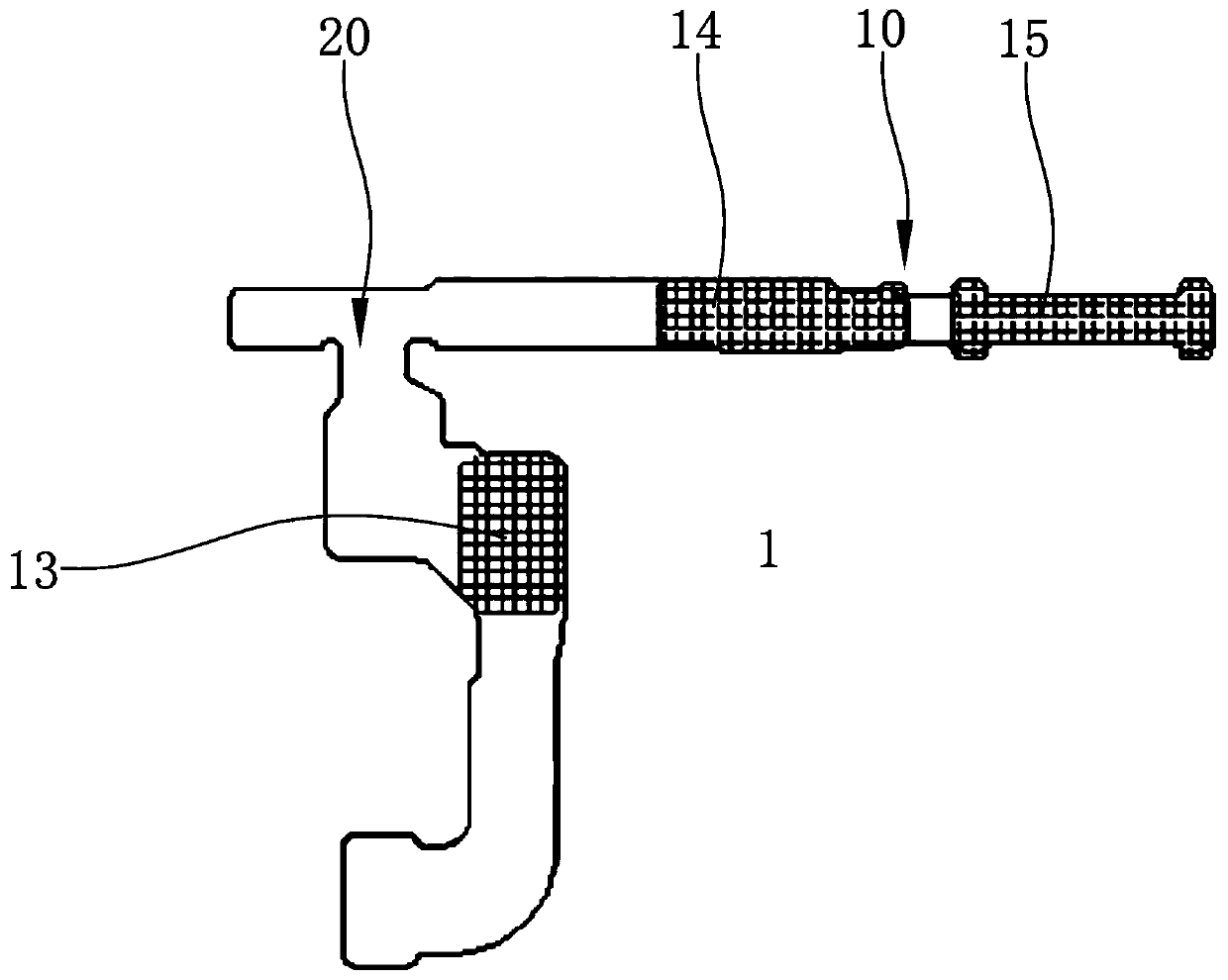

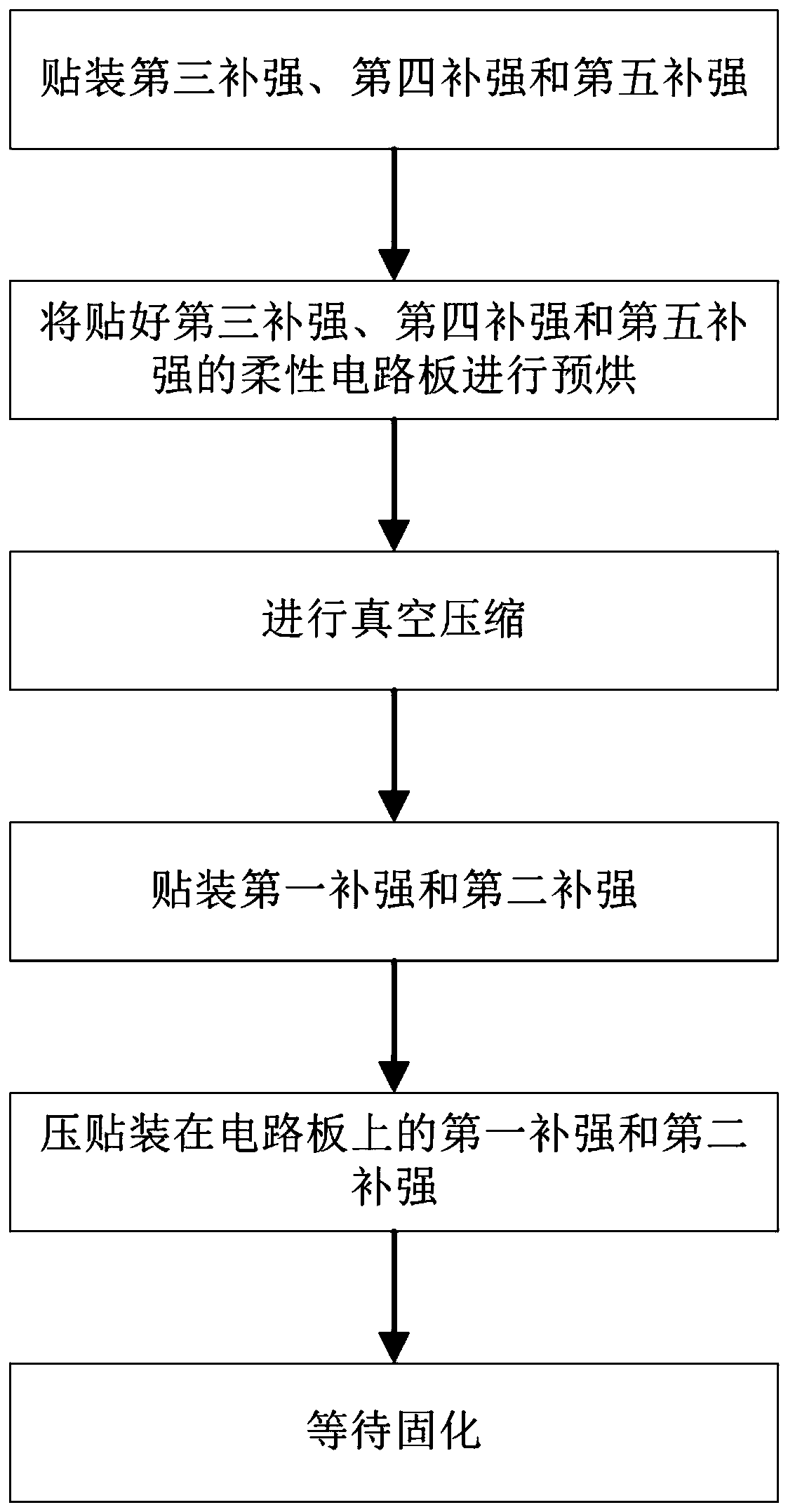

Flexible circuit board and manufacturing method thereof

InactiveCN110267432AGuaranteed ResistanceAvoid resistance problemsCircuit bendability/stretchabilityPrinted circuit aspectsFlexible circuitsAdhesive

The invention discloses a flexible circuit board and a manufacturing method thereof. The flexible circuit board comprises reinforcements and a circuit board body, wherein the reinforcements are composed of a first reinforcement, a second reinforcement, a third reinforcement, a fourth reinforcement and a fifth reinforcement; the first reinforcement and the second reinforcement are arranged on the top of the circuit board body; the third reinforcement, the fourth reinforcement and the fifth reinforcement are arranged on the bottom of the circuit board body; the first reinforcement, the second reinforcement, the third reinforcement, the fourth reinforcement and the fifth reinforcement are staggered. The manufacturing method comprises the following steps: affixing the third reinforcement, the fourth reinforcement and the fifth reinforcement on the circuit board body; pre-baking the circuit board body with the third reinforcement, the fourth reinforcement and the fifth reinforcement; performing vacuum compression; affixing the first reinforcement and the second reinforcement; pressing the first reinforcement and the second reinforcement affixed on the circuit board; and waiting for curing. Thus, such a manufacturing method can prepare the flexible circuit board without indentation and can ensure the resistance value of a conductive adhesive during pressing.

Owner:SHENZHEN XINYU TENGYUE ELECTRONICS

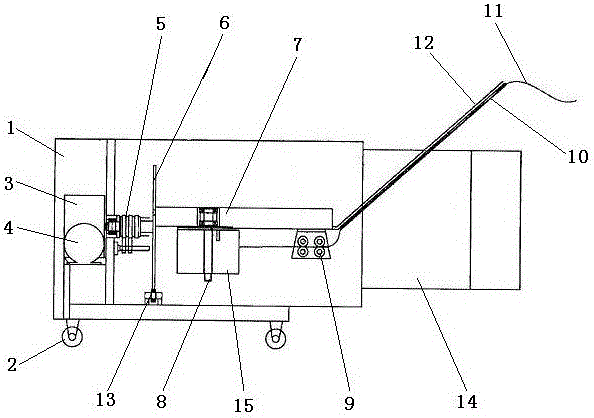

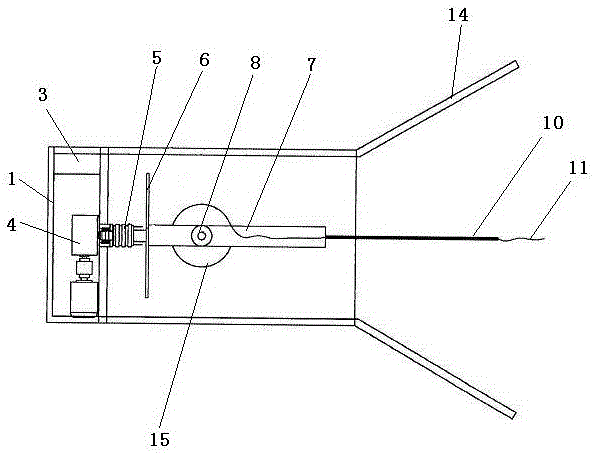

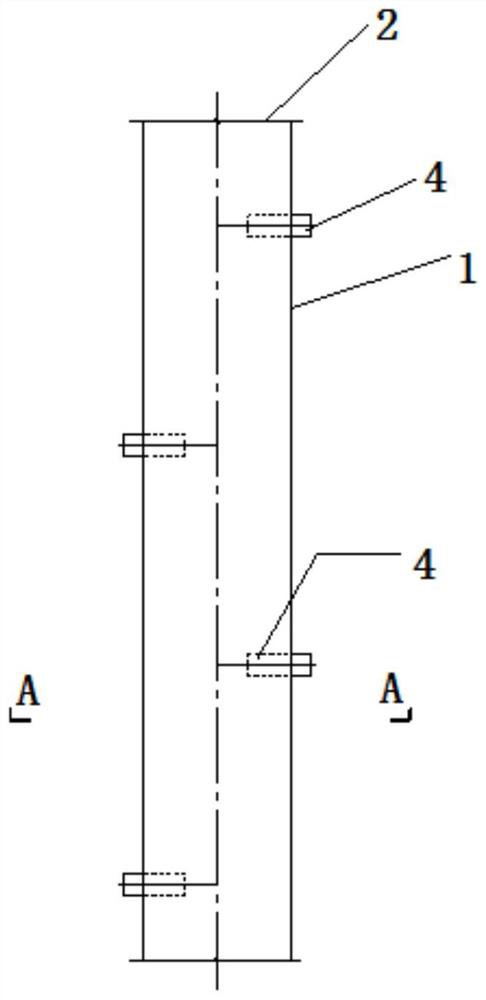

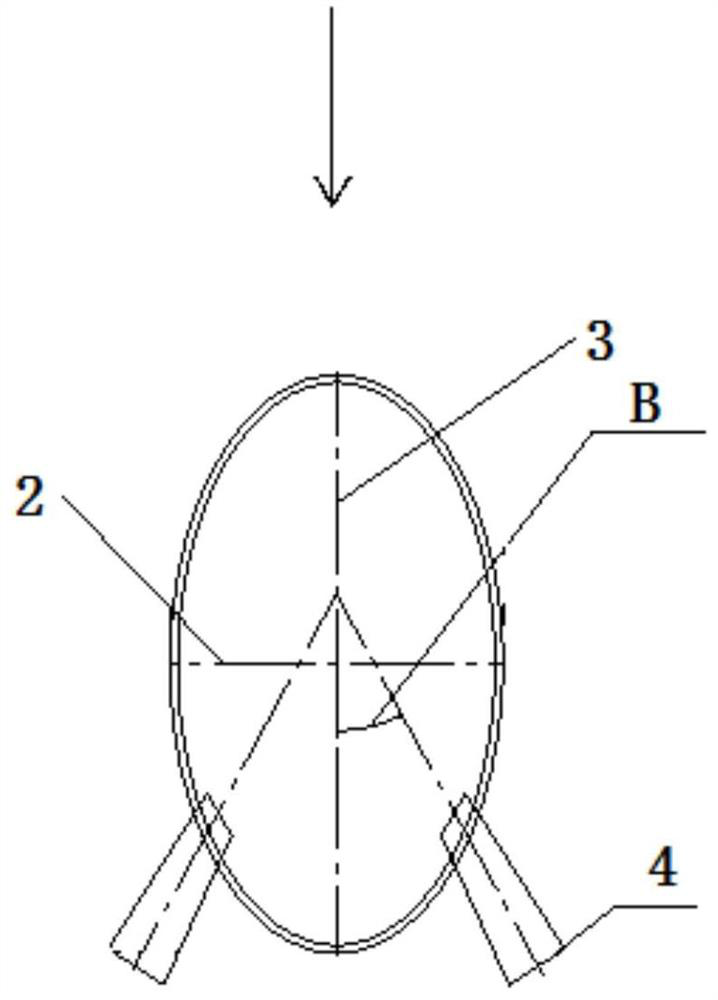

Steel wire feeder for special-shaped rubber tube dedicated to engineering machinery and use method of steel wire feeder

The invention belongs to the technical field of wire feeder machinery and discloses a steel wire feeder for a special-shaped rubber tube dedicated to engineering machinery and a use method of the steel wire feeder. The steel wire feeder is mainly technically characterized by comprising a rack with traveling wheels, wherein an electric cabinet connected with a turnover motor is arranged on the rack; the turnover motor is connected with a turnover turntable through a collecting ring; an upright is eccentrically arranged on the turnover turntable; a steel wire shaft and a wire feeder are arranged on the upright; the wire feeder is connected with the electric cabinet; a large-diameter steel wire support bar is arranged at the top end of the upright and forms a V-shaped together with the upright; an elastic pipe through which a steel wire penetrates is arranged on the large-diameter steel wire support bar. The steel wire feeder for the special-shaped rubber tube dedicated to engineering machinery can meet the demand for winding a steel wire enhancing layer of the special-shaped tube, and has the advantages of being simple in structure, convenient to operate and use, uniform in wire feeding, low in labor force and energy consumption, safe, reliable, and high in operating efficiency.

Owner:HEBEI JIGONG HOSE

Ammonia spraying device and flue gas denitration device

PendingCN112870960AImprove bending resistanceReduce distortionGas treatmentDispersed particle separationFlue gasProcess engineering

The invention relates to the technical field of environmental protection, in particular to an ammonia spraying device and a flue gas denitration device.The ammonia spraying device comprises an ammonia spraying pipeline suitable for being horizontally arranged in a flue, wherein the cross section of the ammonia spraying pipeline is in an oval shape, the short axis of the oval shape is perpendicular to the flowing direction of flue gas in the flue, the long axis of the oval shape is parallel to the flowing direction of flue gas in the flue; and a nozzle which is arranged on the ammonia spraying pipeline. Due to the fact that the short axis is perpendicular to the flowing direction of the flue gas, on the premise that the length of the ammonia spraying pipeline is not changed, the projection area of the ammonia spraying pipeline is the product of the length of the short axis and the length of the ammonia spraying pipeline, the flue gas blocking area can be greatly reduced, the deamination efficiency of the system is guaranteed, and the system resistance is effectively reduced. The mass transfer path and area are increased, and the deamination efficiency is improved. In addition, due to the oval shape, flowing of the smoke can be guided, the smoke flows smoothly, and abrasion to the ammonia spraying pipeline is small.

Owner:CHINA HUADIAN ENG +1

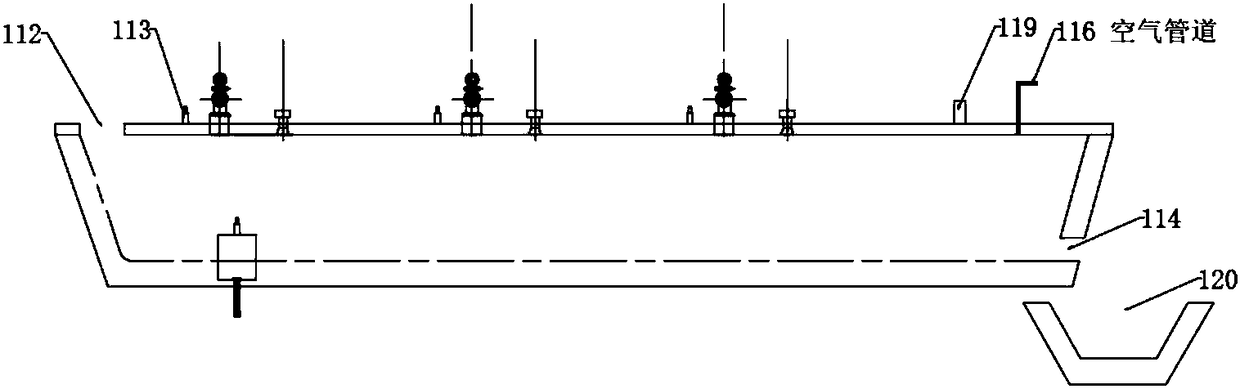

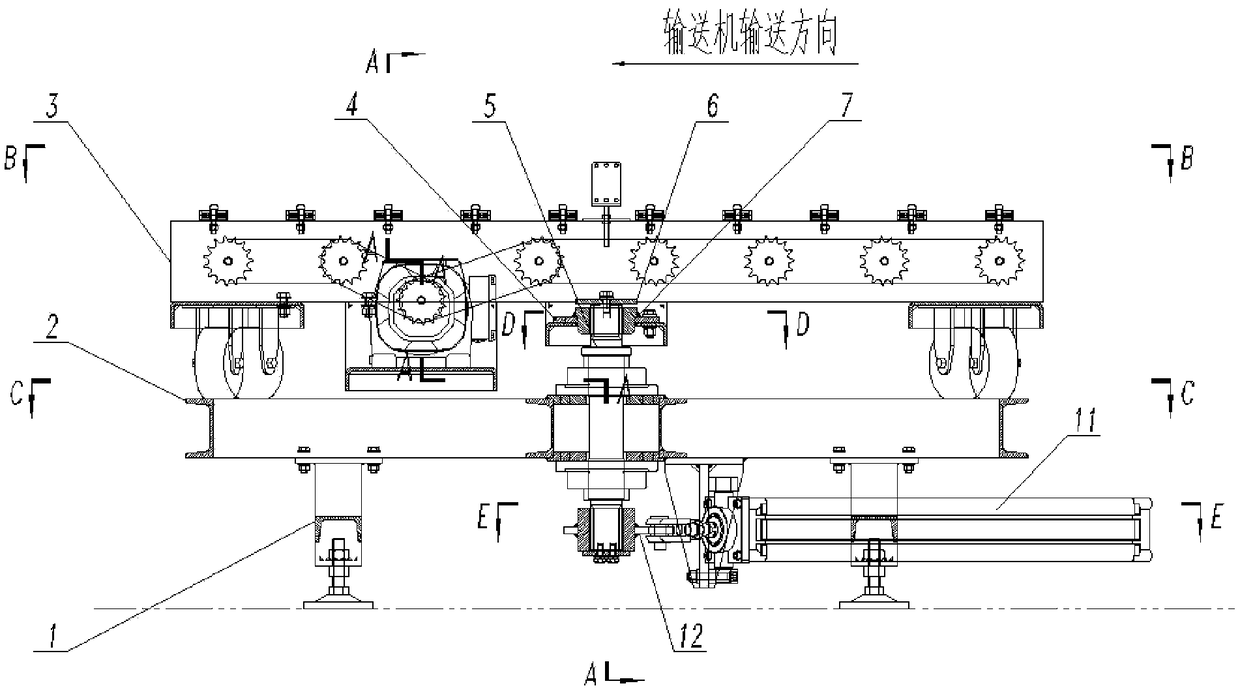

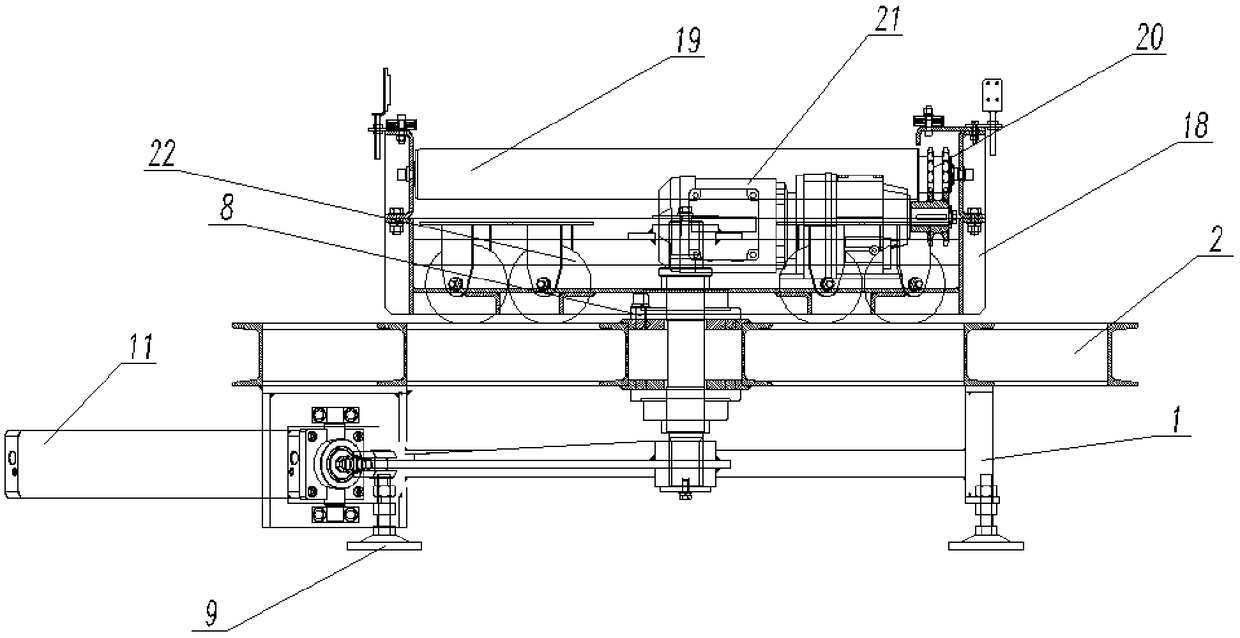

Pneumatic steering conveyor

InactiveCN109051608AReduce resistanceGuaranteed connection reliabilitySupporting framesHigh resistanceEngineering

The invention discloses a pneumatic steering conveyor. The pneumatic steering conveyor comprises a support roller conveying module, a bracket module and a cylinder; the support roller conveying modulecomprises a conveying frame, a conveying motor and a support roller; the bracket module comprises a circular frame, a bracket for supporting the circular frame, and a center rotating shaft mounted inthe center of the circular frame through a bearing; the upper end of the center rotating shaft is fixedly connected with the conveying frame; a cylinder rotating shaft is vertically fixed at the ends, with a piston rod, of a cylinder block of the cylinder; a hinge base rotationally connected with a rotating shaft of the cylinder, is fixed on the lower surface of the circular frame; a rotary connecting rod is fixed at the lower end of the center rotating shaft; the end part of the rotary connecting rod is hinged with an extension end of the piston rod; and the piston rod and the rotary connecting rod are perpendicular to the center rotating shaft. During rotating, the cylinder can overcome higher resistance to meet transportation of materials with higher weights.

Owner:WUHU NEW UNIVERSAL ENVIRONMENTAL SCI TECH

Piece cutting device for vertical conveying of bamboo piece green and yellow faces

InactiveCN105082279AGuaranteed resistanceSmooth goingCane mechanical workingWood working apparatusMechanical engineeringEngineering

The invention relates to a piece cutting device for vertical conveying of bamboo piece green and yellow faces and belongs to the technical field of bamboo piece processing. The piece cutting device comprises a channel body enabling the green faces and the yellow faces of bamboo pieces to be placed vertically. The channel body comprises a conveying bottom face and conveying blocking edges arranged on the two sides of the conveying bottom face. The conveying blocking edges are provided with outer surface primary processing devices. A bamboo piece conveying line behind the channel body is provided with a vertical piece cutter in a matched mode. A piece dividing conveying rail which is symmetric with the piece cutter as the symmetry axis is arranged behind the piece cutter. A power stabilizing structure is arranged between the piece cutter and the piece dividing conveying rail. By means of the scheme, cutting of multiple bamboo pieces can be achieved through vertical arrangement of the blocking edges. Besides, the bamboo pieces are quickly cut and divided through a thin piece cutter. A front conveying channel used for drawing the bamboo pieces more conveniently and more efficiently is further arranged.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

Lubricating grease for optical instruments and preparation method thereof

InactiveCN106701257AExtended service lifeGuaranteed resistanceLubricant compositionLithium soapOxidation resistant

The invention discloses a lubricating grease for optical instruments, belonging to the technical field of special lubricating greases. The technical scheme is as follows: the lubricating grease for optical instruments is prepared from the following raw materials in percentage by weight: 55-80% of base oil, 13-38% of thickener, 3-5% of additive and 5-10% of tackifier. The invention also particularly discloses a preparation method of the lubricating grease for optical instruments. The lubricating grease for optical instruments is prepared by thickening the special base oil by using lithium soap and adding excellent additives, has excellent oxidation resistance and lubricating properties, and ensures longer service life. The tackifier ensures the lubricating grease to have certain resistance. The lithium soap and plastic have favorable compatibility, thereby ensuring the sealability of the lubricating grease.

Owner:XINXIANG HENGXING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com