Printed product inspection machine

A detection mechanism and machine tool technology, applied in the direction of winding strips, sending objects, processing thin materials, etc., can solve the problems of cumbersome, reduce the working efficiency of the inspection machine, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

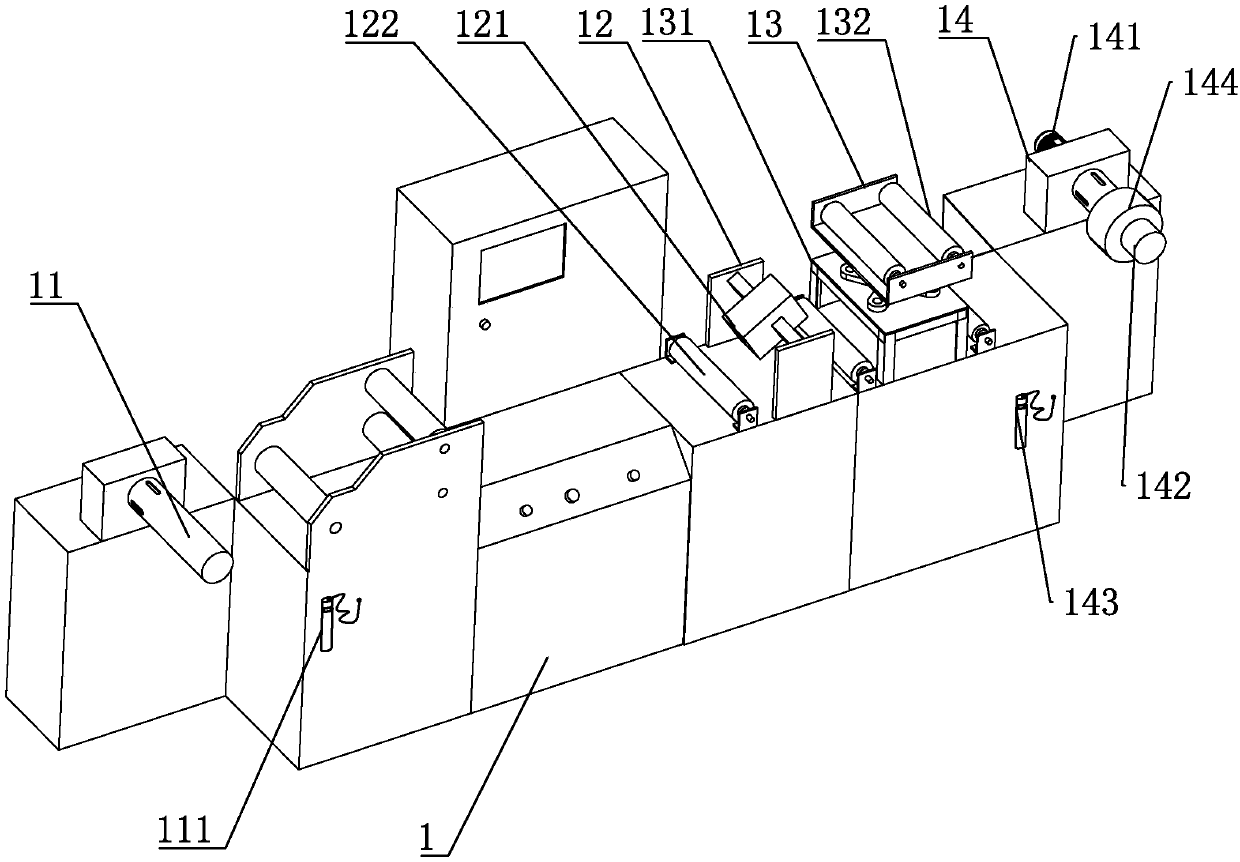

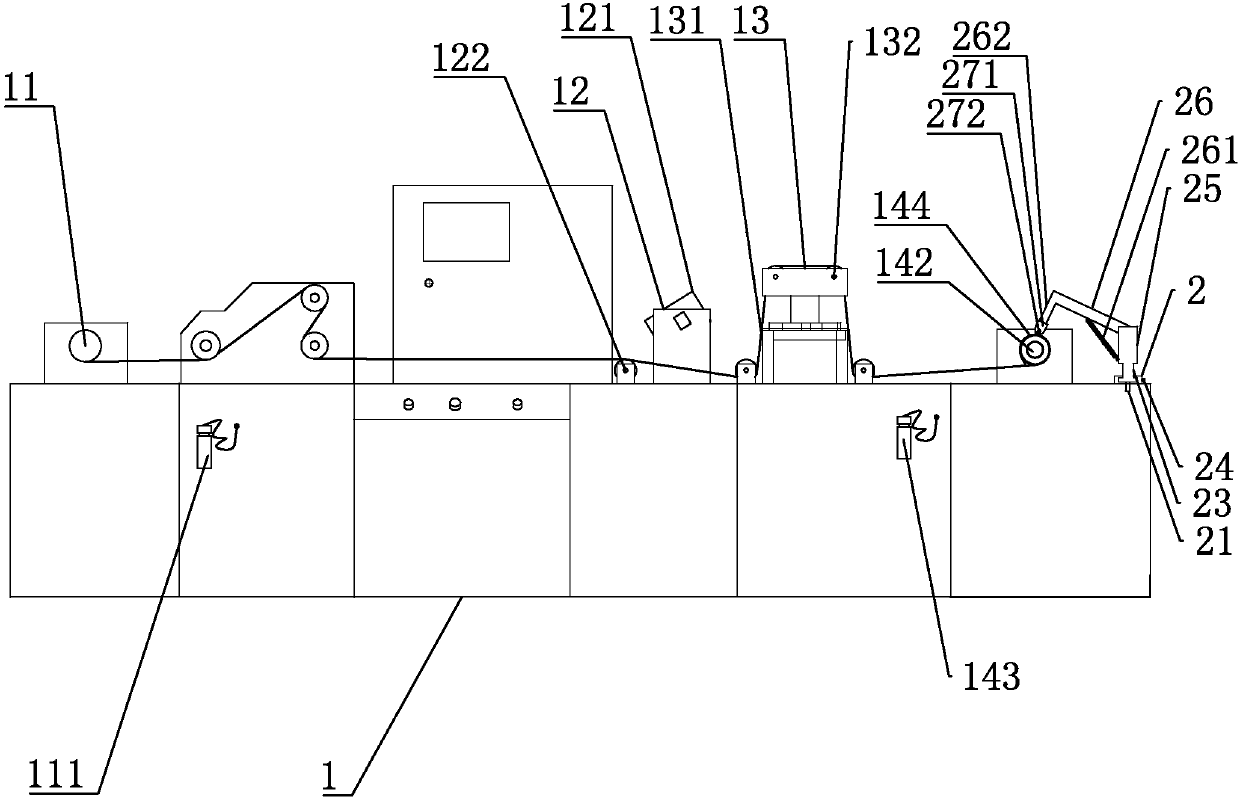

[0029] Embodiment 1, a product inspection machine, such as figure 1 As shown, a machine tool 1 is included, and a feed roller 11 , a detection mechanism 12 , a tension mechanism 13 and a winding mechanism 14 are sequentially arranged on the machine tool 1 .

[0030] The feeding roller 11 is an air-expanding shaft, which is used to place the roll of the packaging bag to be detected. The side of the machine tool 1 near the feeding roller 11 is provided with an air gun-111. After the packaging bag roll is set on the feed roller 11, the feed roller 11 is inflated by the air gun one 111, so that the key bar inside it protrudes and touches the inner ring of the packaging bag roll roller to fix it.

[0031] The detection mechanism 12 includes a strobe light 121, on both sides of the strobe light 121, several driven rollers 122 that play a role in tension are arranged, and the end of the packaging bag on the feeding roller 11 is pulled out and pulled out from the strobe light. The dr...

Embodiment 2

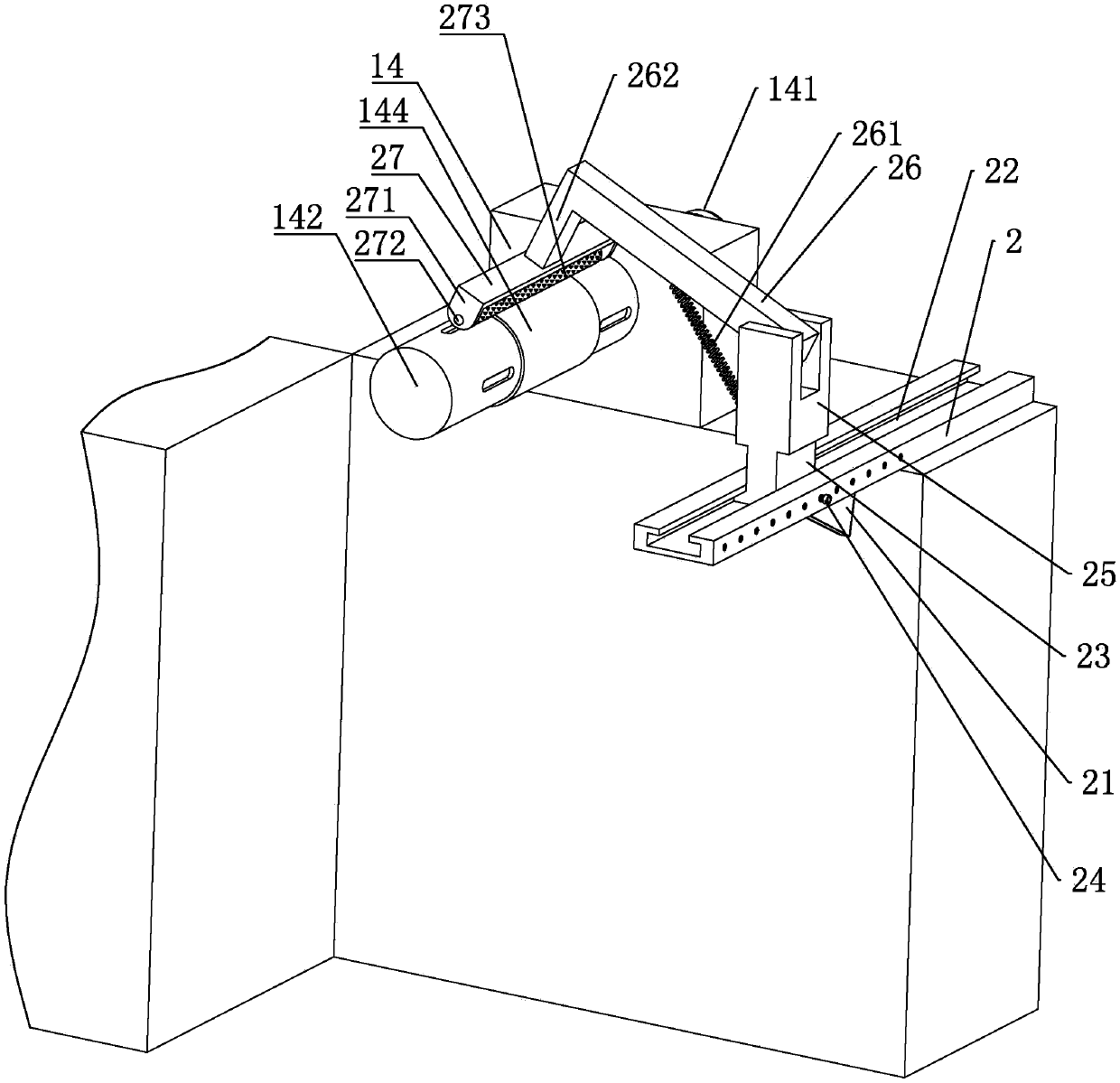

[0034] Embodiment 2, a packaging bag inspection machine, differs from Embodiment 1 in that, as figure 2 and 3 As shown, on the machine tool 1, a support plate 2 is arranged on the side of the motor 141 facing the winding roller 142, a reinforcing rib 21 is arranged under the support plate 2, a slide rail 22 is arranged on the support plate 2, and a slide rail 22 is slidably connected with a slide rail. Block 23, the slide rail 22 is provided with a positioning bolt 24 for fixing the slide block 23, the slide block 23 is vertically provided with a support rod 25, the support rod 25 upper end is hinged with a cantilever 26 towards the winding roller 142, the cantilever 26 and the support The side of the rod 25 facing the winding roller 142 is fixedly connected with a tension spring 261, so that under the action of the tension spring 261, the cantilever 26 has a tendency to rotate towards the winding roller 142; A crossbeam 27 parallel to the winding roller 142 is arranged unde...

Embodiment 3

[0038] Embodiment 3, a packaging bag inspection machine, differs from Embodiment 2 in that, as Figure 4 As shown, the bending part 262 is connected to the crossbeam 27 through the universal joint 28, the end of the crossbeam 27 is provided with an arc-shaped plate 29 along the conveying direction, and a pair of pressure rollers parallel to the crossbeam 27 are arranged between the arc-shaped plates 29 291.

[0039] The specific implementation instructions are as follows:

[0040] Two pinch rollers 291 increase the pinch span of the packaging bag. With the continuous winding of the winding roller 142, the packaging bag on the paper tube 144 is constantly thickened, and the cantilever 26 is continuously lifted, so that the center of the arc plate 29 gradually deviates from the center of the winding roller 142, and the universal The hinge joint 28 can adjust the angle of the arc-shaped plate 29, so that the arc-shaped plate 29 remains concentric with the take-up roller 142 all t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com