Softening device for high-color-fastness polyester-polyamide composite filament super-soft fabric

A polyester-nylon composite yarn, high color fastness technology, applied in the direction of fabric rubbing/softening, fabric surface trimming, spraying/jetting textile material treatment, etc., to achieve the effect of increasing pores, improving softness and facilitating absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

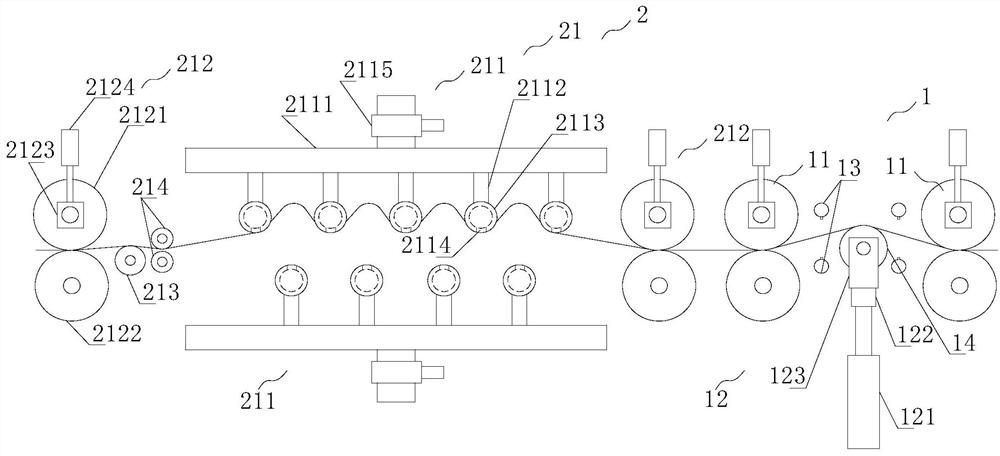

[0018] refer to figure 1 , a kind of high color fastness polyester-nylon composite yarn supersoft fabric softening device of the present invention comprises a softening liquid spraying mechanism 1 and a drying mechanism 2 positioned at the front of the softening liquid spraying mechanism 1, and the drying mechanism 2 includes at least A blowing mechanism 21, the blowing mechanism 21 includes two blowing mechanisms 211 up and down, the blowing mechanism 211 on the top is used to blow the fabric downward and hits on the blowing mechanism 211 below, the blowing mechanism 211 below is used to The fabric blows upwards and impacts on the blowing mechanism 211 above. The blowing mechanism 211 includes a main pipe 2111, several sub-pipes 2112, several blowing pipes 2113 and several blowing ports 2114. The main pipe 2111 is provided with front-to-back The sub-pipes 2112 arranged in sequence, the lower end of the sub-pipe 2112 is provided with a blowing pipe 2113, the blowing pipe 2113 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com