Docking buffer

A technology for docking vehicles and shock absorbers, applied in thin material handling, transportation and packaging, loading/unloading, etc., can solve problems such as loss of elasticity, achieve simple structure, increase possibilities, and save manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

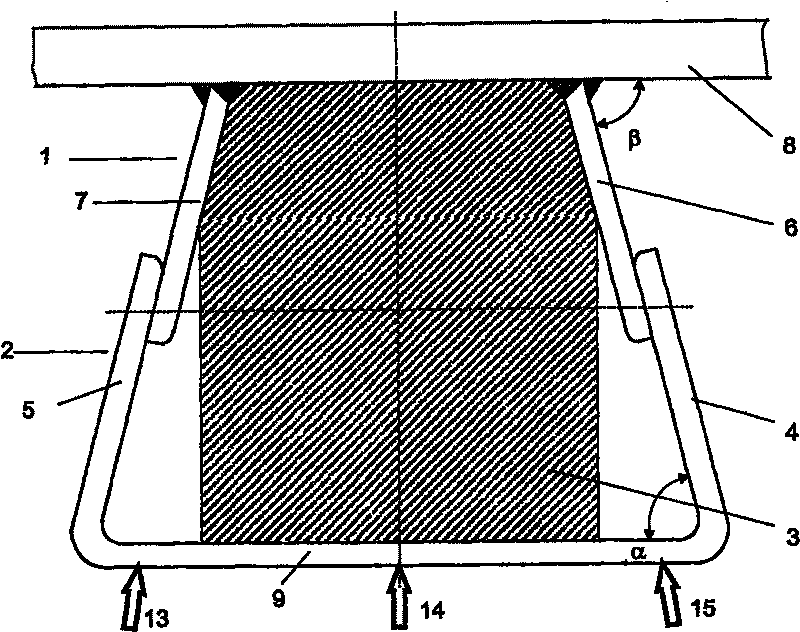

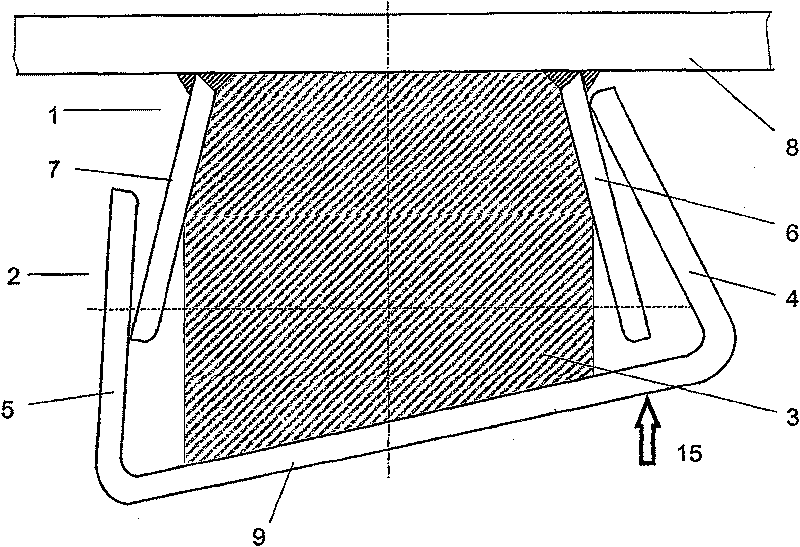

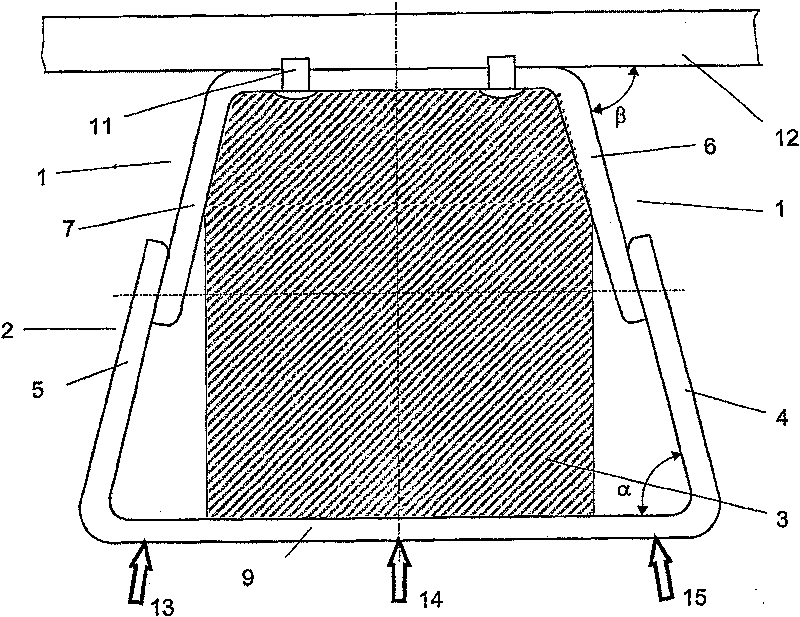

[0026] figure 1 An embodiment of the parked vehicle shock absorber of the present invention is shown, including the basic components of the parked vehicle shock absorber.

[0027] In this case, the U-shaped part 1 with the arms 6 and 7 is formed from a flat steel plate welded to the base plate 8 , which is arranged vertically and diverges at an angle β to the base plate 8 other than 90°. The opening of arms 4 and 5 and 6 and 7 and the angles α and β are chosen such that arms 4 and 5 grip arms 6 and 7 . It can be clearly seen from the figure that the width of the U-shaped part 2 is greater than that of the U-shaped part 1, which provides greater reliability for safely parking the vehicle. The arms 4 and 5 of the U-shaped part 2 converge at an angle α relative to the base surface 9 which is different from 90°. Angles α and β are nominally equal, but their tolerances are chosen such that angles α and β allow a small negative tolerance during manufacturing. This is to avoid too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com