Non-oriented electrical steel for hub motor of portable electric bicycle and manufacturing method of non-oriented electrical steel

A technology of electric bicycles and oriented electrical steel, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of difficult processing and low efficiency of non-oriented steel, and achieve the reduction of processing fracture tendency, low loss, and improvement of transverse electromagnetic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

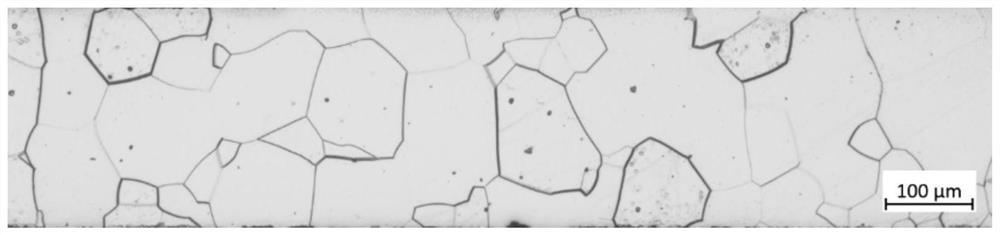

[0042] Such as figure 1 As shown, a non-oriented electrical steel for the hub motor of a portable electric bicycle, including the following components by weight percentage: Si: 2.38%; Als: 1.21%; Mn: 0.45%; P: 0.07%; C: ≤0.0, 3% S: ≤0.003%; N: ≤0.003%; Ti: ≤0.003%, the rest is iron and unavoidable impurities; the weight percentage of C, S, N and Ti satisfies the following formula: C%+S%+ N%+Ti%=0.0082%.

[0043] A method for manufacturing a non-oriented electrical steel for a hub motor of a portable electric bicycle as described above, comprising the following steps:

[0044] The molten steel made of each component is cast to form a slab: the molten iron is pretreated and enters the converter for smelting, and the molten steel after converter smelting is decarburized and alloyed through the RH furnace, and Si, Al, Mn, P, etc. Alloying elements are fine-tuned; molten steel whose composition meets the design requirements is continuously cast into a 230mm slab;

[0045] Slab h...

Embodiment 2

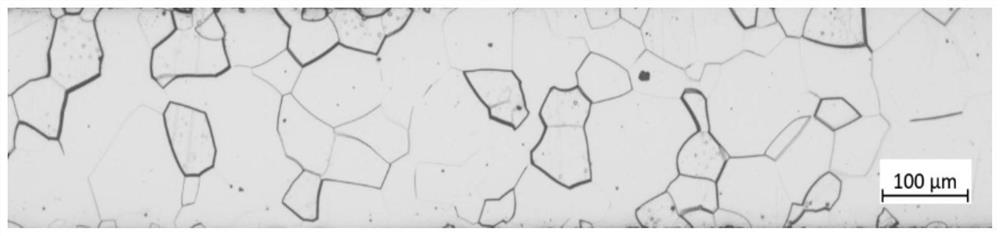

[0054] A non-oriented electrical steel for hub motors of portable electric bicycles, comprising the following components by weight percentage: Si: 2.43%; Als: 1.11%; Mn: 0.38%; P: 0.06%; C: ≤0.0028% S: ≤ 0.0028%; N: ≤0.0028%; Ti: ≤0.0028%, the rest is iron and unavoidable impurities; wherein the weight percentage of C, S, N and Ti satisfies the following formula: C%+S%+N%+Ti% = 0.0080%.

[0055] A method for manufacturing a non-oriented electrical steel for a hub motor of a portable electric bicycle as described above, comprising the following steps:

[0056] The molten steel made of each component is cast to form a slab: the molten iron is pretreated and enters the converter for smelting, and the molten steel after converter smelting is decarburized and alloyed through the RH furnace, and Si, Al, Mn, P, etc. Alloying elements are fine-tuned; molten steel whose composition meets the design requirements is continuously cast into a 230mm slab;

[0057] Slab heating and heat pr...

Embodiment 3

[0066] A non-oriented electrical steel for hub motors of portable electric bicycles, comprising the following components by weight percentage: Si: 2.34%; Als: 1.01%; Mn: 0.40%; P: 0.07%; C: ≤0.003% S: ≤ 0.003%; N: ≤0.003%; Ti: ≤0.003%, the rest is iron and unavoidable impurities; the weight percentage of C, S, N and Ti satisfies the following formula: C%+S%+N%+Ti% = 0.0074%.

[0067] A method for manufacturing a non-oriented electrical steel for a hub motor of a portable electric bicycle as described above, comprising the following steps:

[0068] The molten steel made of each component is cast to form a slab: the molten iron is pretreated and enters the converter for smelting, and the molten steel after converter smelting is decarburized and alloyed through the RH furnace, and Si, Al, Mn, P, etc. Alloying elements are fine-tuned; molten steel whose composition meets the design requirements is continuously cast into a 230mm slab;

[0069] Slab heating and heat preservation: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com