Disc brake and spacer element

A technology of disc brakes and isolation components, which is applied in the direction of brake components, brake types, mechanical equipment, etc., can solve the problems of excessive wear, slipping, and insufficient hardness of brake pads, and achieve reliable buffering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In this document, the terms "axial", "radial", "rotational" and similar expressions are relative to the axle (not shown) to which the brake is connected, and received on the axle directly or through an intermediate member For brake discs, hubs or bushings, etc.

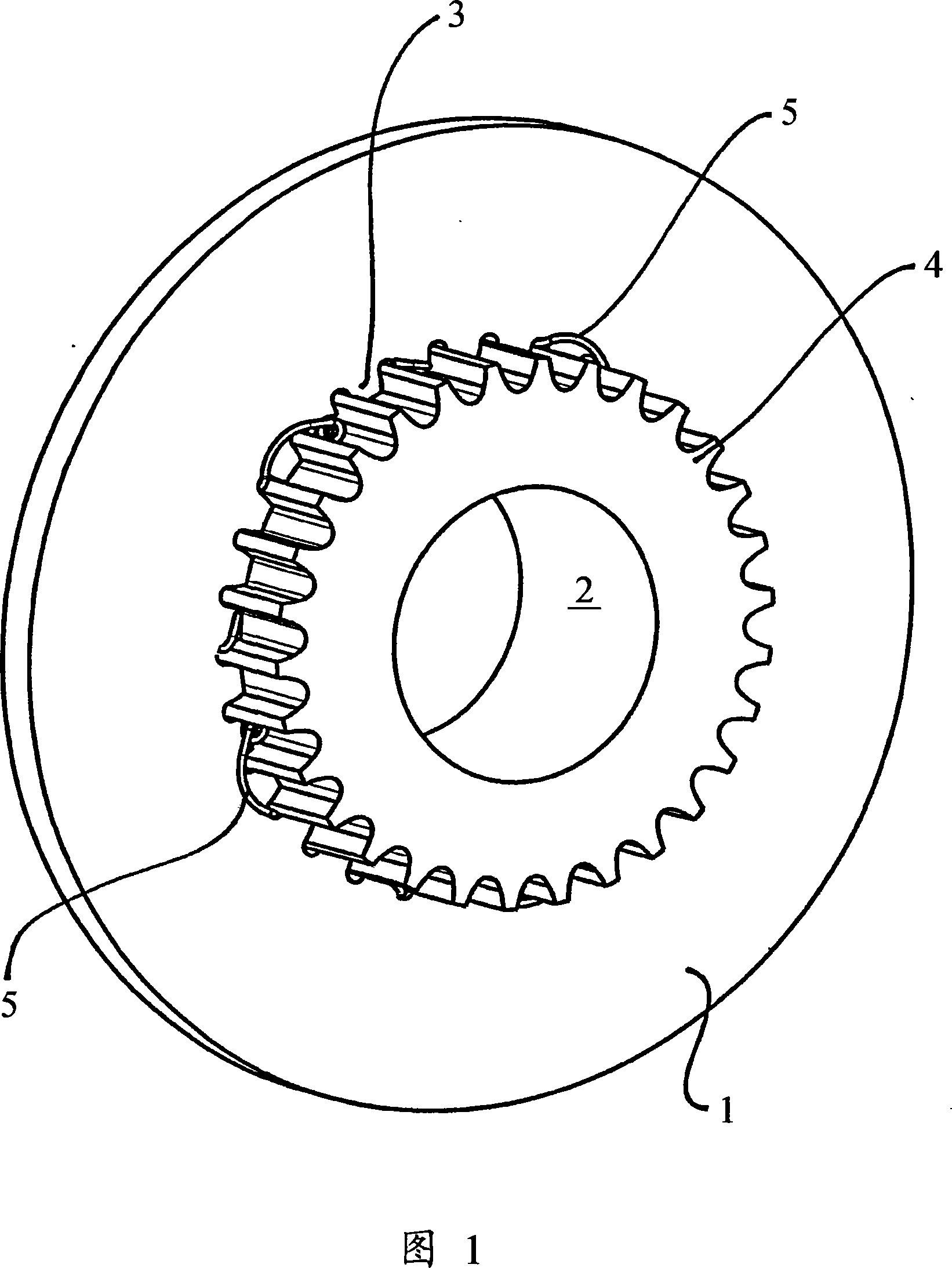

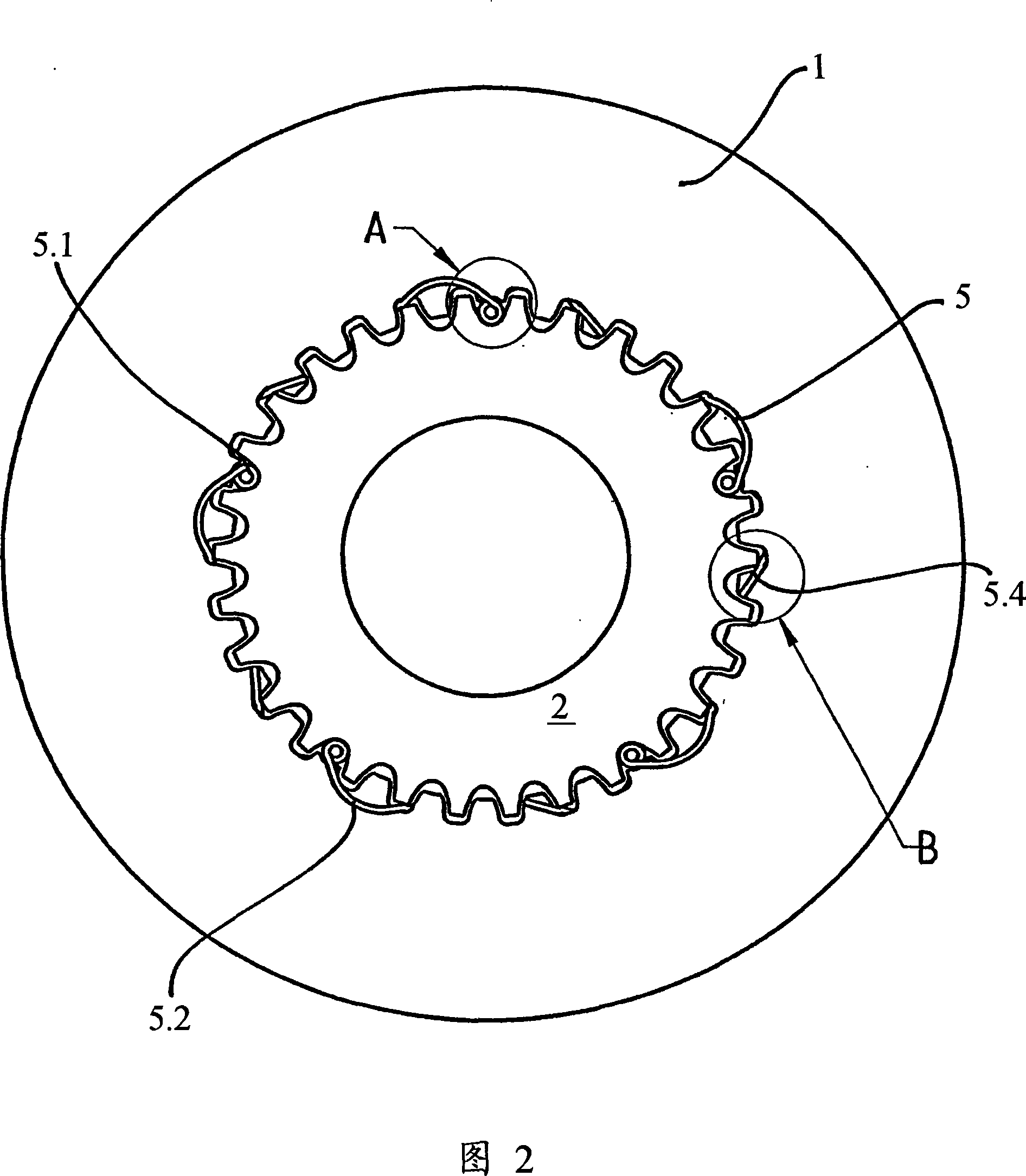

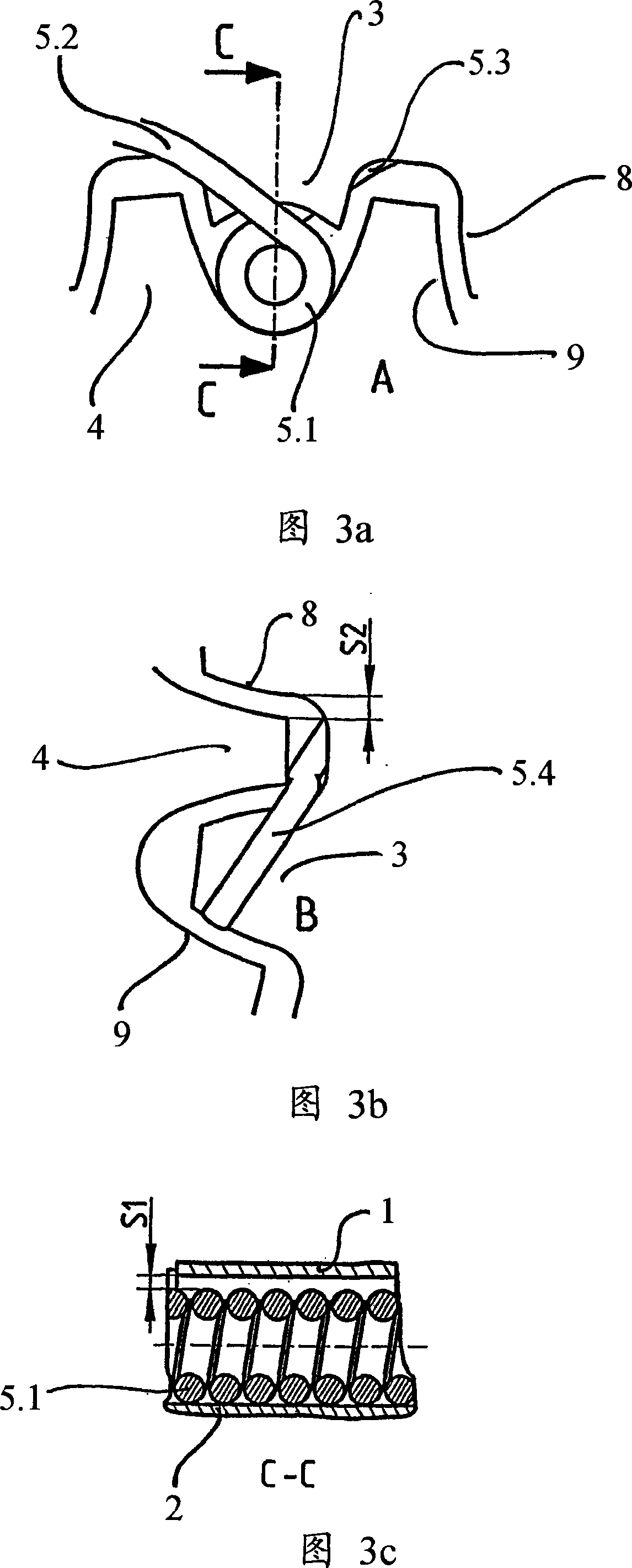

[0065] FIG. 1 schematically shows a brake disk 1 and a hub 2 , wherein the brake disk 1 is guided slidingly on the hub 2 . This arrangement can be used for any type of disc brake assembly in which at least one brake disc is slidingly guided.

[0066] The brake disc 1 comprises radially inward teeth or splines 3 which intermesh with radially outward teeth or splines 4 provided on the hub 2 . The splined engagement allows the transmission of rotational forces or torques when the brake disc 1 and brake pads (not shown) are mated and at the same time the brake disc 1 slides axially on the hub 2 .

[0067] Between the splines 3 of the brake disc 1 and the splines 4 of the hub 2 , spacer elements 5 are arranged equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com