Full-automatic bagging system

A fully automatic, filling system technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as waste of resources, factory trouble, disconnection, etc., to improve work efficiency, reduce labor intensity, and avoid equipment idling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

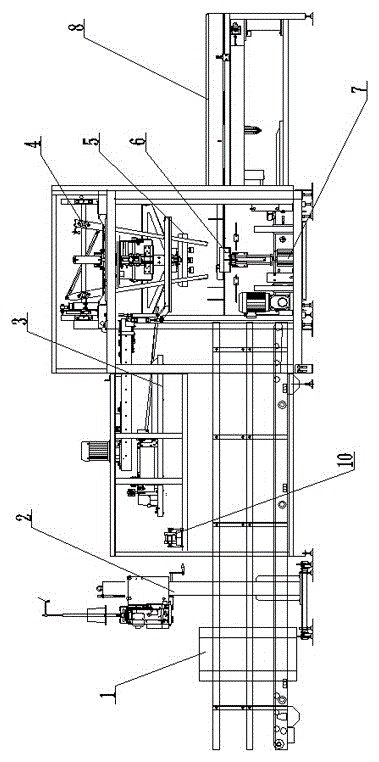

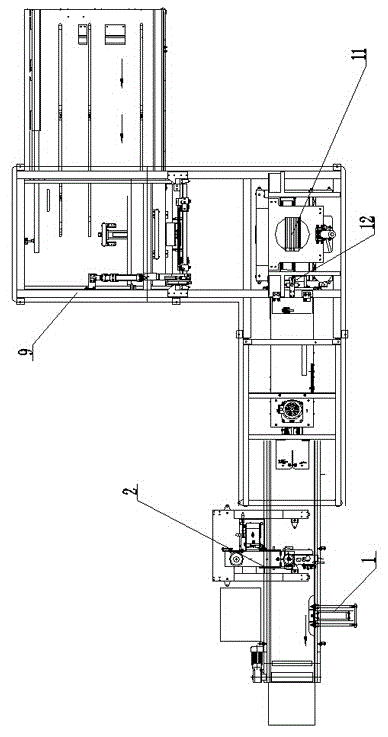

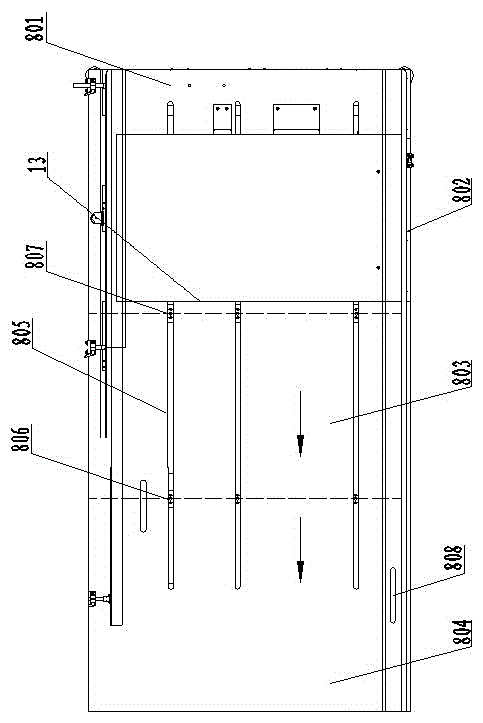

[0045]Fully automatic bag filling system, including sequentially connected bag feeding system, suction bag system, filling system, automatic labeling system and conveying system, bag feeding system includes bag feeding platform 8 and packaging bag stripping set on bag feeding platform 8 Device 9; the suction bag system includes a packaging bag suction device 5 and a faulty bag removal device 6; the filling system includes a bag supporting device 4, a filling device 11 and a packaging bag shaping device 12; the conveying system includes a packaging bag automatic introduction device 3, empty Load balance compensation conveyor 7, automatic labeling machine 10 and automatic sewing bag pushing device; packaging bag peeling device 9 includes peeling lifting cylinder 904, and a fixed cross bar 903 is connected under the peeling lifting cylinder 904, and the two ends of the fixed cross bar 903 are A brush support 906 is connected; a clamping brush 902 is connected under the brush suppo...

Embodiment 2

[0067] The difference between embodiment two and embodiment one is that the packaging bag peeling device 9 is different, and the packaging bag peeling device 9 of embodiment two is as follows: the packaging bag peeling device 9 includes a peeling lifting cylinder 904, and a fixed cross bar 903 is connected under the peeling lifting cylinder 904 , the two ends of the fixed cross bar 903 are connected with a brush bracket 907; the brush bracket 907 is connected with a clamping brush 902, and the front end of the brush bracket 907 is provided with a stripping brush 910; the clamping brush 902 is vertically arranged; The bristles at the bottom of the tight brush 902 are arranged obliquely, and the angle of inclination is 30°-60°; the brush bracket 907 is fixedly connected with the clamping brush 902; the brush bracket 907 is connected to the peeling brush 910 through the brush connecting rod 912; The bottom of the peeling brush 910 is inclined outward, and the included angle betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com