Coupling system intended for use between cladding and structural elements supporting same

A technology of structural elements and linings, applied in the direction of connecting components, thin plate connections, aircraft parts, etc., can solve problems such as non-conformity and labor, and achieve the effects of ensuring resistance, improving joint characteristics, and light metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

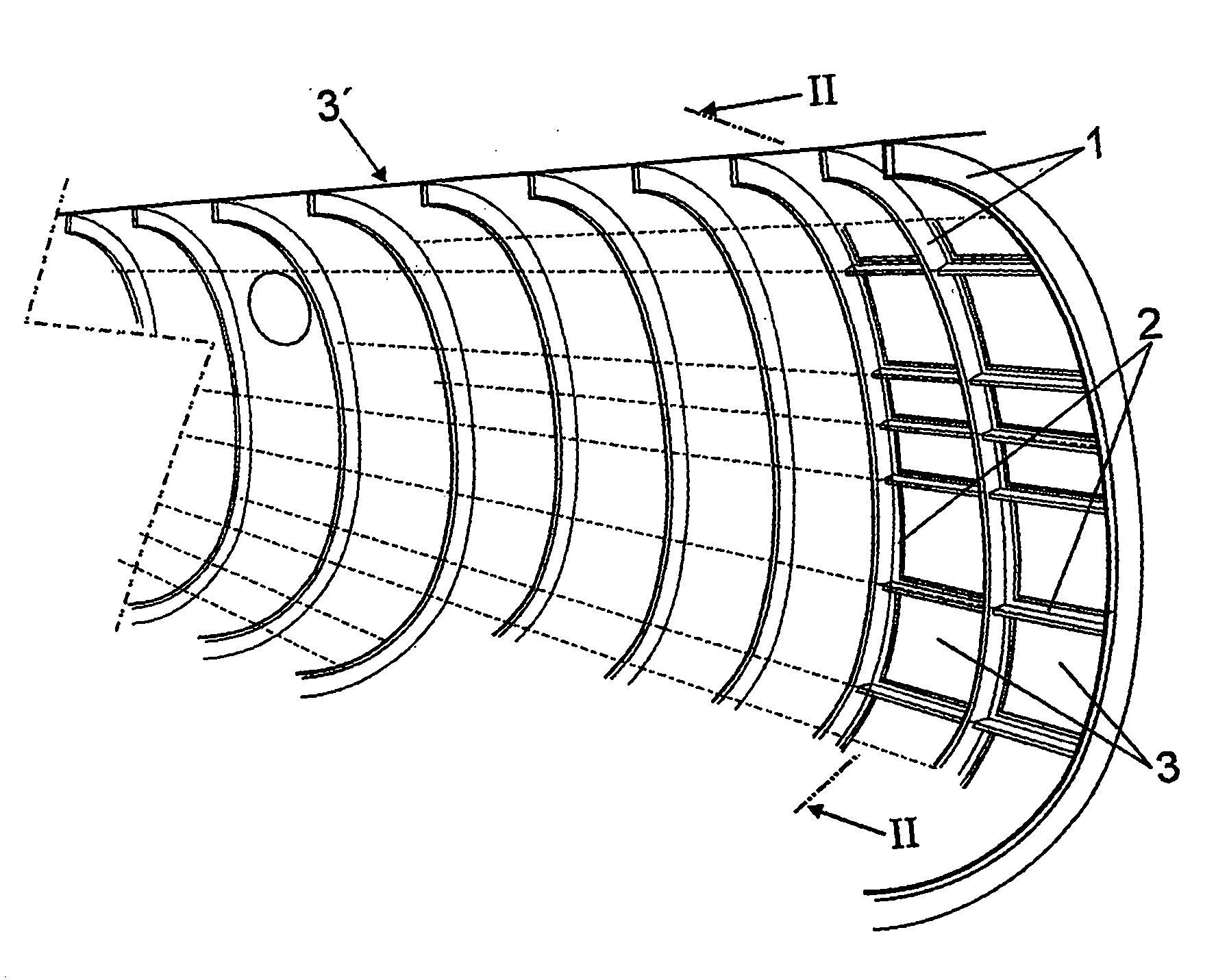

[0046] figure 1 shows an internal perspective view of an aircraft comprising a resistive structure comprising transverse ribs 1 and wing stringers 2, figure 2 The plate 3 forming the lining 3' is shown fastened thereto.

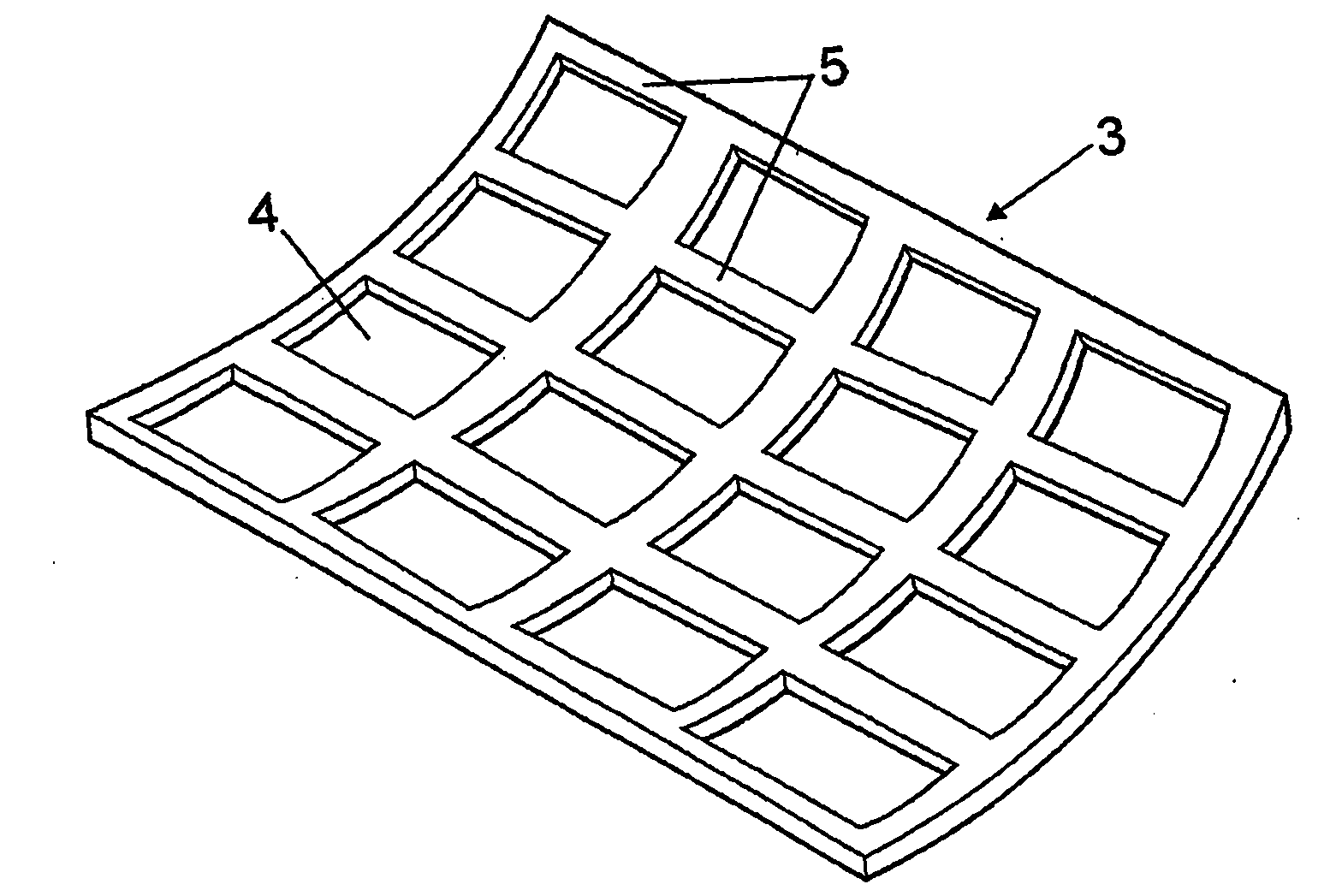

[0047] figure 2 Shown is an internal perspective view of one of these plates 3 having a recessed area 4 called a bay, which is delimited by a non-recessed strip 5 defining a Rib 1 and corresponding rib network for wing stringer 2 fastened thereto. The recess 4 makes it possible to reduce the weight of the lining panel 3 .

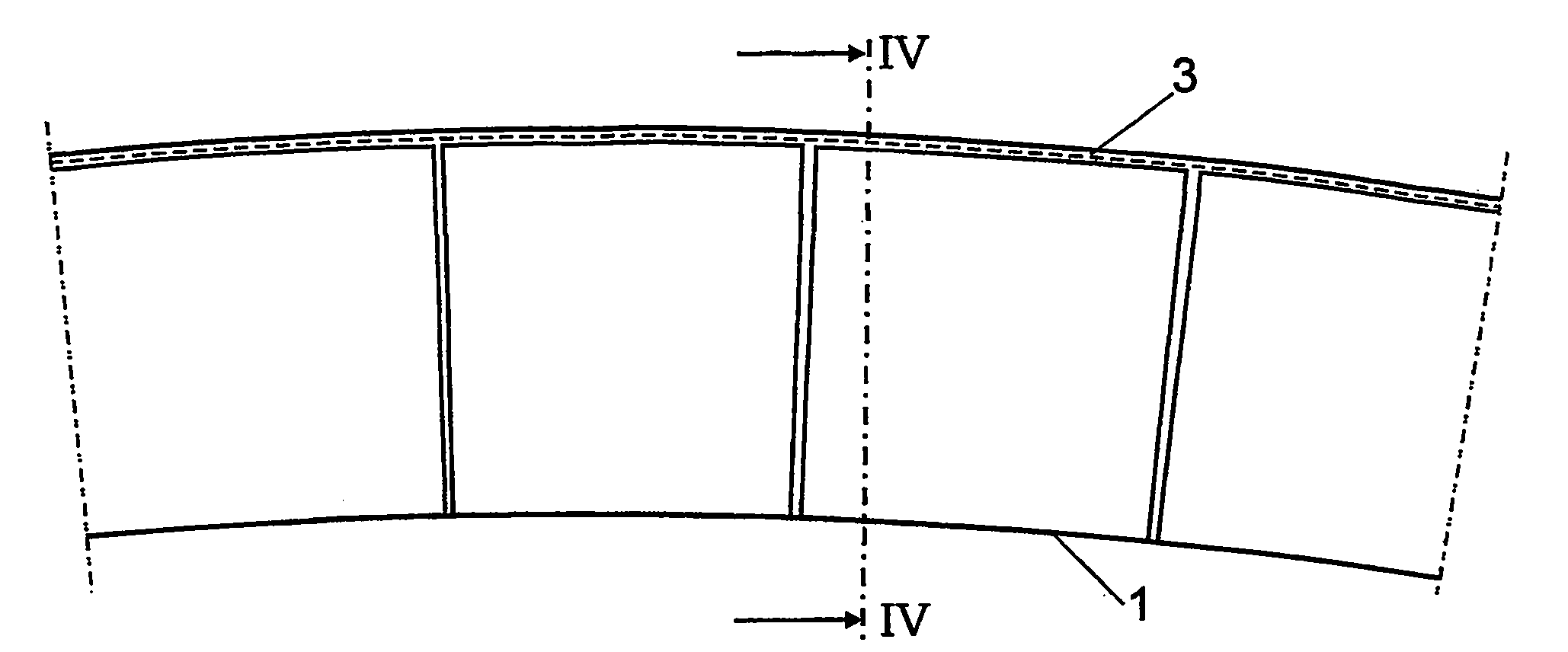

[0048] According to the present invention, in figure 1 The structural elements of the plate 3 on which the lining 3' is fastened, defined by the ribs 1 and the wing stringers 2, and the lining plate 3 comprise joint means consisting of a male dovetail formation 6 and a female The dovetail configuration 7 is defined, which can be obtained from image 3 and Figure 4 observed in. The male formations 6 will preferably form a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com