Patents

Literature

81results about How to "Reduce drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

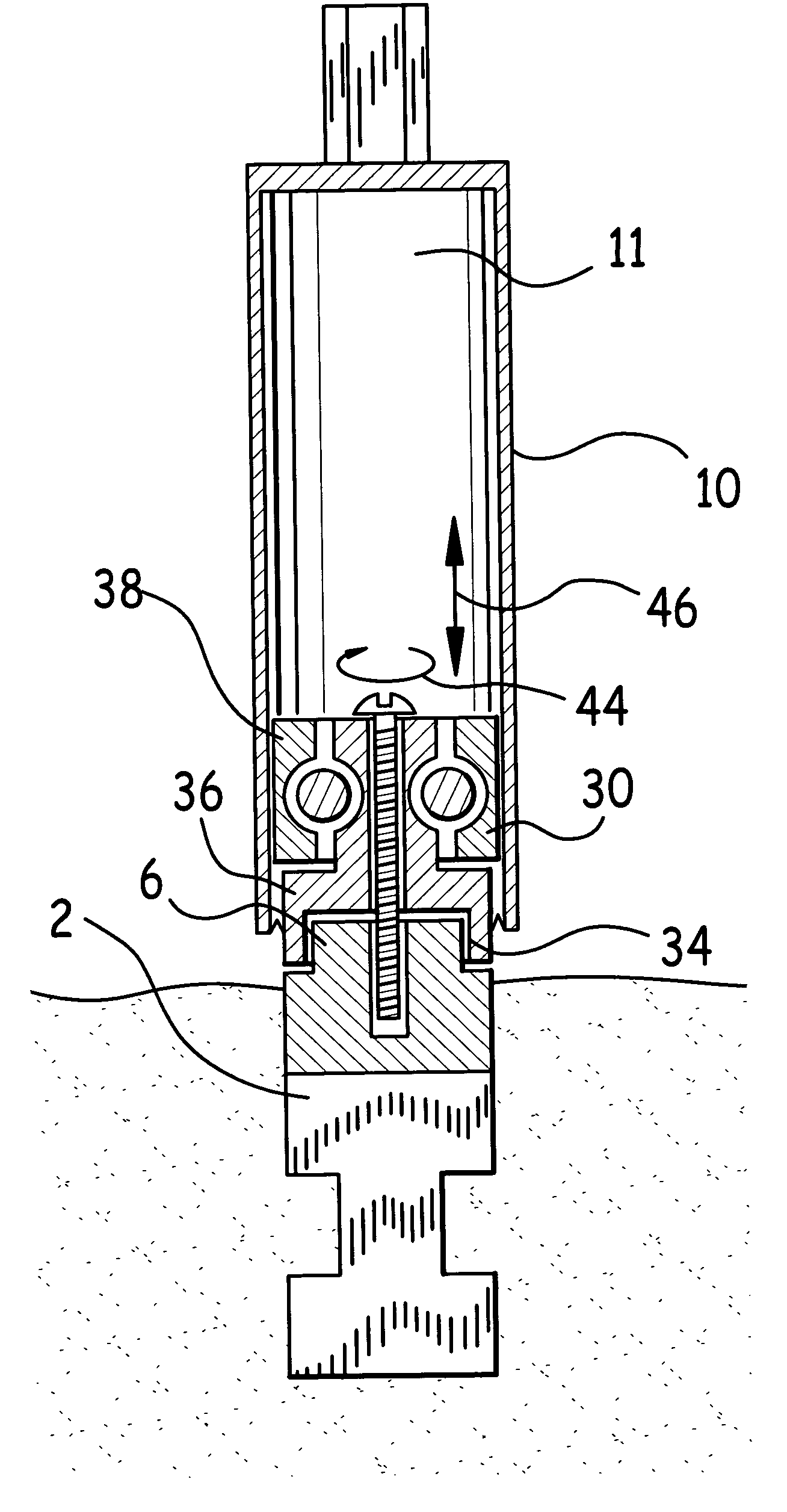

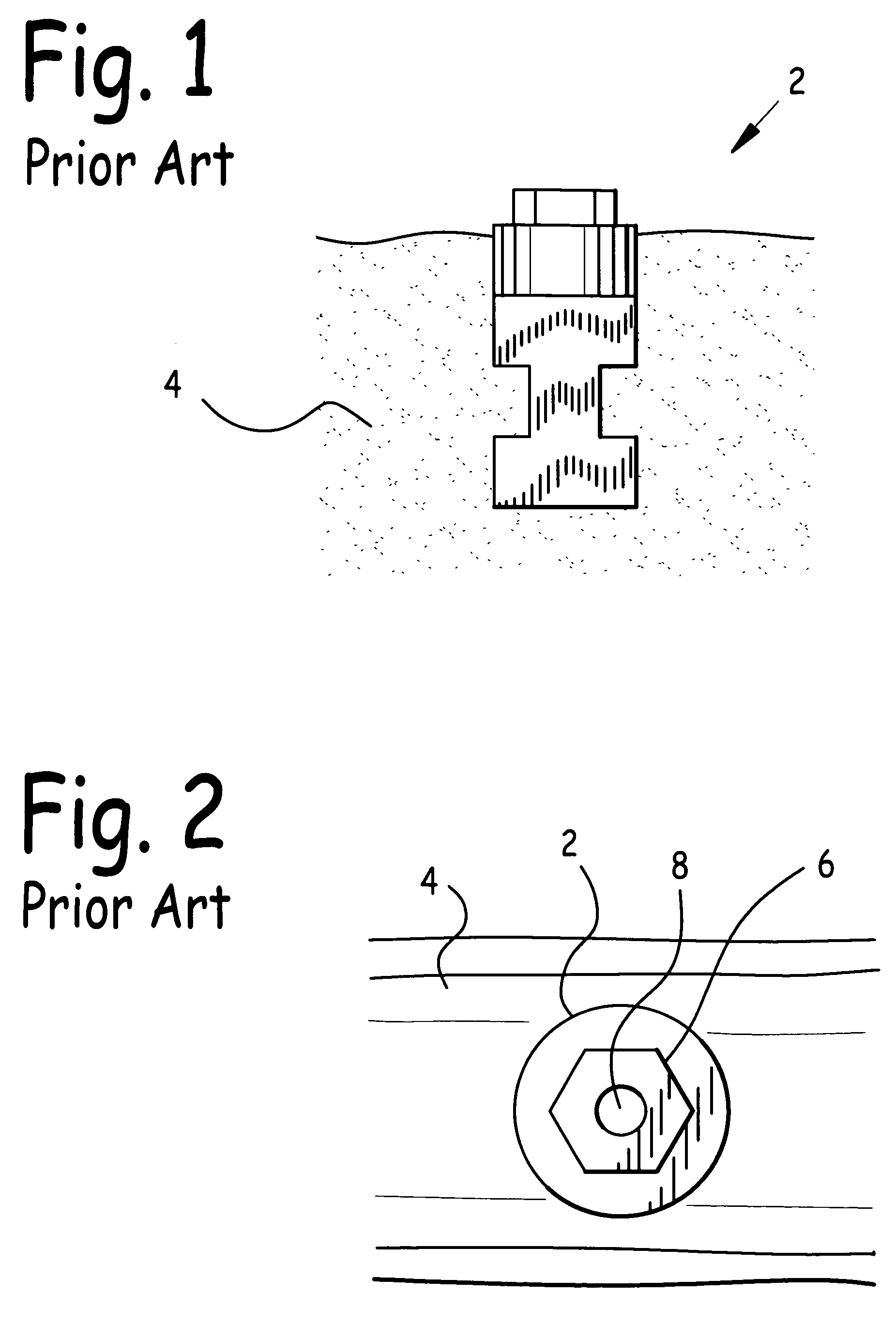

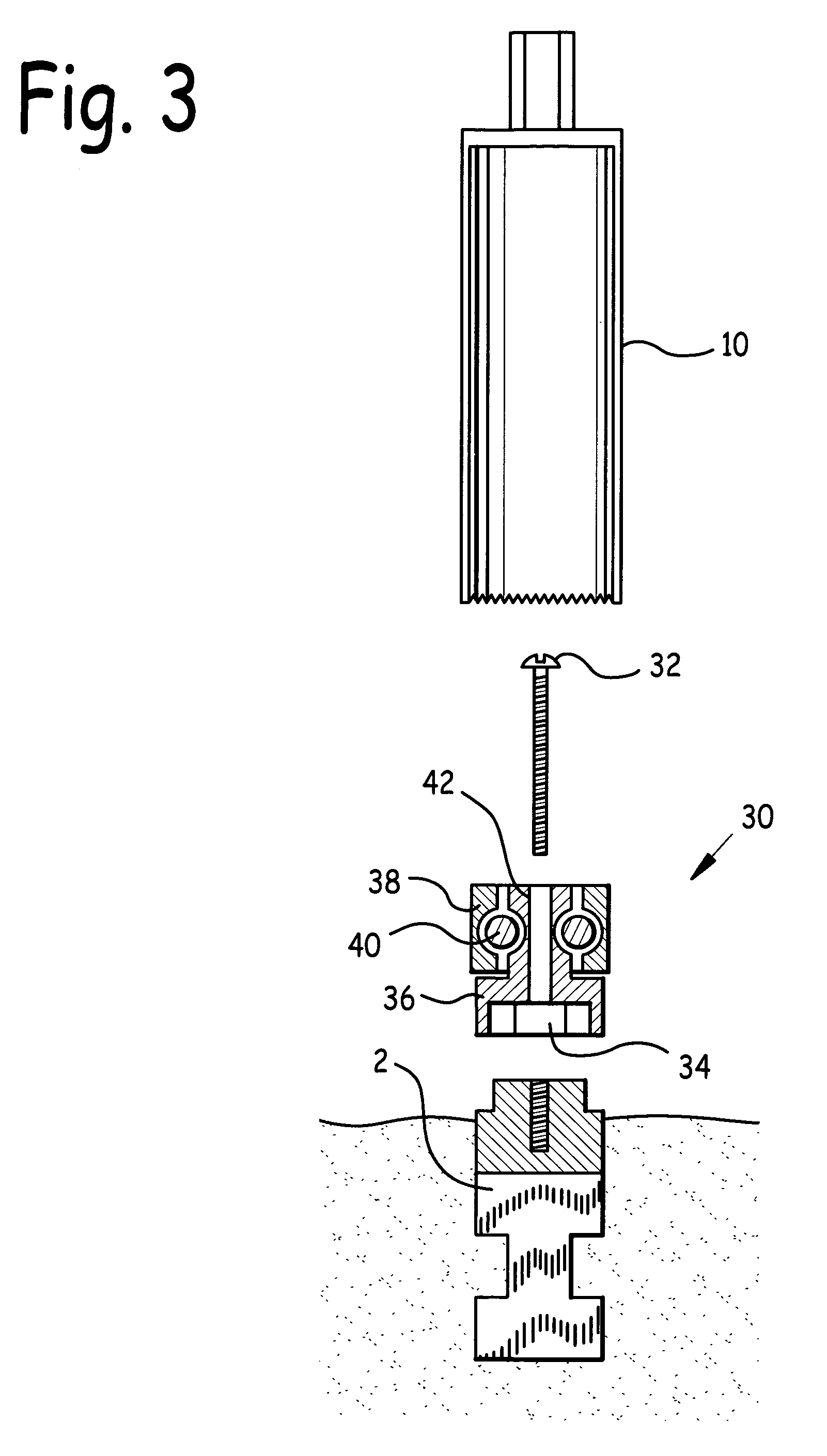

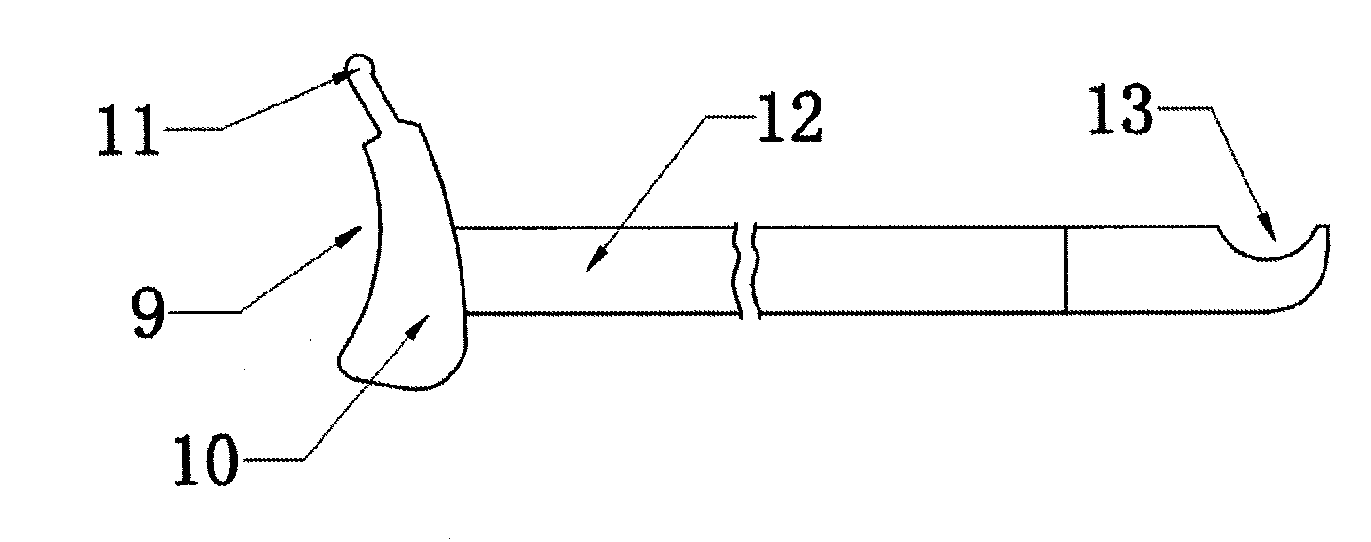

Apparatus and method to remove dental implant

InactiveUS7179084B1Reduce drillingImprove efficiencyDental implantsDental toolsImplanted deviceBone trephine

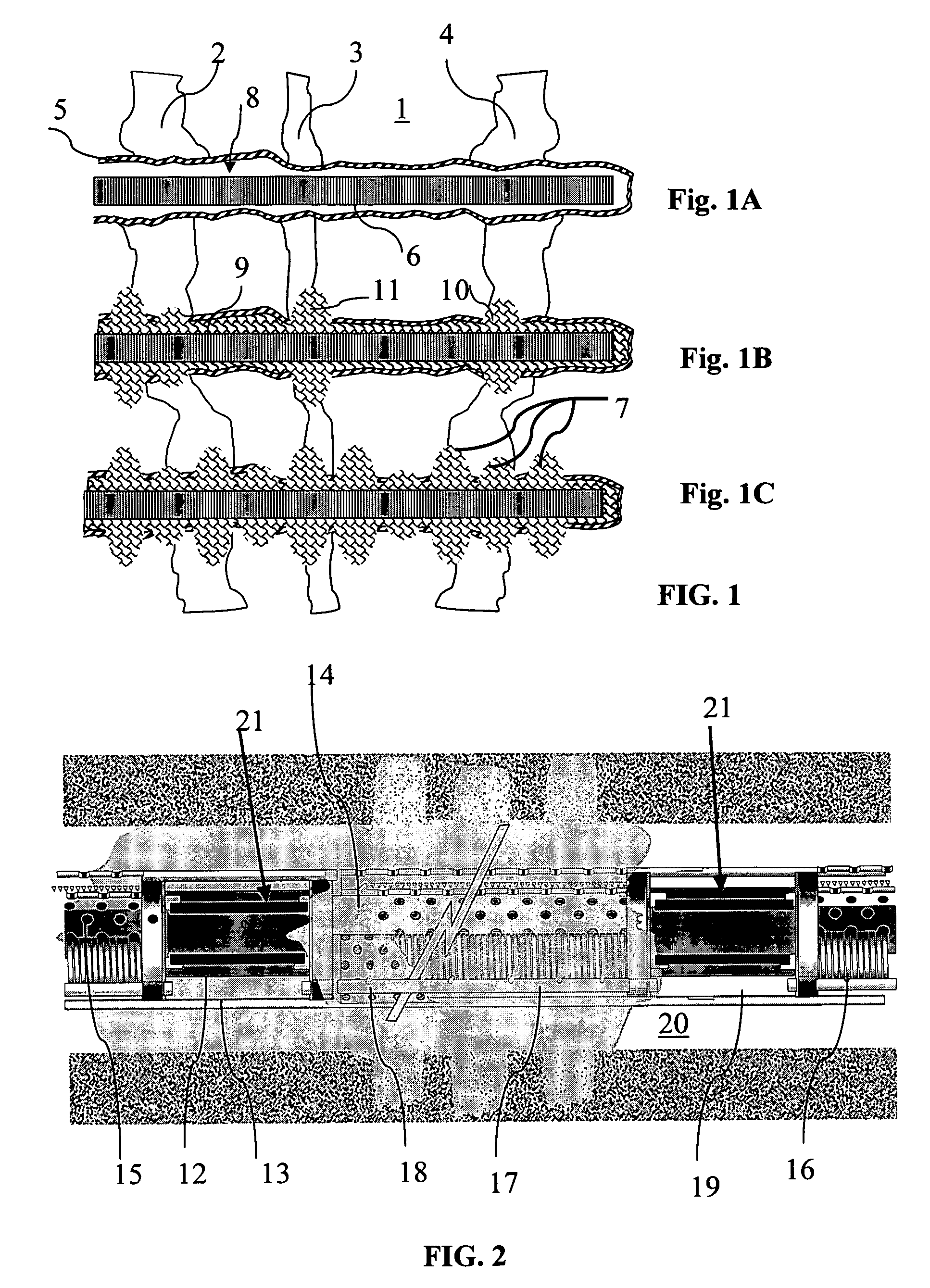

A method and apparatus to remove dental implant. The apparatus comprises a guide ring rotatably attached to a base, means to rotatably attach the guide ring to the base, means to attach the apparatus to an implant, and apparatus to remove dental implant indexing means sized to mate with implant indexing means when the apparatus is attached to the implant. Where an abutment is mounted to the implant, means of attaching the base to the abutment is taught. The method includes the steps of attaching the apparatus to an implant or abutment, sliding a trephine burr bore over the guide ring, and using the guide ring to guide the trephine while drilling into bone in which the implant is implanted, without drilling into the implant or abutment.

Owner:KOMETAS ATHAS N

Method and gravel packing open holes above fracturing pressure

InactiveUS7152677B2Reduce drillingReduce completion costFluid removalVibration devicesSlurryWellbore

The present invention provides a method for gravel packing a open-hole wellbore having a filter cake, comprising pumping a gravel slurry into a first portion of an annulus between the wellbore and a screen, at a sufficient rate and pressure to form at least a first fracture and diverting the gravel slurry to a second portion of said annulus through alternate flowpaths while providing hydraulic isolation between the first and the second portion of said interval, thereby preventing flowback from said second portion to said first portion and resulting extension of the first fracture, and thereby forming a second fracture in said second portion of said interval.

Owner:SCHLUMBERGER TECH CORP

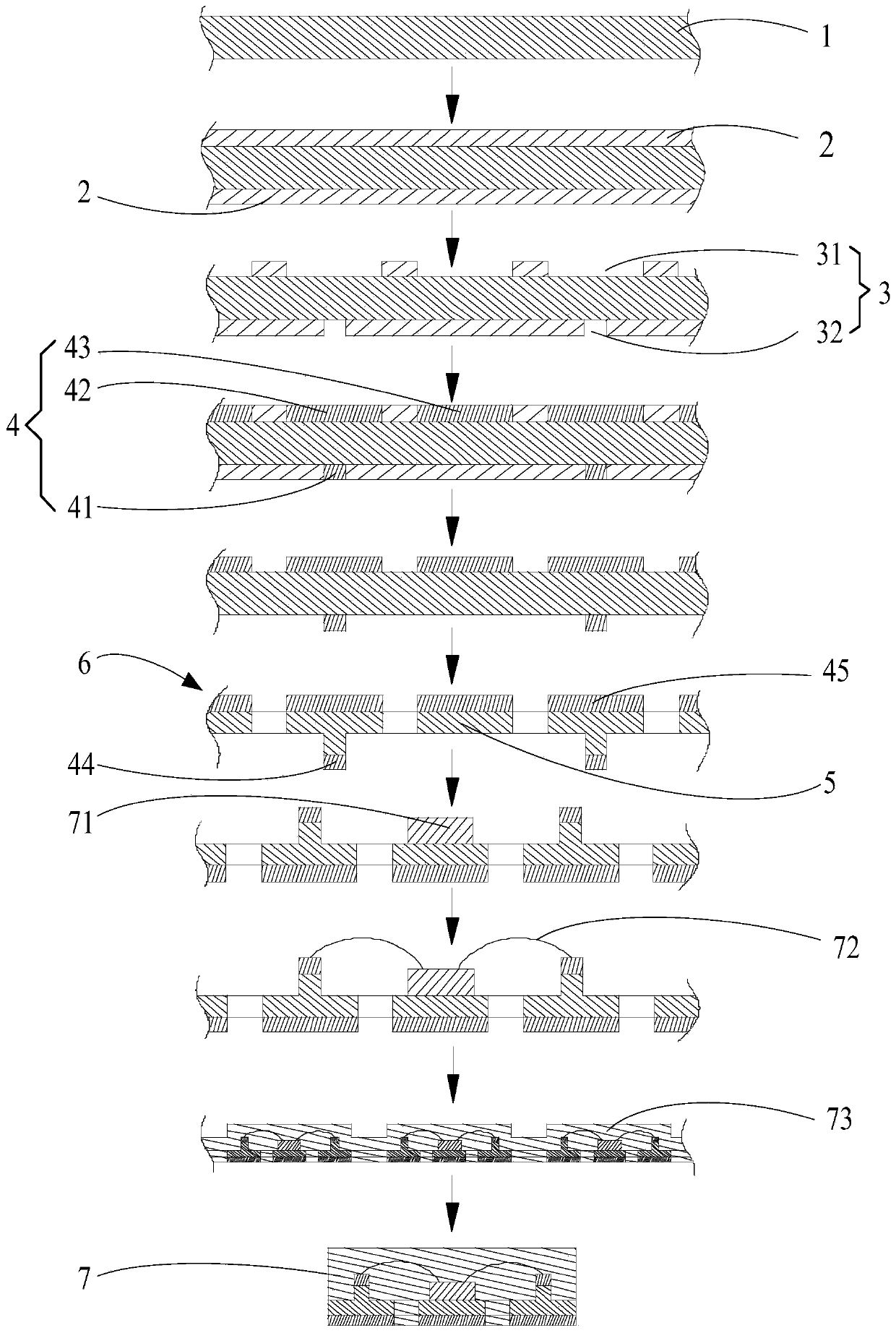

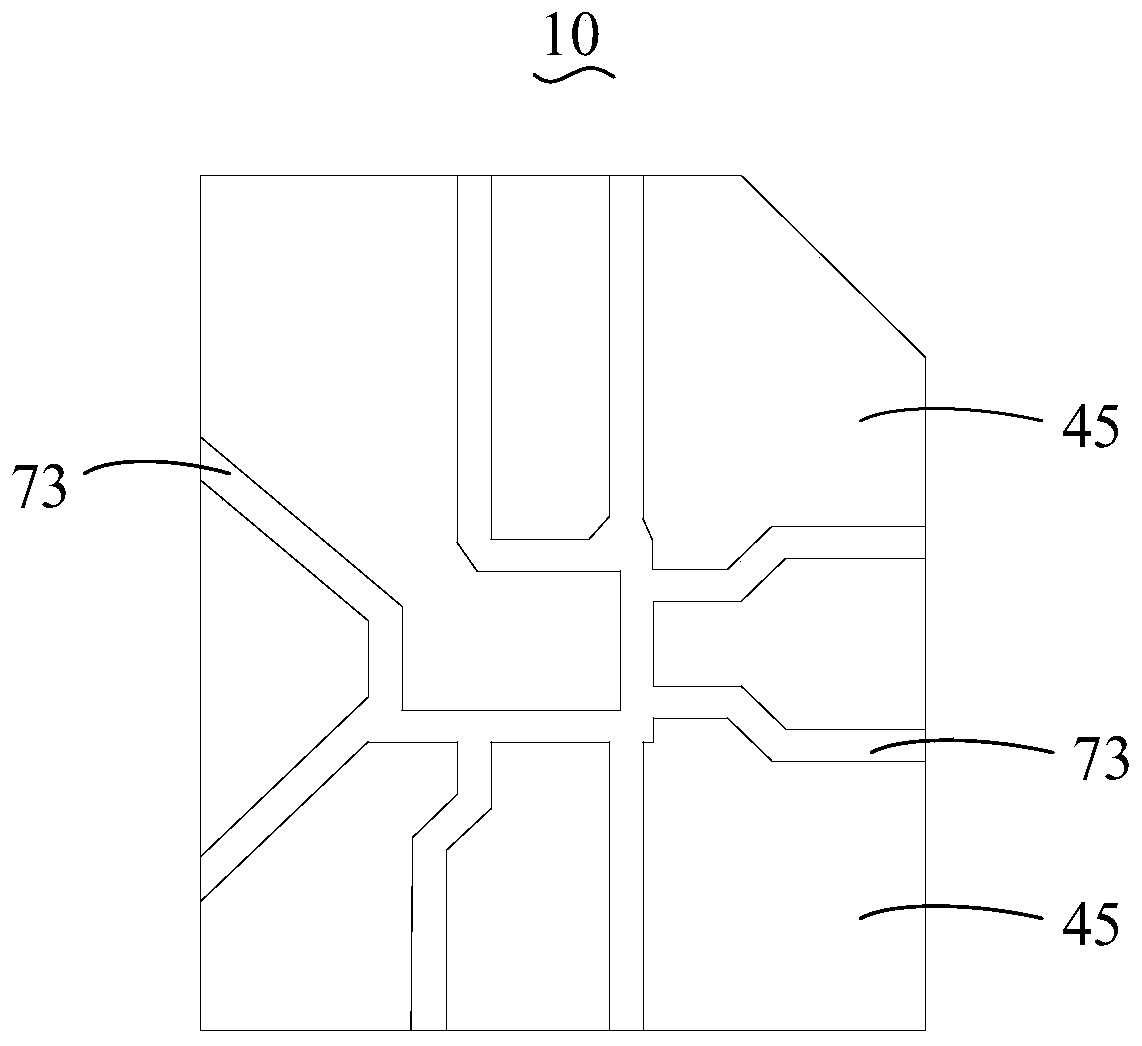

Inner layer bonding pad later-windowed rigid-flexible printed circuit board and manufacturing method thereof

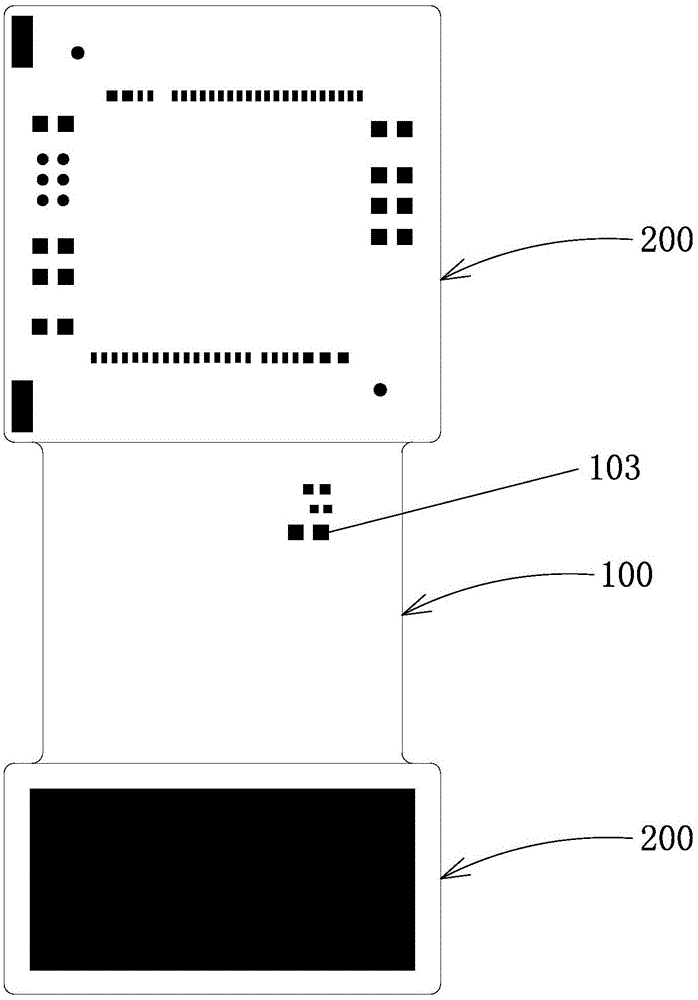

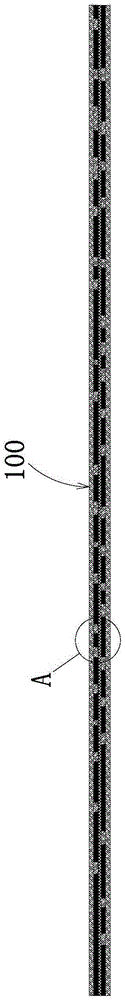

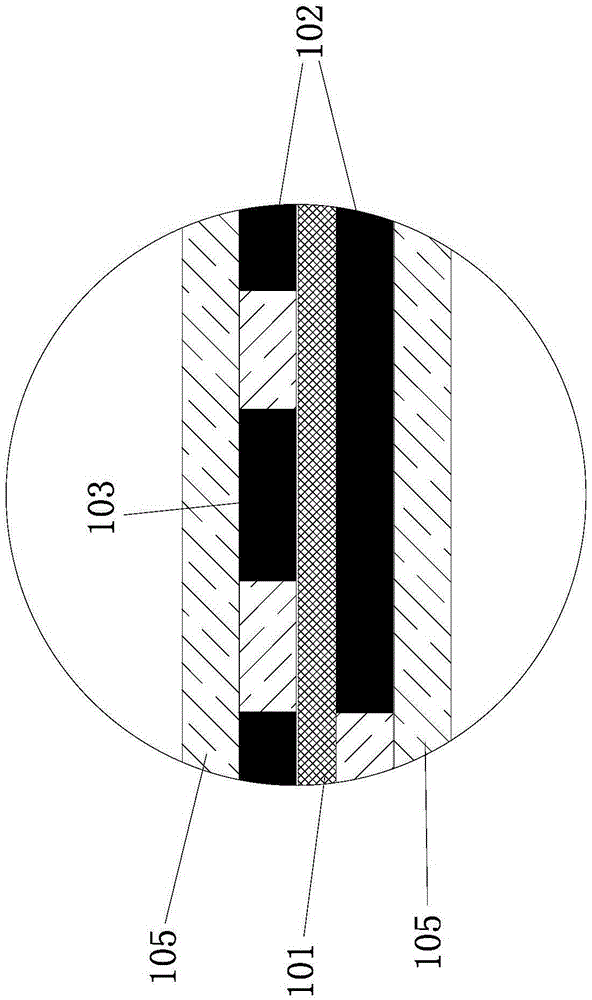

ActiveCN105142337AImprove efficiencyImprove yieldElectrical connection printed elementsMultilayer circuit manufactureCopper foilEngineering

An inner layer bonding pad later-windowed rigid-flexible printed circuit board and a manufacturing method thereof. The manufacturing method includes the steps of: S1. cutting a flexible printed circuit board (FPC) base material, etching an FPC copper layer of the FPC base material to form an inner layer circuit according to a circuit design requirement, etching to form an inner layer bonding pad corresponding a windowing region according to a windowing requirement, the windowing region being guaranteed to fall in the range of the corresponding inner layer bonding pad when the inner layer bonding pad is formed by etching, and then gluing an inner layer covering film without a window on the surface of the FPC base material, thereby obtaining the FPC; S2. attaching an outer layer pure copper coil layer on a rigid printed circuit board base material and pressing the rigid printed circuit board base material in a rigid printed circuit board region of the FPC, thereby obtaining a rigid-flexible printed circuit board; and S3. using CO2 laser to perform windowing firing on a region that needs windowing of the inner layer covering film, and the windowing region being punched through and the inner layer bonding pad of the FPC being exposed, thereby obtaining the inner layer bonding pad later-windowed rigid-flexible printed circuit board. The manufacturing method provided by the invention has relatively high efficiency and yield.

Owner:SHENZHEN HUALIN CIRCUIT TECH

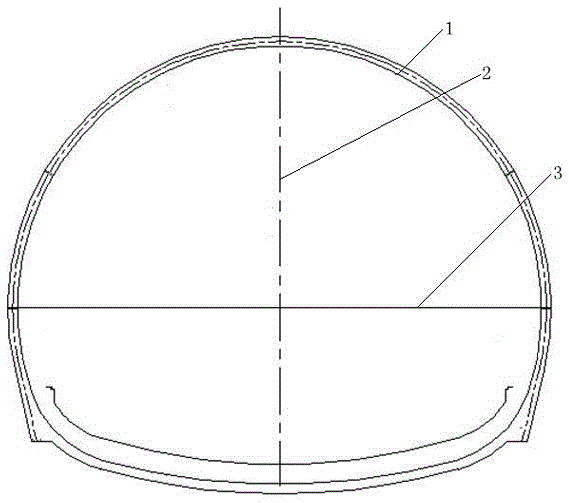

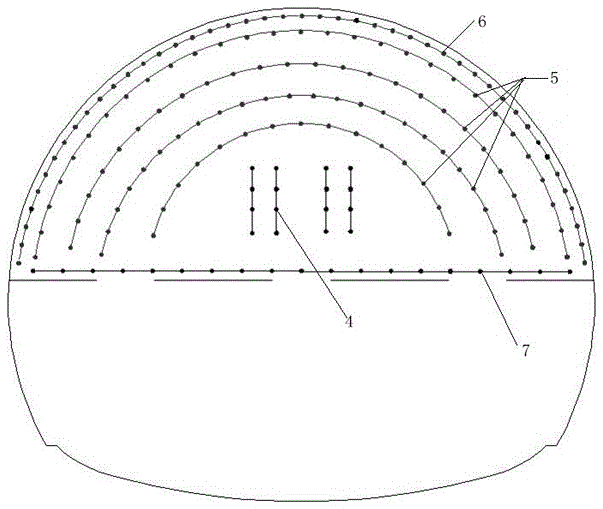

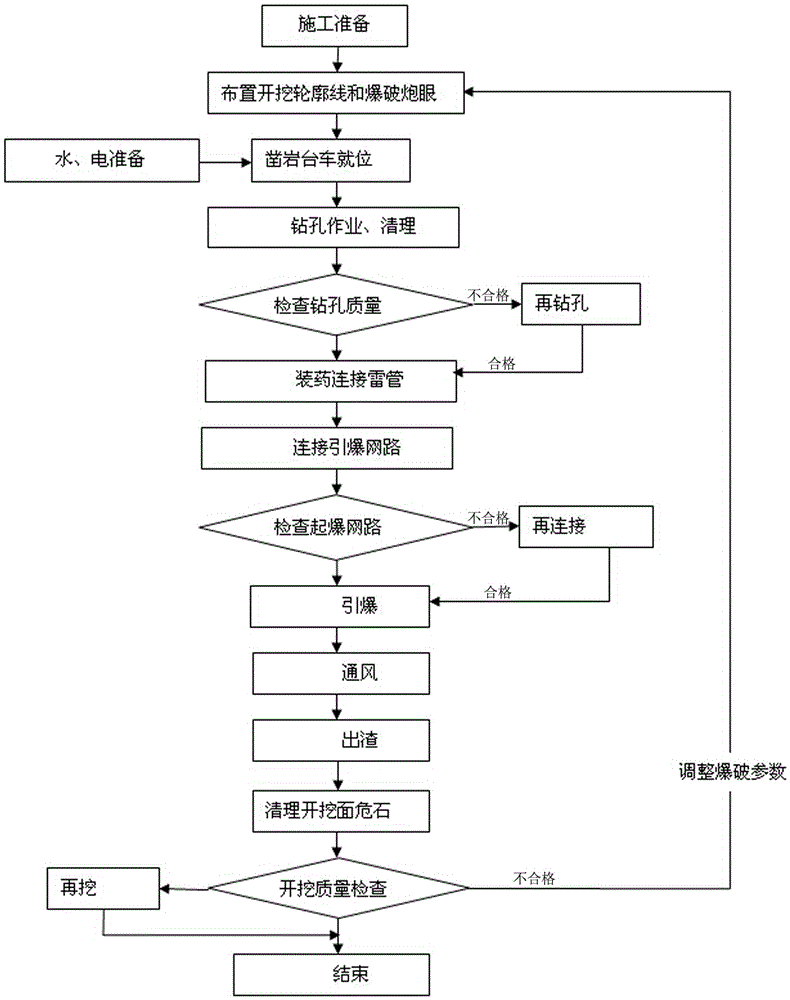

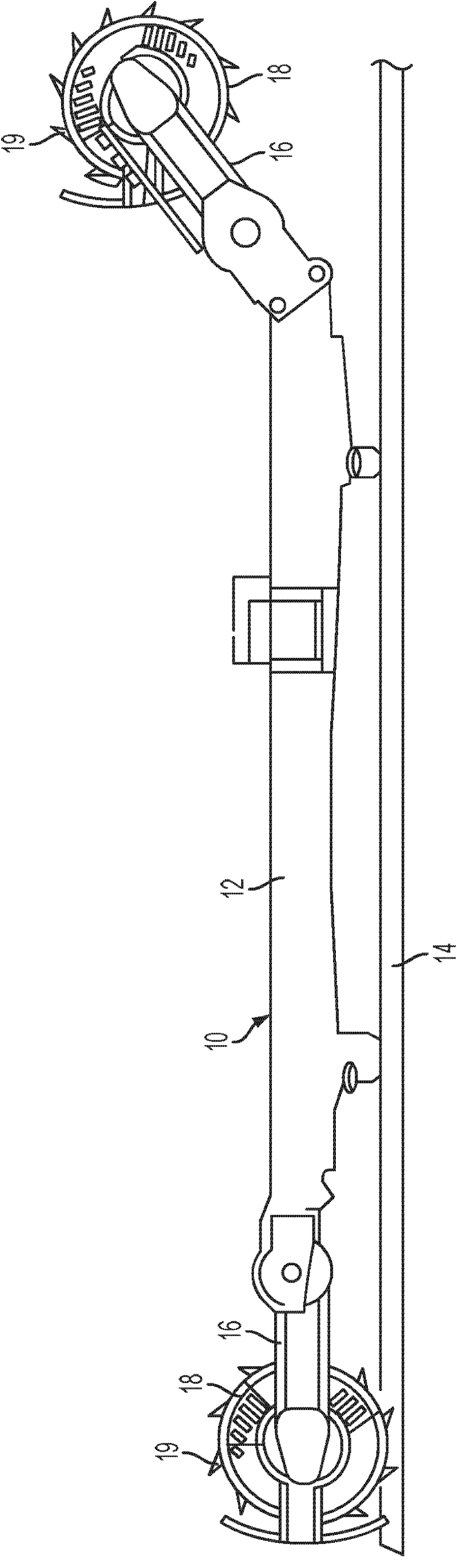

Method for carrying out bench cut method construction in IV-grade surrounding rocks by using three-arm drill jumbo

InactiveCN105605996APrecise positioningDrilling and blasting footage shortenedBlastingRock cuttingDrilling and blasting

The invention belongs to the technical field of tunnel rock mass construction, and particularly relates to a method for carrying out bench cut method construction in IV-grade surrounding rocks by using a three-arm drill jumbo. According to the method for carrying out bench cut method construction in the IV-grade surrounding rocks by using the three-arm drill jumbo, which is disclosed by the invention, a construction section is excavated by adopting smooth blasting; the characteristics of rapidness, positioning accuracy and safety of the three-arm drill jumbo are sufficiently utilized; drilling time is short; an extrapolation angle is easy to control; a drilling and blasting footage of the construction section is shortened; each cycle of drilling and blasting numbers are reduced; and particularly, the three-arm drill jumbo is used for carrying out drilling and blasting for the first time in the excavating process of an upper bench, and manual drilling and blasting are adopted on a lower bench, so that the rapid and accurate drilling operation is achieved, cycle operation time is reduced, and when drilling and blasting quality and operation efficiency are improved, the operation environment is improved, thereby improving integral efficiency of tunnel construction.

Owner:CCCC TUNNEL ENG

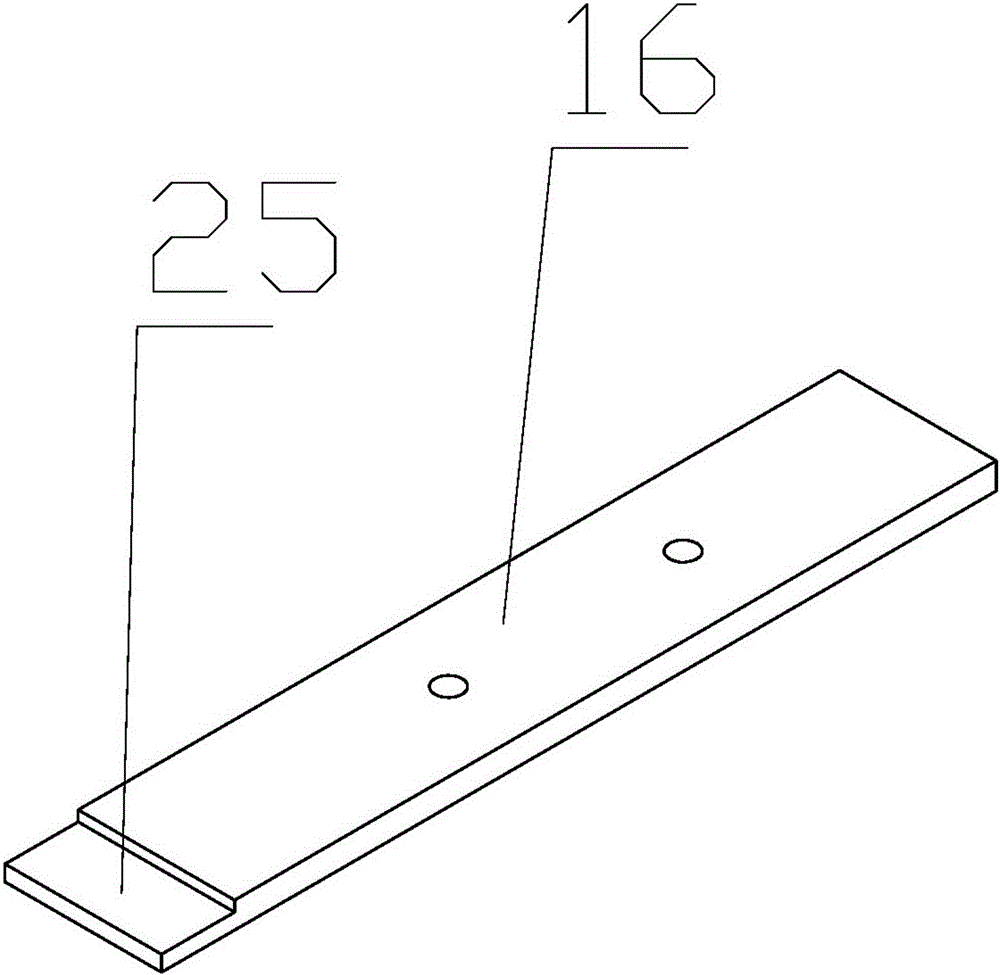

Production method of bamboo sleep mat

ActiveCN105108867AReduce drillingReduce manual weavingPretreated surfacesWood working apparatusEnvironmental resistanceEngineering

The invention discloses a production method of a mahjong block-shaped bamboo sleep mat which is environmental-friendly in property, convenient to process and low in cost. The production method comprises the following steps of bamboo chip processing, base cloth preparing, hot glue applying, hot glue melting into a glue solution, bamboo chip sticking, and cutting, or the following steps of bamboo chip processing, base cloth preparing, polyurethane glue applying, bamboo chip sticking, cutting, and glue solution curing. Bamboo chips are stuck on base cloth, so that processes of drilling and manual weaving in bamboo chip processing are reduced, braided wires such as ox-tendon imitating wires are also omitted, the cost is reduced greatly, the thicknesses of the bamboo chips are also reduced, and the weight and the size of the bamboo sleep mat are reduced greatly to facilitate conveying, folding, carrying and storing of the bamboo sleep mat; and besides, hot glue or polyurethane glue is used for sticking the bamboo chips, so that the environment is protected, the cost is low, the flow-line production can be realized, and the production efficiency is improved greatly.

Owner:TAOJIANG BINGMENG HOUSEHOLD PROD

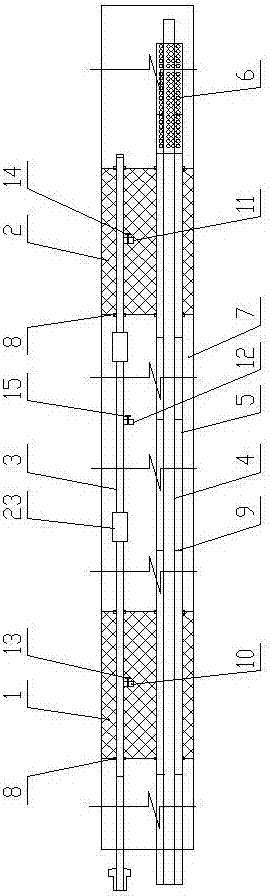

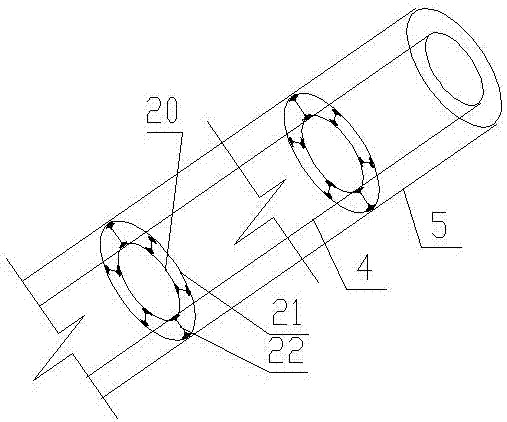

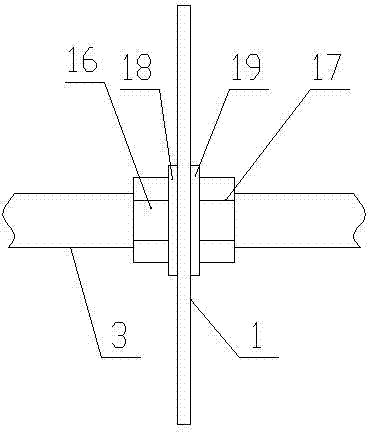

Hole-sealing, hydraulic-fracturing and gas-extraction integrated construction device and construction method thereof

ActiveCN107191172AImprove extraction efficiencyEasy extractionFluid removalGas removalThermodynamicsEngineering

A hole-sealing, hydraulic-fracturing and gas-extraction integrated construction device comprises a first bag, a second bag, a grouting pipe, a hydraulic fracturing pipe, a gas extraction pipe and a perforated pipe. The first bag is arranged in a drilled hole and located near a hole opening, the second bag is arranged in the drilled hole and located near the hole bottom, the grouting pipe and the gas extraction pipe both sequentially penetrate through the first bag and the second bag from left to right and then extend into the hole bottom, and the left end of the perforated pipe is coaxially and fixedly connected with the right end of the gas extraction pipe. The outer diameter of the hydraulic fracturing pipe is smaller than the inner diameter of the gas extraction pipe, the hydraulic fracturing pipe is coaxially arranged in the gas extraction pipe and the perforated pipe, and the right end of the hydraulic fracturing pipe rightwards extends out of the right end of the perforated pipe. The invention further discloses a hole-sealing, hydraulic-fracturing and gas-extraction integrated construction method, that is, after a hydraulic fracturing procedure, the hole continues to be used for gas extraction; and a novel layer-penetrating fracturing-gas extraction integrated hole drilling and sealing process is provided, the good versatility of the drilled hole is guaranteed, the number of drilled holes is reduced, and the construction cost is lowered accordingly.

Owner:HENAN POLYTECHNIC UNIV

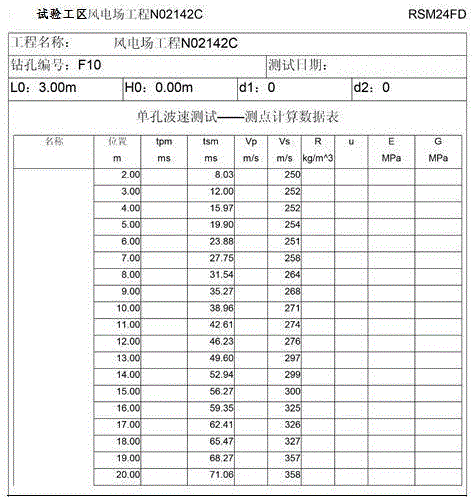

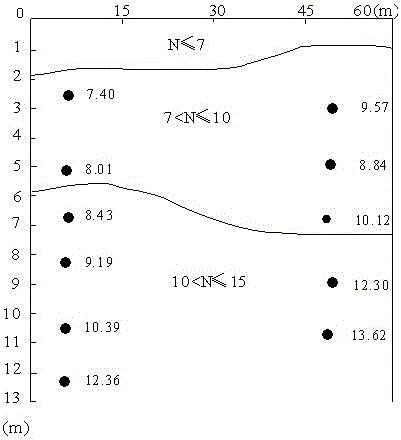

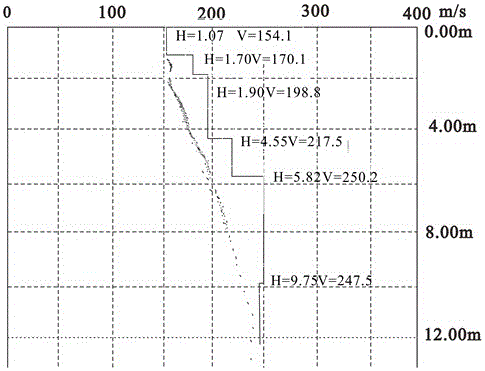

Method for determining mechanical parameters of stratum via Rayleigh wave speed

ActiveCN105676281AAccurate calculationReduce drillingSeismic signal processingEffective solutionMechanical index

The invention discloses a method for determining mechanical parameters of the stratum via the Rayleigh wave speed. According to the method, information from Rayleigh wave exploration is fully utilized, the mechanical parameters of the stratum in geotechnical engineering are inverted according to the Rayleigh wave speed, comparative verification is carried out by combining drilling data, shearing wave speed and indoor geotechnical test, the different mechanical parameters of the stratum are determined via the Rayleigh wave speed, and reference values of stratum mechanical indexes and stratigraphic division are provided for exploration in geotechnical engineering without drilling and pitting data. The method of the invention is efficient, economical and practical, a lot of drilling and pitting work can be reduced, the method is especially suitable for landform and geologic positions which a drilling machine can hardly reach, a result is reasonable and effectively, the working efficiency is greatly improved, the cost is reduced, and an effective solution is provided to determine the mechanical parameters in geotechnical engineering of the stratum.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

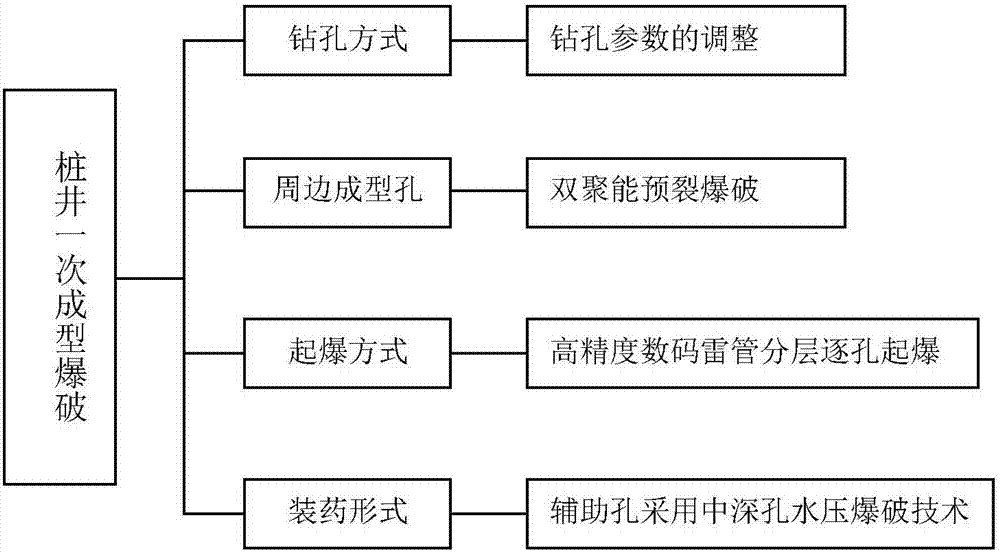

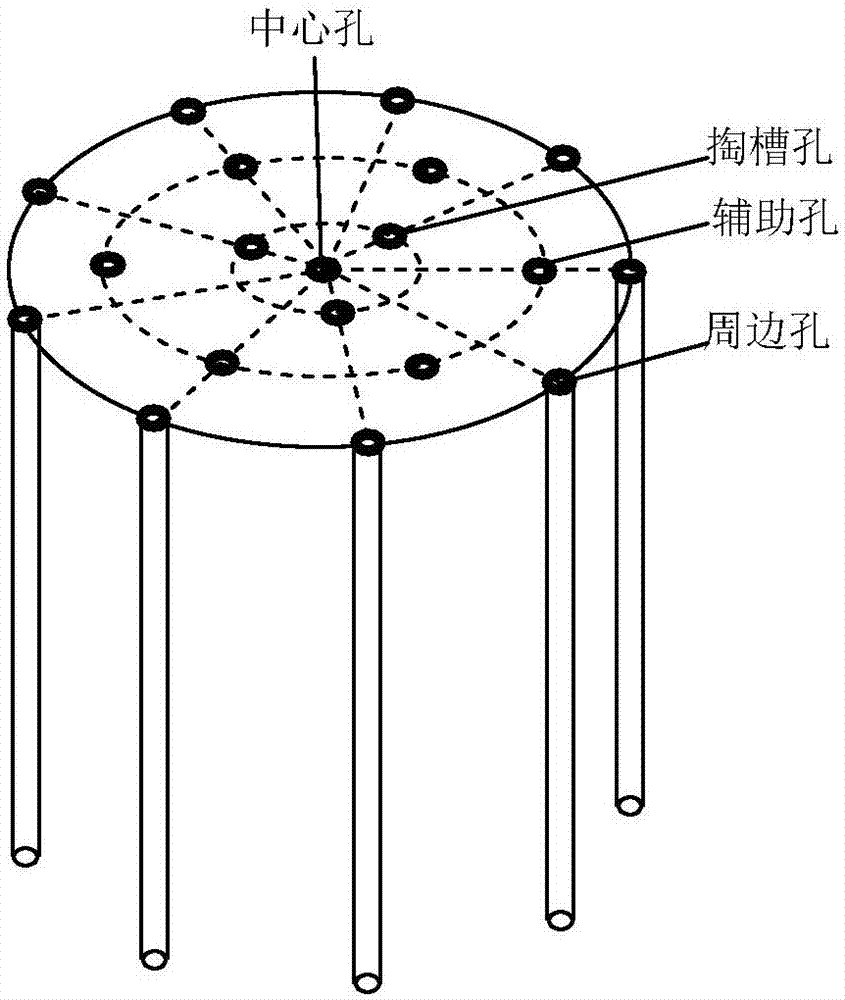

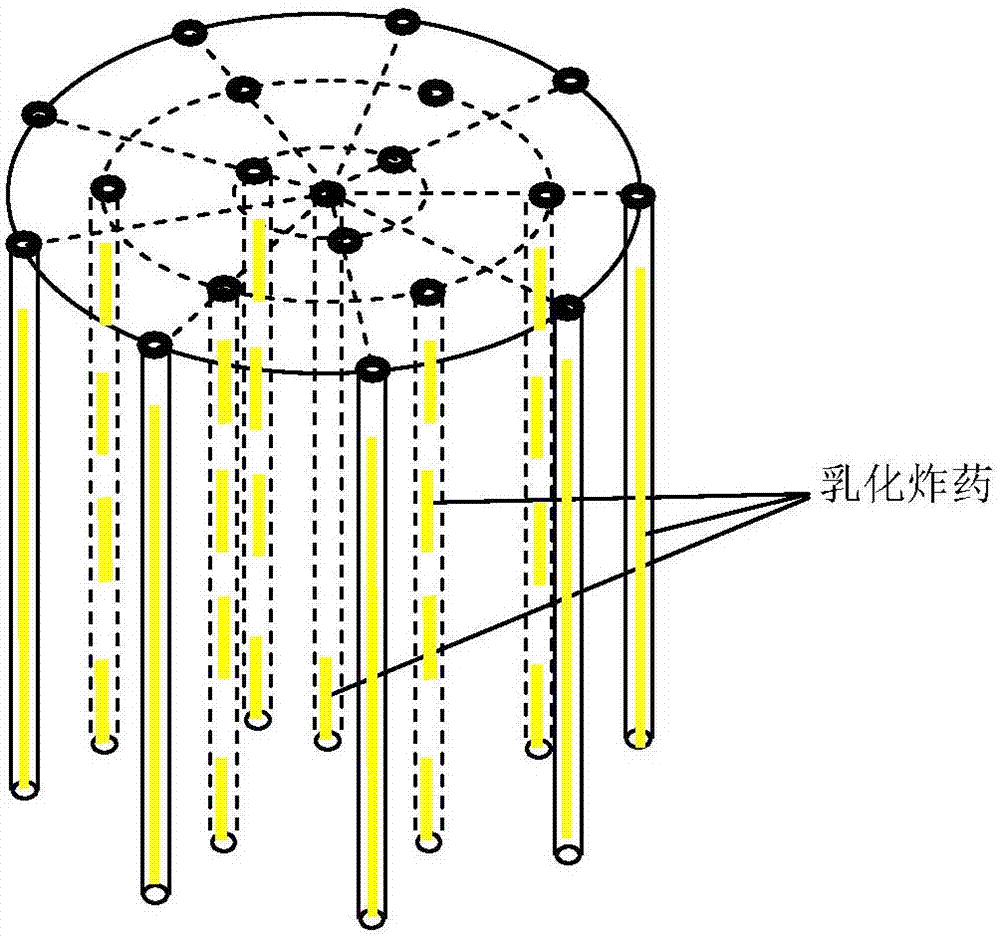

One-time forming blasting method for extra-high voltage electric transmission line pile-well

The invention provides a one-time forming blasting method for an extra-high voltage electric transmission line pile-well for the excavating engineering of the extra-high voltage electric transmission line pile-well (the depth is not larger than 10 meters), wherein the one-time forming blasting method combines large-angle double-energy-gathered pre-split blasting, high-precision digital detonator layered hole-by-hole blasting and mid-depth hole water pressure blasting. The one-time forming blasting method is characterized in that all the designed blastholes of the pile-well are drilled and completed at a time; after the blastholes are loaded with gunpowder, the blastholes are ignited at a time; delay blasting is performed zone by zone and layer by layer; and the whole pile-well is blasted and formed at a time. Compared with the prior art, the pile-well blasting completing one-time hole drilling and one-time blasting and forming is achieved, the manual underground work amount and time for excavation of the extra-high voltage electric transmission line pile-well are obviously lowered, the number of blasting times is greatly reduced, traditional multiple times of cycle blasting are turned into the one-time igniting blasting, and the safety risk of the construction process is lowered.

Owner:EAST CHINA POWER TRANSMISSION & TRANSFORMATION ENG +1

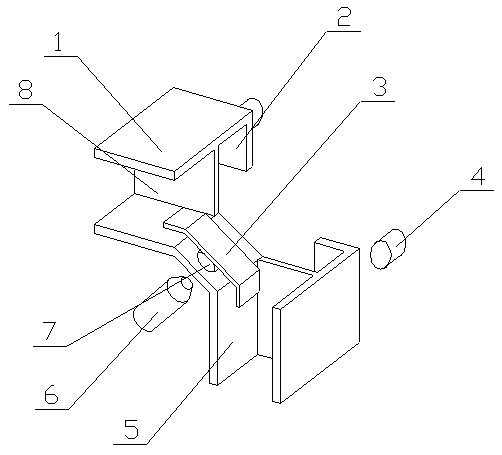

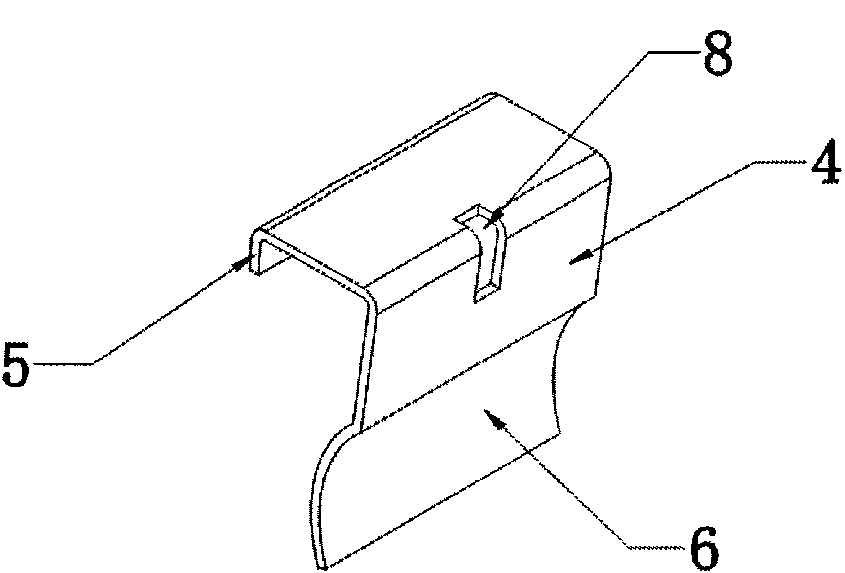

Furniture combined connecting buckle

The invention relates to a furniture combined connecting buckle. According to the connecting buckle, drilling on panels is not needed, dismounting and mounting combination is facilitated, and three panels can be mounted. The efficiency of combined mounting of furniture can be effectively improved. The buckle is characterized in that an angle mounting panel is formed by continuously bending a metalpanel twice, three bending parts are formed, a locking part is arranged on the bending part in the middle of the angle mounting plate, and two clamping parts are arranged on the other two bending parts at the exterior of the angle mounting panel respectively; the extension lines of center lines of the two bending parts at the exterior of the angle mounting panel are perpendicular to each other, the length of the bending part in the vertical direction of the angle mounting plate is the same as that of the bending part in the horizontal part and twice that of the bending part in the middle, a threaded hole is formed in the middle of the angle mounting panel, the locking part is composed of a push plate and a locking screw, and a fastening screw is correspondingly in screw joint in the threaded hole formed in the angle mounting panel.

Owner:淮北创之社信息科技有限公司

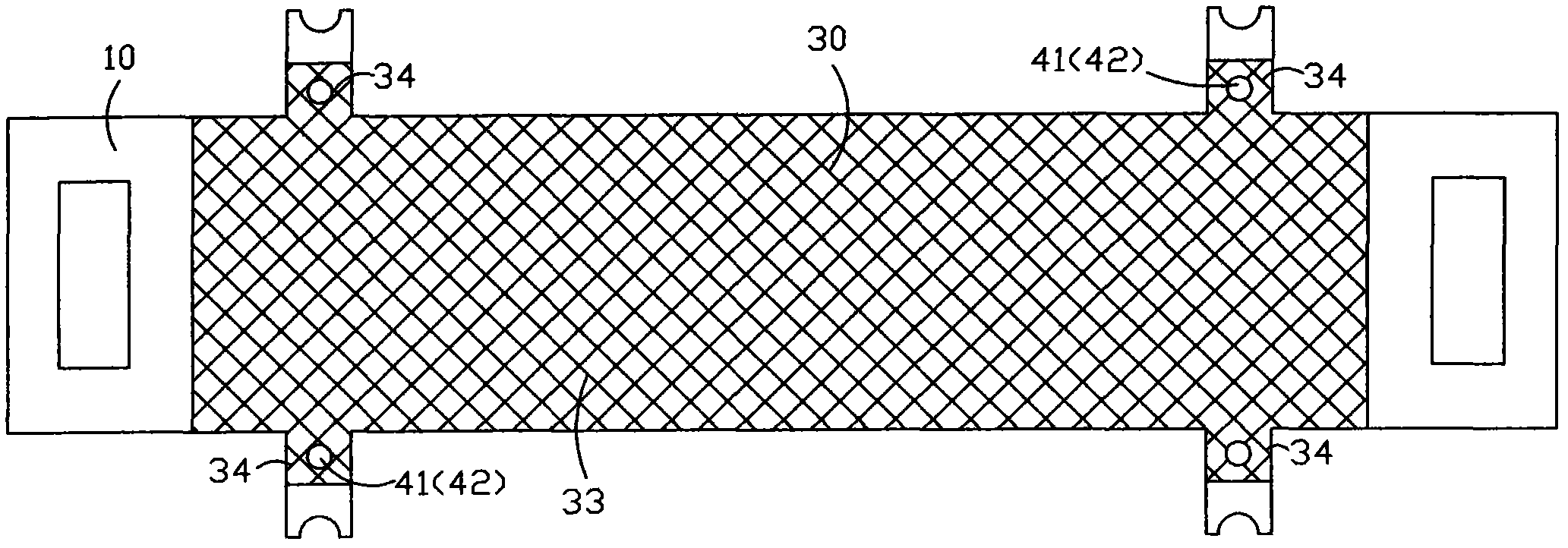

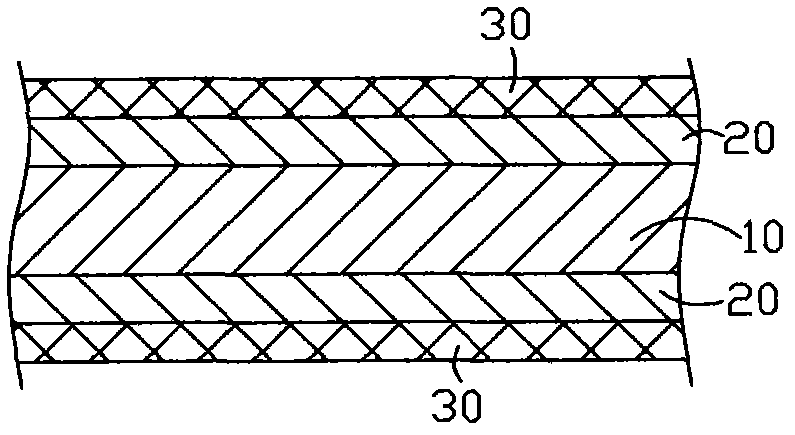

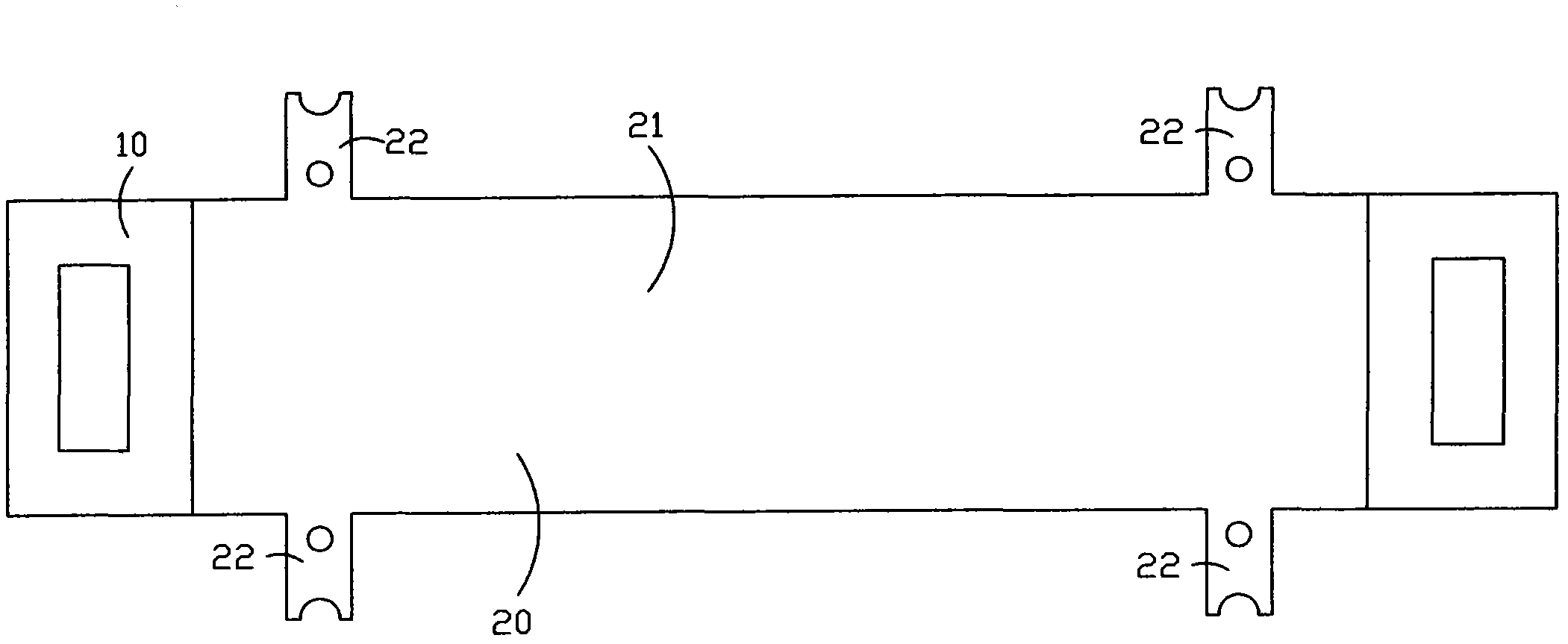

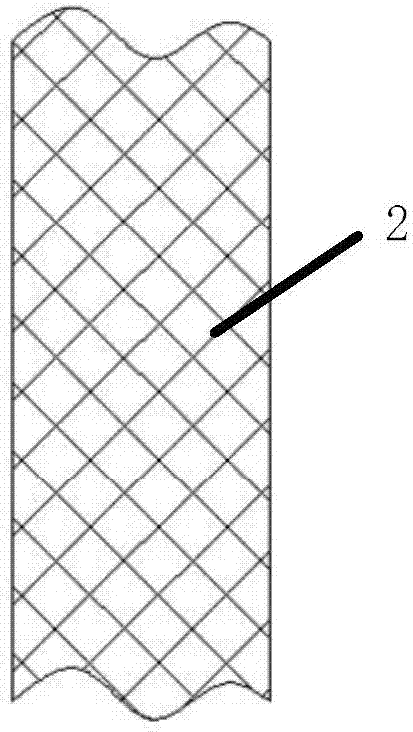

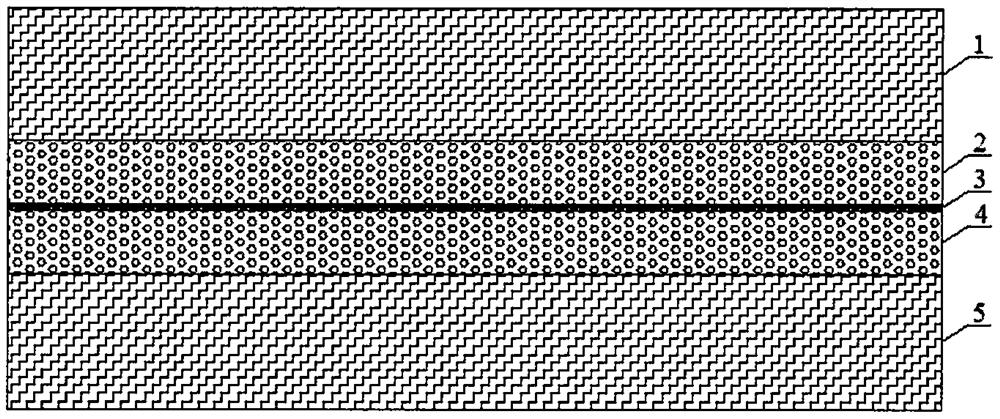

Double-layer flexible circuit board

ActiveCN102355794AReduce pollutionShorten the timeElectrical connection printed elementsFlexible circuitsCopper foil

The invention relates to a double-layer flexible circuit board, which comprises a circuit board substrate, copper foil layers and a shielding layer. The circuit board substrate is provided with a top surface and a bottom surface. The copper foil layers are simultaneously arranged on the top surface and bottom surface of the circuit board substrate, and comprise a circuit part and a circuit board grounding metal part respectively. A communicating drilled hole is reserved on the circuit board substrate and positioned in the circuit board grounding metal part on the circuit board substrate, and runs through the circuit board substrate and the copper foil layers. A through hole is reserved on the shielding layer and communicated with the communicating drilled hole. A metal switching-on part is arranged in the through hole and the communicating drilled hole from top down, and is communicated with the copper file layer and the shielding layer to electrically connect the copper foil layers arranged on the top surface and bottom surface of the circuit board substrate by the through hole, the communicating drilled hole and the shielding layer.

Owner:珠海市超赢电子科技有限公司

Powder injection molding process

The invention relates to a powder injection molding process. The method includes steps of a) mixing, b) injection molding, c) degreasing and sintering, d) quenching and e) subzero processing. In the step a), metal powder materials, anti-friction metallic elements and organic binding materials are fed into an internal mixer and, under an airtight environment and at the temperature of 180 degrees, are stirred to be formed into particles. In the step b), a mold with a hole pattern and a thread pattern is adopted, and the particles are injected into an injection opening of the mold by an injection molding machine. In the step c), a processed semi-product is put into a sintering furnace to be subjected to degreasing and sintering. In the step d), the processed semi-product is put into a vacuum furnace to be subjected to quenching. In the step e), the processed semi-product is subjected to subzero processing. The powder injection molding process is adopted to produce guide rails and sliding blocks to lead to fewer processes such as drilling holes and tapping, thus the process is simple and environment-friendly, production cycle is shortened, and production speed is increased.

Owner:王统

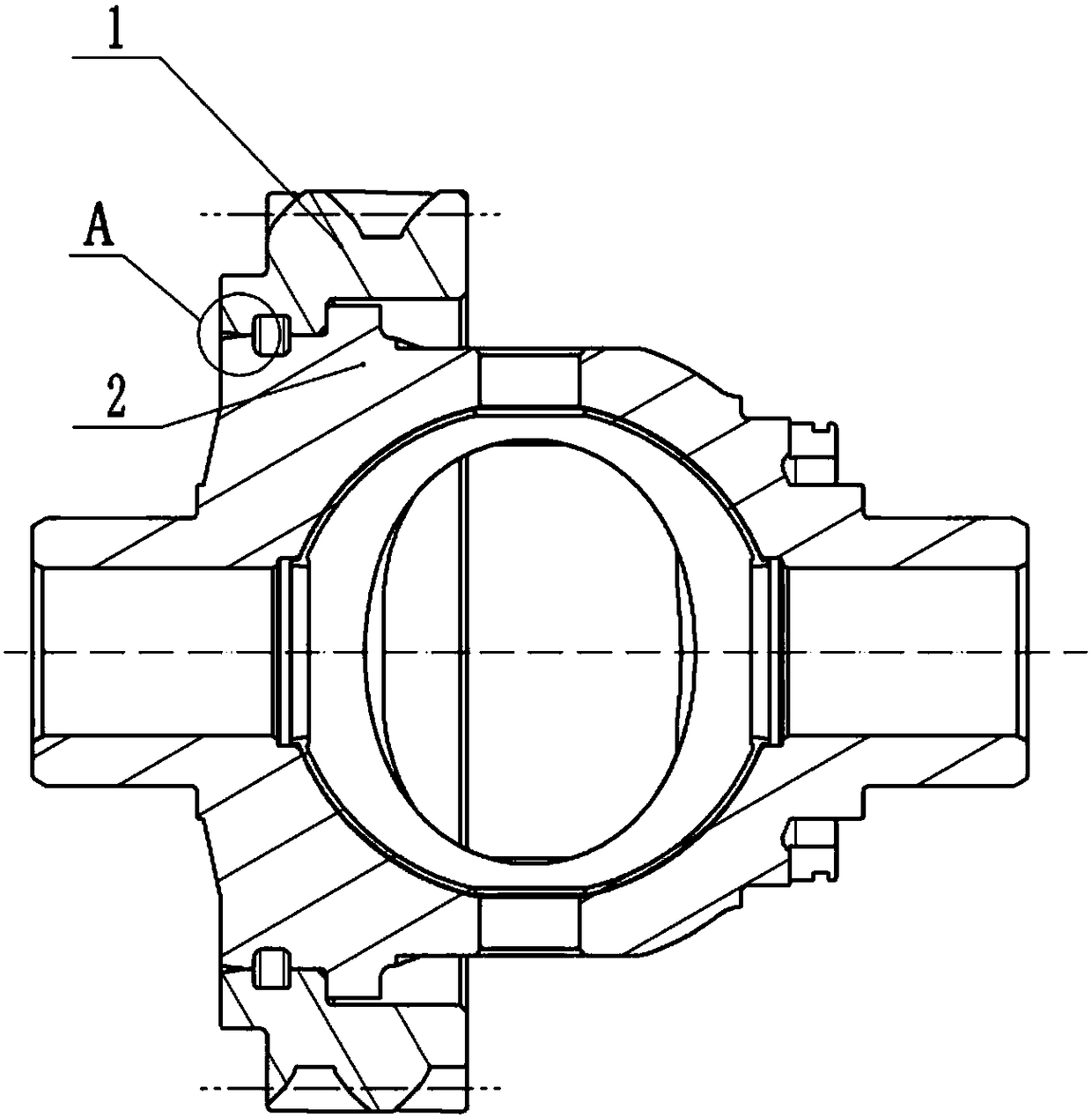

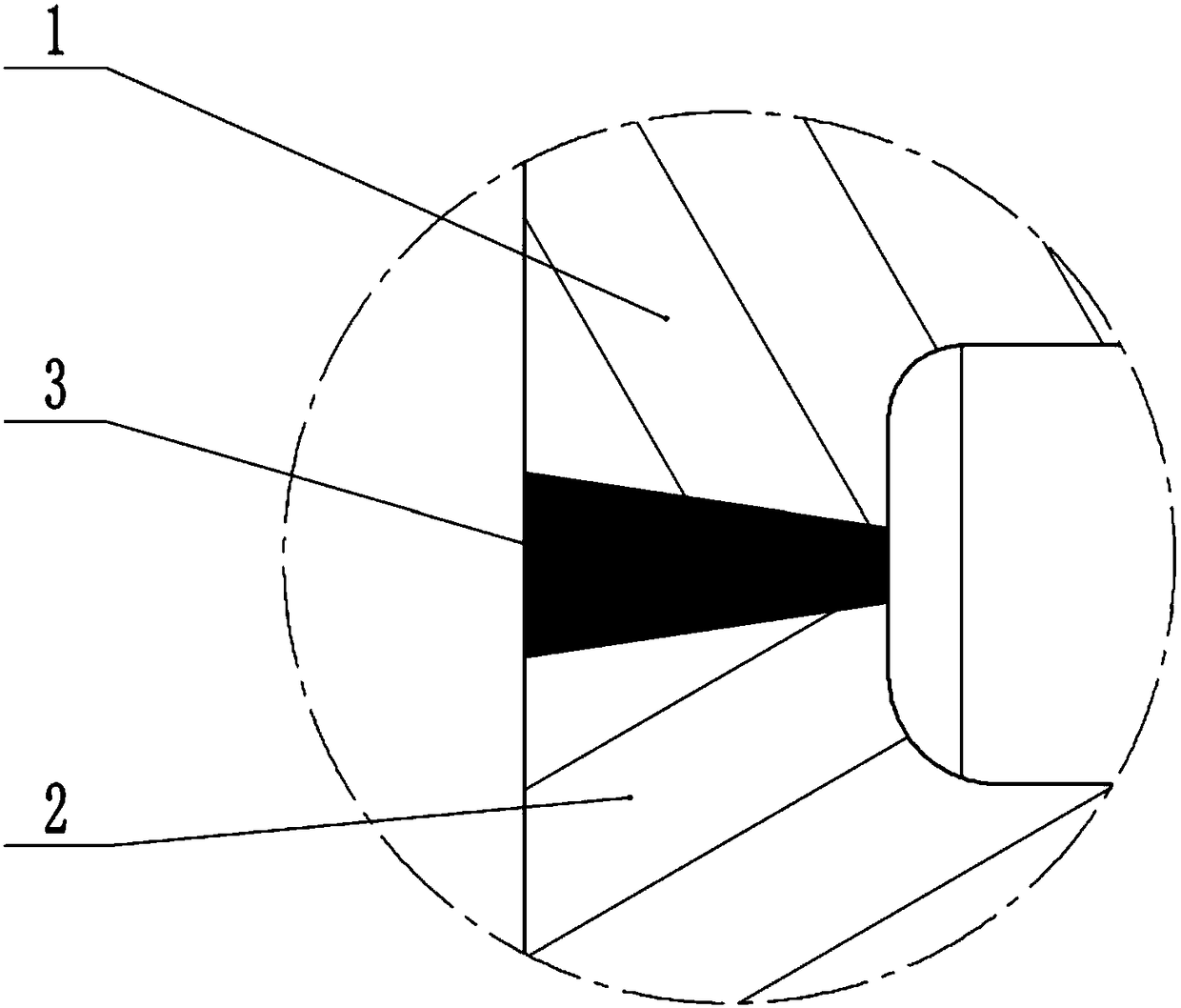

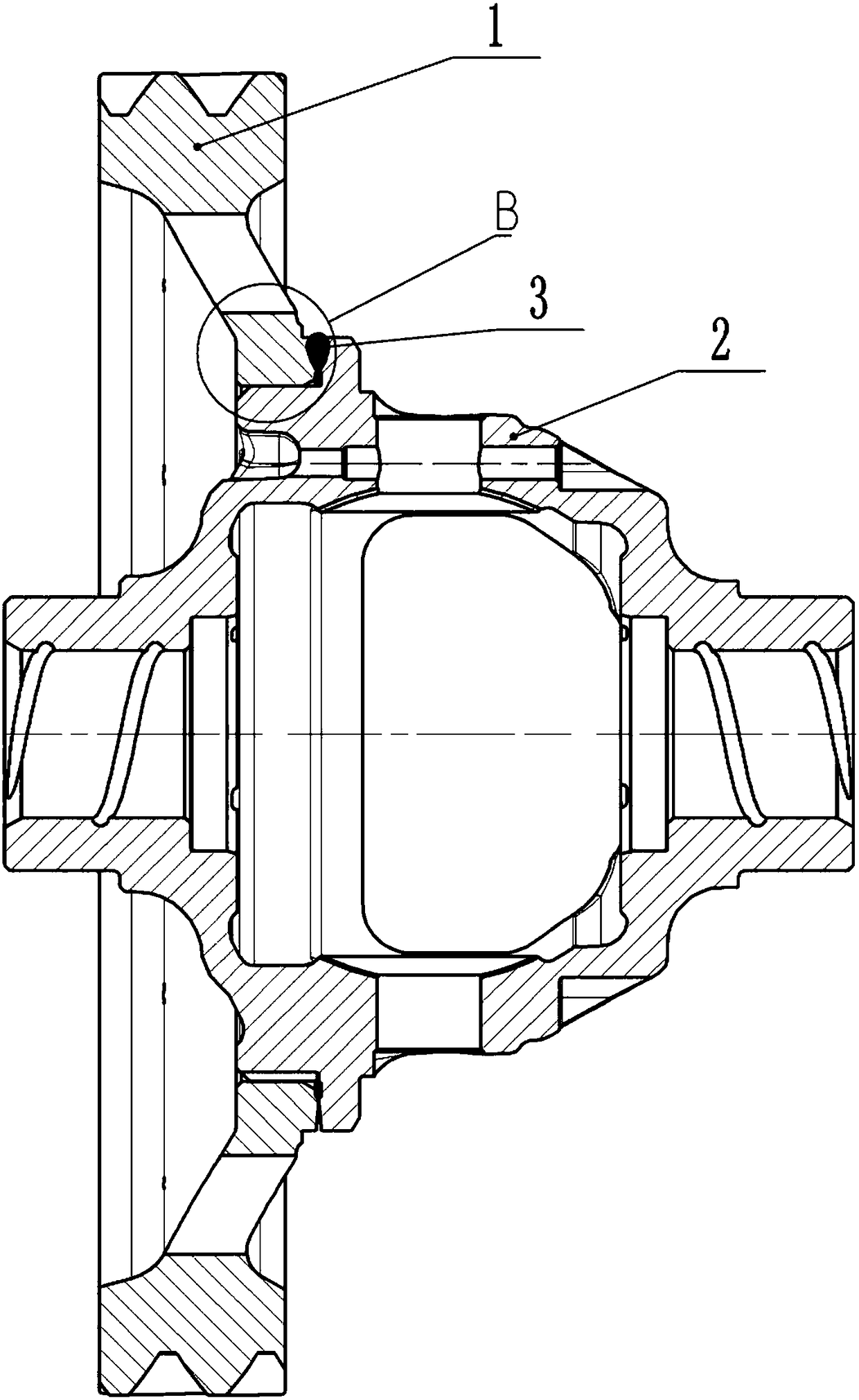

Welding technology of differential mechanism assembly

InactiveCN108500576AAvoid Accuracy ImpactReduce drillingVehicle componentsWelding/soldering/cutting articlesManufacturing technologyGear wheel

The invention belongs to the technical field of car spare part manufacturing and particularly discloses a welding technology of a differential mechanism assembly. The welding technology comprises thefollowing steps that 1, a differential mechanism shell and a differential mechanism gear which can be matched mutually are prepared; 2, laser washing is carried out; 3, press fitting is carried out; 4, welding wire filling and laser spot welding are carried out; 5, ring welding is carried out; 6, weld seams are cleared; 7, ultrasonic flow detection is carried out; and 8, tooth milling is carried out. Compared with the prior art, the technology is easy to operate, and the produced differential mechanism assembly is simple in structure, low in machining cost, high in precision and lighter in total mass.

Owner:CHONGQING LIANHAO TECH CO LTD

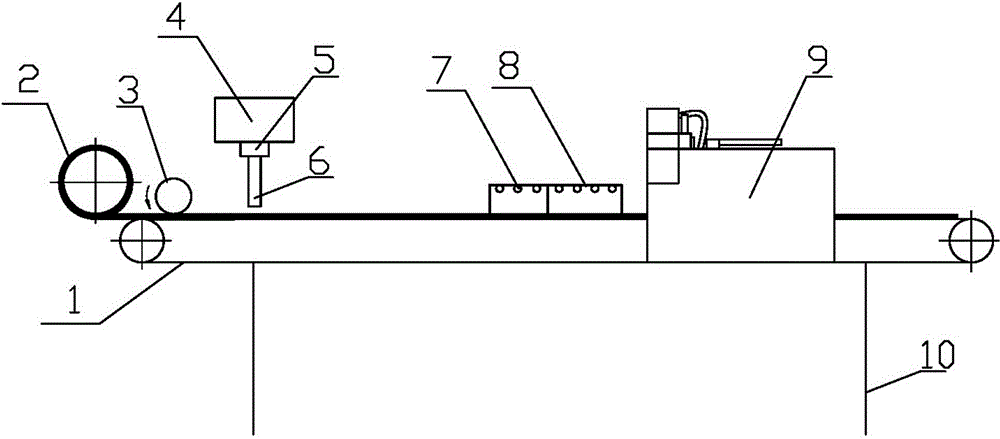

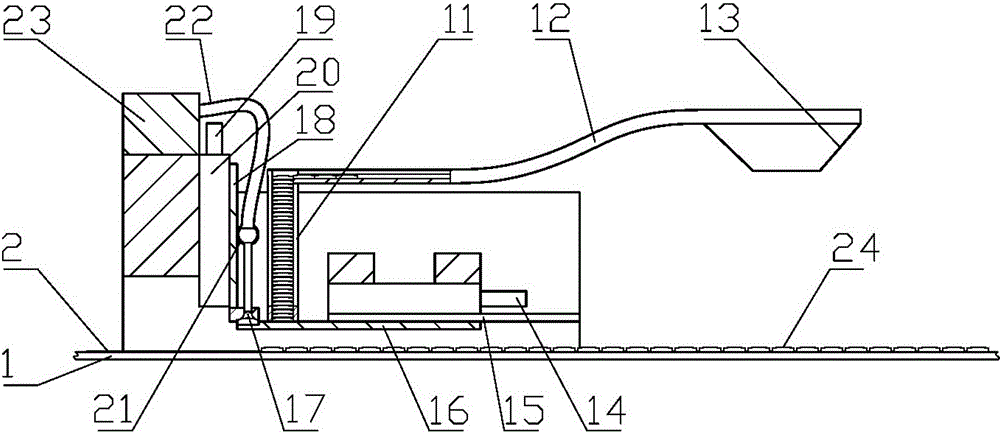

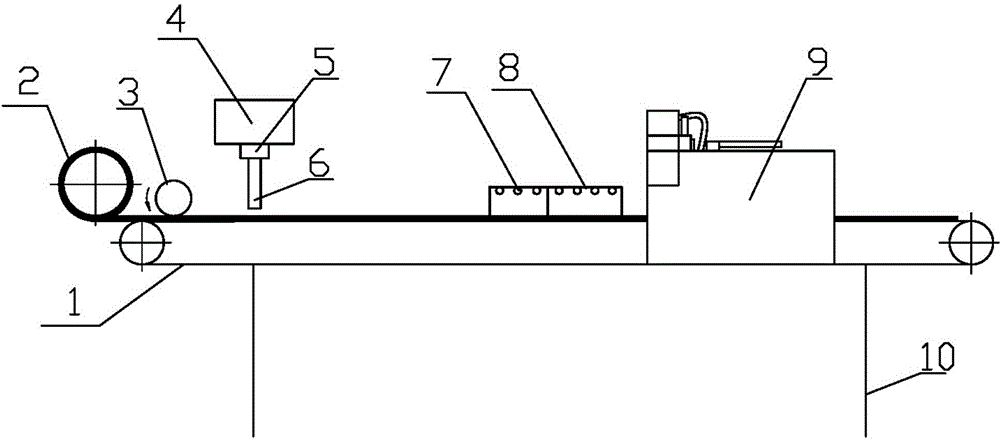

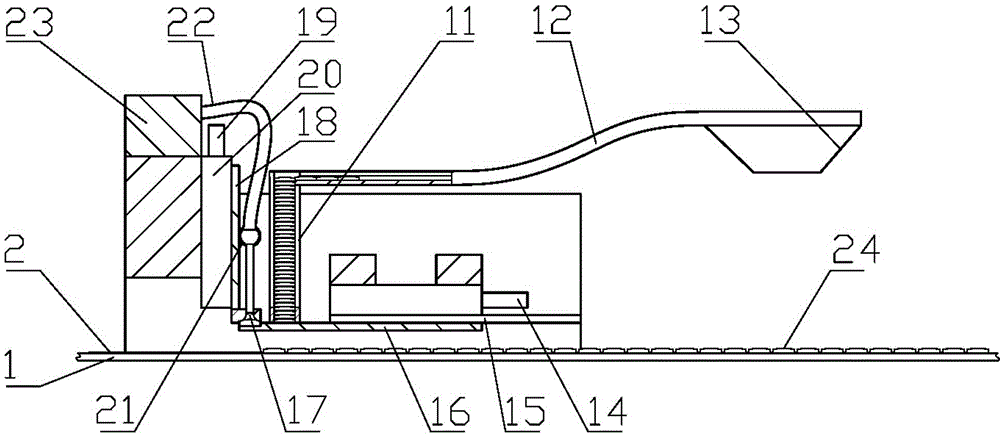

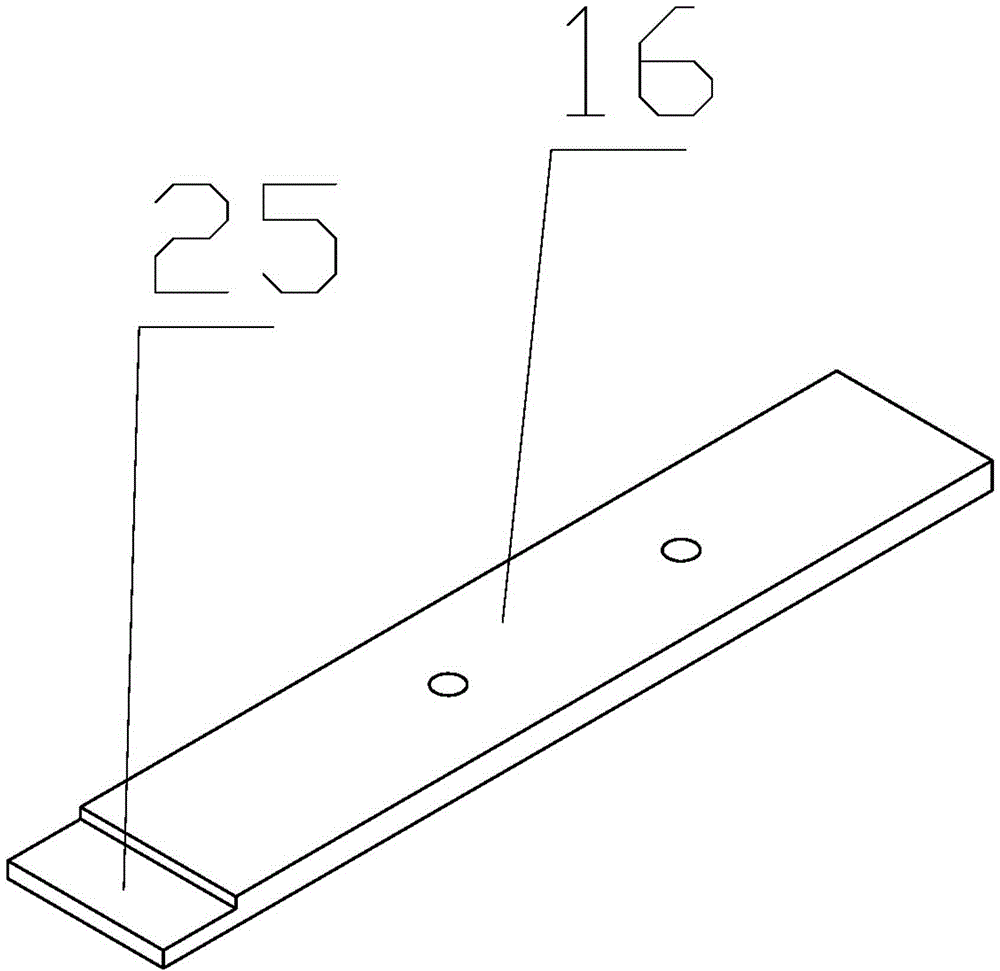

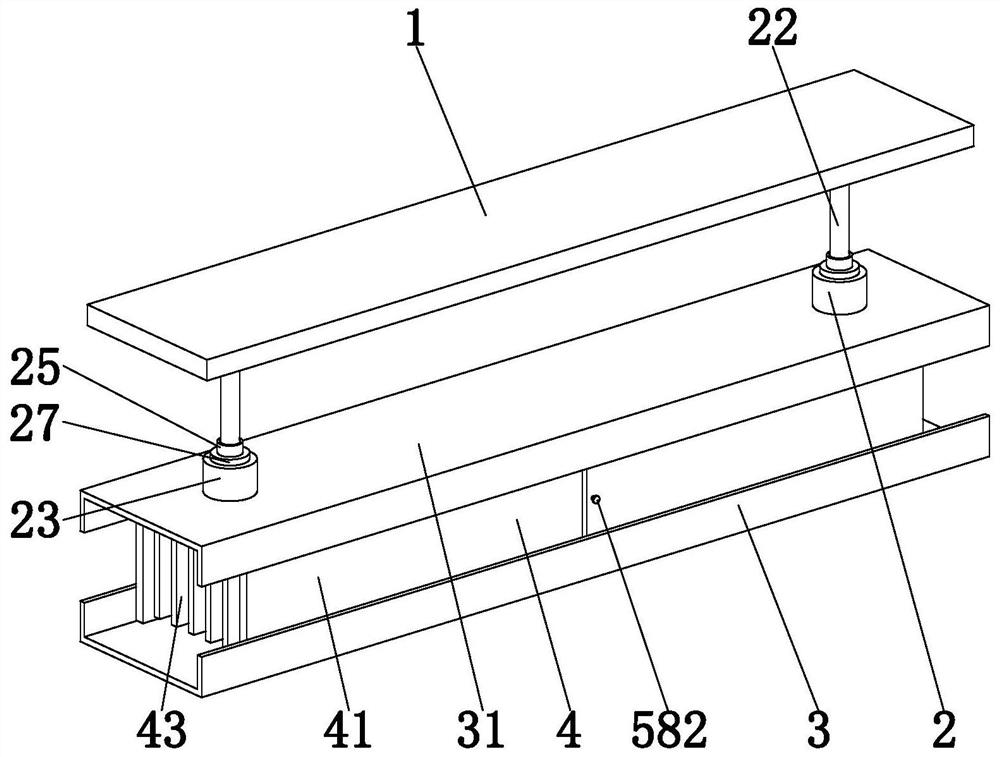

Pasting mechanism for bamboo pieces of bamboo mat and pasting device

ActiveCN104963918AReduce drillingReduce manual weavingMaterial gluingBed-coversEngineeringHot-melt adhesive

The invention discloses a pasting mechanism for mahjong piece-shaped bamboo pieces of a bamboo mat featuring environmental protection, convenient processing and low cost. The pasting mechanism is characterized in that the pasting mechanism comprises an ordering part, a feeding part and a pasting part; the ordering part comprises an ordering vibration disc, a feeding tank connected with the ordering vibration disc and a material storage tank connected with the feeding tank; the feeding part comprises a feeding plate driven by a horizontal servo motor; one end of the feeding plate is provided with a concave surface corresponding to the material storage tank; the pasting part comprises a material-pressing plate driven by a vertical servo motor; a sucking disc is arranged on the material-pressing plate; a pasting device comprises a frame, on which an annular conveyer belt is arranged; and a gluing mechanism, a heating mechanism and the pasting mechanism are arranged on the frame in sequence. The pasting mechanism for bamboo pieces of the bamboo mat and the pasting device have following beneficial effects: the bamboo pieces are pasted onto base cloth in order to decrease production cost of the bamboo pieces, reduce thicknesses of the bamboo pieces, and greatly reduce weight and size of the mahjong piece-shaped mat; therefore, the bamboo mat is conveniently transported, folded, carried and stored; at the same time, by utilizing hot glue or polyurethane glue to paste the bamboo pieces, the purpose of green and environmental protection is fulfilled; cost is low; and streamlined flow production is achieved so that production efficiency is greatly increased.

Owner:HUNAN CITY UNIV

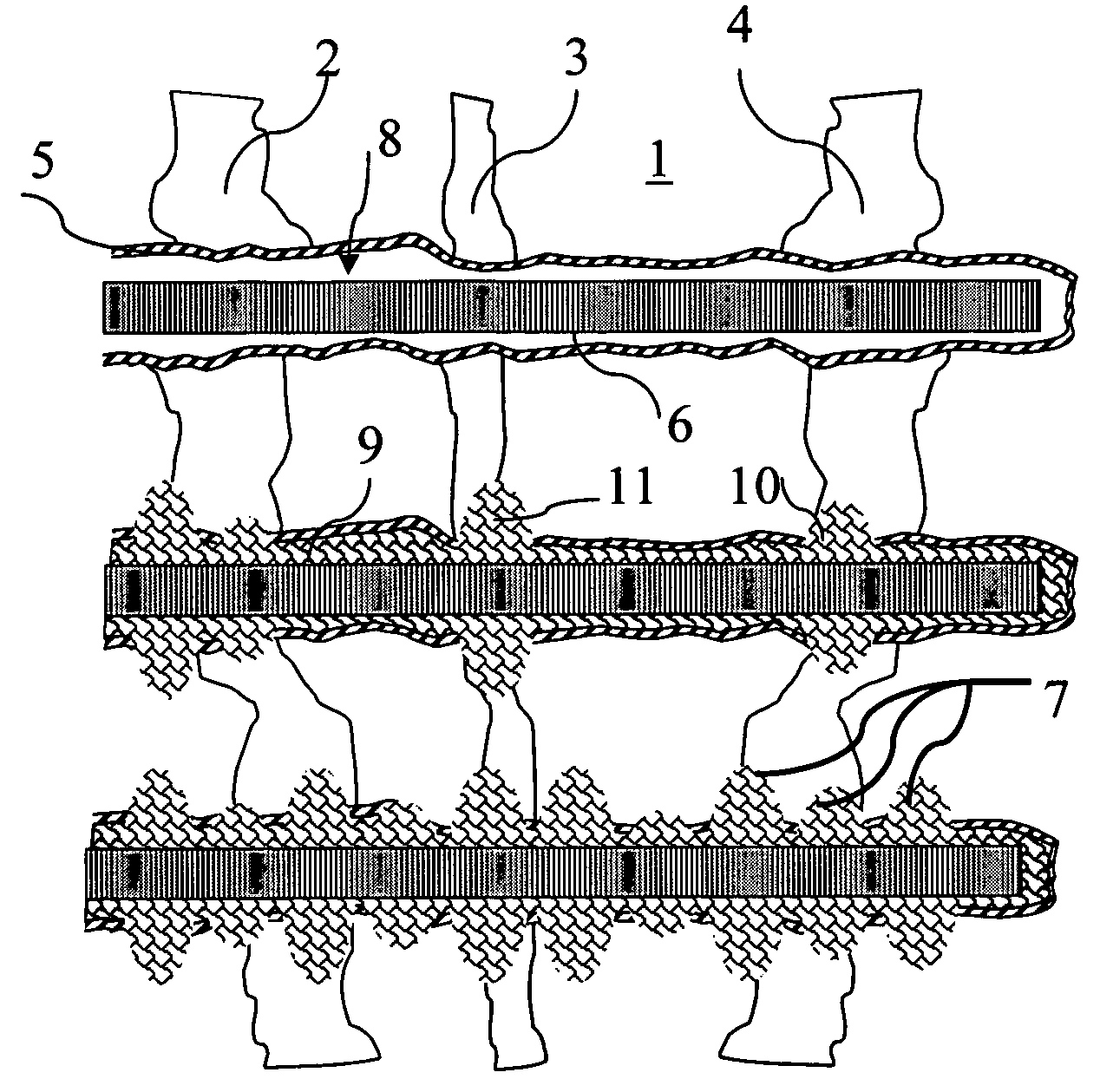

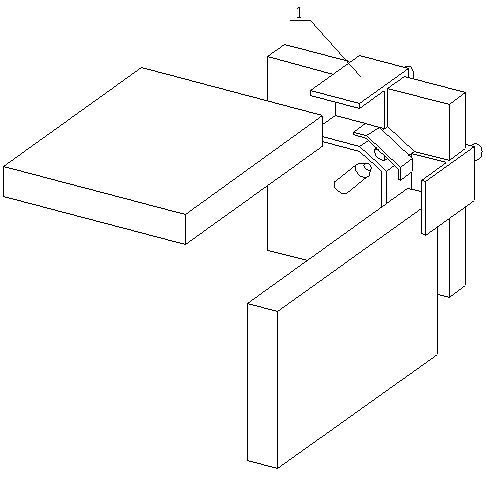

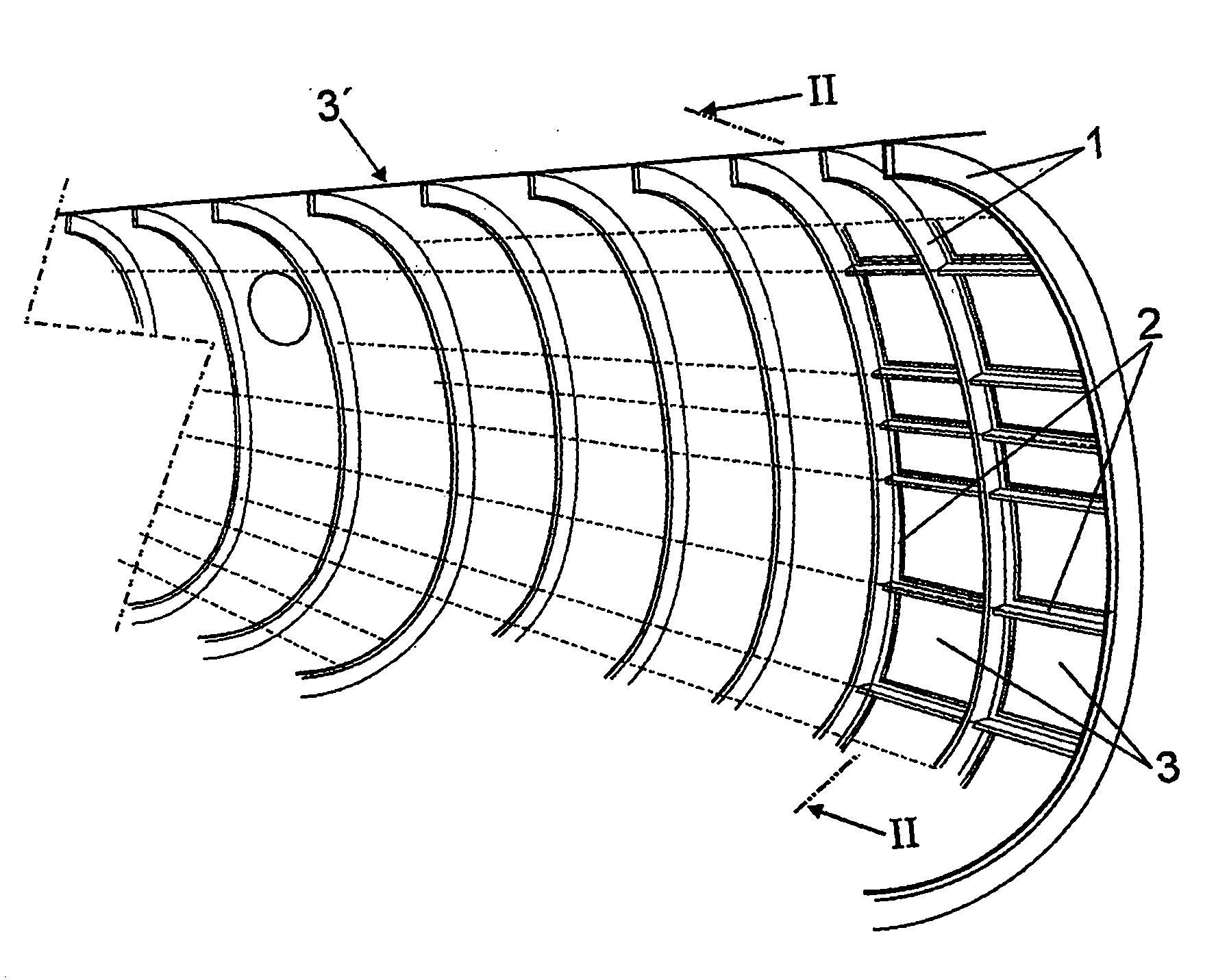

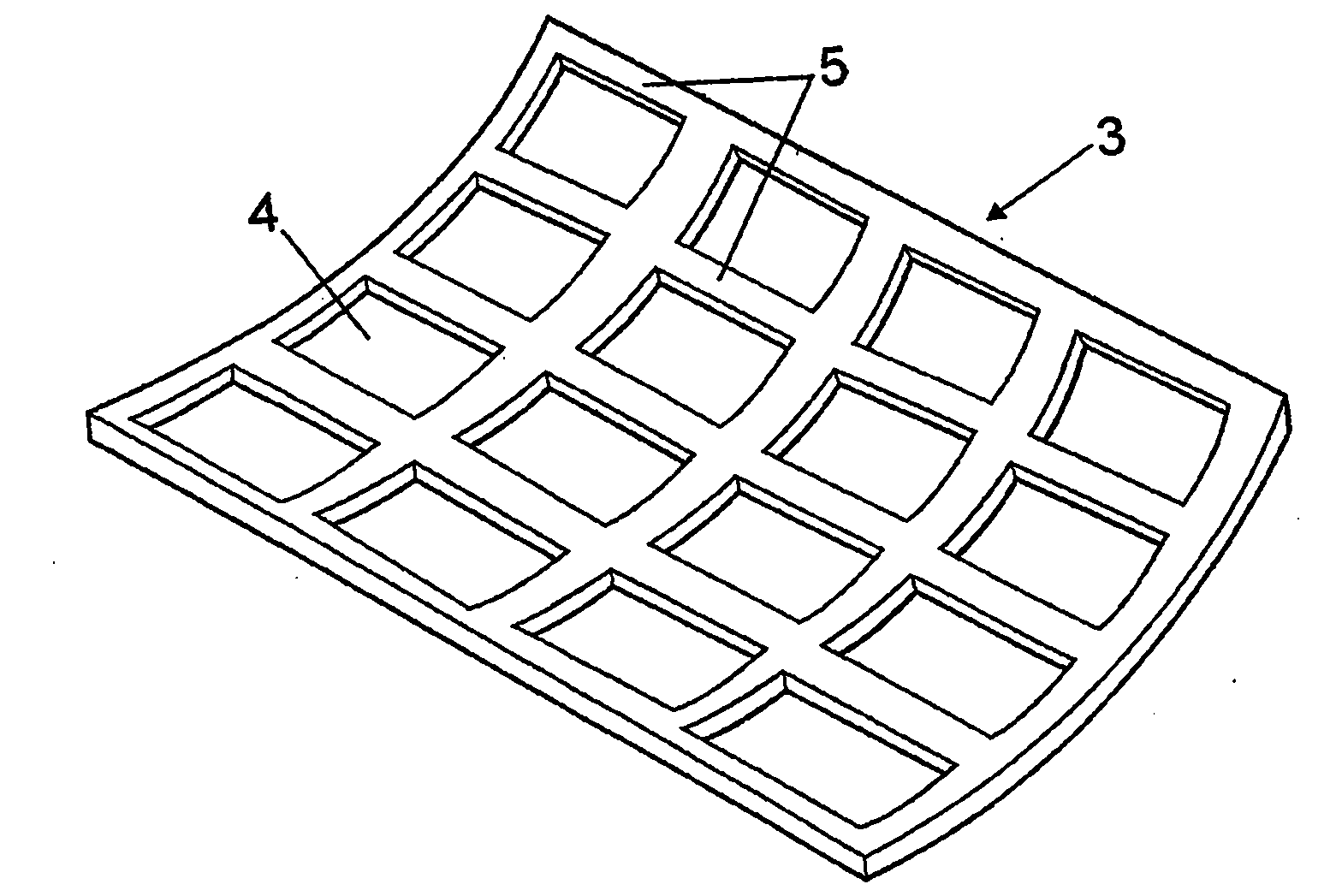

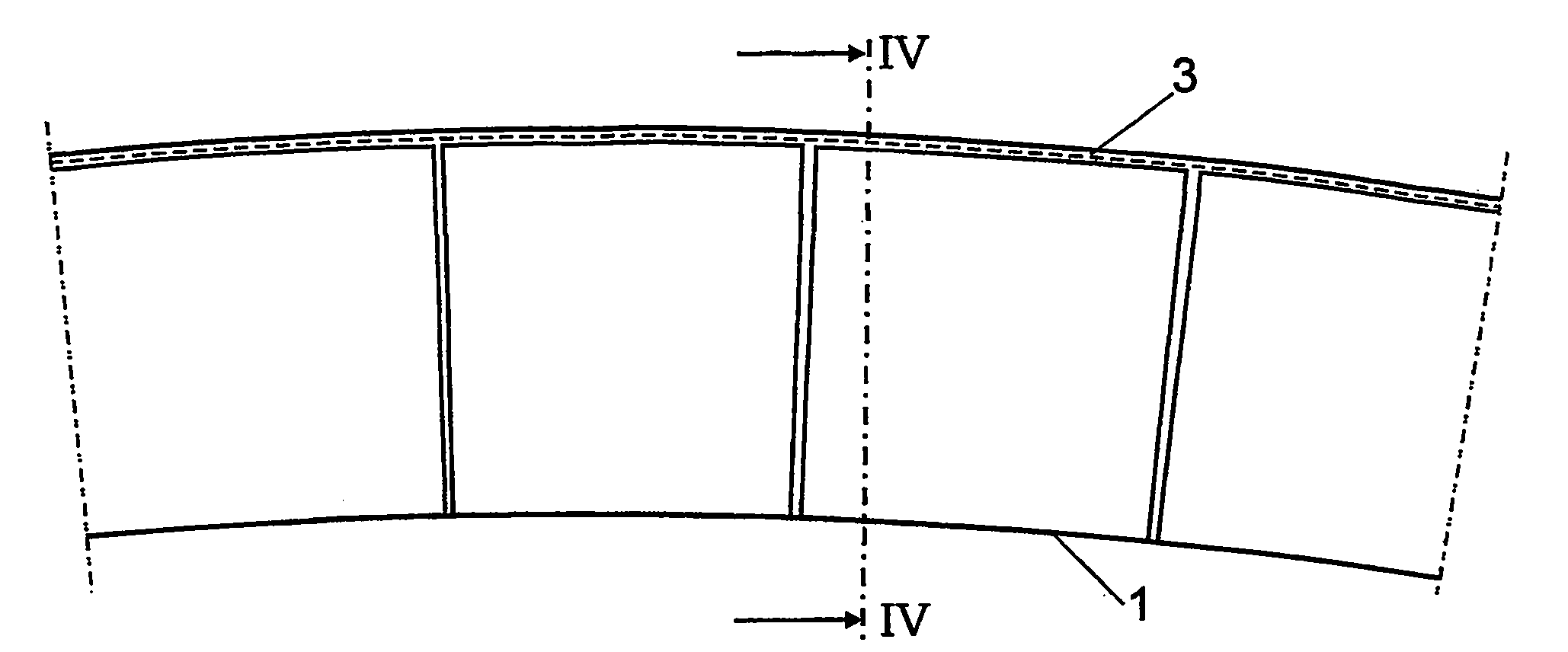

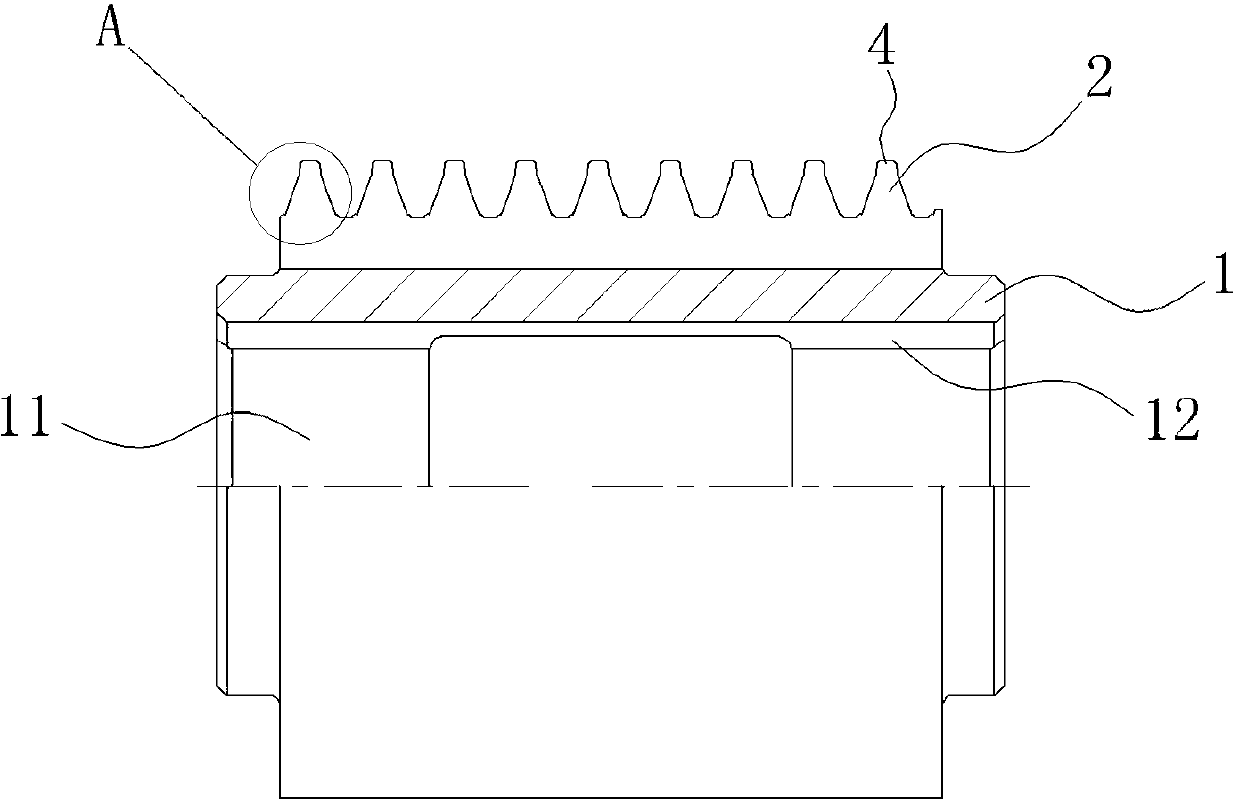

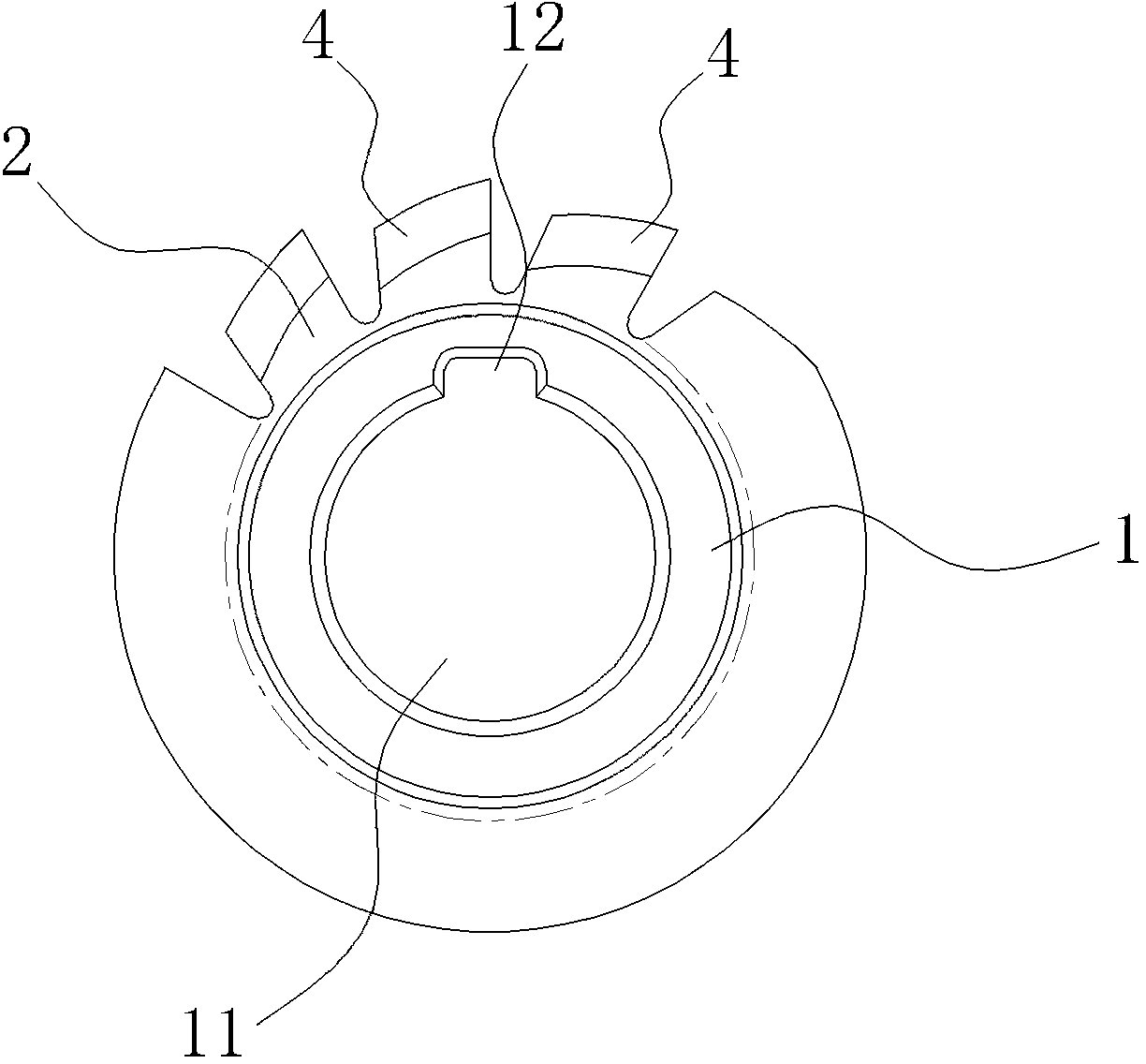

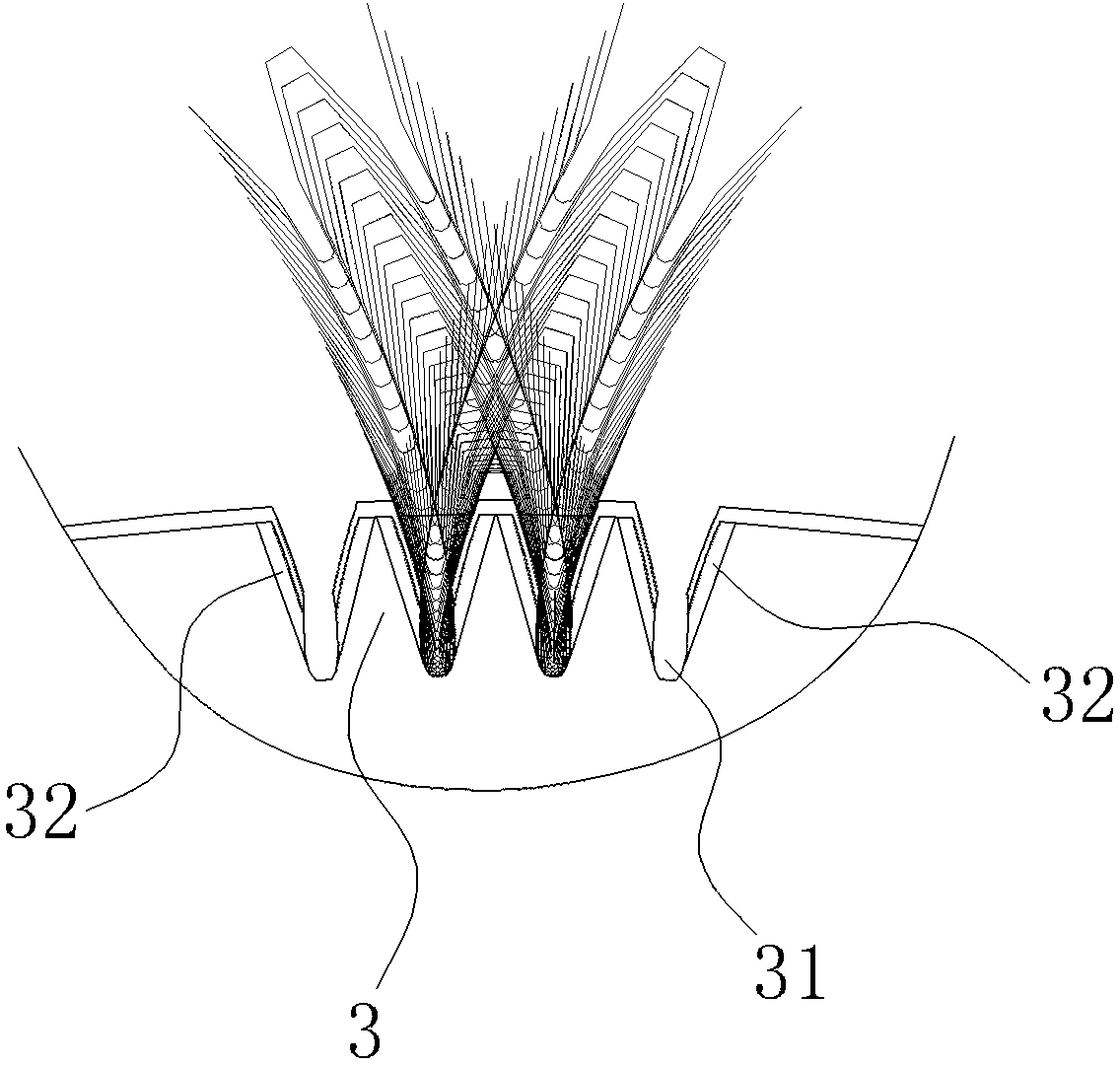

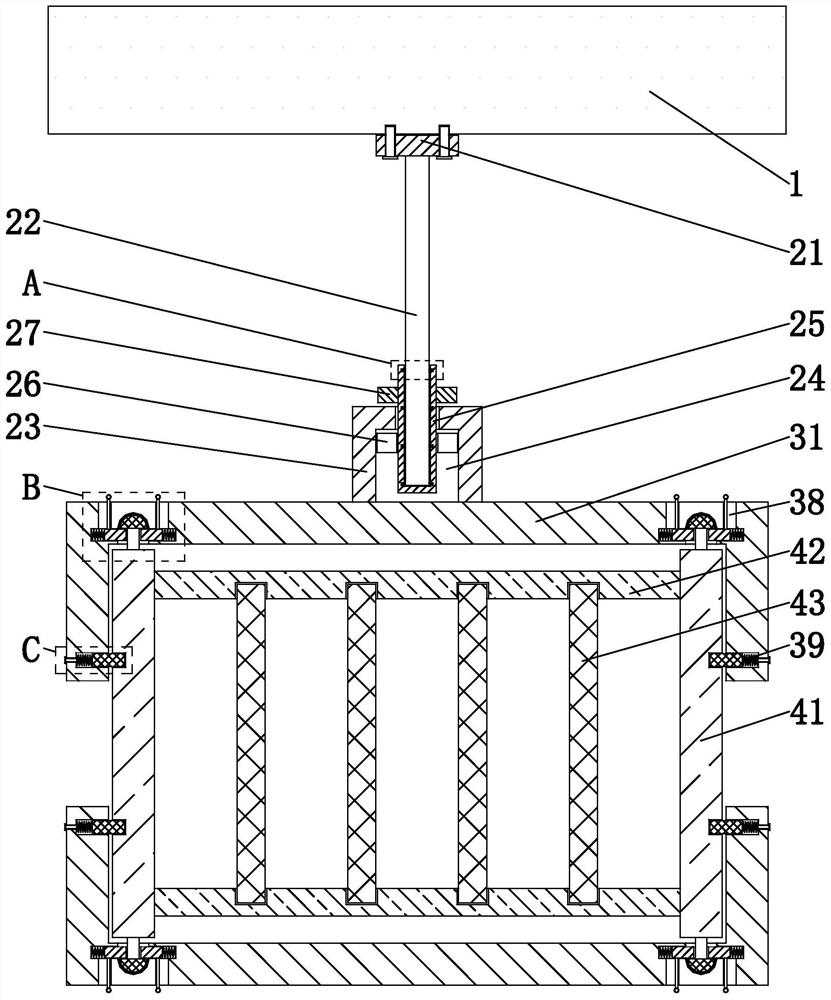

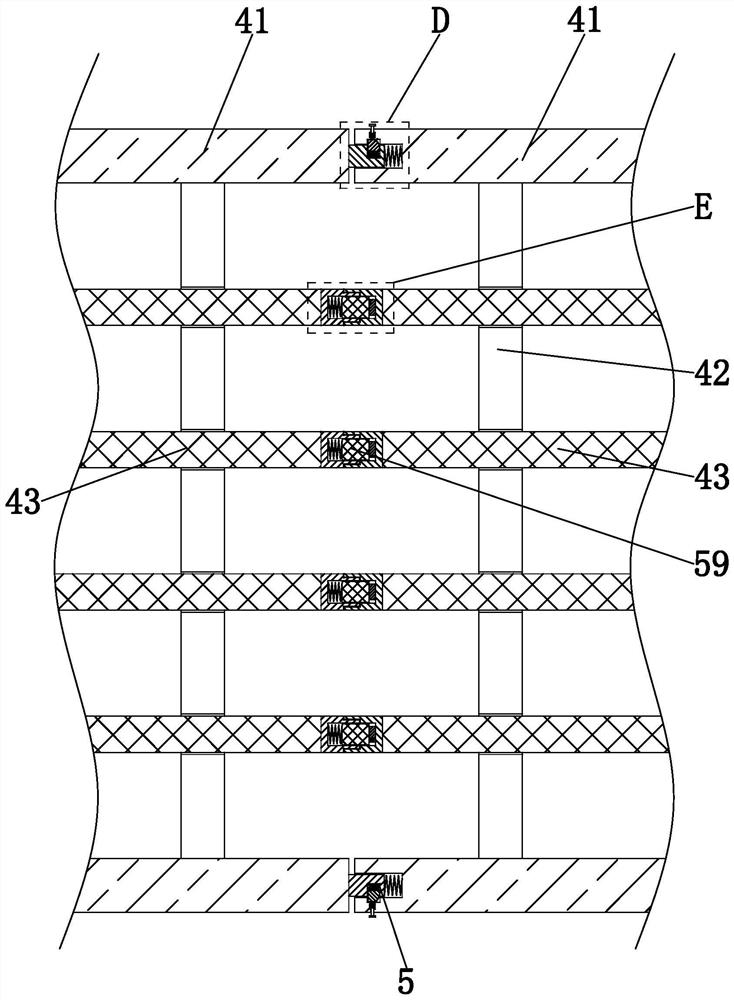

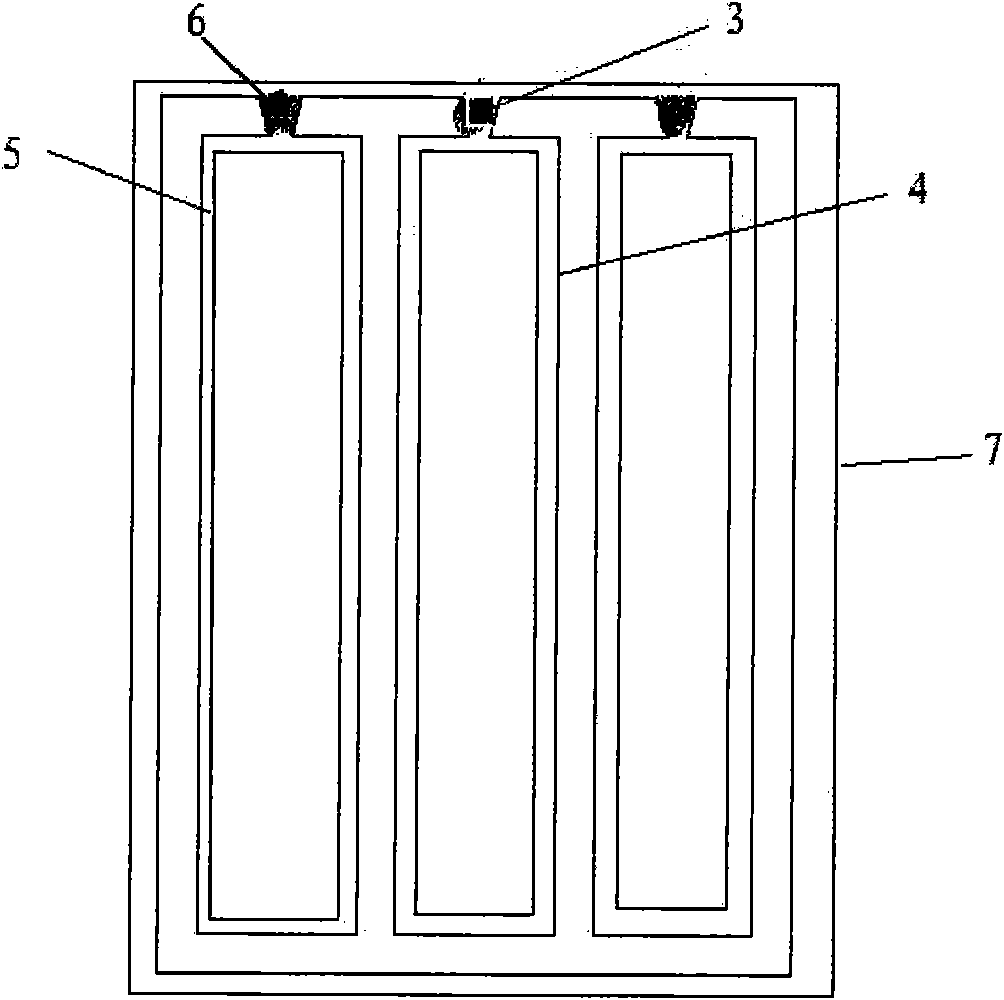

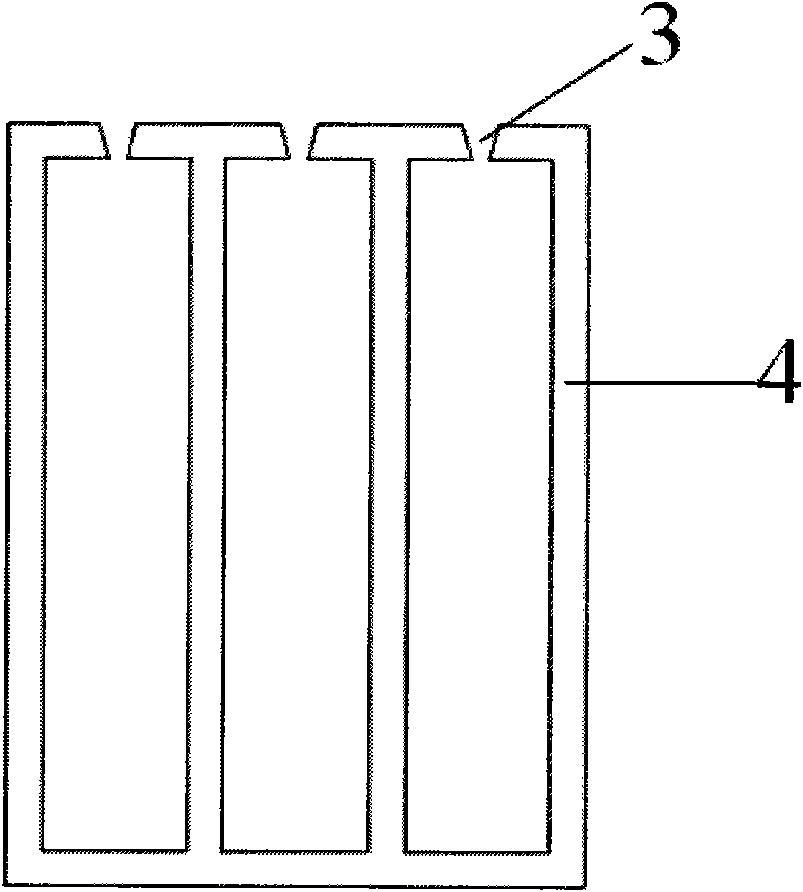

Coupling system intended for use between cladding and structural elements supporting same

ActiveCN102046465AEasy to cleanAvoid the risk of pressure leaksWingsFuselage bulkheadsCoupling systemEngineering

The invention relates to a coupling system for use between cladding and structural elements supporting same, said cladding comprising thin sheets (3) of alloys or composite materials. The facing surfaces of the sheets (3) and the structural elements (1 and 2) bear means for coupling said sheets and structural elements, which means are formed by male (6) and female (7) tongue-and-groove configurations provided along the length of at least part of the contact areas between the sheets and the structural elements.

Owner:FORPLAN METALES

Special-shaped hobbing cutter for machining gear shaving cutter

The invention provides a special-shaped hobbing cutter for machining a gear shaving cutter and belongs to the technical field of machining cutters. The special-shaped hobbing cutter can be used for solving the problems that a cutter relief groove of an existing gear shaving cutter needs a drilling or slot milling process, and the machining is troublesome. The special-shaped hobbing cutter for machining the gear shaving cutter comprises a cutter body with an axial inner hole, wherein a plurality of chip cutting cutter teeth are uniformly distributed in the circumferential direction of the cutter body, the side parts of the chip cutting cutter teeth are provided with chip cutting blades which are designed by adopting transposition and used for machining involute profile of the gear shaving cutter, the tops of the chip cutting cutter teeth are provided with groove cutting cutter teeth which are protruded outwards along the radial direction of the cutter body and used for machining the cutter relief groove of the gear shaving cutter, the tips of the groove cutting cutter teeth are in a shape of a circular bead, and the side cutting edges of the groove cutting cutter teeth are tangent to or intersected with the bottom of a chip containing groove to be machined. The special-shaped hobbing cutter has the advantages of high machining accuracy and machining efficiency, convenience in machining and the like.

Owner:ZHEJIANG SHANGYOU TOOLS

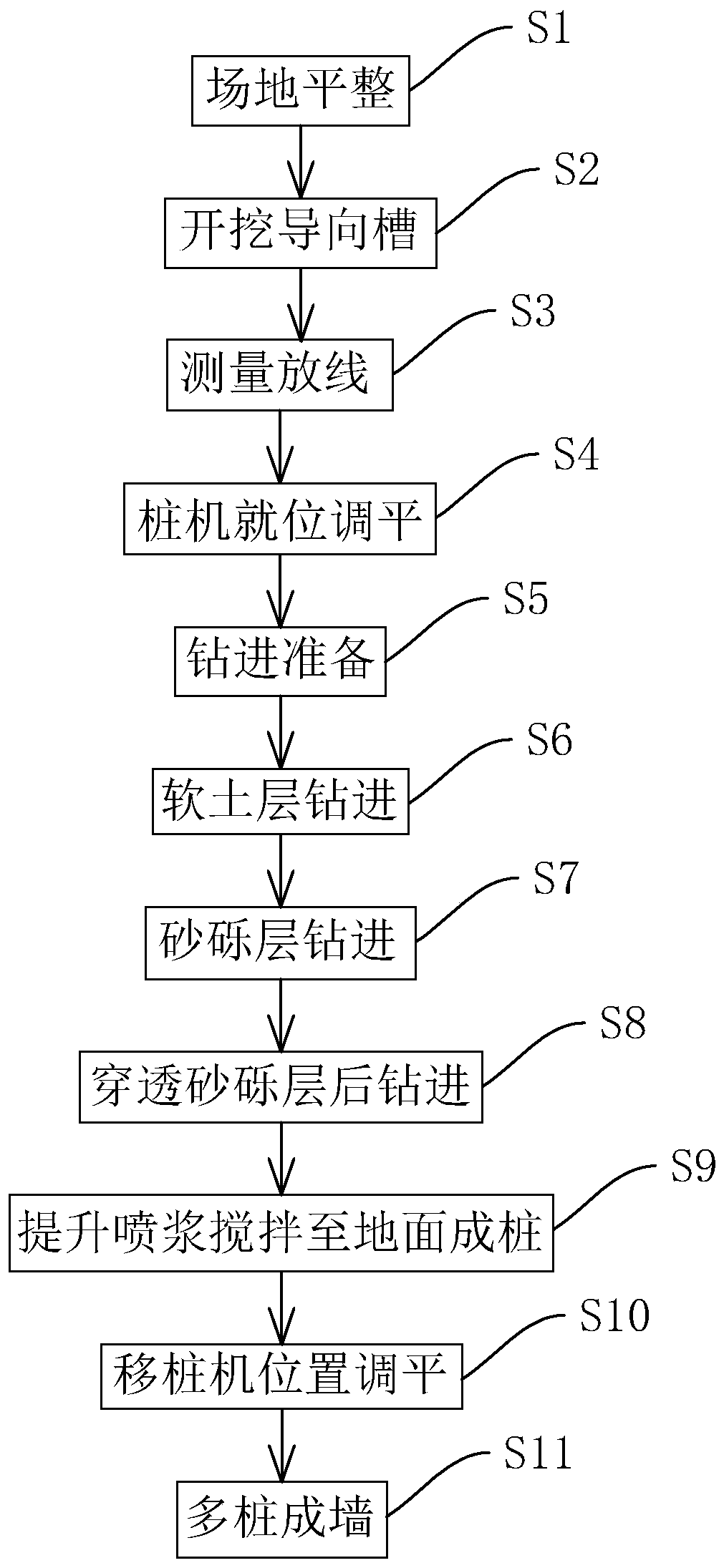

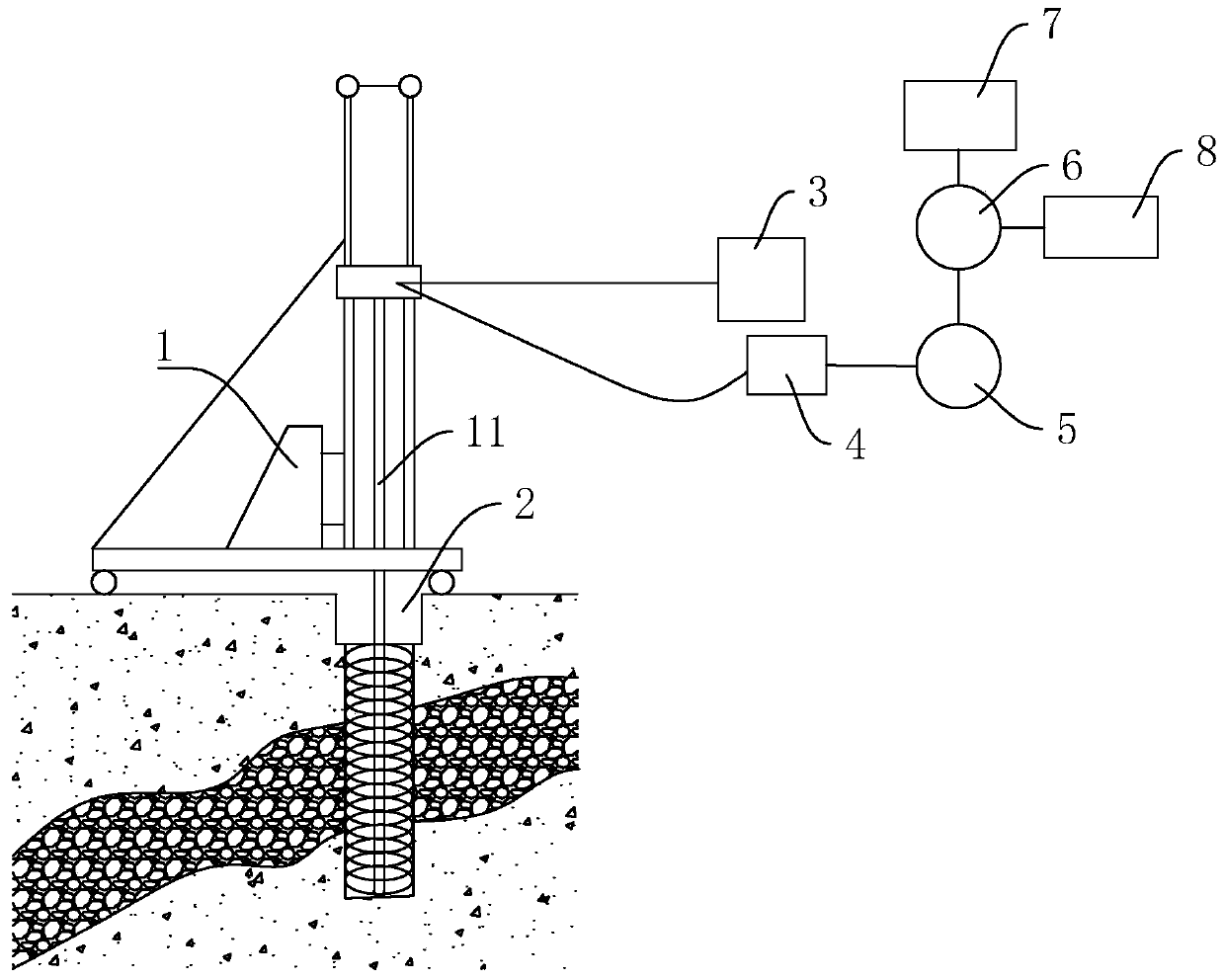

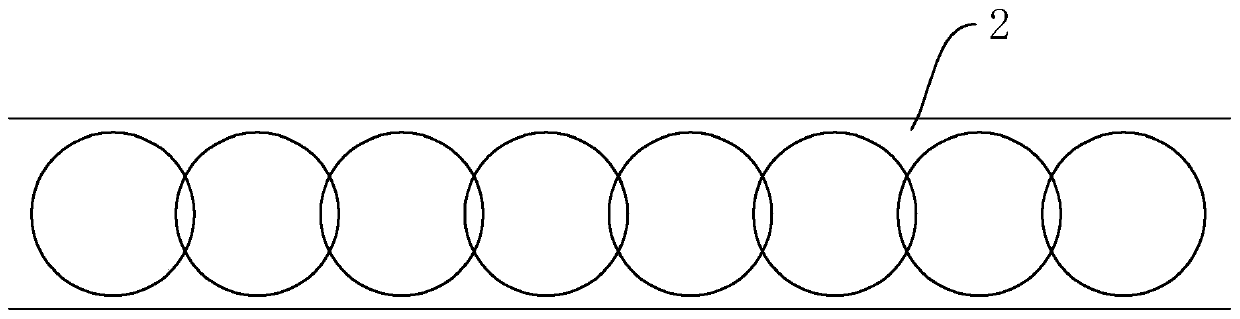

Gravel bed foundation deep-cement-mixing pile impervious wall construction method

InactiveCN110747848AImprove accuracyReduce subsequent drilling and grouting workloadBulkheads/pilesSoil preservationCement groutGeotechnical engineering

The invention relates to a gravel bed foundation deep-cement-mixing pile impervious wall construction method, and relates to the technical field of cement mixing pile impervious wall construction. Thegravel bed foundation deep-cement-mixing pile impervious wall construction method sequentially comprises the following steps of levelling a ground, excavating a guide slot, surveying and setting out,placing a pile machine in position and levelling, preparing for drilling, drilling a soft soil layer, drilling a gravel bed, drilling after penetrating through the gravel bed, and lifting, spouting and stirring until forming a pile on the ground. According to the gravel bed foundation deep-cement-mixing pile impervious wall construction method provided by the invention, aiming at a foundation with the gravel bed, a soil body can be smoothly drilled, cut and stirred, and a cement grout is quickly fully-filled in a clearance of the gravel bed, so that the quality of a finally formed cement mixing pile impervious wall is further improved.

Owner:湖北盛达泰水利水电工程有限公司

Flame-retardant fireproof power wiring bus duct

InactiveCN112886337AReduce damageHold firmlyCoupling device detailsPartially enclosed bus-bar installationsStructural engineeringElectrical conductor

The invention provides a flame-retardant fireproof power wiring bus duct. The flame-retardant fireproof power wiring bus duct comprises a wall body, a suspension mechanism, an outer clamping mechanism, a conductor assembly and a butt joint mechanism. The flame-retardant fireproof power wiring bus duct can solve the following problems existing in the use process of the flame-retardant fireproof power wiring bus duct: a, most of traditional bus ducts are directly fixed on a wall body in the installation process, wiring is distributed according to the wall body, and a large amount of holes need to be drilled in the wall body, so that the wall body is damaged to a certain extent, the appearance is influenced, meanwhile, the bus duct is inconvenient to disassemble and assemble, and the operation is inconvenient during later maintenance or part replacement; and b, a plurality of bus ducts are connected and then fixed on a wall body after the bus ducts are assembled in the prior art, so that the connection between the adjacent bus ducts is easy to loosen in the process, the bus duct lines are disconnected and cannot be electrified, and troubles are caused when fault reasons and positions are troubleshot at the same time.

Owner:武汉冬官尚科技有限公司

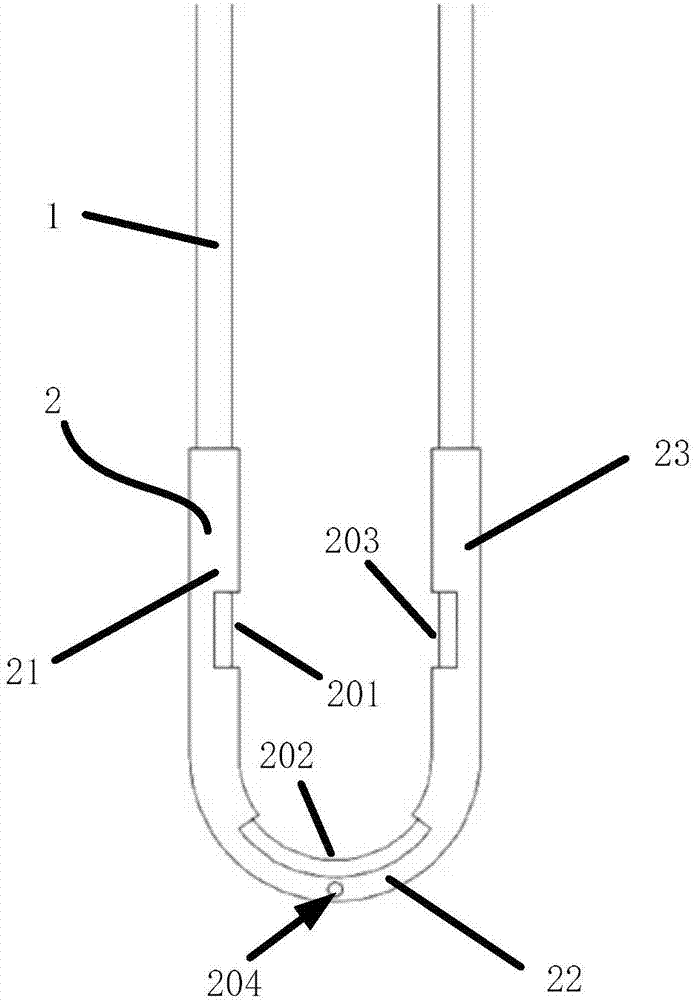

Dye-sensitized solar battery with sealing structure and preparation method thereof

InactiveCN101916668APrevent volatilizationPrevent leakageLight-sensitive devicesSolid-state devicesSolar batteryMaterials science

The invention discloses a dye-sensitized solar battery with a sealing structure, which comprises conducting glass and a platinum electrode substrate, and an electrolyte is filled between the platinum electrode and the conducting glass. The conducting glass is printed with a plurality of silver grids, light anodes smaller than the silver grids are printed inside the silver grids, and the silver grids are coated with at least one layer of film with an injection hole. The film seals the silver grids, the electrolyte is filled between the film and the silver grids, and the platinum electrode substrate covers the film. Moreover, the injection hole is sealed by curing glue. Because of the combination of the film, the silver grids and the platinum electrode substrate in the structure, the probability that the electrolyte corrodes the silver grids and a packing material is reduced, so that the problems of volatilization and leakage of the electrolyte are finally avoided, the stability of the dye-sensitized solar battery is ensured, and the dye-sensitized solar battery has good technical effect. In addition, the invention also discloses a preparation method of the dye-sensitized solar battery.

Owner:上海联孚新能源科技集团有限公司

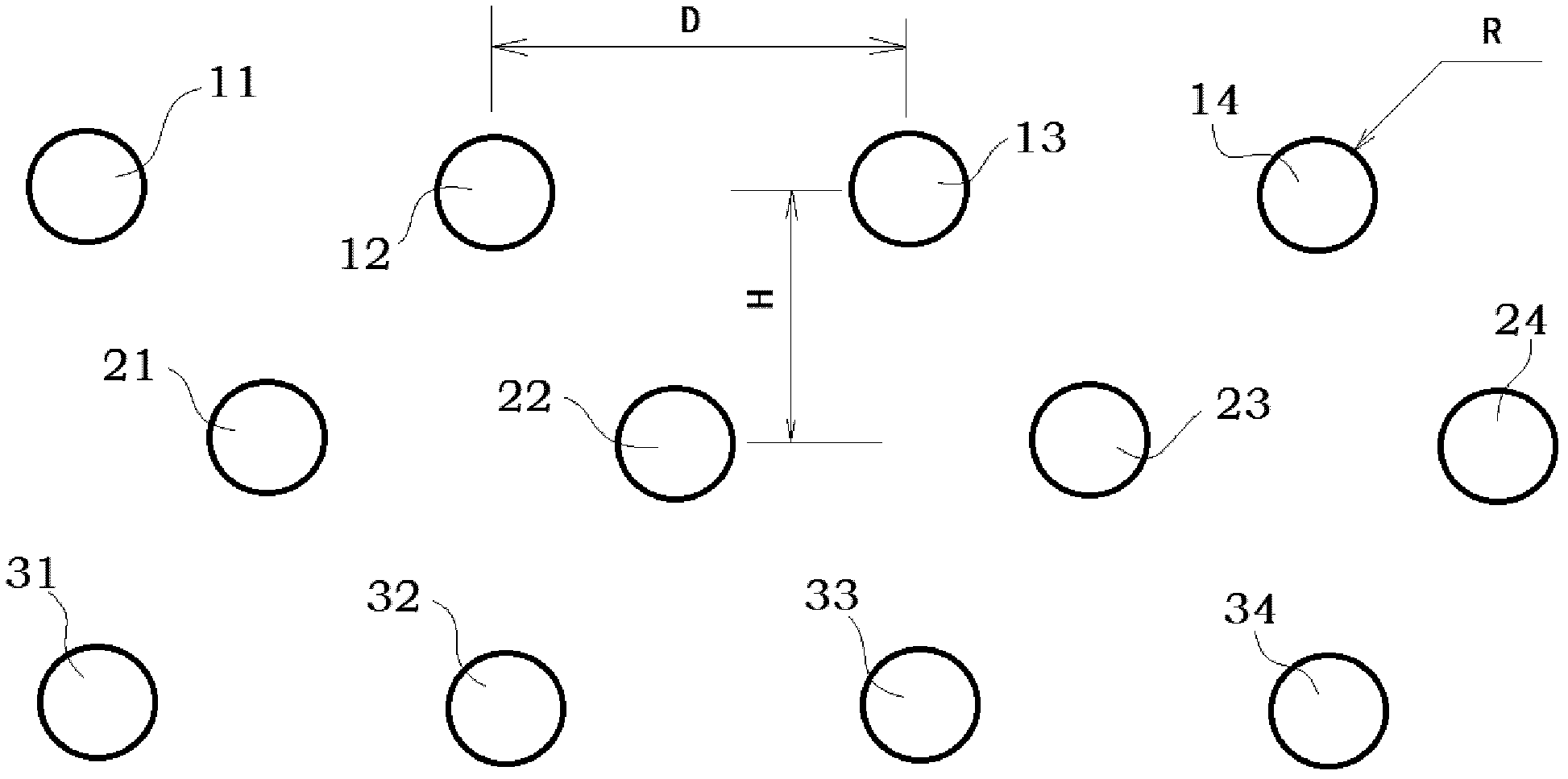

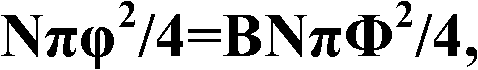

Process and system for striping and mining solid ore rock masses of surface mine

InactiveCN102562070AImproved drilling processLarge block rate and gun root residual rate decreasedOpen-pit miningPetrologyDrill hole

The invention relates to a process for striping and mining solid ore rock masses of a surface mine, which comprises a step of drilling a blast hole array, wherein the blasthole array comprises a plurality of rows of blast holes; adjacent rows of blast holes are mutually staggered along the directions of the rows; each blast hole corresponds to a non-blast hole of the adjacent row of blast holes; on each row, the distance between each two adjacent blast holes serves as a hole pitch; and the distance between each two adjacent blast hole rows serves as a row pitch. The process is characterized in that a small-aperture drill bit and a small hole network spacing are selected to drill the holes; the rock drilling speed is improved for more A times than before; the construction operation is carried out according to the small hole network spacing; the number of the drilled holes is increased to B times that of the original drilled holes; the area of each drilled hole is equivalent to one Bth of the area of the original drilled hole; and both A and B are natural numbers greater than 1. According to the invention, the boulder frequency and the blast root residual ratio can be greatly reduced, the striping and mining operations are continuously carried out, the process is convenient to operate, other investment is not required, the explosive load is unchanged, the drilling time is shortened, and the secondary blast quantity is greatly reduced.

Owner:江西分宜珠江矿业有限公司

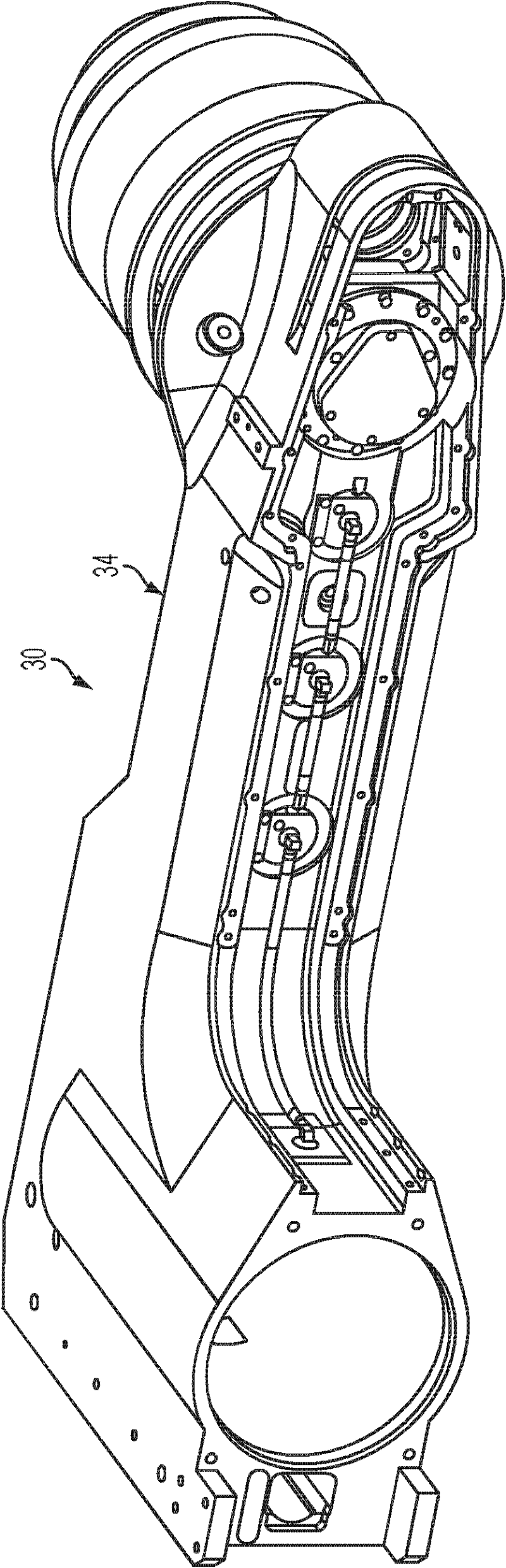

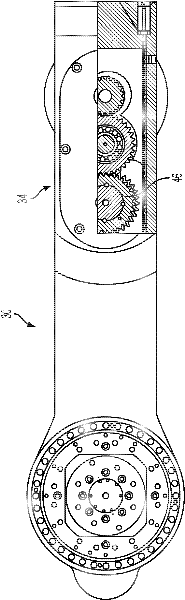

Longwall shearer or other machine with a gear case for transmitting rotational power

ActiveCN102654190ALow costNo need to add bulkGear lubrication/coolingDriving meansCooling fluidTransmitted power

A longwall shearer or other machine with a gear case for transmitting rotational power from a drive to a driven member. The gear case comprises a drive, a driven member, at least one axle including at least one aperture formed therein to circulate cooling fluid through the axle, and a gear mounted to rotate on the axle and positioned to transmit power from the drive to the driven member. 50- 58 S iliIVIE66

Owner:JOY GLOBAL UNDERGROUND MINING LLC

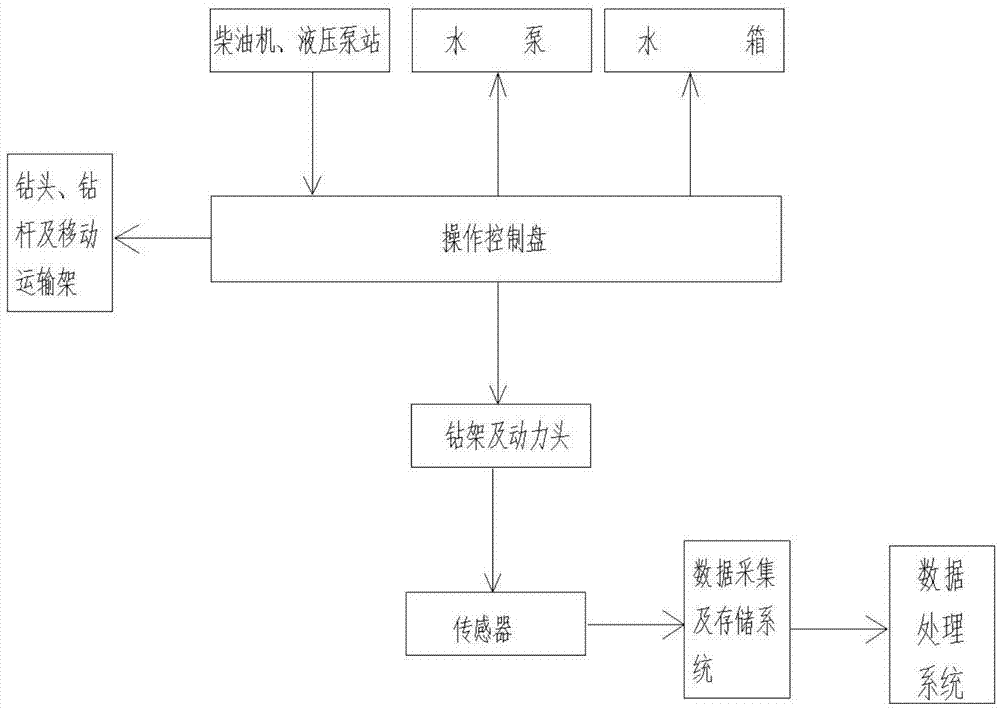

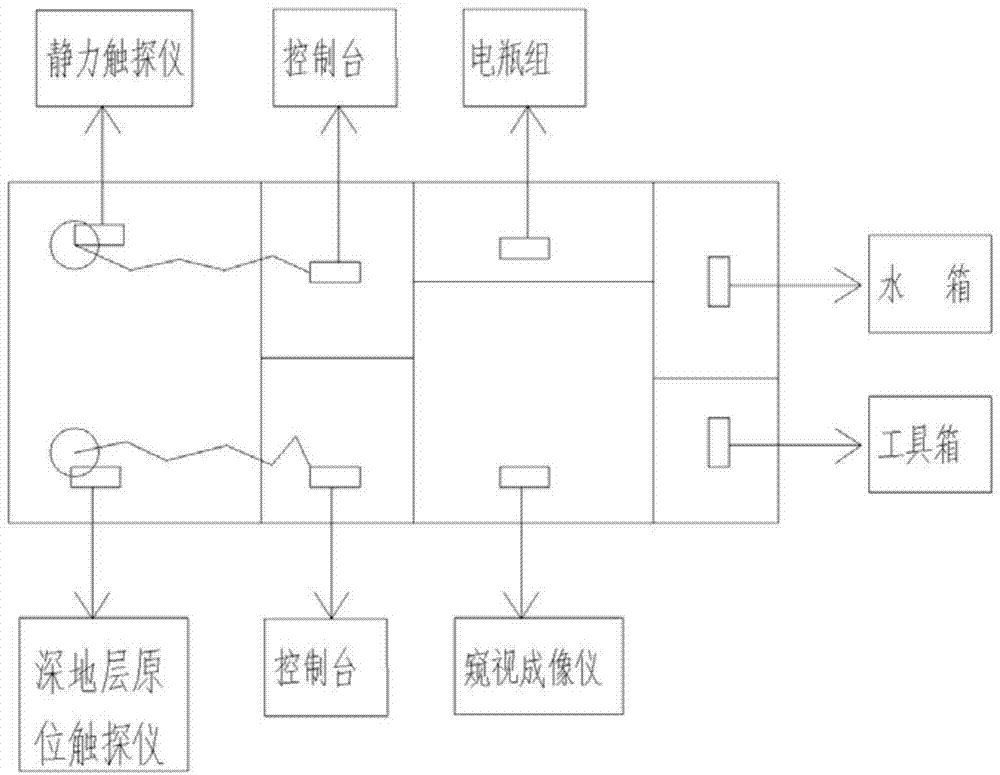

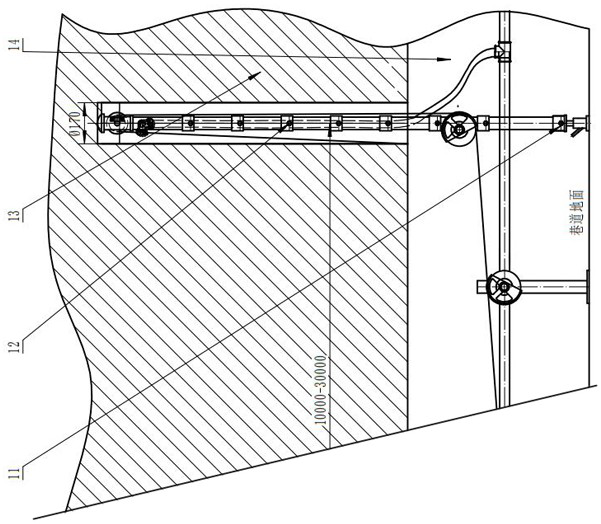

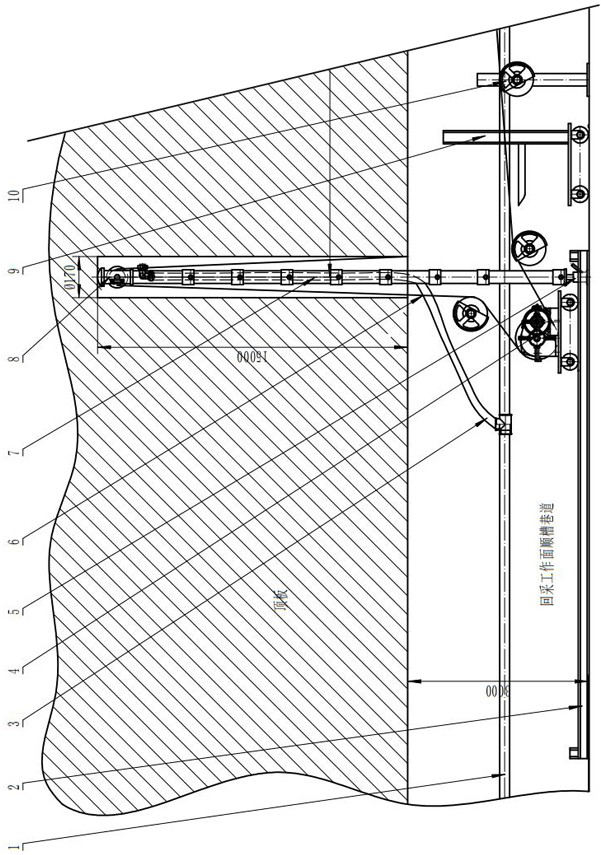

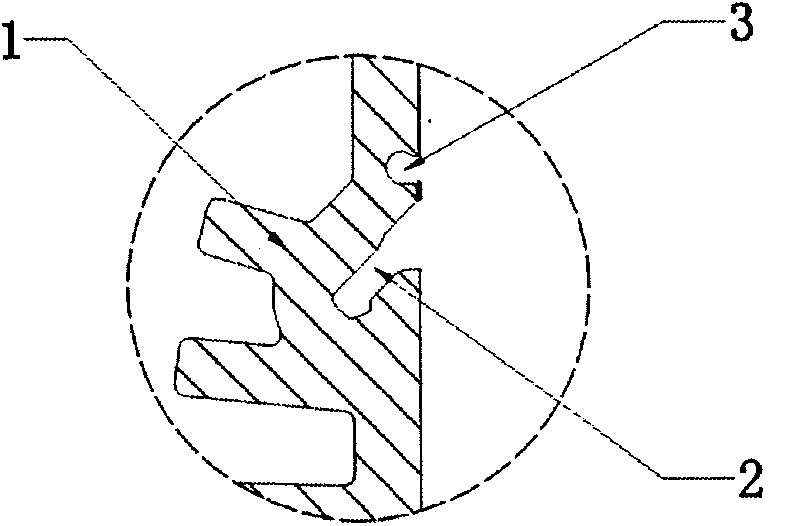

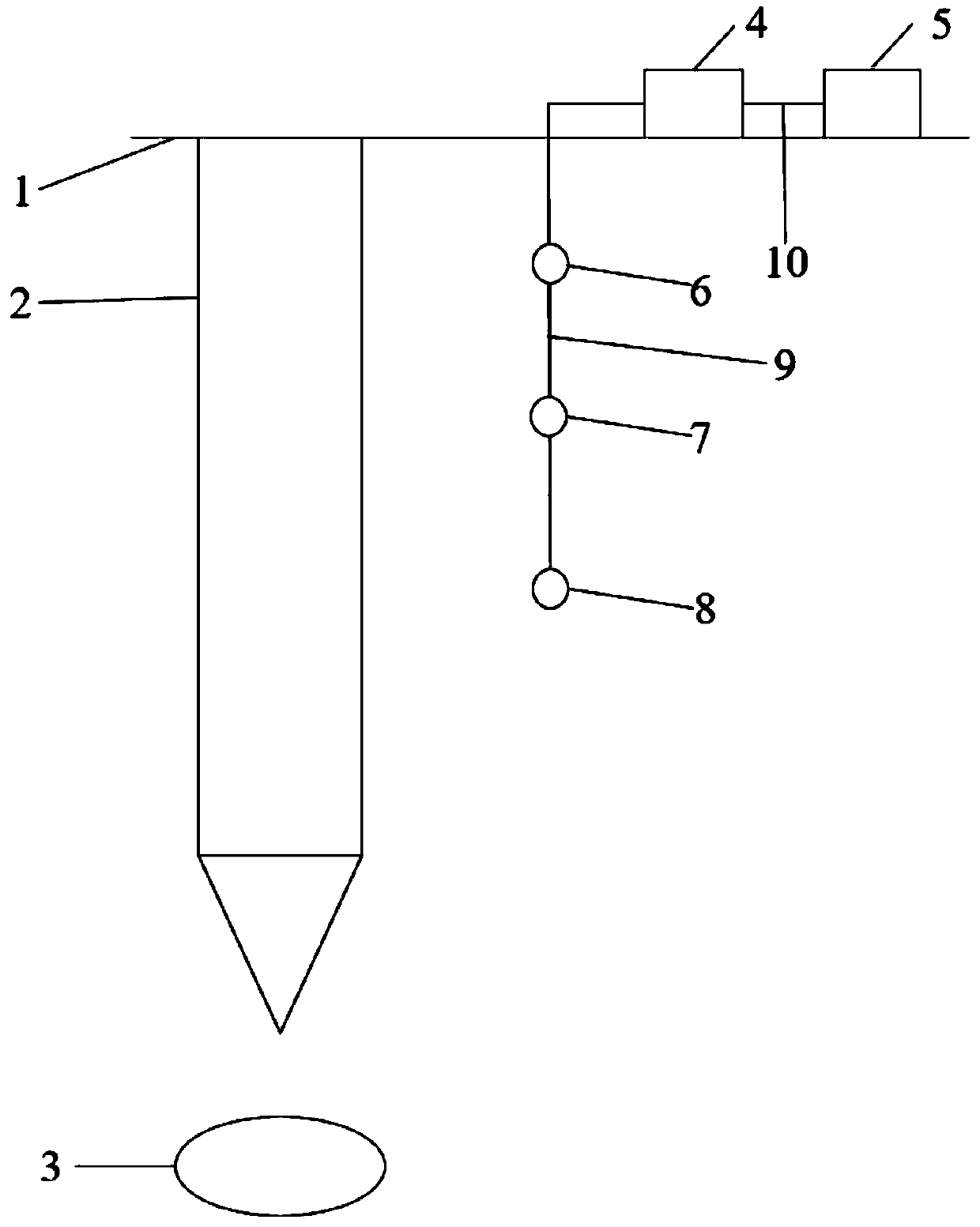

Deep-stratum in-situ penetrometer, penetration sounding trolley comprising the same and using method thereof

InactiveCN104846800AContinuous measurementRapid determinationIn situ soil foundationData processing systemHydraulic pump

The invention discloses a deep-stratum in-situ penetrometer which can carry out continuous, quick and accurate measuring on a hard, thick and deep stratum. The penetrometer comprises a diesel engine, a hydraulic pump station, a water pump, a water tank, an operation control disc, a drilling rig, a power head, sensors, a drill bit drill rod, a moving conveying frame, a data collecting and storing system and a data processing system. The diesel engine and the hydraulic pump station are connected with the power head. The water pump and the water tank are used for cooling the drill bit drill rod. The operation control disc is used for controlling the depth of a drill bit drilled into a stratum. The sensors comprise a torque sensor, a propulsive force sensor and a displacement sensor. The sensors transmit torque data, propulsive force data and drilling speed data to the data collecting and storing system. The data processing system receive the data of the data collecting and storing system for processing. A penetration sounding trolley and a using method of the deep-stratum in-situ penetrometer and the penetration sounding trolley are further provided.

Owner:BEIJING MUNICIPAL ENG RES INST

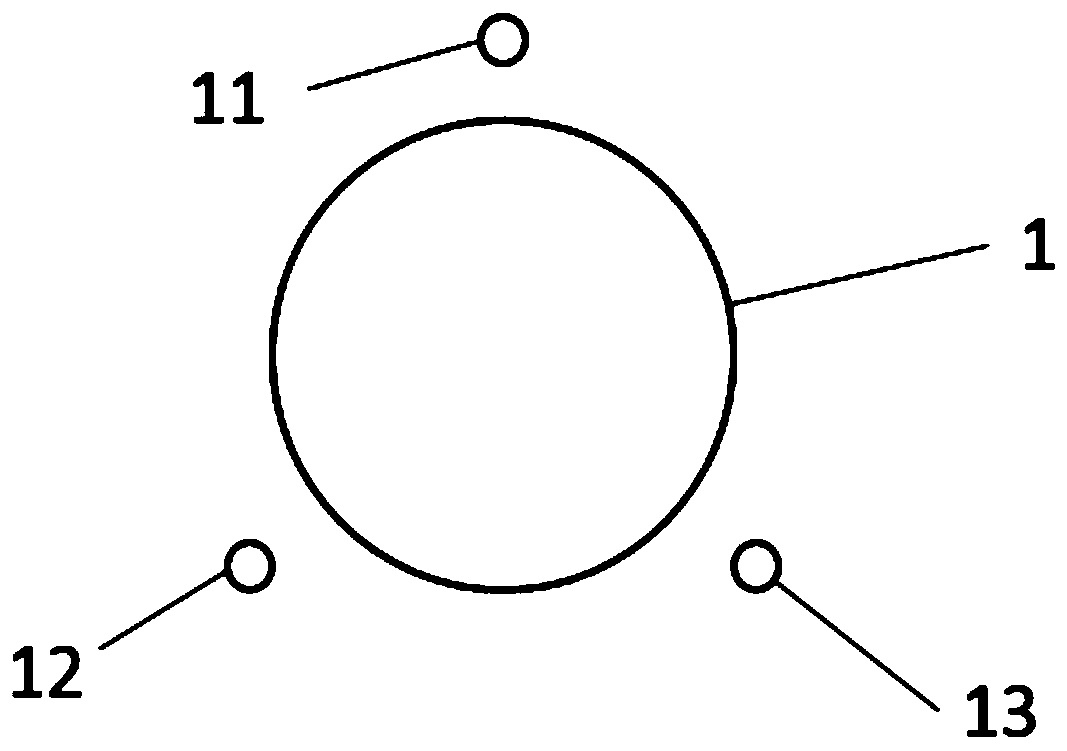

Gob-side entry retaining method for reversely and flexibly cutting top plate and cutting device of gob-side entry retaining method

PendingCN112917703AReduce usageImprove work efficiencyWorking accessoriesStone-like material working toolsStructural engineeringMachine

The invention discloses a gob-side entry retaining method for reversely and flexibly cutting a top plate and a cutting device of the gob-side entry retaining method. The gob-side entry retaining method for reversely and flexibly cutting the top plate comprises the following steps that S1, a drilling machine is used for drilling a plurality of drill holes in the top end of a roadway; S2, a rope saw cutting machine is arranged on a walking track; S3, a diamond bead stringing rope is hung on rotating wheels at the tops of reverse cutting frame tubes, and the top ends of the reverse cutting frame tubes are fed into the drill holes; S4, guide wheels are installed, the diamond bead stringing rope forms a reverse cutting annular closed line, and the diamond bead stringing rope cuts the top plate; and S5, the drill holes are replaced until the top plate cutting operation is completed. The cutting device comprises the rope saw cutting machine and the reverse cutting frame tubes; the rope saw cutting machine is arranged on the walking track; and the two reverse cutting frame tubes are inserted into the two adjacent drill holes correspondingly, the rotating wheels are connected to the tops of the reverse cutting frame tubes, the diamond bead stringing rope is arranged on the rope saw cutting machine, and the diamond bead stringing rope penetrates through wheel grooves of the rotating wheels and wheel grooves of the guide wheels respectively to form the reverse cutting annular closed line.

Owner:河南明德矿山技术开发有限公司

Heat-dissipating fastener fixing structure and tool for demounting heat-dissipating fastener

InactiveCN103545274AReduce drillingEasy to disassembleSemiconductor/solid-state device detailsSolid-state devicesPunchingEngineering

The invention discloses a heat-dissipating fastener fixing structure and a tool for demounting a heat-dissipating fastener. The heat-dissipating fastener fixing structure comprises a chute and a heat-dissipating fastener body. The chute is formed at the back of a heat-dissipating device, and a fastening groove is formed above the chute. The heat-dissipating fastener body is a U-shaped plate with a long side and a short side. A section of inwards-recessed arc-shaped face is arranged on the long side of the heat-dissipating fastener body. The short side of the heat-dissipating fastener body can be fastened in the chute. The arc-shaped face on the long side of the heat-dissipating fastener body can be pressed on a power element at the back of the heat-dissipating device. A gap is formed between the long side of the heat-dissipating fastener body and the bottom side of the U-shaped plate. The heat-dissipating fastener fixing structure has the advantages that demounting of the heat-dissipating fastener body is facilitated, assembly efficiency is obviously improved, reliable fit of the power element and the heat-dissipating device is guaranteed, uniformity in assembly is good, process steps such as punching of the heat-dissipating device and shaping of the power element are reduced, and the heat-dissipating fastener fixing structure is simple in structure, convenient to process, high in assembly efficiency, good in uniformity and reliable in fixation.

Owner:青岛美奂电子科技有限公司

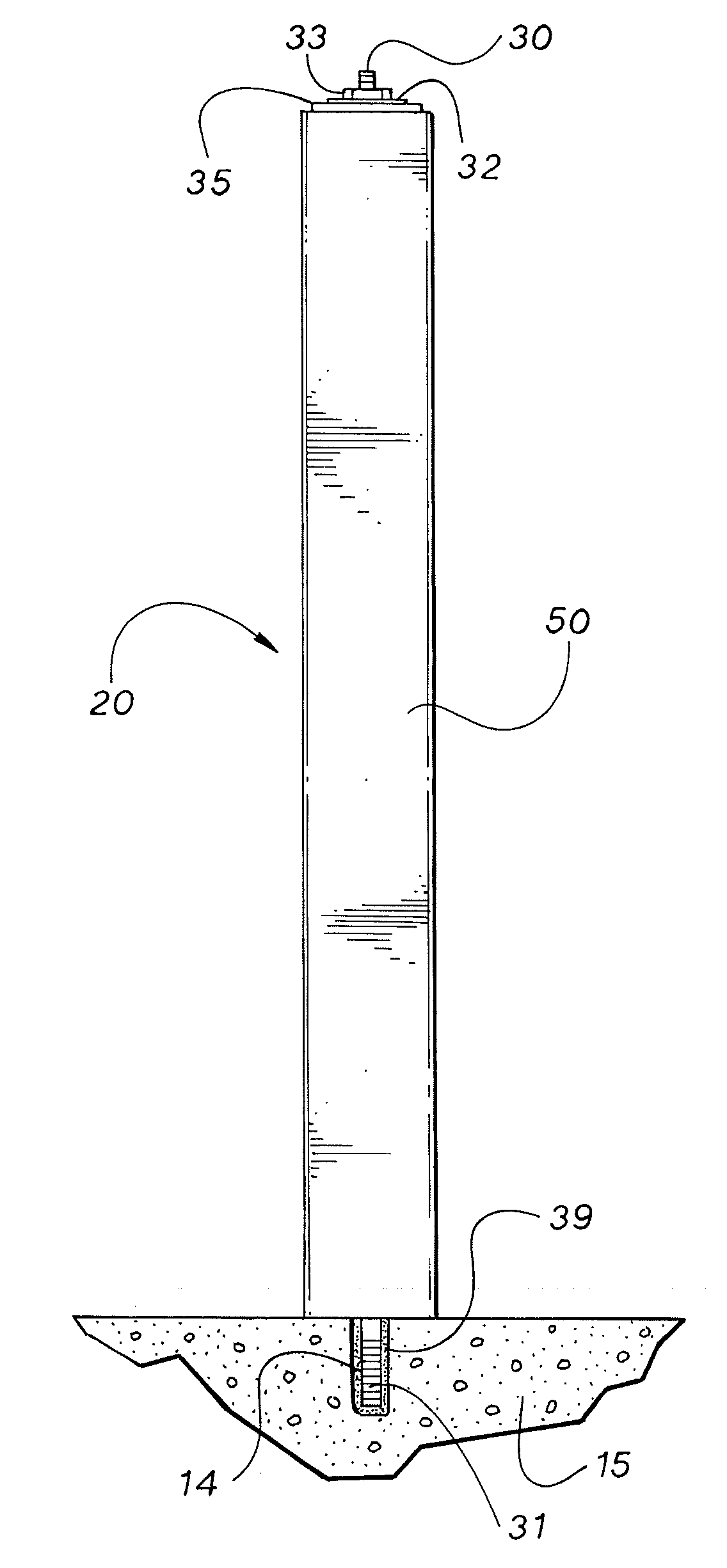

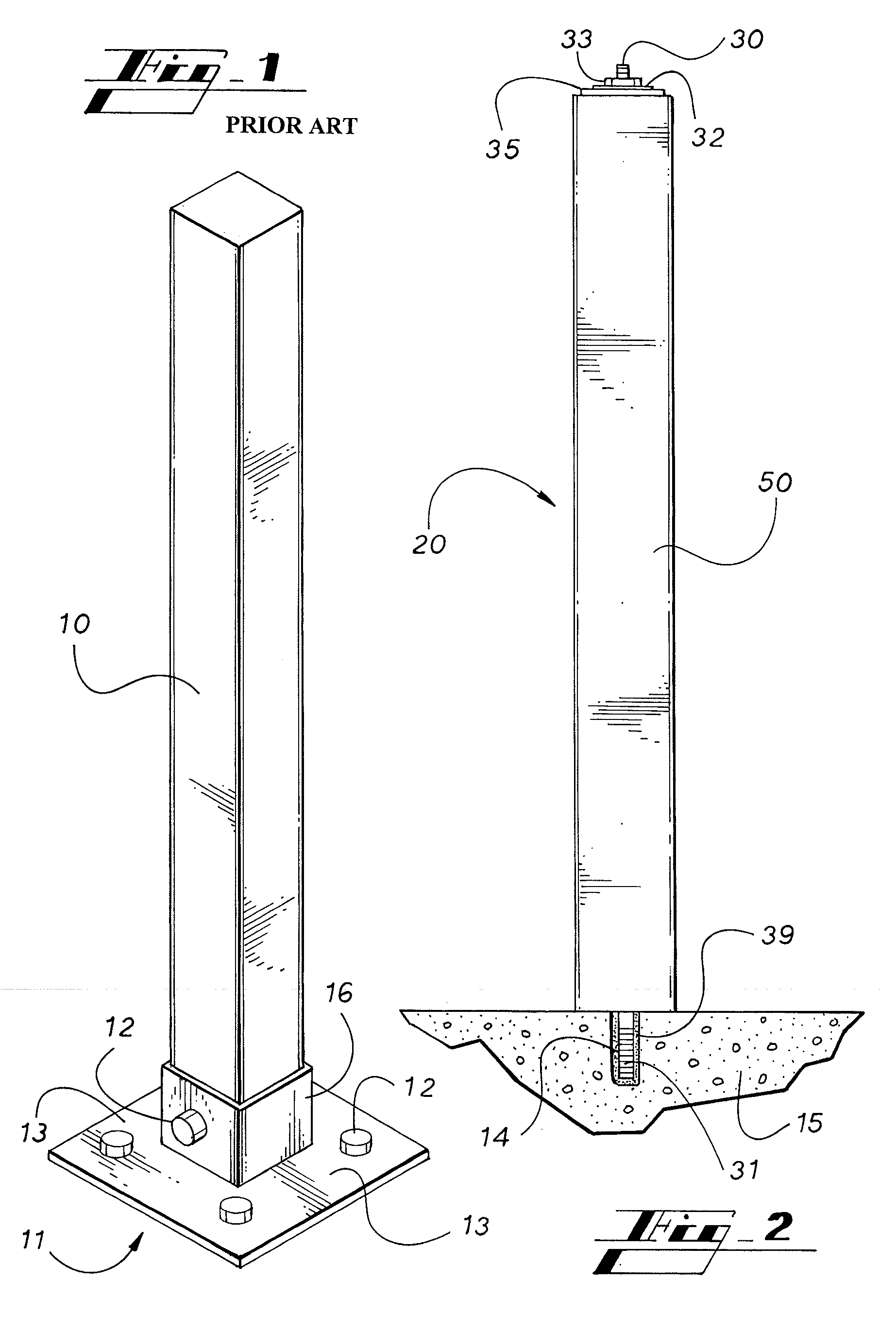

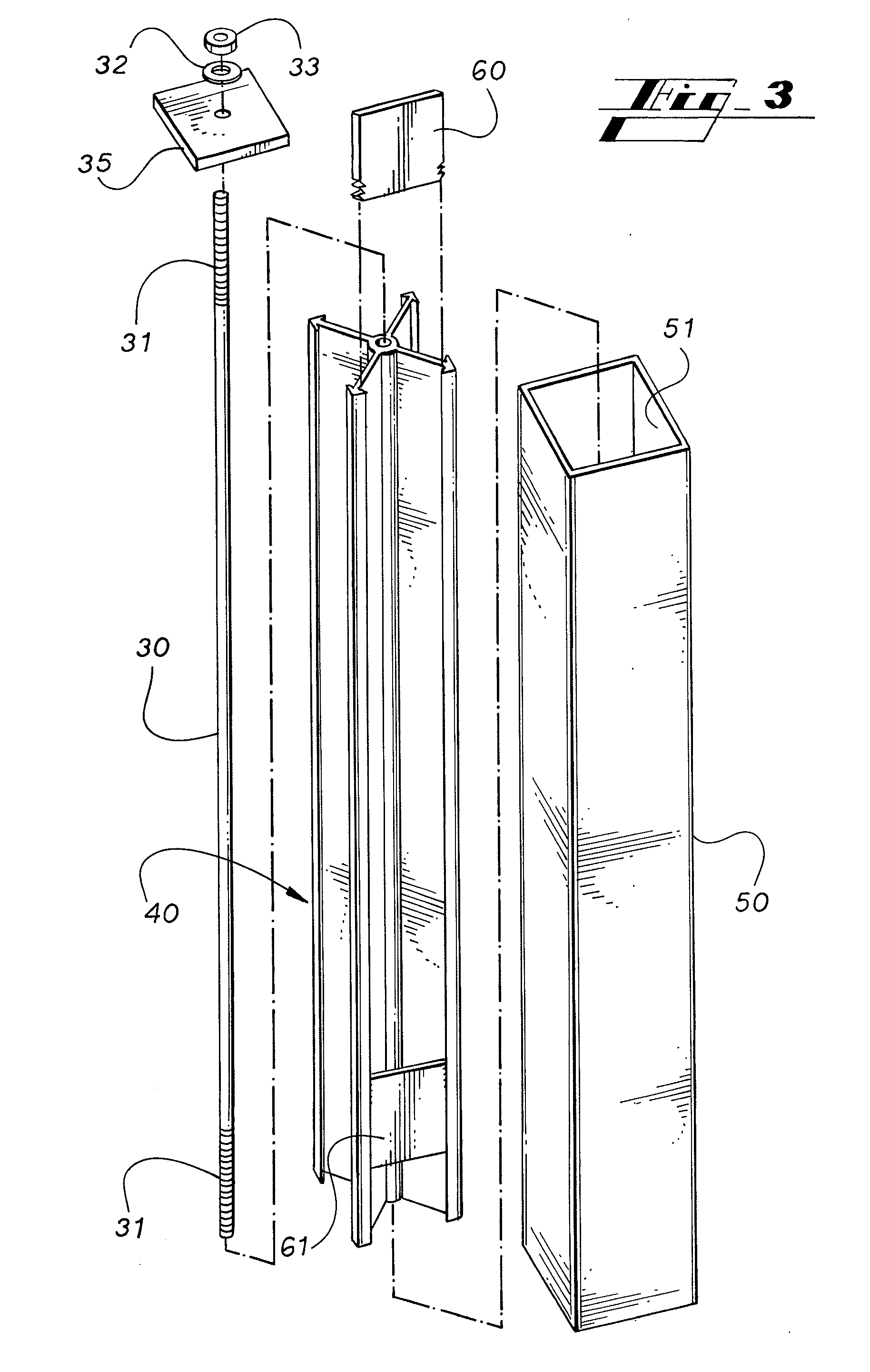

Compression Post Mount

InactiveUS20090183354A1Improve structural strengthReduce crackingFencingLoad-supporting pillarsEngineeringSubstructure

A fence post assembly for mounting to a substructure with a single point of attachment. The post assembly has an outer sleeve surrounding a support member and an attachment rod extending through the support member. The post assembly is mounted to the substructure by securing one end of the attachment rod in the substructure and securing the support member between a compression plate and the substructure by tensioning the upper end of the attachment rod. Attachment points for securing additional fence components to the post are provided by inserting an adapter into a receiving channel defined along a longitudinal length of the support member.

Owner:HOMELAND VINYL PRODS

Full-suture anchor and implanting mechanism

Owner:SHANGHAI LIGETAI BIOTECH CO LTD

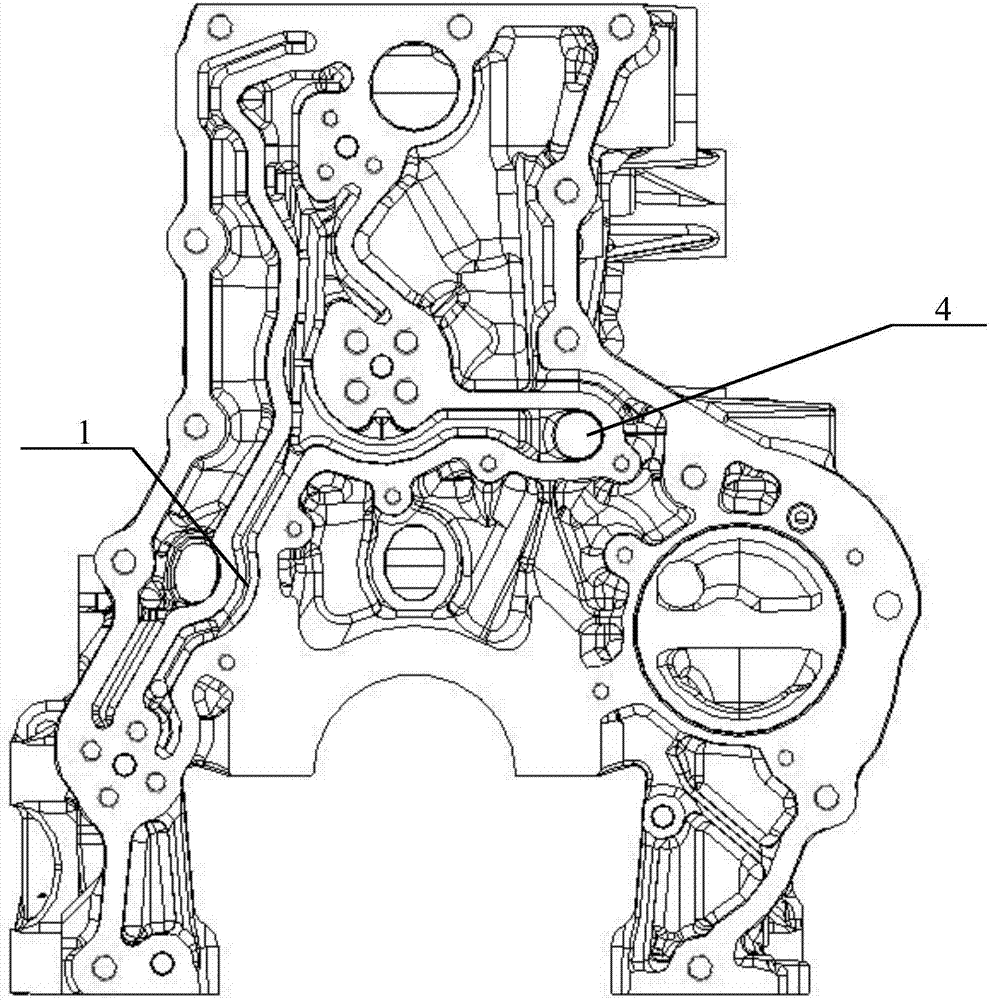

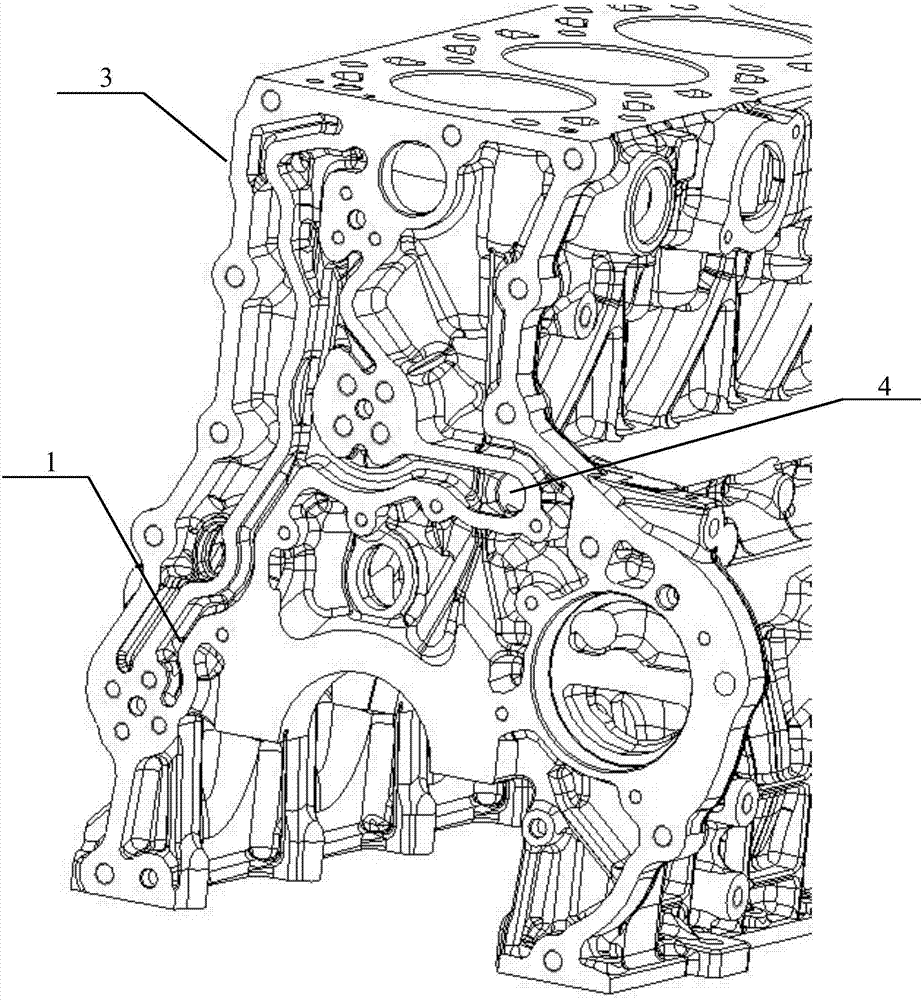

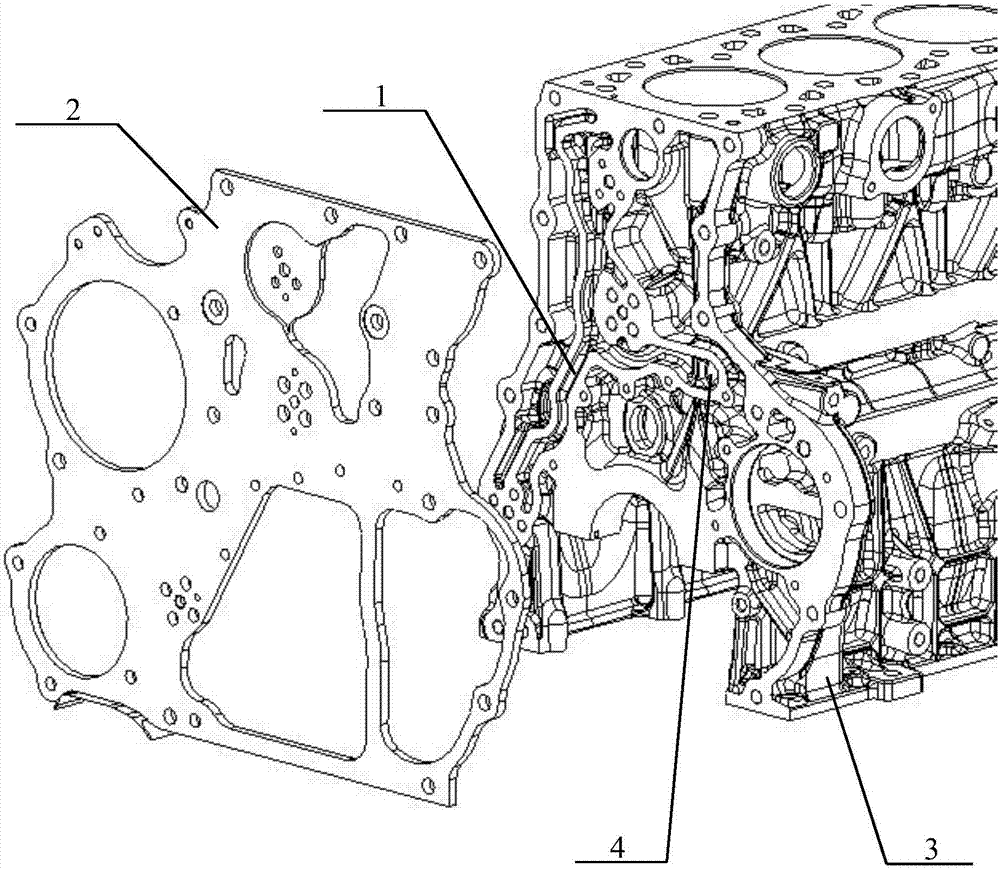

Gear lubrication oil path

The invention discloses a gear lubrication oil path applied to engine gear lubrication. The gear lubrication oil path comprises an oil groove cast to the gear installing end face of an engine body. The oil groove is connected with a main oil way of the engine body. A gear chamber cover plate covers the gear installing end of the engine body in a covering manner. The gear lubrication oil path is formed through closing of the gear chamber cover plate and the oil groove. The oil groove of the gear lubrication oil path is formed through casting, machining is not needed, the machining abrasion of the engine body is reduced, and gears at multiple positions can be effectively lubricated through a plurality of through holes in the gear chamber cover plate.

Owner:GUANGXI YUCHAI MASCH CO LTD

Stratum abnormal discontinuous change depth measuring device based on acoustic emission during injection of prefabricated piles

ActiveCN110067268ALow costReduce Engineering AccidentsFoundation testingControl systemAcoustic emission

The invention relates to a stratum abnormal discontinuous change depth measuring device based on acoustic emission during injection of prefabricated piles, and belongs to the technical field of civilengineering instrument manufacturing. The stratum abnormal discontinuous change depth measuring device is composed of a pile driving device, a monitoring device, a transmission device and an output system, is the novel measuring device, and has the main value that first, the device can be reused, and the equipment cost is reduced; second, the abnormal discontinuous change of a stratum during piledriving is monitored, continuous stratum mutation, the karst roof thickness, the boulder burial depth and the like are detected and early-warned in advance, and the probability of engineering accidents is decreased; third, through a way of synchronously conducting prefabricated pile driving and monitoring, the frequency of drilling and geological exploration is decreased, and the construction costis lowered; and fourth, an acoustic emission sensor is matched with a ground interpretation device, a system is controlled for monitoring, operation is easy, transmission is convenient and rapid, results are accurate, and use is convenient.

Owner:SUN YAT SEN UNIV

A sealing rubber strip

ActiveCN110341447AReduce wearReduce the problem of excessive wear and loss of elasticityEngine sealsVehicle sealing arrangementsEngineeringMechanical engineering

The invention belongs to the technical field of sealing accessories, in particular relates to a sealing rubber strip comprising a main body and a fixing groove. The cross section of the main body is annular. A set of partition plates are arranged inside the main body, and a connecting block is arranged below the main body. The fixing groove is arranged in the middle portion of the connecting block, and the fixing groove is used for fixing the main body on edgings. The partition plates are elastically arranged, and the middle portions of the partition plates are all provided with interval cavities. An auxiliary sealing unit is arranged inside each interval cavity, and the auxiliary sealing unit is used for auxiliary support of the interior of the main body. Each auxiliary sealing unit comprises two symmetric semi-circular plates. Both the semi-circular arc plates are fixedly connected to the inner wall of the main body. The middle portions of each two adjacent semi-circular arc plates are in contact with each other. The invention achieves a better sealing effect by the internal auxiliary sealing units and supporting components, and reduces the problem that the sealing rubber strip wears too much and loses the elastic force, thereby enhancing the overall sealing property of the vehicle and improving the safety of night work.

Owner:北京龙苑伟业新材料有限公司

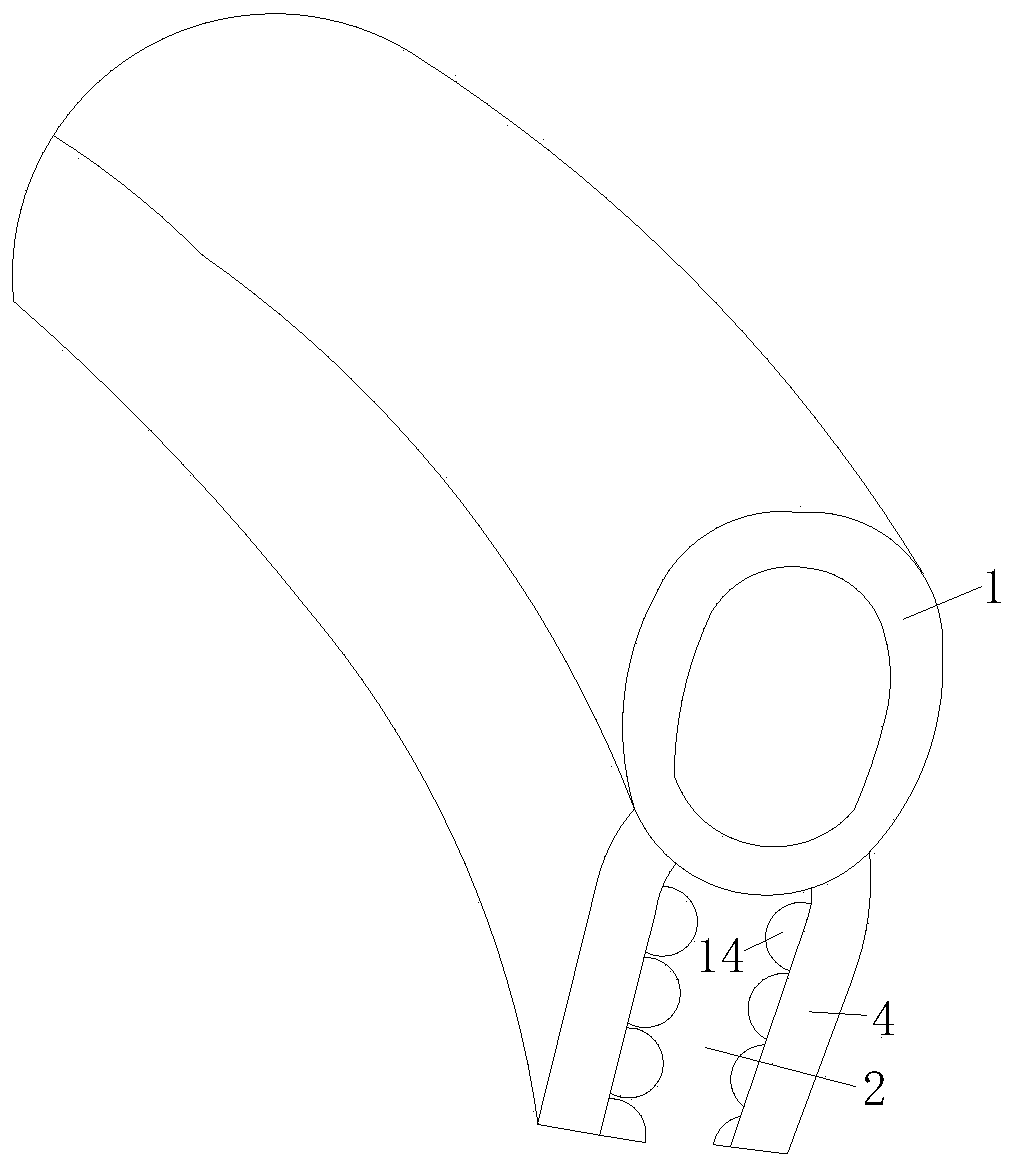

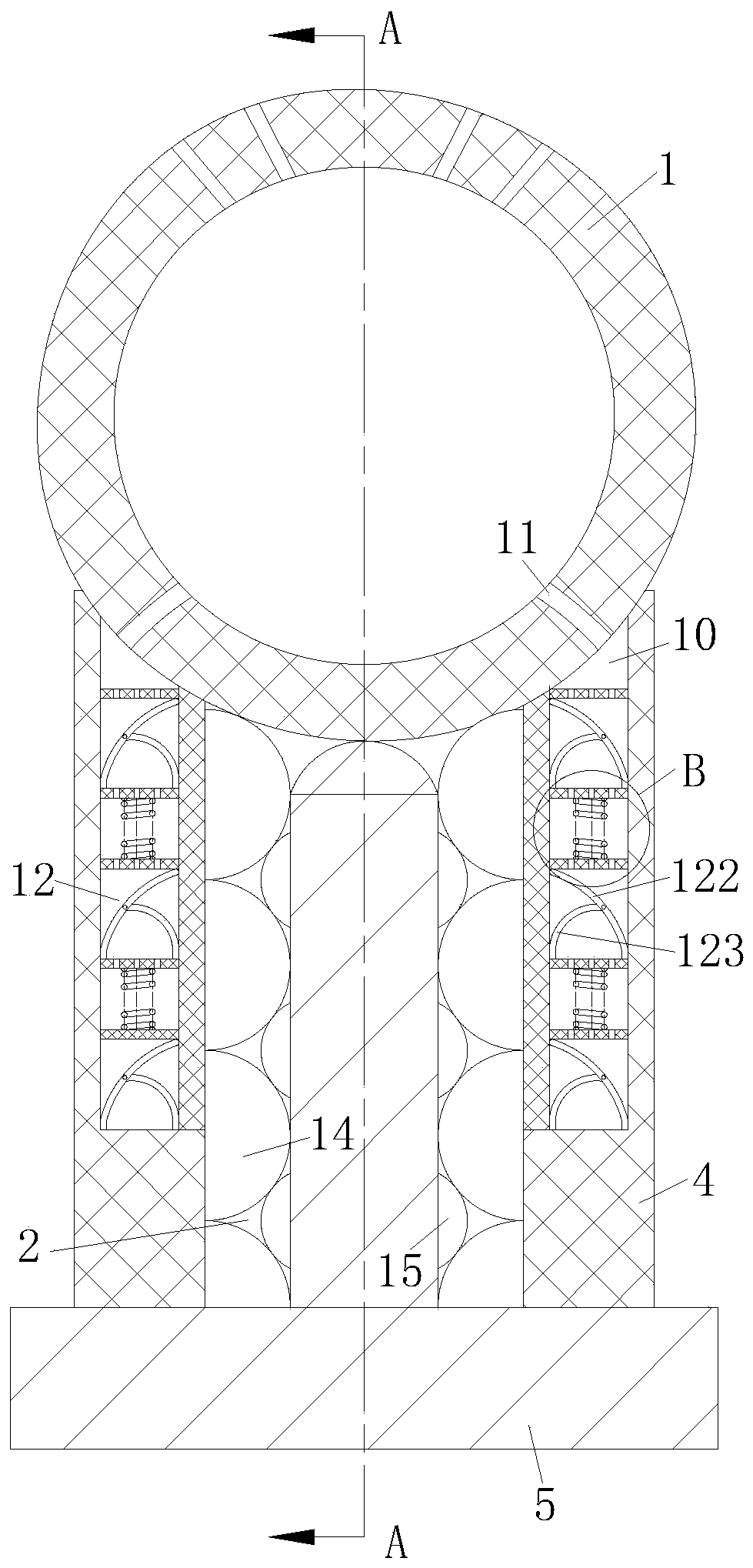

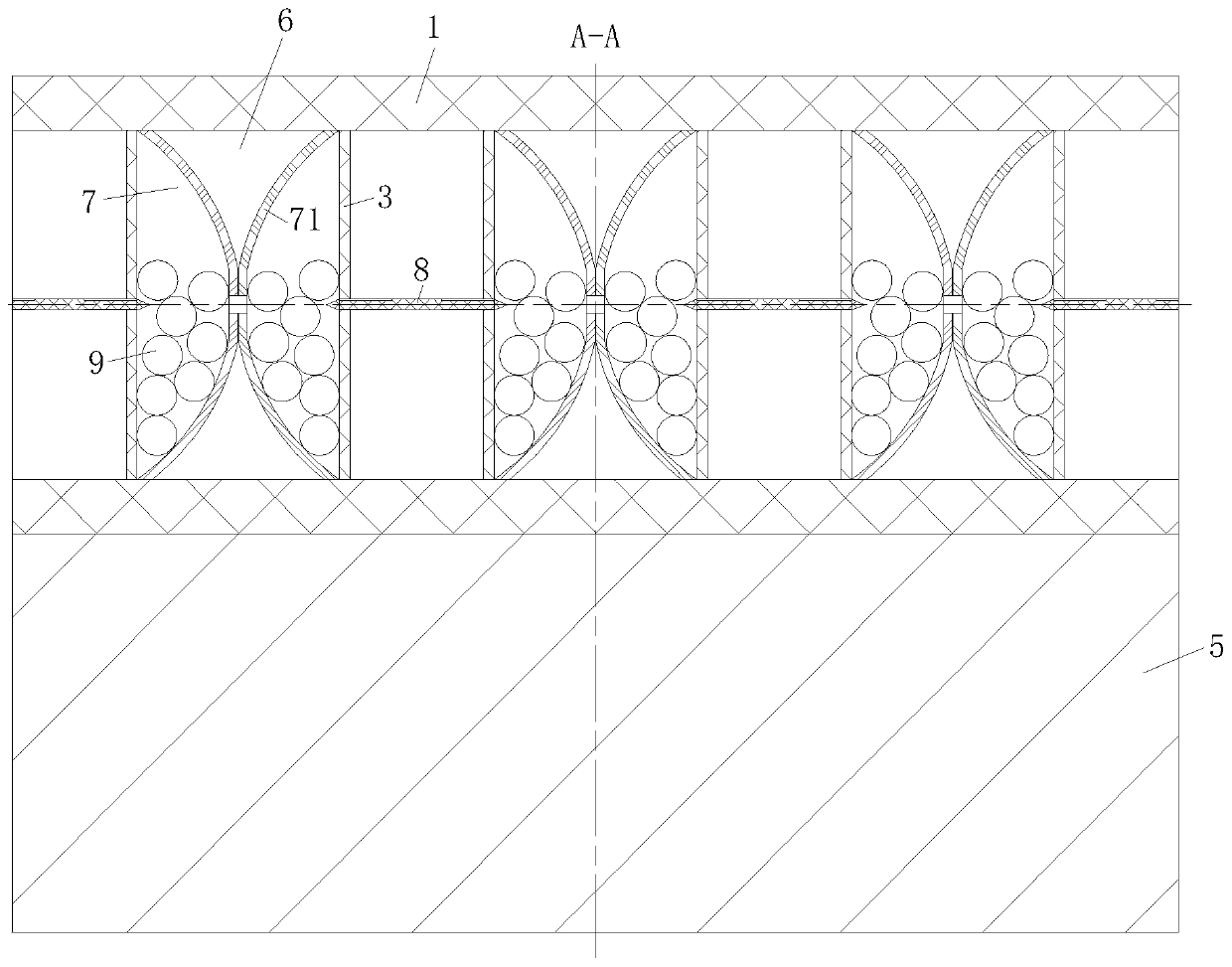

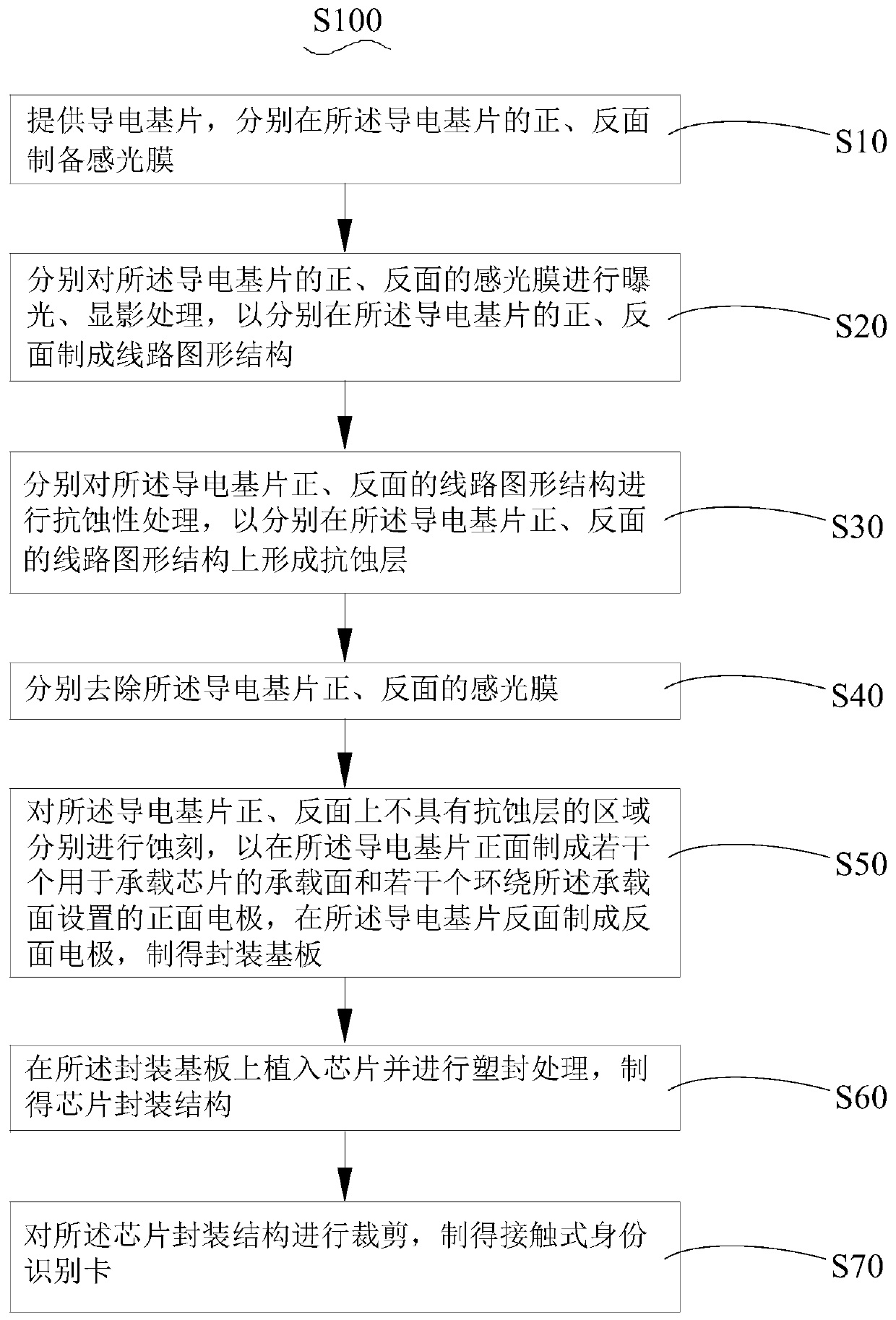

Packaging process of contact identity card and contact identity card

PendingCN110429036AReduce manufacturing costReduce product thicknessSemiconductor/solid-state device detailsSolid-state devicesBearing surfaceResist

The invention discloses a packaging process of a contact identity card and a contact identity card. The packaging process of the contact identity card comprises the following steps of: providing a conductive substrate, and separately preparing photosensitive films on the front and back surfaces of the conductive substrate; exposing and developing the photosensitive films to form a line pattern structure; forming a resist layer in the region of the line pattern structure; removing the photosensitive films; etching a region on the conductive substrate that does not have the resist layer, forminga plurality of bearing surfaces and a plurality of front electrodes on the front surface of the conductive substrate, and forming a back electrode on the back surface of the conductive substrate to obtain a packaging substrate; implanting a chip into the packaging substrate and performing a plastic packaging process to obtain a chip packaging structure; cutting the chip packaging structure to obtain the contact identity card. The manufacturing process uses the conductive substrate as a base material, reduces the production cost and the product thickness, avoids steps of drilling, electroplating copper, solder resist printing and the like compared with a conventional process, and is simpler.

Owner:惠州市志金电子科技有限公司

Anti-radiation ODS steel-steel composite plate and preparation method

InactiveCN112170531AReduce drillingReduce vacuuming and other processesElectron beam welding apparatusAuxillary arrangementsComposite plateHeating furnace

The invention relates to an anti-radiation ODS steel-steel composite plate and a preparation method. The anti-radiation ODS steel-steel composite plate comprises a base layer steel and an ODS steel composite layer compounded on a base layer in a rolling manner, the contact surfaces of composite materials and a base material are polished, the non-polished surfaces of the two composite materials arecoated with a separant and dried, the composite materials and the base material are stacked in sequence to form composite blanks, the assembled composite blanks are conveyed to a vacuum chamber, gapsbetween the composite blanks are welded through vacuum electron beams, and the blanks are conveyed to a heating furnace to be heated, rolled, tailed-out, straightened, cooled, cut and divided into plates. The anti-radiation ODS steel composite plate with good metallurgical bonding effectively solves the problem of online process anti-radiation performance of the base material ODS steel in the composite plate, the process is simple, and the rolling success rate is high.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com