Pasting mechanism for bamboo pieces of bamboo mat and pasting device

A technology for pasting devices and mats, which is applied in the direction of connecting components, mechanical equipment, and material gluing, and can solve the problems of large bamboo pieces, many processing procedures, and inconvenient storage, transportation, and carrying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

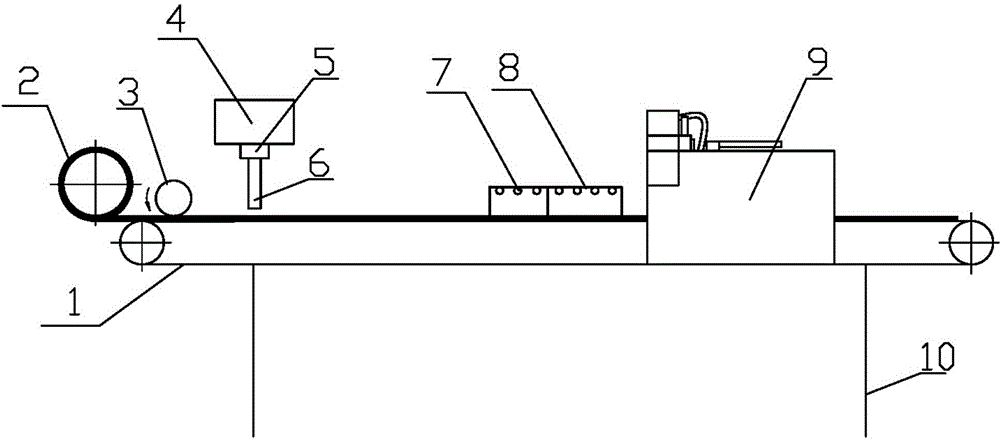

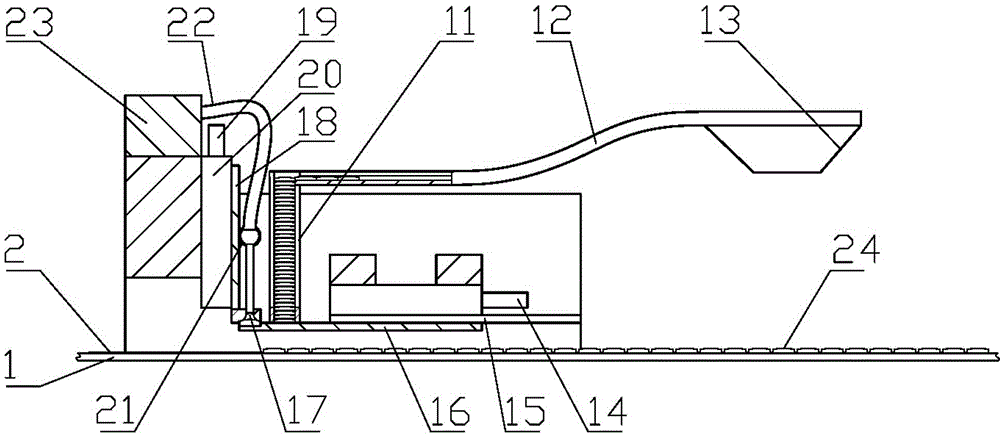

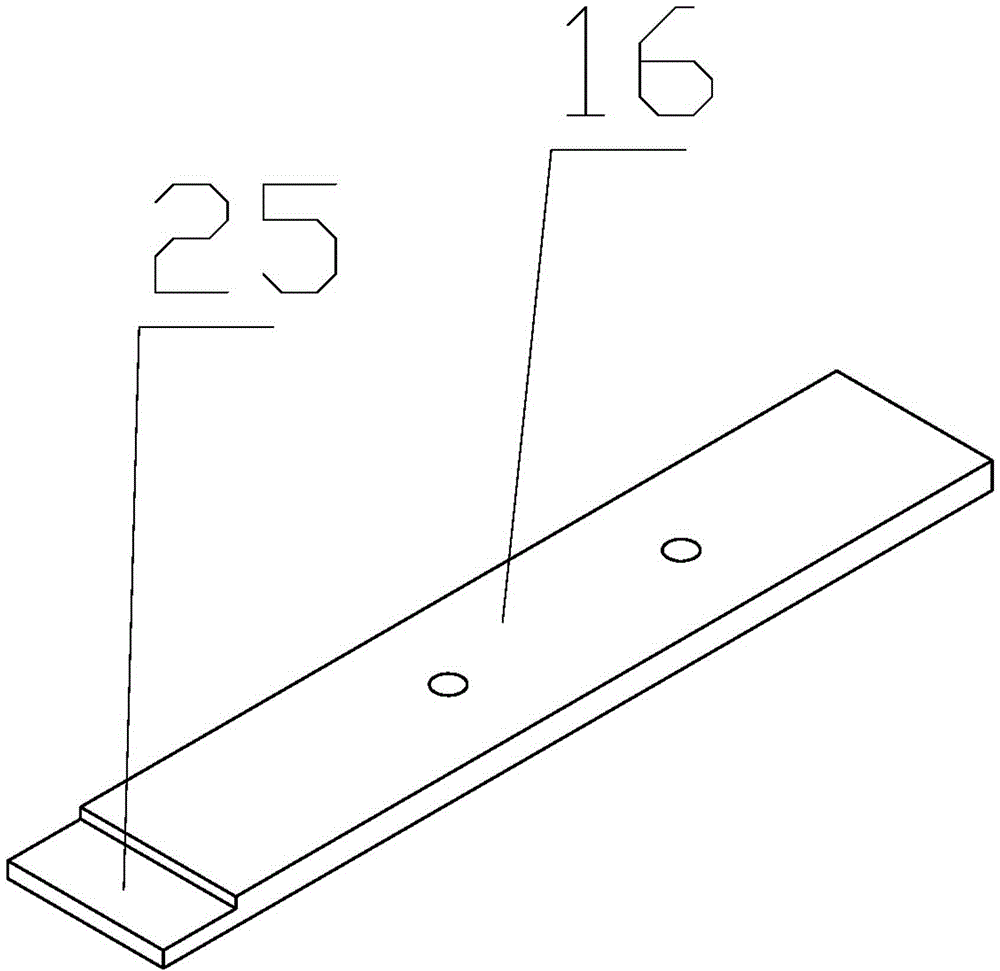

[0043] A kind of sticking device of bamboo mat bamboo chip, it comprises frame 10, and endless conveyer belt 1 is installed on frame 10, and gluing mechanism, sticking mechanism 9 are arranged on frame 10 sequentially; Described gluing mechanism comprises coating Roller 26 and glue amount control roller 27, coating roller 26 is provided with the protrusion corresponding to the size and shape of bamboo slice 24, the amount of glue is controlled by adjusting the distance between coating roller 26 and glue amount control roller 27 , the amount of glue applied is controlled at 120g / m 2 ~170g / m 2 The pasting mechanism 9 includes a sorting section, a feeding section, and a pasting section, and the sorting section includes a sorting vibrating plate 13, a feed tank 12 connected with the sorting vibrating plate 13, and a storage tank 11 connected with the feed tank 12; The feeding part comprises a feeding plate 16 driven by a horizontal servo motor 14, and one end of the feeding plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com