Anti-radiation ODS steel-steel composite plate and preparation method

A composite plate, ODS technology, applied in the direction of metal rolling, manufacturing tools, welding equipment, etc., to achieve the effect of reducing drilling, excellent comprehensive performance, and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

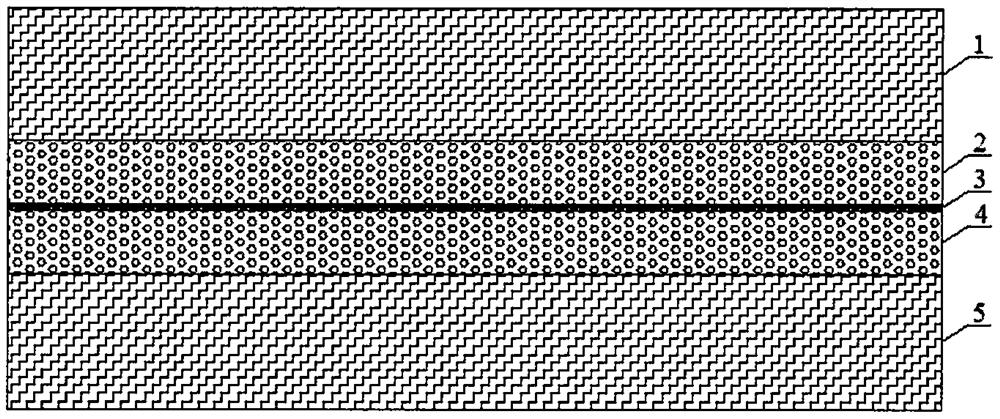

[0027] A method for preparing a radiation-resistant ODS steel-steel clad plate, comprising a base material and an ODS steel clad material blank rolled and compounded on the base material; the chemical composition and mass percentage of the base material blank are as follows: C: 0.02% , Si: 0.53%, Mn: 1.36%, P: 0.016%, S: 0.001%, Mo: 0.08%, Alt: 0.015%, and the balance is Fe and a small amount of unavoidable impurities.

[0028] The preparation method of a radiation-resistant ODS steel-steel composite plate provided in this example is as follows: select the radiation-resistant ODS steel with a thickness of 15 mm for the composite material blank and the Q345R steel type with a thickness of 80 mm for the base material blank, and the thickness of the rolled product 2+14mm ODS+Q345R composite board;

[0029] One of the surfaces of the two Q345R base material blanks and the two ODS composite material blanks, that is, the contact surface between the composite material and the base ma...

Embodiment 2

[0037] A method for preparing a radiation-resistant ODS steel-steel clad plate, comprising a base material and an ODS steel clad material blank rolled and compounded on the base material; the chemical composition and mass percentage of the base material blank are as follows: C: 0.013% , Si: 0.56%, Mn: 1.32%, P: 0.014%, S: 0.001%, Mo: 0.05%, Alt: 0.012%, and the balance is Fe and a small amount of unavoidable impurities.

[0038] The preparation method of a radiation-resistant ODS steel-steel composite plate provided in this embodiment is as follows: select the radiation-resistant ODS steel with a thickness of 8 mm for the composite material blank and the Q345R steel type with a thickness of 120 mm for the base material blank, and the thickness of the rolled product is 3+40mm ODS+Q345R composite board;

[0039] One of the surfaces of the two Q345R base material blanks and the two ODS composite material blanks, that is, the surface where the composite material and the base mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com